Three-roll Mechanism and Method for Immediately Improving the Relative Rotating Speed of Its Variable-Speed Driving Roll

A technology of variable speed drive and relative speed, applied in the direction of winding strip, thin material processing, transportation and packaging, etc., can solve the problem that the relative speed of the variable speed drive roller is not fast enough to increase, and achieve the effect of increasing the absolute speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

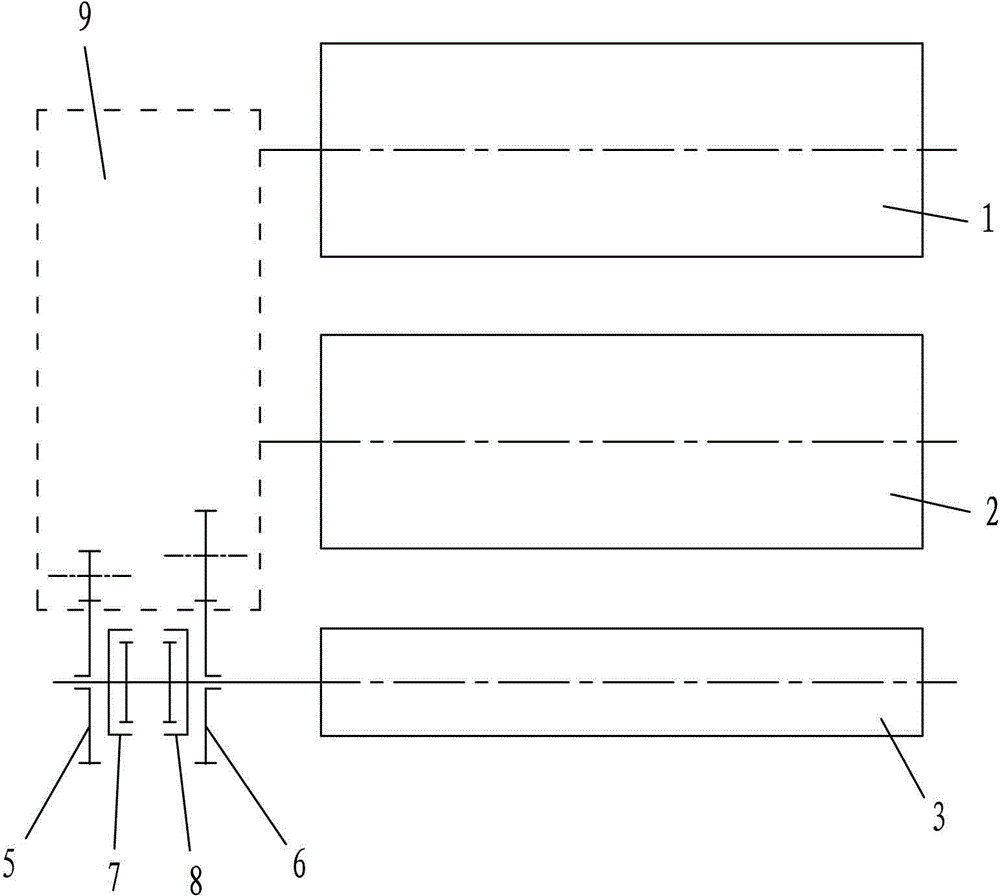

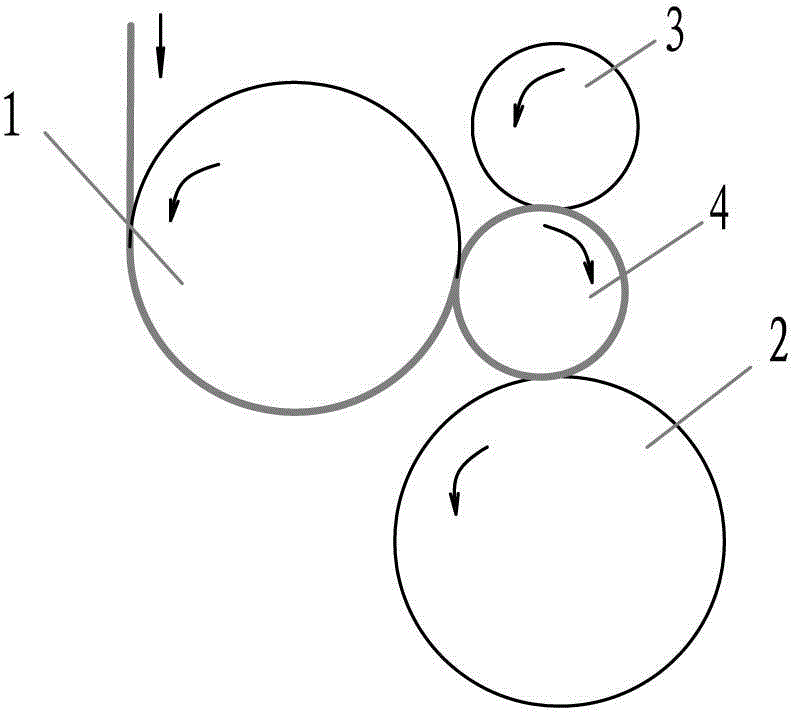

[0019] The three-roll mechanism of the present invention is as figure 1 As shown, it includes three driving rollers that rotate around the same passive member 4, two of which are reference driving rollers 1 and 2, and the remaining one is a variable speed driving roller 3. The specific functions to be completed by the three-roller mechanism, and what the passive member 4 is, depends on the specific equipment used by the three-roller mechanism. For example, if figure 1 The three-roll mechanism shown is applied in a rewinder for paper roll products, then figure 1 The passive part 4 shown is the paper roll, which is formed by rewinding the paper together with two reference drive rollers 1, 2 and a variable speed drive roller 3, and each time a roll of paper roll is completed after rewinding, The paper at the tail of the paper roll will also be torn off by instantly increasing the speed of the variable speed drive roller 3 relative to the other two reference drive rollers 1, 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com