Milk replacer for dairy calves and production method thereof

A production method and milk replacer technology, applied in whey, application, dairy products, etc., can solve the problems of antibiotic resistance, high breeding cost, calf infection, etc., to enhance resistance, improve production performance, The effect of reducing the incidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

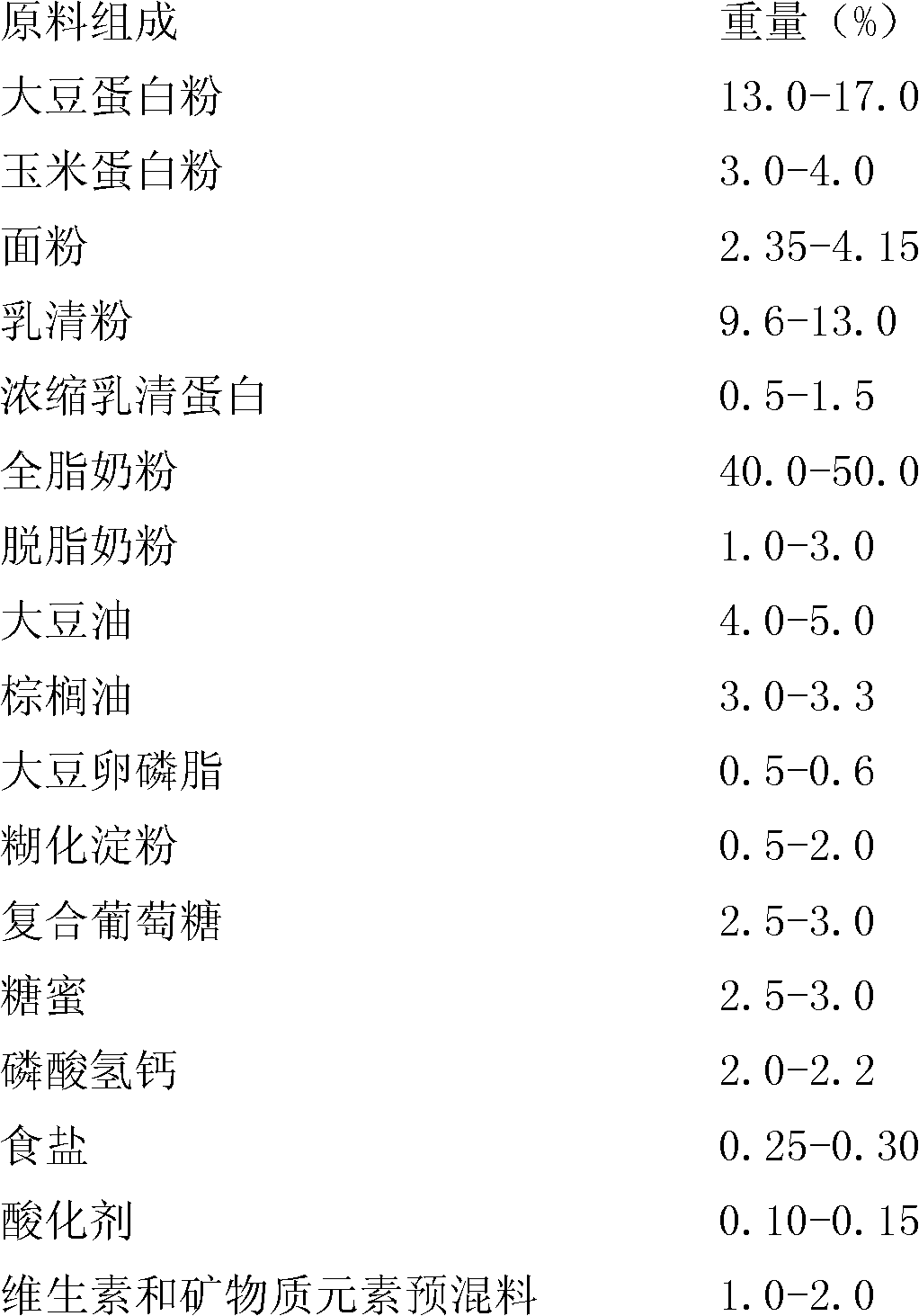

[0036] Calf milk replacer formula for milk is calculated by weight percentage (%): soybean protein powder 17.0, corn gluten powder 4.0, flour 4.15, whey powder 13.0, whey protein concentrate 0.5, whole milk powder 40.0, skimmed milk powder 1.0, large Soybean oil 5.0, palm oil 3.0, soybean lecithin 0.5, gelatinized starch 2.0, compound glucose 2.5, molasses 3.0, calcium hydrogen phosphate 2.0, salt 0.25, acidulant 0.1, vitamin and mineral element premix 2.0.

[0037] The formula of the acidulant described in the calf milk replacer formula for milk is by weight percentage (%): citric acid 30.0, malic acid 20.0, fumaric acid 30.0, sodium diacetate 20.0.

[0038] The vitamin and mineral element premix formula described in the formula of the calf milk replacer for above-mentioned milk is calculated by weight percentage (%): vitamin A 0.32, vitamin D 3 0.064, vitamin E 1.6, vitamin K 3 0.024, vitamin B 1 0.075, vitamin B 2 0.094, vitamin B 6 0.075, vitamin B 120.08, niacin...

Embodiment 2

[0047] Calf milk replacer formula for milk is calculated by weight percentage (%): soybean protein powder 13.0, corn gluten powder 3.0, flour 2.35, whey powder 9.6, whey protein concentrate 1.5, whole milk powder 50.0, skimmed milk powder 3.0, large Soybean oil 4.0, palm oil 3.3, soybean lecithin 0.6, gelatinized starch 0.5, compound glucose 3.0, molasses 2.5, calcium hydrogen phosphate 2.2, salt 0.3, acidulant 0.15, vitamin and mineral element premix 1.0.

[0048] The formula of the acidulant described in the calf milk replacer formula for milk is by weight percentage (%): citric acid 25.0, malic acid 30.0, fumaric acid 20.0, sodium diacetate 25.0.

[0049] The vitamin and mineral element premix formula described in the formula of the calf milk replacer for above-mentioned milk is calculated by weight percentage (%): vitamin A 0.4, vitamin D 3 0.08, vitamin E 2.0, vitamin K 3 0.03, vitamin B 1 0.095, vitamin B 2 0.119, vitamin B 6 0.095, vitamin B 12 0.1, niacin 0.2...

Embodiment 3

[0060] Calf milk replacer formula for milk is calculated by weight percentage (%): soybean protein powder 15.0, corn gluten powder 3.5, flour 3.25, whey powder 11.3, whey protein concentrate 1.0, whole milk powder 45.0, skimmed milk powder 2.0, large Soybean oil 4.5, palm oil 3.15, soybean lecithin 0.55, gelatinized starch 1.25, compound glucose 2.75, molasses 2.75, calcium hydrogen phosphate 2.1, salt 0.275, acidulant 0.125, vitamin and mineral element premix 1.5.

[0061] The formula of the acidulant described in the calf milk replacer formula for milk is by weight percentage (%): citric acid 27.5, malic acid 25.0, fumaric acid 25.0, sodium diacetate 22.5.

[0062] The vitamins and mineral element premix formulations described in the formula of calf milk replacer for above-mentioned milk are calculated by weight percentage (%): vitamin A 0.36, vitamin D 3 0.072, vitamin E 1.8, vitamin K 3 0.027, vitamin B 1 0.085, vitamin B 2 0.106, vitamin B 6 0.085, vitamin B 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com