Novel composite premix for milking cow in nonlactating period and production method thereof

A technology of pre-mixed feed and production method, applied in the direction of animal feed, animal feed, application, etc., to achieve the effect of ensuring uniformity, reasonable formula and improving body condition

Active Publication Date: 2010-08-25

BEIJING ORIENTAL KINGHERD BIOTECH

View PDF3 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Weighing of raw materials→preparation of vitamin premix additives→preparation of trace element premix additives→co-mixing→inspection→packaging→finished products

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a novel composite premix for a milking cow in a nonlactating period and a production method thereof, and belongs to the technical field of feed mixing technology and production. Aiming at the characteristics of nutrition physiological characteristics of the cow in the nonlactating period, the premix is prepared by using vitamin A, vitamin D3, vitamin E, niacin, biotin, copper oxychloride, ferric sulfate, zinc sulfate, manganese sulfate, potassium iodide, sodium selenite, cobalt chloride, urease inhibitor, dihydropyridine, 2,6-di-tert-butyl-methyl phenol, palm fatty acid, calcium hydrophosphate, mountain flour, powdered rice hulls and zeolite powder as raw materials through the processes of raw material weighing, vitamin premix additive preparation, trace element premix additive preparation, co-mixing, inspection, package and finishing product. The premix has reasonable formula, balanced nutrition and scientific production and processing technique. Tests prove that the premix effectively improves the body condition of dry cows, reduces generation rate of metabolic diseases, improves productivity of postpartum cows, and has clear feed effect and obvious economic benefit.

Description

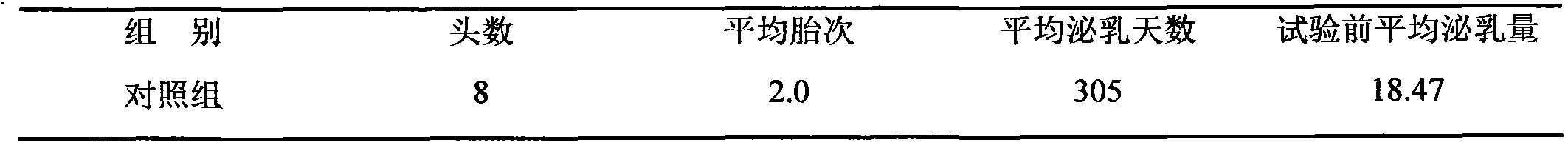

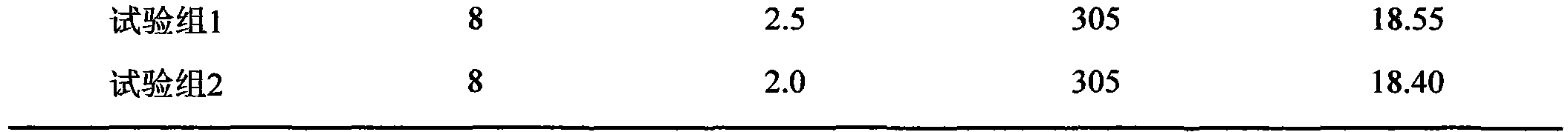

technical field The invention relates to a compound premixed feed, which belongs to the field of feed compounding technology and production technology. Background technique The dry period refers to the period when the cows stop lactating before giving birth. The reasonable nutritional level at this stage is directly related to the lactation performance of the postpartum cows, and even more related to the health and high yield of the cows in the future. The dry milk period is the storage period of nutrients, the regeneration period of mammary gland tissue, the rapid growth and development period of the fetus, and an important stage for the recovery of the whole body function. Therefore, the nutritional level during the dry period is extremely important for dairy cows. However, because this physiological stage has no economic benefits, some dairy farmers have not paid enough attention to this physiological process, resulting in many unnecessary losses. The invention uses mul...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A23K1/175A23K1/14A23K1/18

CPCY02P60/87

Inventor 李寰旭

Owner BEIJING ORIENTAL KINGHERD BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com