Floating catalyst chemical vapor deposition method of single-walled carbon nanotubes

A single-walled carbon nanotube, chemical vapor deposition technology, applied in the direction of single-walled carbon nanotubes, carbon nanotubes, chemical instruments and methods, etc., can solve the problems of low growth efficiency and carbon source conversion rate, and improve the carbon source The effect of conversion rate, increased yield, and reduced impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032]In this example, a mixed solution of toluene, ferrocene, and thiophene (hereinafter referred to as the mixed solution) with a mass ratio of 100:7.5:1.5 was prepared first, and was subjected to ultrasonic treatment for 10 minutes for later use. Under the protection of a hydrogen atmosphere, the temperature of the horizontal tube furnace was raised to 1200°C, then the hydrogen flow rate was adjusted to 4300sccm, and 11sccm ethylene was introduced, and 2ppm water vapor was introduced at the same time, and then the prepared mixed solution was fed with 0.9ml / h It is injected into the horizontal tube furnace at a constant speed, and enters the reaction zone under the carrying of the mixed gas of hydrogen and ethylene to grow carbon nanotubes. The reaction time is 1 hour.

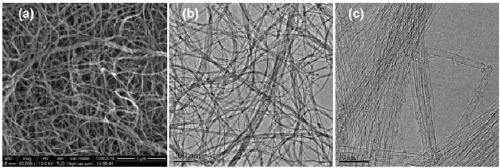

[0033] Such as figure 1 Shown, the optical picture of obtained product, this sample weight is 350mg. Using the yield calculation formula: η=(sample weight / gram equivalent of carbon source used)×100%, the ca...

Embodiment 2

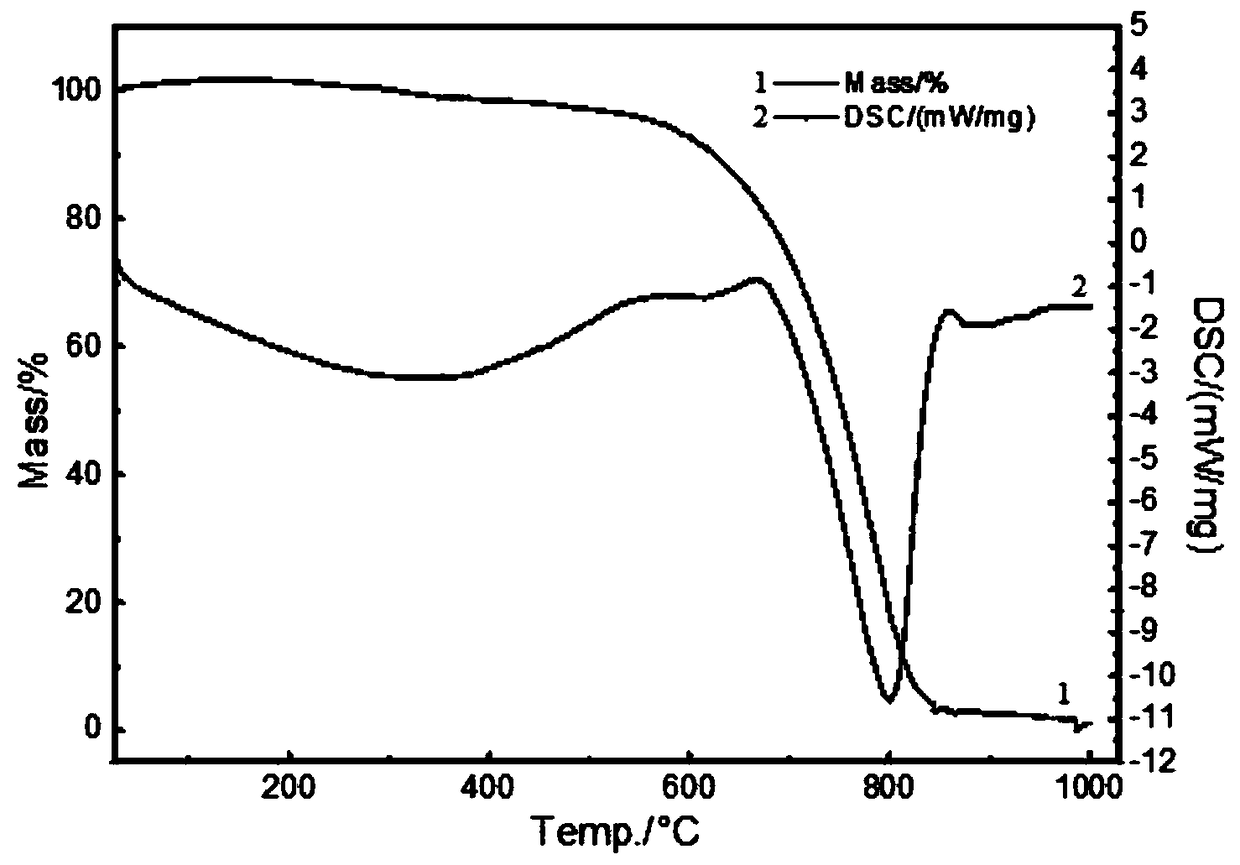

[0036] In this example, firstly, a mixed solution of toluene, ferrocene and thiophene with a mass ratio of 100:6:1.6 was prepared, and the solution was ultrasonically treated for 10 minutes for later use. Under the protection of a hydrogen atmosphere, raise the temperature of the horizontal tube furnace to 1100°C, then adjust the hydrogen flow rate to 3900sccm, and feed 11sccm ethylene and 0.5ppm water vapor at the same time, then feed the prepared mixed solution at 0.9ml / h The rate is injected into the horizontal tube furnace at a constant speed, and enters the reaction zone under the carrying of the mixed gas of hydrogen and ethylene to grow carbon nanotubes. The reaction time is 1.5 hours. Under the process parameters, the carbon source conversion efficiency is 17%, the obtained sample has high purity, the catalyst content is 1.08wt%, the crystallinity of carbon nanotubes is high, and the concentrated oxidation temperature is 785°C.

Embodiment 3

[0038] In this example, firstly, a mixed solution of toluene, nickelocene and thiophene with a mass ratio of 100:6:1.8 was prepared, and the solution was ultrasonically treated for 10 minutes for later use. Under the protection of a hydrogen atmosphere, the temperature of the horizontal tube furnace was raised to 1300°C, and then the hydrogen flow rate was adjusted to 4800 sccm, and 13 sccm of ethylene was introduced, and 3.5 ppm of water vapor was introduced at the same time, and then the prepared mixed solution was fed at a rate of 1 ml / h. It is injected into the horizontal tube furnace at a constant speed, and enters the reaction zone under the carrying of the mixed gas of hydrogen and ethylene to grow carbon nanotubes. The reaction time is 1.5 hours. Under the process parameters, the carbon source conversion efficiency is 22%, the obtained sample has high purity, the catalyst content is 1.02wt%, the crystallinity of carbon nanotubes is high, and the concentrated oxidation t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com