Laser preparation method for large-area patterned graphene

A large-area, graphene technology, applied in graphene, nano-carbon, etc., can solve the problems of high quality, low efficiency, small size, etc., and achieve the effects of reduced nucleation rate, fast cooling, and large growth area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1, CO 2 Laser efficient preparation of graphene

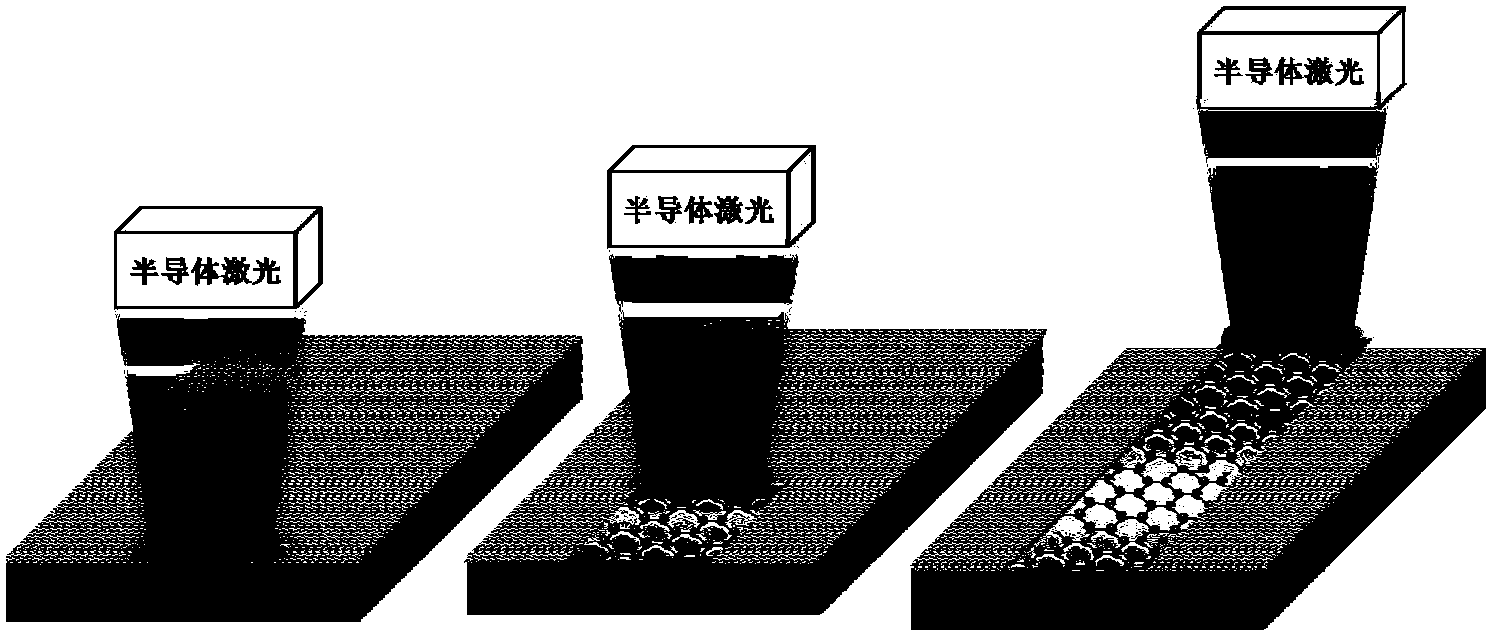

[0037] In this embodiment, CO 2 Laser efficient preparation of graphene, the schematic diagram of the preparation process is as follows figure 1 shown.

[0038] (1) First remove the oxides on the surface of the platinum plate by mechanical grinding, then grind and polish with a polishing machine, and finally use alcohol for ultrasonic cleaning; the size of the platinum plate is 20mm×20mm×5mm;

[0039] (2) Disperse the nano-scale graphite powder into alcohol, use a dropper to absorb the alcohol solution containing carbon source and drop it on the surface of the treated platinum plate, then put the platinum plate in the glue homogenizer to shake and dry it evenly. To ensure uniformity and a certain thickness, stepwise acceleration is adopted to obtain a carbon coating with a thickness of 0.05mm; the graphite powder particle size is 350nm.

[0040] (3) Using 3000W CO 2 The graphite layer is irradiated by the la...

Embodiment 2

[0044] Embodiment 2, large-area and high-efficiency preparation of graphene by semiconductor laser

[0045] The semiconductor laser has a compact structure, stable laser output, high electro-optic efficiency, and long life. In particular, the semiconductor laser can output a rectangular uniform spot, which can realize large-area preparation of graphene. In this embodiment, the semiconductor laser is irradiated. Rapid preparation of large-area graphene, the schematic diagram of the preparation process is as follows figure 1 shown.

[0046] (1) Firstly, use mechanical grinding to remove oxides on the surface of the nickel plate, then use a grinding and polishing machine for grinding and polishing, and finally use alcohol for ultrasonic cleaning; the size of the nickel plate is 20mm×20mm×5mm.

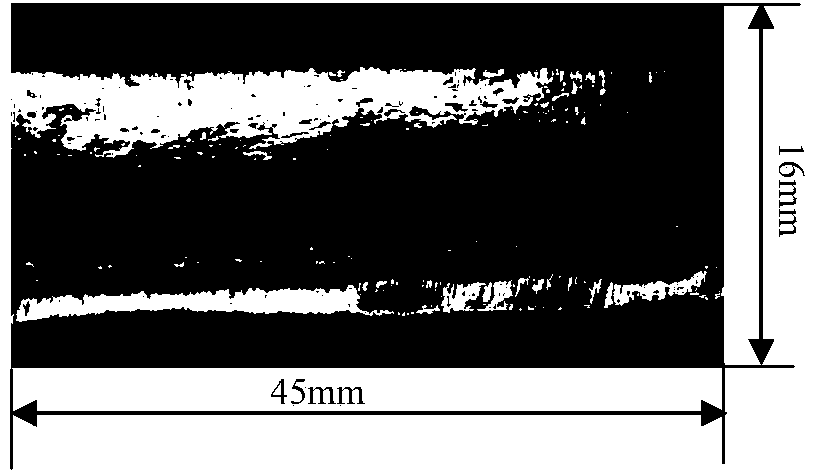

[0047] (2) Disperse the graphite powder into alcohol, use a dropper to absorb the alcohol solution containing carbon source and drop it on the surface of the treated nickel plate, then pu...

Embodiment 3

[0052] Example 3. Efficient preparation of patterned graphene by fiber laser

[0053] Fiber lasers have the advantages of high beam quality, high power density, and high stability, and are widely used in the field of advanced manufacturing. In this example, patterned graphene is rapidly prepared by fiber laser irradiation on a titanium substrate pre-coated with micron graphite. The preparation process Schematic such as figure 1 shown.

[0054] (1) First, remove the surface oxide of the titanium plate by chemical corrosion, then grind and polish it with a polishing machine, and finally clean it ultrasonically with alcohol; the size of the titanium plate is 20mm×20mm×5mm.

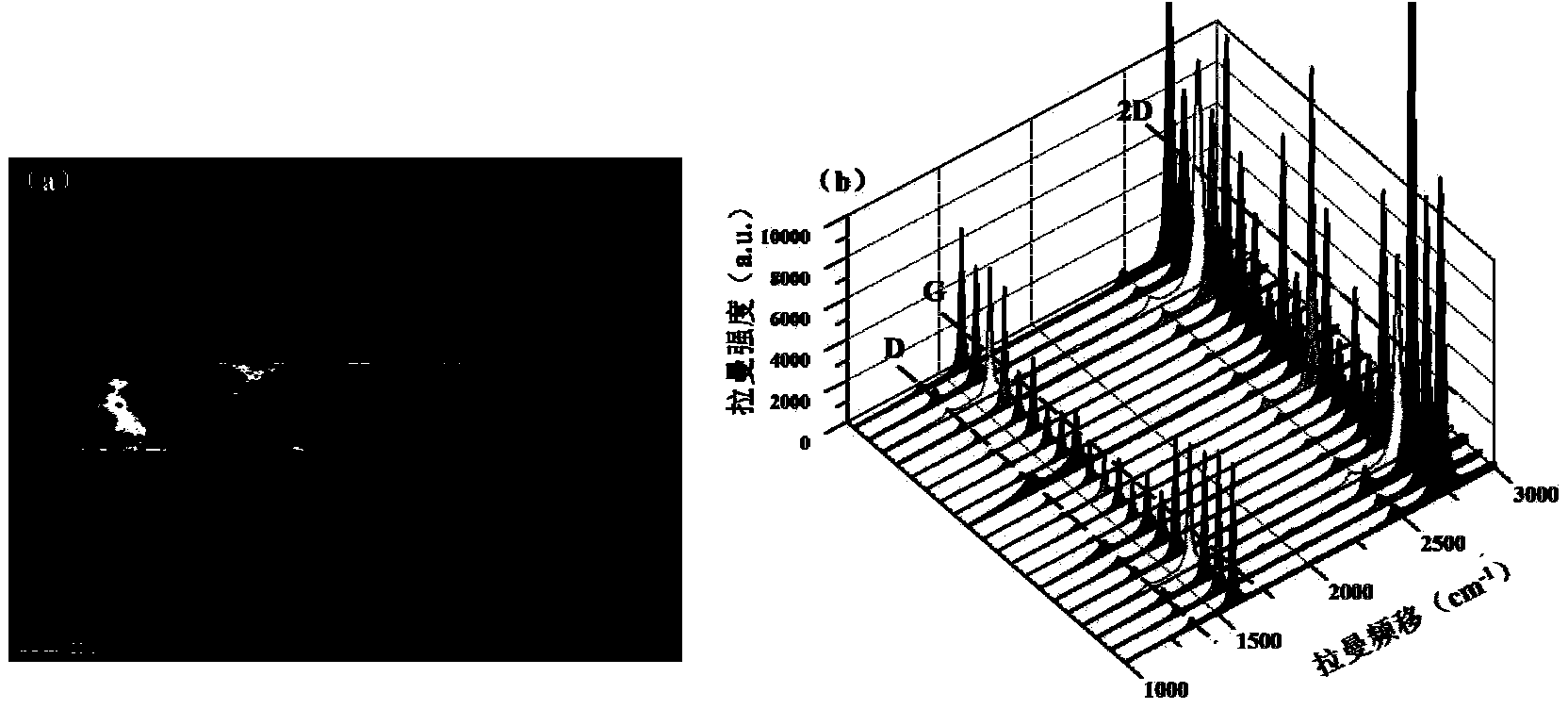

[0055] (2) Disperse the graphite powder into the alcohol, use a dropper to absorb the alcohol solution containing the carbon source and drop it on the surface of the treated titanium plate, then put the titanium plate in the homogenizer for shaking and drying, in order to ensure uniform and a certain thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com