Solid-liquid mixing device and mixing method using the same

A technology of solid-liquid mixing and equipment, applied in the direction of mixing methods, mixers with rotating stirring devices, mixers, etc., can solve the problem of slow dispersion process, inability to adapt to widely different powder and liquid material characteristics, poor efficiency, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

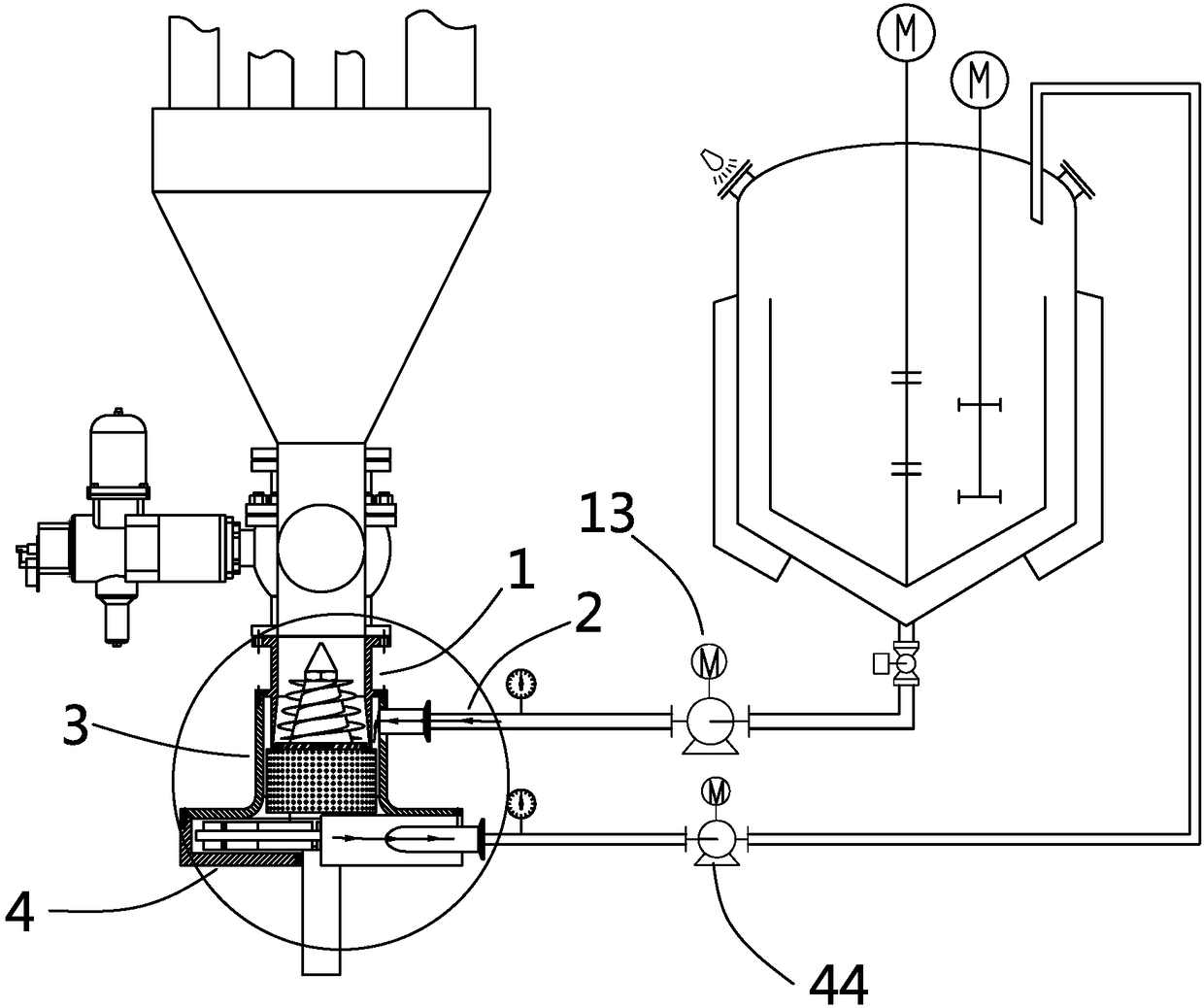

[0055] refer to figure 1 , 2 , 3, which discloses a solid-liquid mixing device, including a powder dispersion module 1, a liquid distribution module 2, a solid-liquid mixing module 3 and a discharge module 4, wherein:

[0056] In this embodiment, the powder dispersing module 1 is an impact-type powder dispersing and crushing device. It includes a powder dispersion chamber 11, a spiral conical impact module 12 and a powder discharge structure 13 arranged therein, wherein:

[0057] The powder dispersion chamber 11 is shaped like a barrel with upper and lower openings, a retaining wall 111 is provided in the middle of the outer wall, and a positioning hole 112 is provided on the retaining wall 111 .

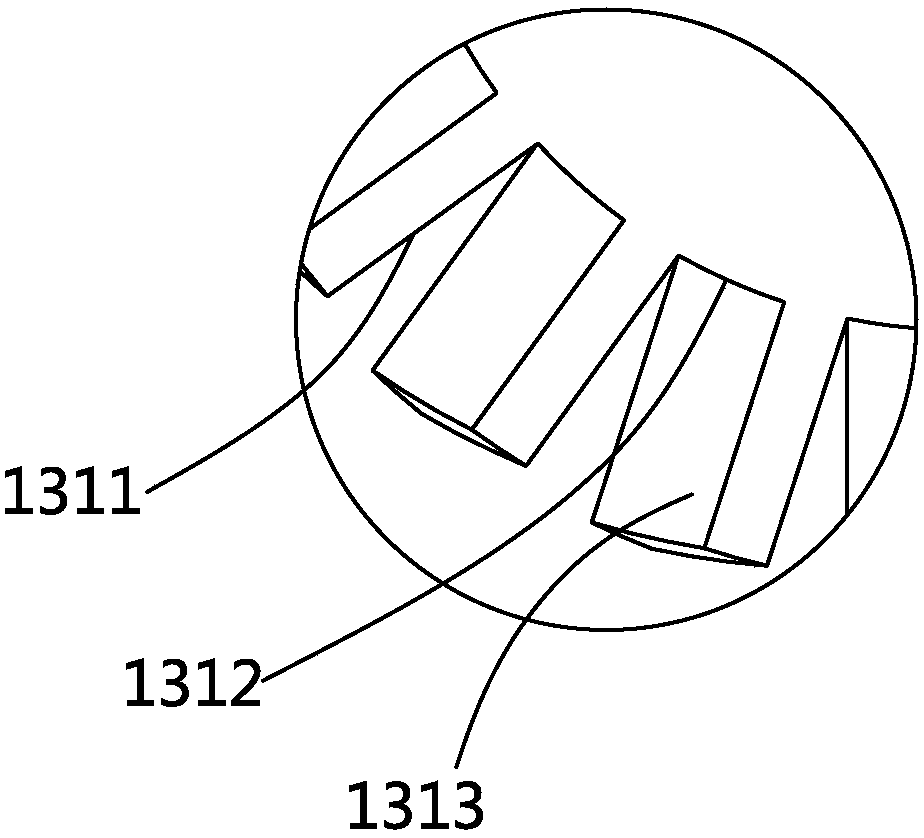

[0058] The spiral conical impact module 12 includes a conical body 121 and a cutting piece 122 arranged on the surface of the conical body and spirals upward. Through this structural arrangement, the contact chance or collision probability between the powder and the spiral conica...

Embodiment 2

[0071] The present invention also discloses a mixing method using the above-mentioned solid-liquid mixing equipment, which includes the following steps:

[0072] Step 1, the liquid to be mixed is delivered to the mixing module 3 through the liquid distribution module 2;

[0073] The liquid to be mixed is first delivered to the annular slit 23 through the joint action of the pump 21 and the liquid feed pipe 22, so that the liquid passes through the annular slit 23 and goes vertically downward with a certain acceleration. The magnitude of this acceleration depends on the pressure of the liquid to be mixed input by the pump 21.

[0074] In practice, the total cross-sectional area of the liquid feed pipe 22 should be greater than or equal to the flow area of the annular slit 23 .

[0075] Step 2, after the powder to be mixed is dispersed and / or pulverized by the powder dispersion module, it collides with the liquid to be mixed vertically downward at a certain angle of inclina...

Embodiment 3

[0081] refer to Figure 8 , 9 , 10, which is a schematic structural view of the third embodiment of the present invention; compared with the first embodiment, the difference is:

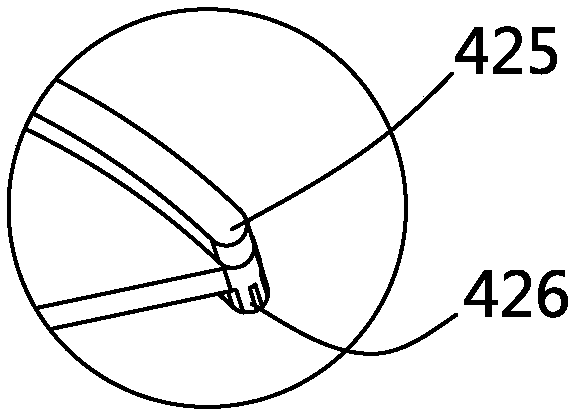

[0082] The stirrer 32' in this embodiment includes a stirrer body 321' and blades 326 set on the circumference of the body. The blades 326 are upright arranged on the circumference of the mixer body 321′. The center of the agitator body 321' is provided with an axis hole 325'.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com