Patents

Literature

63results about How to "Reduced nucleation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of controlling drug release from a coated medical device through the use of nucleating agents

InactiveUS20060088566A1Reduced nucleation rateSmall sizeSurgeryPharmaceutical delivery mechanismControlled drugsDrug release

A coated medical device have a drug and a nucleating agent thereon. Also provided are methods of increasing or decreasing the size of drug particles on a coated substrate through the use of nucleating agents to thereby increase or decrease the release rate of the drug from the coated substrate.

Owner:BOSTON SCI SCIMED INC

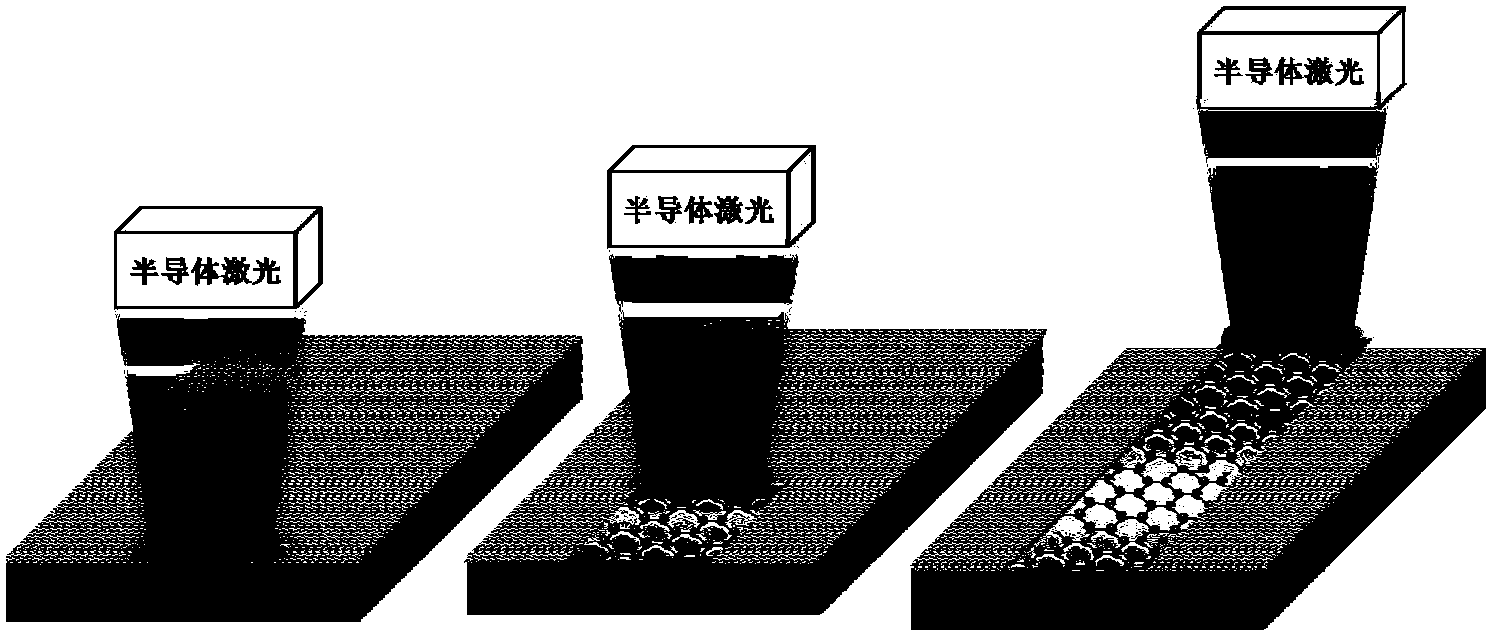

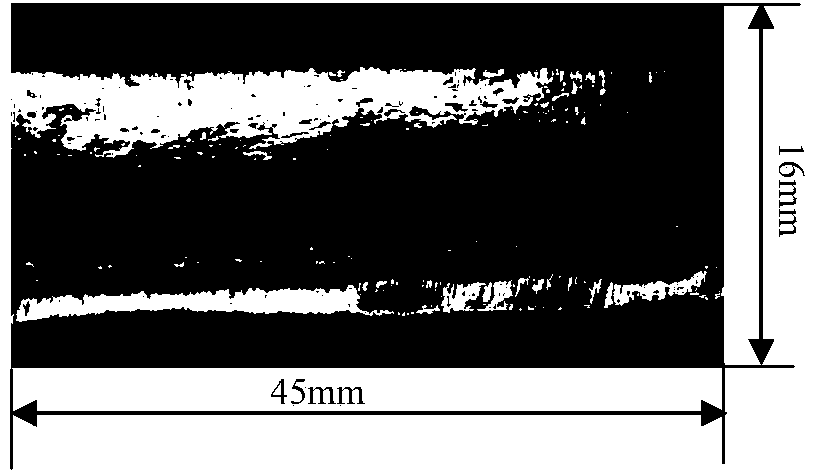

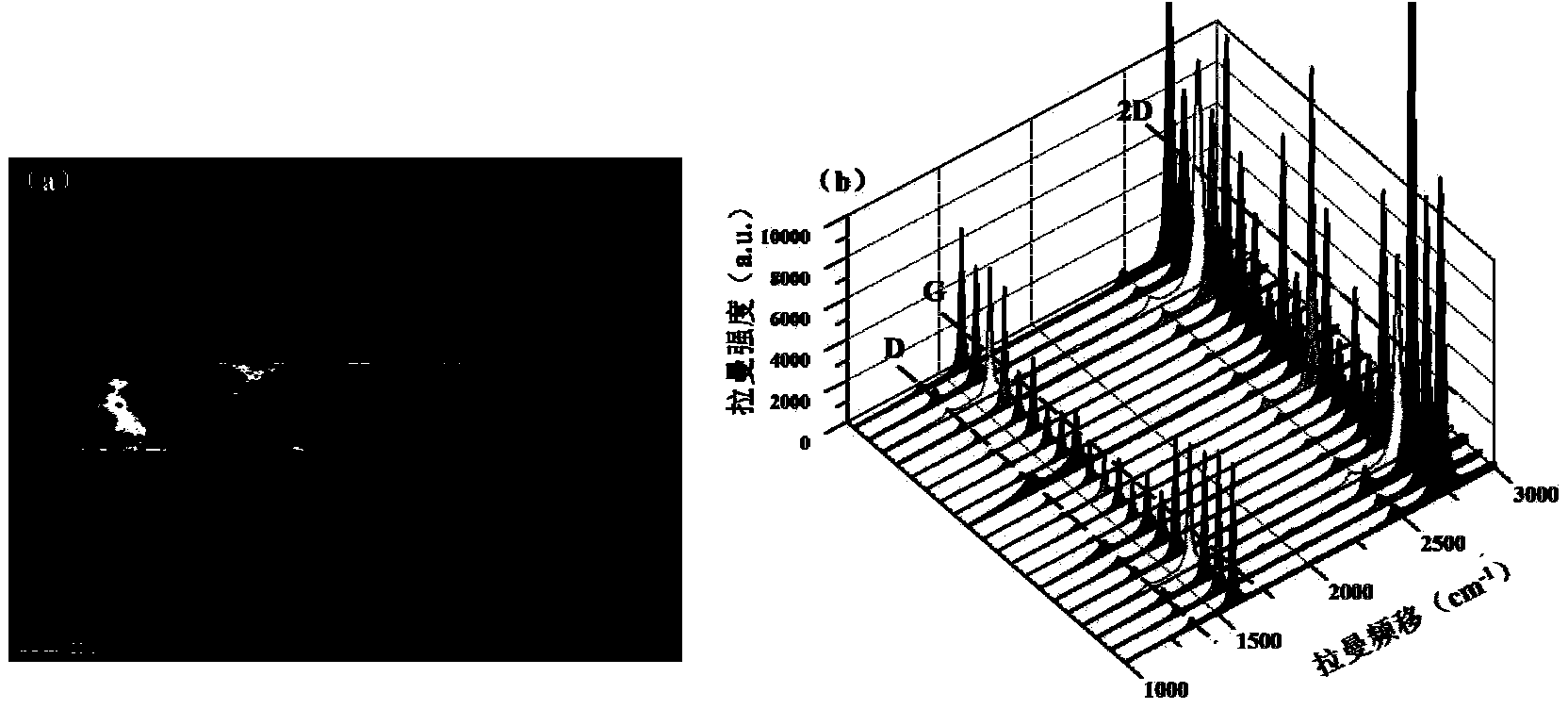

Laser preparation method for large-area patterned graphene

The invention discloses a laser preparation method for large-area patterned graphene. The preparation method comprises the following steps: (1) a solid carbon source is dispersed in an organic solvent to obtain a dispersion liquid, and the surface of a metal substrate is coated with the dispersion liquid in a spinning manner to obtain a uniform carbon coating; (2) under the condition of the protection of inert gas, a high power density laser beam is adopted to irradiate the carbon coating, and carbon atoms in the solid carbon source and metal atoms in the metal substrate are formed into a solid solution under function of irradiation; the high power density laser beam is moved away or the irradiation operation is stopped, when the metal substrate is cooled, the oversaturated solid solution is formed, and the carbon atoms are separated out of the oversaturated solid solution and formed on the surface of the substrate to form graphene. The invention provides a novel method which is convenient, fast, low in cost and high in efficiency and prepares the large-area patterned graphene. The product obtained through the method can be applied to the following fields: next generation microcomputers, flat-panel displays, super-capacitors, transparent conductive electrodes, sensors, solar batteries, micro-nano electronic devices, photoelectronic devices, self-spinning quantum devices, novel compound materials and so on.

Owner:TSINGHUA UNIV

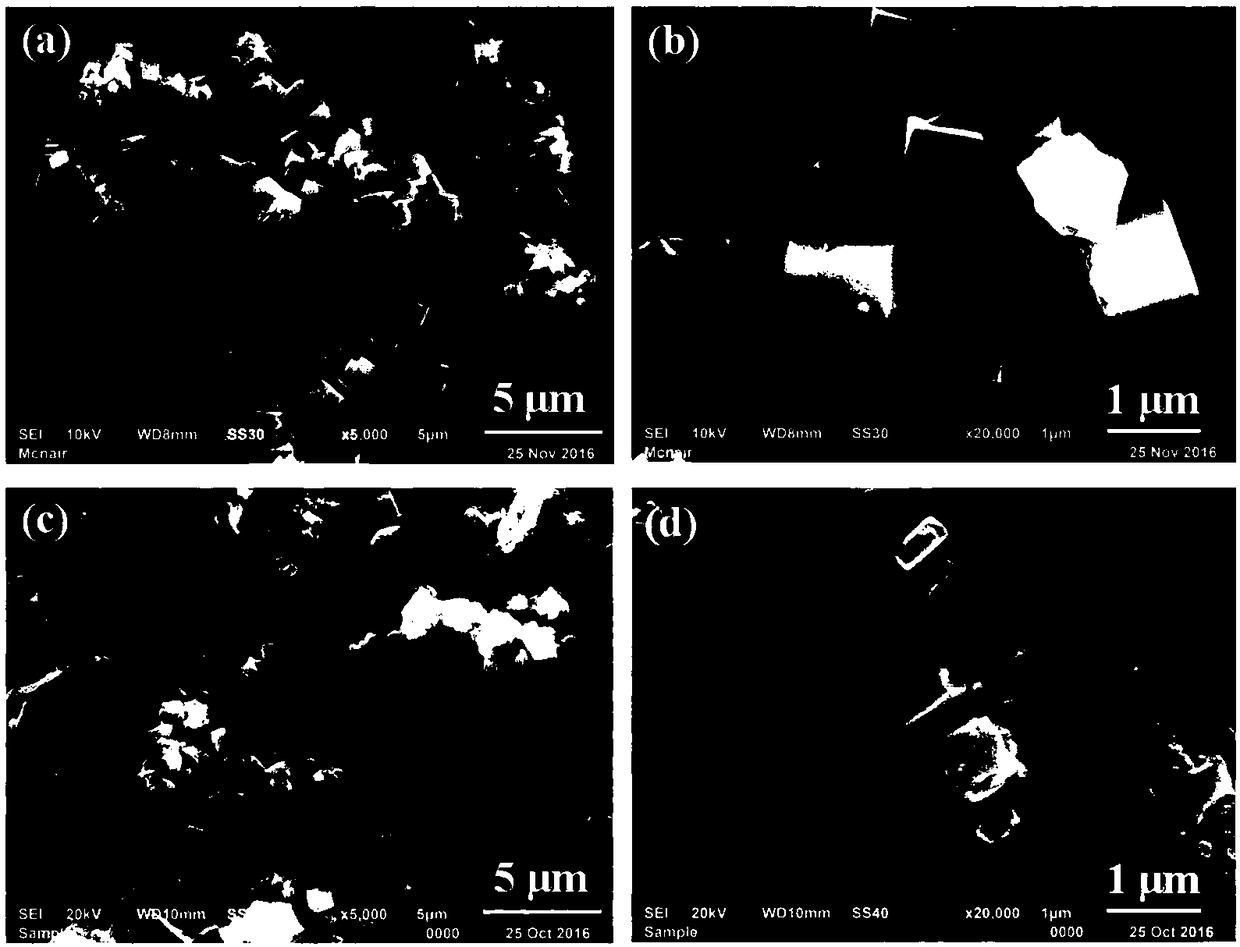

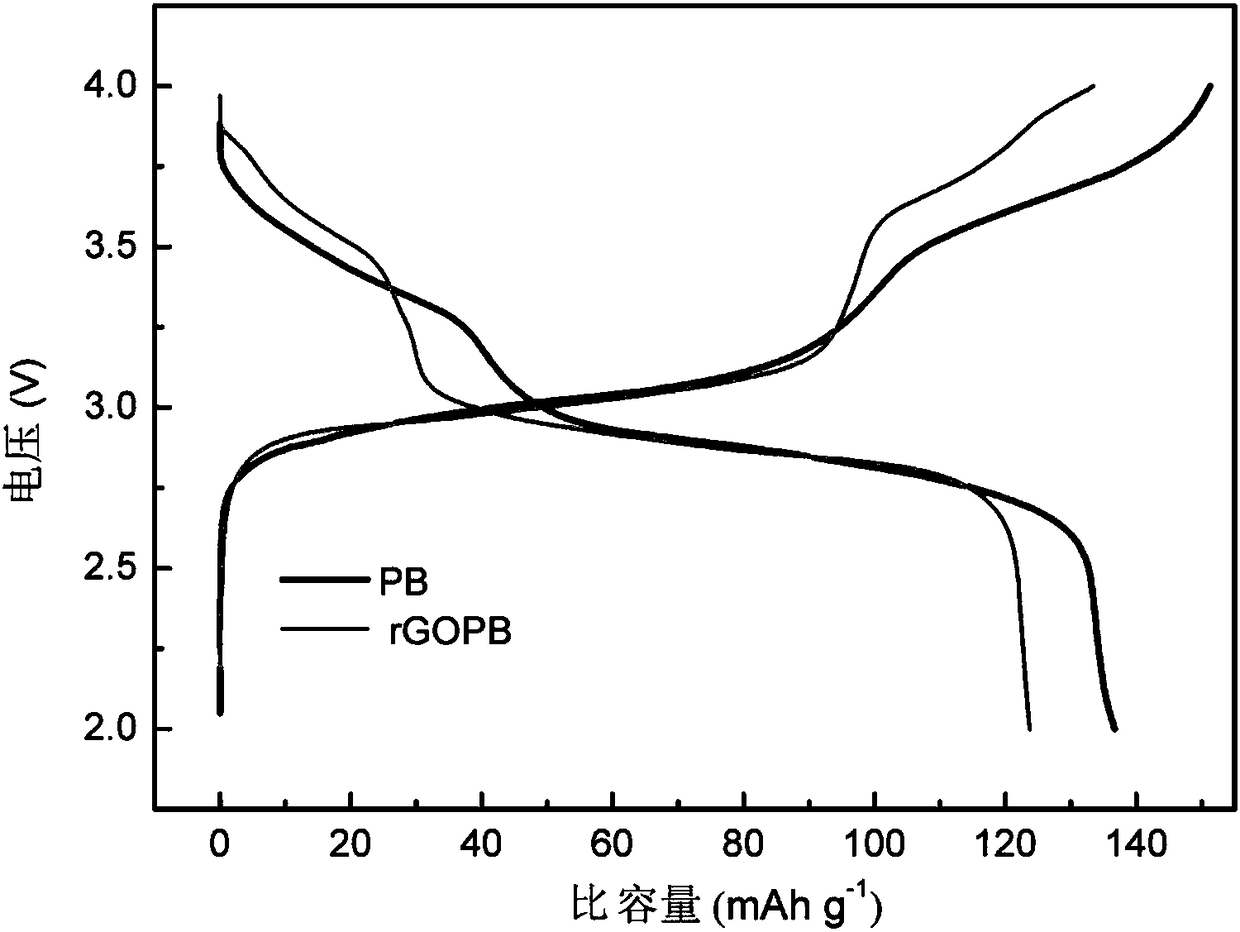

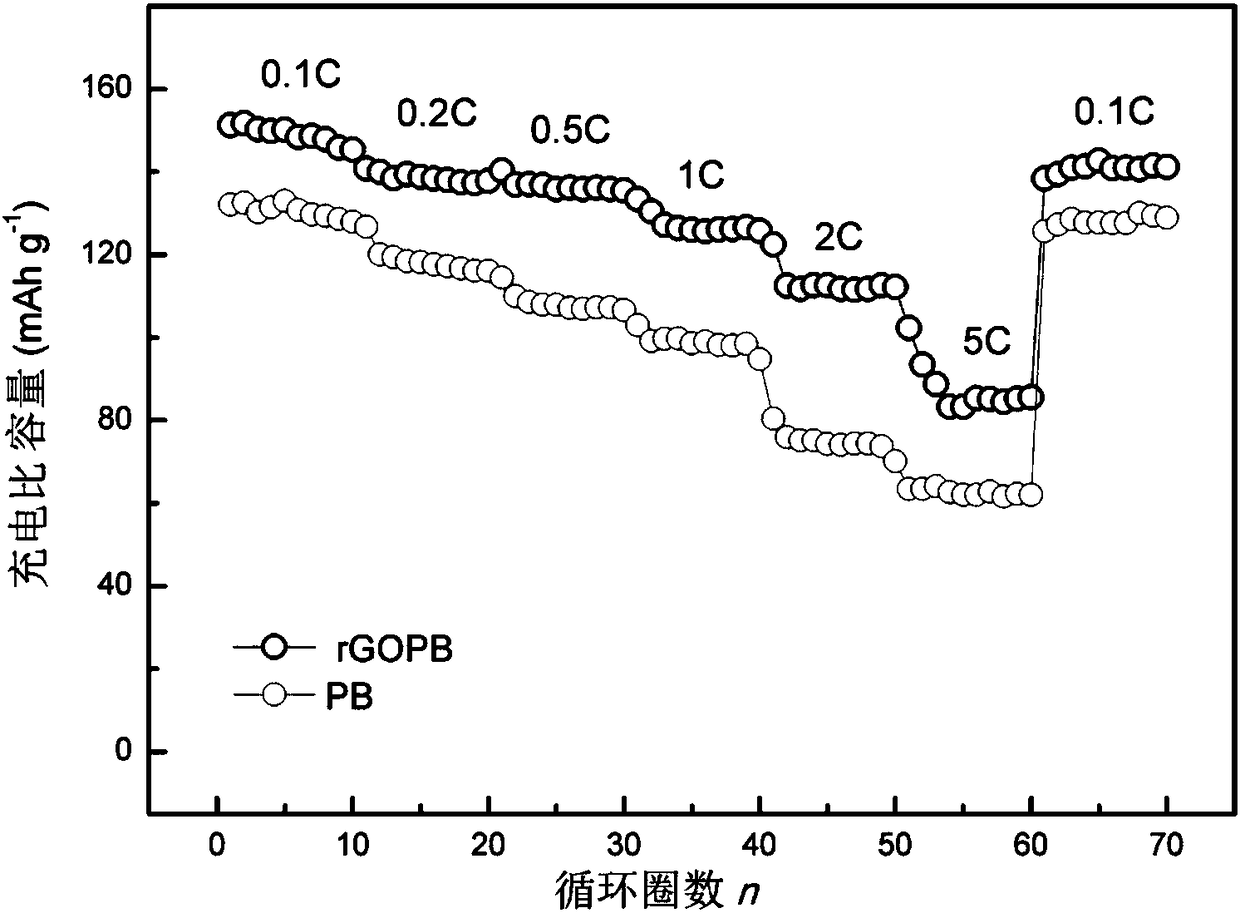

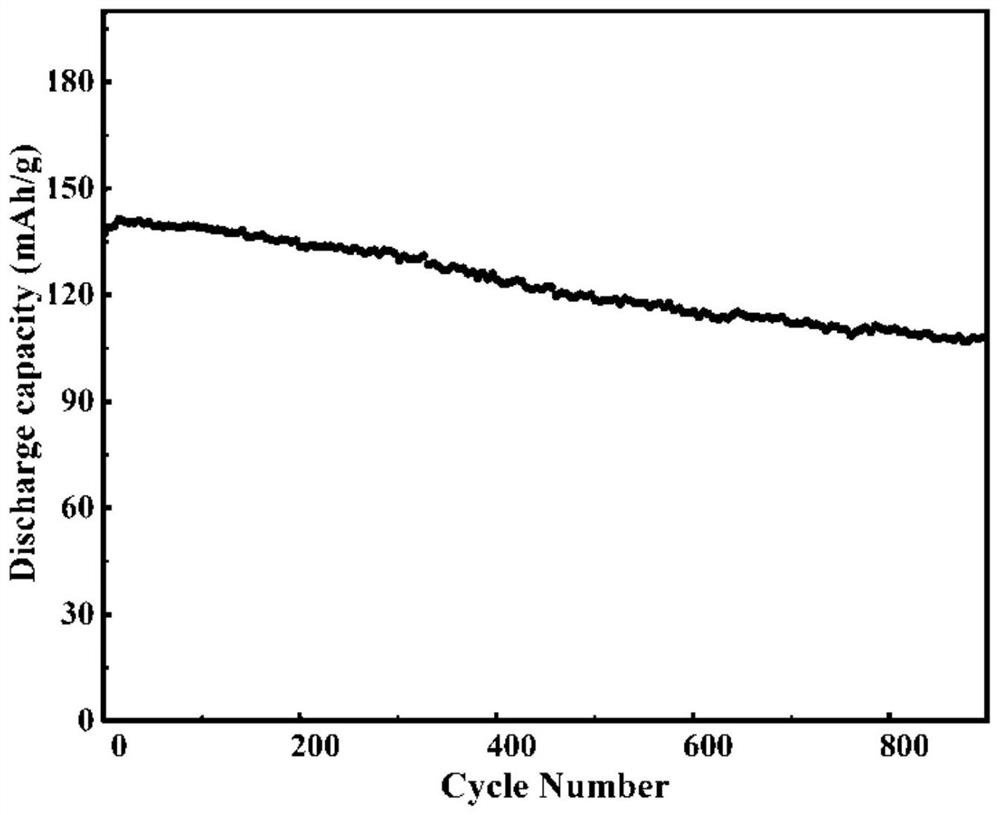

Method for preparing prussian blue material through composite reduction of graphene oxide, and application

InactiveCN108217630AHigh specific capacityImprove cycle stabilityCell electrodesSecondary cellsReaction rateSodium-ion battery

The invention relates to a method for preparing a prussian blue material through reduction of graphene oxide, and application. The preparation method comprises the steps of ultrasonically dispersing the graphene oxide into a sodium ferrocyanide water solution, adding ascorbic acid for resisting oxidation, adding sodium citrate for reducing a reaction rate, dropwise adding hydrochloric acid for adjusting the solution to be acidic, heating and stirring for reacting under the inert gas protection to obtain a material, washing, vacuum drying, and carrying out microwave irradiation for reducing thegraphene oxide to obtain the product. When the prussian blue material prepared through composite reduction of the graphene oxide provided by the invention is used as a sodium-ion battery anode, the specific capacity, the cycle performance and the rate capability of a battery are greatly improved, the charge and discharge specific capacity of the battery in an organic system reaches up to not lessthan 153mAh.g<-1>, and the specific capacity of the battery in a water system single platform reaches up to not less than 81mAh.g<-1>; the preparation method is low in cost, fast, simple, and favorable in application prospect.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

High practicality lithium nickel manganese oxide and preparation method thereof

InactiveCN104900865ASmall specific surface areaGuaranteed cycle performanceCell electrodesSecondary cellsCarbon layerMaterials processing

The invention discloses a high practicality lithium nickel manganese oxide and a preparation method thereof. The lithium nickel manganese oxide is characterized in that manganese source, lithium source, nickel source and a certain amount of grinding aid are blended by a dry grinding mode, the lithium nickel manganese oxide material with low specific surface area is prepared by using the characteristics of slow crystal nucleation rate and little nucleation of a precursor, contact area of the material and an electrolyte is increased, cycle life of the material is increased; cation disorder degree and crystal structure dislocation of the crystal can be controlled through a multi-step calcining technology for guaranteeing the multiplying power performance of the material; the obtained lithium nickel manganese oxide coats the surface of a carbon layer by using a vapour deposition method, anchoring strength of the material and a current collector is enhanced, peeling intensity of pole sheet is enhanced, material processing property is ensured, and multiplying power performance is increased. The material has the advantages of long service life and good processing property, and is the lithium nickel manganese oxide material with high practicality, the preparation method is economic and easy to operate, and is suitable for commercialization popularization.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

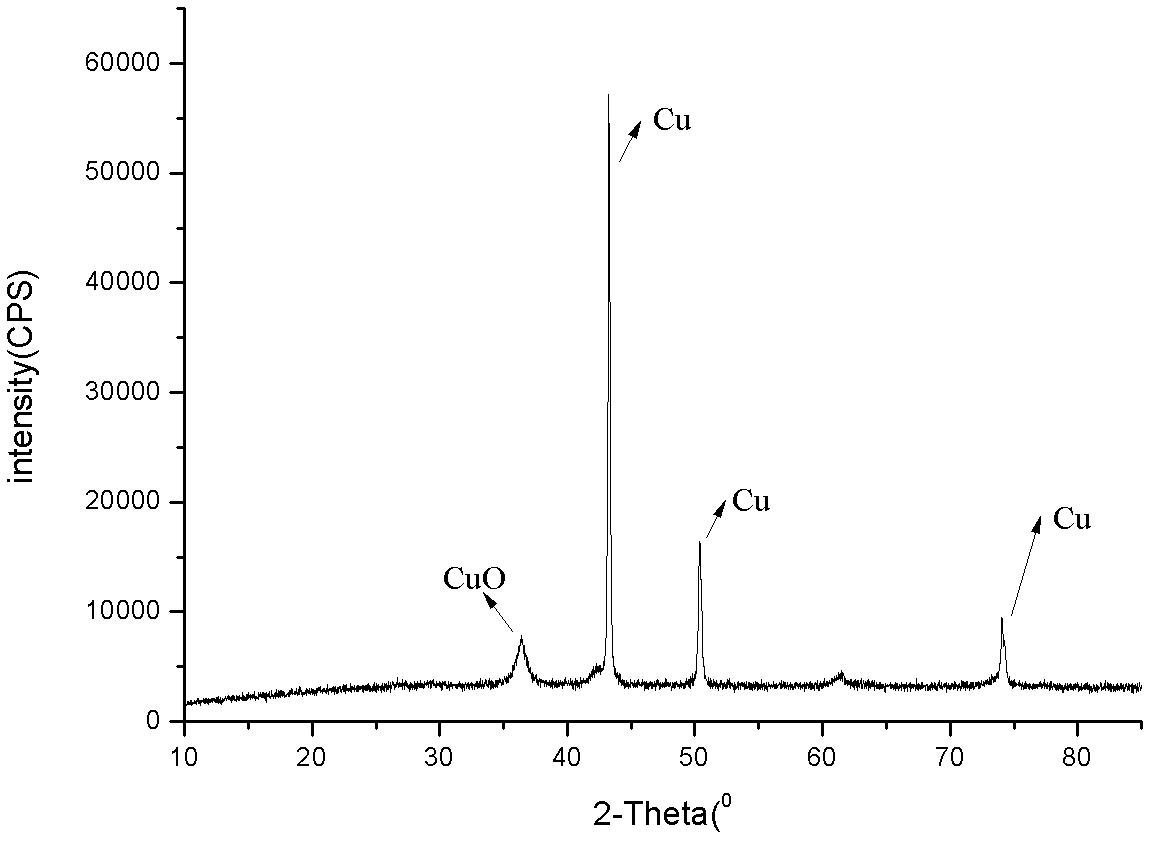

Method for preparing nano copper particle

The invention relates to a method for preparing a nano copper particle, in particular to a novel method for preparing a nano copper particle serving as a lubricating oil additive. The synthesis method comprises the following steps of: dissolving water-soluble divalent copper salt into water; adding a proper amount of acid organic extracting agent and coating agent into the solution; extracting divalent copper ions to an organic phase; and then simply and efficiently preparing spherical nano copper particles which have good dispersion, uniform particle size and good oxidation resistance by adopting a two-step liquid phase reduction method. The method provided by the invention has the advantages such as simple process, convenience for operation, low cost, easiness for industrialization and the like; and the prepared nano copper particle has the advantages of good dispersion, uniform particle size, good oxidation resistance, good friction property and the like.

Owner:CENT SOUTH UNIV

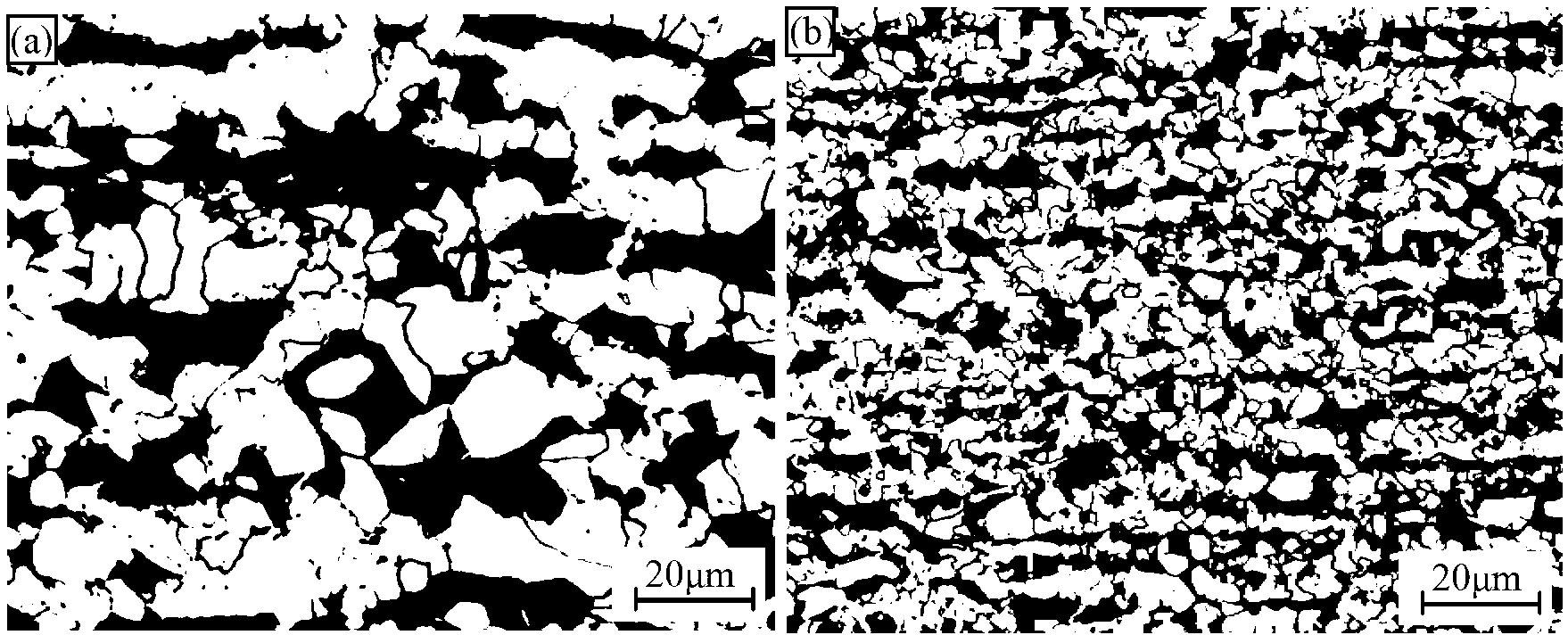

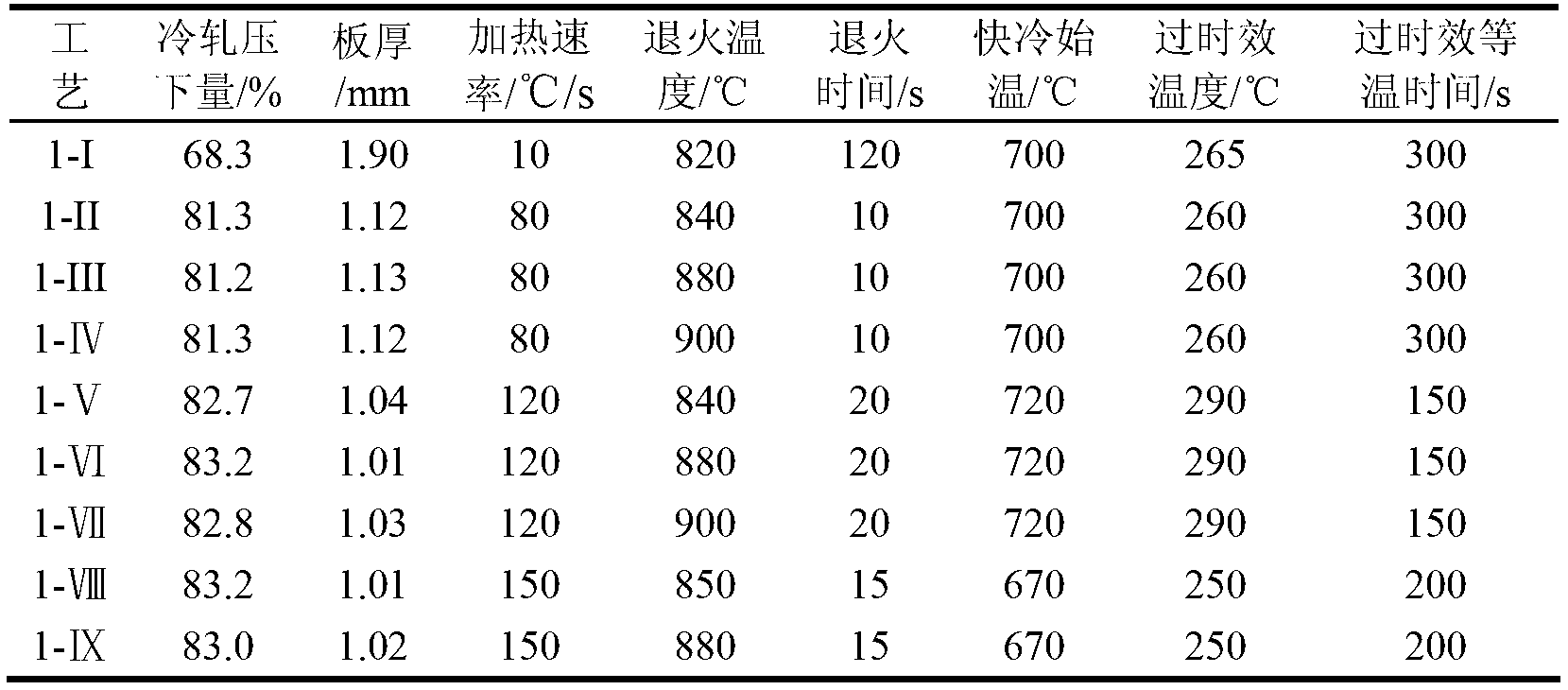

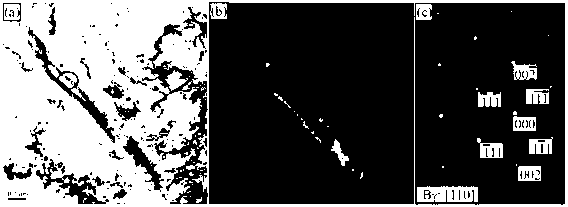

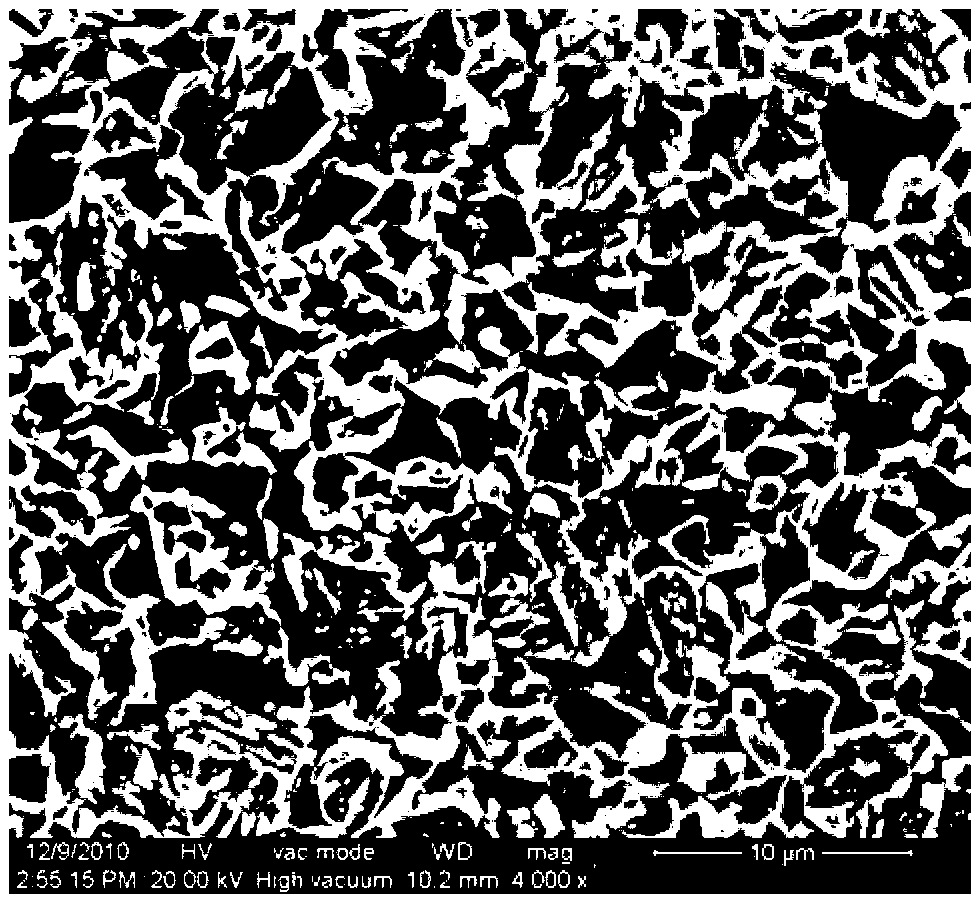

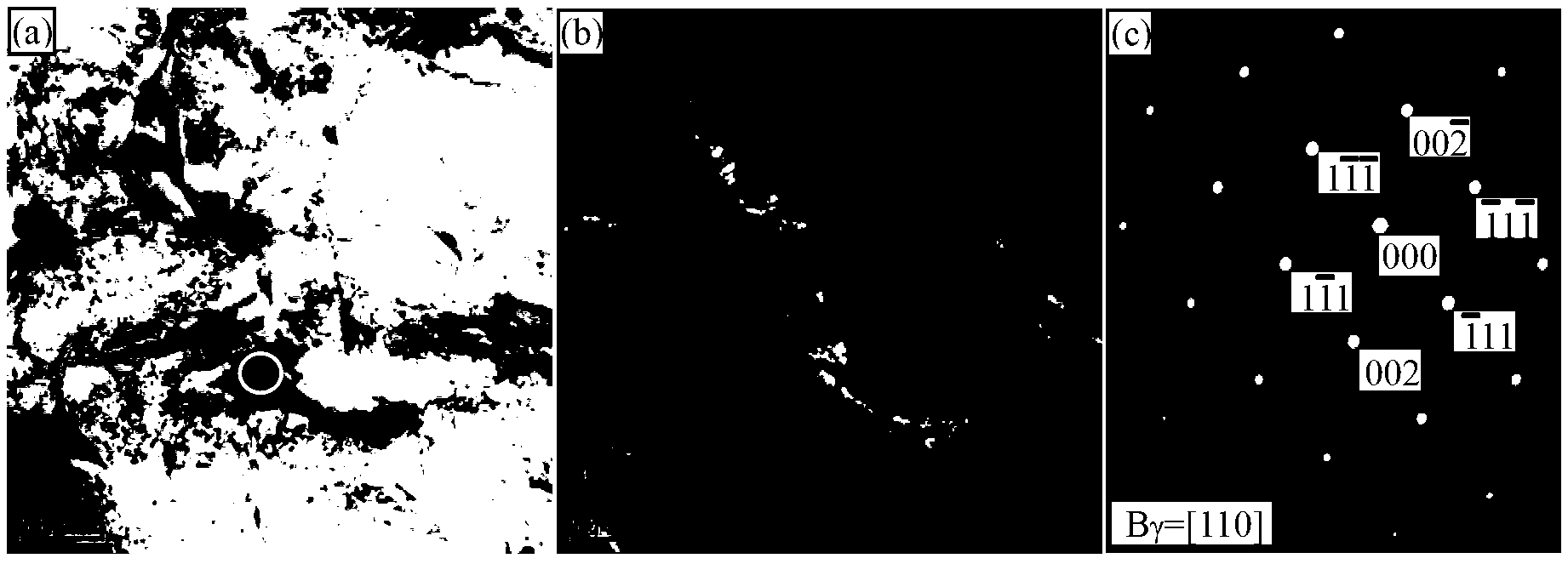

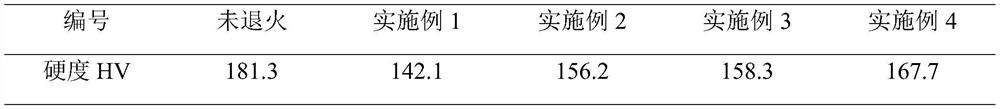

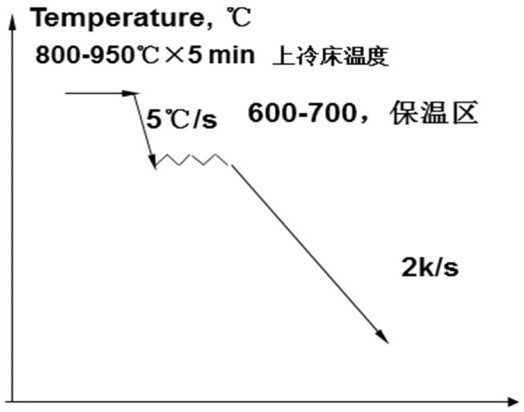

Method for improving mechanical property of low-carbon silicomanganese series cold rolling dual-phase steel

The invention belongs to the technical field of roll steel and relates to a method for improving the mechanical property of low-carbon silicomanganese series cold rolling dual-phase steel. The method comprises the following steps of: smelting and forging the low-carbon silicomanganese series cold rolling dual-phase steel to manufacture a plate blank, heating to 1100-1250 DEG C, carrying out heat preservation, carrying out rough rolling and finish rolling at 820-1100 DEG C, wherein the hot rolling and finish rolling temperature is (Ar3+30) DEG C-(Ar3+100) DEG C, then carrying out laminar cooling to (Ar3-50) DEG C-(Ar3-100) DEG C at cooling rate of 20 DEG C, and carrying out air cooling to room temperature; pickling, heating to (Ac3-50 DEG C)-(Ac3+100 DEG C) after cold rolling by adopting higher than or equal to 80% of rolling reduction, carrying out annealing treatment for 10-20s, carrying out slow cooling to 600-720 DEG C at rate of 5-8 DEG C / s, cooling to 250-300 DEG C at rate of higher than or equal to 30 DEG C / s for isothermal treatment, and carrying out air cooling and water-cooling or naturally cooling to room temperature. A cold rolling dual-phase steel plate with excellent mechanical property can be obtained by adopting the preparation method; the strength, the total percentage elongation after fracture and the work-hardening index of the cold rolling dual-phase steel plate are improved; and the strength of the cold rolling dual-phase steel plate is obviously improved.

Owner:LAIWU IRON & STEEL GRP

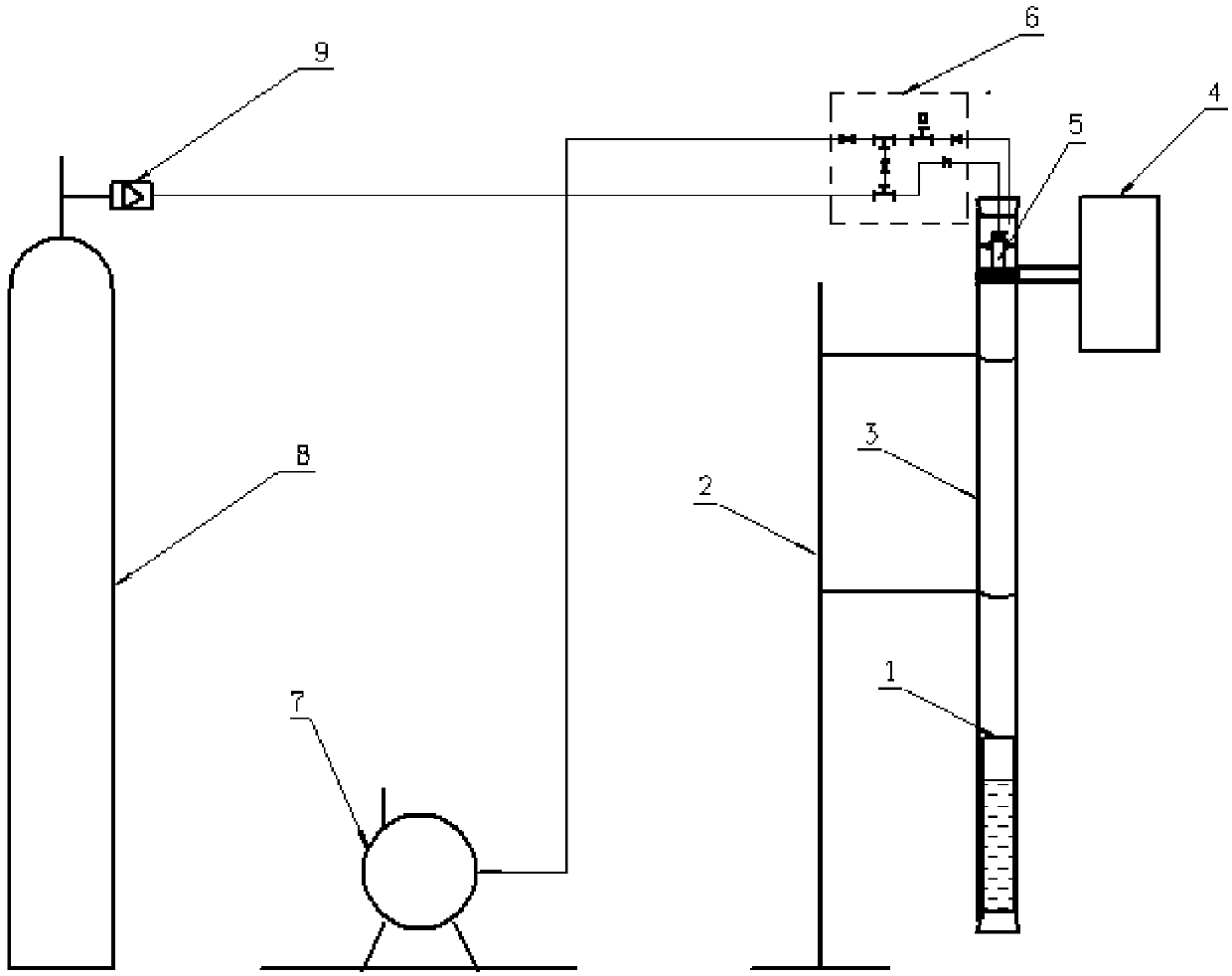

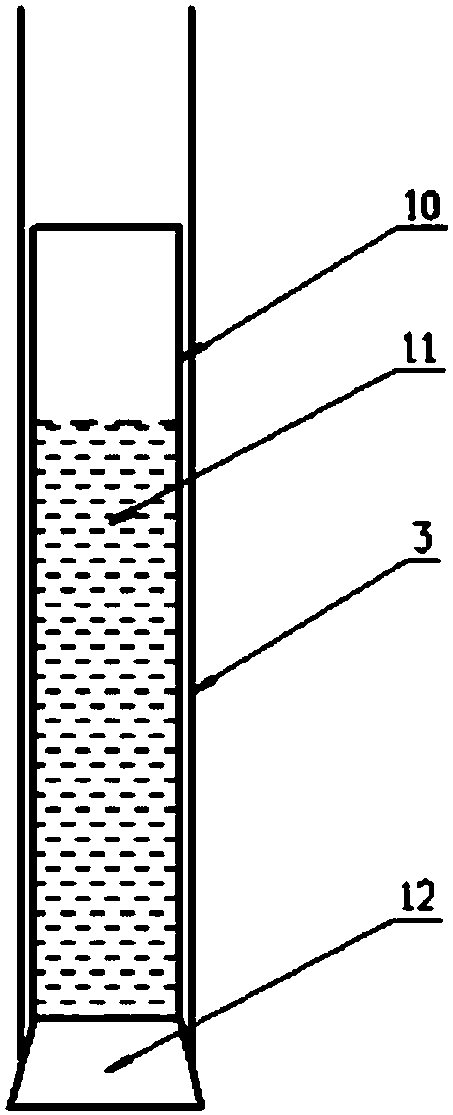

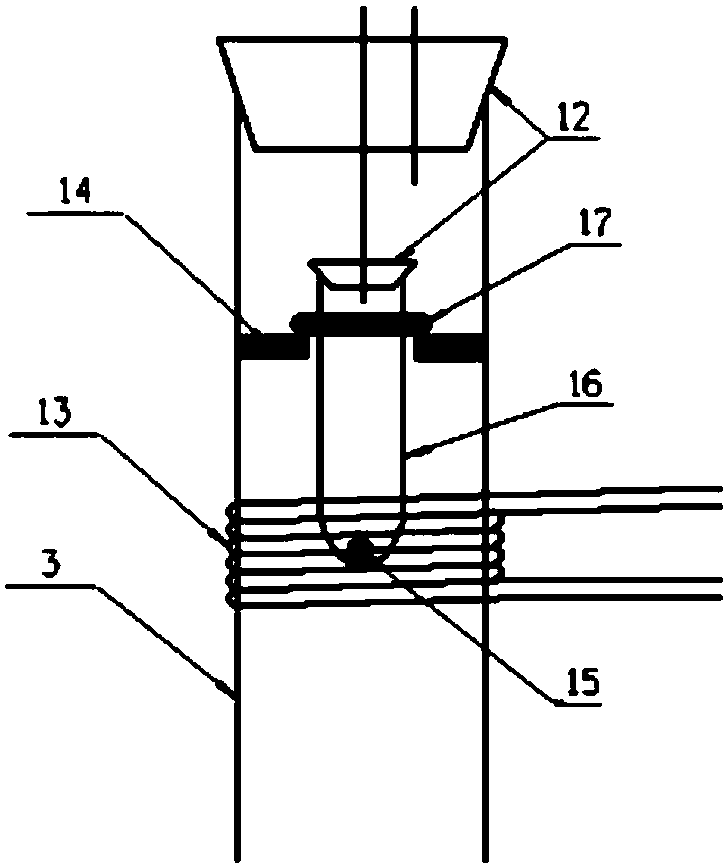

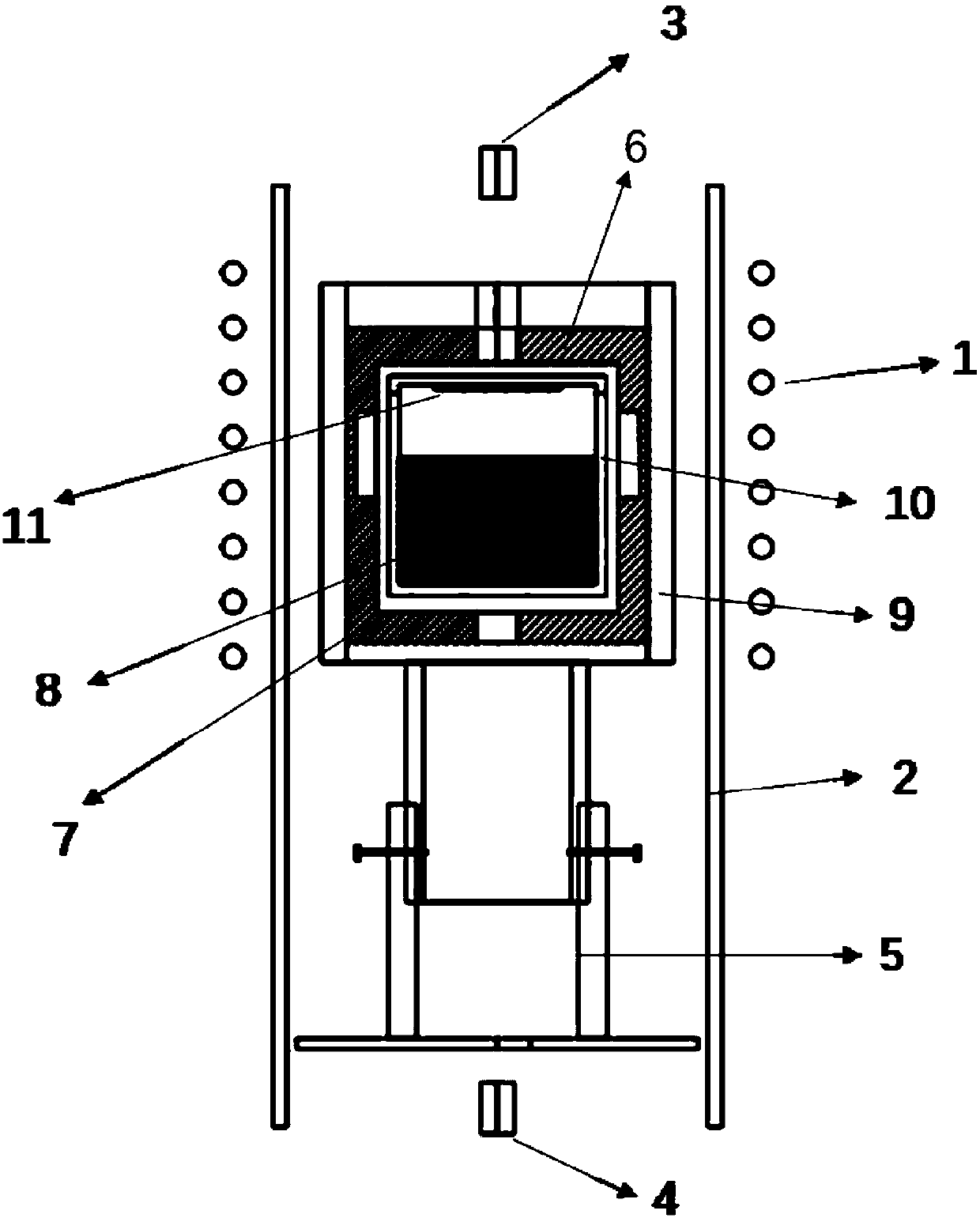

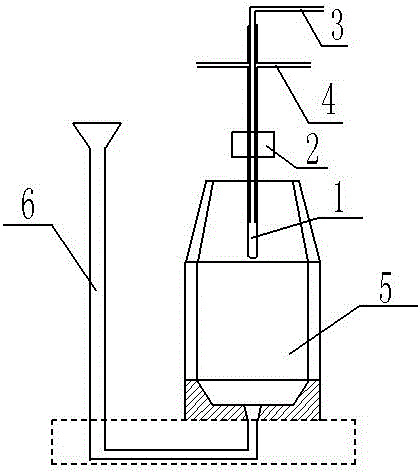

Microgravity solidification device for metal droplets

ActiveCN107589145AEliminate macrosegregationEliminate tissue inhomogeneitiesInvestigating phase/state changeQuenchingShock cooling

The invention discloses a microgravity solidification device for metal liquid droplets. The upper end of a tube body is a sample installation section, and a liquid quenching collector is placed in a tube at the lower end. A sample is placed at the bottom in the test tube located in the sample installation section. A heating coil sleeves the tube body and is located at the lower end of the test tube, so that the sample is located in the middle of the axial height of the heating coil. The test tube communicates with an experimental atmosphere source through a gas flow controller. A vacuum pump and the experimental atmosphere source both communicate with the sample installation section and the test tube through a gas path control end. The center of the bottom end of the test tube is providedwith a through hole, the through hole is used for dispersing a sample after being melted into droplets with different diameters, and the droplets fall freely into the liquid quenching collector at thelower end of the tube body through the tube body. With adopting of a microgravity and liquid quenching effect integrated rapid solidification technology, free falling of the metal liquid droplets inthe tube body is combined with subsequent liquid quenching shock cooling, so that rapid solidification of the large-size millimeter-level metal liquid droplets in the shorter tube body under the action of microgravity is achieved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for improving high plasticity of low-carbon silicomanganese cold-rolling transformation induced plasticity steels

The invention belongs to the technical field of rolled steel, and in particular relates to a method for improving high plasticity of low-carbon silicomanganese cold-rolling phase-change induced plasticity steel. The method comprises the following steps of: selecting the low-carbon silicomanganese cold-rolling transformation induced plasticity steels, smelting and forging so as to manufacture plate blanks, heating the plate blanks to be 1100-1250 DEG C, keeping the temperature, rough-rolling and finish-rolling the plate blanks and air-cooling the hot rolled plates to be 600-750 DEGC, coiling, and subsequently pickling so as to obtain steel plates for cold rolling; cold-rolling in a rolling reduction greater than or equal to 80%; heating the cold-rolled steel plates to be (Ac3-40 DEG C) to (Ac3+30 DEG C) at a heating velocity of at least 80 DEG C / s, carrying out annealing treatment for 5-15 seconds, subsequently cooling to a bainite area of 380-450 DEG C at a velocity of 40-80 DEG C / s, carrying out isothermal treatment for 10-50 seconds, and finally cooling to the room temperature. By utilizing the preparation method, cold-rolling transformation induced plasticity steels with high and strong plasticity is obtained, and the strength of the low-carbon silicomanganese cold-rolling transformation induced plasticity steels is greatly improved on the premise that the plasticity is not lost.

Owner:LAIWU IRON & STEEL GRP

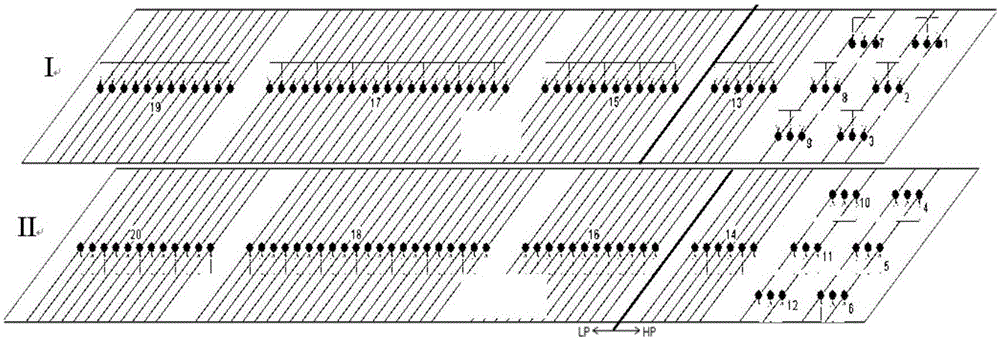

Quenching machine accelerated cooling method for improving strength of normalized steel plate with thickness specification of being greater than or equal to 50 mm

InactiveCN105154631AGood water cooling uniformityIncrease nucleation rateFurnace typesHeat treatment process controlFree coolingUltimate tensile strength

The invention discloses a quenching machine accelerated cooling method for improving the strength of a normalized steel plate with the thickness specification of being greater than or equal to 50 mm. The quenching machine accelerated cooling method comprises the following steps: the normalized steel plate enters a quenching machine along a quenching machine roller way after being discharged from a quenching furnace to be subjected to water cooling, four or six low-pressure sections are confirmed to be opened according to steel varieties and specifications, and the opening degrees, the upper and lower opening degree ratios and the roller way speeds of the areas of the low-pressure sections are adjusted, so that the steel plate is naturally cooled after the 'self-tempering' temperature reaches 580-630 DEG C, wherein the water yield control parameters are as follows: the opening degree of a flow control valve at the 15 area of the low-pressure sections is 30-40%, and the opening degree of a flow control valve at the 16 area of the low-pressure sections is 35-50%; the opening degree of a flow control valve at the 17 area of the low-pressure sections is 40-50%, and the opening degree of a flow control valve at the 18 area of the low-pressure sections is 45-60%; the opening degree of a flow control valve at the 19 area of the low-pressure sections is 60-70%, and the opening degree of a flow control valve at the 20 area of the low-pressure sections is 65-80%; the steel plate cooling speed is controlled to be 8-10 DEG C / S. The water cooling uniformity is good, the plate form after the cooling is good, and the strength of the normalized steel plate can be greatly improved through water cooling.

Owner:SHANDONG IRON & STEEL CO LTD

Method for preparing anti-oxidation conductive glue

InactiveCN107760242AImprove antioxidant capacityPrice increaseNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyDiethylenetriamine

The invention relates to the technical field of electronic product preparation and particularly relates to a method for preparing anti-oxidation conductive glue. The method comprises preparing a copper sulfate solution and a reducing solution, blending the two solutions to obtain a reaction solution, treating the reaction solution to obtain ultrafine copper powder, dispersing the ultrafine copperpowder in deionized water, blending the ultrafine copper powder and a silver ammonia solution for a reaction, treating the reaction product to obtain silver-coated copper powder, adding the silver-coated copper powder and polyurethane granules into diluted hot-melt epoxy resin, and adding diethylenetriamine and tributyl phosphate into the diluted hot-melt epoxy resin to obtain the anti-oxidation conductive glue. Silver on the copper powder surfaces has high electrical conductivity and chemical stability. The potential difference between copper ions and silver can prevent silver from falling off because of electrochemical corrosion and improve oxidation resistance of the conductive glue. Through use of polyurethane in the epoxy resin, the brittleness of the conductive glue is well improved,silver-coated copper powder precipitation under gravity is prevented and the electro-migration caused by precipitation of conductive particles in the conductive glue is prevented. The method has a wide application prospect.

Owner:CHANGZHOU LANXU CHEM CO LTD

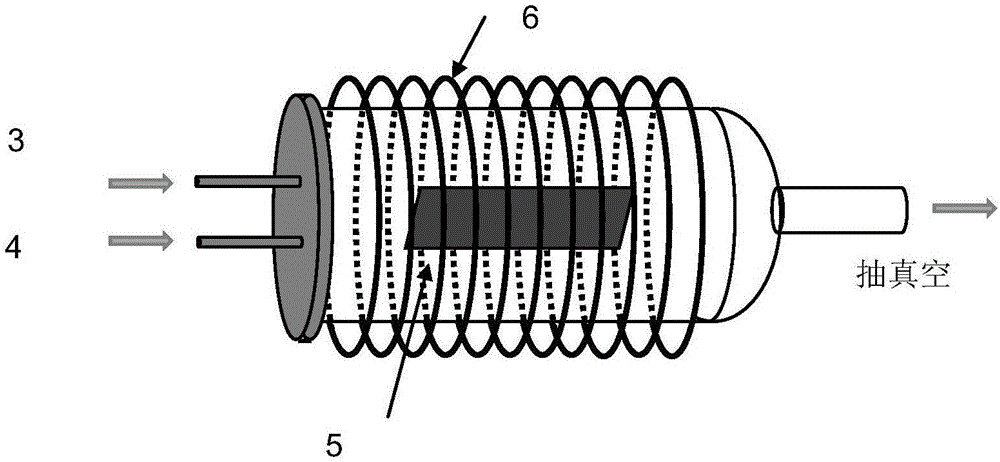

Growth method of low-stress aluminum nitride crystal

ActiveCN107904661AQuality improvementReduced nucleation ratePolycrystalline material growthFrom condensed vaporsTemperature controlDecomposition

The invention discloses a growth method of a low-stress aluminum nitride crystal. According to the growth method, rapid two-dimensional mode growth of an AIN (Aluminum Nitride) crystal is achieved ina temperature and pressure variable mode, the stress of a single aluminum nitride crystal is reduced, and the single aluminum nitride crystal which has no crack on a growth surface and has naturally grown steps is grown. According to the growth method, a temperature control process and a mode that the temperate and the pressure of a specific temperature interval are varied in the growth process are adopted, the atom nucleation rate is reduced because of high pressure and low temperatures at a former stage, the primary nucleation tidiness is improved, and substrate decomposition failure is inhibited; at a middle growth stage, the pressure is reduced, so that the growth velocity is increased, and substrate decomposition is retarded; at a later stage, the temperature and the pressure are increased, nitrogen source supply is increased, a three-dimension island growth mode is avoided, the phenomena of non-uniform deposition and relatively large stress are reduced, secondary temperature increasing is implemented after cooling, the stress inside the crystal is reduced, cracks on the surface of the crystal is healed, a silicon carbide substrate is decomposed, and thus a self-striped high-quality single aluminum nitride crystal is grown.

Owner:BEIJING HUAJINCHUANGWEI ELECTRONICS CO LTD

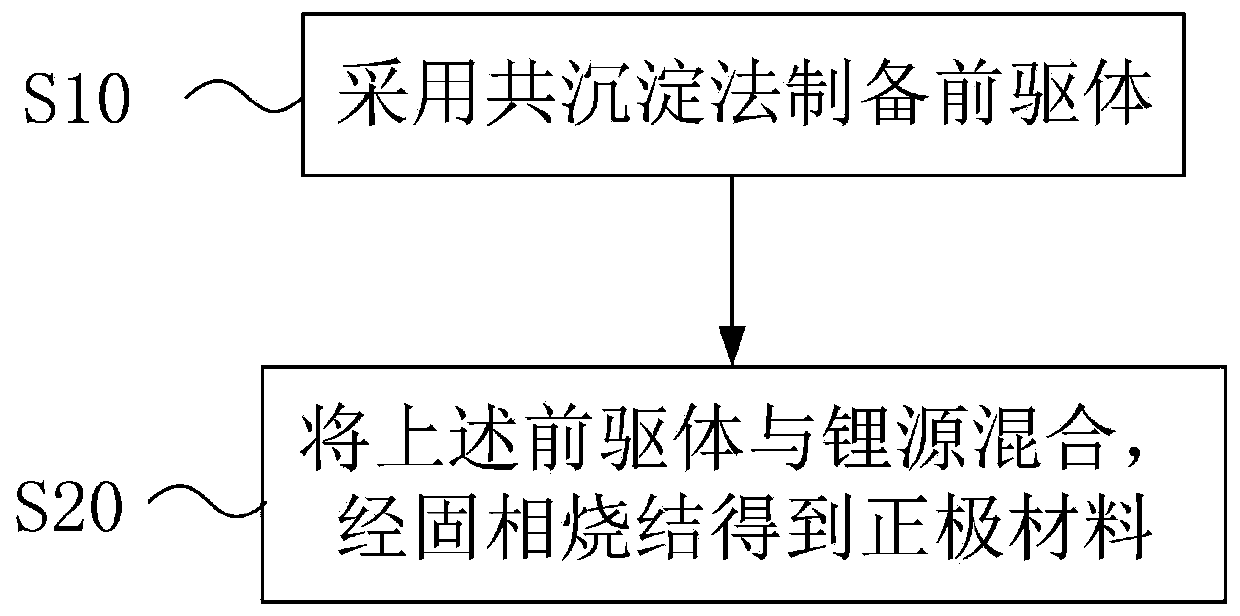

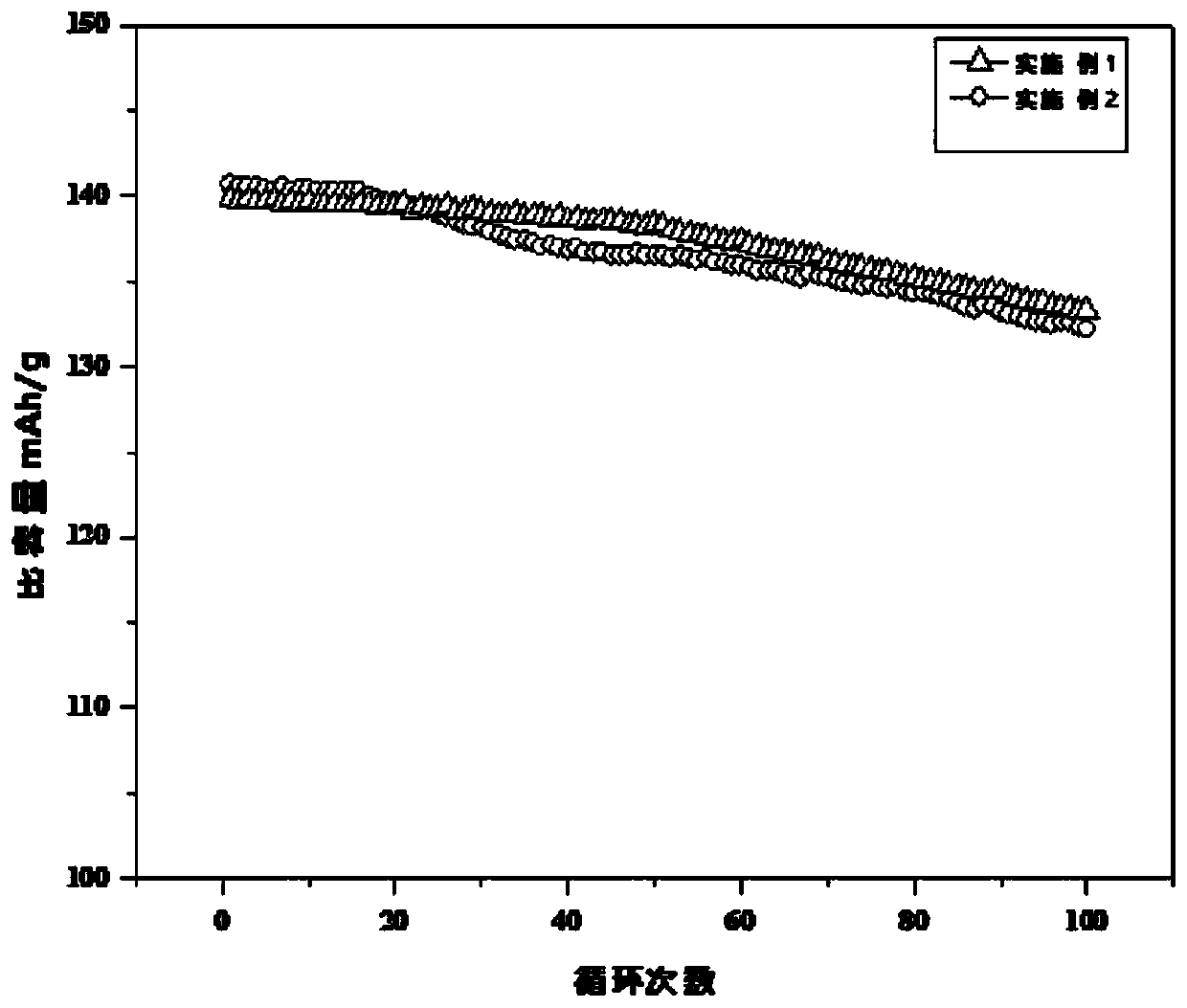

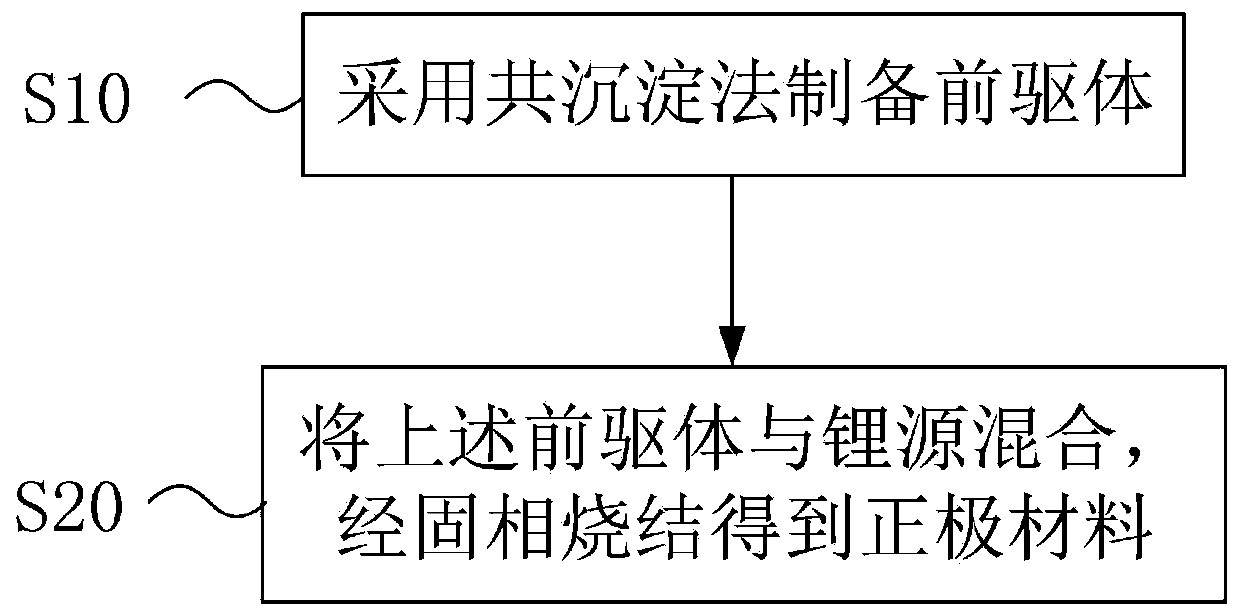

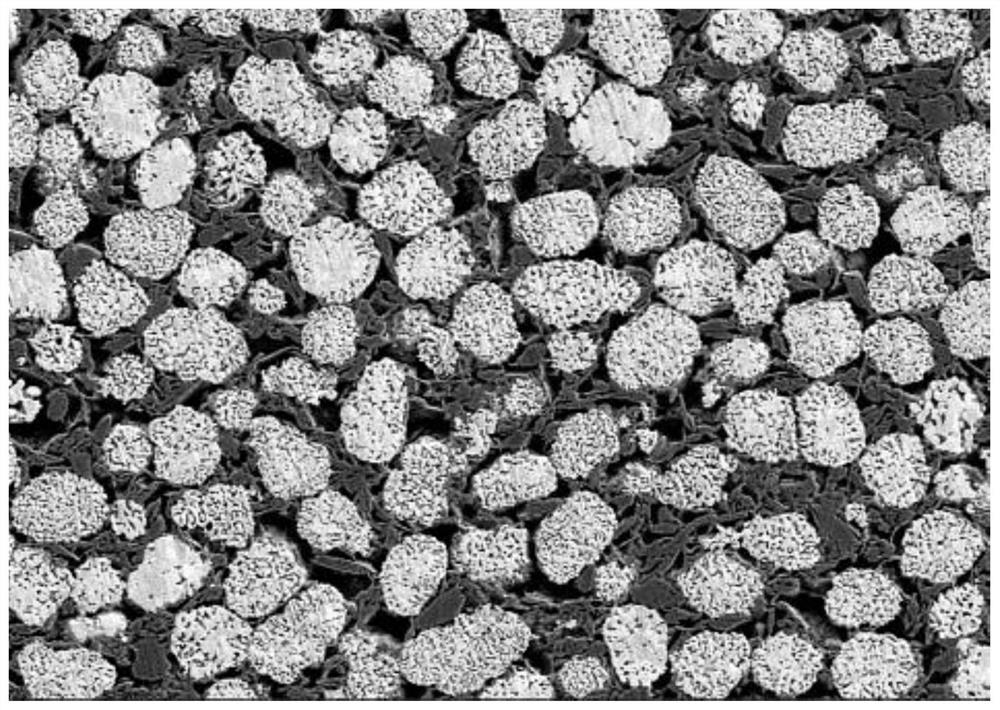

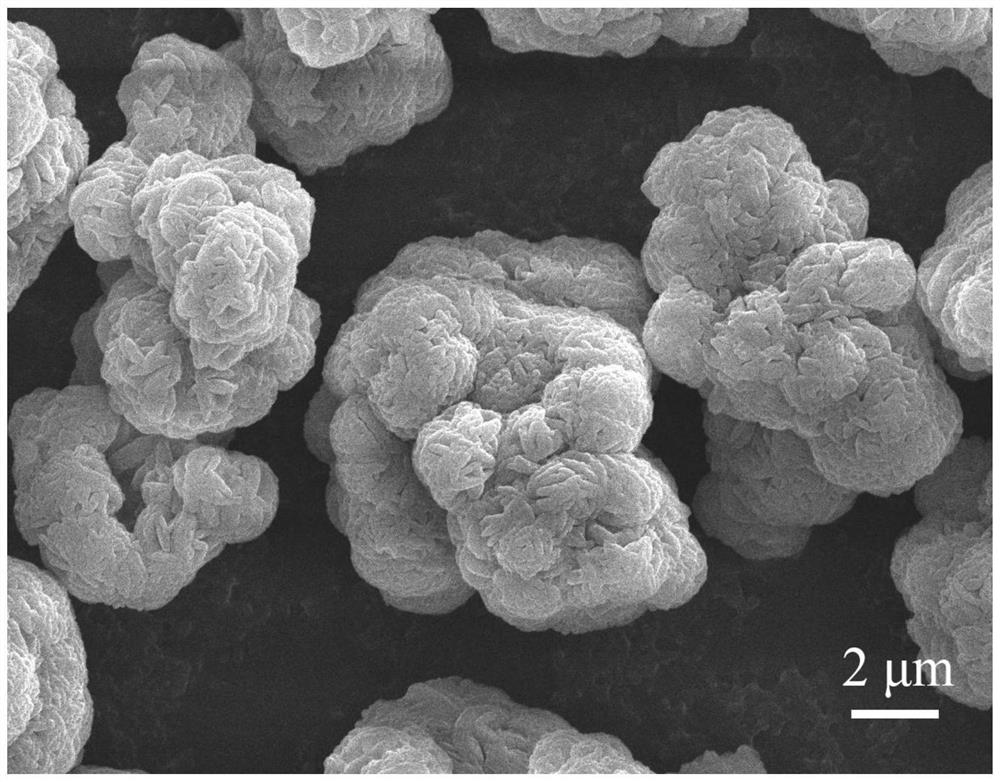

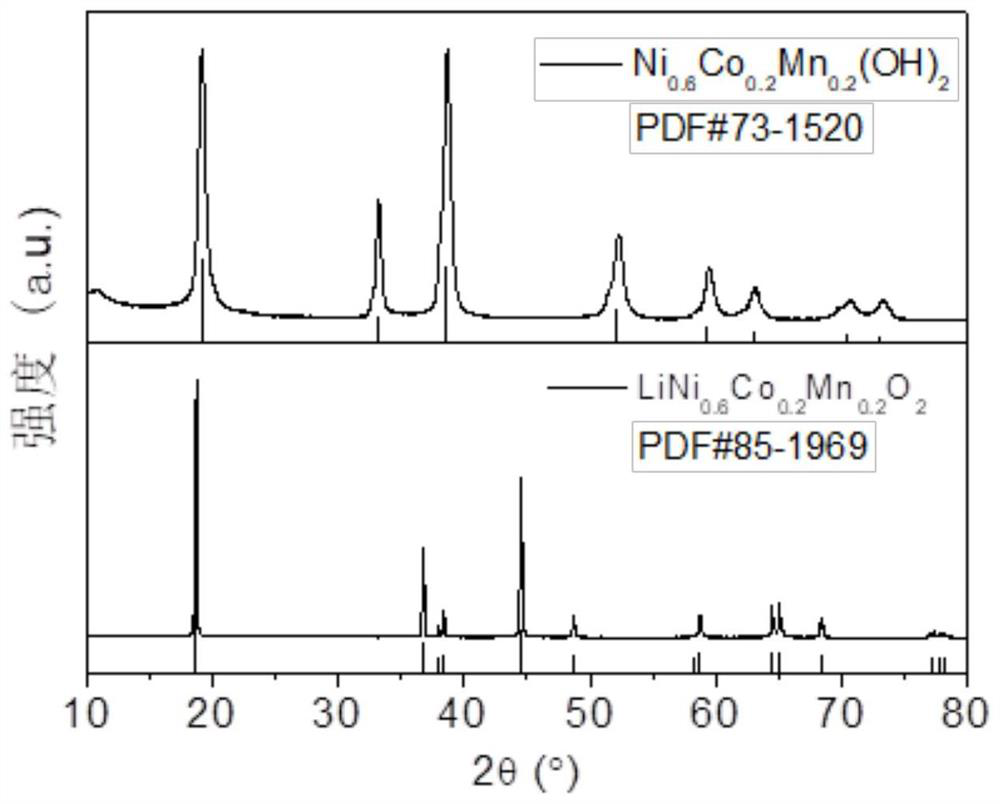

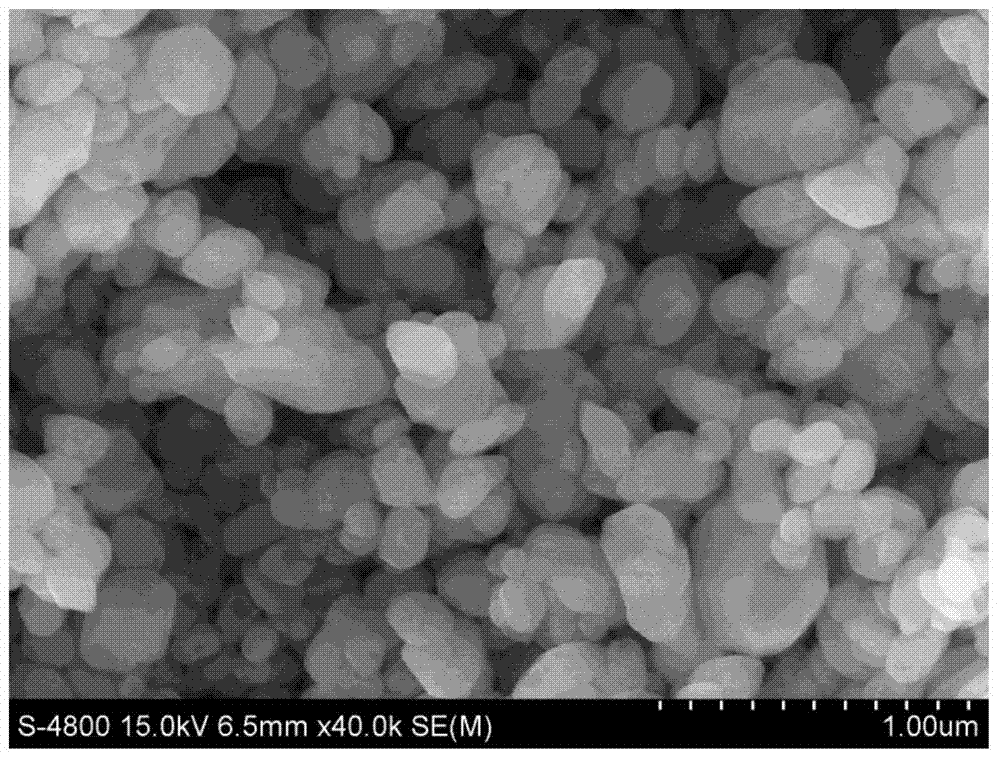

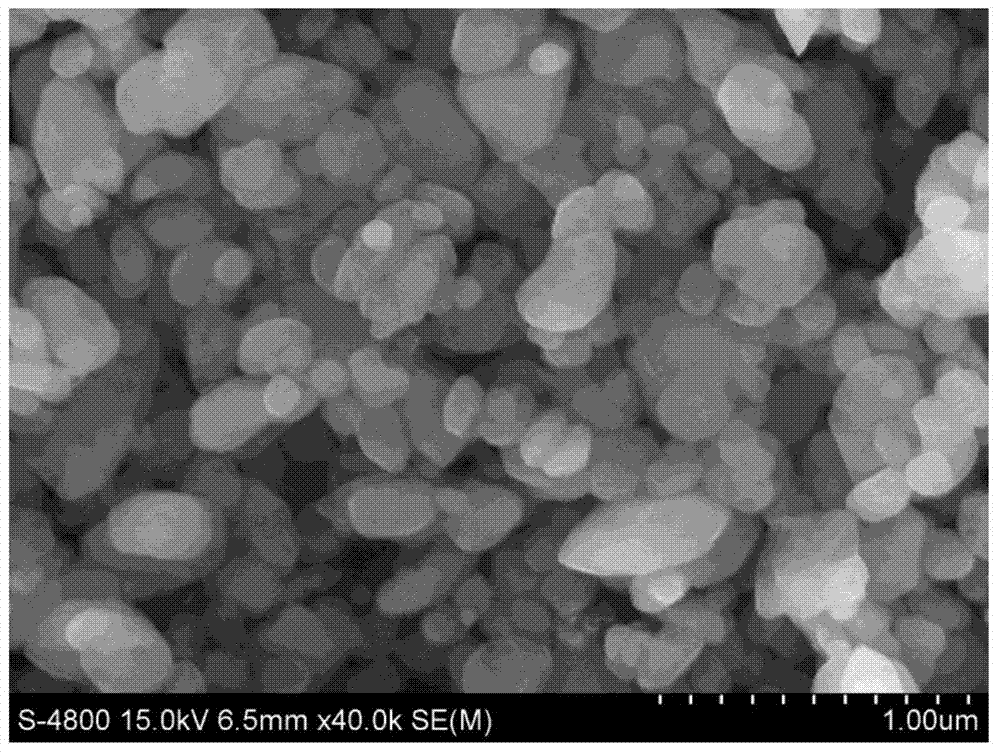

Lithium nickel manganese oxide positive electrode material and preparation method thereof

ActiveCN109704411AShape is easy to controlImprove electrochemical performanceCell electrodesSecondary cellsManganateCoprecipitation

The invention discloses a preparation method of a lithium nickel manganese oxide positive electrode material, and relates to the technical field of battery materials. The preparation method comprisesthe following steps: preparing a precursor by adopting a coprecipitation method, mixing the precursor with a lithium source, and carrying out solid-phase sintering to obtain the lithium nickel manganese oxide positive electrode material. The nickel lithium manganate positive electrode material provided by the invention has a high material uniformity degree, controllable morphology and particle size and good electrochemical performance, and performance of a battery made of the lithium nickel manganese oxide positive electrode material can be improved. Meanwhile, a chelating agent in the preparation method is environmentally friendly and is free of pollution, the process flow is simple, operation is easy, cost is low, the synthesis period is short, the product composition is uniform, and uniformity of product batches is good, so that the preparation method is very suitable for industrial production and is an efficient and energy-saving method for preparing the high-voltage lithium nickelmanganese oxide positive electrode material.

Owner:YINLONG ENERGY CO LTD

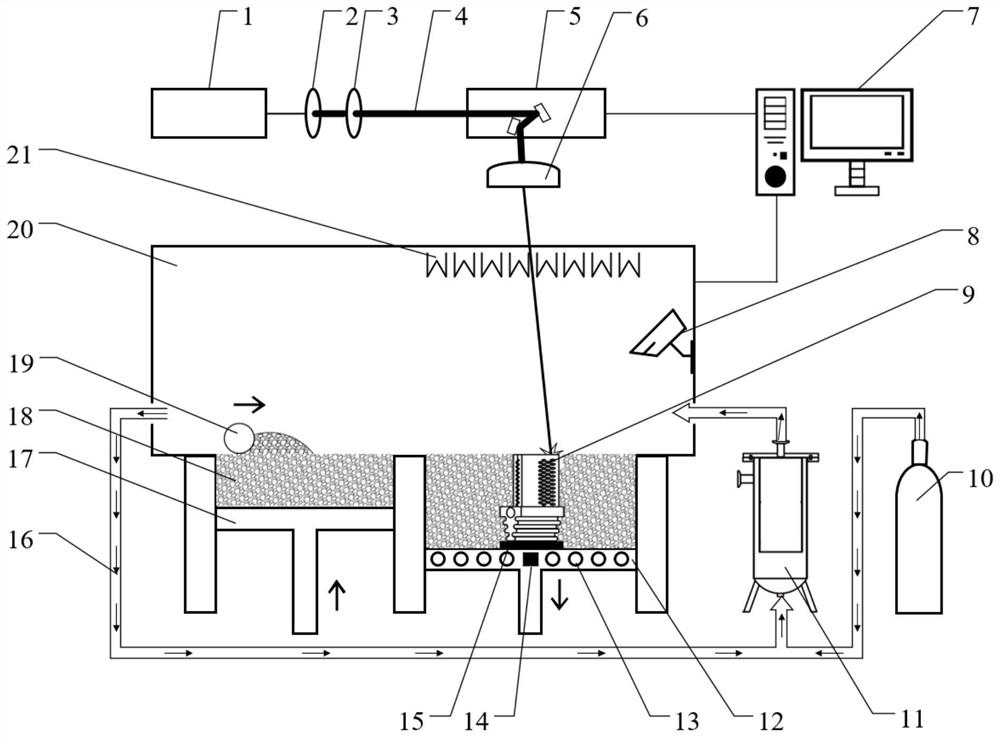

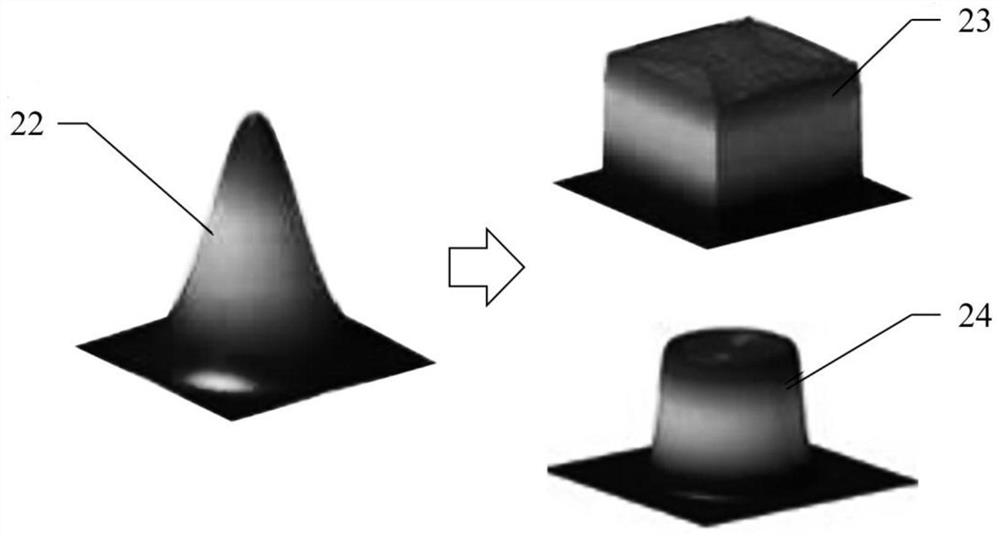

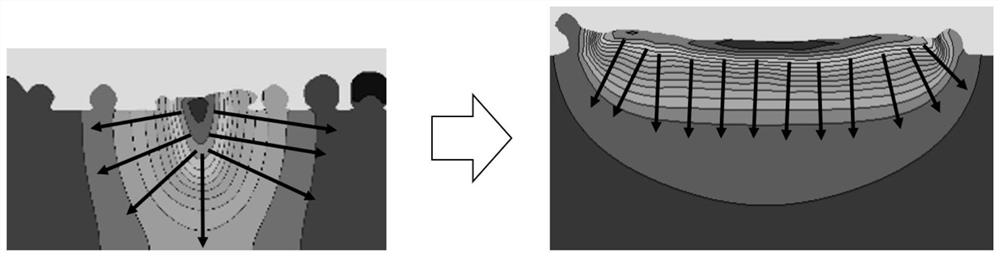

3D printing device and method for oriented crystal or single crystal high-temperature alloy and product

InactiveCN112893874AReduce energy variabilityReduce disruptionTurbinesPolycrystalline material growthSingle crystal superalloySingle crystal

The invention belongs to the related technical field of additive manufacturing, and discloses a 3D printing device and method for an oriented crystal or single crystal high-temperature alloy and a product. The device comprises a forming unit, a shape righting light path unit and a forced temperature difference unit; a DOE diffraction optical element is arranged in the shape righting light path unit, and the shape righting light path unit is used for converting laser spot energy generated by a laser emitting element into uniform distribution from Gaussian distribution; the forced temperature difference unit is arranged in the forming cavity and comprises an infrared heating pipe and a cooling pipeline, heating is conducted above a cooling substrate through the infrared heating pipe, cooling is conducted in the cooling substrate through the cooling pipeline, thus an environment temperature field with the temperature strictly and gradually reduced is formed above the cooling substrate, and then crystals grow in the opposite direction of gradually-reduced temperature when a molten pool is solidified. By means of the device and the method, the temperature gradient in the molten pool can be controlled from top to bottom strictly, mixed crystals such as isometric crystals and the like are reduced or even eliminated, and layer-by-layer stable epitaxial growth of oriented crystals or single crystals along [001] is achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

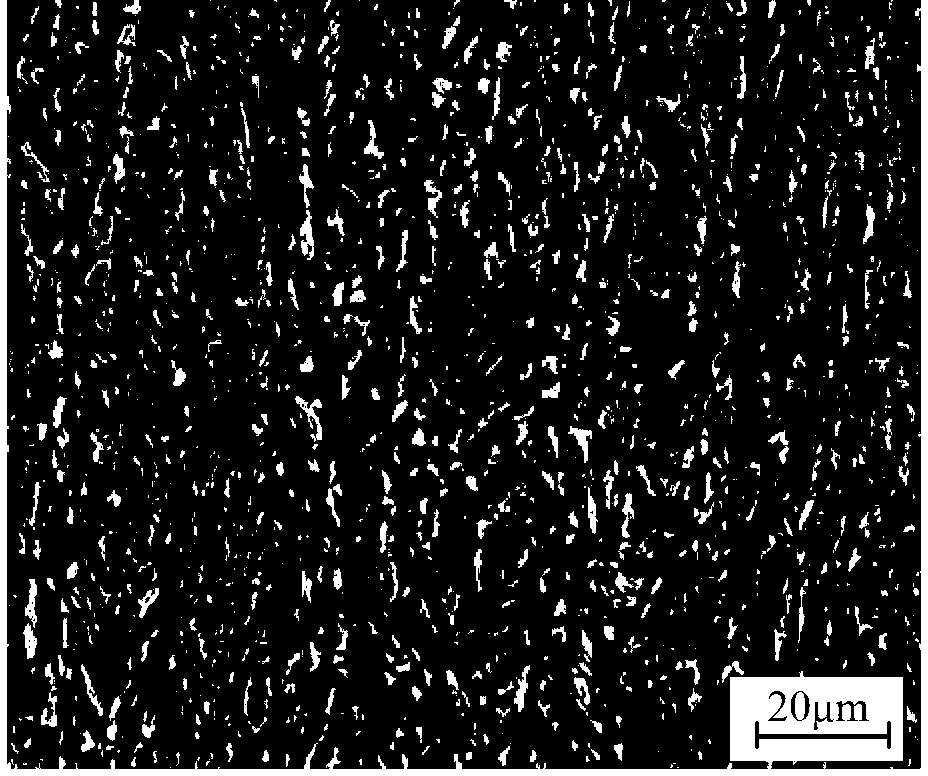

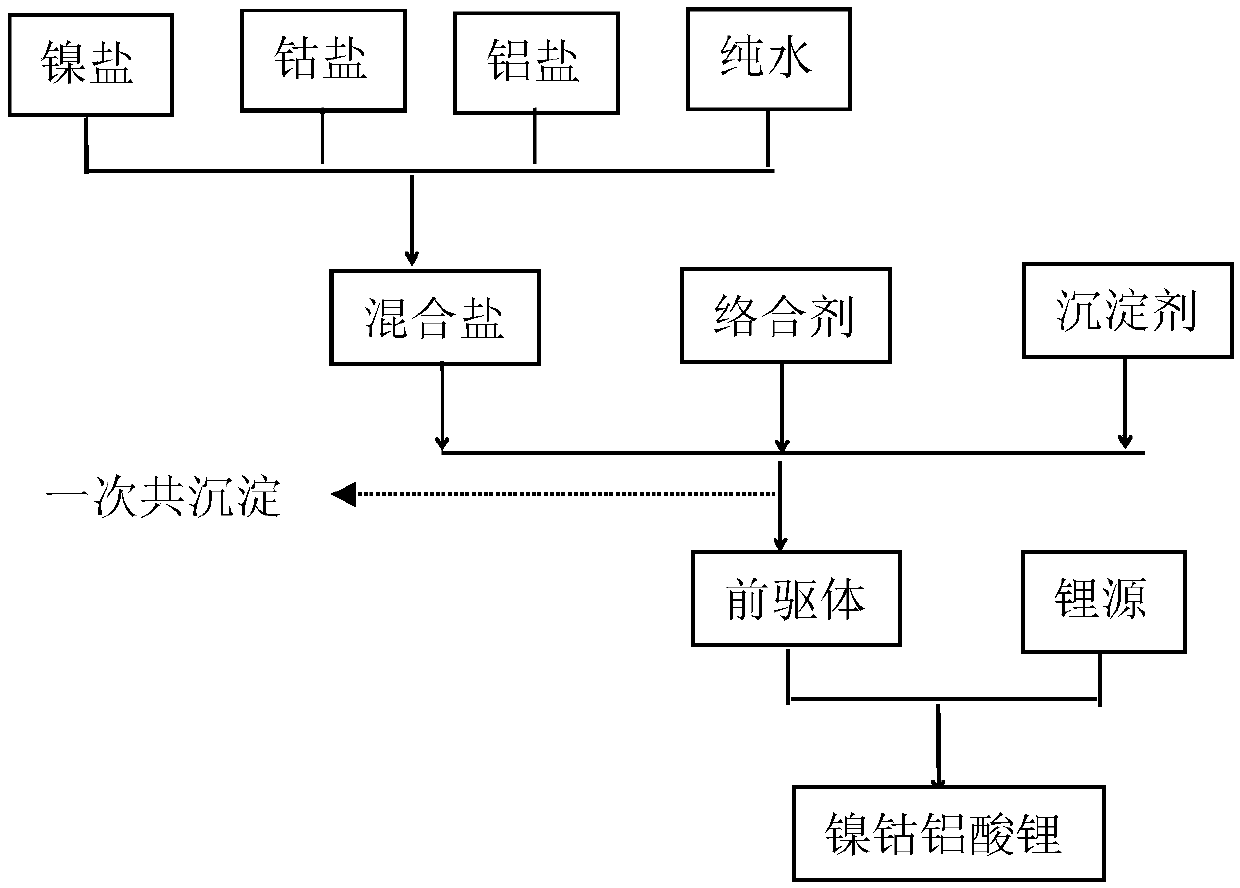

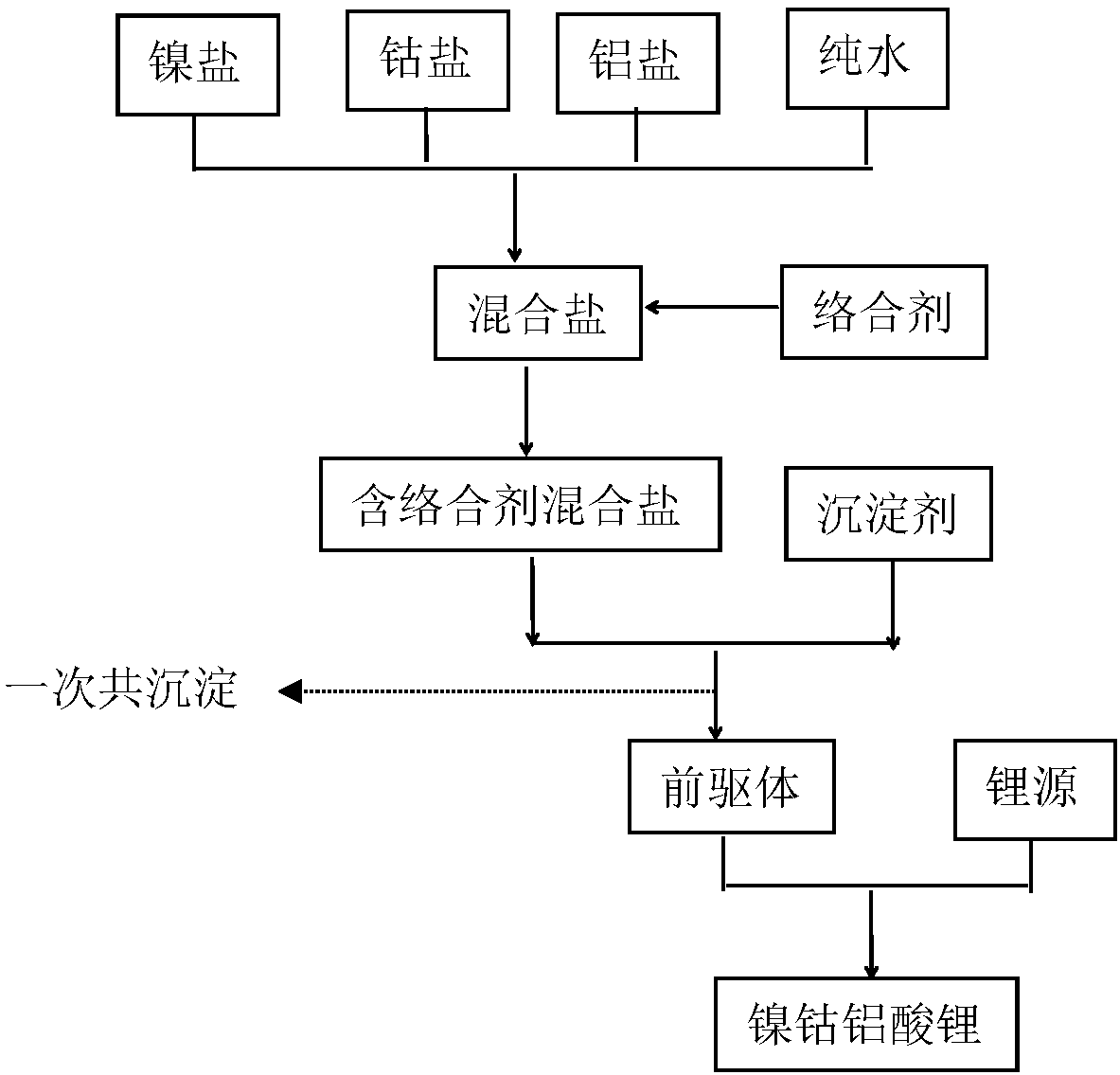

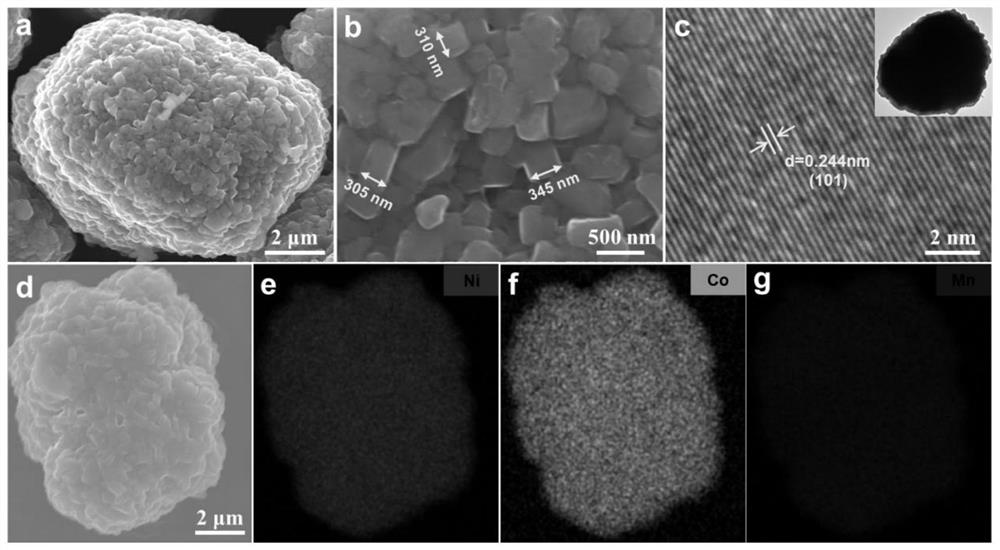

Lithium nickel cobalt aluminum oxide positive electrode material and preparation method therefor

ActiveCN107681143AReduced nucleation rateUniform particle size distributionCell electrodesSecondary cellsPhosphoric acidCobalt

The invention provides a lithium nickel cobalt aluminum oxide positive electrode material and a preparation method therefor. A nickel cobalt aluminum precursor is prepared by mixing a metal salt solution comprising Ni<2+>, Co<2+> and Al<3+>, and a complexing agent solution and a precipitator solution by adopting a liquid phase control crystallization method, wherein the complexing agent comprisesone or more of fluoride, an alcohol amine type compound, a phosphoric acid type compound and a carbonyl compound; and the nickel cobalt aluminum precursor and a solid-phase lithium source are mixed and sintered to obtain the lithium nickel cobalt aluminum oxide positive electrode material. Through complexing between the limited complexing agent and Al<3+>, the nucleating rate of Al<3+> is lowered,so that uniform coprecipitation and crystallization among Al<3+> and Ni<2+> and Co<2+> can be ensured, thereby obtaining the spherical Ni<x>Co<y>Al<z>(OH)<2> precursor with uniform grain fineness distribution and high tap density; and therefore, the obtained lithium nickel cobalt aluminum oxide positive electrode material is uniform in composition and high in uniformity.

Owner:GANNAN NORMAL UNIV

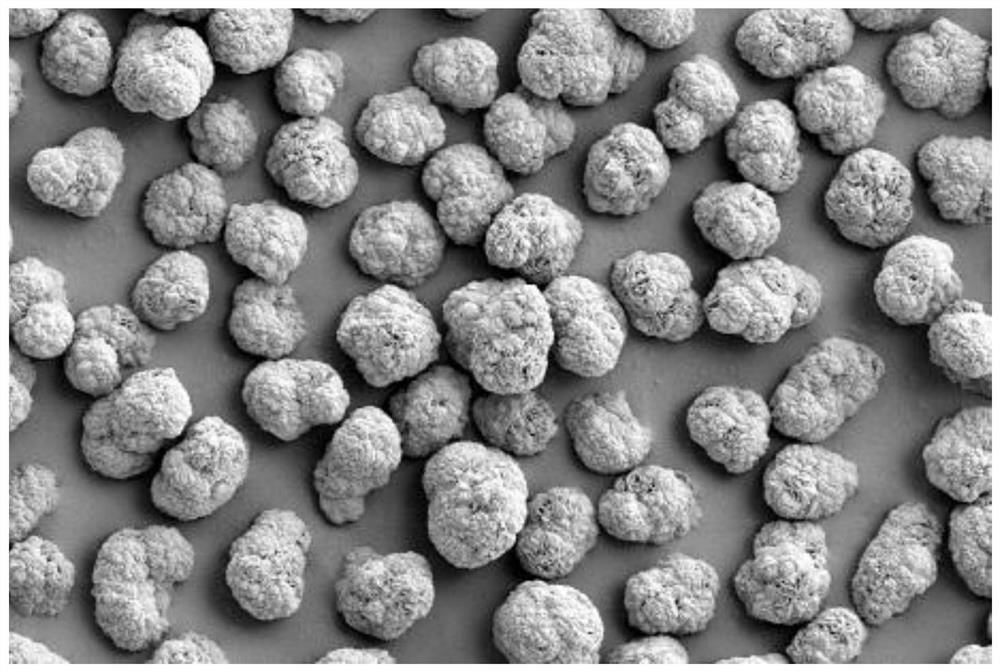

Preparation method of high-aluminum-doped small-particle-size cobalt carbonate particles

PendingCN113636604AConsistent crystallinitySolve for uniformityCobalt carbonatesSeed crystalCarbonate

The invention discloses a preparation method of high-aluminum-doped small-particle-size cobalt carbonate particles, and the method mainly comprises the following steps: preparing a mixed salt solution of soluble cobalt salt and aluminum salt, the mass ratio of the aluminum element to the cobalt element being 0.011-0.014; adding a mixed salt solution of cobalt and aluminum sulfate and an ammonium bicarbonate solution into a diluted ammonium bicarbonate solution, and preparing a cobalt carbonate seed crystal with D50 of 1.3-1.5 [mu] m by adopting a low-temperature and low-feeding-rate synthesis process; and then preparing small-particle-size cobalt carbonate particles through a subsequent synthesis growth process. The prepared cobalt carbonate has the characteristics of high aluminum doping amount and consistent overall crystallinity of particles, and the problems that aluminum in cobaltosic oxide particles obtained after high-aluminum-doping cobalt carbonate is calcined is not uniformly distributed, and the interiors of the particles are porous are effectively solved.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드 +1

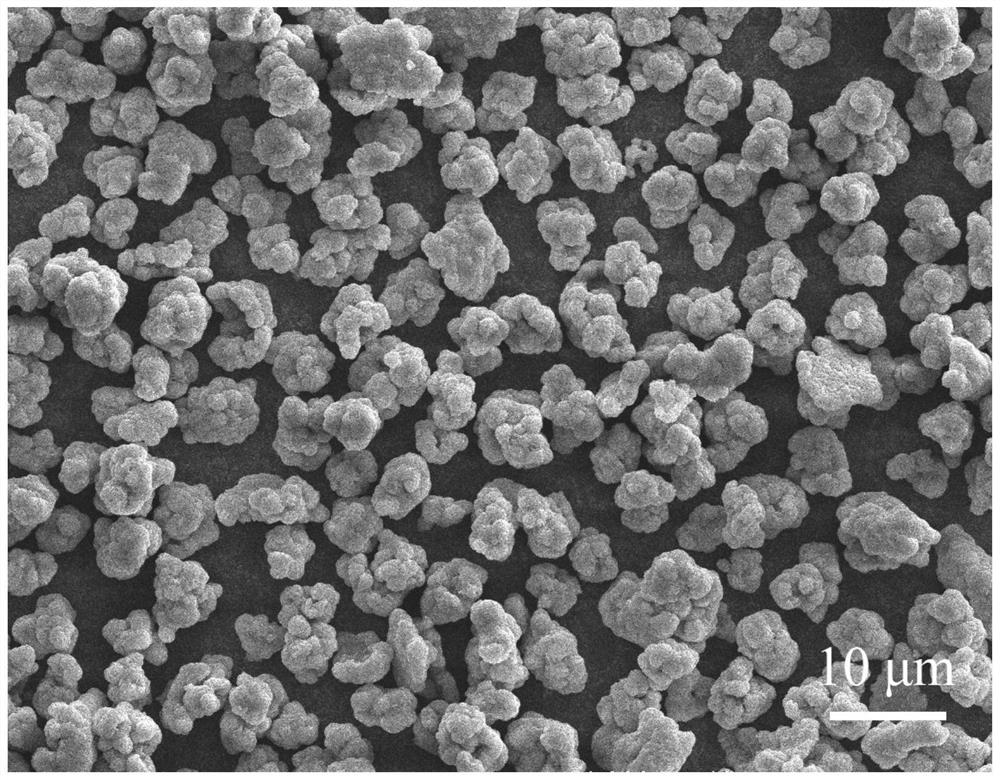

Preparation method of high-tap-density iron phosphate material

InactiveCN112573496AIncreased chance of collisionStable reunionCell electrodesSecondary cellsHigh concentrationPhysical chemistry

The invention discloses a preparation method of a high-tap-density iron phosphate material. The preparation method comprises the following steps: S1, quickly reacting a high-concentration iron sourcesolution with a high-concentration phosphorus source solution to obtain an iron phosphate seed crystal; and S2, slowly adding a low-concentration iron source solution and a low-concentration phosphorus source solution at a constant speed to realize growth of iron phosphate crystals so as to obtain the high-tap-density iron phosphate material. According to the method, the seed crystal reaction andthe crystallization reaction of iron phosphate are effectively separated, and the sphere-like micron-sized iron phosphate particles are successfully prepared. According to the spheroidic large-particle iron phosphate, primary particles are closely agglomerated, secondary particles are uniform in size, and extremely high tap density (larger than 1.05 g / cm<3>) is shown.

Owner:HUNAN YACHENG NEW MATERIAL CO LTD

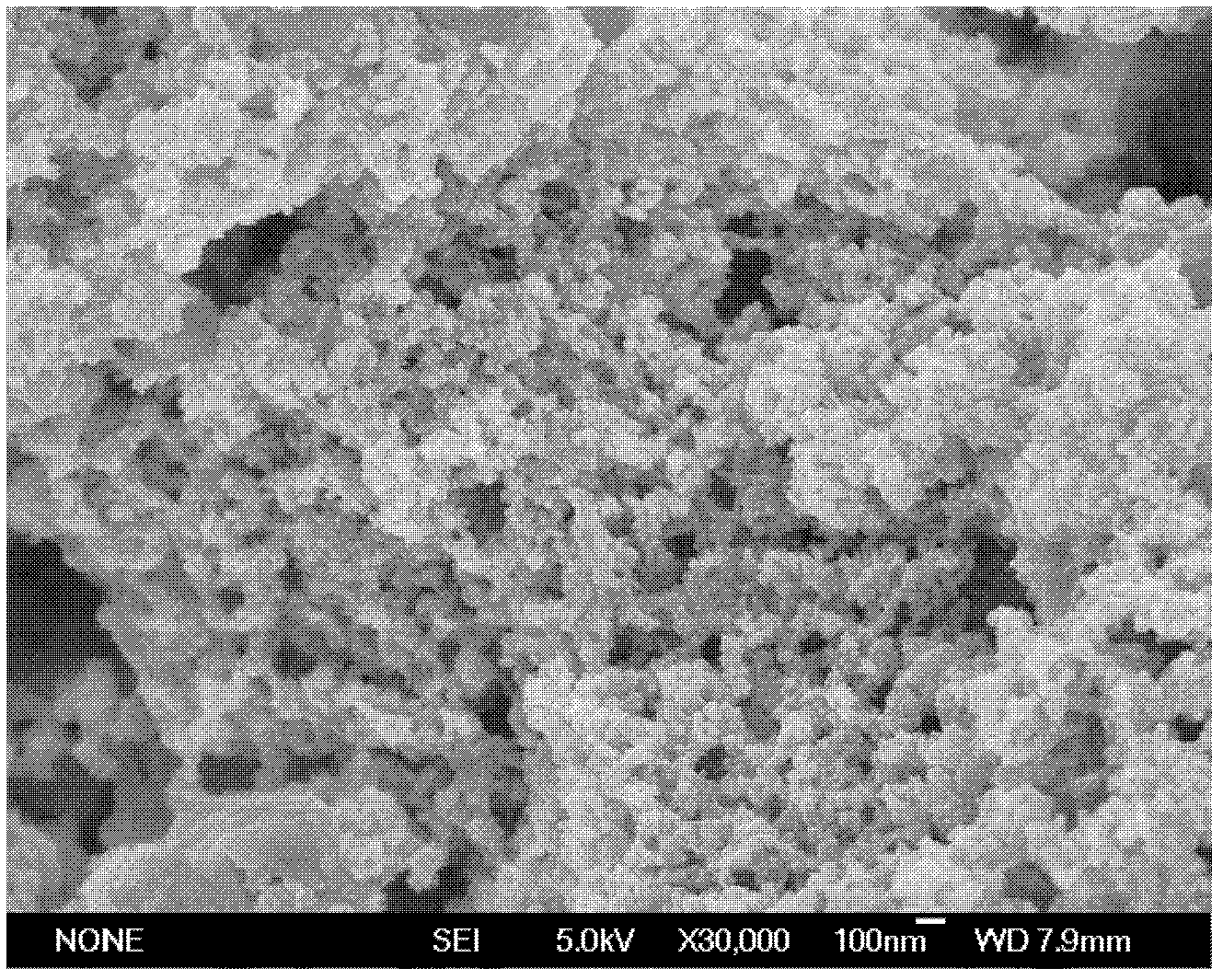

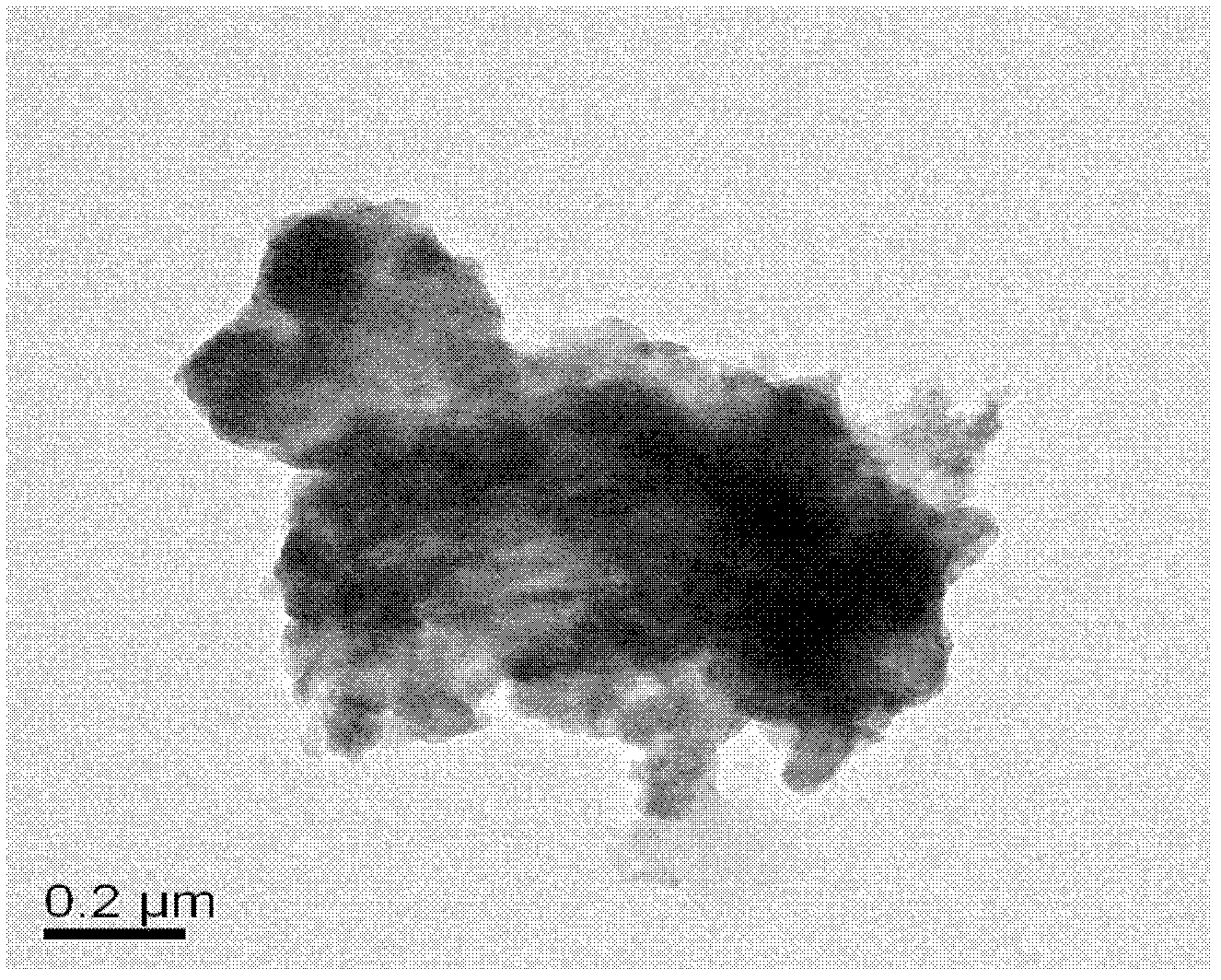

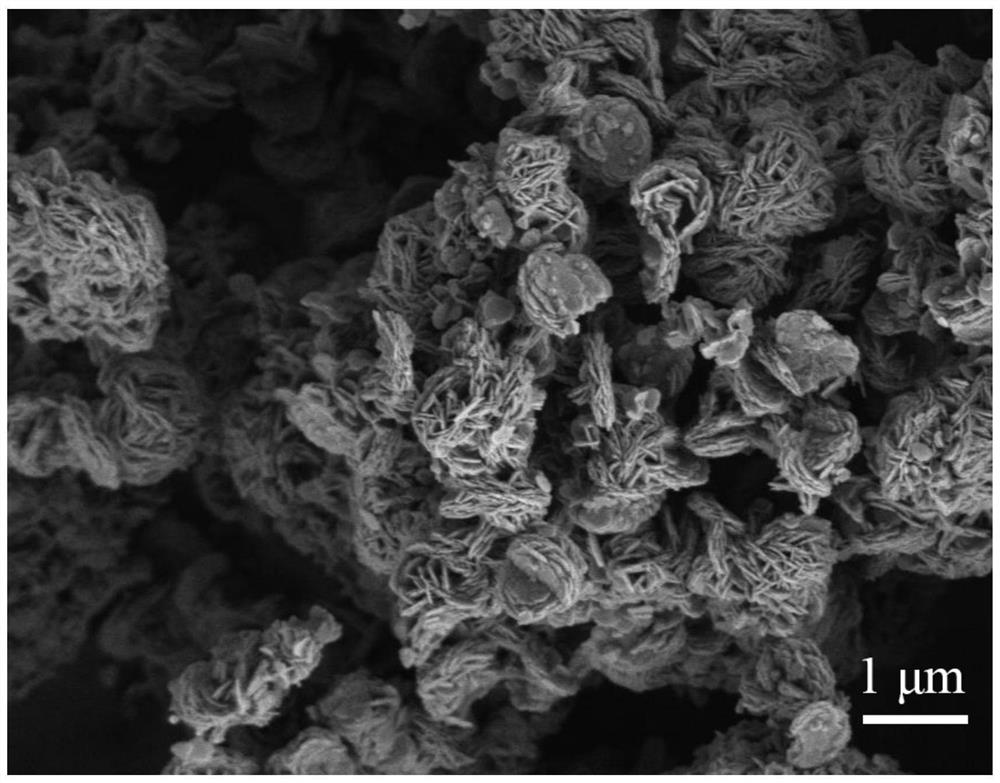

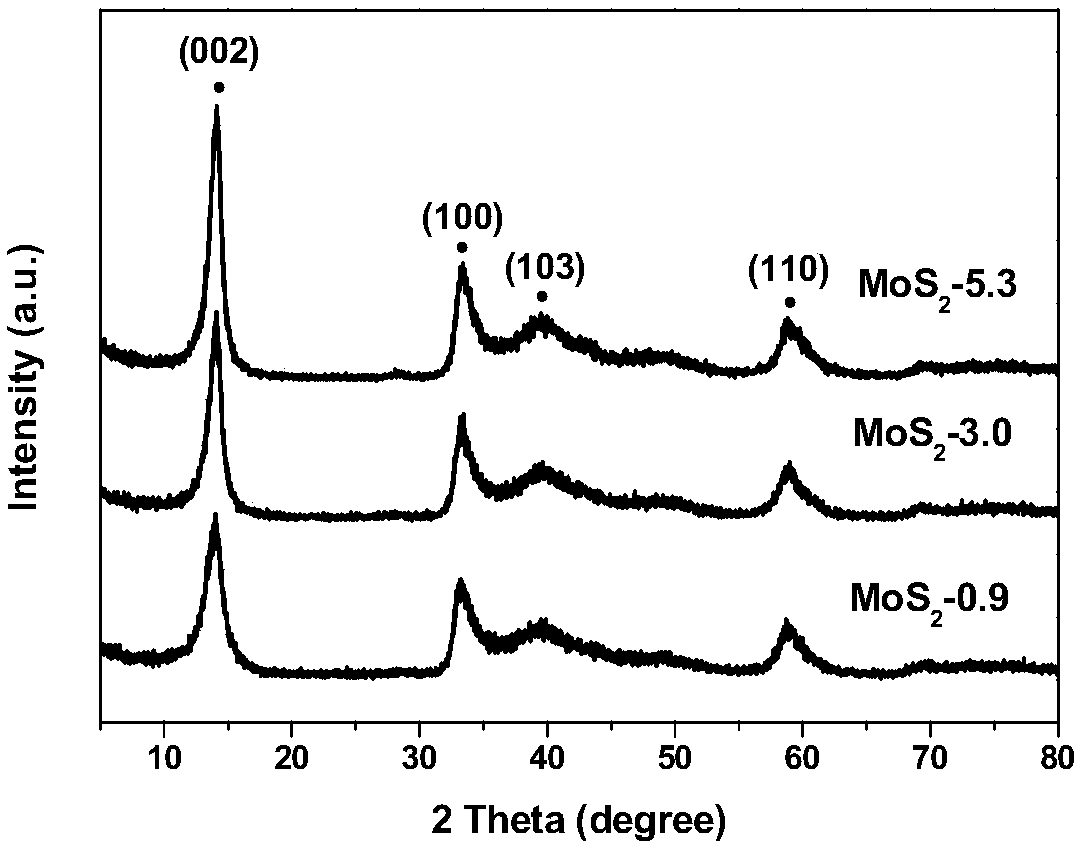

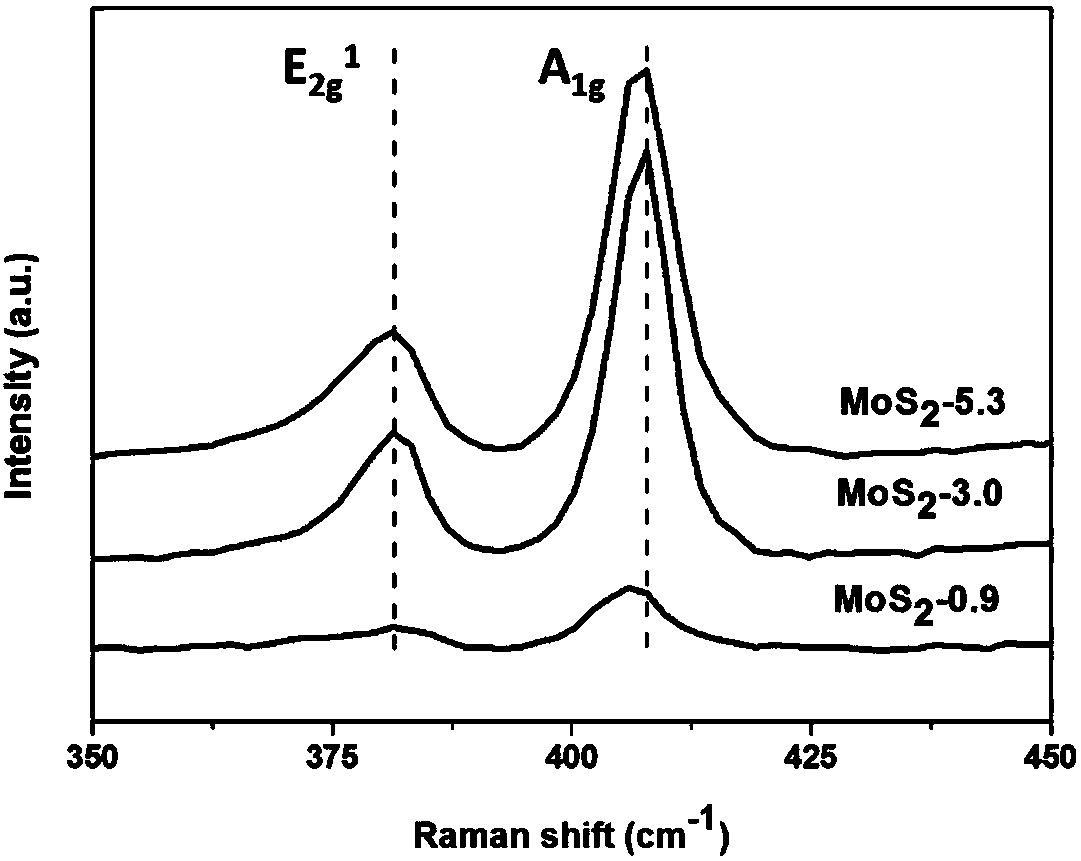

Shape-controlled preparation method of MoS2 nano particles

InactiveCN108217728AFast grain sizeRefine the grain sizeMaterial nanotechnologyMolybdenum sulfidesHydrodesulfurizationSulfur

The invention discloses a shape-controlled preparation method of MoS2 nano particles. The shape-controlled preparation method disclosed by the invention mainly comprises the following steps: sequentially adding a molybdenum source and a sulfur source into deionized water for stirring until the substances are completely dissolved, adding acid or alkali and adjusting the pH value of a solution to acertain value, wherein the ratio of the molybdenum source to the sulfur source is (1 to 2) to (1 to 6) and the pH value is 0.1 to 14; putting the obtained solution into a hydrothermal reactor, carrying out static reaction at the reaction temperature of 160 to 350 DEG C for 2 to 72 hours; after the reaction is ended, cooling, washing and carrying out vacuum drying to obtain shape-controlled MoS2 nano particles. The synthetic method disclosed by the invention has the advantages of mild conditions, simple operation, controllable particle shape, homogeneous products, high yield and the like. The MoS2 synthesized by the preparation method disclosed by the invention has a good application prospect in the fields of gasoline and diesel hydrodesulfurization, photoelectric catalysis, lithium ion batteries, super capacitors, lubrication and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing large grain anhydrous sodium sulfate

InactiveCN101007640AExtended induction periodEnhanced interface energyAlkali metal sulfite/sulfate dehydrationPhosphatePolyethylene glycol

The invention discloses a making method of large-particle anhydrous sodium sulfate, which comprises the following steps: adding 0.01%-10% surface activator with one or more of dodecyl phosphate ester, dodecyl sodium benzosulfonate, dodecyl dimethyl amine oxide, phenylethene or carbowax; adding water under 60-260 deg.c; keeping the constant density of solution to react 1.5-3.0h; stopping heating; filtering; drying; obtaining 80% product over 40 order.

Owner:HEBEI UNIVERSITY

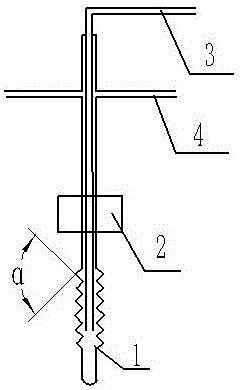

Device for refining grain structure and application method

The invention discloses a device for refining grain structure and an application method, and belongs to the technical field of metallurgy. The device comprises a vibration device inserted in a steel ingot mold; the vibration device includes a vibration rod making direct contact with molten steel; the vibration rod is provided with a vibration generation source for driving the vibration rod to move; an introduction pipe for circulating a cooling medium is arranged in the center of the vibration rod; and discharge pipes for circulating the cooking medium are arranged on two sides of the upper end of the vibration rod. A steel ingot is vibrated in the solidification process to urge fusing and breakage of dendrites; and the number of free cold crystals is increased to inhibit growth of columnar crystals, so that the isometric crystal rate is increased, the solidification structure is refined, and the purpose of relieving segregation is achieved.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

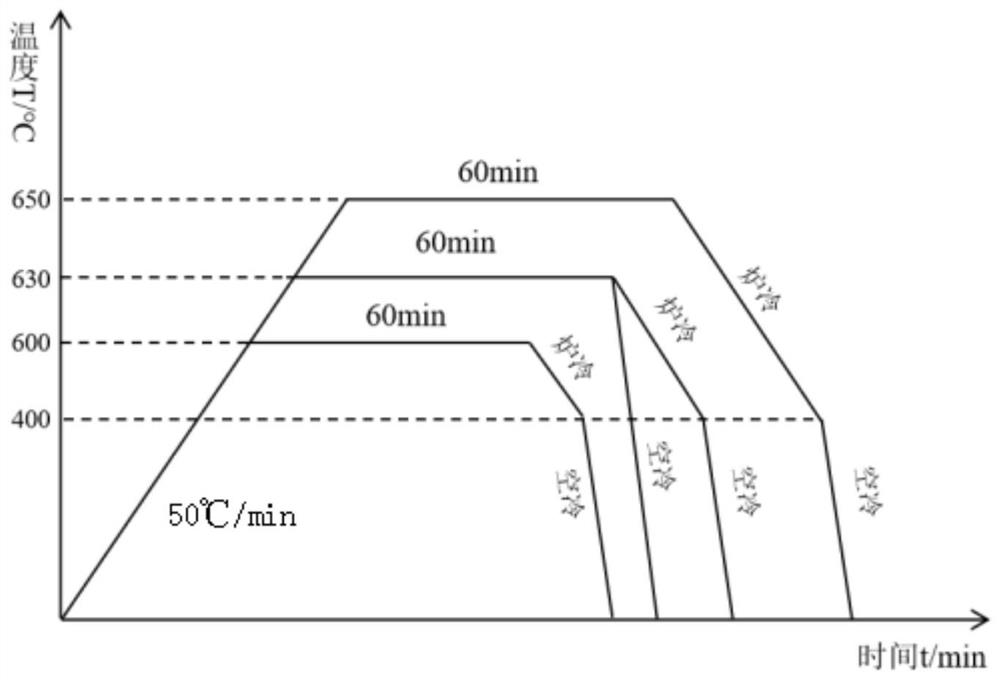

Method for eliminating residual stress of titanium part subjected to powerful spinning deformation

PendingCN112921259AEliminate residual internal stressReduced risk of deformationSpinningHeat conservation

A method for eliminating residual stress of a titanium part subjected to powerful spinning deformation comprises the following steps that 1, the titanium part subjected to spinning is placed in a heat treatment furnace, the temperature is increased to the target temperature of 530-560 DEG C at the heating speed of 10-52 DEG C / min, and the heat preservation time is 60-100 min; and 2, after heat preservation is conducted, cooling is conducted to 380-410 DEG C in a furnace cooling manner, and then discharging and air cooling are conducted to the room temperature. According to the process, the residual internal stress of the TA1 part after the powerful spinning deformation can be eliminated, so that the risk of deformation of a thin-walled cylinder part due to the release of the residual stress in the subsequent machining process is reduced, and the microstructure excellence and the use performance of the material are improved.

Owner:XIAN TAIJIN INDAL ELECTROCHEM TECH

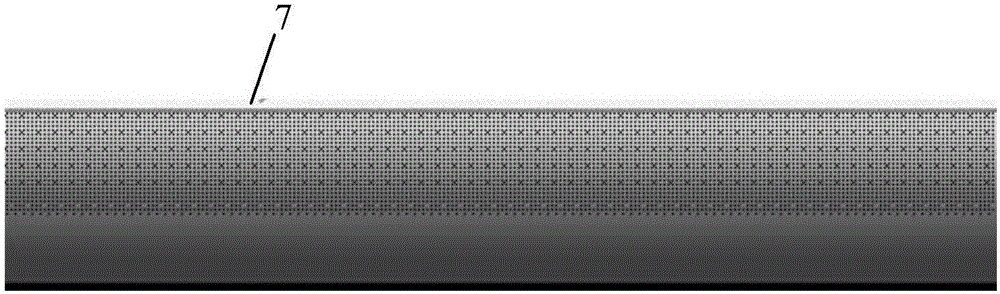

Preparation method of large-dimension high-quality graphene based on self limitation nucleation growth

ActiveCN107522191AReduced nucleation rateFast film formationVacuum evaporation coatingSputtering coatingSurface layerSingle crystal

The invention relates to a preparation method of large-dimension high-quality graphene based on self limitation nucleation growth. The method concretely comprises the following steps of preparing a nickel-covered copper substrate; fast raising the temperature in the vacuum protection atmosphere; after the specific growth temperature is reached, introducing process gas to perform graphene growth. In the primary growth period, the surface of the metal is nickel; the nucleation point of the graphene can be effectively controlled. In the growth process, the copper gradually diffuses to the nickel layer to form rich-nickel copper nickel alloy; the fast growth of the nucleation point can be promoted. Along with the continuous increase of the copper ingredients in the surface layer, the large-dimension single crystal formation of the single-layer graphene can be effectively facilitated; meanwhile, the fast growth of single crystals can be maintained; a large-dimension high-quality continuous graphene film can be realized.

Owner:XI AN JIAOTONG UNIV +1

High-calcium active lime

ActiveCN110981228ALess impuritiesIncrease contentProcess efficiency improvementPhysical chemistryCalcium content

The invention belongs to the field of materials, and particularly relates to high-calcium active lime. A preparation method comprises the steps of pretreatment, activation, impurity removal and the like. According to the method, low-grade limestone with the total content of SiO2 and Fe2O3 being greater than 3% is utilized; the calcium content of the active lime produced by the process disclosed bythe invention reaches 97.3%, the carbon content is lower than 0.5%, the sulfur content is lower than 0.02%, the SiO2 content is lower than 1.0%, and the Fe2O3 content is lower than 1.0%, the producedactive lime has few impurities and can reach the standards of various fields, and the application range is expanded.

Owner:GUIZHOU ANKAIDA IND

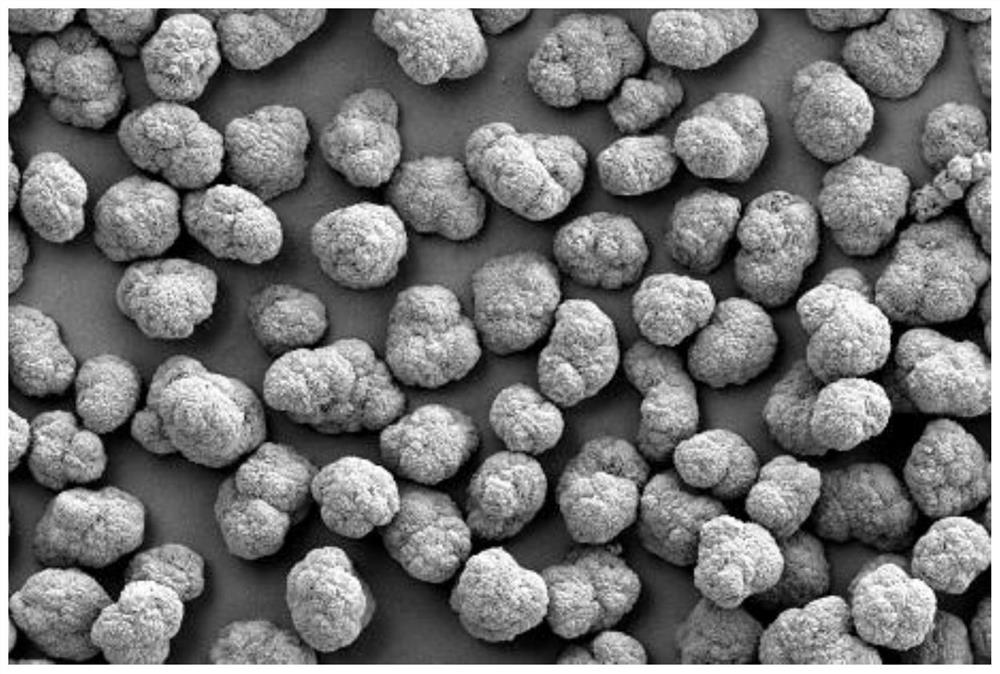

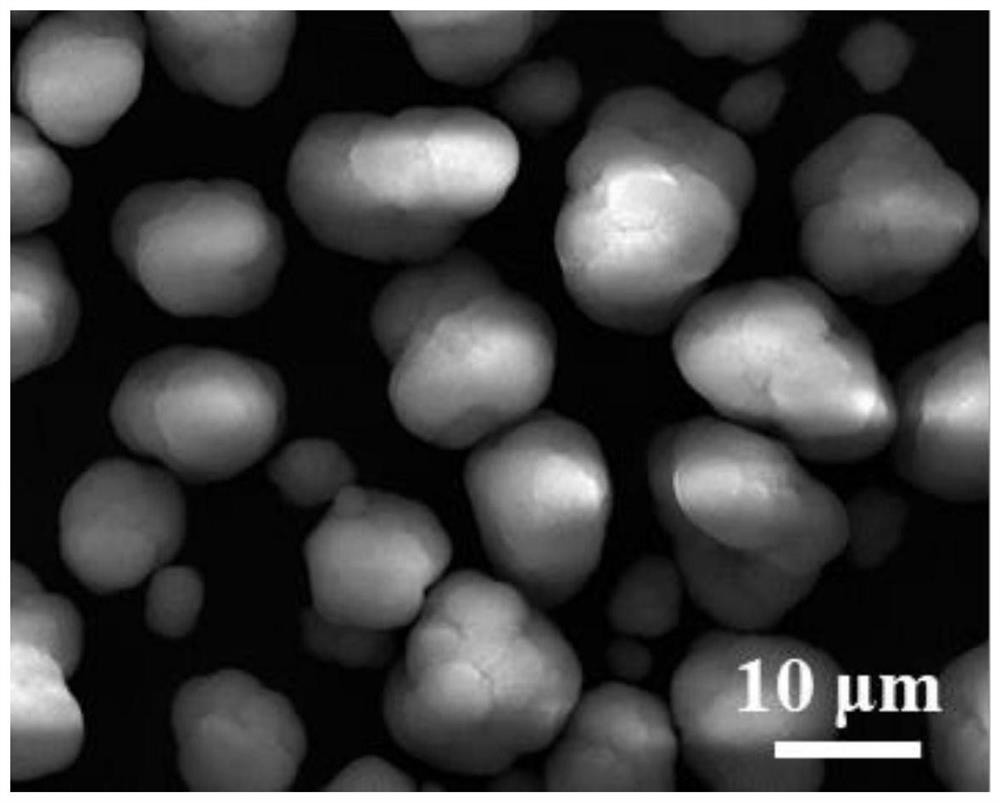

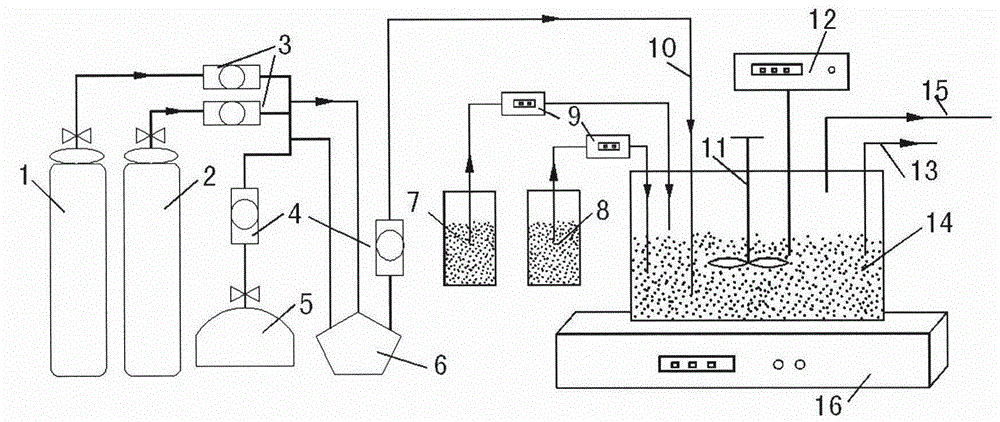

Method for preparing ternary positive electrode material of high-performance lithium ion battery at low ammonia concentration

InactiveCN111807425AReduced nucleation rateEasy reunionSecondary cellsPositive electrodesElectrical batteryManganese

The invention discloses a method for preparing a ternary positive electrode material of a high-performance lithium ion battery at low ammonia concentration, and belongs to the technical field of positive electrode materials of lithium ion batteries. The method comprises the following steps: dissolving salt containing nickel, cobalt and manganese in deionized water to prepare a mixed salt solution,adding a complexing agent into the mixed salt solution, adding acid to obtain a mixed solution; continuously pumping the mixed solution and the NaOH solution into a continuous coprecipitation reaction kettle filled with bottom liquid ammonia water respectively, enabling the total ammonia concentration of the reaction kettle to be the same as the concentration of the bottom liquid ammonia water inthe reaction process, continuously reacting to obtain a precursor material, grinding and mixing the precursor material and LiOH.H2O, and sintering to obtain the lithiated ternary material. The prepared NCM622 material is good in morphology, complete in crystal structure and uniform in element distribution, the material has high discharge capacity, good cycling stability and rate capability, and atotal battery matched with graphite and a Si / C negative electrode also has good electrochemical performance.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Gypsum crystallization regulator suitable for wet type calcium-based flue gas desulphurization poisoning slurry

InactiveCN104147910AReduce mass transfer rateImprove the crystallization processDispersed particle separationSlurryContamination

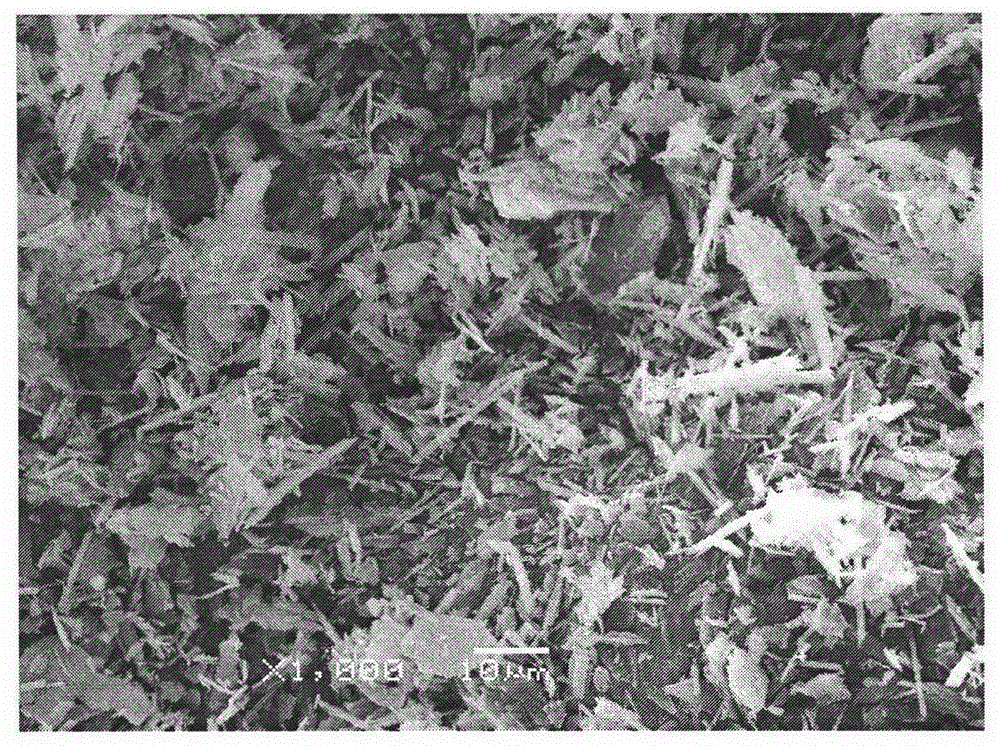

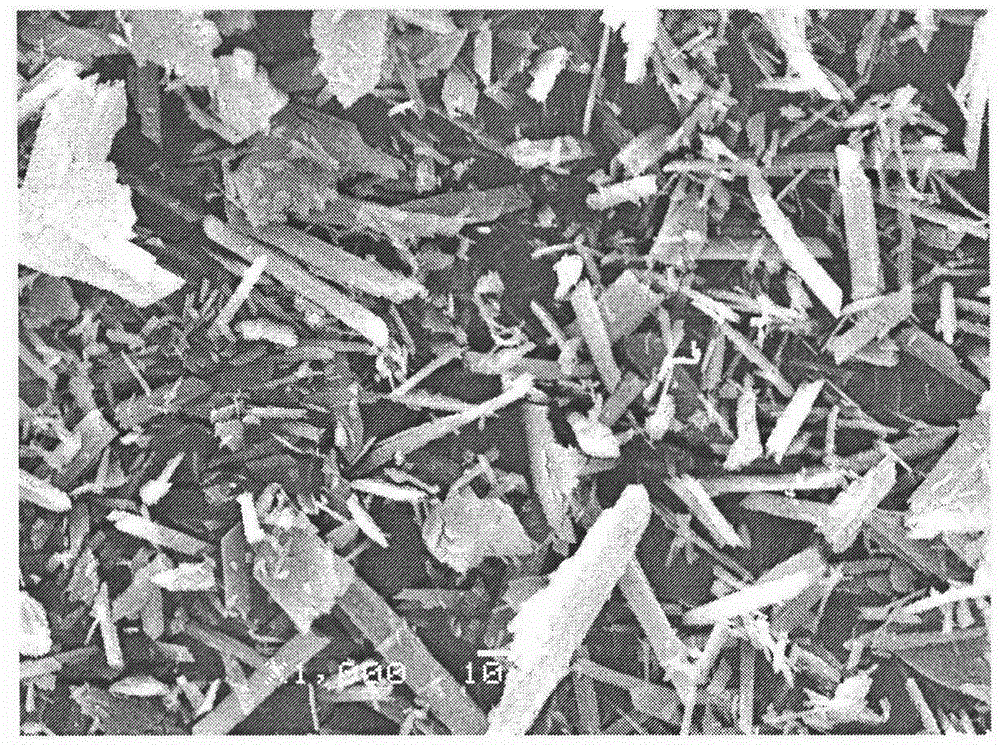

The invention discloses a gypsum crystallization modifier suitable for wet type calcium-based desulphurization of a thermal power generating unit, and the gypsum crystallization modifier can effectively eliminate the impact of heavy metal ions and oil contaminations in gypsum slurry on gypsum crystallization process to obtain gypsum crystals with coarse and large particles and low water content, increases stability of the desulfurization system, and belongs to the technical field of environmental protection. The gypsum crystallization modifier comprises the following components by weight: 0.1-5% of an oil-removing agent, 85-95% of a metal complexing agent and 5-10% of a surfactant, and is characterized in that the gypsum crystallization modifier can be directly added into an absorption tower or an absorption tower filtrate pit, then mixed evenly and dissolved for pumping. The gypsum crystallization modifier can accelerate the oxidation of sulfites and the gypsum crystallization process, is appropriate to improve the efficiency of the desulfurization system. In the embodiment, the gypsum crystallization modifier concentration is increased from 0% to 0.1%, the by-product gypsum purity is improved from 78% to 93%, the gypsum water content is reduced from 19% to 10%, the crystal size distribution is more uniform, acicular gypsum crystals are decreased, rhombic crystal share and columnar crystal share increase, the crystal specific surface area increases, and the gypsum dewatering performance is better.

Owner:NANJING INST OF TECH

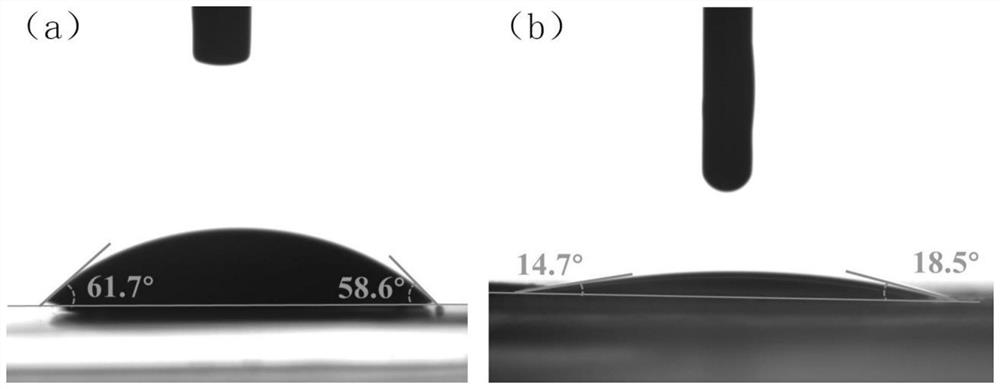

Preparation method of high-performance cellulose-based lithium ion battery diaphragm

ActiveCN113690539AImprove wettabilityFacilitate transmissionConjugated cellulose/protein artificial filamentsSecondary cellsLithium dendriteOrganosolv

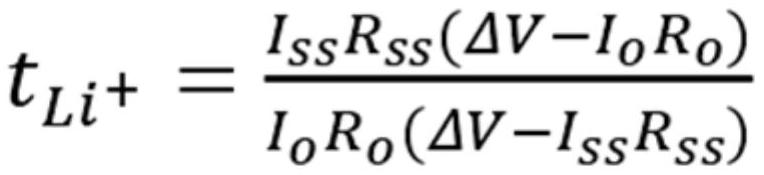

The invention discloses a preparation method of a high-performance cellulose-based lithium ion battery diaphragm, and belongs to the technical field of lithium ion batteries. The preparation method comprises the following steps: dispersing UIO-67 nanoparticles in an organic solvent, adding cellulose acetate (CA) and polyurethane (PU), and preparing a CA / PU / UIO-67 diaphragm by adopting an electrostatic spinning process. The CA / PU / UIO-67 diaphragm prepared by the method provided by the invention has the advantages of high lithium ion transference number, good thermal stability, uniform pore size distribution, smaller pore size and the like, and can effectively delay the nucleation rate of lithium dendrites and improve the electrochemical performance of a lithium ion battery.

Owner:NANJING FORESTRY UNIV

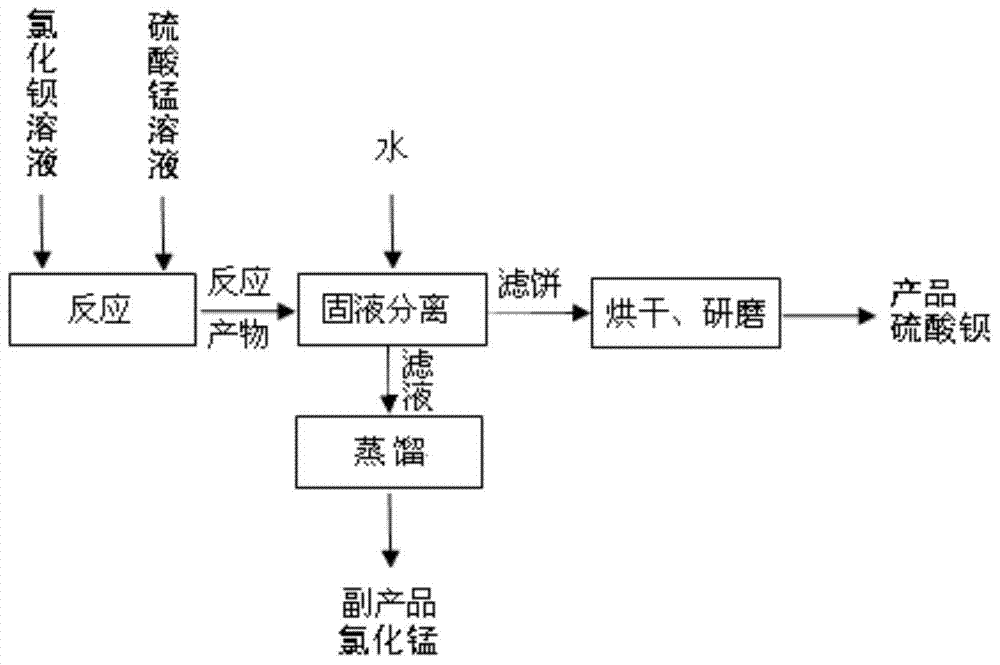

Method for producing precipitated barium sulfate and co-producing manganese chloride

ActiveCN104843760AAbundant resourcesSimple geological conditionsCalcium/strontium/barium sulfatesManganese halidesBarium dichlorideSulfate

The invention discloses a method for producing precipitated barium sulfate and co-producing manganese chloride. The method comprises the following steps: A, preparing a barium chloride solution; B, preparing a manganese sulfate solution; C, dipping the manganese sulfate solution prepared by the step B into the barium chloride solution prepared by the step A to perform replacement reaction; D, filtering the product after performing the replacement reaction by the step C, and respectively collecting filtrate and filter cakes; E, performing SO4<2-> decontamination on the filtrate collected by the step D, filtering the decontaminated filtrate, and distilling to obtain manganese chloride; F, rinsing the filter cakes collected by the step D till no chloride ion, baking the rinsed filter cakes in an oven, grinding and sieving to obtain barium sulfate. When precipitated barium sulfate is prepared, simultaneously a byproduct, namely manganese chloride is recovered. The byproduct is high in added value, the utilization rate of the energy is effectively increased, and relatively high economical benefits can be obtained.

Owner:河北日新化工有限公司

6061 aluminum alloy bar production method capable of eliminating coarse grain rings

PendingCN112725668ARaise the recrystallization temperatureIncrease reinforcement effectMechanical properties of carbon nanotubesMetallurgy

The invention discloses a 6061 aluminum alloy bar production method capable of eliminating coarse grain rings, and relates to the technical field of aluminum alloy machining. The technical problem that in an existing 6061 aluminum alloy bar production process, coarse grain rings frequently appear in the extrusion process, and consequently the physical performance of materials is obviously reduced is solved. The method comprises the steps of cast ingot casting, cast ingot heating, an extrusion process, bar quenching, stretching straightening and bar artificial aging. The aluminum alloy product extruded by the method has no coarse grain ring structure defect, various performance indexes meet the standard requirements, the mechanical property of the material is improved, the bearing capacity, the service life and the use safety of the material are improved, and the use risk of the material is reduced. The method is used for preparing 6061 aluminum alloy bars.

Owner:NORTHEAST LIGHT ALLOY CO LTD

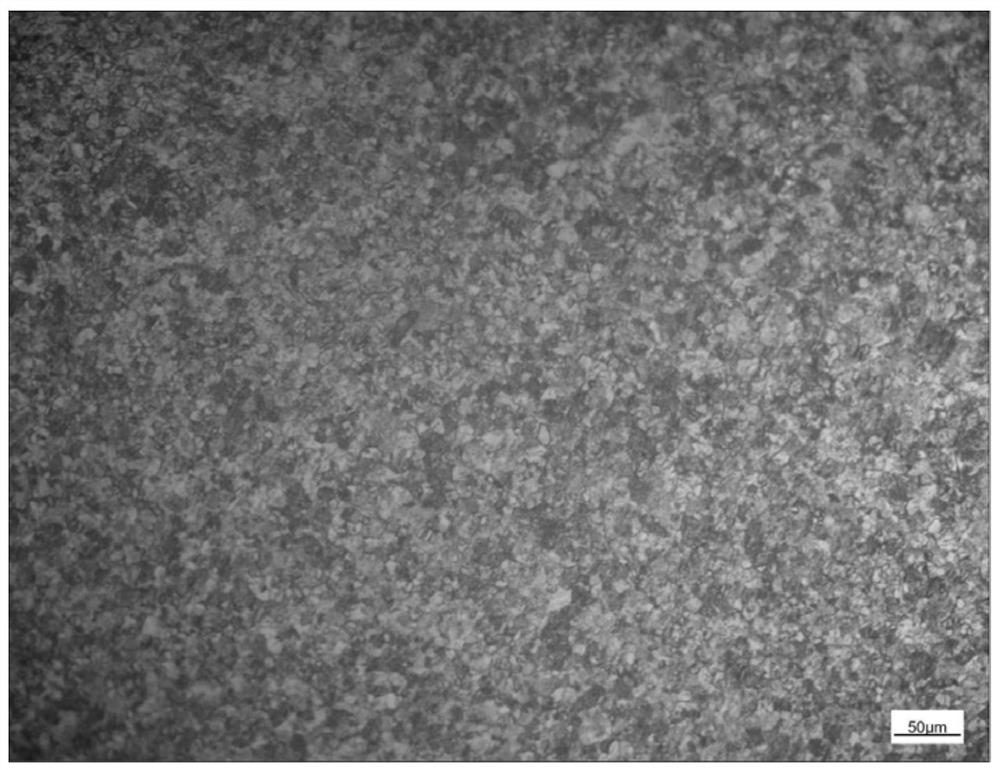

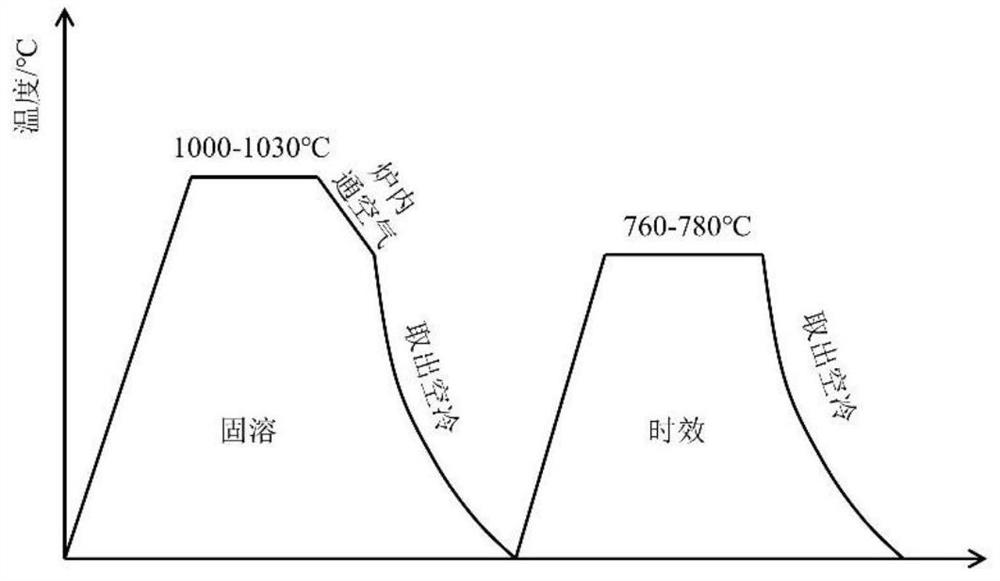

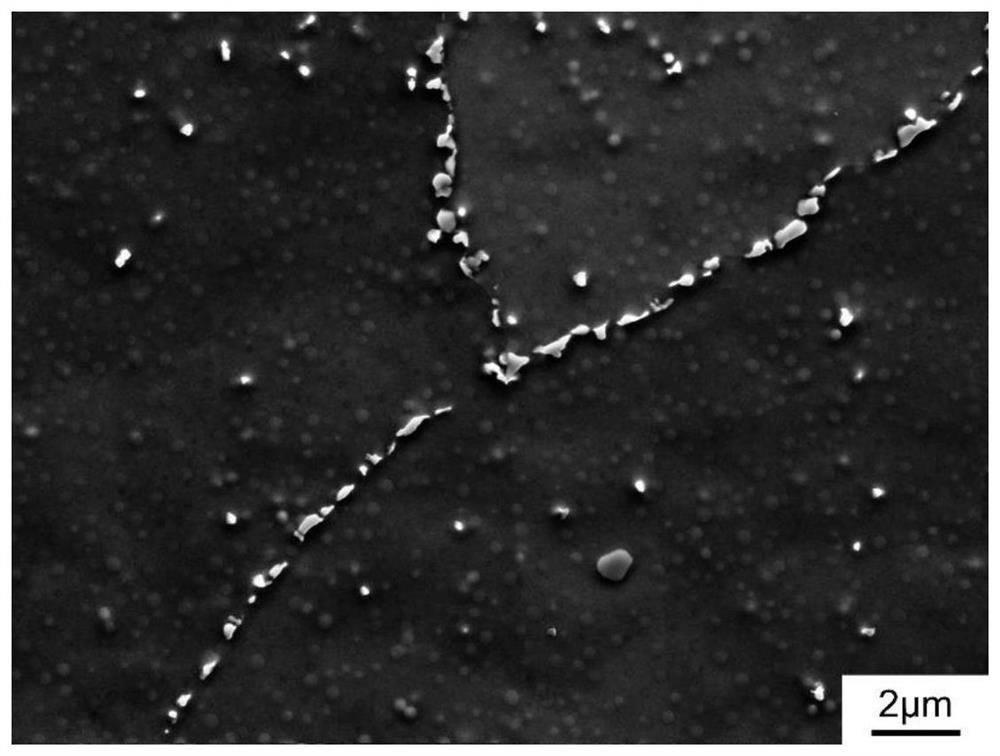

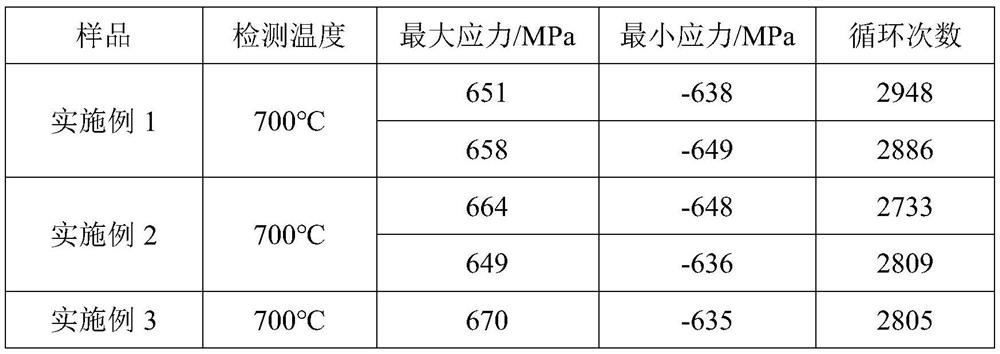

Heat treatment process for prolonging fatigue life of GH4738 alloy

The invention discloses a heat treatment process for prolonging the fatigue life of a GH4738 alloy, and belongs to the technical field of high-temperature alloy heat treatment. The process comprises the following steps that solution treatment is carried out on the GH4738 alloy under the condition that the temperature is 1000-1030 DEG C, and slow cooling and discharging air cooling are carried out in sequence; and then aging treatment is carried out at the temperature of 760-780 DEG C, and discharging air cooling is carried out to the room temperature. According to the heat treatment process, grain boundary carbide distribution in a matrix is optimized, the fatigue cycle of the alloy under the fatigue test condition is increased by 36% or above, the fatigue life of the GH4738 alloy is greatly prolonged, and then the service safety of alloy parts is improved. The heat treatment process is obvious in technical advantage and wide in market popularization prospect.

Owner:UNIV OF SCI & TECH BEIJING

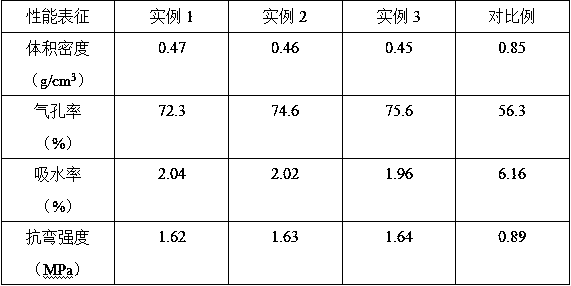

Preparing method of microcrystalline foam glass

InactiveCN108503226AStabilize the porous structureReduced nucleation rateGlass shaping apparatusSlagFoam glass

The invention relates to a preparing method of microcrystalline foam glass, and belongs to the technical field of energy-saving building materials. Coal ash serves as the raw material for producing the microcrystalline foam glass, TiO2 in high-titanium blast furnace slag is sufficiently used as the nucleation agent, the nucleation speed of glass crystallization is reduced, and a large amount of tiny CaTi21O38 crystal nucleus is formed by well mixing and dissolving the glass; a foaming agent (calcium carbonate) is wrapped by a small amount of molten material to form a bubble cavity, when the foaming time is prolonged, the heat absorbed by calcium carbonate is increased, calcium carbonate starts to be decomposed to generate a large amount of gas, the temperature in the decomposition reactionof calcium carbonate is basically consistent with the softening temperature of the basic glass material, the viscosity of the glass material is reduced, the gas pressure in the bubble is increased, the gas wall starts to be thinned and the size of the bubble is increased when the gas pressure in the bubble is larger than the surface tension of the glass material so that a bubble with a certain diameter can be formed, and the microcrystalline foam glass of the stable porous structure is formed through cooling after the foaming process ends.

Owner:史茜赟

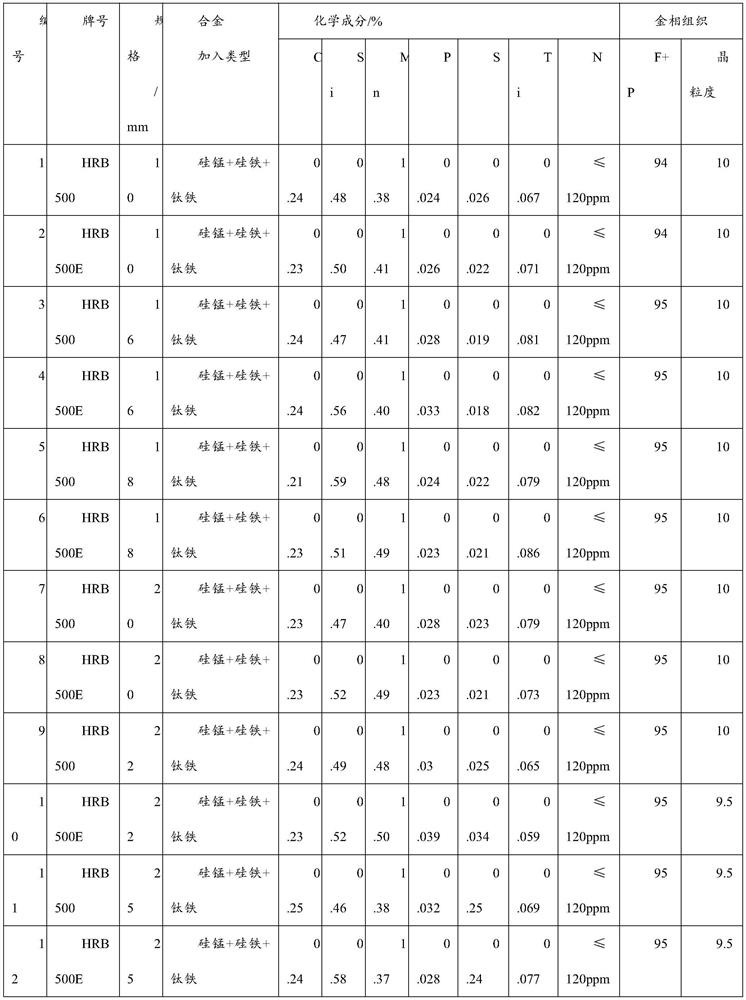

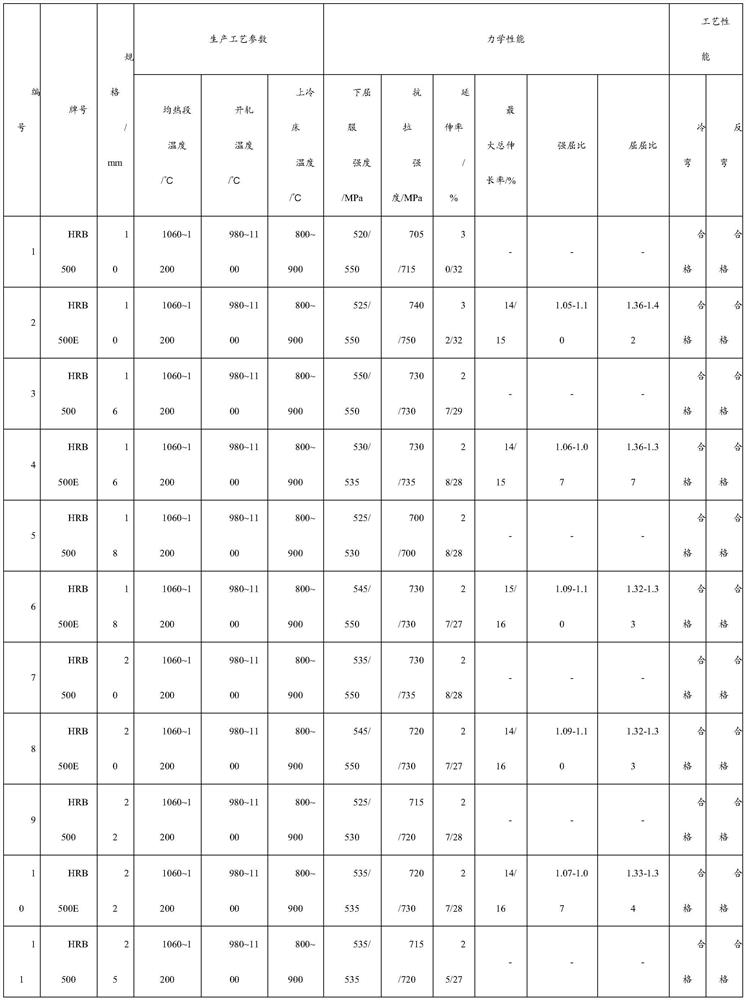

Economical 500MPa-grade steel bar and preparation method thereof

The invention discloses an economical 500MPa-grade steel bar and a preparation method thereof. The economical 500MPa-grade steel bar comprises 0.20-0.25 wt% of C, less than or equal to 1.60 wt% of Mn,less than or equal to 0.80% of Si, less than or equal to 0.045% of P, less than or equal to 0.045% of S, more than or equal to 0.05% of Ti and the balance iron and inevitable impurity elements. The key Si content of the preparation method is achieved by silicomanganese and ferrosilicon alloy, and ferrotitanium is added in the tapping process; and compared with an existing 500 MPa-grade traditional vanadium and niobium hot rolling process, the alloy consumption is low, no precious metal element is contained, economical efficiency is achieved, and the cost can be reduced.

Owner:ZHANGJIAGANG RONGSHENG SPECIAL STEEL CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com