Machining method and device for preparing micro-nano two-dimensional structure on surface of workpiece

A technology of workpiece surface and two-dimensional structure, which is applied in the direction of electrolytic components, cells, electrolytic process, etc., can solve the problem of affecting the stability of super-hydrophobic/hydrophilic performance, and it is difficult to prepare bionic micro-nano structure surface, surface microstructure and Solve problems such as low substrate adhesion, achieve the effects of promoting rapid and efficient growth, enhancing processing localization, and improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

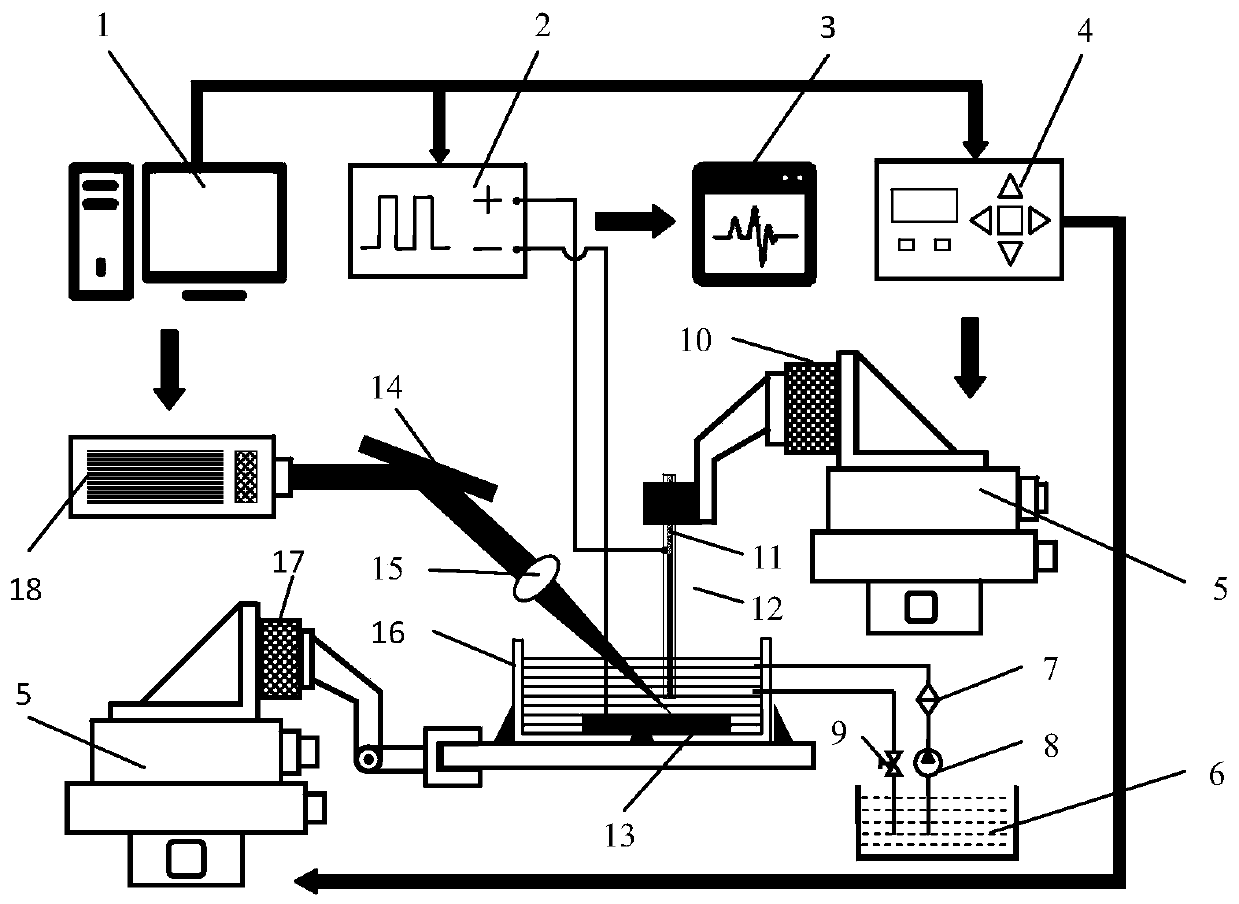

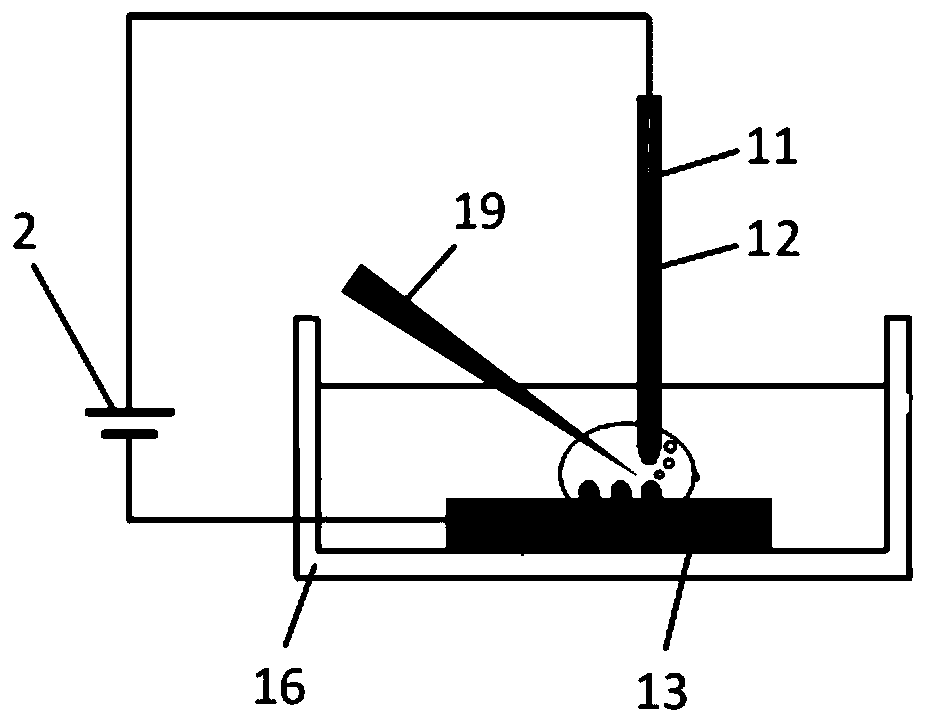

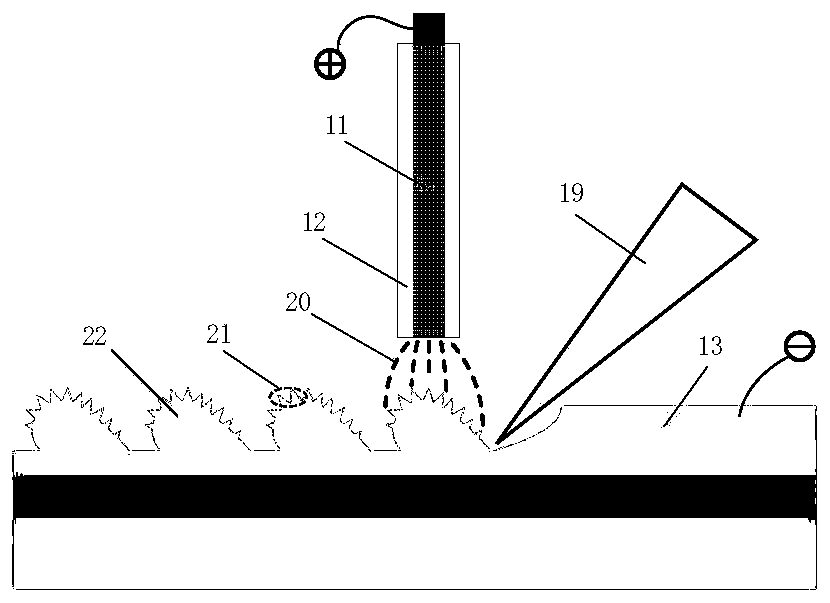

[0042]A processing method for preparing a micro-nano two-dimensional structure on the surface of a workpiece, using laser beam ablation and electrochemical deposition to simultaneously generate a micro-nano two-dimensional structure on the surface of the workpiece to obtain the super-repellent / hydrophilic function of the surface of the part; the laser emits The laser beam is focused by the optical path transmission system and the convex lens, irradiates on the surface of the workpiece substrate 13, and ablates a micron-scale structure on the surface of the workpiece substrate 13; at the same time, the positive pole and negative pole of the DC power supply are respectively connected to the tool anode 11 and the workpiece substrate 13, and connected to the workpiece substrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com