Twin exhaust gas purifying tower

A purification tower and exhaust gas technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of increased difficulty and cost of installation and maintenance, increased difficulty of operation and control, and high consumption of circulating washing kinetic energy, and can achieve installation and maintenance. And the effect of easy maintenance, reduced manufacturing cost and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

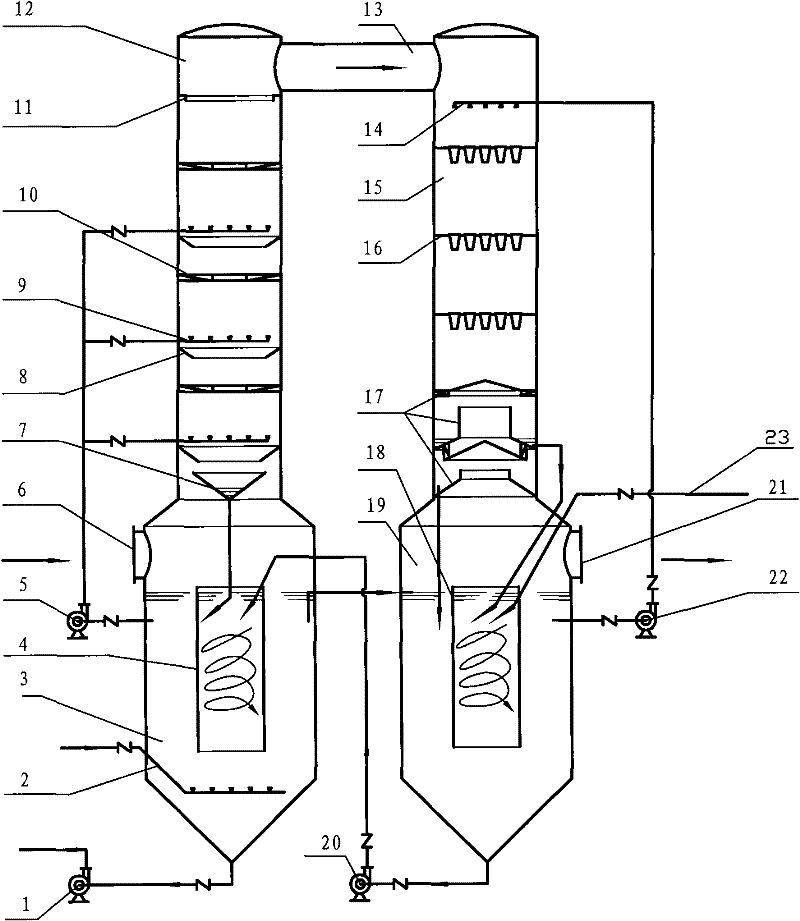

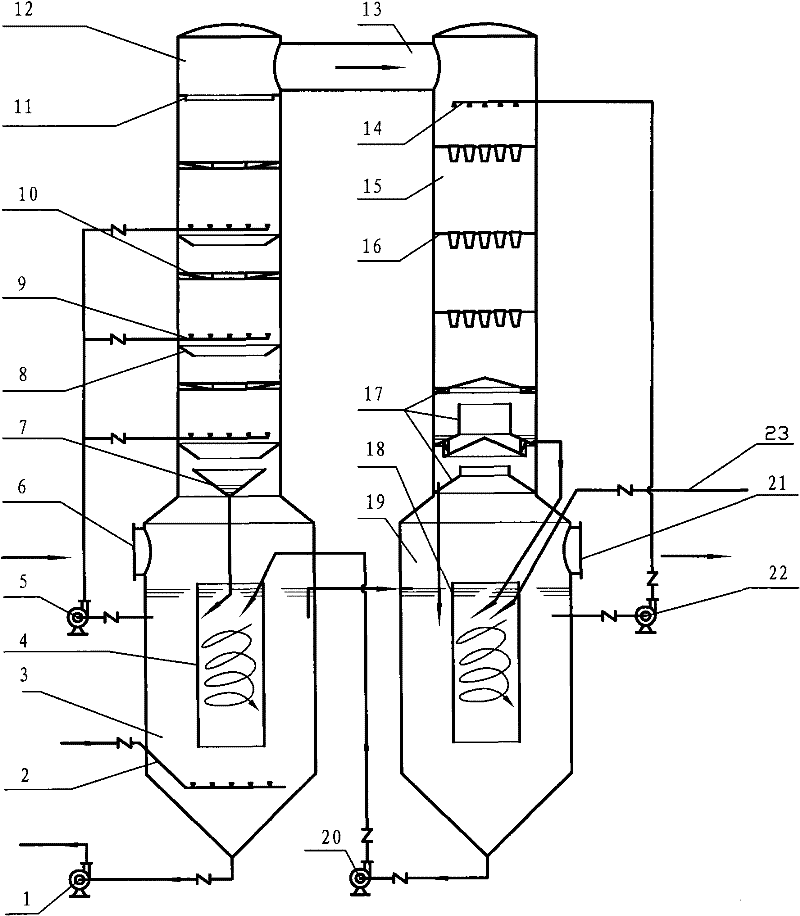

[0014] The present invention will be further described below in conjunction with the accompanying drawings, and this embodiment does not constitute a limitation to the present invention.

[0015] The structure of twin exhaust gas purification towers of the present invention is:

[0016] The twin exhaust gas purification towers as shown in the figure include parallel I towers 12, II towers 15, corresponding lower I tower circulation pools 3, II tower circulation pools 19, and connecting pipes 13 connected by the top two towers. In 12, the liquid collection bucket 7, the three-layer liquid guide ring 8, the three-layer nozzle 9, the three-layer swirl plate 10, and the top liquid ring 11 are respectively arranged from bottom to top, and the waste gas provided on the I tower circulation pool 3 Inlet 6, exhaust gas enters tower I from exhaust gas inlet 6, tower I spacer 4 is set in tower I circulation pool 3, air enters tower I from oxidation device 2, and tower cloth liquid II is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com