Patents

Literature

257results about How to "Efficient growth process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

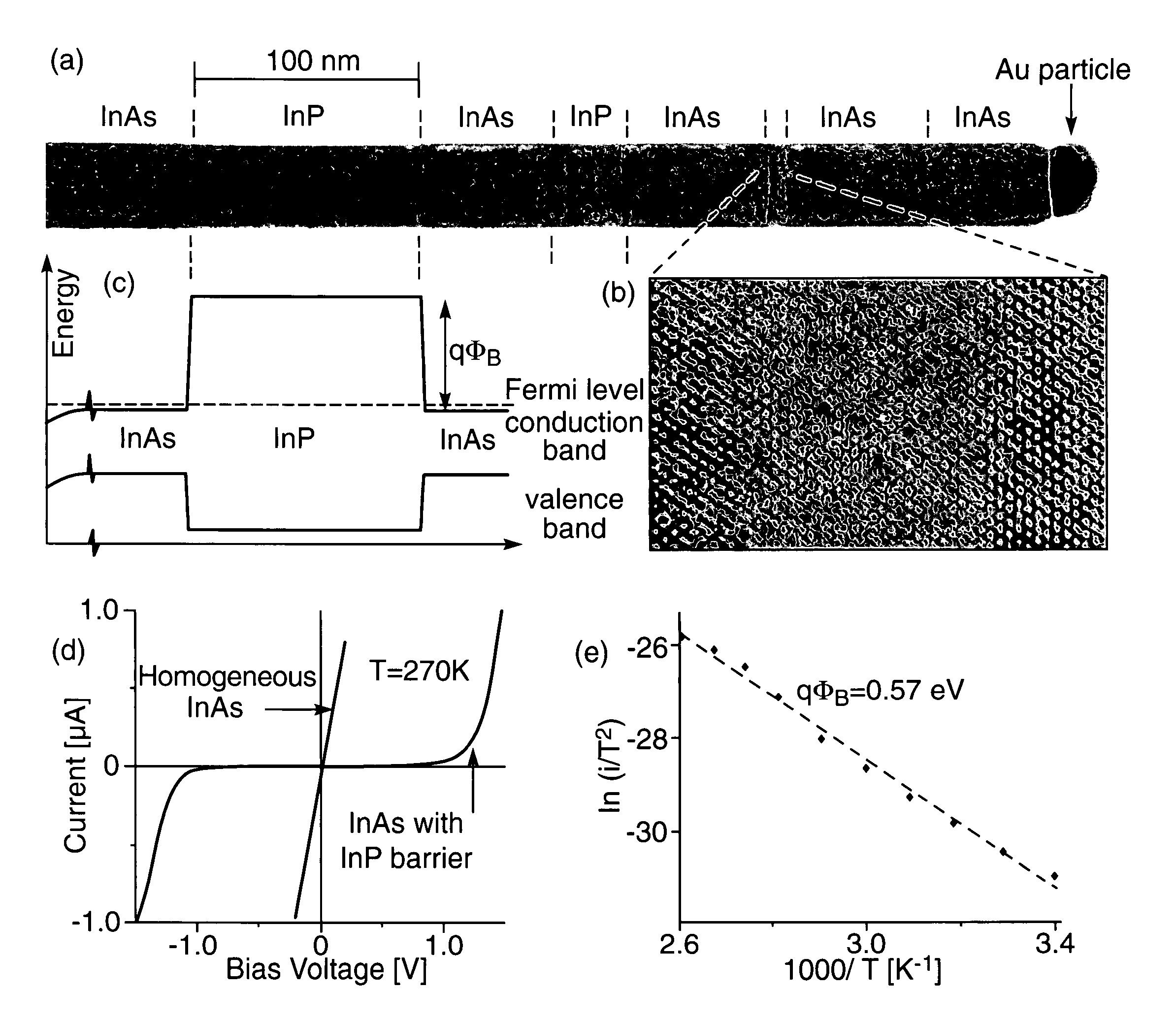

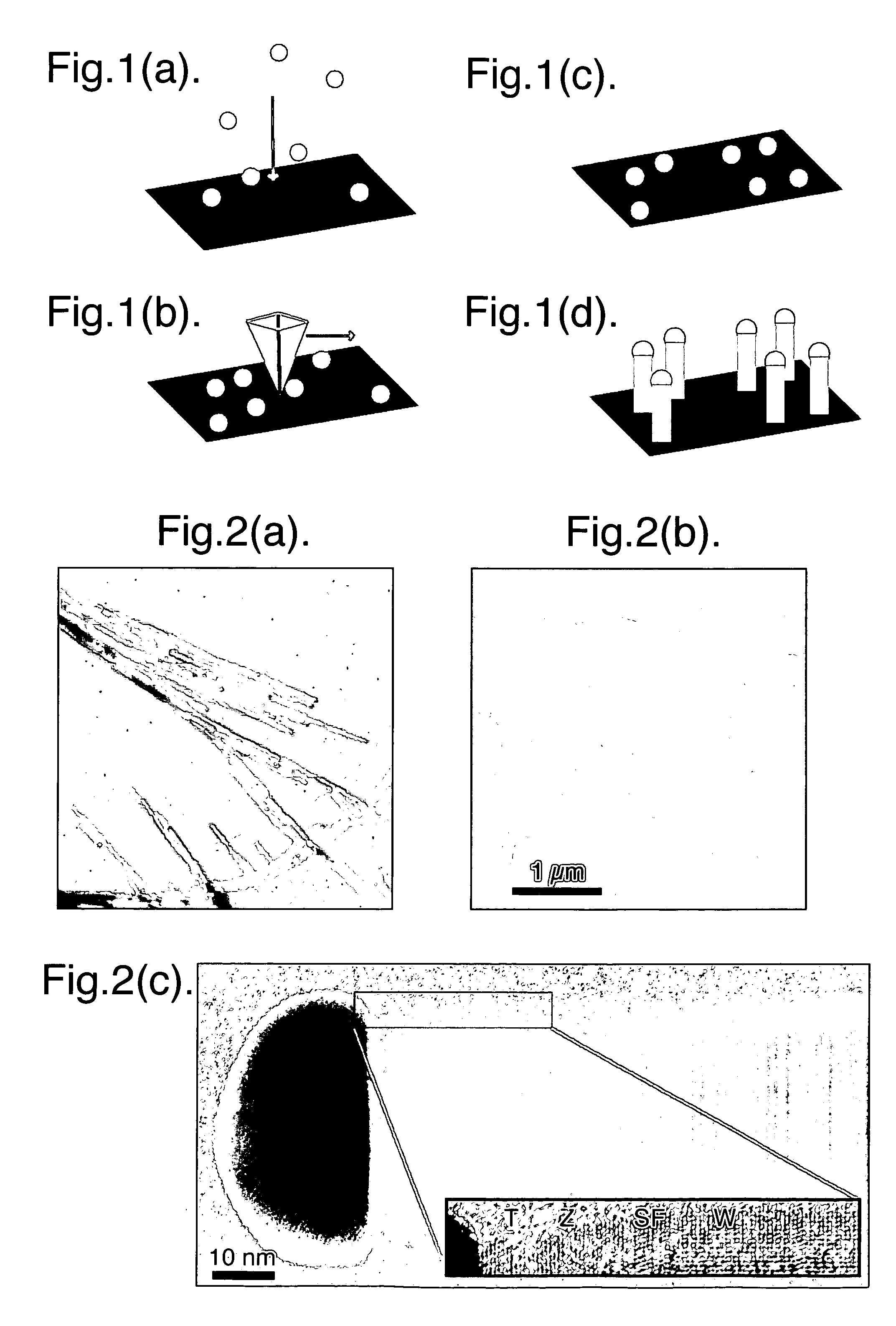

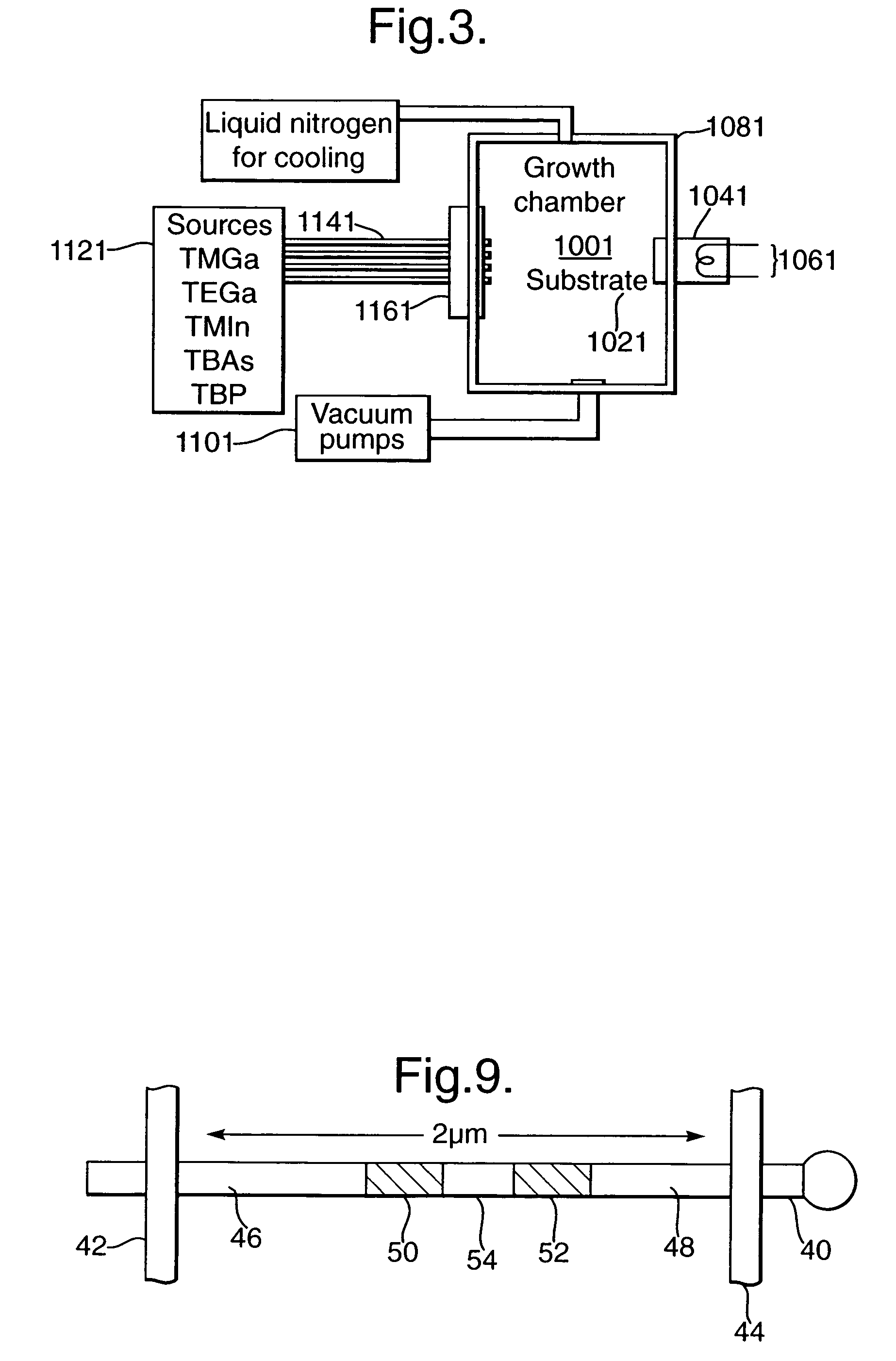

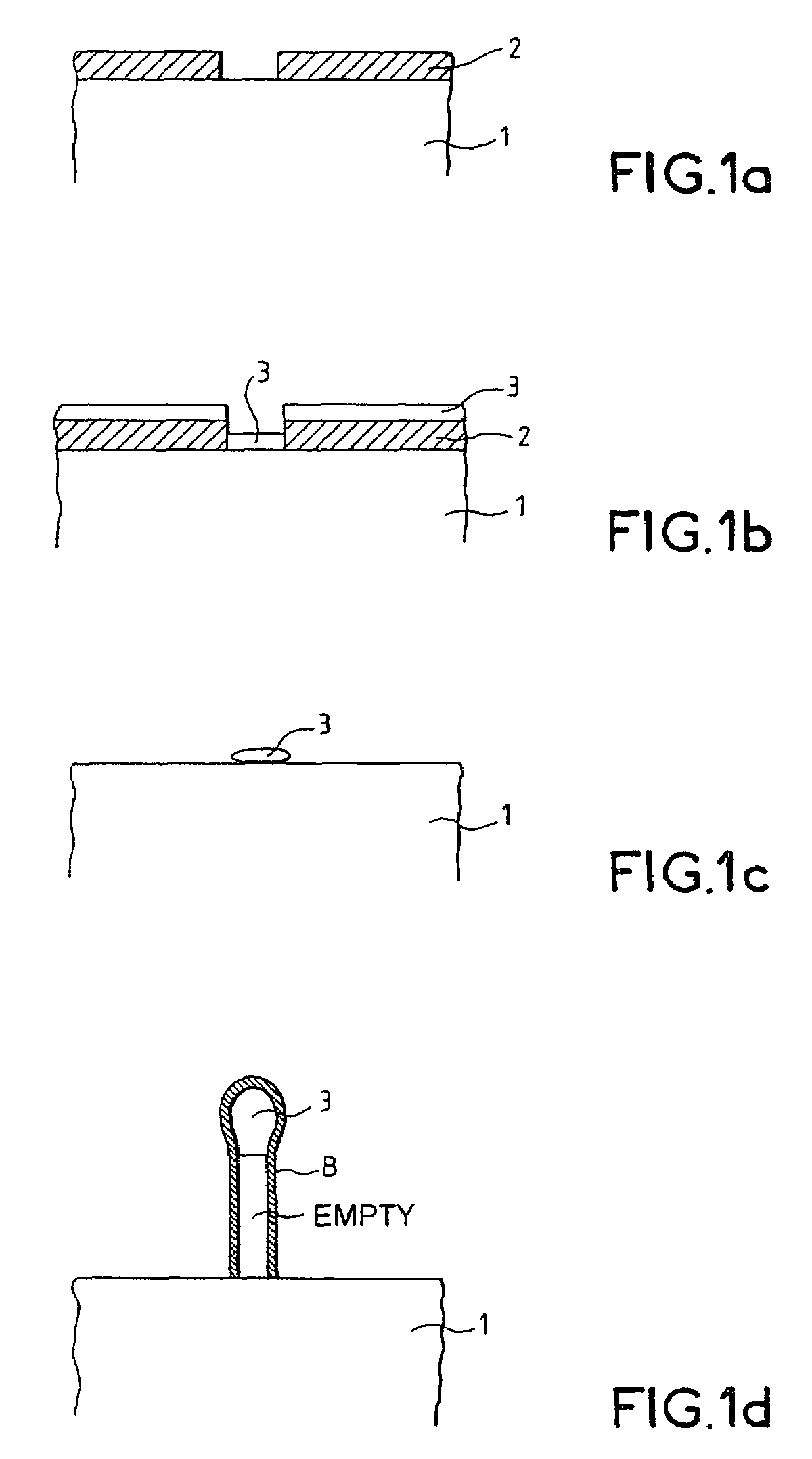

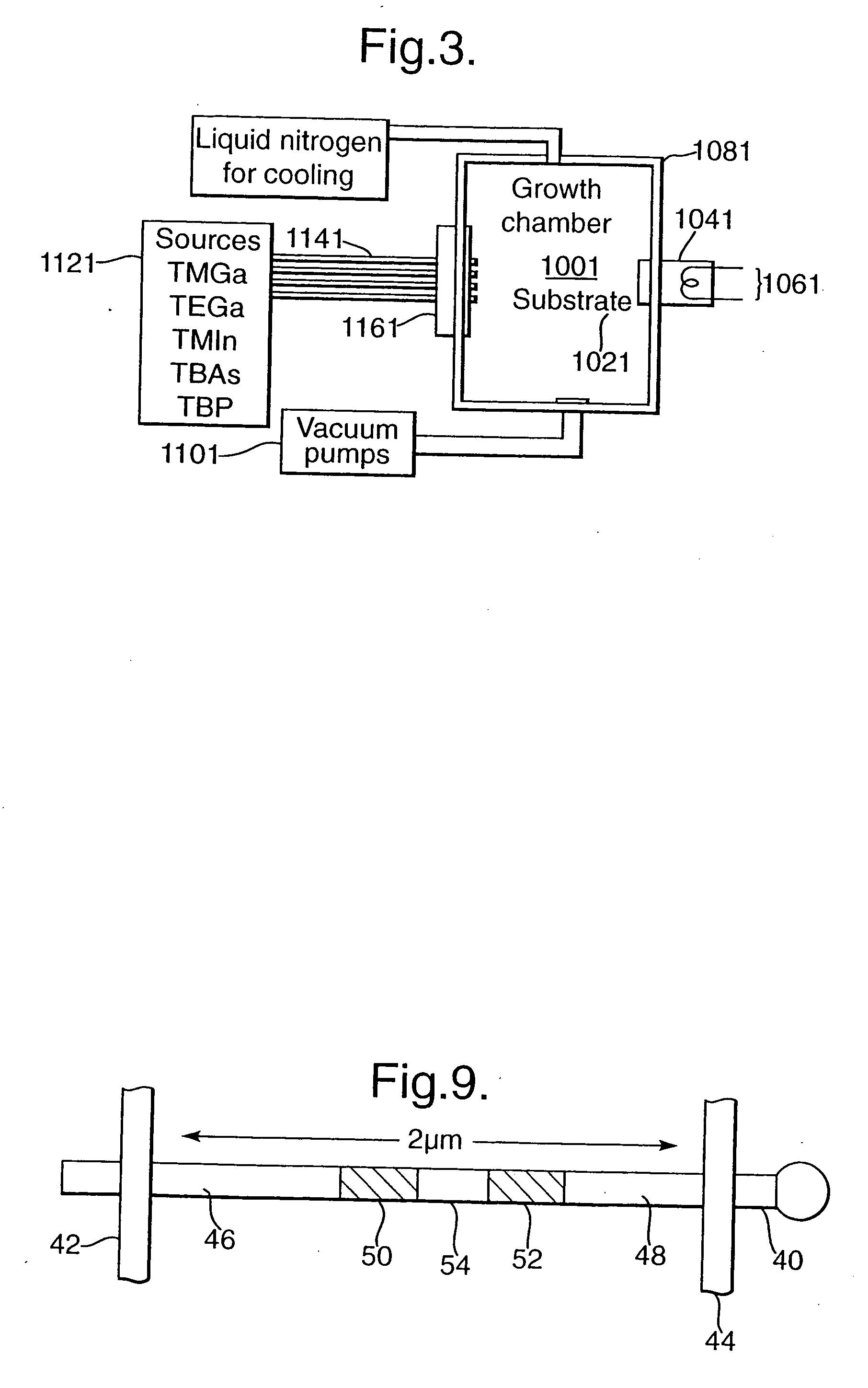

Nanostructures and methods for manufacturing the same

InactiveUS7335908B2Accurate weighingEnhances width controlPolycrystalline material growthIndividual molecule manipulationPhotonicsWhiskers

A resonant tunneling diode, and other one dimensional electronic, photonic structures, and electromechanical MEMS devices, are formed as a heterostructure in a nanowhisker by forming length segments of the whisker with different materials having different band gaps.

Owner:QUNANO

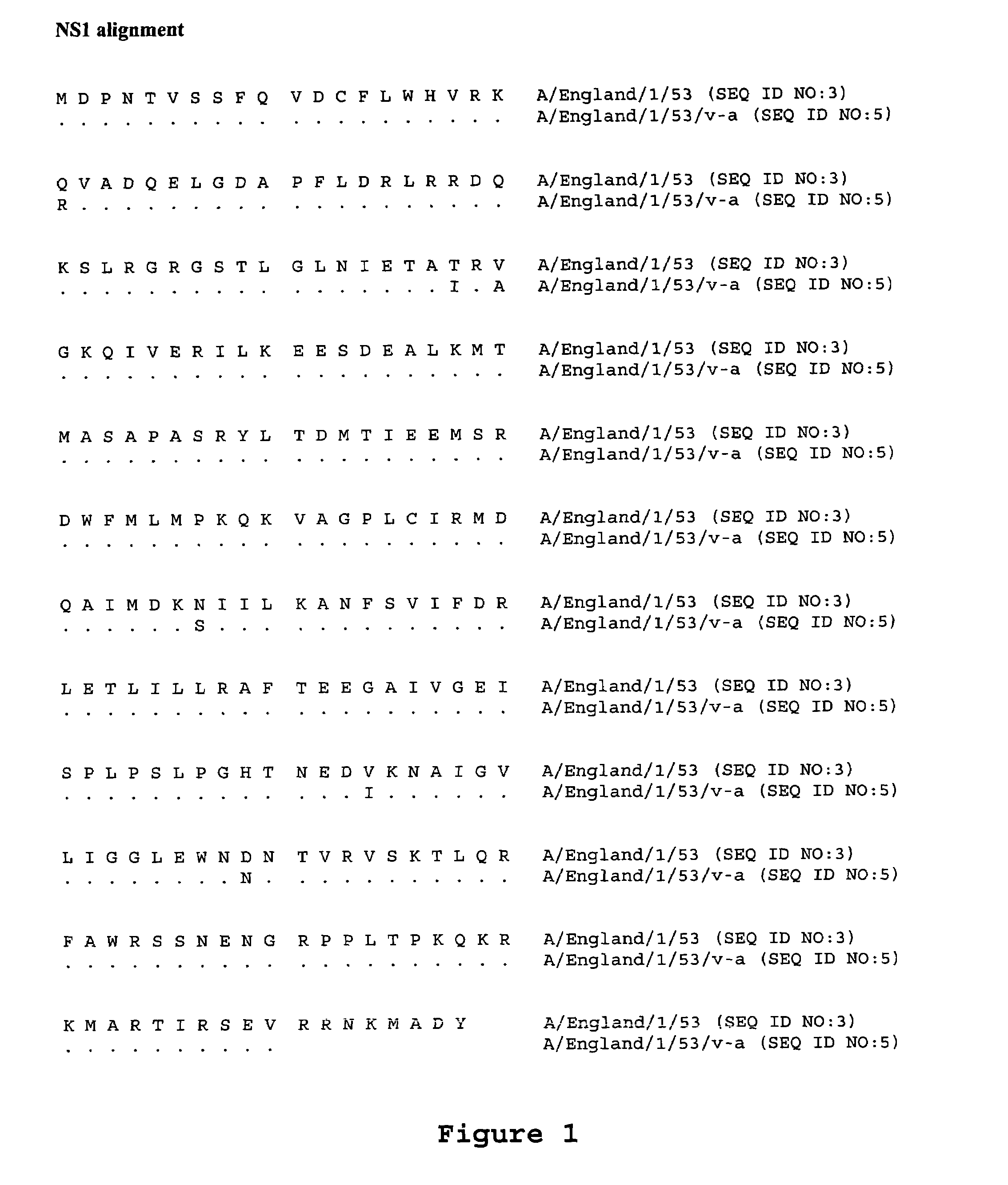

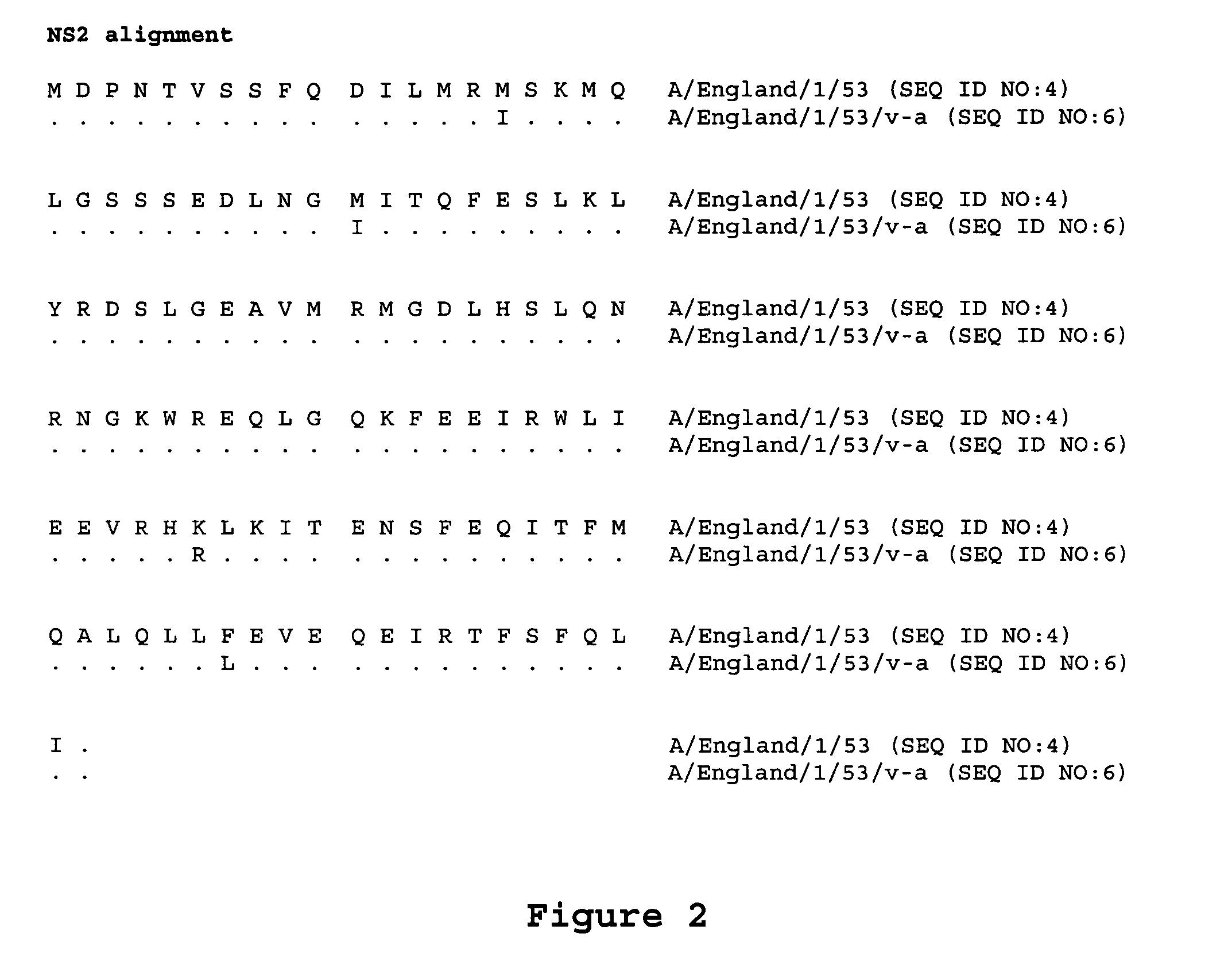

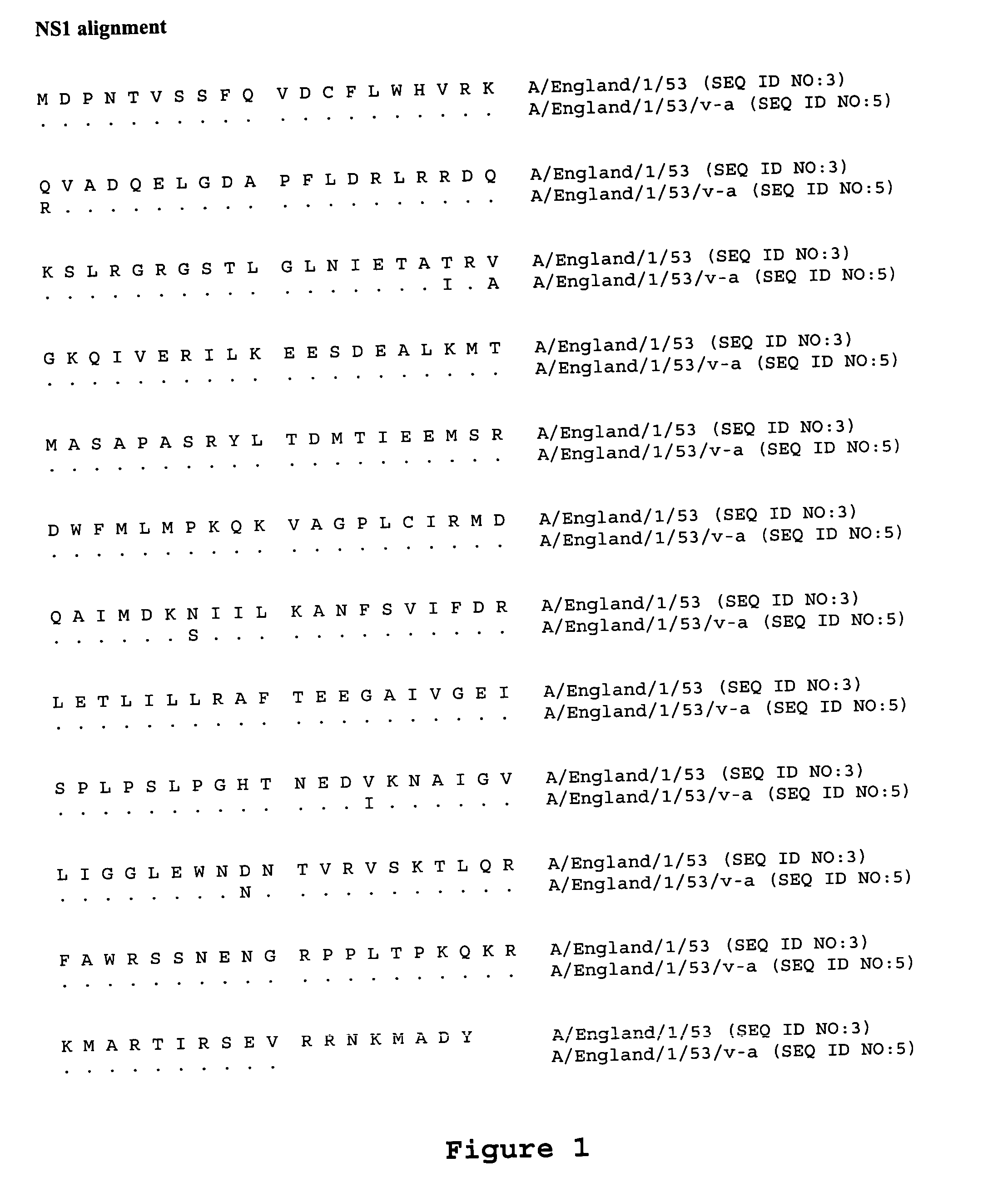

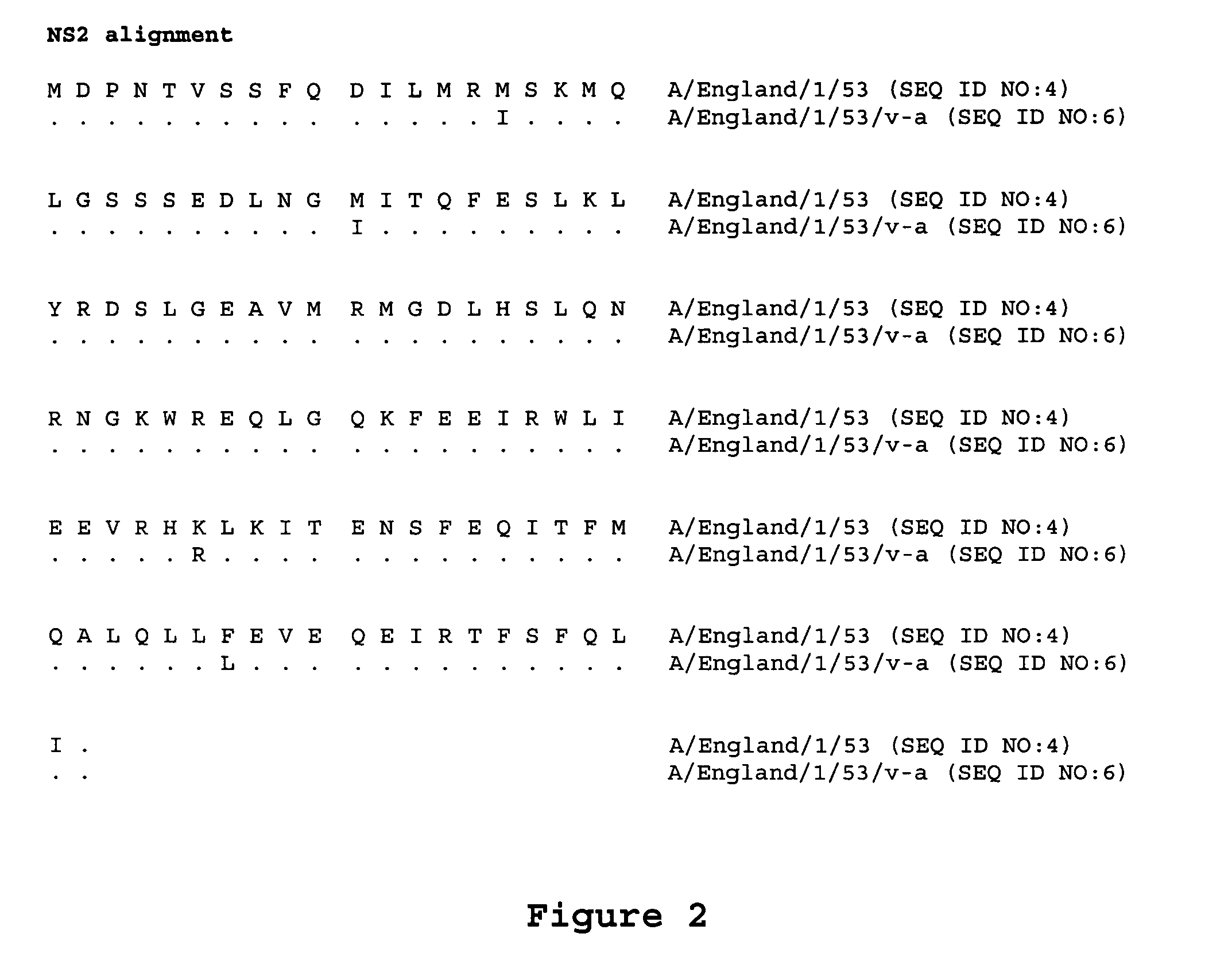

Method for generating influenza viruses and vaccines

InactiveUS7037707B2Grows more efficientlyEfficient growth processSsRNA viruses negative-senseBiocideMammalian cellGene

Owner:ST JUDE CHILDRENS RES HOSPITAL INC

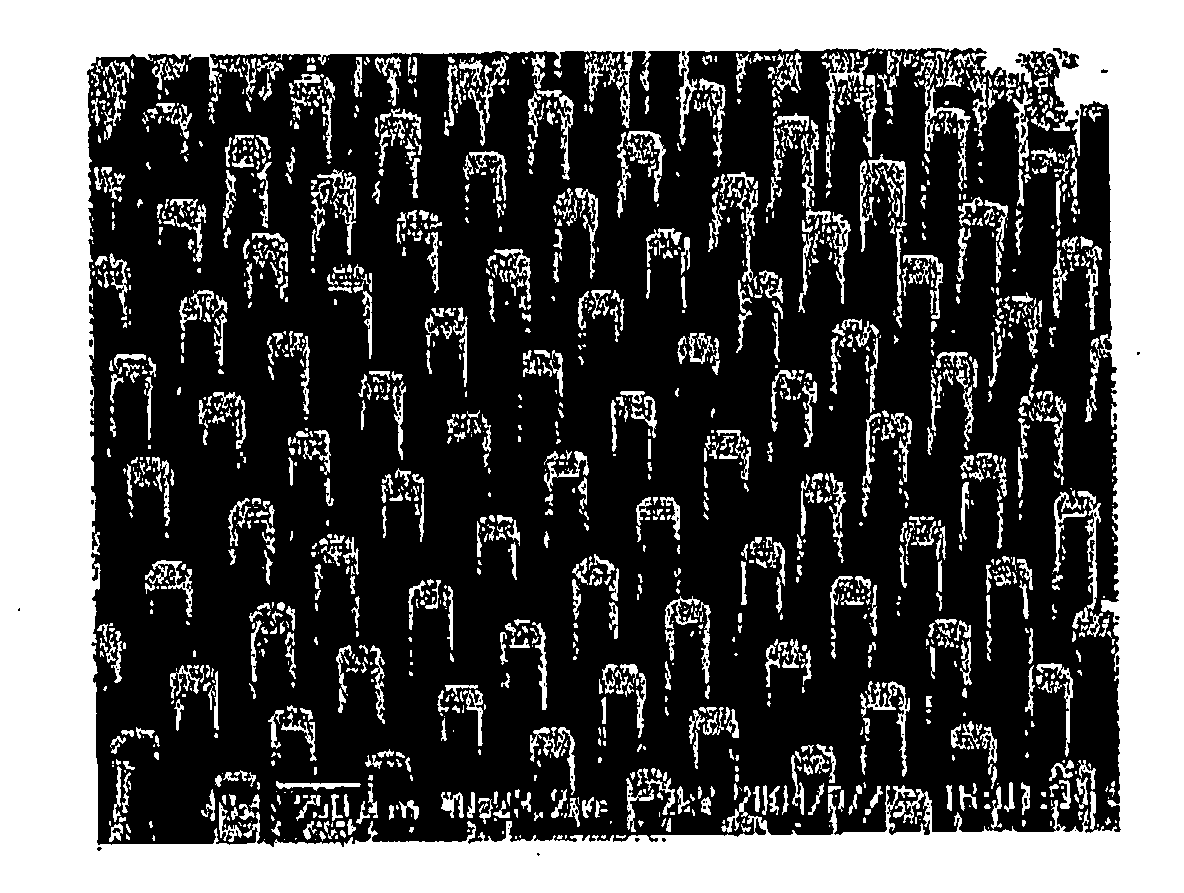

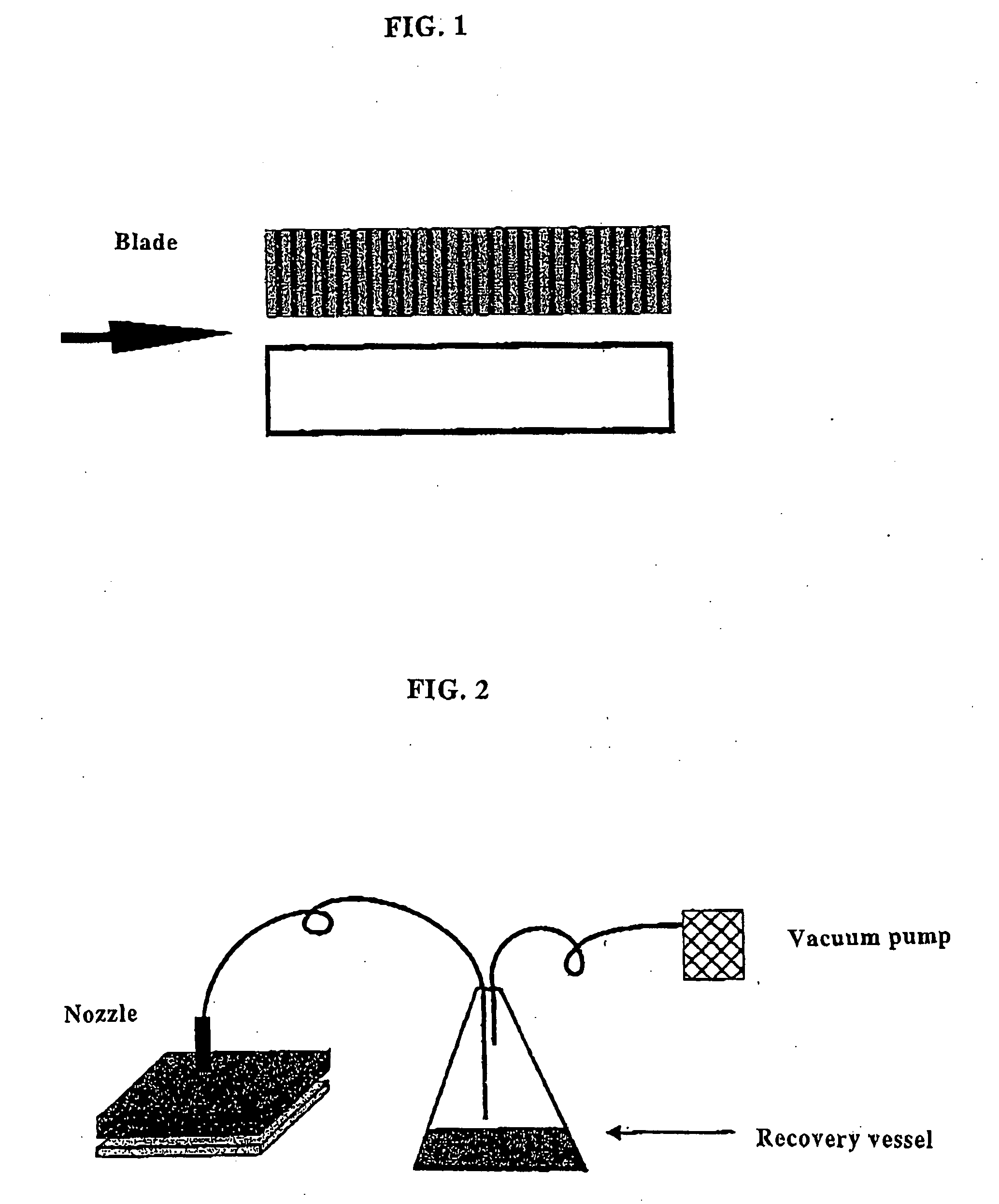

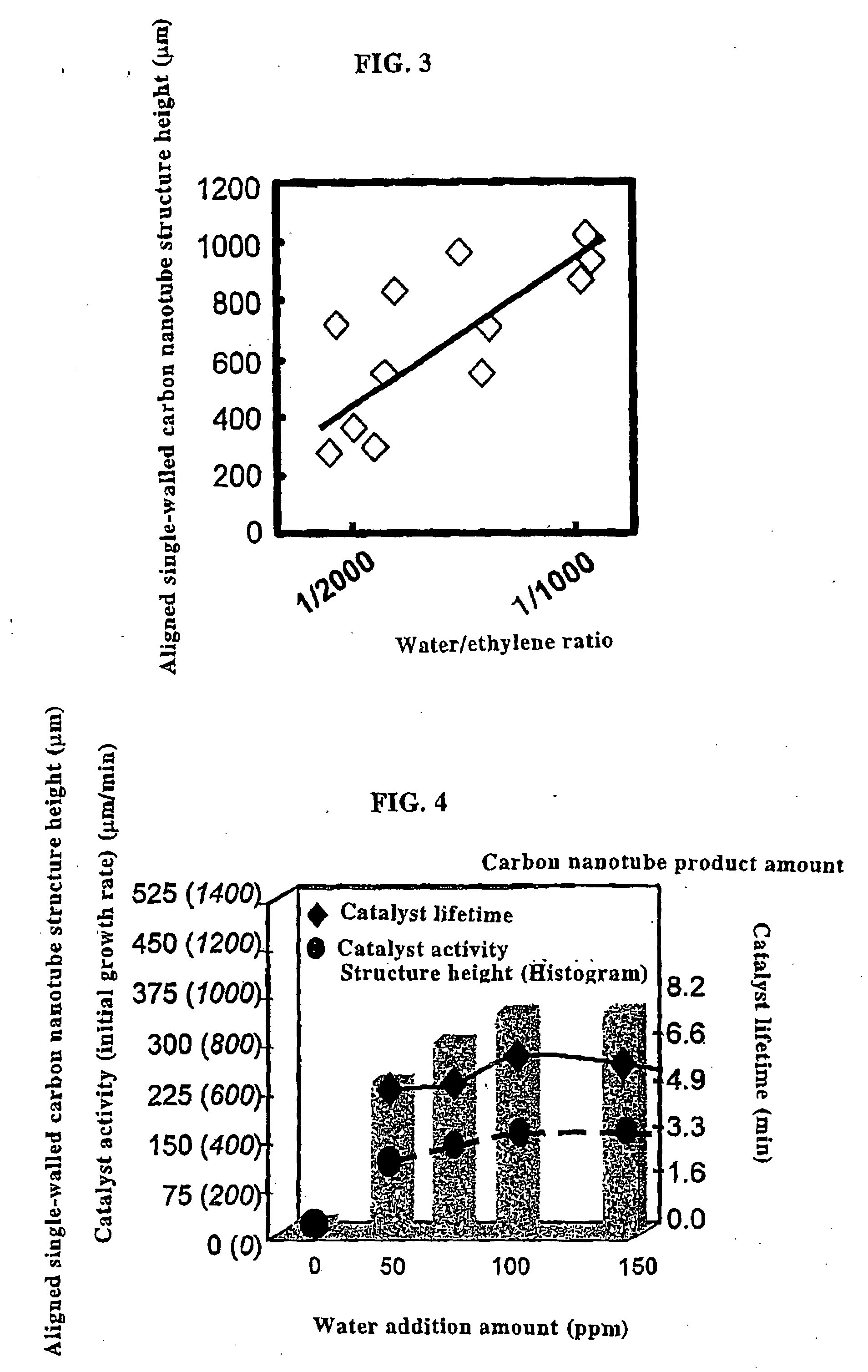

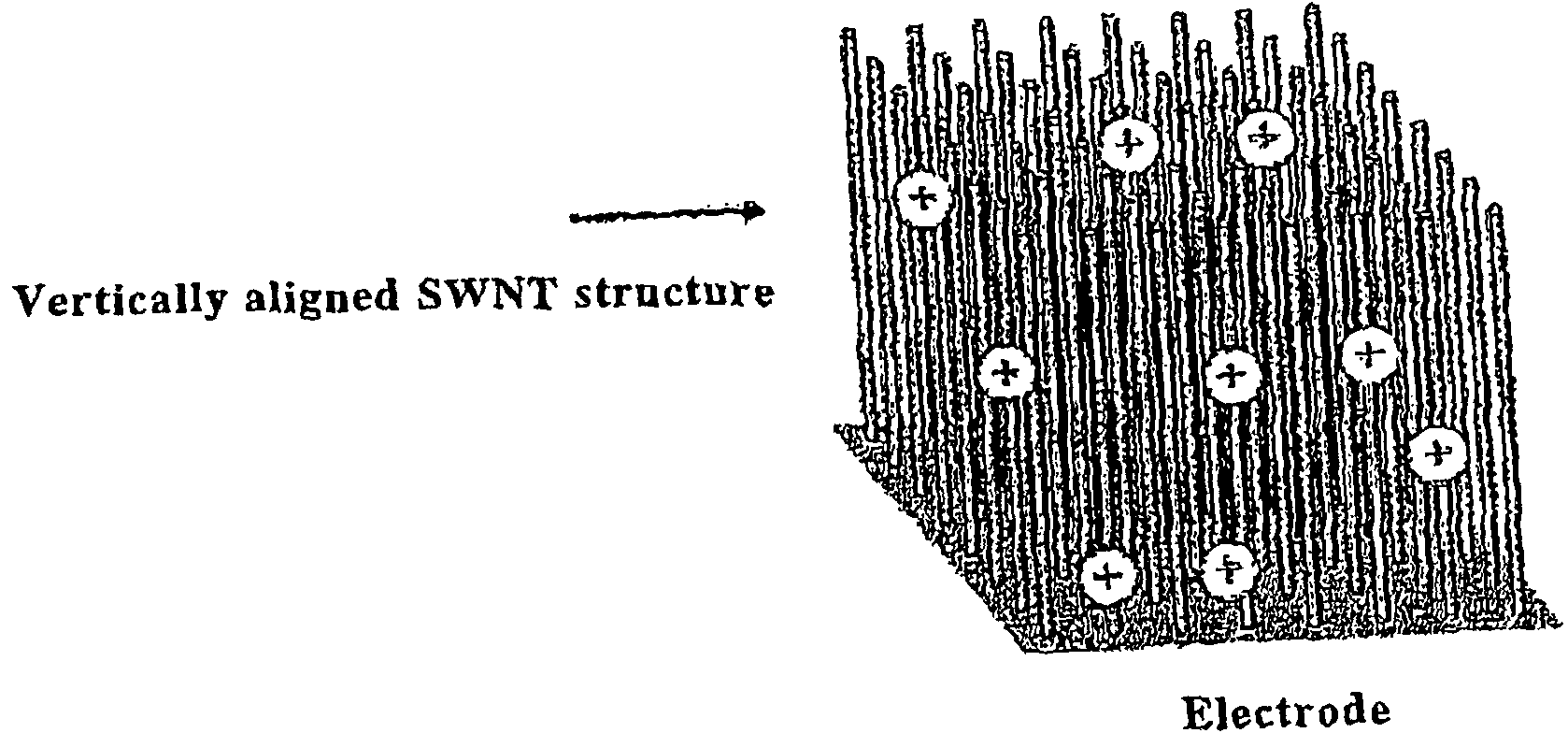

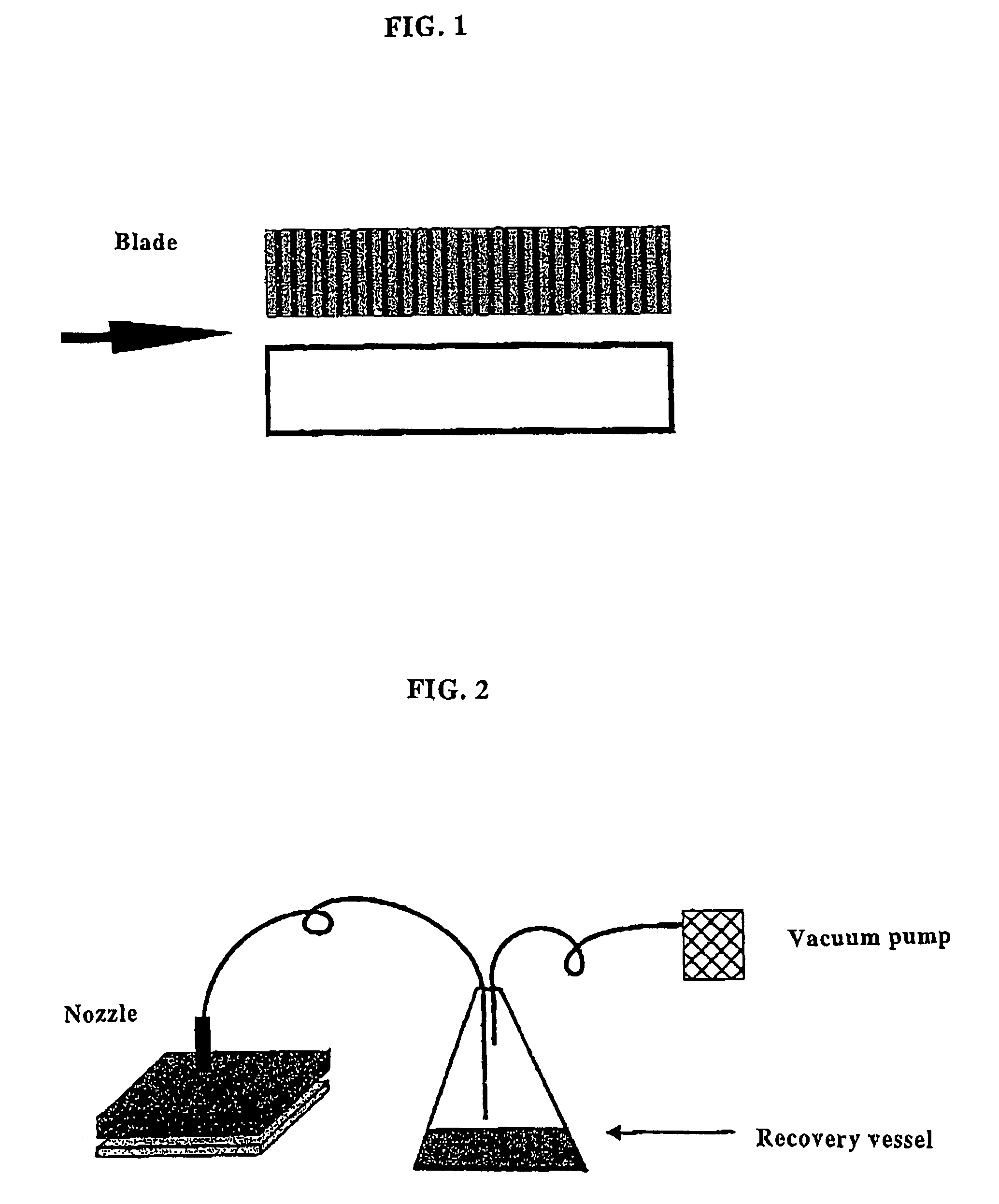

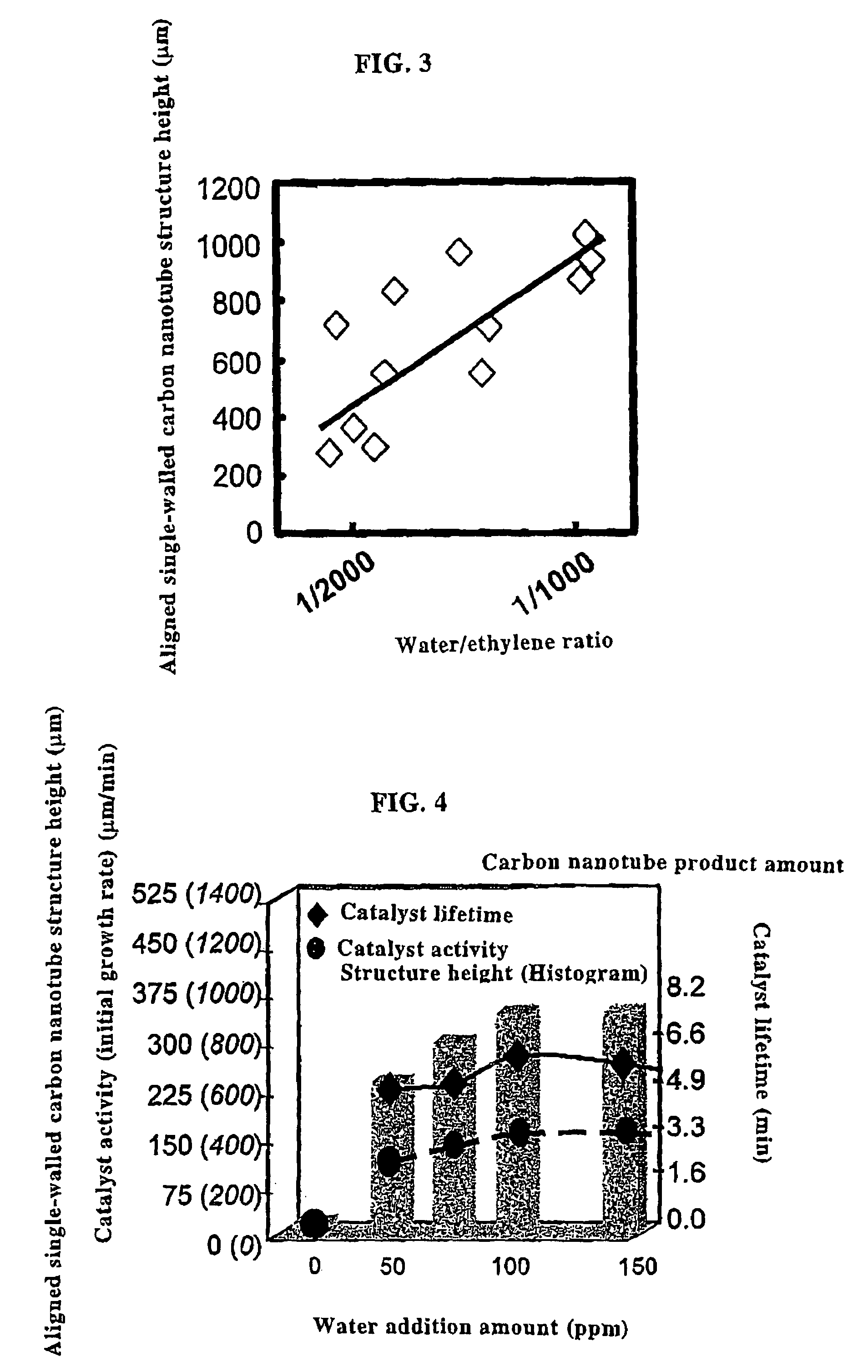

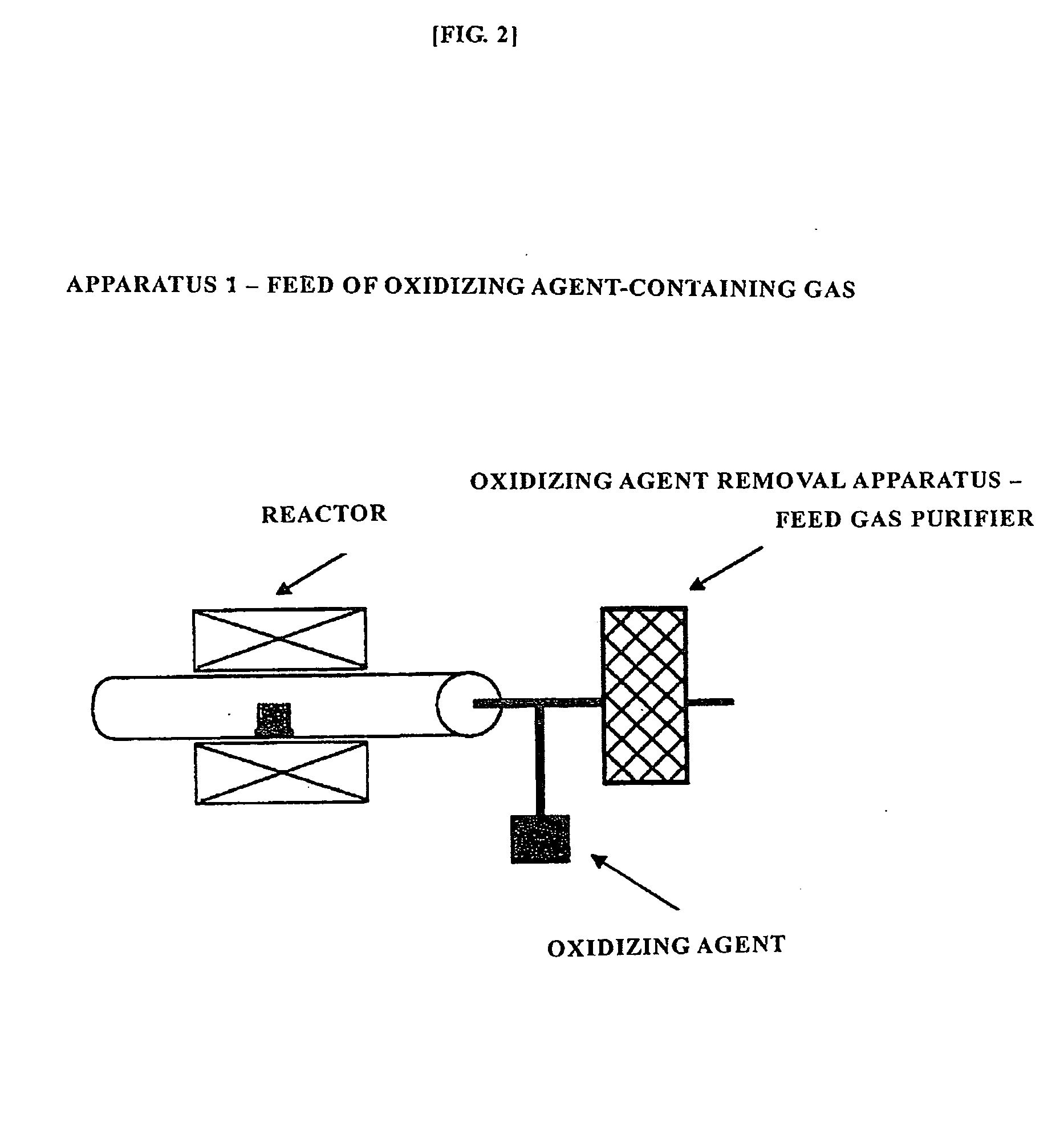

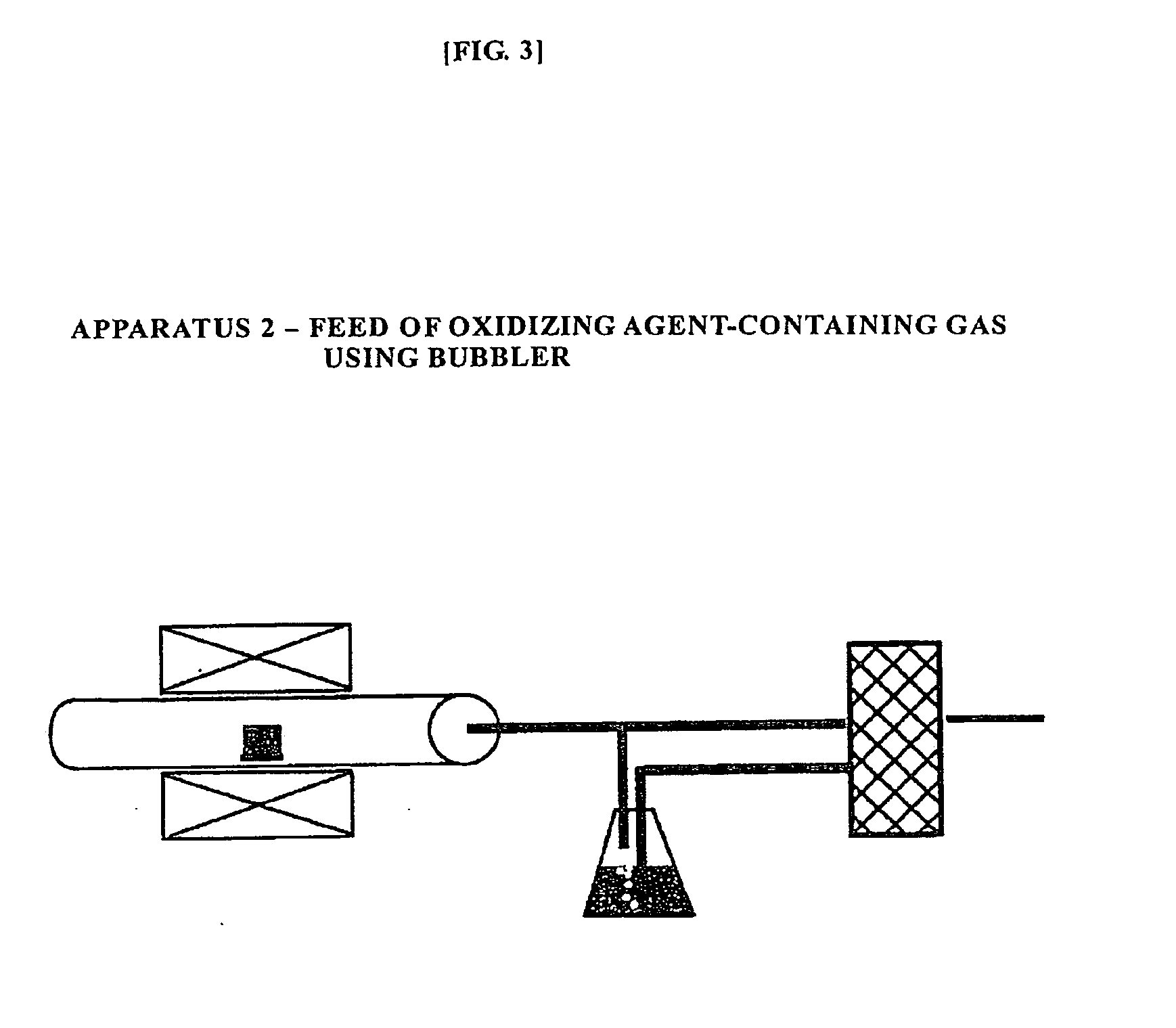

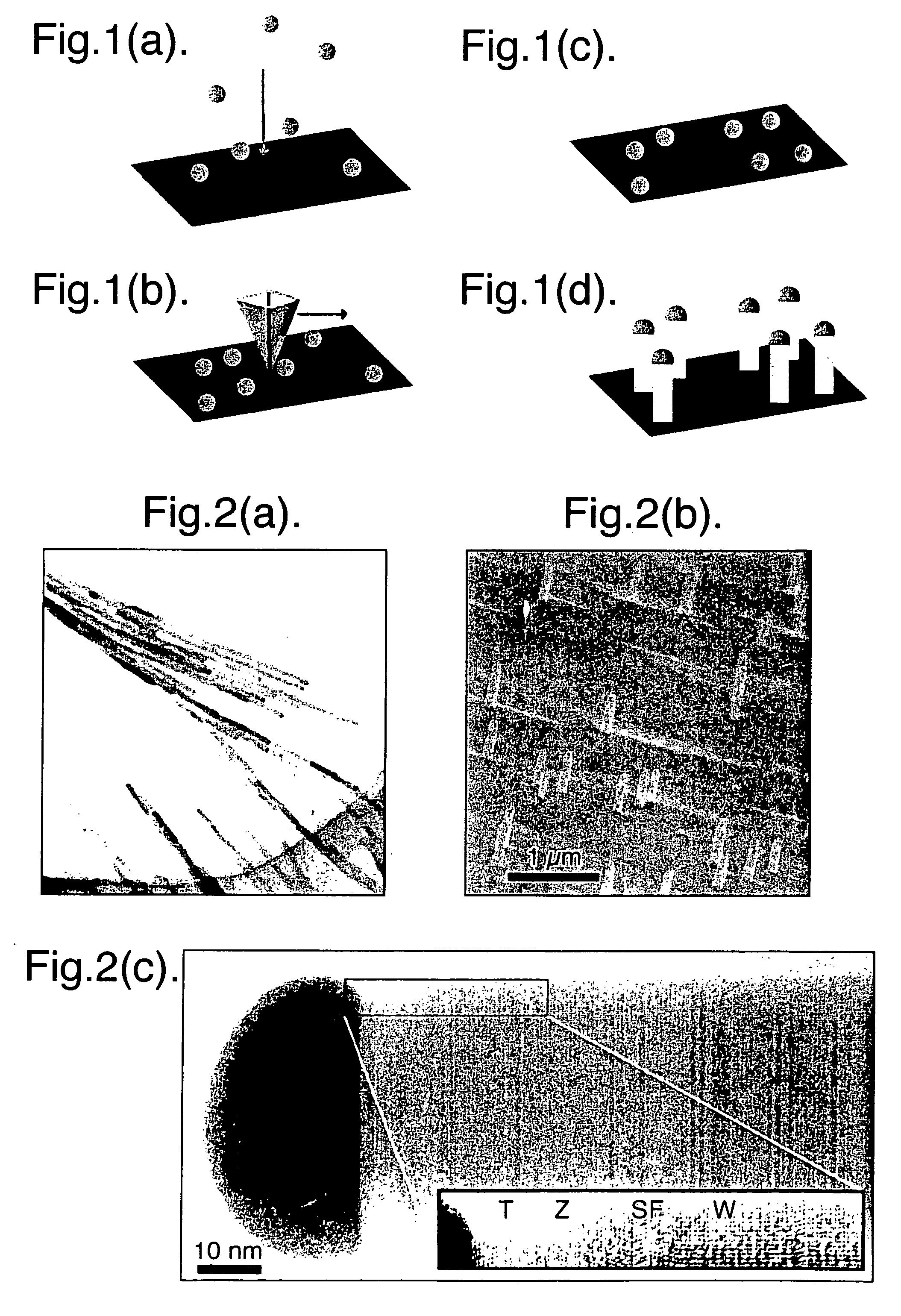

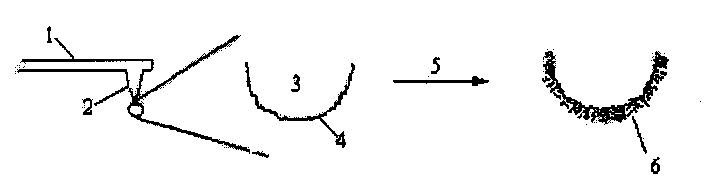

Single-Walled Carbon Nanotube and Aligned Single-Walled Carbon Nanotube Bulk Structure, and Their Production Process, Production Apparatus and Application Use

ActiveUS20080318049A1Efficient productionIncrease freedomMaterial nanotechnologyCell electrodesMetal catalystCarbon nanotube

This invention provides an aligned single-layer carbon nanotube bulk structure, which comprises an assembly of a plurality of aligned single-layer carbon nanotube and has a height of not less than 10 μm, and an aligned single-layer carbon nanotube bulk structure which comprises an assembly of a plurality of aligned single-layer carbon nanotubes and has been patterned in a predetermined form. This structure is produced by chemical vapor deposition (CVD) of carbon nanotubes in the presence of a metal catalyst in a reaction atmosphere with an oxidizing agent, preferably water, added thereto. An aligned single-layer carbon nanotube bulk structure, which has realized high purify and significantly large scaled length or height, its production process and apparatus, and its applied products are provided.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Single-walled carbon nanotube and aligned single-walled carbon nanotube bulk structure, and their production process, production apparatus and application use

ActiveUS7854991B2Prolong lifeIncrease probabilityMaterial nanotechnologyCell electrodesMetal catalystCarbon nanotube

This invention provides an aligned single-layer carbon nanotube bulk structure, which comprises an assembly of a plurality of aligned single-layer carbon nanotube and has a height of not less than 10 μm, and an aligned single-layer carbon nanotube bulk structure which comprises an assembly of a plurality of aligned single-layer carbon nanotubes and has been patterned in a predetermined form. This structure is produced by chemical vapor deposition (CVD) of carbon nanotubes in the presence of a metal catalyst in a reaction atmosphere with an oxidizing agent, preferably water, added thereto. An aligned single-layer carbon nanotube bulk structure, which has realized high purify and significantly large scaled length or height, its production process and apparatus, and its applied products are provided.

Owner:NAT INST OF ADVANCED IND SCI & TECH

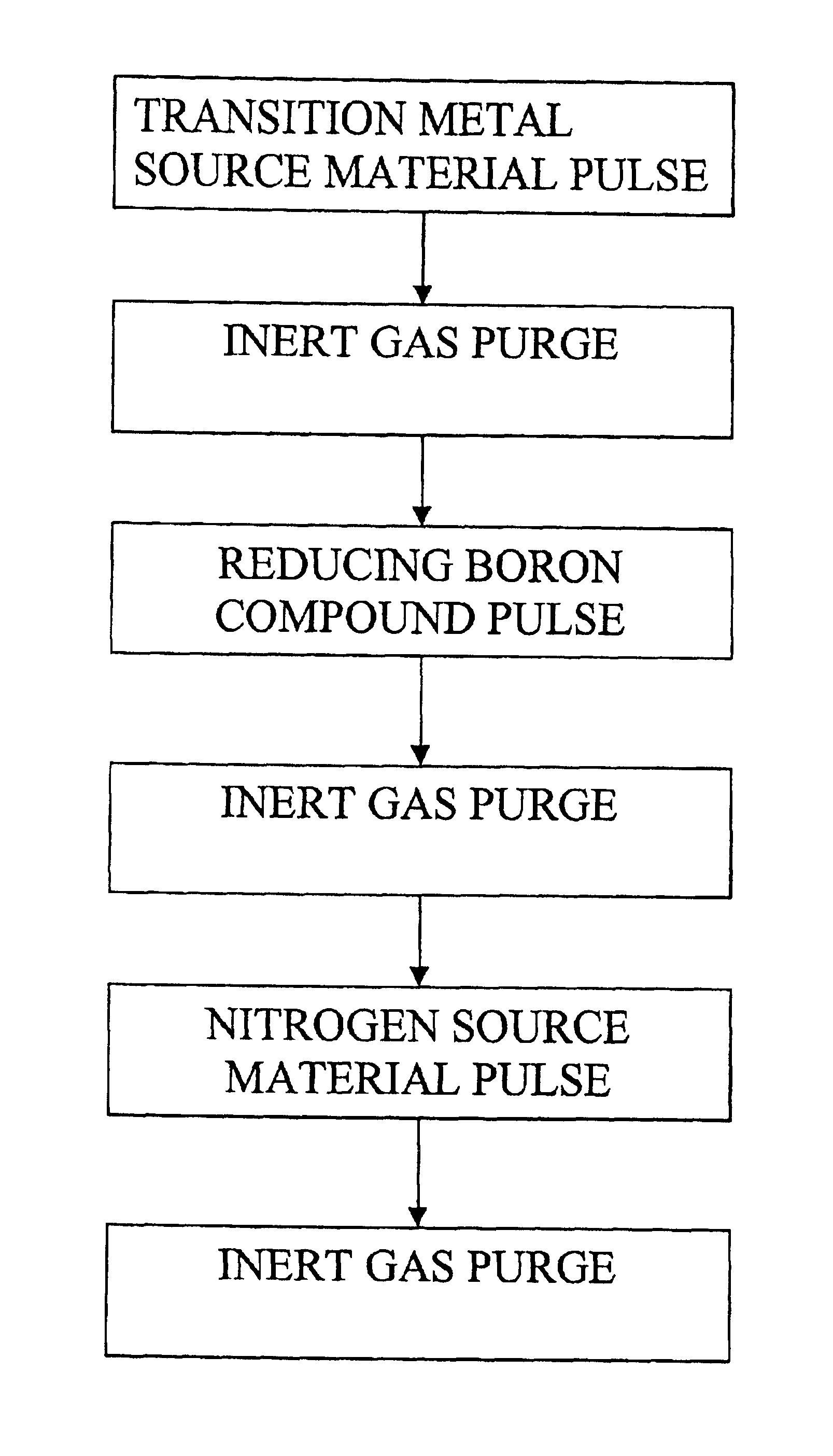

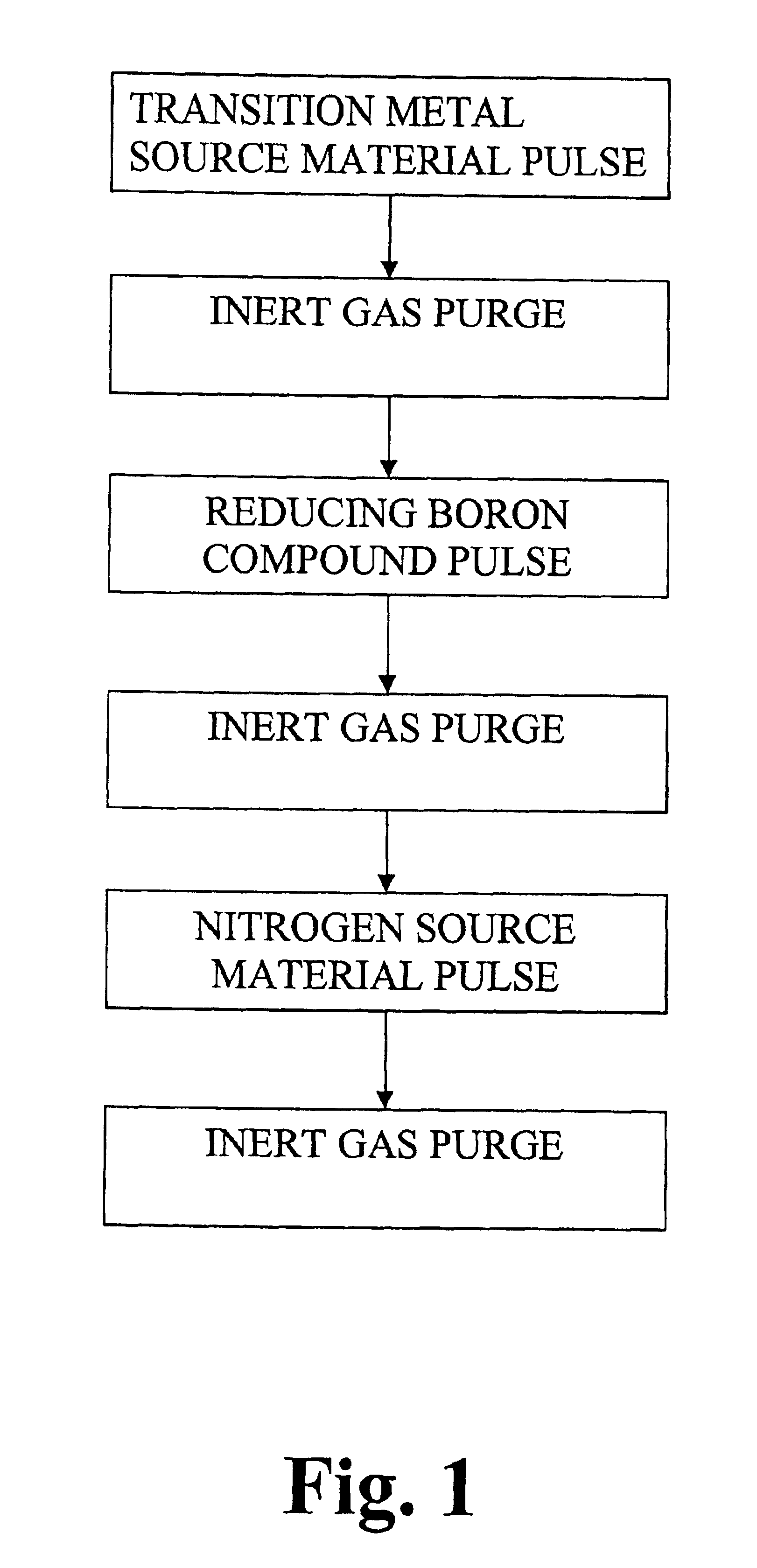

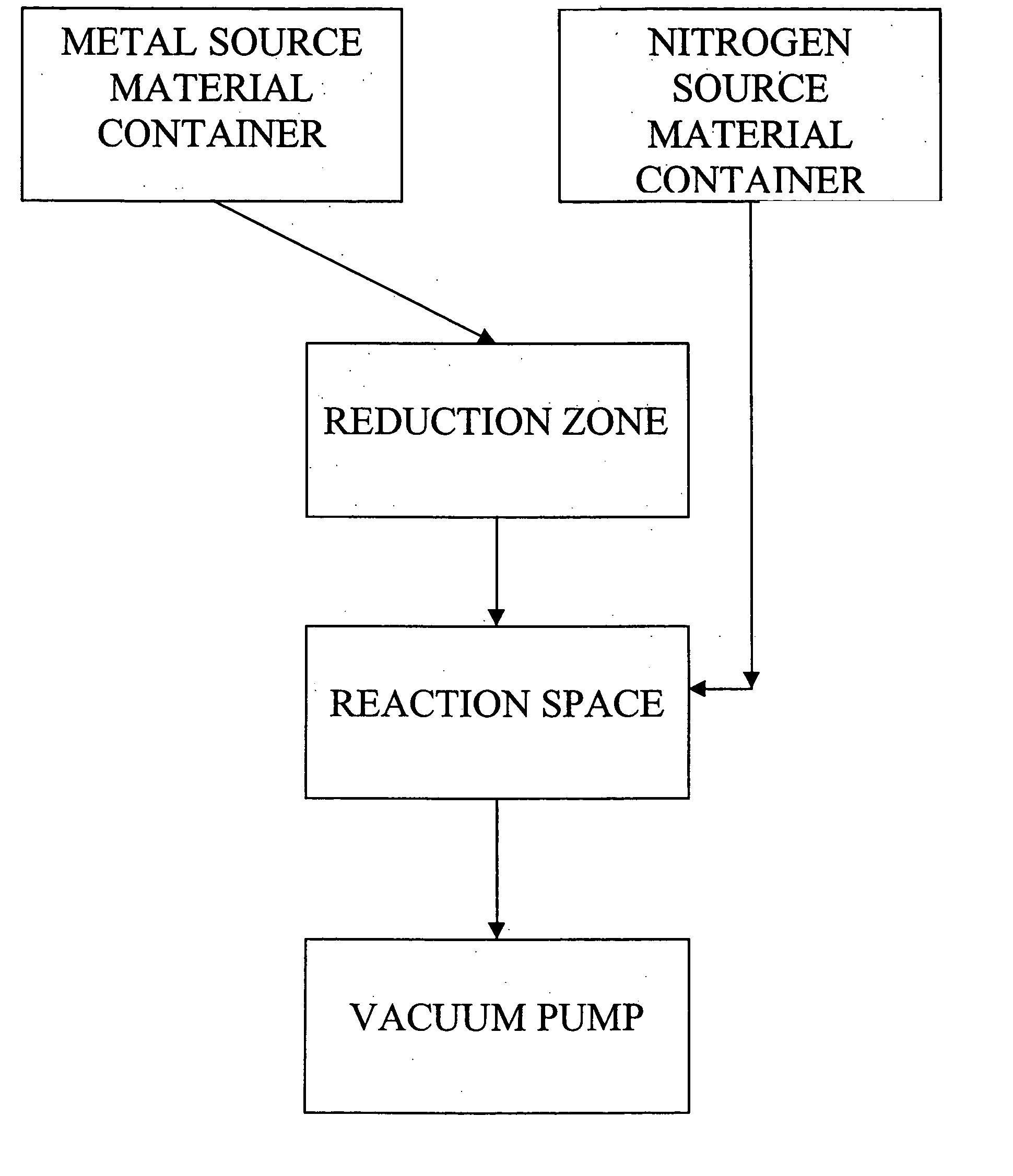

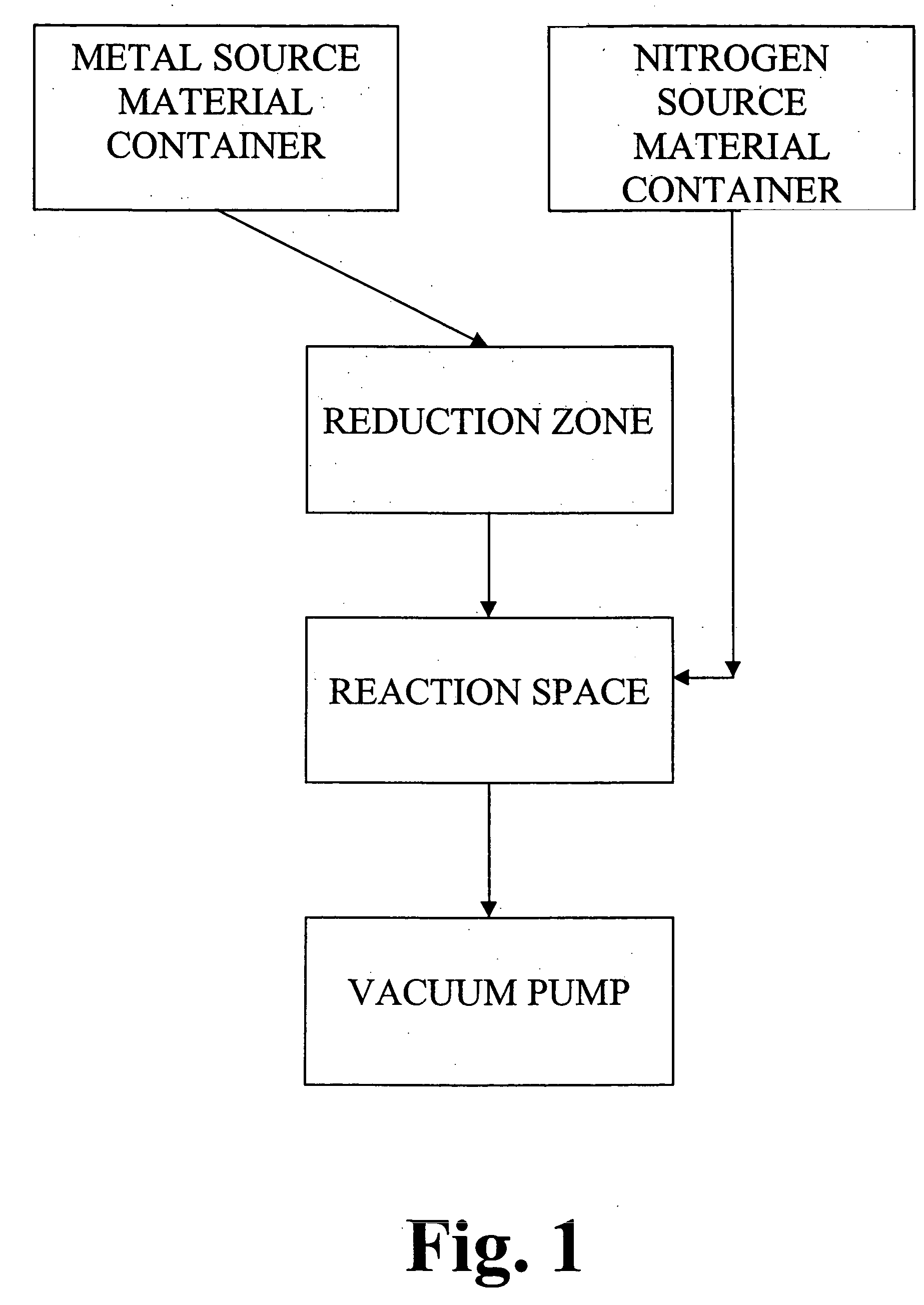

Method of depositing transition metal nitride thin films

InactiveUS6863727B1Low resistivityEasy to disassemblePolycrystalline material growthSemiconductor/solid-state device manufacturingGas phaseSource material

This invention concerns a method for depositing transition metal nitride thin films by an Atomic Layer Deposition (ALD) type process. According to the method vapor-phase pulse of a source material, a reducing agent capable of reducing metal source material, and a nitrogen source material capable of reacting with the reduced metal source material are alternately and sequentially fed into a reaction space and contacted with the substrate. According to the invention as the reducing agent is used a boron compound which is capable of forming gaseous reaction byproducts when reacting with the metal source material.

Owner:ASM INTERNATIONAL

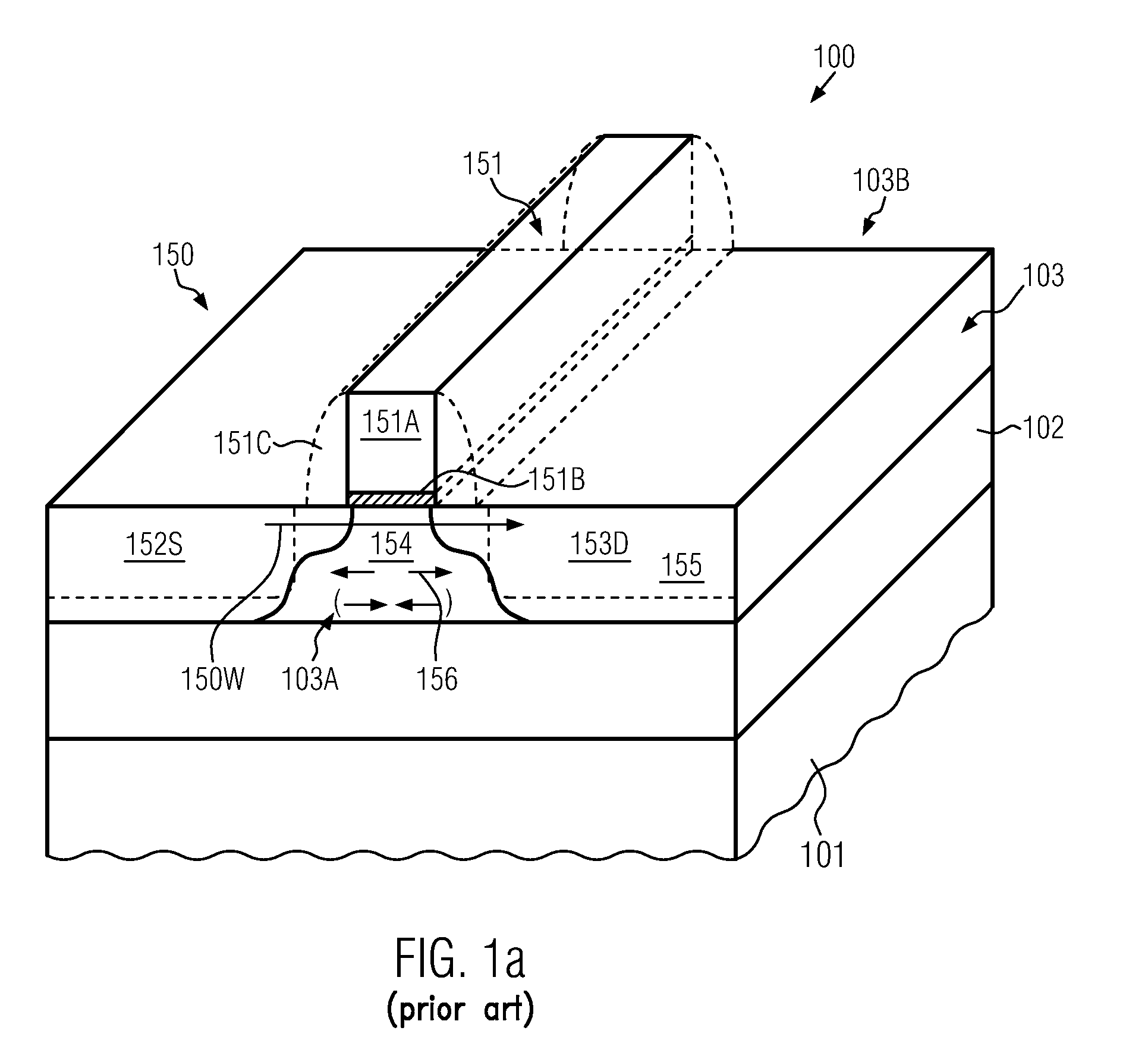

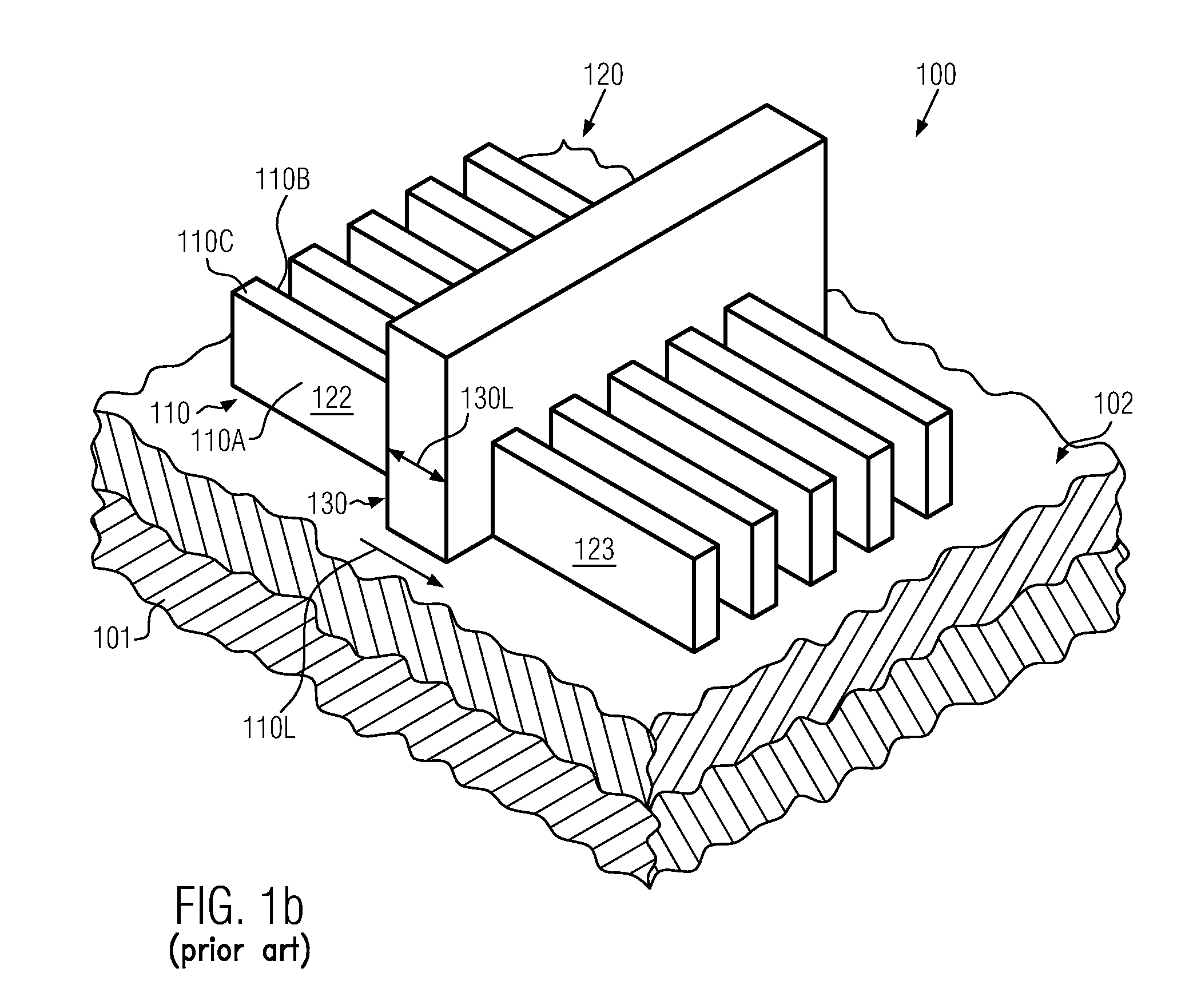

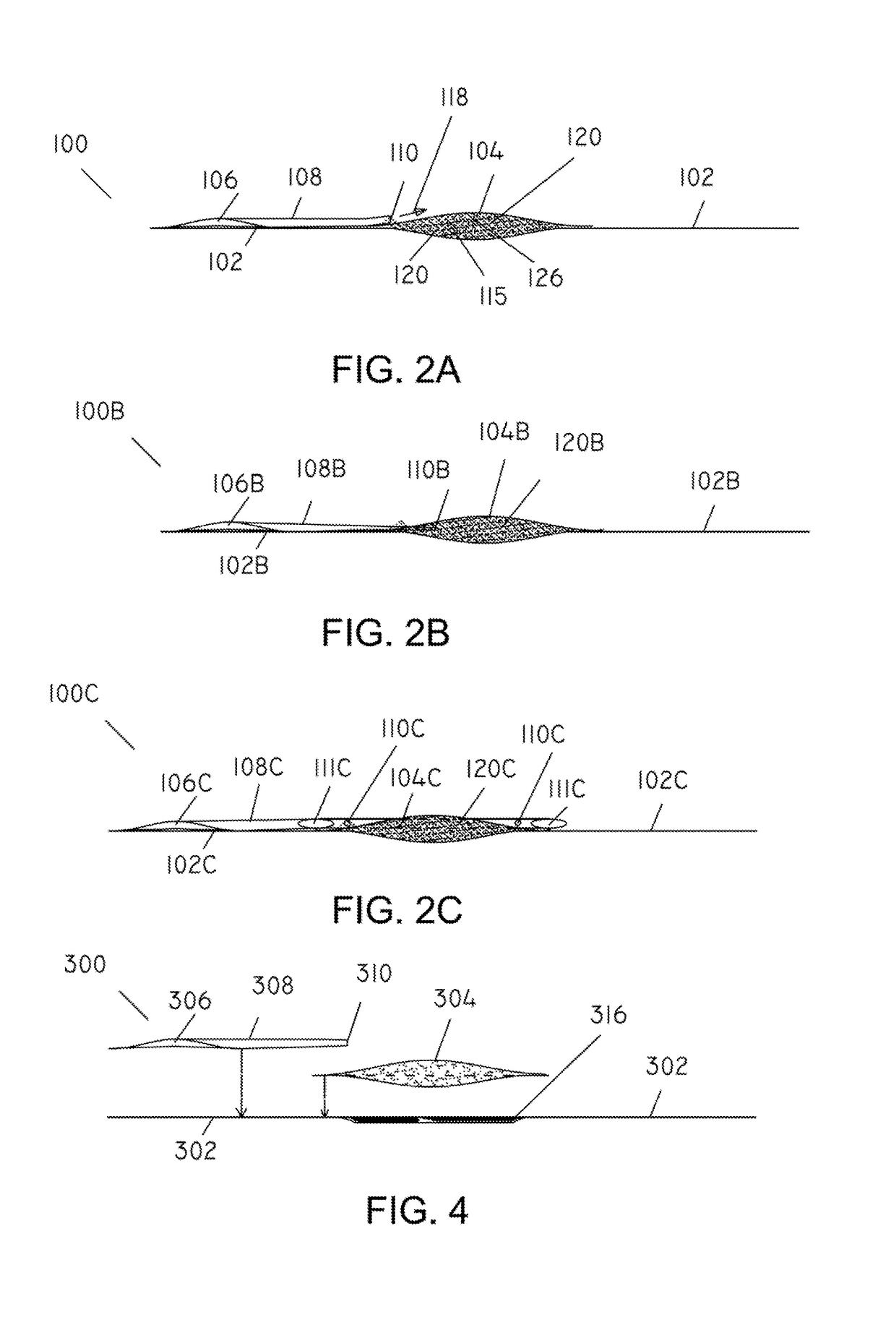

Strain Engineering in Three-Dimensional Transistors Based on a Strained Channel Semiconductor Material

InactiveUS20120025312A1Efficiently formedEfficient growth processSolid-state devicesSemiconductor/solid-state device manufacturingPower flowSemiconductor materials

In three-dimensional transistor configurations, such as finFETs, at least one surface of the semiconductor fin may be provided with a strained semiconductor material, which may thus have a pronounced uniaxial strain component along the current flow direction. The strained semiconductor material may be provided at any appropriate manufacturing stage, for instance, prior to actually patterning the semiconductor fins and / or after the patterning the semiconductor fins, thereby providing superior performance and flexibility in adjusting the overall characteristics of three-dimensional transistors.

Owner:GLOBALFOUNDRIES INC

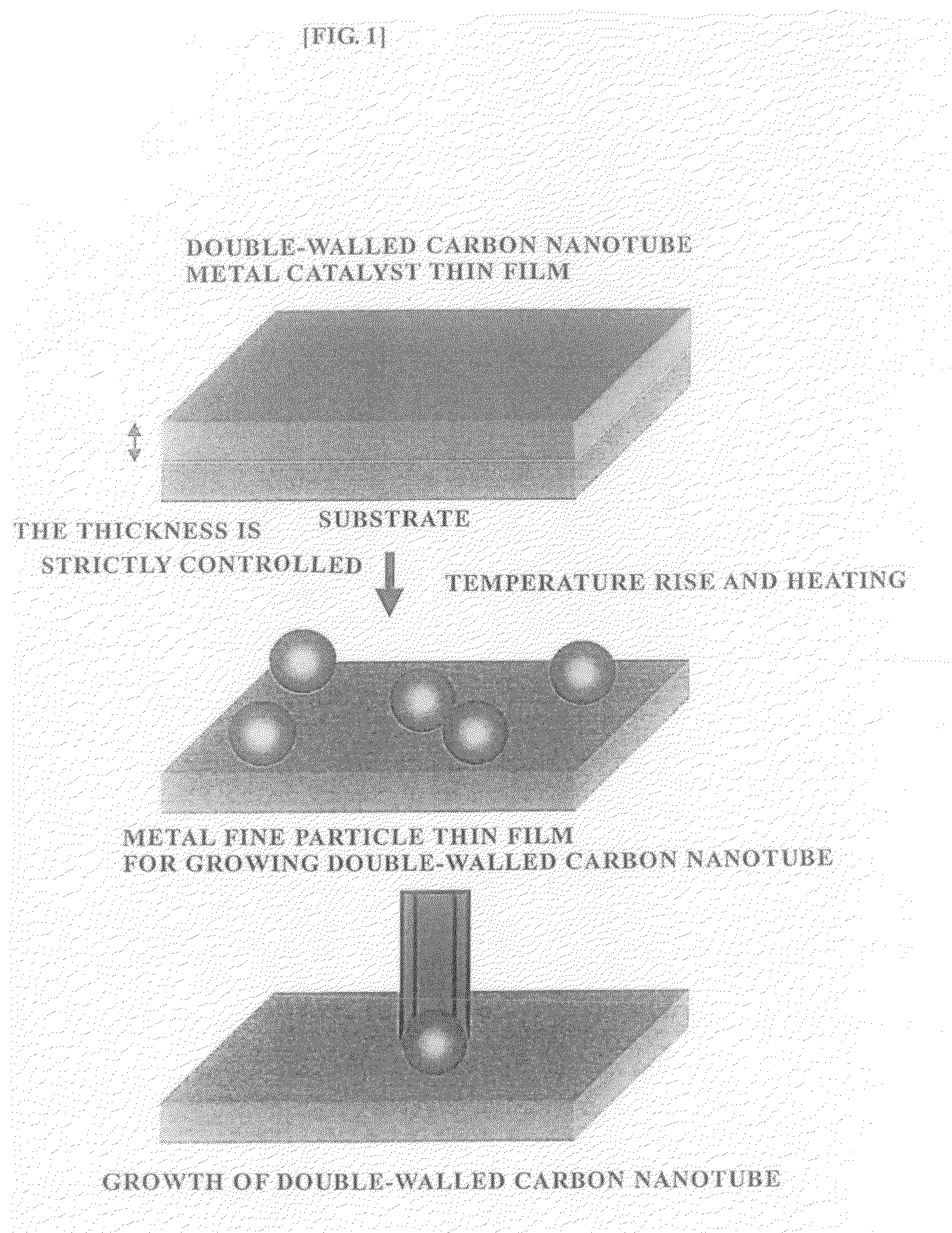

Double-Walled Carbon Nanotube, Aligned Double-Walled Carbon Nanotube Bulk Structure and Process for Producing the Same

InactiveUS20090297846A1High purityEasy to control alignmentMaterial nanotechnologyCarbon compoundsMetal catalystChemical vapor deposition

An aligned double-walled carbon nanotube bulk structure composed of plural aligned double-walled carbon nanotubes and having a height of 0.1 μm or more and a double-walled carbon nanotube are produced by chemically vapor depositing (CVD) a carbon nanotube in the presence of a metal catalyst with controlled particle size and thickness, preferably in the presence of moisture. According to this, it is possible to provide a double-walled nanotube which is free from inclusion of the catalyst, has high purity, is easy to control the alignment and growth, is able to achieve the fabrication through the formation of a bulk structure and has excellent electron emission characteristic (particularly, a double-walled carbon nanotube bulk structure) and also to provide a production technology thereof.

Owner:NAT INST OF ADVANCED IND SCI & TECH

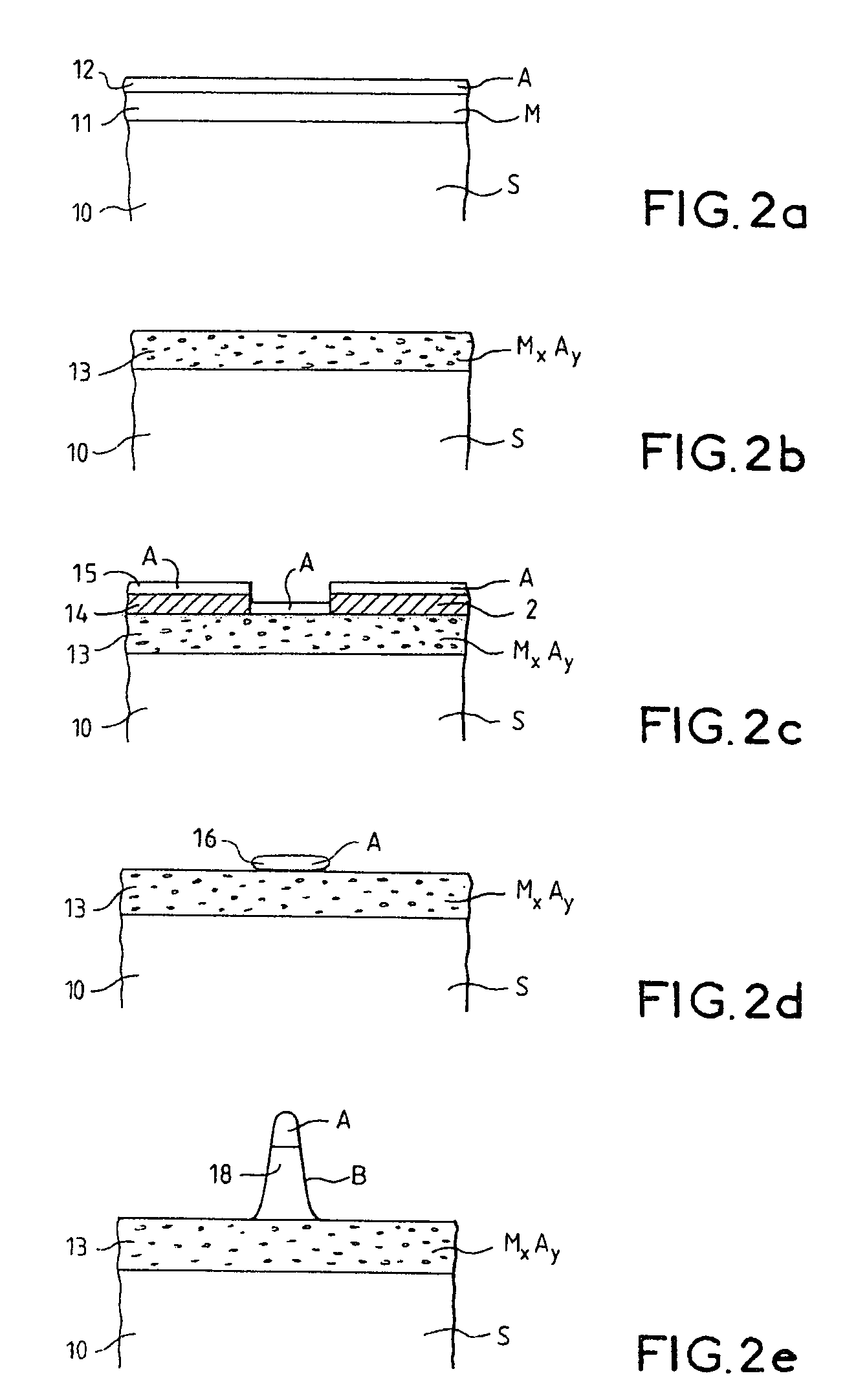

Method for catalytic growth of nanotubes or nanofibers comprising a NiSi alloy diffusion barrier

InactiveUS7491269B2Efficient growth processMaterial nanotechnologyPolycrystalline material growthFiberNanofiber

The invention relates to a process for the growth of nanotubes or nanofibers on a substrate comprising at least an upper layer made of a first material, wherein: the formation, on the surface of the upper layer, of a barrier layer made of an alloy of the first material and of a second material, said alloy being stable at a first temperature; the formation of spots of catalyst that are made of the second material, on the surface of the alloy layer; and the growth of nanotubes or nanofibers at a second temperature below said first temperature. The alloy layer allows effective growth of nanotubes / nanofibers from catalyst spots on the surface of said alloy layer. This is because the alloy layer constitutes a diffusion barrier preventing the catalyst from diffusing into the growth substrate, which barrier is stable at the catalytic nanotube / nanofiber growth temperature.

Owner:THALES SA

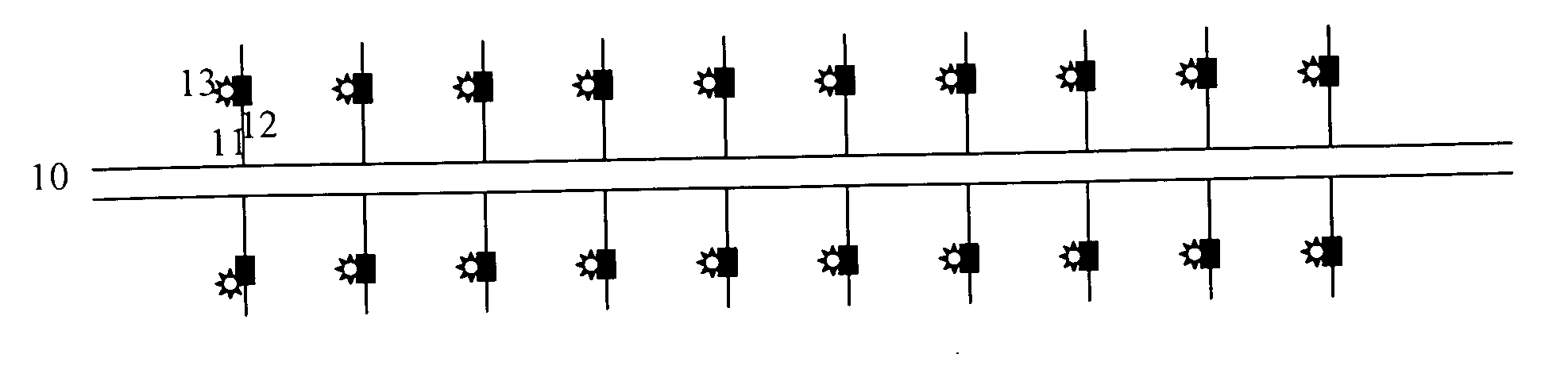

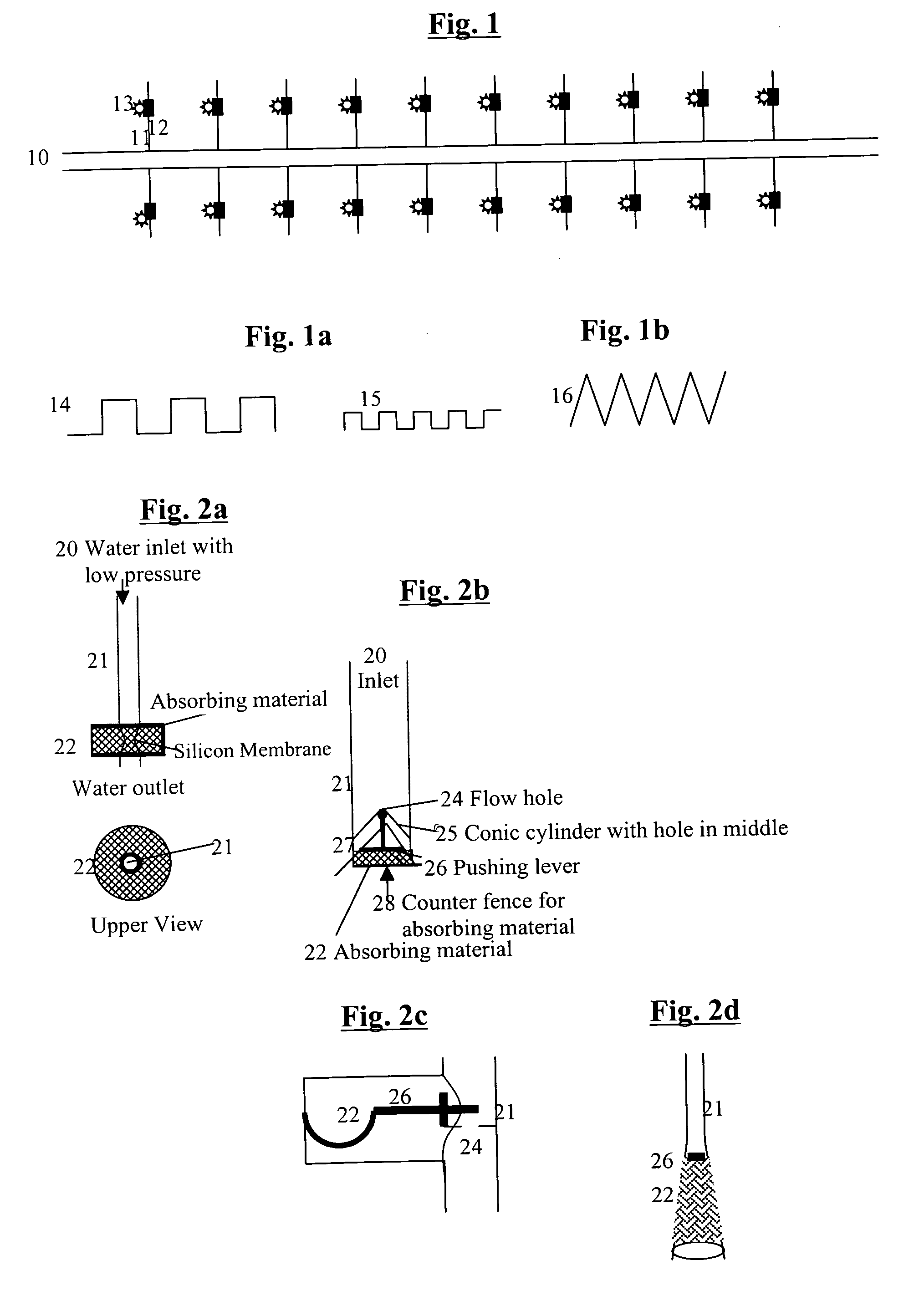

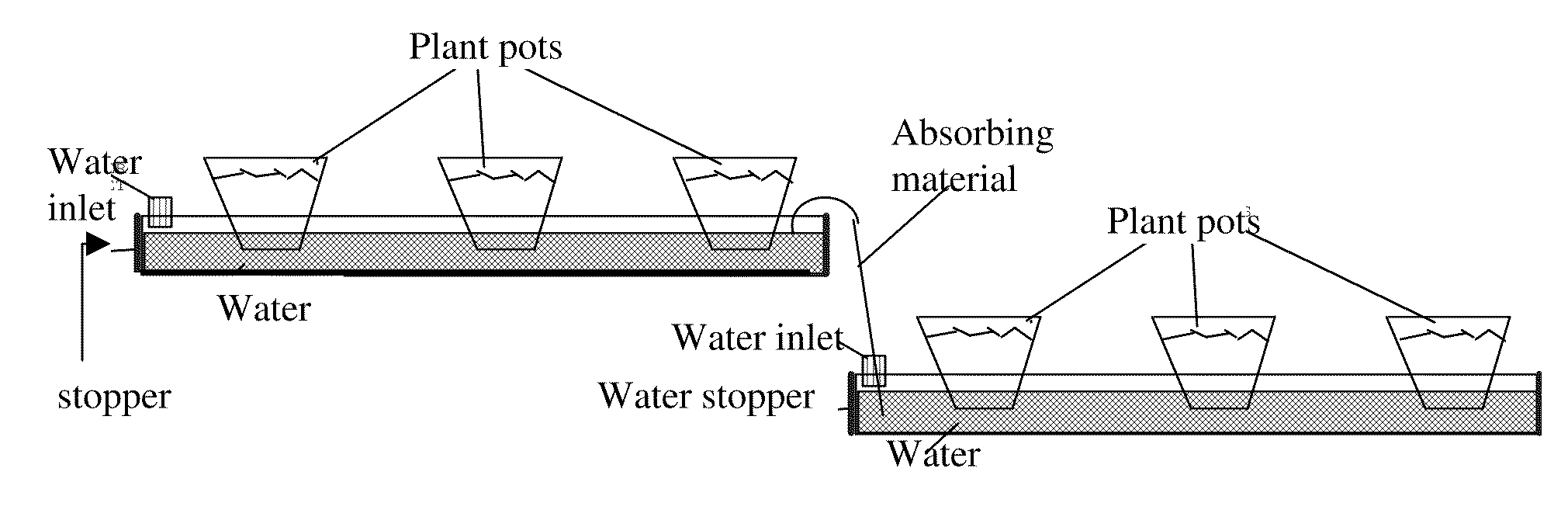

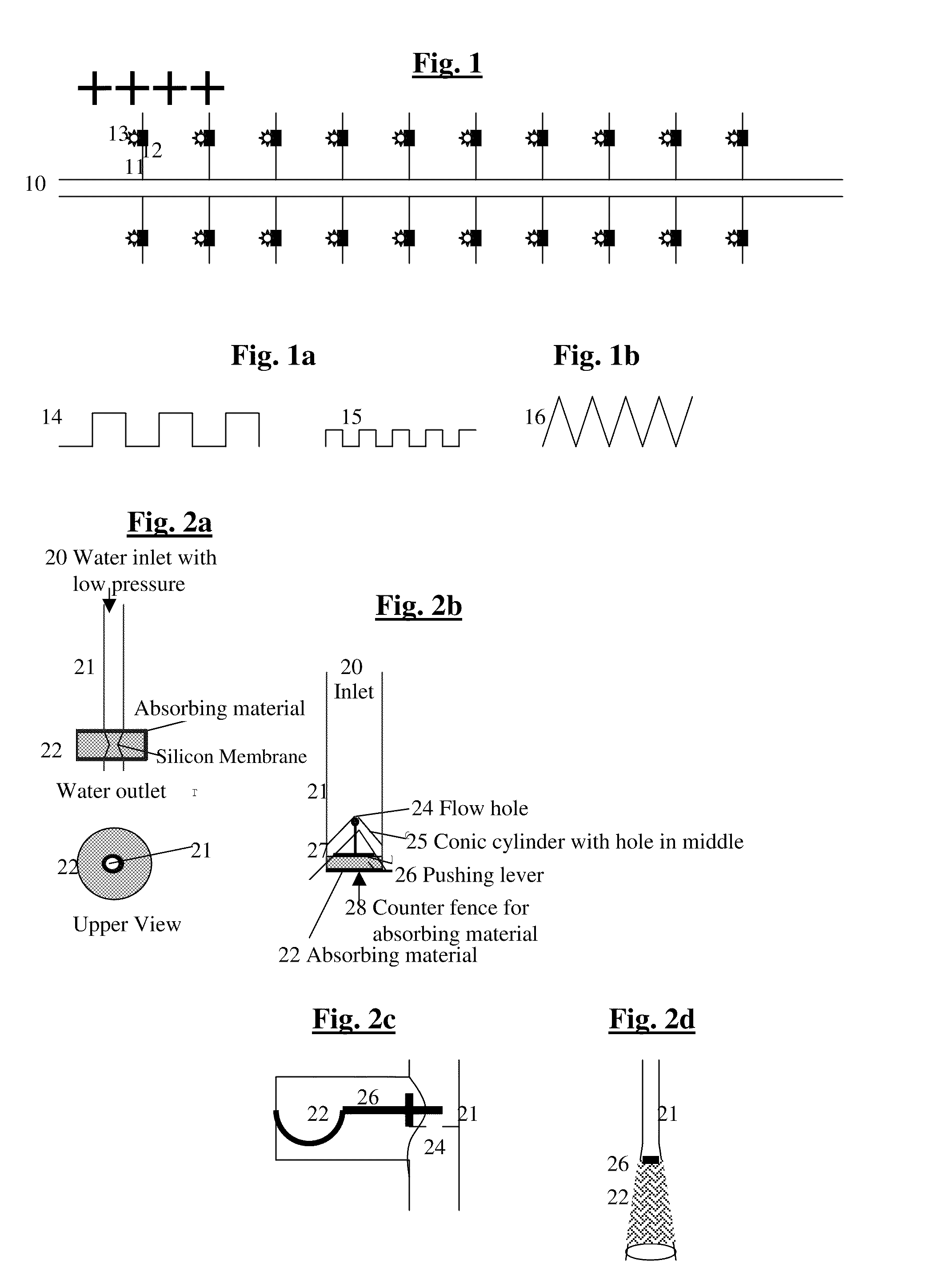

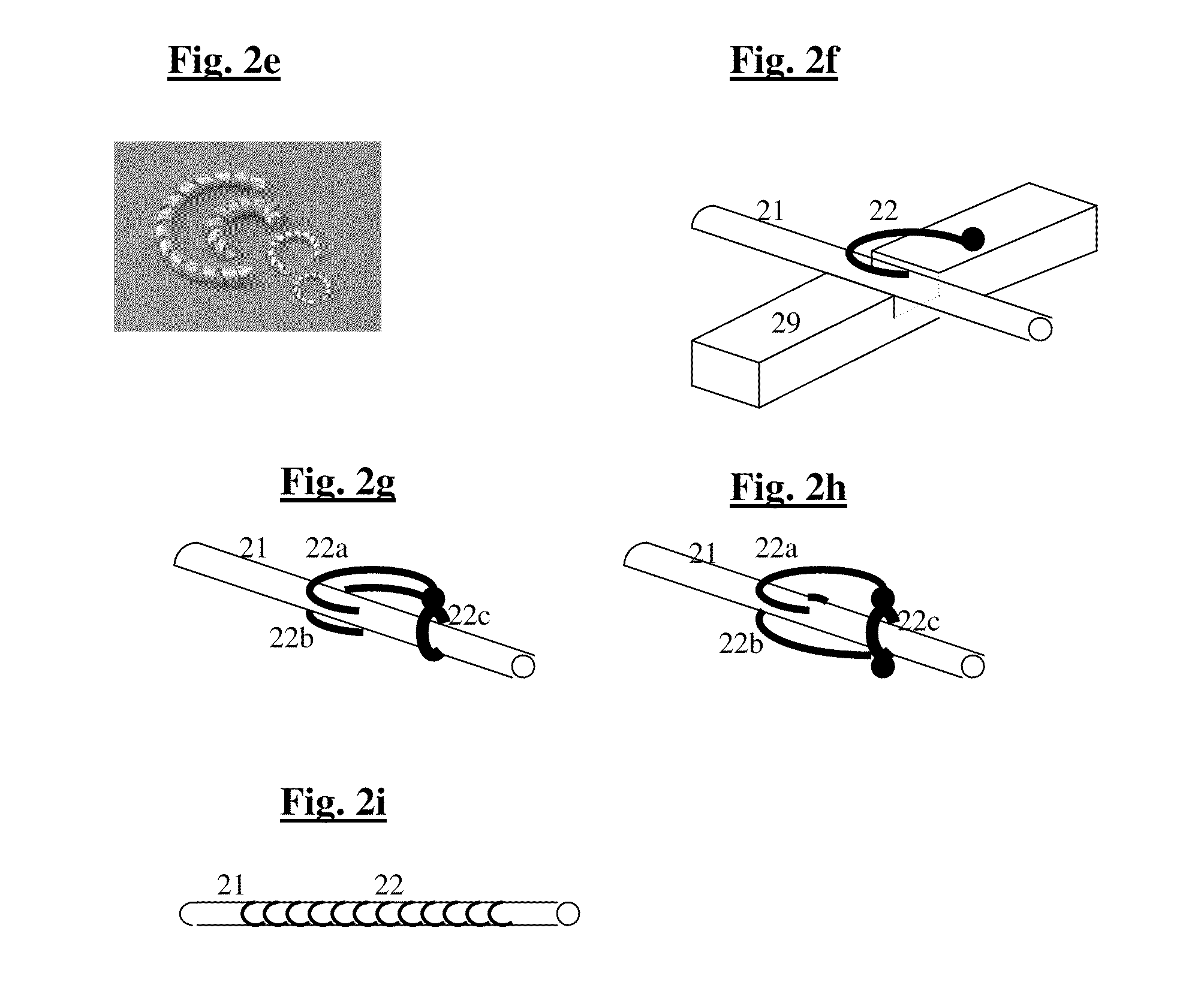

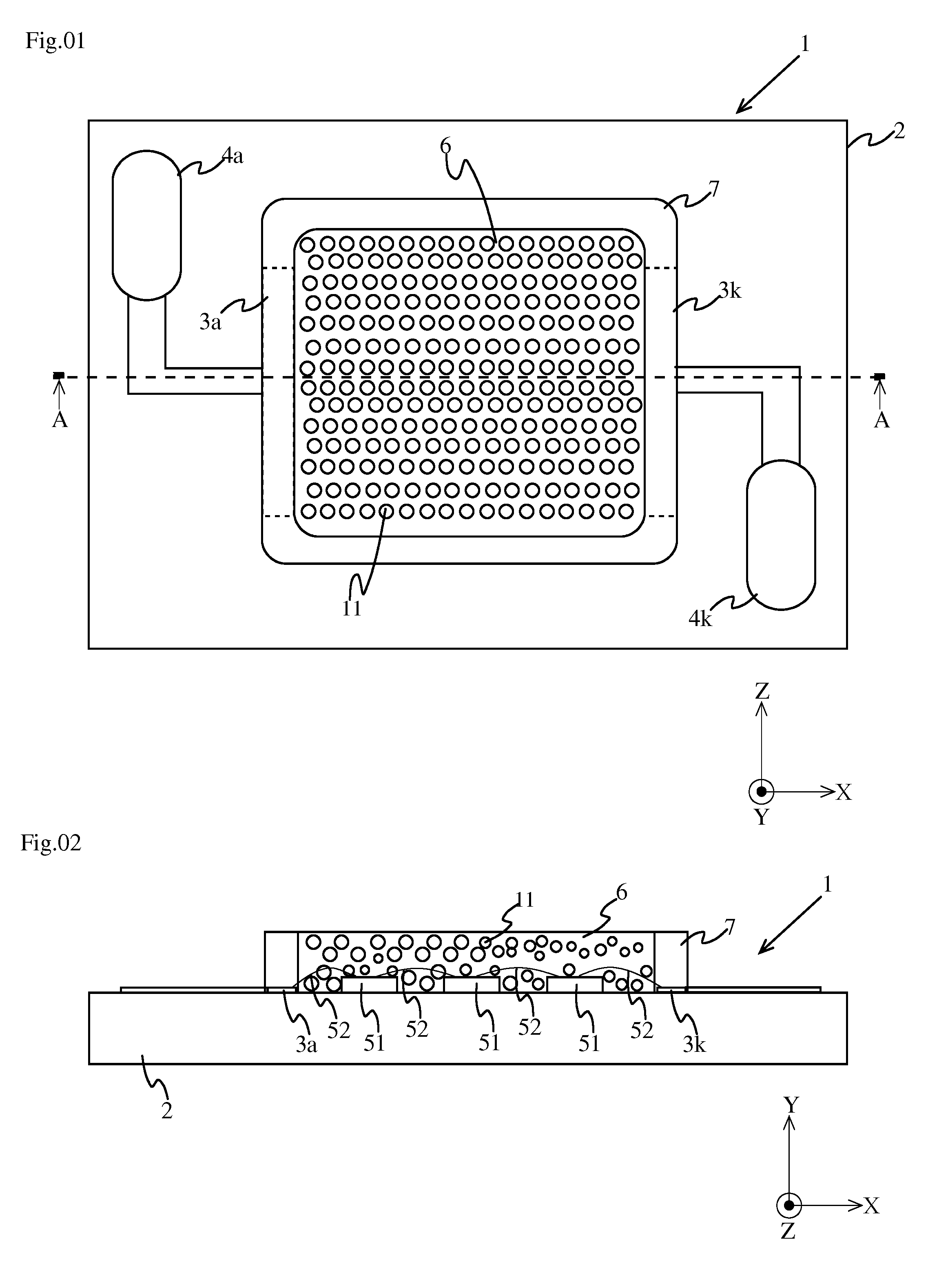

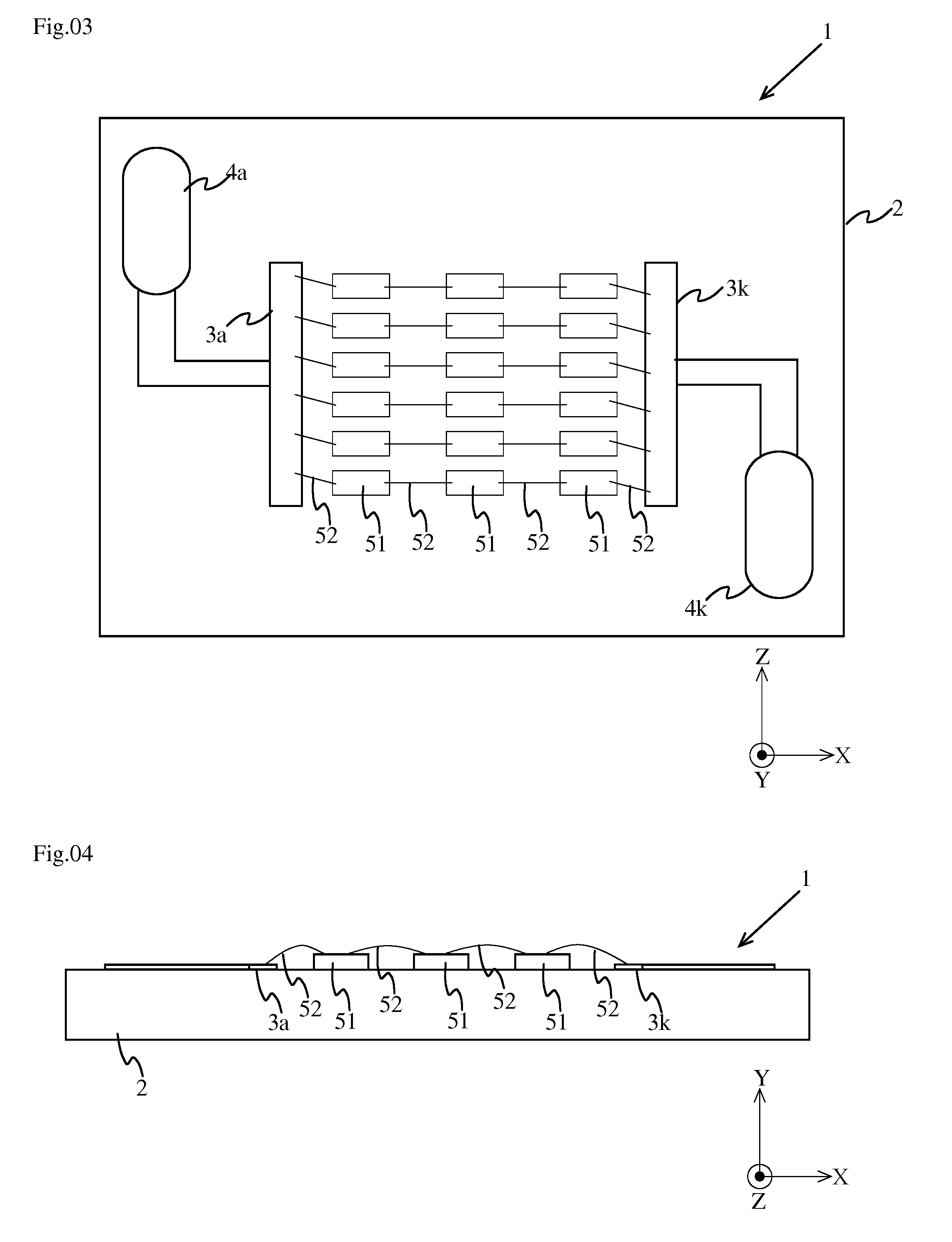

System and method for more efficient automatic irrigation based on a large number of cheap humidity sensors and automatic faucets

InactiveUS20050133613A1Control can be done more efficiently and moreProtection worksSelf-acting watering devicesWatering devicesMechanical sensorAutomatic faucet

The present invention provides an irrigation system with cheap humidity sensors and cheap automatic faucets preferably by using at the end nodes of the system low water pressure, so that much less force is needed to open and close the local waterway and then either using simple electrical valves that do not require engines, or using for example mechanical sensors based on a bi-material of two or more materials which expand differently when they become wet, thus converting the difference of the expansion into convenient movement. Another possible variation, instead of mechanical sensors and valves, is to use for example a preferably synthetic material that tends to behave like a normal root preferably at the edge of each side channel, so that the “root” counter-balances the water supply and reaches equilibrium with it when the soil becomes wet enough, based preferably on asymmetric capillary materials.

Owner:MAYER YARON +2

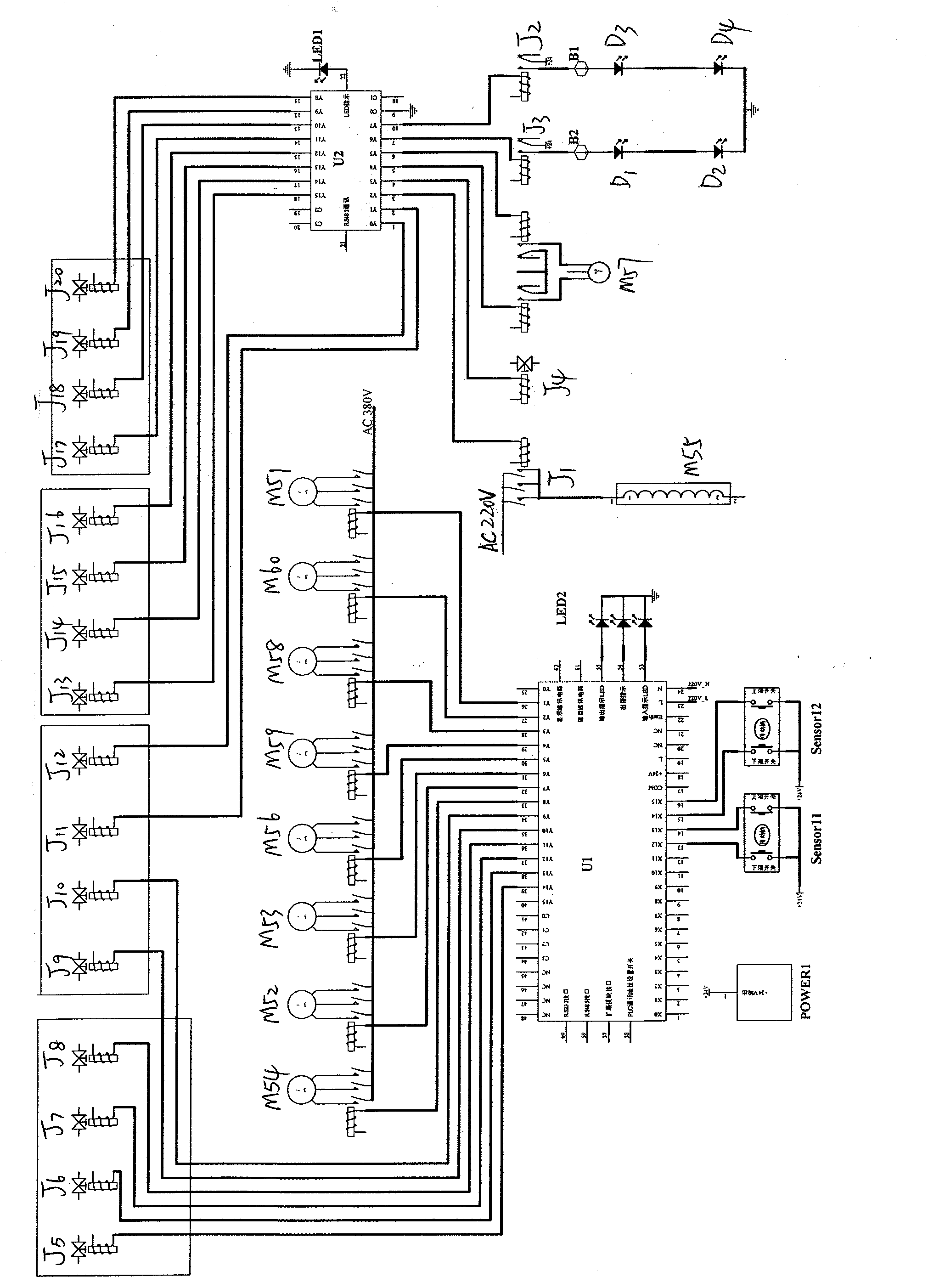

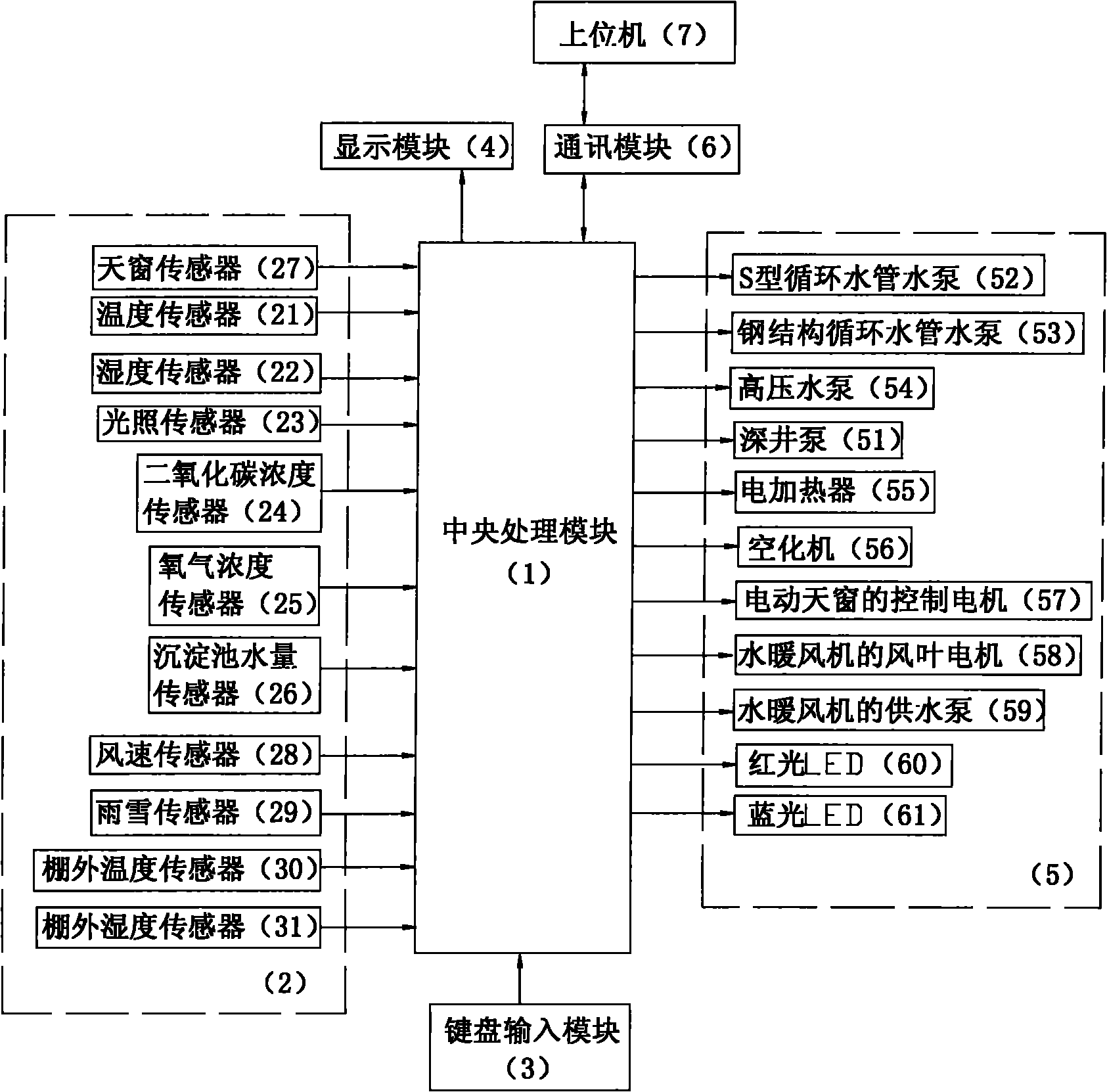

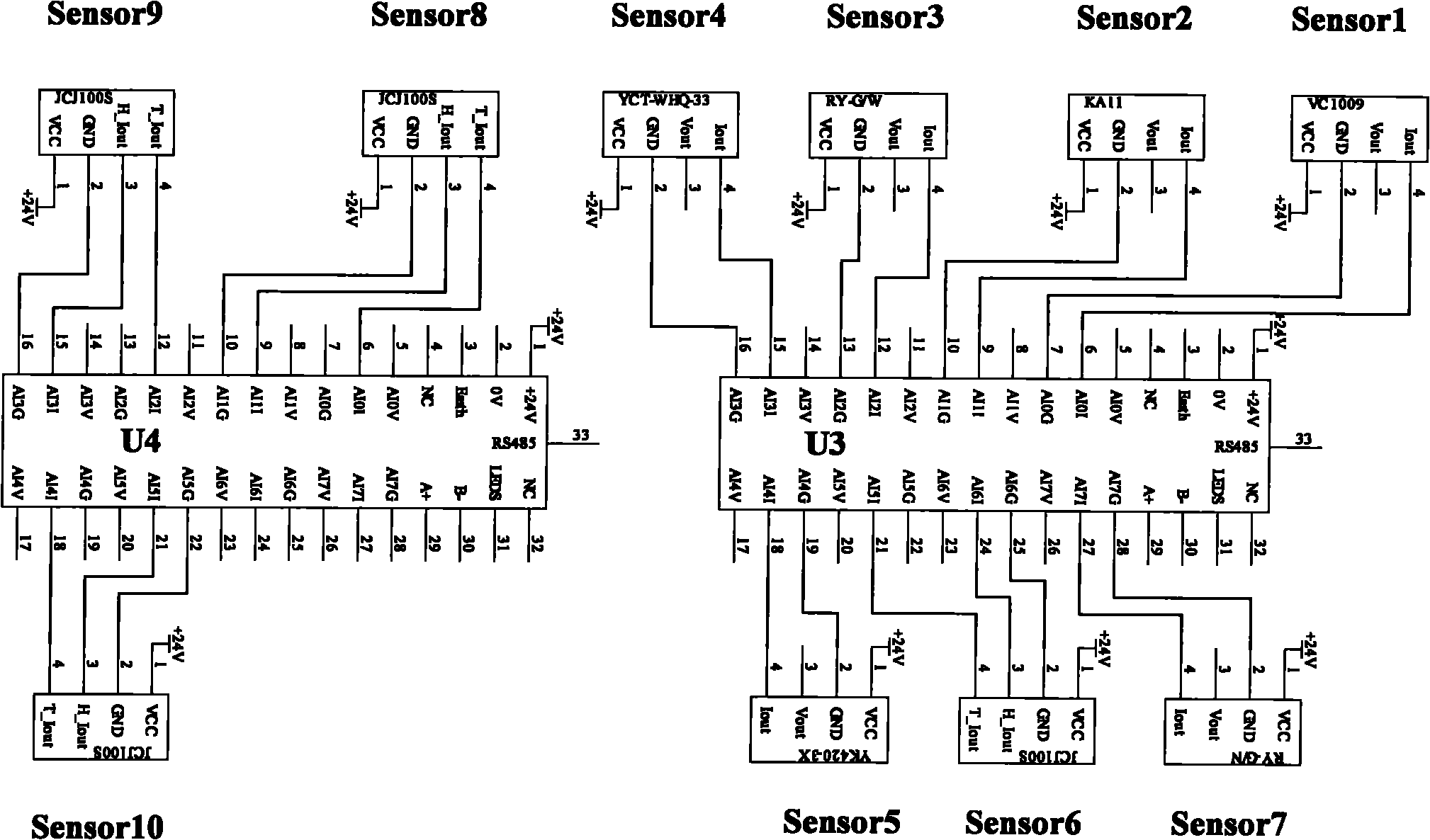

Automatic control system for intelligent and efficient greenhouse agricultural production

InactiveCN102012698AEfficient growth processGrow fastSimultaneous control of multiple variablesProgramme total factory controlAutomatic controlNutrient

The invention relates to an automatic control system for intelligent and efficient greenhouse agricultural production, which comprises a central processing module, and a detection module, a keyboard input module, a display module, a communication module and an execution module which are connected with the central processing module, wherein the detection model comprises a temperature sensor, a humidity sensor, an illumination sensor, a carbon dioxide concentration sensor, an oxygen concentration sensor and a settling pond water yield sensor, which are arranged in a shed, and a wind speed sensor, a rain and snow sensor, a shed-outside temperature sensor and a shed-outside humidity sensor, which are arranged outside the shed; the execution module comprises a cooling unit, a warming unit, a ventilating unit, a light filling unit and a deep-well pump; and the communication module is connected with an upper computer away from the shed by a communication cable. By the automatic control system, the growth environment in the shed can be detected in real time, moisture, other nutrients and the growth environment required by plants are supplied and controlled intelligently, so that animals and the plants can grow quickly with high efficiency and nutrition in ideal environment, the labor cost is reduced, and the output efficiency is improved.

Owner:宁波金太阳光伏科技有限公司

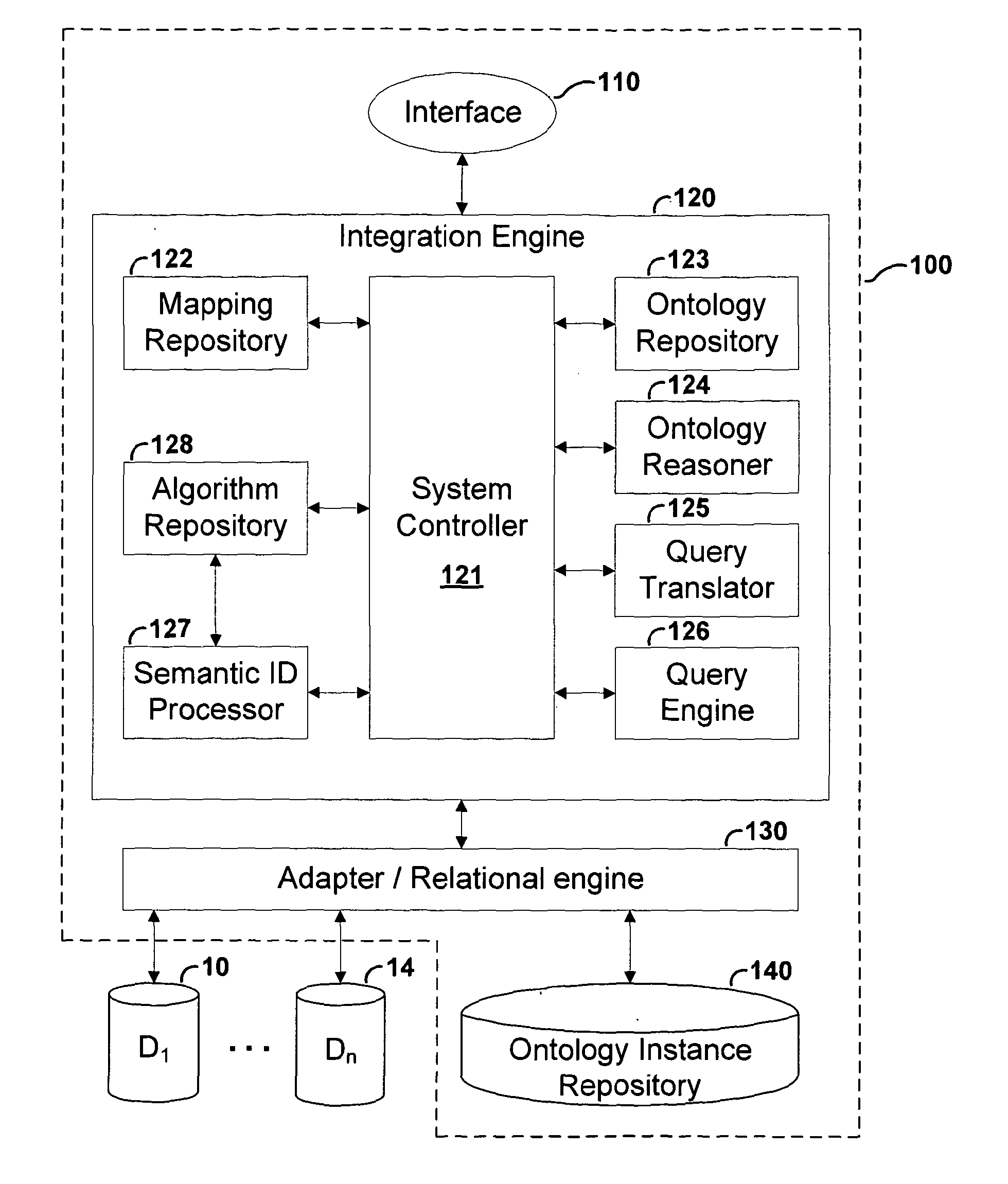

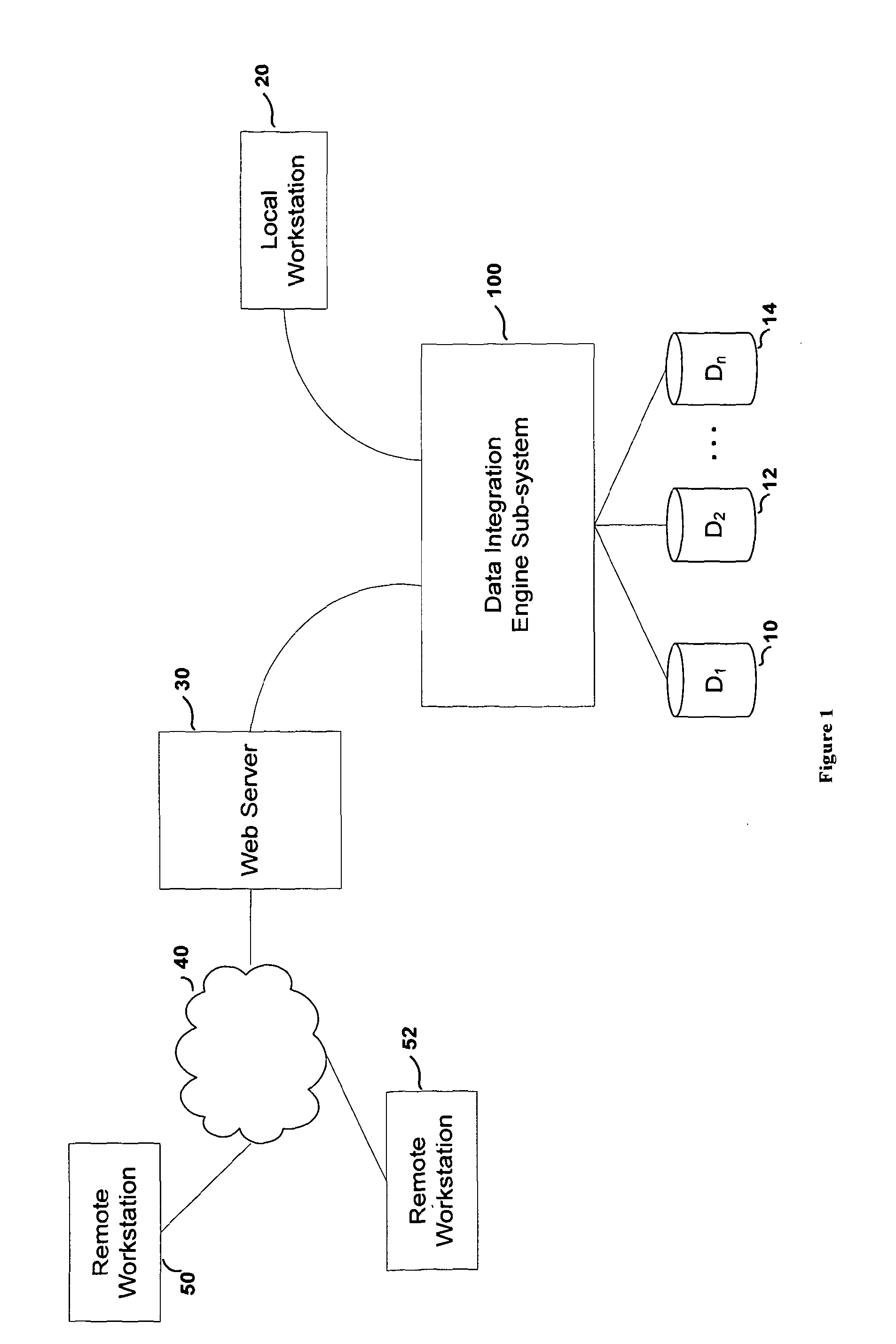

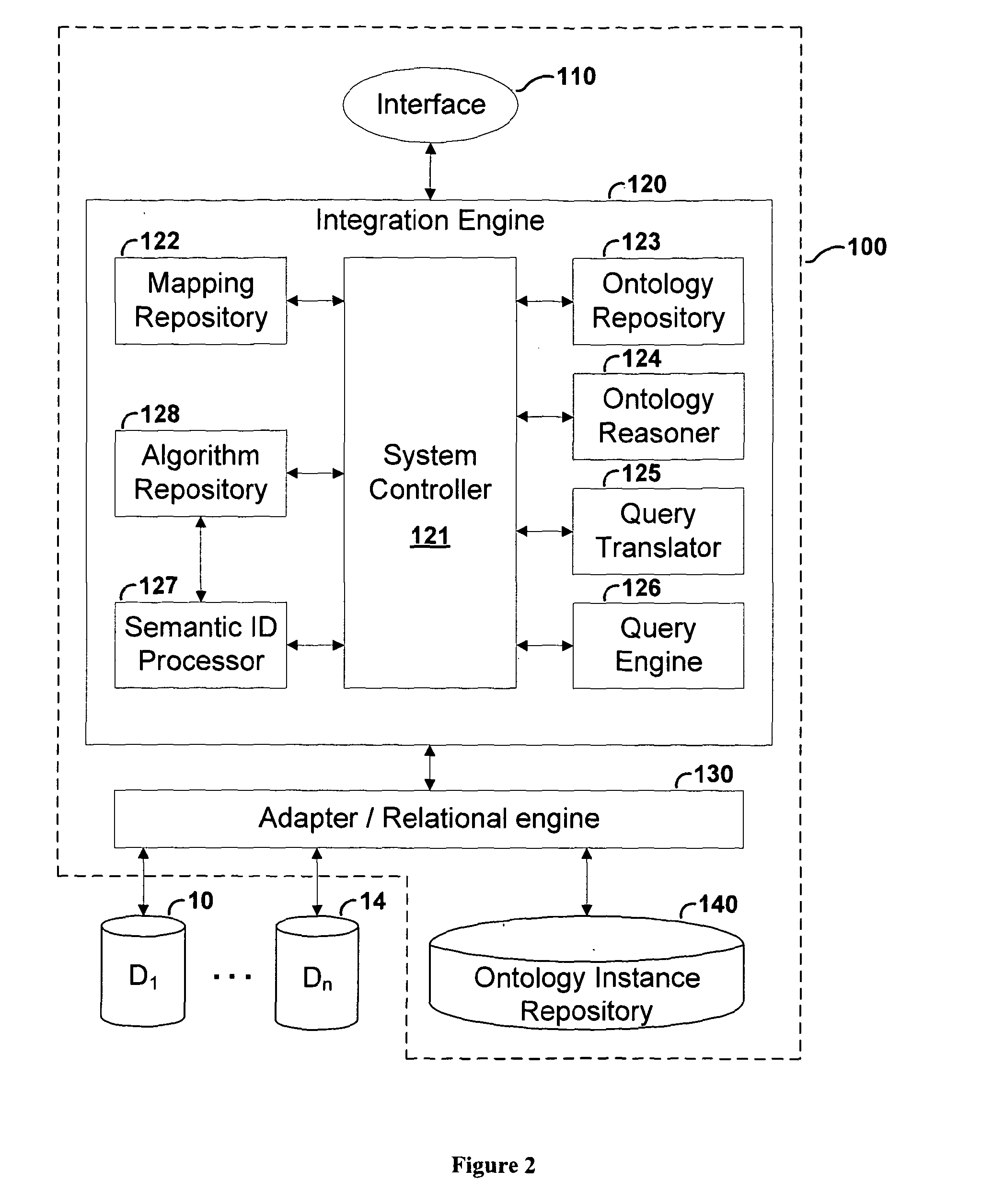

Data integration system

InactiveUS20130006968A1Simple structureEasy to manageDatabase management systemsDigital data processing detailsSchema mappingData source

A data integration system (100, 10-14) comprises a plurality of data sources (10-14) and a mapping system (120, 121, 122, 125, 126, 127, 128) for providing mapping between the data sources (10-14) and a global ontology. The global ontology comprises a plurality of elements including at least a plurality of concepts, at least some of which include one or more attributes. The data integration system further comprises a user interface (110). The user interface (110) is operable in use to provide an integrated, global view of the data contained in the data sources (10-14) and to permit a user to interact with the data sources (10-14) using the global ontology. The mapping system (120) includes a schema mapping portion (122) and a semantic identifier portion (127), wherein the schema mapping portion (127) includes a plurality of single data source element mappings each of which specifies how one or more elements from a single data source map to one or more elements of the global ontology, and the semantic identifier portion (127) comprises a plurality of semantic identifiers each of which is operable to specify in terms of the global ontology how to identify and merge duplicate rough instances of concepts of the global ontology derived from queries to the possibly heterogeneous data sources, which duplicate rough instances represent the same actual instances.

Owner:BRITISH TELECOMM PLC

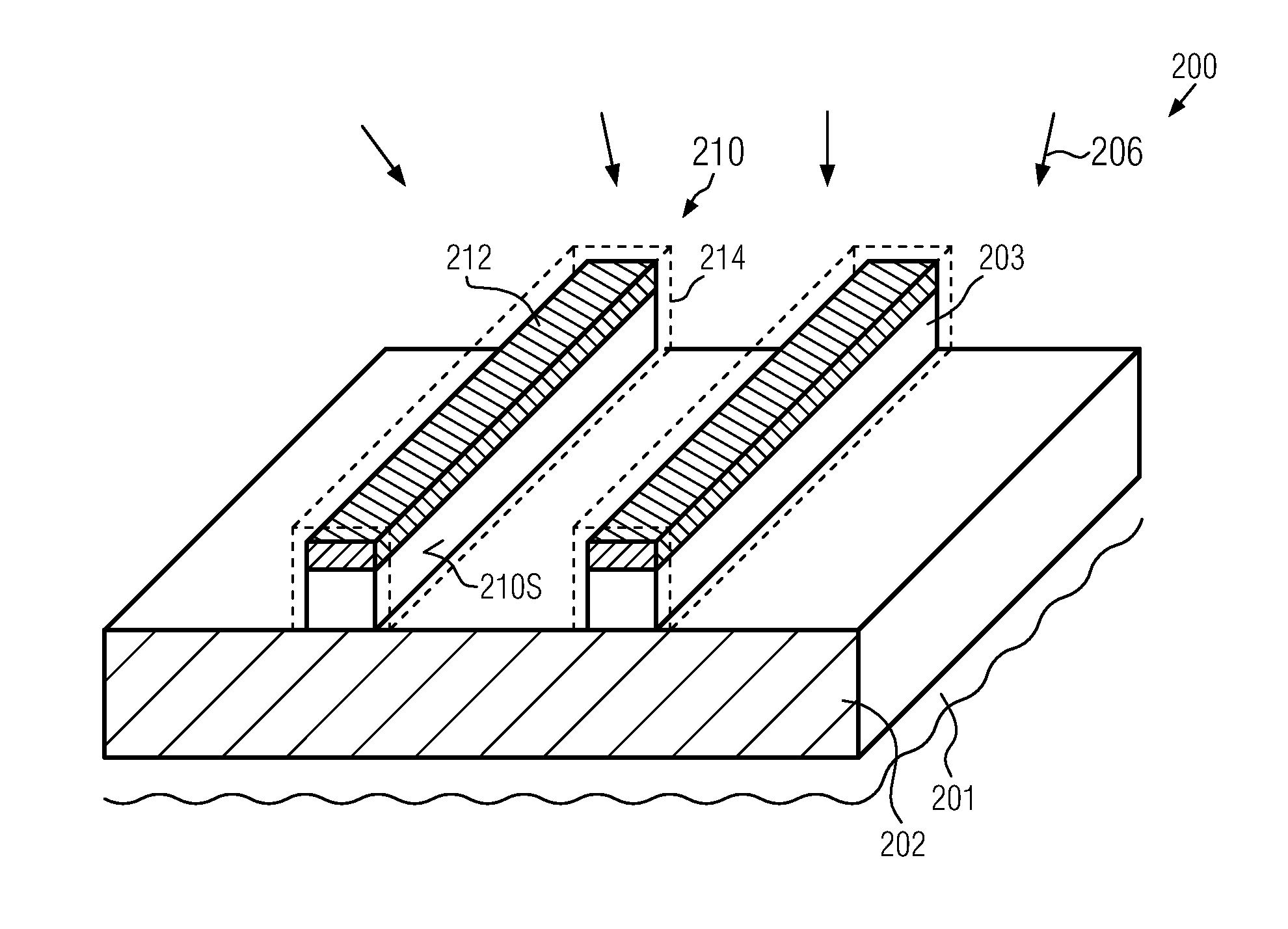

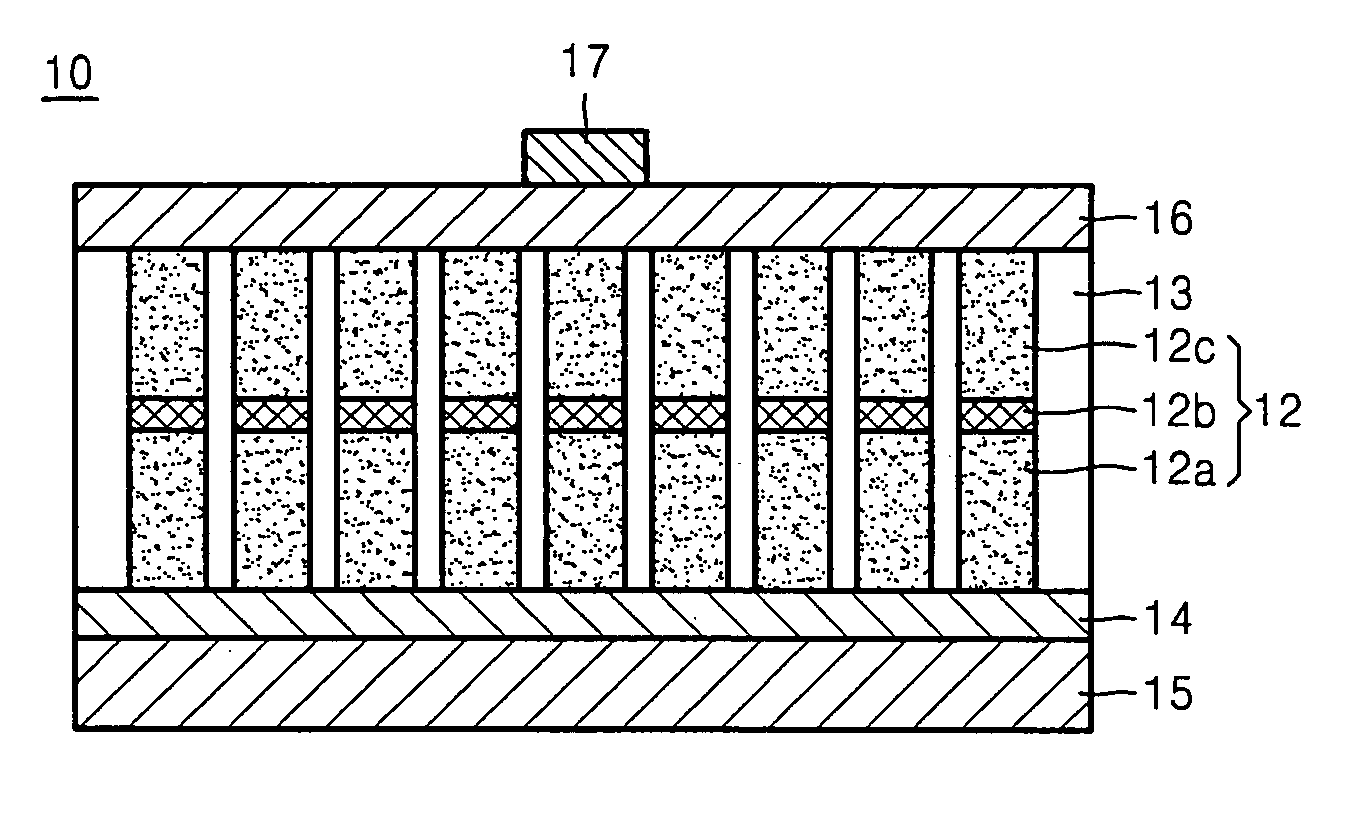

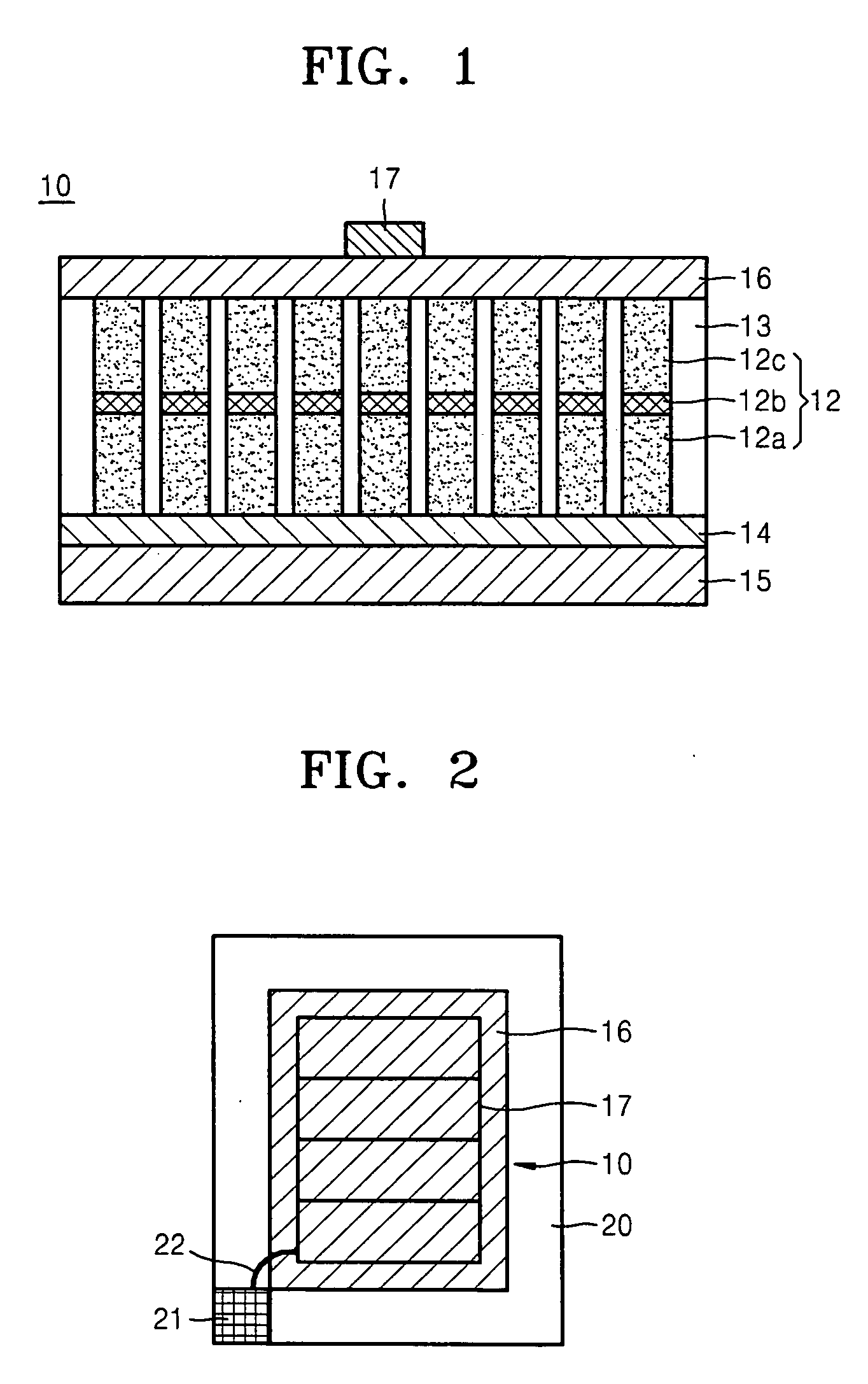

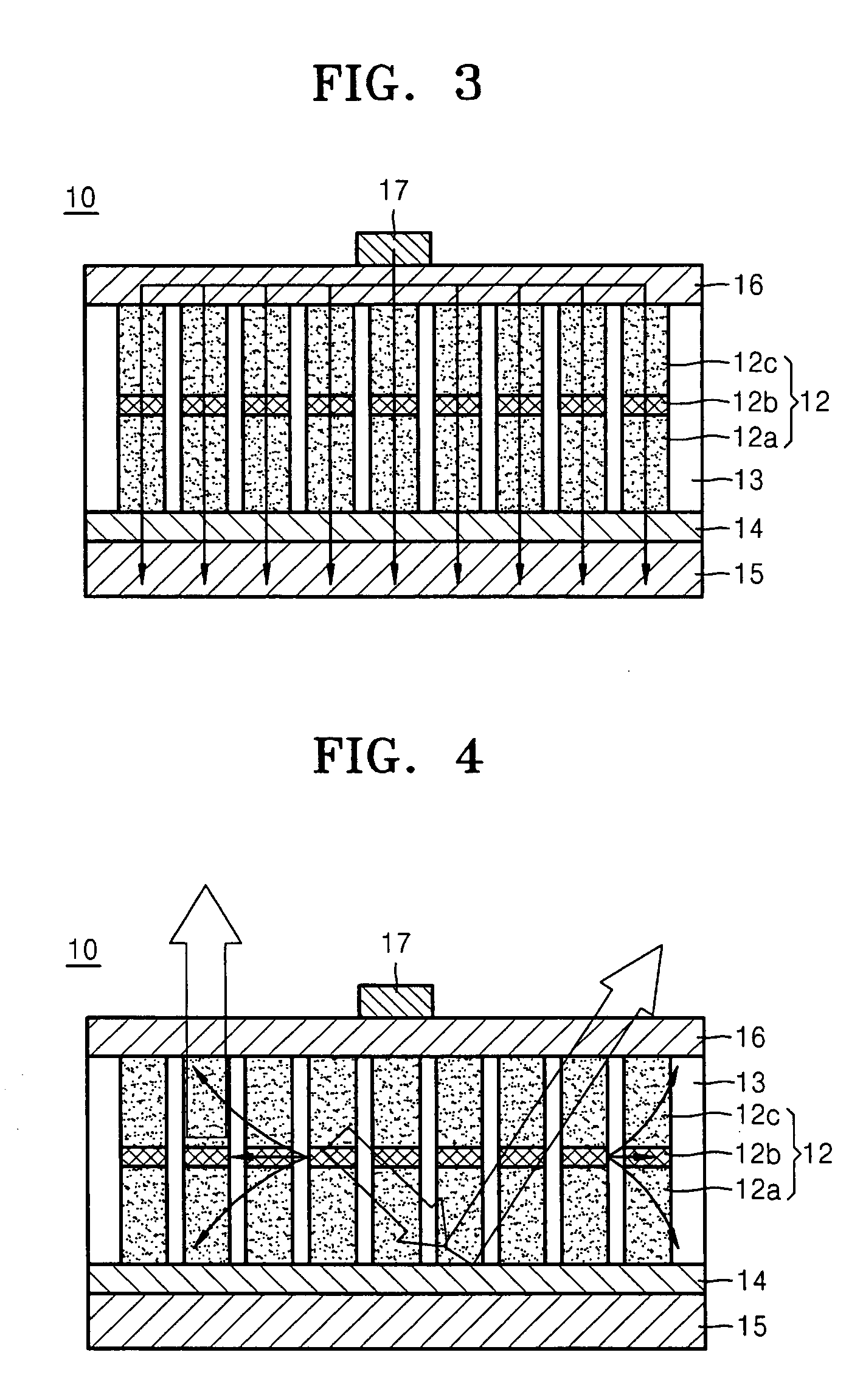

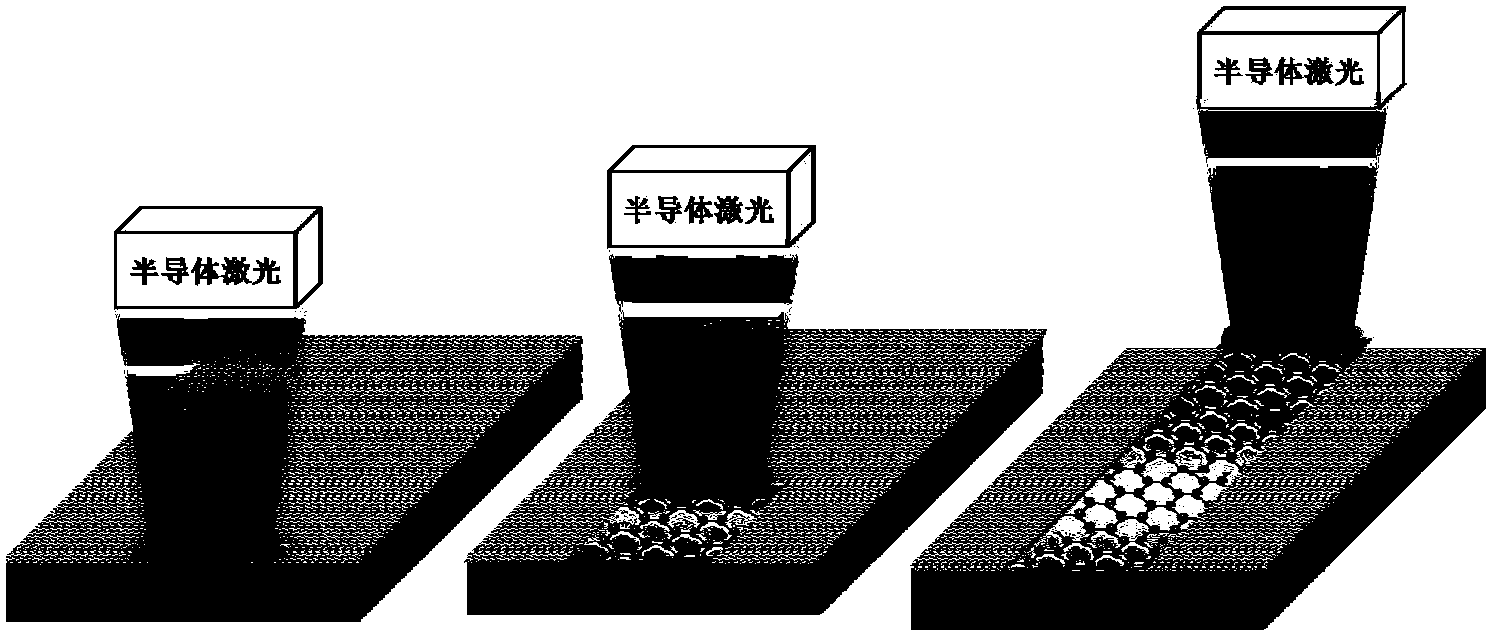

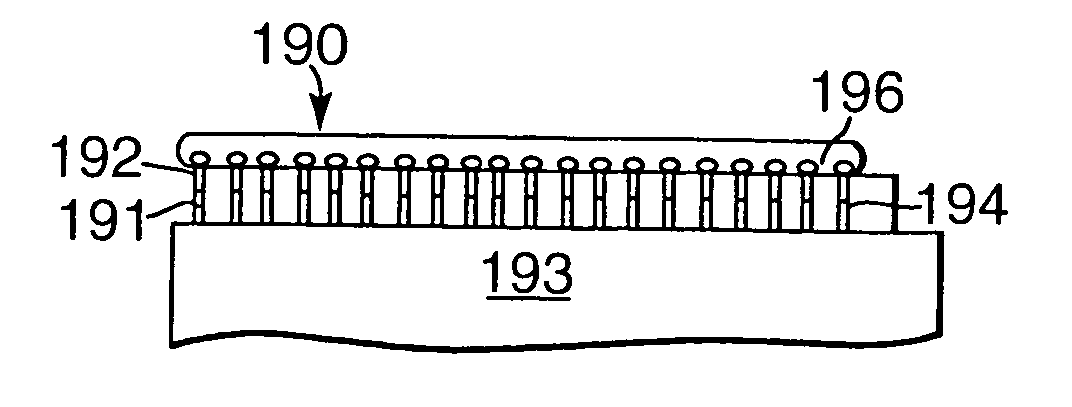

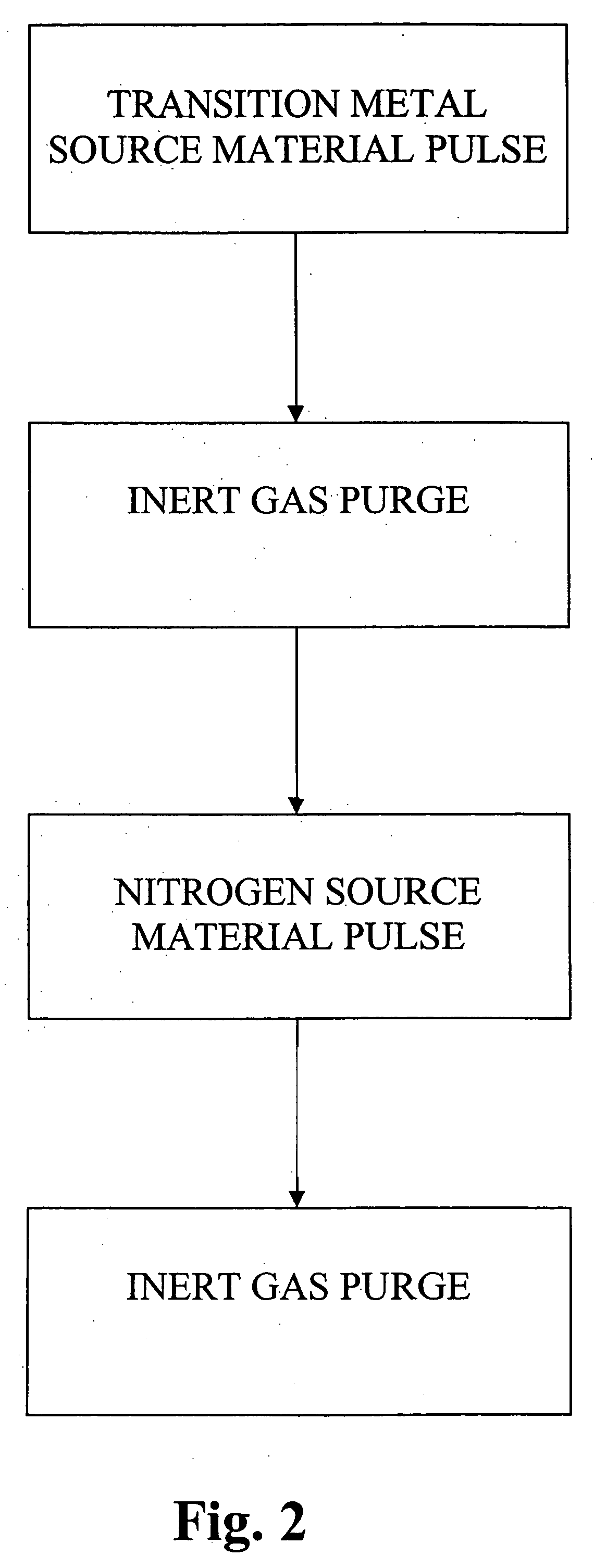

Light-emitting diodes using nano-rods and methods of manufacturing a light-emitting diode

ActiveUS20100051986A1Efficient growth processUniform supplySolid-state devicesSemiconductor/solid-state device manufacturingDopantEngineering

Light-emitting diodes, and methods of manufacturing the light-emitting diode, are provided wherein a plurality of nano-rods may be formed on a reflection electrode. The plurality of nano-rods extend perpendicularly from an upper surface of the reflection electrode. Each of the nano-rods includes a first region doped with a first type dopant, a second region doped with a second type dopant that is an opposite type to the first type dopant, and an active region between the first region and the second region. A transparent insulating layer may be formed between the plurality of nano-rods. A transparent electrode may be formed on the plurality of nano-rods and the transparent insulating layer.

Owner:SAMSUNG ELECTRONICS CO LTD

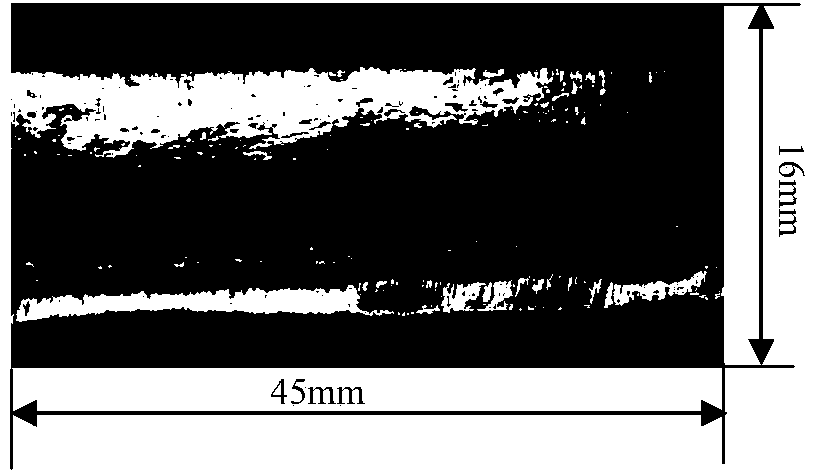

Laser preparation method for large-area patterned graphene

The invention discloses a laser preparation method for large-area patterned graphene. The preparation method comprises the following steps: (1) a solid carbon source is dispersed in an organic solvent to obtain a dispersion liquid, and the surface of a metal substrate is coated with the dispersion liquid in a spinning manner to obtain a uniform carbon coating; (2) under the condition of the protection of inert gas, a high power density laser beam is adopted to irradiate the carbon coating, and carbon atoms in the solid carbon source and metal atoms in the metal substrate are formed into a solid solution under function of irradiation; the high power density laser beam is moved away or the irradiation operation is stopped, when the metal substrate is cooled, the oversaturated solid solution is formed, and the carbon atoms are separated out of the oversaturated solid solution and formed on the surface of the substrate to form graphene. The invention provides a novel method which is convenient, fast, low in cost and high in efficiency and prepares the large-area patterned graphene. The product obtained through the method can be applied to the following fields: next generation microcomputers, flat-panel displays, super-capacitors, transparent conductive electrodes, sensors, solar batteries, micro-nano electronic devices, photoelectronic devices, self-spinning quantum devices, novel compound materials and so on.

Owner:TSINGHUA UNIV

System and method for more efficient automatic irrigation based on a large number of cheap humidity sensors and automatic faucets

ActiveUS20090145985A1Control can be done more efficiently and moreProtection worksSelf-acting watering devicesWatering devicesMulti materialSynthetic materials

The present invention provides an irrigation system with cheap humidity sensors and cheap automatic faucets preferably by using at the end nodes of the system low water pressure, so that much less force is needed to open and close the local waterway, and then either using simple electrical valves that do not require engines, or using for example mechanical sensors based on a bi-material of two or more materials which expand differently when they become wet, thus converting the difference of the expansion into convenient movement. Another possible variation, instead of mechanical sensors and valves, is to use for example a preferably synthetic material that tends to behave like a normal root preferably at the edge of each side channel, so that the “root” counter-balances the water supply and reaches equilibrium with it when the soil becomes wet enough, based preferably on asymmetric capillary materials.

Owner:MAYER BATYA BARHON +1

Method for generating influenza viruses and vaccines

InactiveUS20050054846A1Grows more efficientlyEfficient growth processSsRNA viruses negative-senseBiocideVirusMammalian cell

The present invention is based on the discovery that a high titer reassortant influenza virus is produced in mammalian cell culture by replacing the NS gene of the A / PuertoRico / 3 / 24 master strain with the NS gene of the A / England / 1 / 53 strain. The invention provides influenza viruses and vaccines generated in mammalian cells as well as methods for producing such. The invention further provides an influenza virus master strain and kits for generating reassortant influenza viruses in mammalian cell culture and methods of making and using the master strain.

Owner:ST JUDE CHILDRENS RES HOSPITAL INC

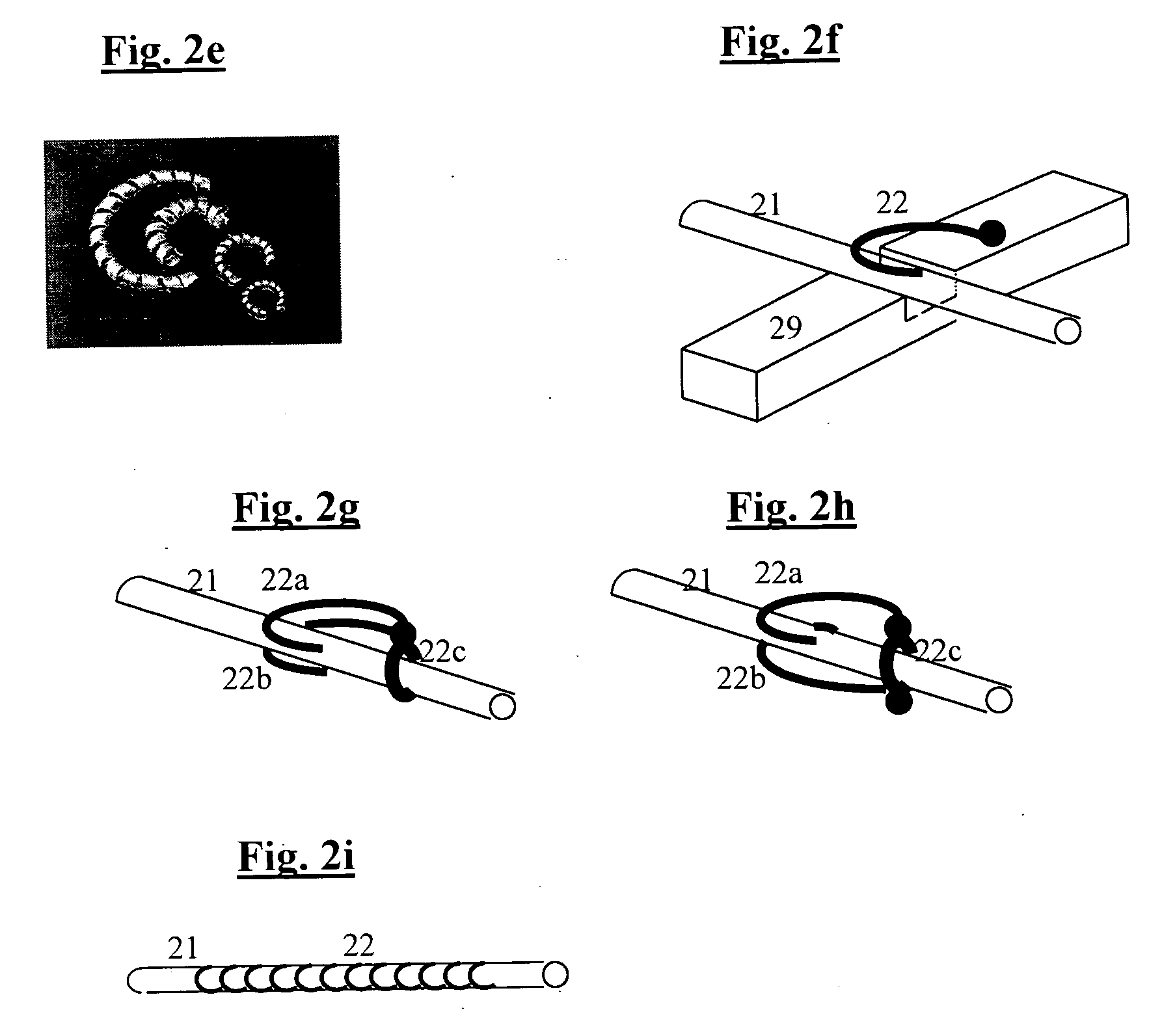

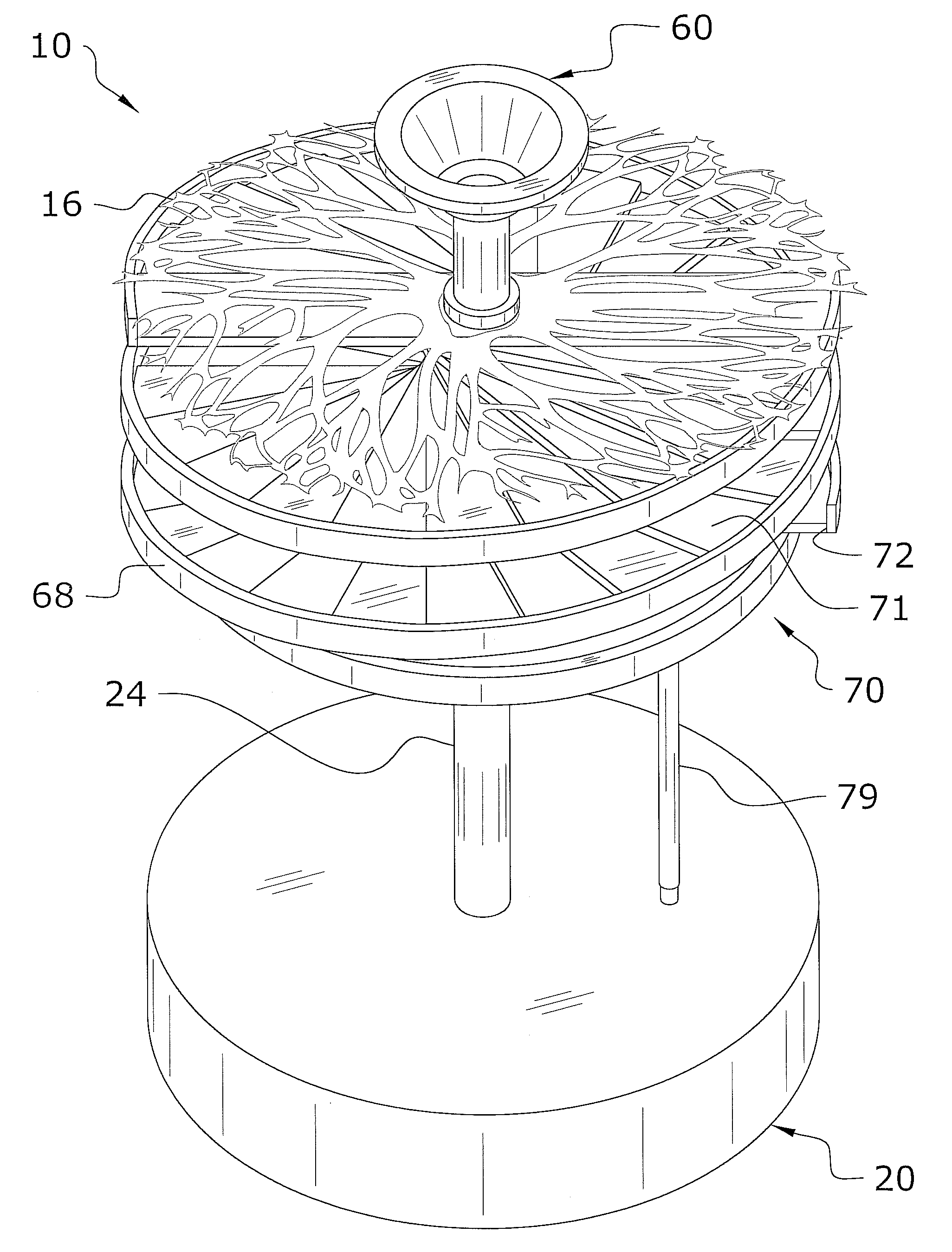

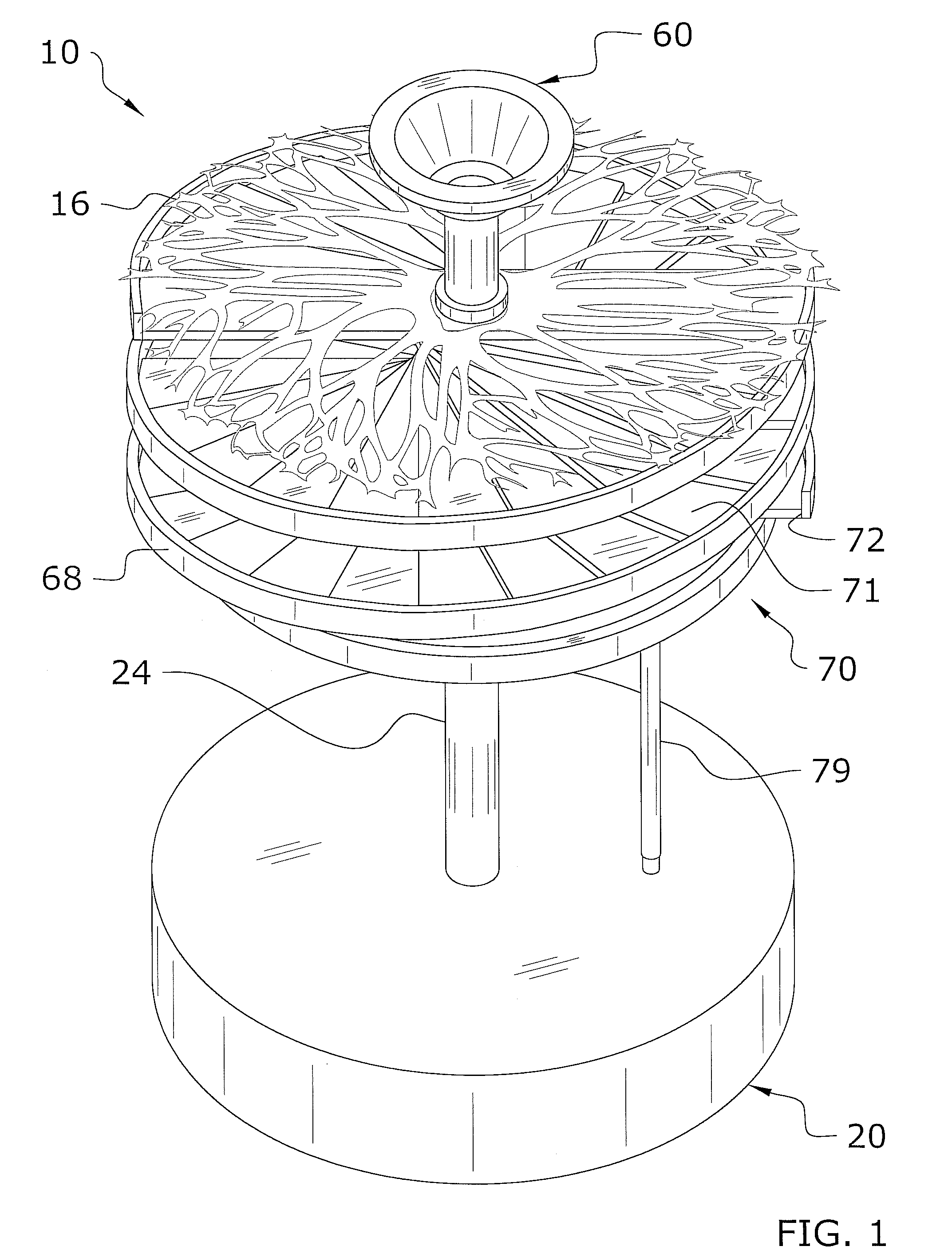

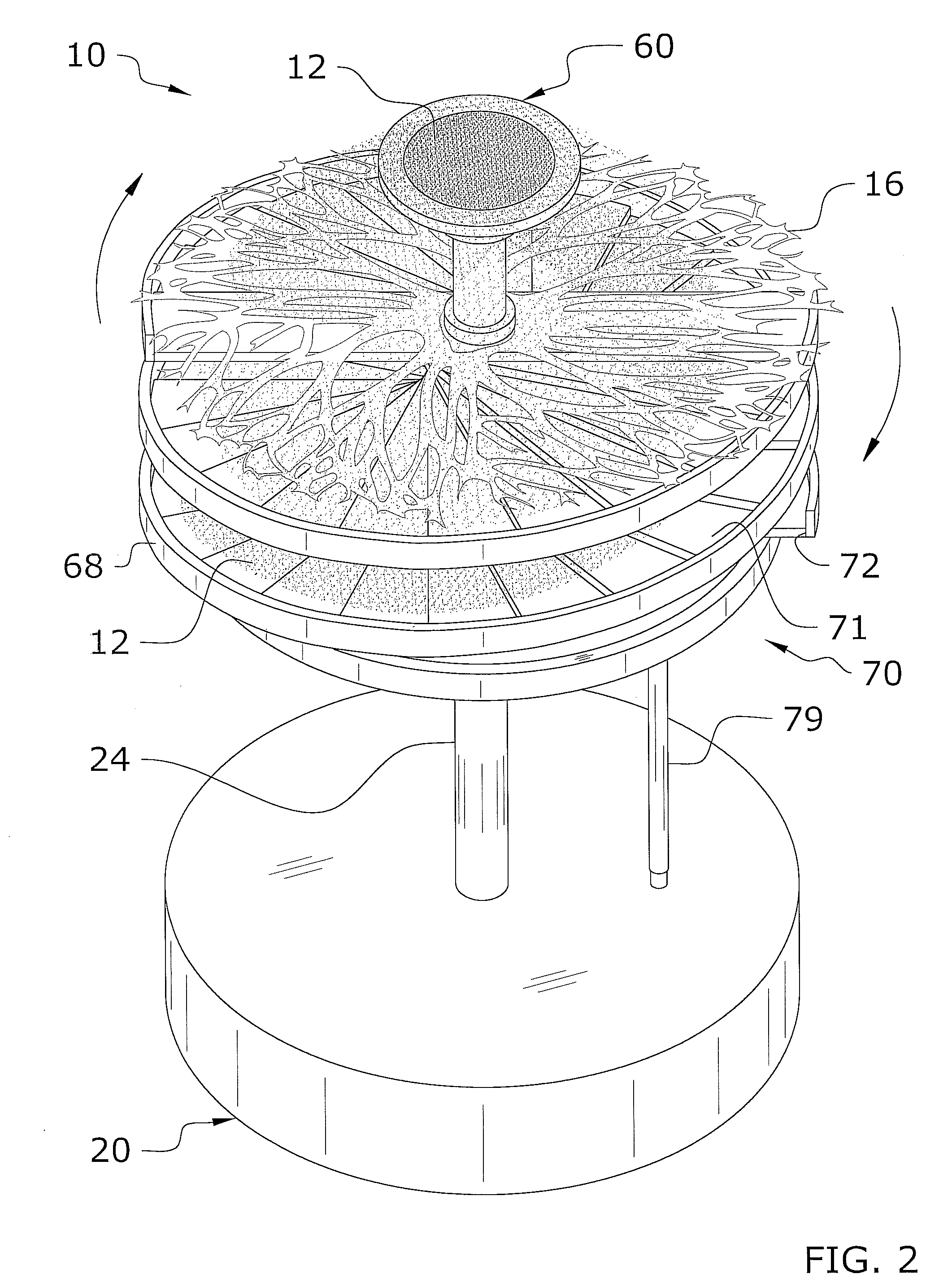

Helical Plant Growing System

InactiveUS20090265986A1Alleviate needEasily utilizedSelf-acting watering devicesFlower holdersEngineeringHelix

A helical plant growing system for efficiently growing various types of plants. The helical plant growing system generally includes a reservoir, a support column including a passageway, wherein the support column is fluidly connected to the reservoir. A pump is fluidly connected between the reservoir and the support column. A plant bed extends outwardly from the support column opposite the reservoir, wherein the plant bed is comprised of a helical configuration.

Owner:YOUNG NOLAN W

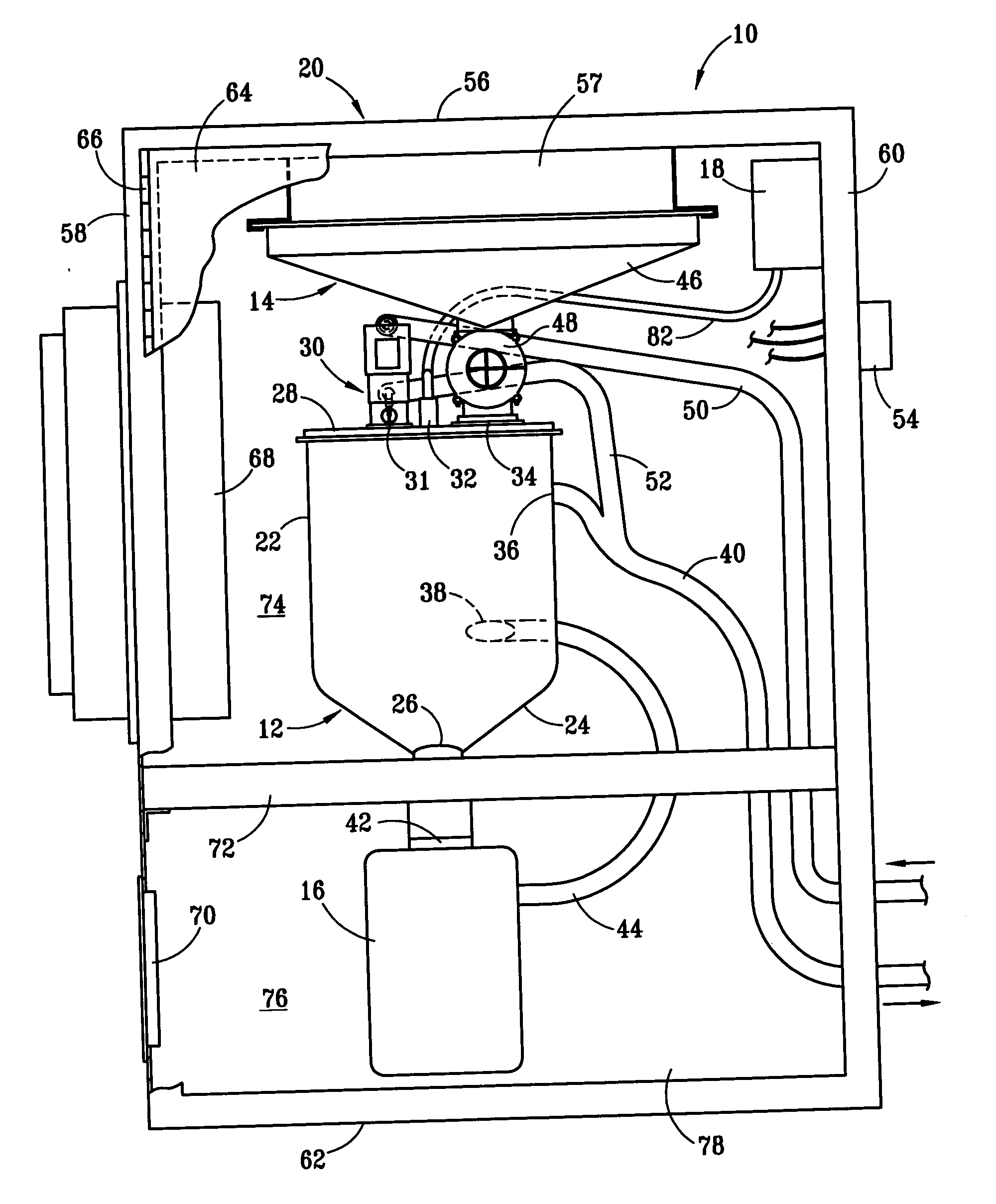

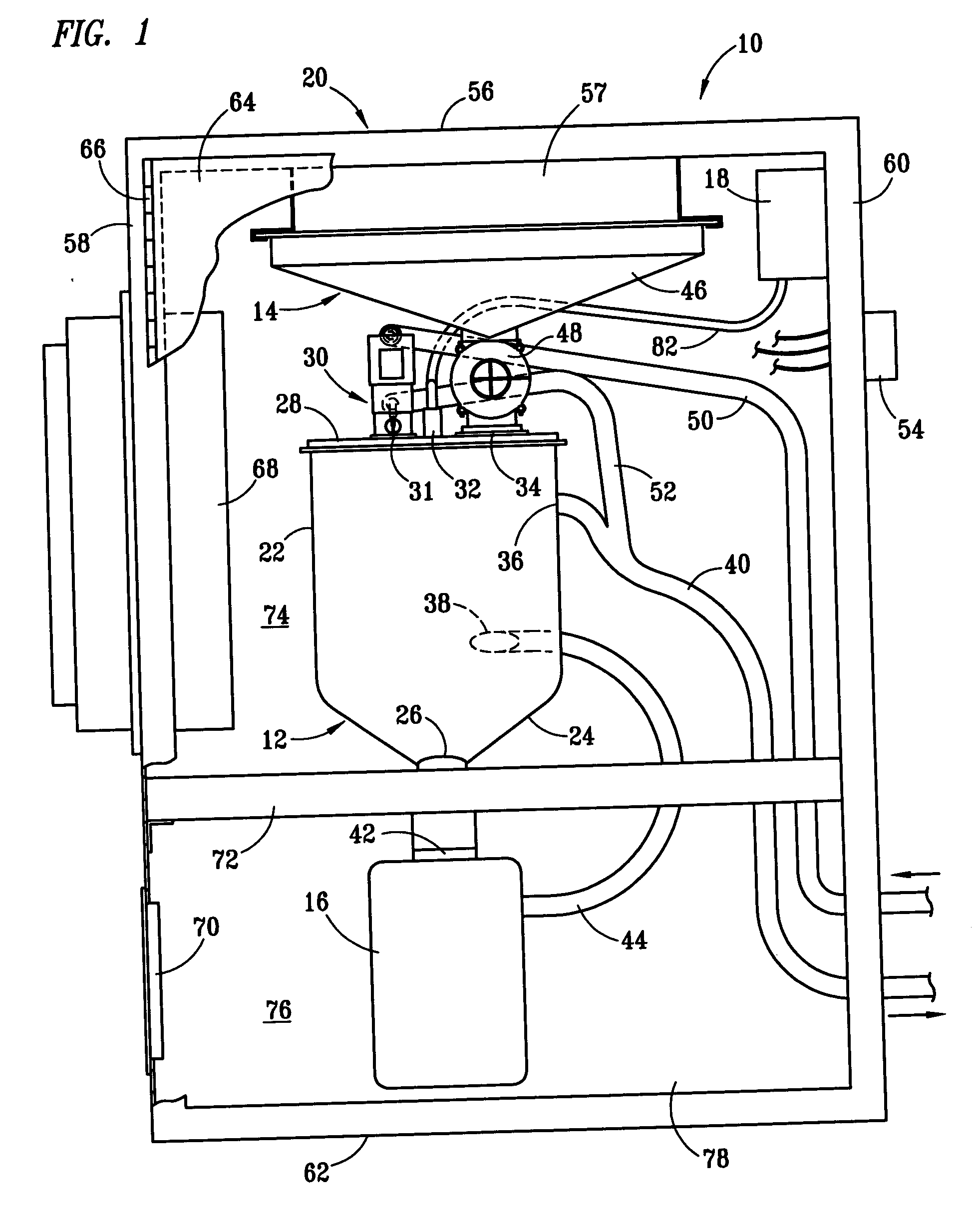

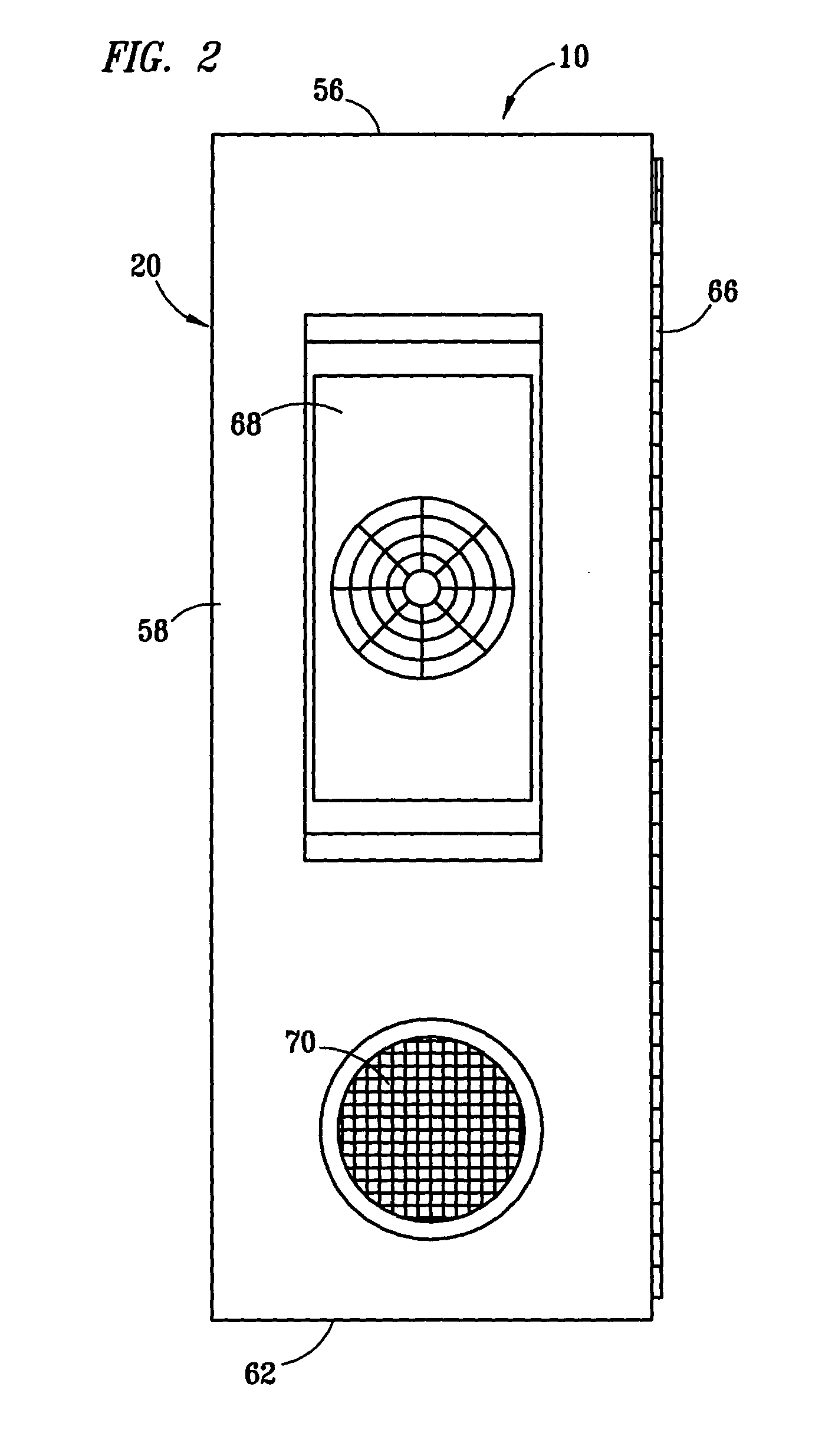

Biomass generator

InactiveUS20050032032A1Increase aerationEasy temperature controlBioreactor/fermenter combinationsBiological substance pretreatmentsCavitationWash water

A biomass generator useful for continuously growing and withdrawing bacteria to be used in a desired beneficial application, the generator having a bacteria growth chamber; water and nutrient inlet ports; upper and lower outlet ports; a recirculating pump withdrawing and reintroducing fluid to establish a vortex in the growth chamber while controlling foaming and pump cavitation; a low pressure air inlet line discharging air inside the growth chamber above the vortex; a fluid discharge line receiving bacteria-containing fluid from the upper outlet port of the growth chamber; a flush line discharging wash water into the fluid discharge line; and an electrical controller cooperating with solenoid-operated valves and a feeder mechanism to periodically introduce water and nutrients into the chamber, thereby simultaneously causing bacteria-containing fluid to be discharged from the growth chamber through the upper outlet port. A method for growing bacteria using the subject apparatus is also disclosed.

Owner:NCH CORP

Nanostructures and methods for manufacturing the same

InactiveUS20080105296A1Enhances width controlAccurate diameterPolycrystalline material growthIndividual molecule manipulationTunnel diodePhotonics

Owner:QUNANO

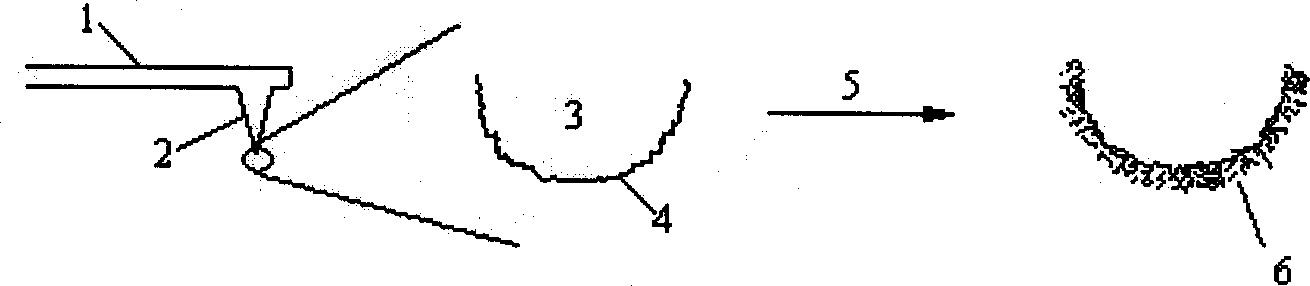

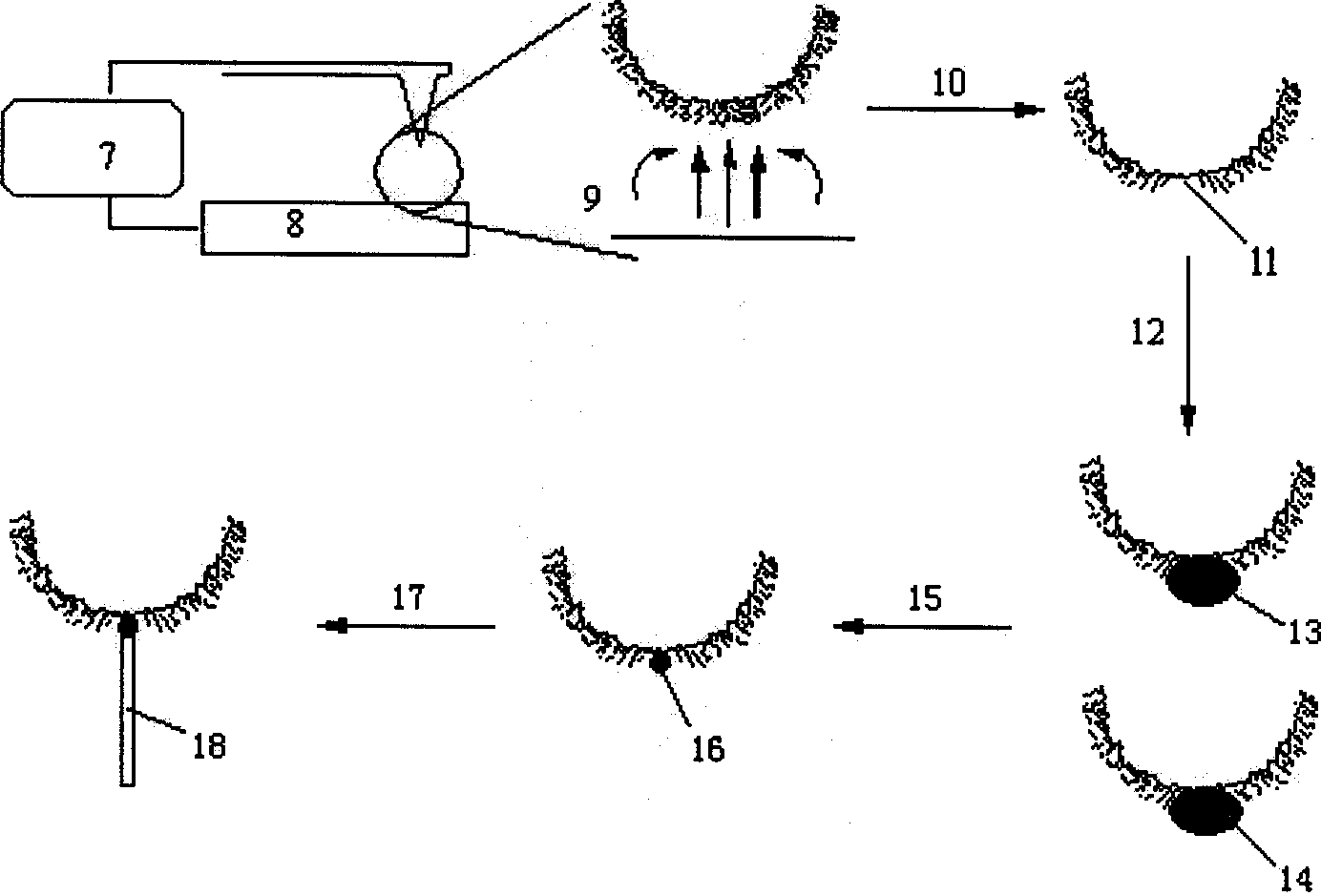

Method for preparing probe tip of nano tube

InactiveCN1434461AEasy to controlGuaranteed efficient growthSurface/boundary effectInstrumental componentsPtru catalystHydrophile

The invention is a method for manufacturing nano tube probe tip; the pin applies to various mode of atom microscope. At first, the method decorates hydrophobe single layer film on the surface of various silicon probe pin, then it uses electrical field to eliminate the film or oxides the film into hydrophile film, it calculates the size of the activated area through the action that the pin acts onthe standard sample surface, then it fixed catalyst particles in the hydrophile area on the surface of the pin, finally, puts the pin which carries catalyst nano particles in the nano reactor and forms into nano tube.

Owner:SOUTHEAST UNIV

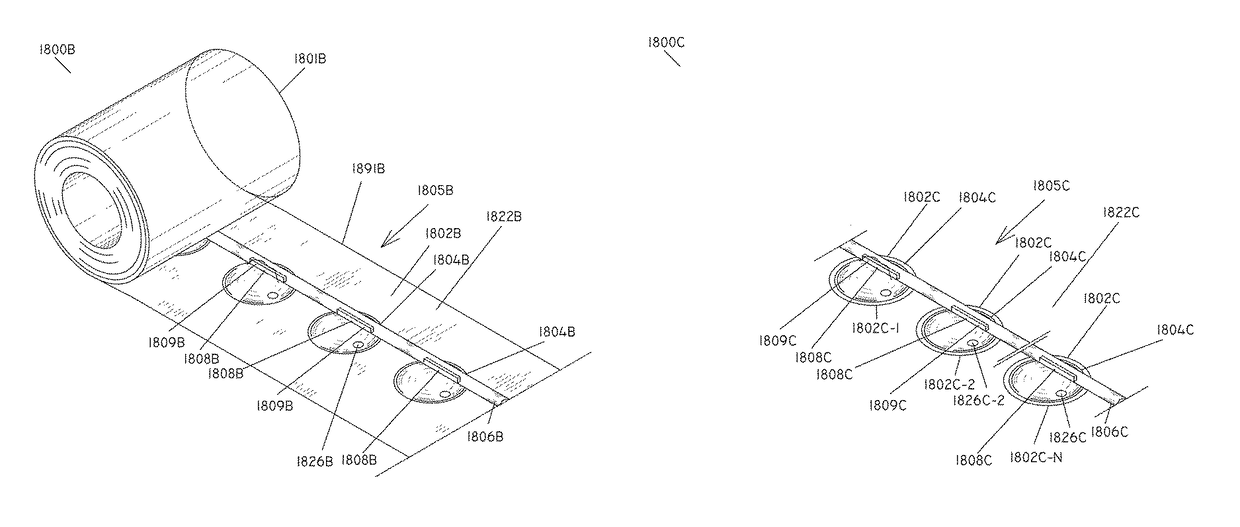

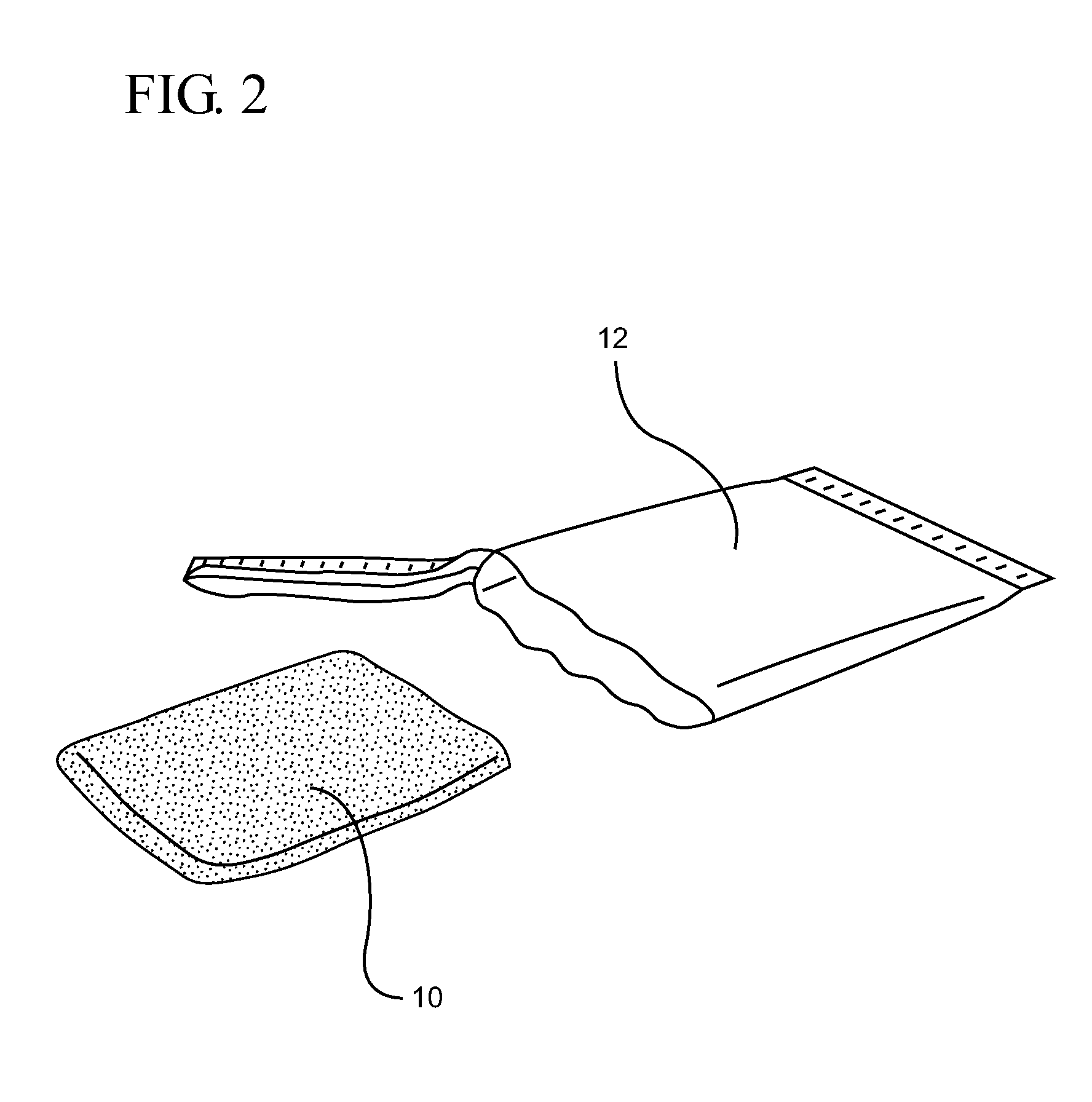

System for growing plants and method of operation thereof

ActiveUS9629313B1Prevent growth of undesirableReduce growthSelf-acting watering devicesClimate change adaptationIrrigationEngineering

A system for growing plants, the system may include a substrate having one or more weakened areas or openings: one or more grow portions coupled to the substrate and situated at the one or more weakened areas or openings and having at least one seed or plant; and / or a fluid distribution portion coupled to the substrate and configured to provide fluid to the one or more grow portions. The system may further include a method of operation including one or more acts of: obtaining a weather forecast for a future time period; determining whether rain is expected during the future time period; and preventing, terminating, or restricting an irrigation cycle when it is determined that rain is expected during the fare time period. The restricting may restrict a flow of liquid during the irrigation cycle or shorten the irrigation interval.

Owner:GROSSMAN VICTOR A

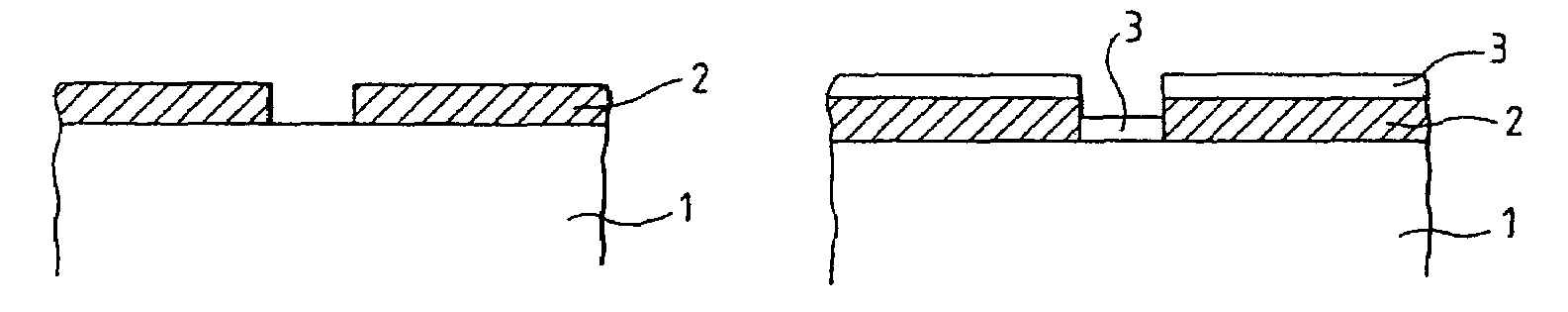

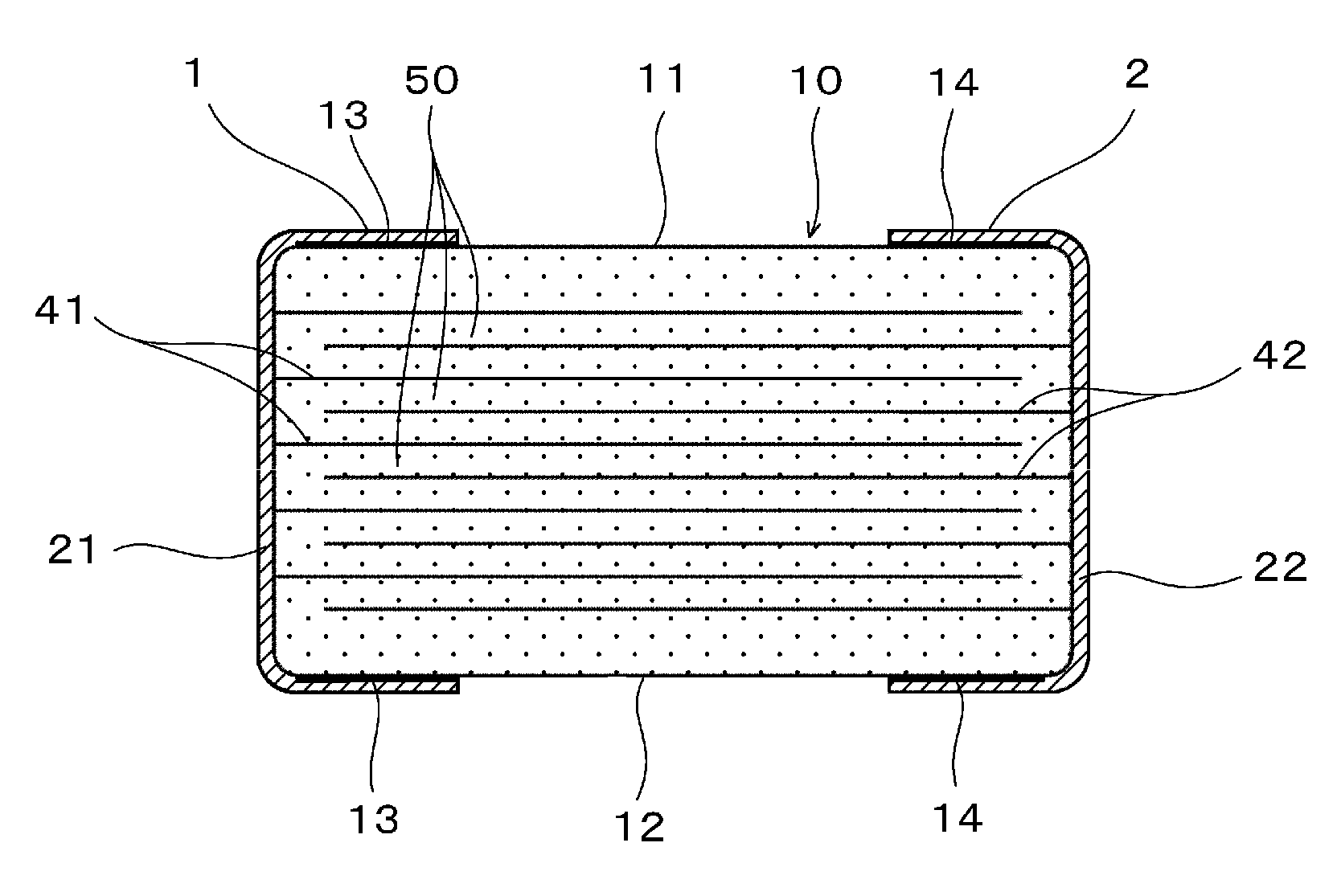

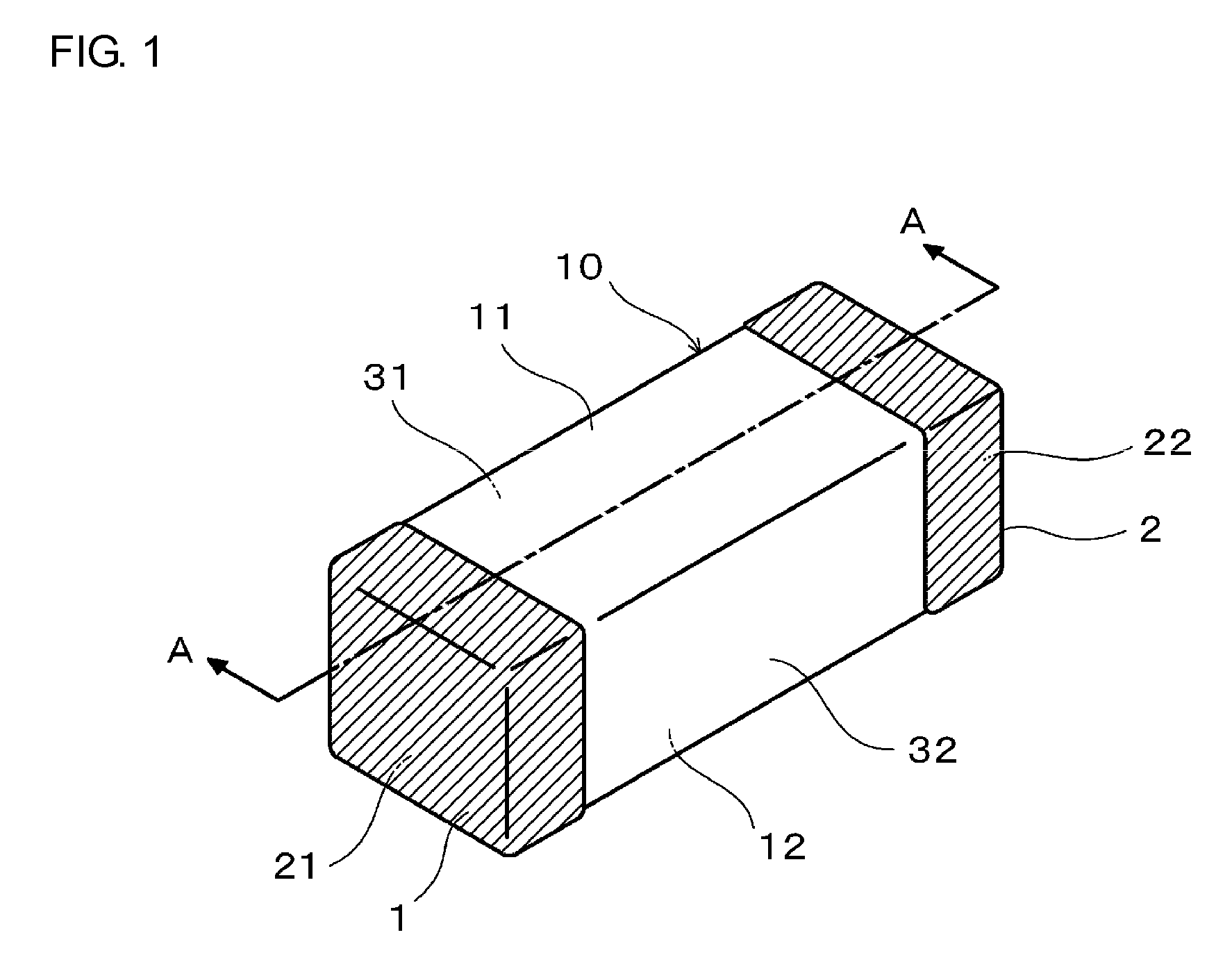

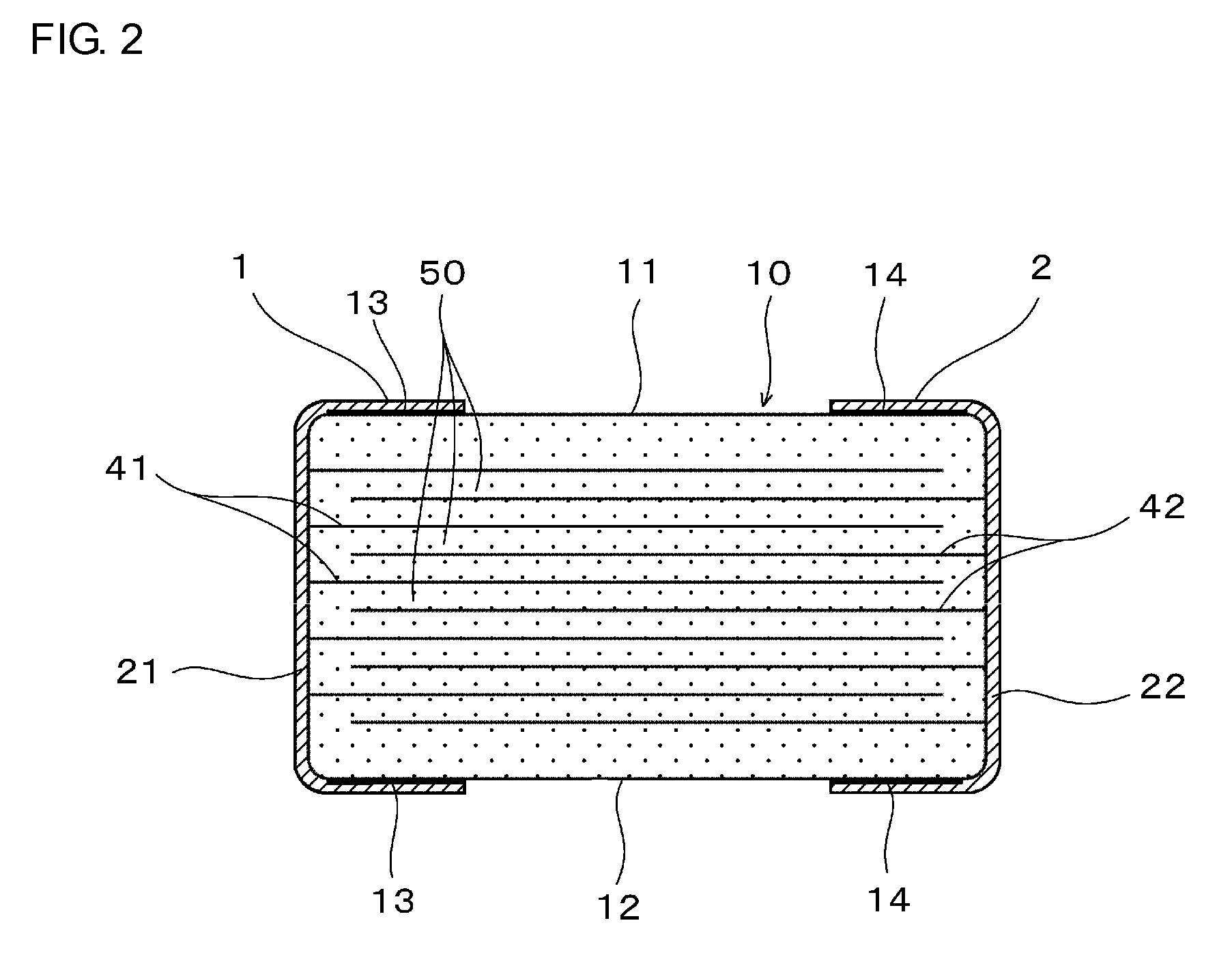

Multilayer electronic component and method for manufacturing the same

ActiveUS20090310278A1Efficient growth processImprove productivityFixed capacitor electrodesThin/thick film capacitorElectrical conductorElectronic component

A multilayer electronic component includes a ceramic body including ceramic layers that are laminated to one another and internal conductors having exposed portions at side surfaces of the ceramic body. Substantially linear connection portions extend in the lamination direction of the ceramic layers so as to connect the exposed portions to one another. External terminal electrodes cover the exposed portions of the internal conductors and the connection portions and include base plating films directly disposed on the side surfaces by plating. The connection portions are formed by polishing the side surfaces in which the internal conductors are exposed using, for example, a brush so as to elongate the exposed portions of the internal conductors.

Owner:MURATA MFG CO LTD

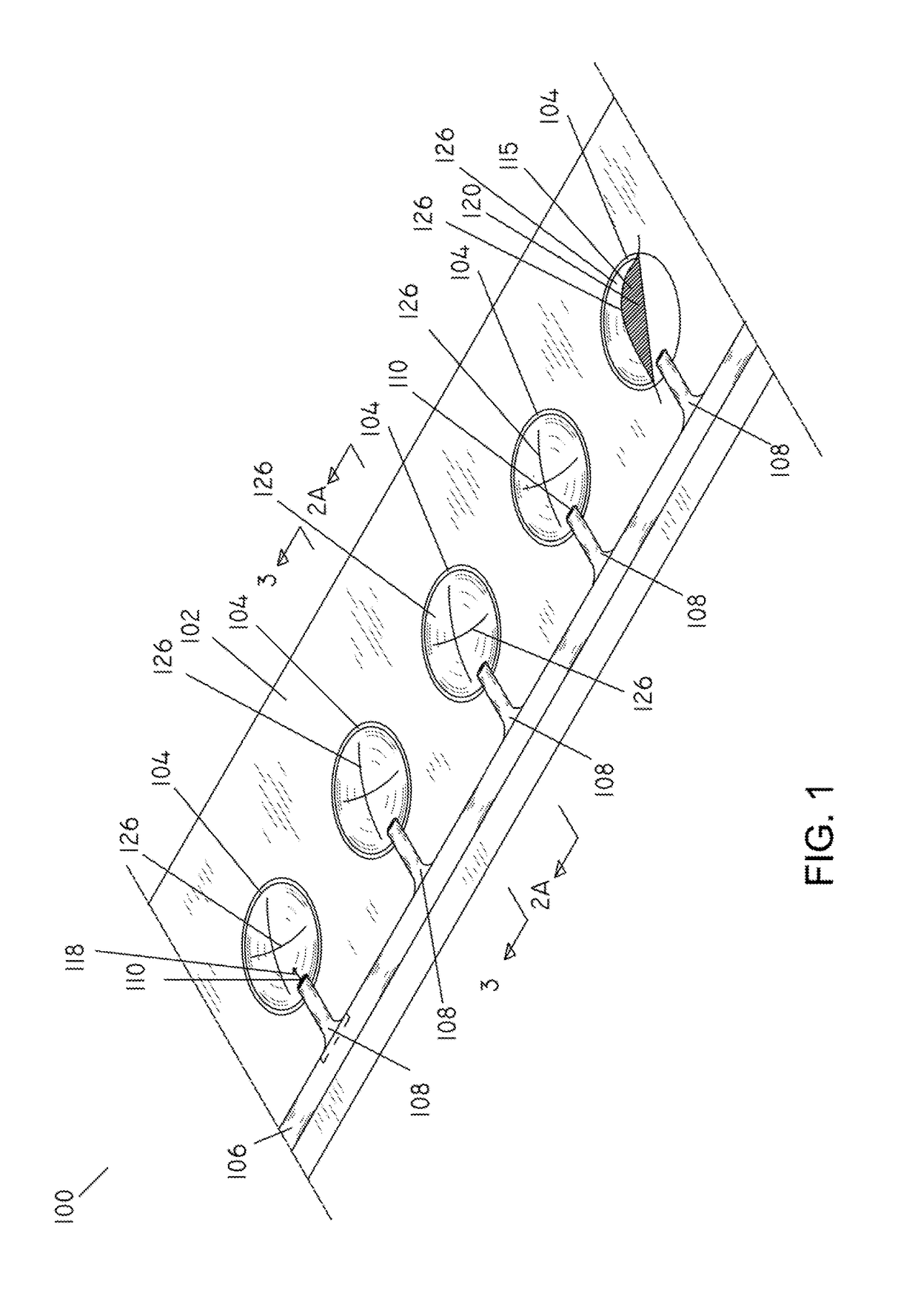

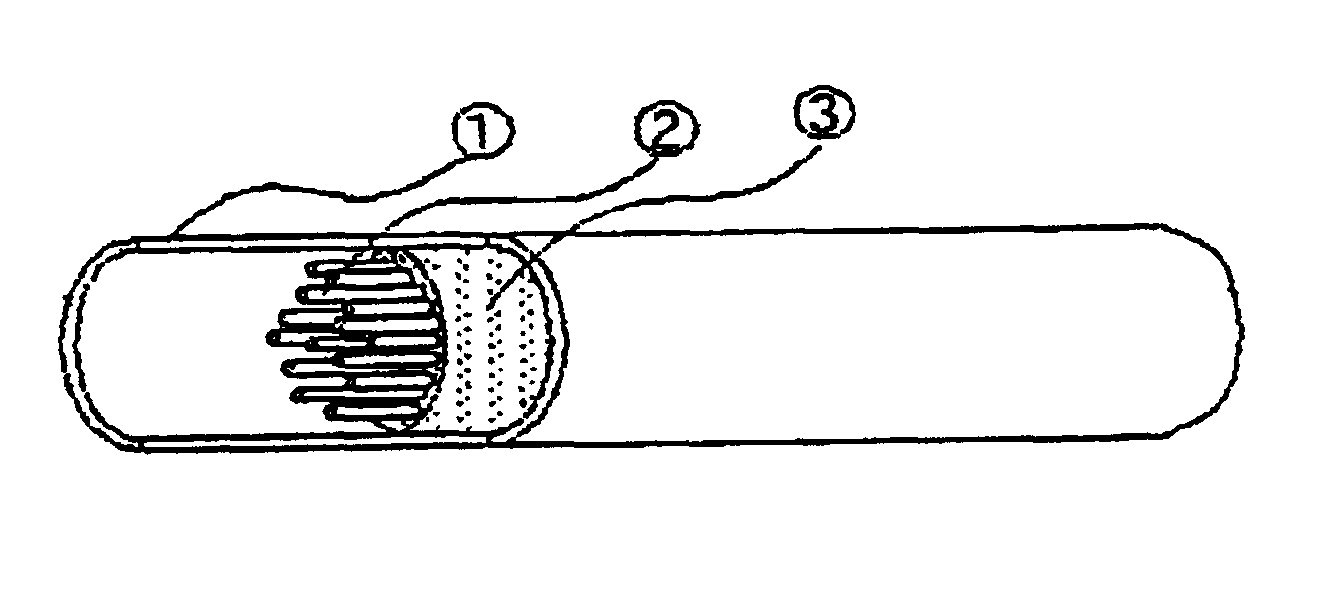

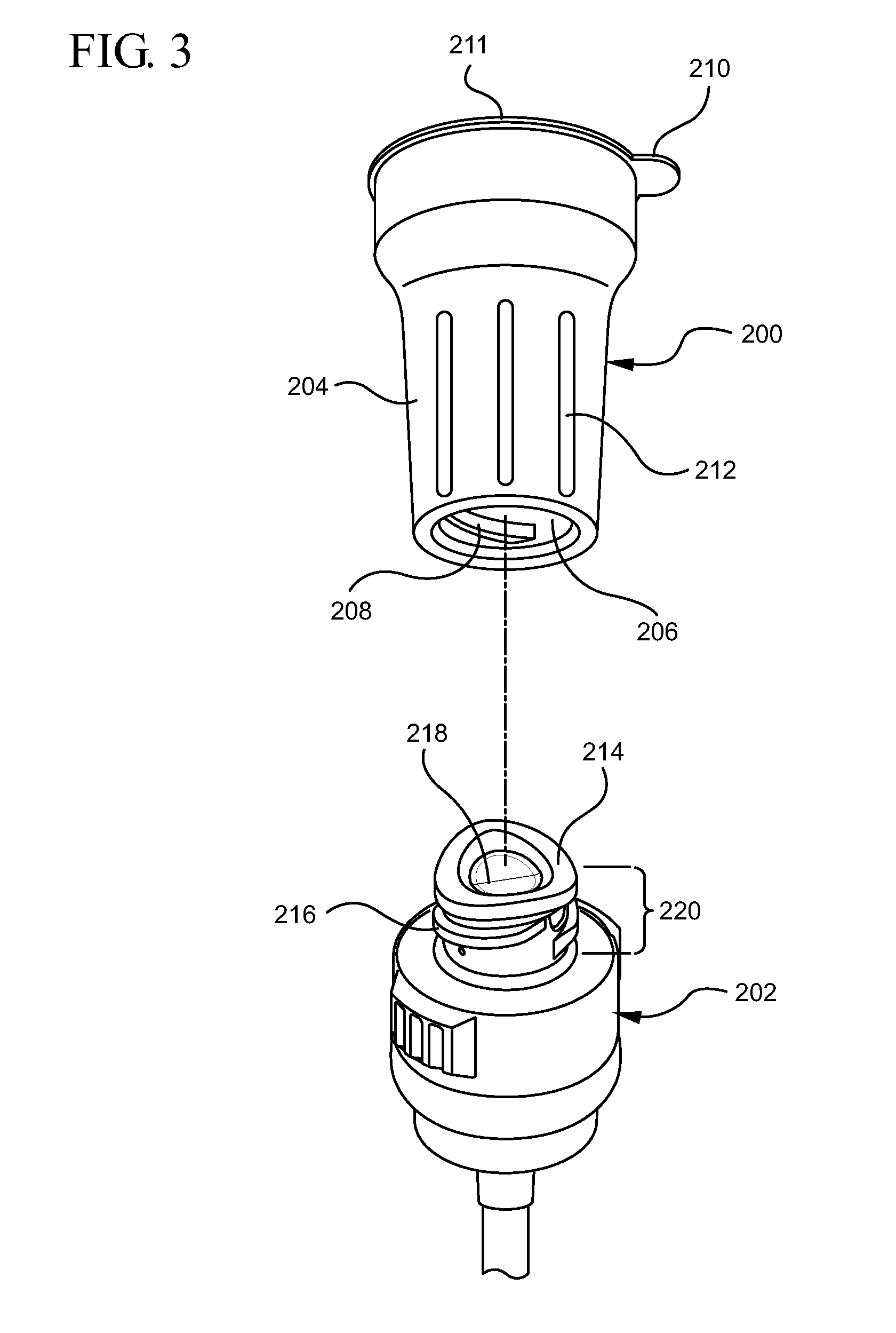

Instrument for regenerating living organism tissue or organ

InactiveUS6953482B2Efficient growth processEasy to insertSurgeryJoint implantsBiological bodyAnatomy

This invention relates to an instrument for regenerating a living organism tissue or organ, characterized in that a support (A) formed from a biodegradable material or a bioabsorbable material includes a sponge-like fine matrix (B) formed from a biodegradable material or a bioabsorbable material and a linear guide channel (C) for a living organism tissue or organ.

Owner:UEDA MINORU

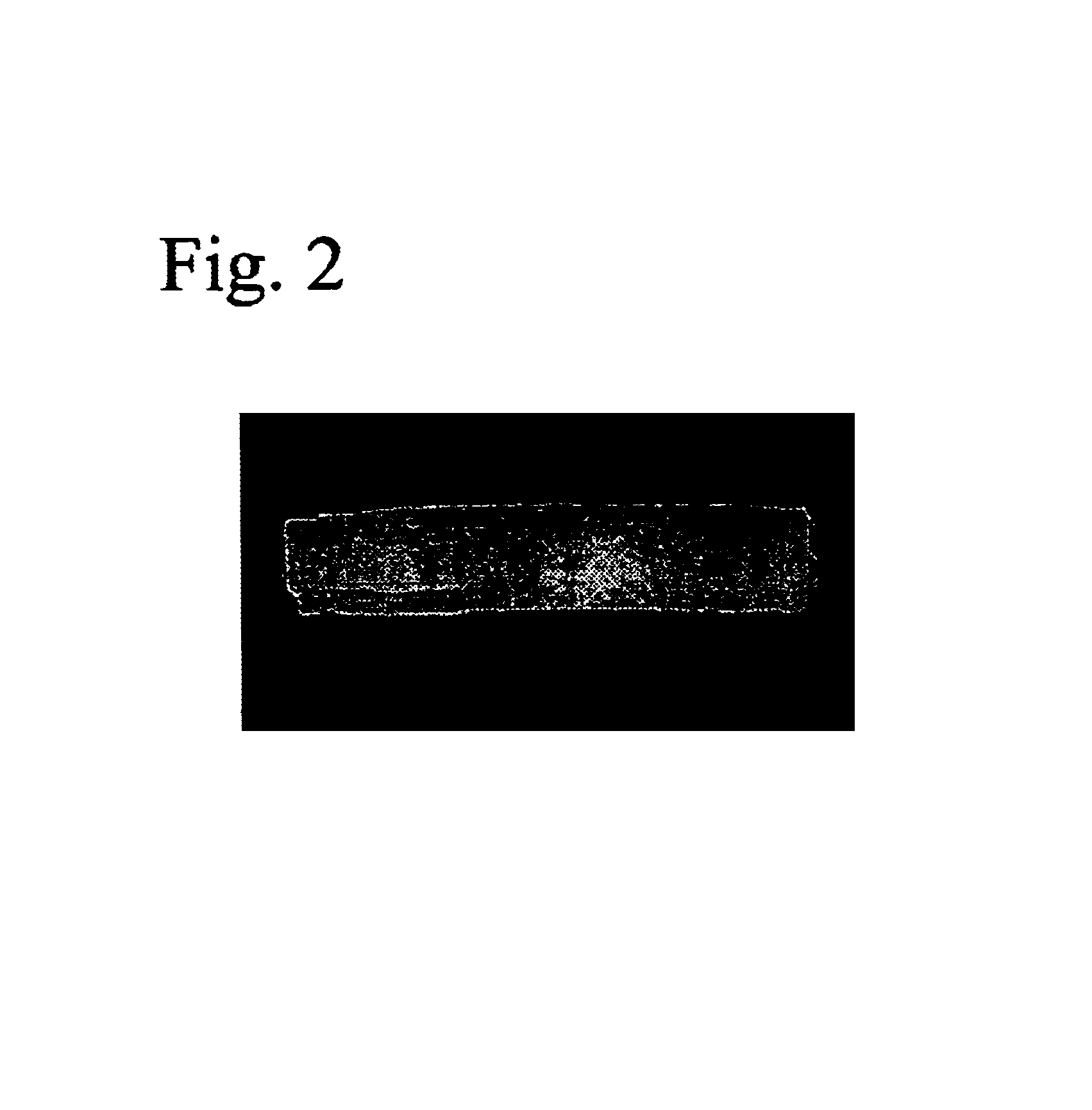

Chlorhexidine acetate antiseptic cleaning agent

ActiveUS8343525B2Efficient growth processKilling or preventing/impeding pathogen growthCosmetic preparationsBiocidePolyesterTriclosan

An antiseptic cleaning agent, generally, comprising chlorhexidine acetate and a solvent, such as an alcohol and / or water. The chlorhexidine acetate acts as a highly effective biocide. Additionally, the chlorhexidine acetate allows the cleaning agent to dry without leaving a tacky residue. Where the cleaning agent comprises one or more alcohols, the alcohols may comprise any suitable alcohols, including lower alcohols having from 1 to 6 carbon atoms, such as ethanol and isopropanol. Where the ratio of ethanol to isopropanol may be from between about 1:1000 to about 1000:1. In addition to chlorhexidine acetate, the cleaning agent optionally comprises another non-alcohol biocide, such as triclosan. The cleaning agent can be used in any suitable manner. For instance, the cleaning agent may be impregnated in an absorbent material, such as a towelette, swabstick, or gauze. Additionally, the absorbent material may comprise a positively charged or a non-ionic substance, such as polypropylene or polyester.

Owner:BECTON DICKINSON & CO

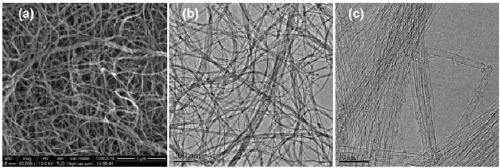

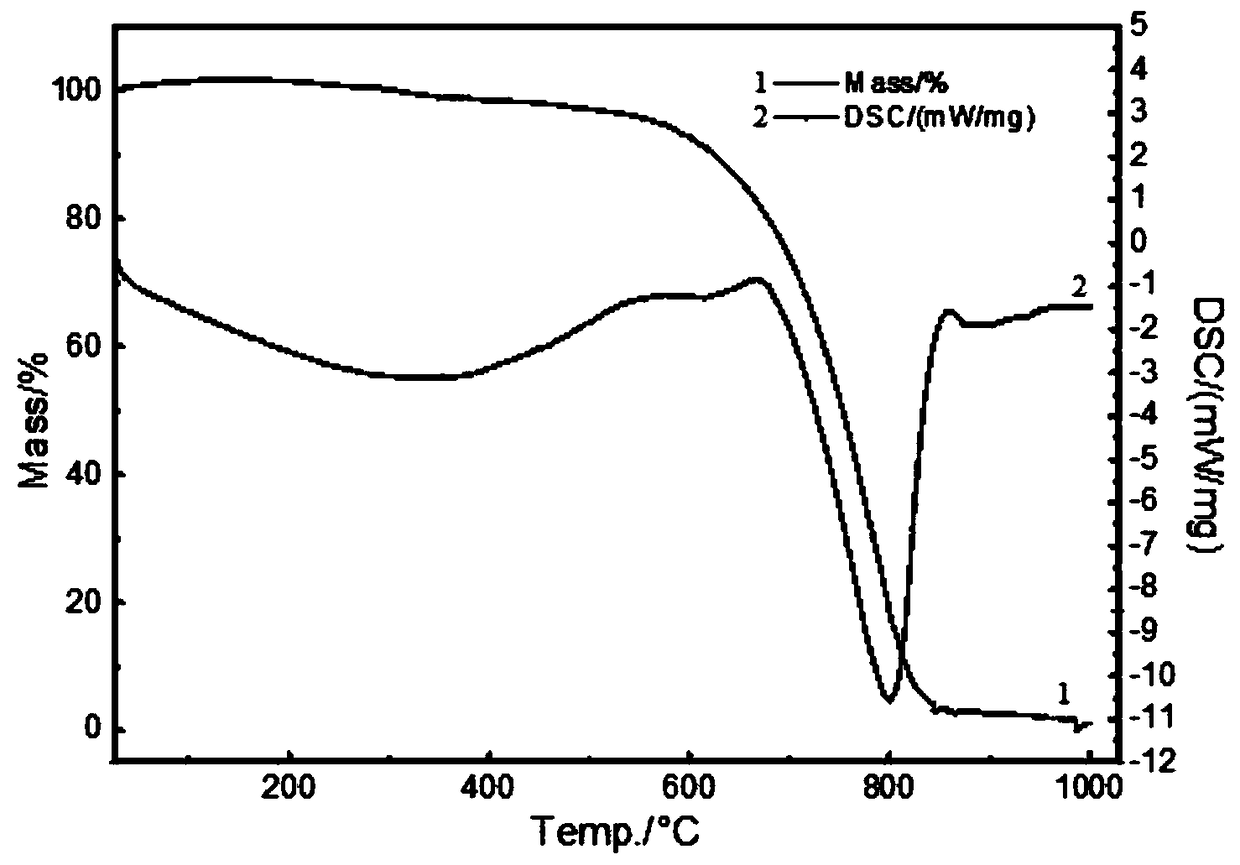

Floating catalyst chemical vapor deposition method of single-walled carbon nanotubes

ActiveCN109437157AHigh catalytic efficiencyImprove the conversion rate of carbon sourceMaterial nanotechnologySingle-walled nanotubesGas phaseWater vapor

The invention relates to the technical field of control preparation of carbon nanotubes, in particular to a floating catalyst chemical vapor deposition method of single-walled carbon nanotubes. Hydrogen is used as carrier gas, transition metal is used as a catalyst, sulfur is used as a growth promoter, trace vapor is introduced in a reaction system, the catalytic efficiency of the metal particle catalyst in a growth area is improved, the service life of the catalyst is prolonged, and efficient growth of the single-walled carbon nanotubes with high purity and high crystallinity degree is realized. The conversion efficiency of a carbon source is as high as 25% under an optimized condition; the prepared carbon nanotubes have uniform diameter, high crystallinity degree and the highest centralized oxidation-resistant temperature up to 816 DEG C; very few catalyst impurities are left and the content of the catalyst is lower than 1.1wt%. The method realizes high efficiency of the preparationprocess and high quality of products, provides an effective way for mass preparation and industrial development of high-quality single-walled carbon nanotubes, and has great significance in large-scale application of the high-quality single-walled carbon nanotubes.

Owner:唯碳纳米科技(沈阳)有限公司

Method of modifying source chemicals in an ALD process

InactiveUS20050000431A1Short cycleEfficient growth processPolycrystalline material growthSolid-state devicesSource materialCompound (substance)

The invention concerns a method for modifying a source material used in an ALD process, a method for depositing transition metal nitride thin films by an ALD process and apparatus for use in such process. According to the present invention, transition metal source materials are reduced by vaporizing a metal source material, conducting the vaporized metal source material into a reducing zone comprising a solid reducing agent maintained at an elevated temperature. Thereafter, the metal source material is contacted with the solid or liquid reducing agent in order to convert the source material into a reduced metal compound and reaction byproducts having a sufficiently high vapor pressure for transporting in gaseous form.

Owner:ELERS KAI ERIK

Light emitting device

ActiveUS20150357532A1Sufficient crystal growthBrighter lightSolid-state devicesSaving energy measuresPhosphorFar-red

This light emitting device is provided with: a light emitting element which emits excitation light; and a far-red phosphor which is excited by the light of the light emitting element and emits light that has a peak wavelength within the range of 700-800 nm. The far-red phosphor has a median diameter within the range of 1-20 μm.

Owner:SHARP KK

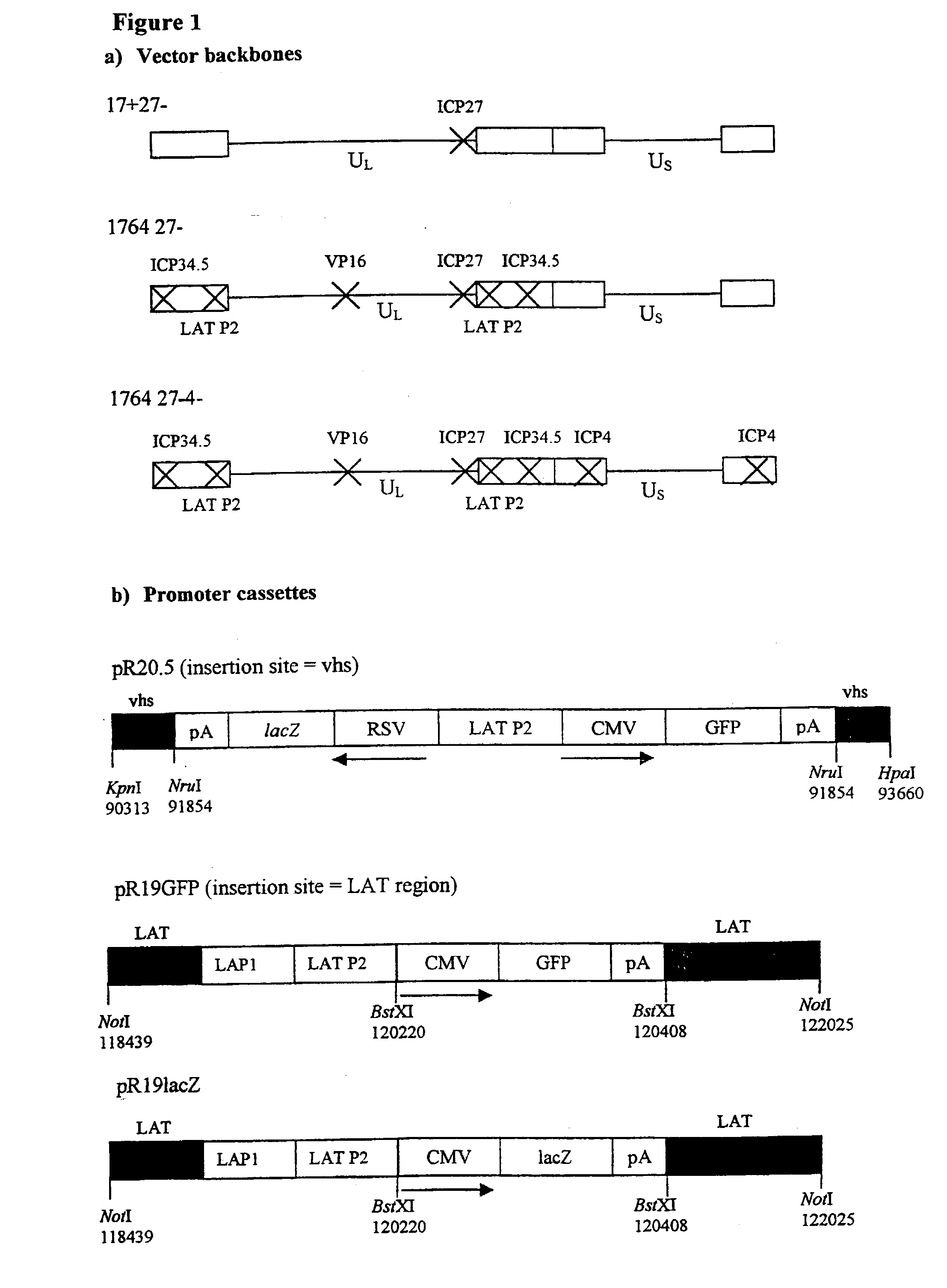

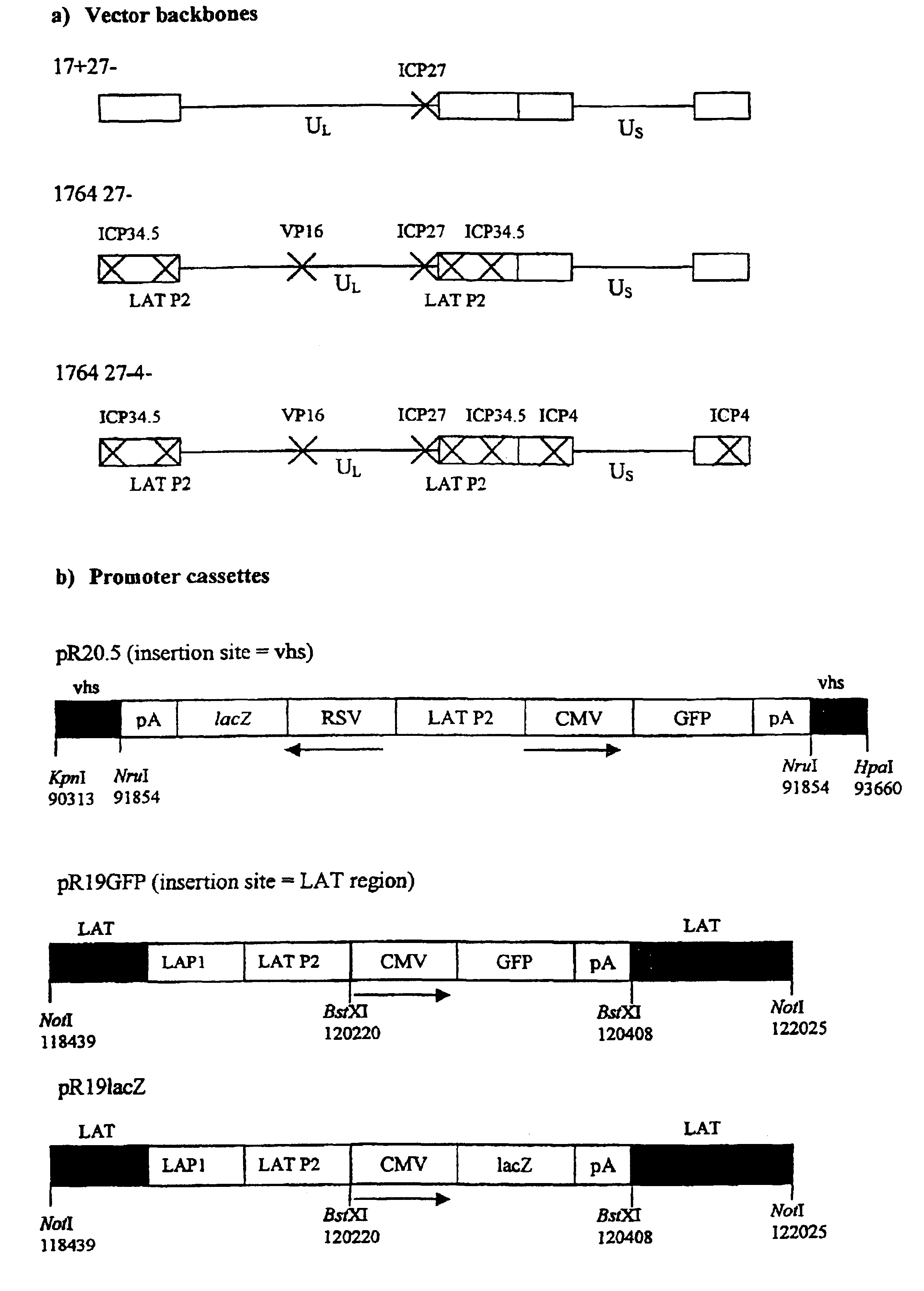

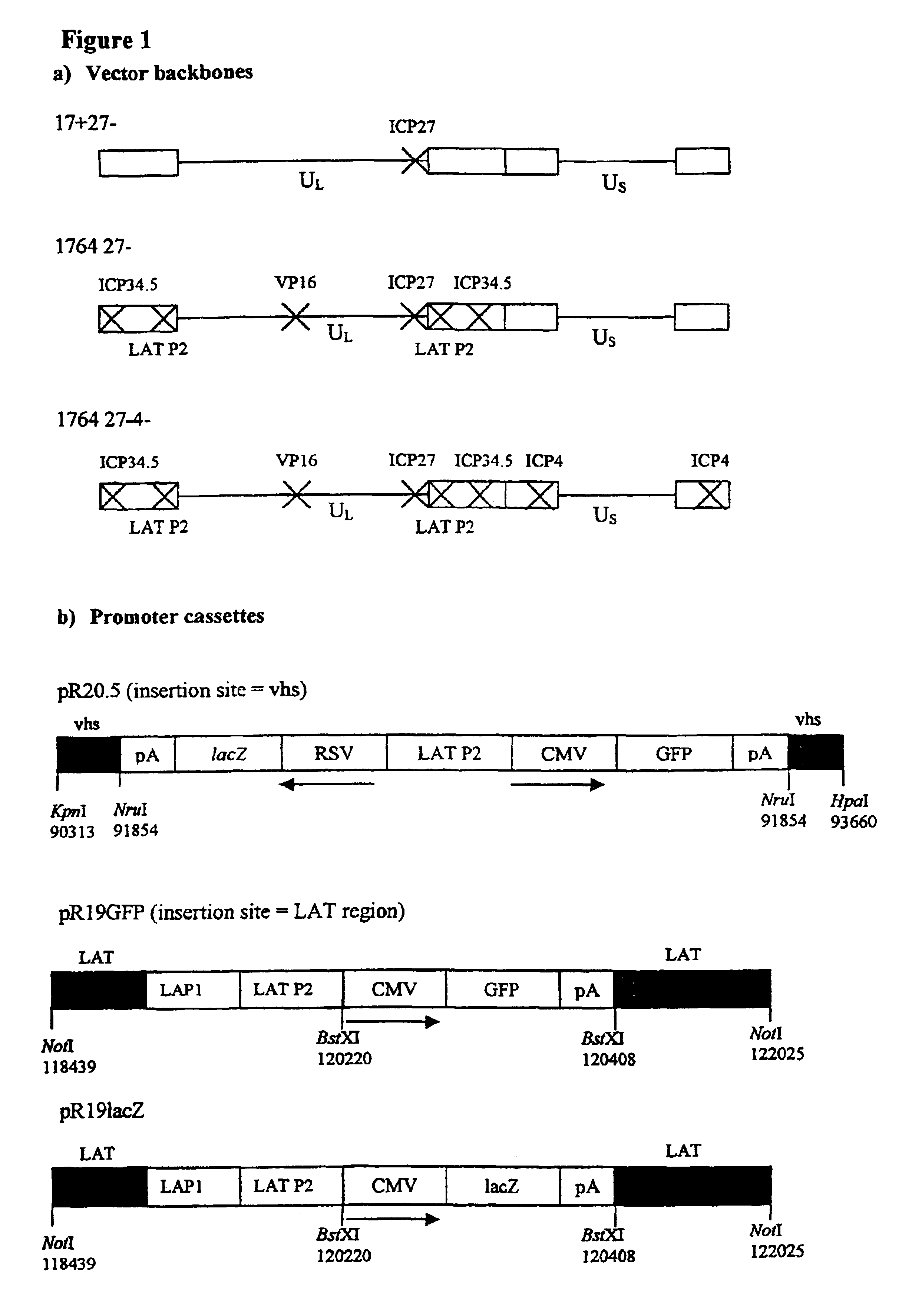

Replication incompetent herpes viruses for use in gene therapy

InactiveUS20030082142A1Minimize the possibilityReduced activityBiocideNervous disorderGene deliveryHeterologous

Use of a replication incompetent herpes virus capable of delivering a gene to multiple connected sites within the nervous system, which virus comprises: (a) a mutation which prevents or reduces the expression of at least two immediate early genes; and (b) a heterologous gene operably linked to a promoter active during herpes virus latency; in the manufacture of a medicament for the treatment of a central nervous system disorder, a method of determining whether a gene has an effect on a phenotype associated with a central nervous system disorder and in a method of treatment of a disorder of the central nervous system are described.

Owner:BIOVEX LTD

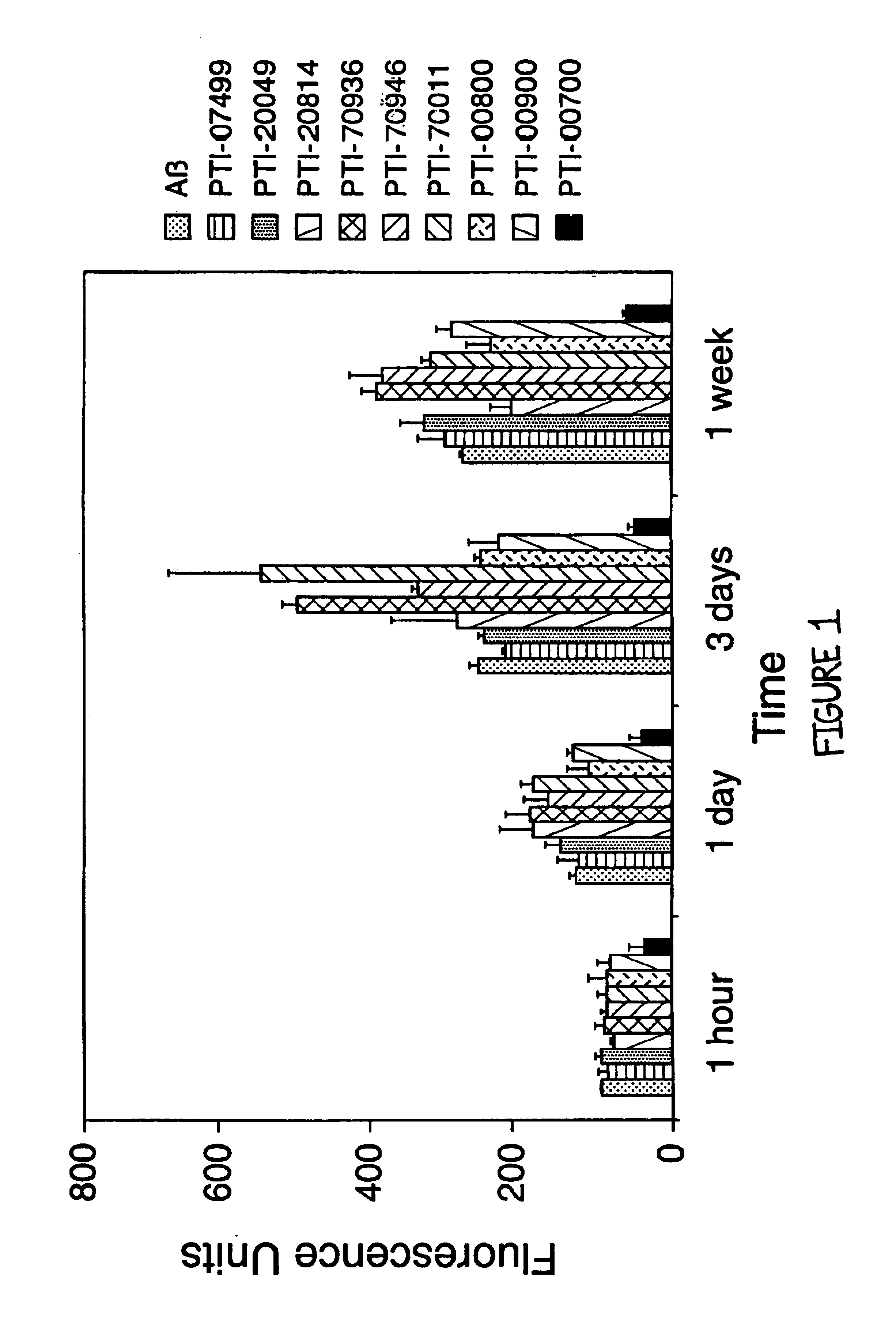

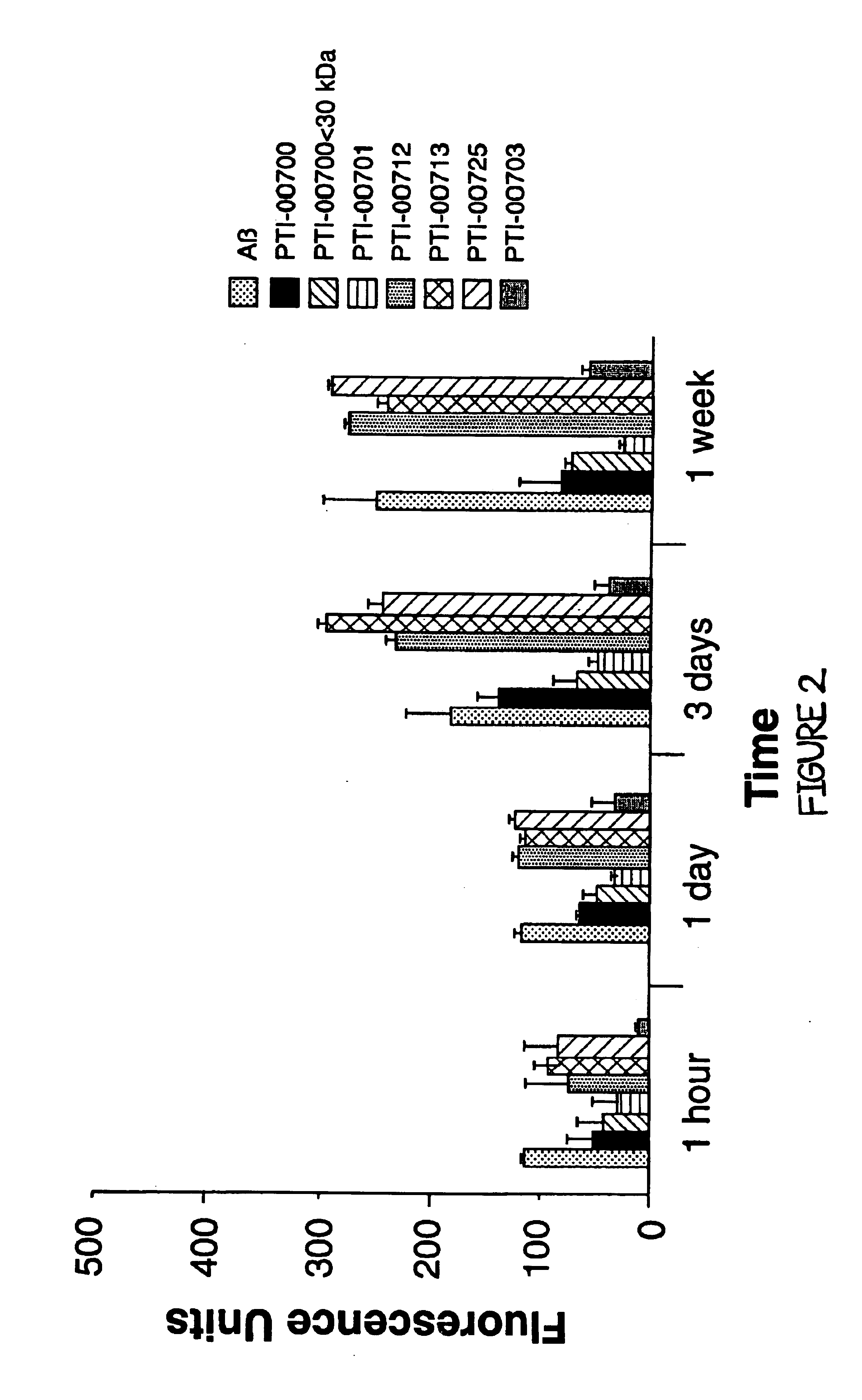

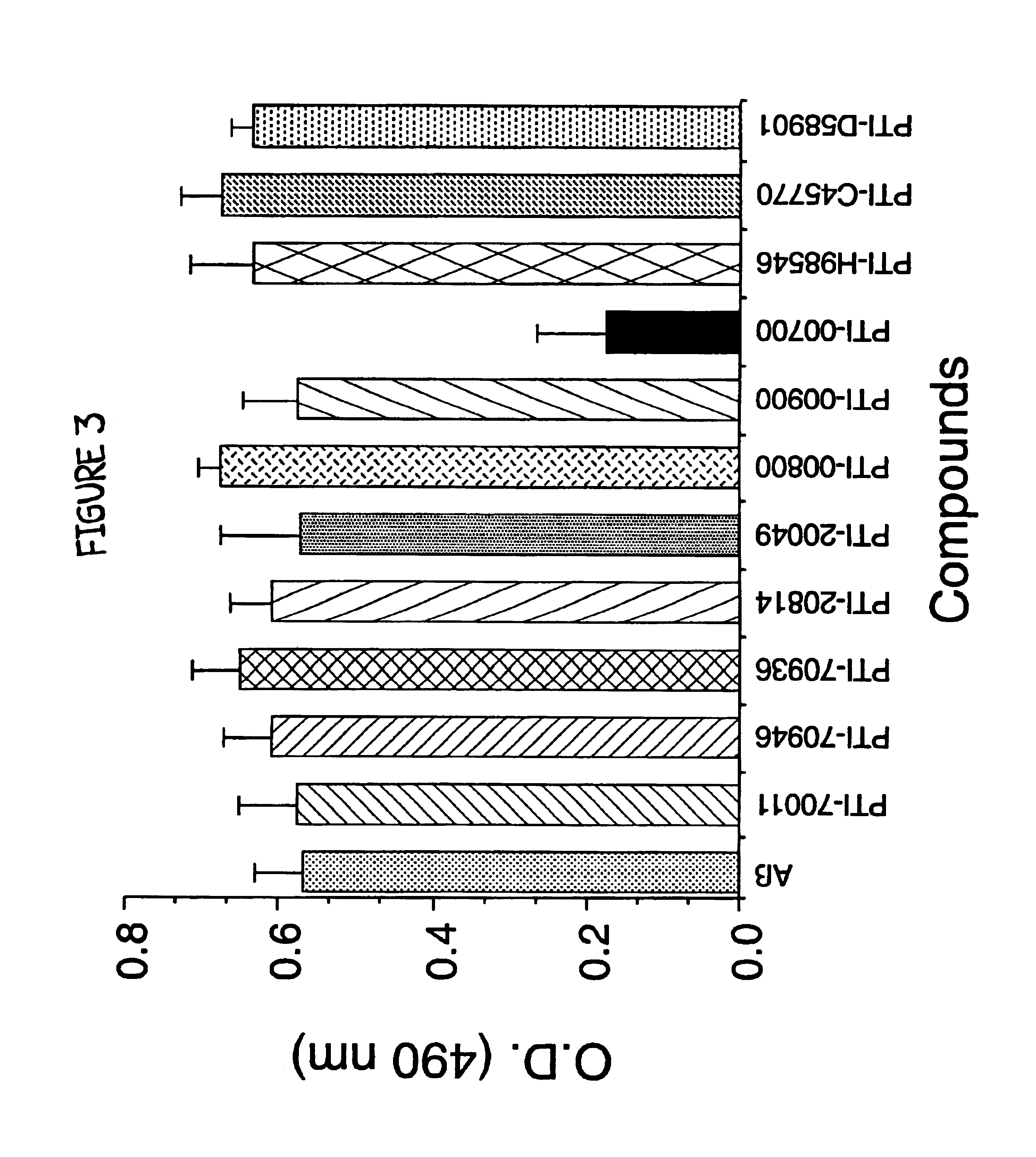

Composition and methods for treating Alzheimer's disease and other amyloidoses

A pharmaceutical agent for treating an amyloid disease such as Alzheimer's Disease that includes a therapeutically effective amount of an extract obtained from the inner bark or root tissue of a plant of the genus Uncaria, species tomentosa, wherein the weight percentage of plant extract in the agent is in the range of from about 70% to about 95%.

Owner:UNIV OF WASHINGTON

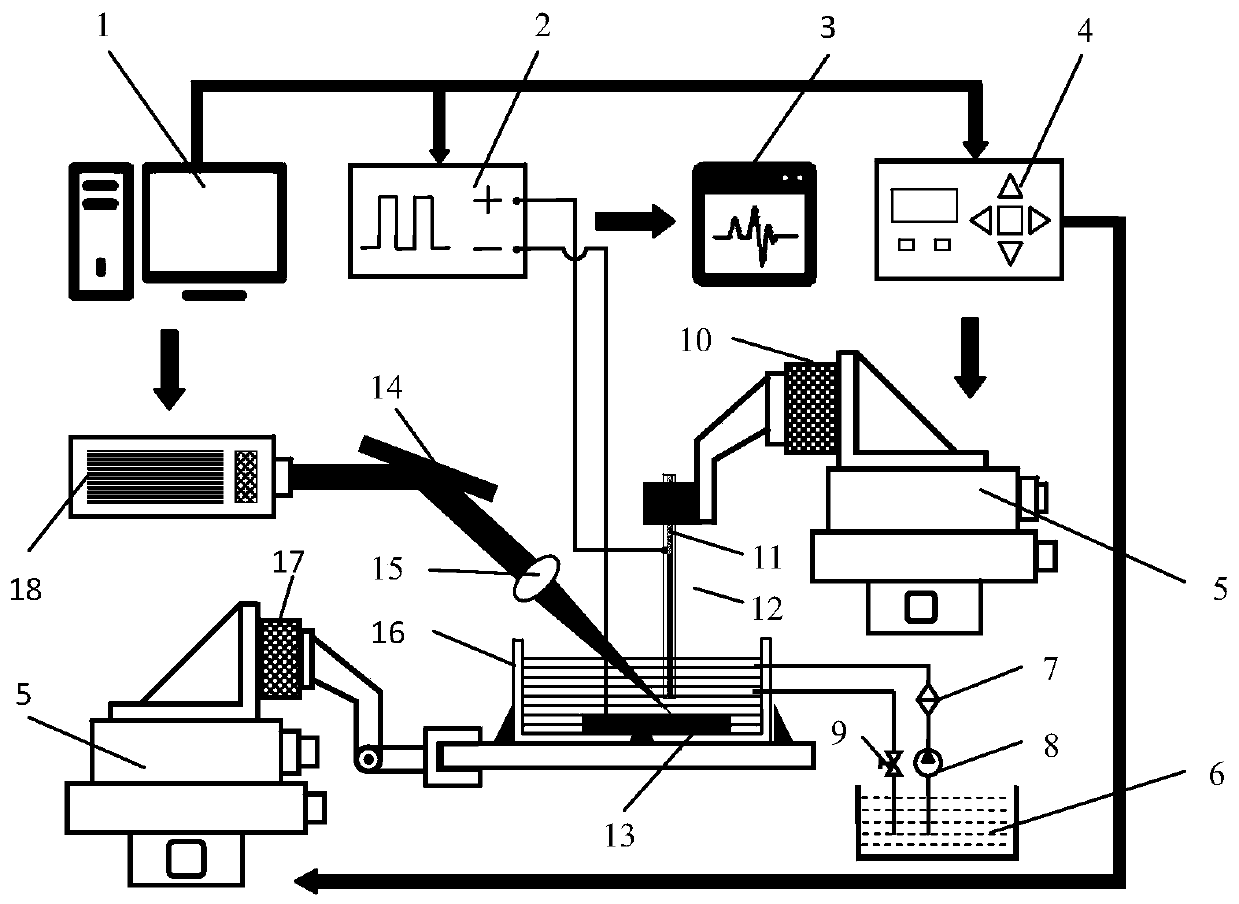

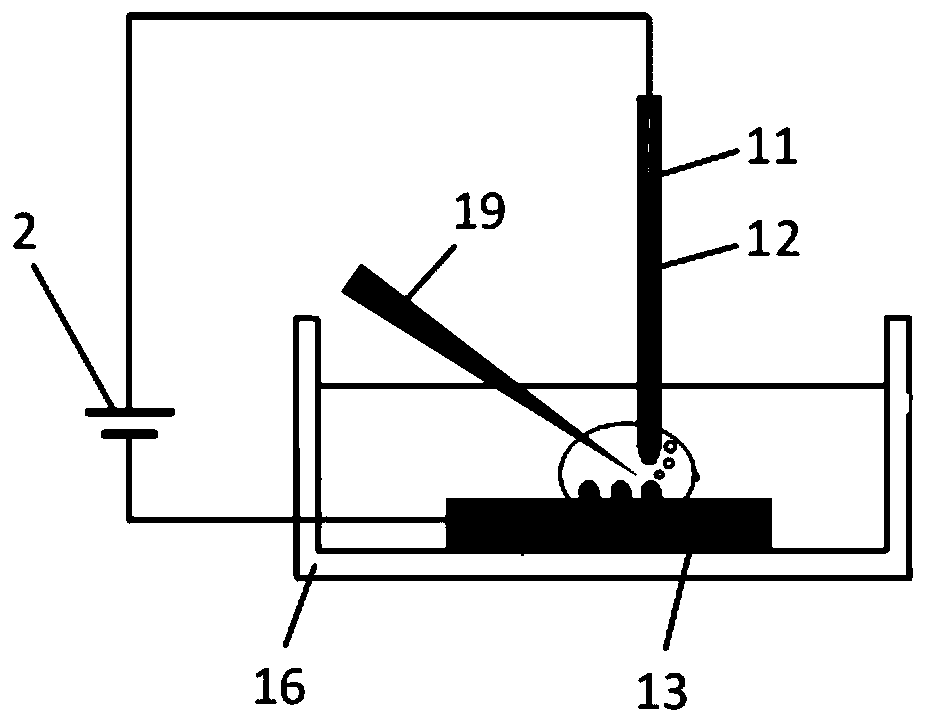

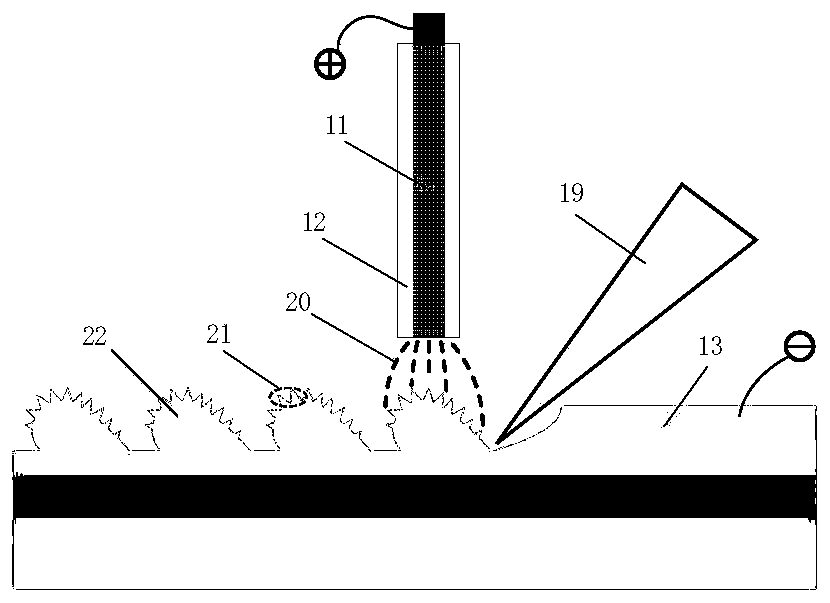

Machining method and device for preparing micro-nano two-dimensional structure on surface of workpiece

The invention discloses a machining method and device for preparing a micro-nano two-dimensional structure on the surface of a workpiece, and belongs to the field of special machining. In the machining process, a laser ablation and electrochemical deposition coupling method is adopted, a laser beam is focused on the surface of a workpiece substrate, the area and path of laser ablation are controlled through a numerical control system, and a micron-grade structure is machined on the surface of the workpiece substrate; and a tool anode keeps being aligned with the ablation area while laser ablation is conducted, and then a nano structure is deposited on the micron-grade structure in the area of the workpiece substrate. In order to restrain an anodic electric field in a top end area of an electrode to the maximum limit, the tool anode penetrates into an insulated glass pipe to achieve side wall insulating. In addition, the temperature of a solution in an irradiation area is increased through the thermal-mechanical effect of laser light, and meanwhile the strong stirring effect is generated to accelerate circular flow updating of deposition liquid and promote quick and efficient growthof the nano structure. The machining method and device are suitable for efficient machining and manufacturing of the micro-nano two-dimensional structure on the surface of a part.

Owner:JIANGSU UNIV

Replication incompetent herpes viruses for use in gene therapy

InactiveUS6821753B2Minimize the possibilityReduced activityNervous disorderPeptide/protein ingredientsDiseaseGene delivery

Use of a replication incompetent herpes virus capable of delivering a gene to multiple connected sites within the nervous system, which virus comprises: (a) a mutation which prevents or reduces the expression of at least two immediate early genes; and (b) a heterologous gene operably linked to a promoter active during herpes virus latency; in the manufacture of a medicament for the treatment of a central nervous system disorder, a method of determining whether a gene has an effect on a phenotype associated with a central nervous system disorder and in a method of treatment of a disorder of the central nervous system are described.

Owner:BIOVEX LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com