Novel composite premix for milking cow in nonlactating period and production method thereof

A technology of premixed feed and production method, applied in the direction of animal feed, animal feed, application, etc., can solve the problems of loss, no economic benefit, not enough attention, etc., to enhance resistance, obvious feeding effect, reduce The effect of incidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

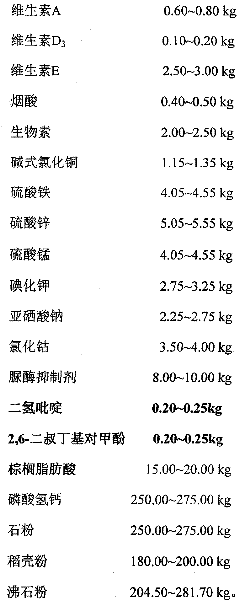

[0048] The formula of the new compound premixed feed during the dry period of lactating cows is by weight: vitamin A 0.80kg, vitamin D 3 0.20kg, vitamin E 3.00kg, niacin 0.50kg, biotin 2.50kg, basic copper chloride 1.35kg, iron sulfate 4.55kg, zinc sulfate 5.55kg, manganese sulfate 4.55kg, potassium iodide 3.25kg, sodium selenite 2.75 kg, cobalt chloride 4.00kg, urease inhibitor 10.00kg, dihydropyridine 0.25kg, 2,6-di-tert-butyl-p-cresol 0.25kg, palm fatty acid 20.00kg, calcium hydrogen phosphate 275.00kg, stone powder 275.00kg, rice Shell powder 200.00kg and zeolite powder 204.50kg.

[0049] Choose high-quality raw materials, according to the formula, weigh the raw materials with an electronic balance with a sensitivity of 0.01g, and ensure the accuracy of the quality of the raw materials when weighing. Use different sampling spoons for raw materials with different trace components to avoid cross-contamination; mix vitamin A, vitamin D3, vitamin E, niacin, biotin, dihydropy...

Embodiment 2

[0062] The formula of the new compound premixed feed during the dry period of lactating cows is by weight: vitamin A 0.60kg, vitamin D 3 0.10kg, vitamin E 2.50kg, niacin 0.40kg, biotin 2.00kg, basic copper chloride 1.15kg, iron sulfate 4.05kg, zinc sulfate 5.05kg, manganese sulfate 4.05kg, potassium iodide 2.75kg, sodium selenite 2.25 kg, cobalt chloride 3.50kg, urease inhibitor 8.00kg, dihydropyridine 0.2kg, 2,6-di-tert-butyl-p-cresol 0.20kg, palm fatty acid 15.00kg, calcium hydrogen phosphate 250.00kg, stone powder 250.00kg, rice Shell powder 180.00kg and zeolite powder 281.70kg.

[0063] Production method is with embodiment 1.

Embodiment 3

[0065] The formula of the new compound premixed feed during the dry period of lactating cows is by weight: vitamin A 0.70kg, vitamin D 3 0.15kg, vitamin E 2.75kg, niacin 0.45kg, biotin 2.25kg, basic copper chloride 1.25kg, iron sulfate 4.30kg, zinc sulfate 5.30kg, manganese sulfate 4.30kg, potassium iodide 3.00kg, sodium selenite 2.50 kg, cobalt chloride 3.75kg, urease inhibitor 9.00kg, dihydropyridine 0.225kg, 2,6-di-tert-butyl-p-cresol 0.225kg, palm fatty acid 17.50kg, calcium hydrogen phosphate 262.50kg, stone powder 262.50kg, rice Shell powder 190.00kg and zeolite powder 243.10kg.

[0066] Production method is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com