Screw propeller for aerator

An aerator and propeller-type technology, applied in the field of propeller-type aerators, can solve the problems of low stirring force of sewage, shortened reach, and increased fluid loss at the inlet of the propeller, etc., so as to increase the stirring force and reduce the fluid Loss, effect of increasing absolute speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

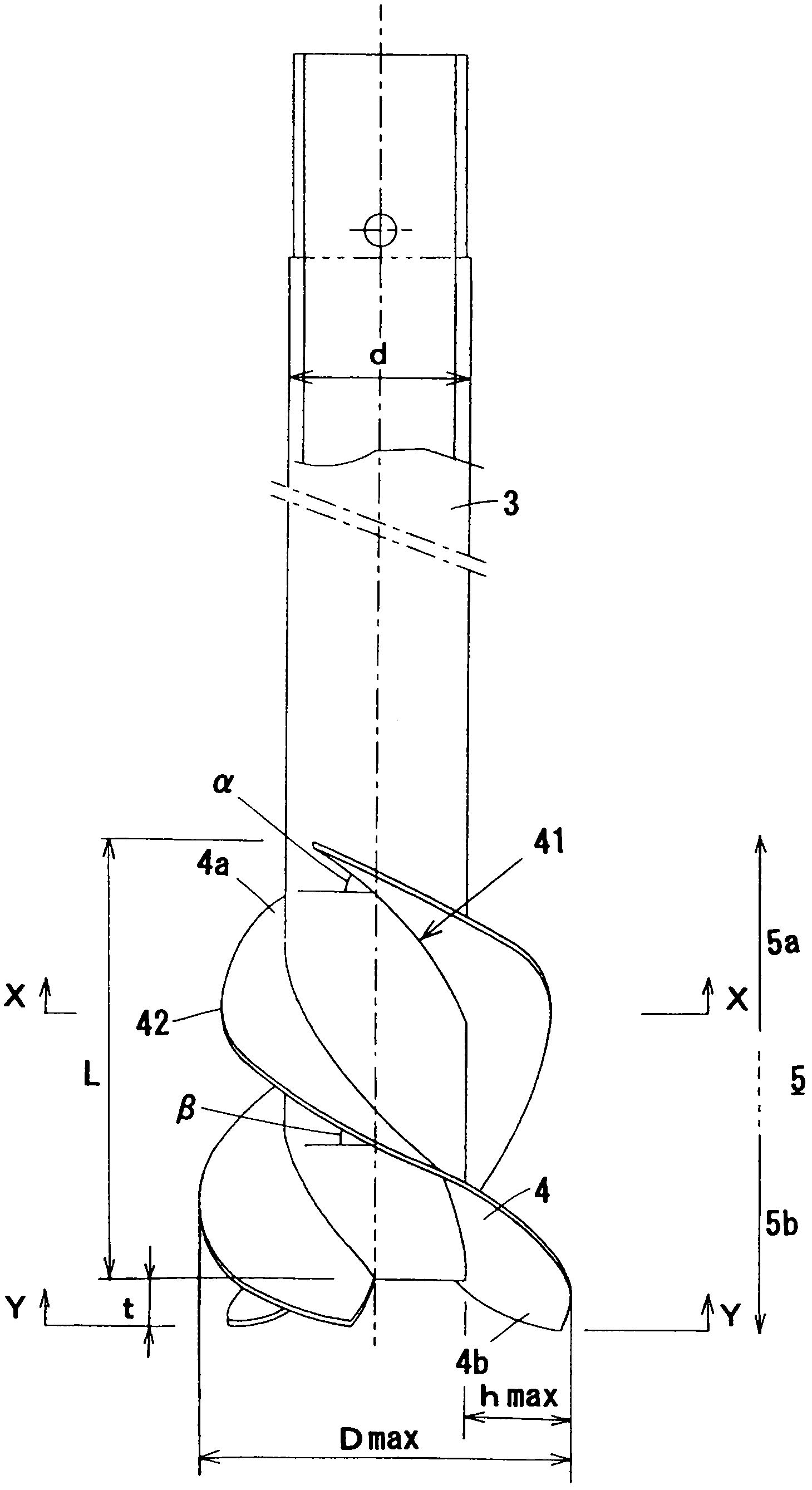

[0041] Next, embodiments of the propeller type aerator according to the present invention will be described with reference to the drawings.

[0042] Figure 1 to Figure 5 It is an example which shows the propeller type aerator of this invention.

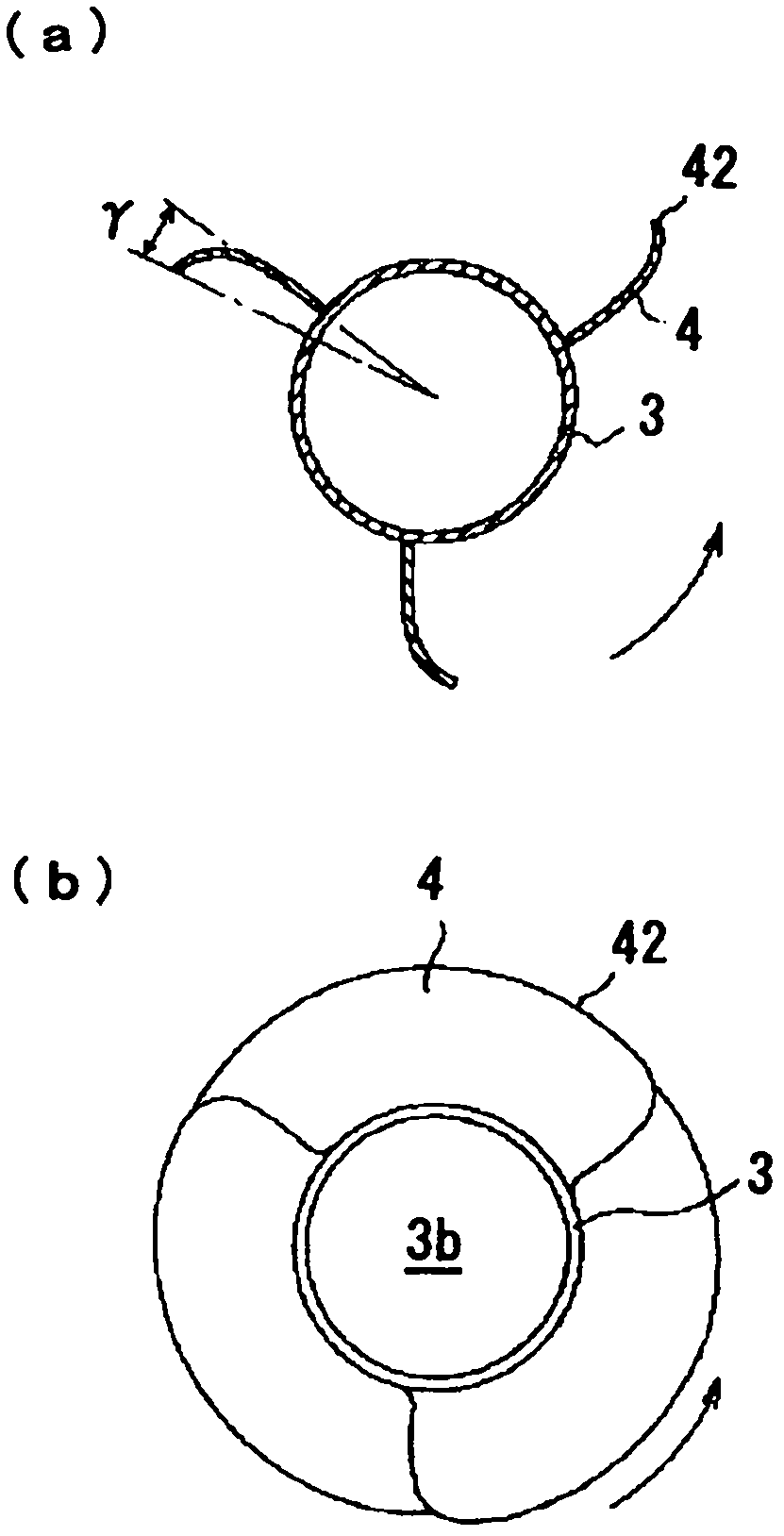

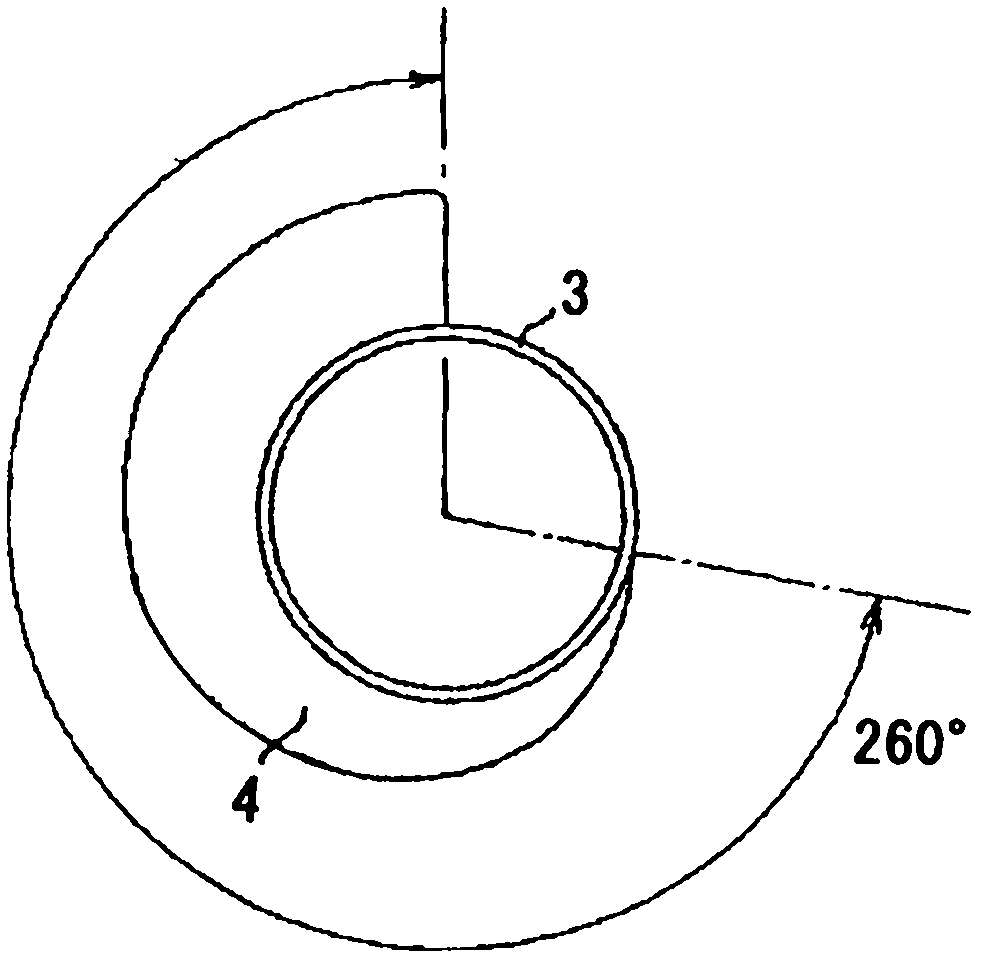

[0043]The propeller-type aerator 1 is arranged in an aeration tank of a wastewater treatment plant, etc., and is rotated by a drive motor 2, and one or more pieces are arranged at the front end of a hollow shaft 3 having an opening 3b at the shaft end to form a spiral. Plate-like blades 4 constitute a propeller 5 .

[0044] The base end of the hollow shaft 3 is penetrated with an air suction hole 3a, and the propeller 5 is rotated in the sewage by the drive motor 2 through the hollow shaft 3, and a negative pressure is generated in the sewage in the front area of the propeller 5. The hole 3 a sucks air, and the sucked air is supplied into the sewage from the opening 3 b formed at the shaft end of the hollow shaft 3 .

[0045] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com