Water-holding and cultivating functional compound fertilizer and preparation method thereof

A compound fertilizer and functional technology, applied in the direction of fertilizer mixture, fertilization device, application, etc., can solve the problems of unbalanced nutrient elements, waste of resources, low nutrient absorption rate, etc., to increase production and income, save resources, and maintain soil moisture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

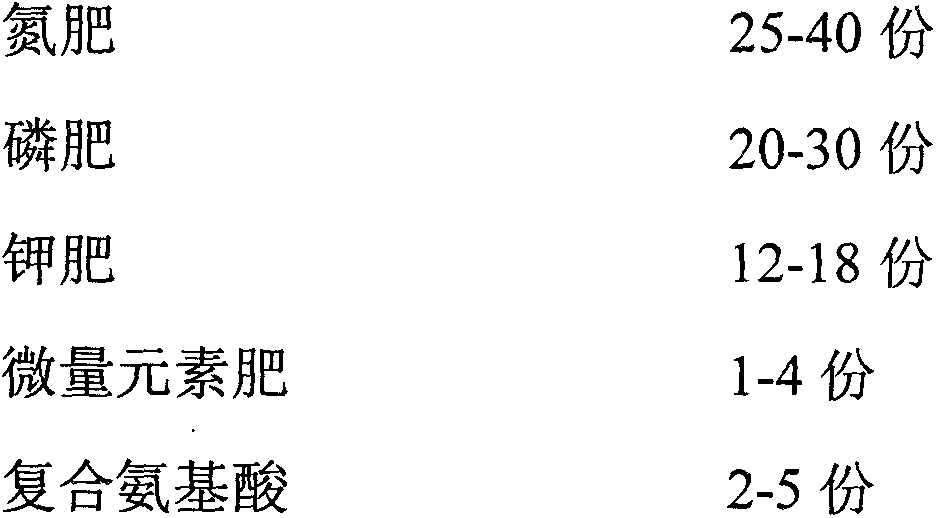

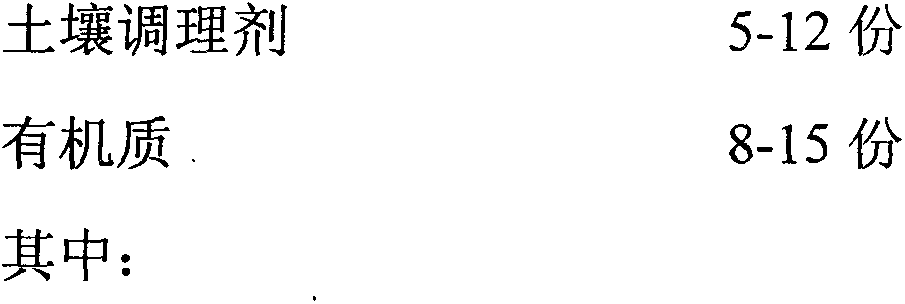

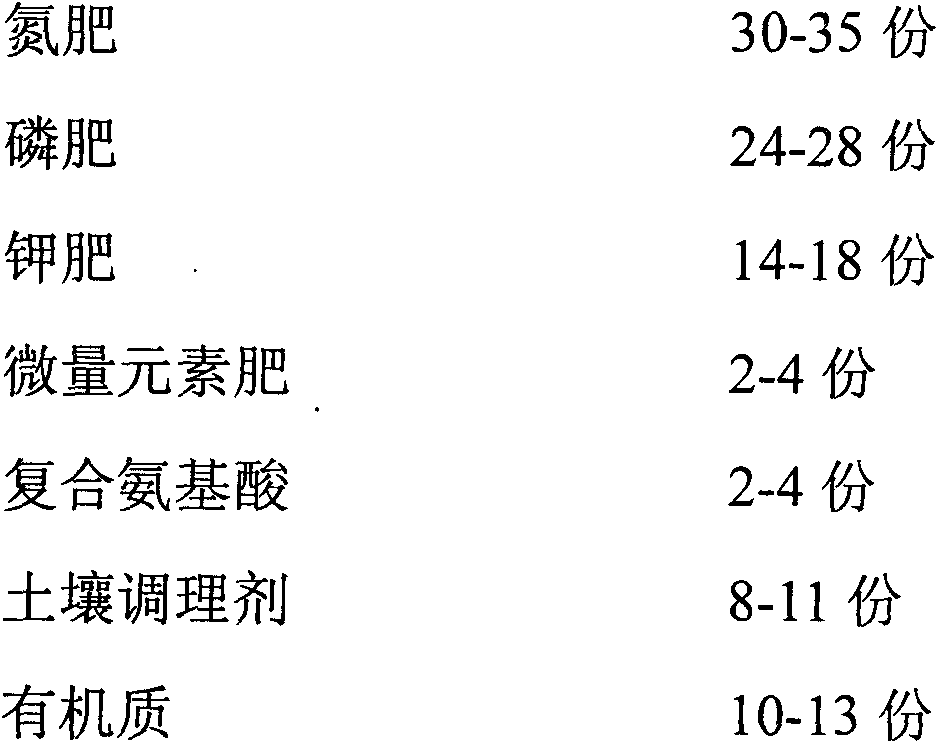

Method used

Image

Examples

Embodiment 1

[0071] Get urea 16kg, ammonium nitrate 16kg, superphosphate 15kg, superphosphate superphosphate 10kg, potassium chloride 4kg, potassium sulfate 12kg, ammonium molybdate 1kg, cobalt sulfate 2kg, amino acid content be the compound amino acid 3kg of 50% by weight, calcium + 9 kg of bentonite with a total weight content of magnesium of 500 mg / kg bentonite was crushed to 80-120 mesh, and then the components were uniformly mixed to obtain a mixed material 1.

[0072] Weigh 6 kg of humic acid and 6 kg of peat soil, and pulverize them to obtain mixed material 2.

[0073] Mix mixture 2 into mixture 1 and mix evenly to obtain mixture 3.

[0074] The mixed material 3 is drum granulated and sieved to obtain granules with a particle size of 2-6 mm.

Embodiment 2

[0076] Get urea 20kg, ammonium nitrate 10kg, superphosphate 9kg, superphosphate superphosphate 18kg, potassium chloride 8kg, potassium sulfate 8kg, ammonium molybdate 2kg, cobalt sulfate 2kg, amino acid content are 4kg of compound amino acid of 48% by weight, calcium superphosphate respectively. + 11 kg of bentonite with a total weight content of magnesium of 600 mg / kg bentonite was crushed to 80-120 mesh, and then the components were uniformly mixed to obtain a mixed material 1.

[0077] Weigh 5 kg of humic acid and 5 kg of peat soil, and pulverize them to obtain mixed material 2.

[0078] Mix mixture 2 into mixture 1 and mix evenly to obtain mixture 3.

[0079] The mixed material 3 is drum granulated and sieved to obtain granules with a particle size of 2-6 mm.

Embodiment 3

[0081] Get ammonium sulfate 25kg, monoammonium phosphate 30kg, potassium sulfate 12kg, manganese sulfate 4kg, amino acid content be the compound amino acid 2kg of 45% by weight, calcium+magnesium total weight content be the bentonite 12kg of 300mg / kg bentonite respectively, be pulverized respectively to 80-120 mesh, and then mix the components uniformly to obtain the mixed material 1.

[0082] Weigh 8 kg of peat soil and pulverize it to obtain mixed material 2.

[0083] Mix mixture 2 into mixture 1 and mix evenly to obtain mixture 3.

[0084] The mixed material 3 is drum granulated and sieved to obtain granules with a particle size of 2-6 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com