Antenna radiation body made of low-melting-point metal or metal alloy, and manufacturing method

A low-melting-point metal and antenna radiator technology, applied in the field of wireless communication, can solve the problems of large equipment investment, high production cost, and long production cycle, and achieve the effects of improving efficiency, low cost, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0029] The method for making an antenna radiator from a low-melting-point metal or a metal alloy of the present invention comprises the following steps:

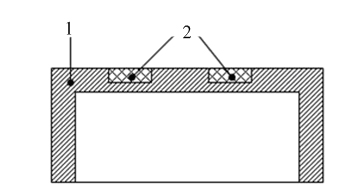

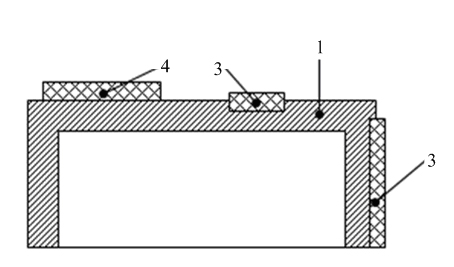

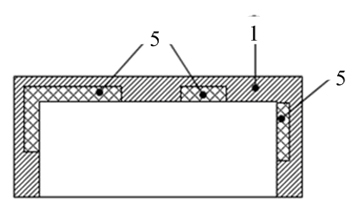

[0030] (1) A plastic bracket is injection-molded in the mold, and several grooves are formed on the plastic bracket. These grooves can be distributed on the outside of the plastic bracket, or on the inside of the plastic bracket, or both on the outside and inside of the plastic bracket. ;

[0031] (2) Melt the low-melting-point metal or metal alloy, inject the melted low-melting-point metal or metal alloy into the groove of the plastic bracket, cool and solidify to make the antenna radiator. The low-melting point metal or metal alloy may not protrude from the plastic support or may protrude from the plastic support.

[0032] Wherein, the melting point of the low-melting-point metal or metal alloy is lower than t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com