Preparing method of microcrystalline foam glass

A microcrystalline foaming and glass technology, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of limited content and difficulty in preparation density, and achieve the effect of low density and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

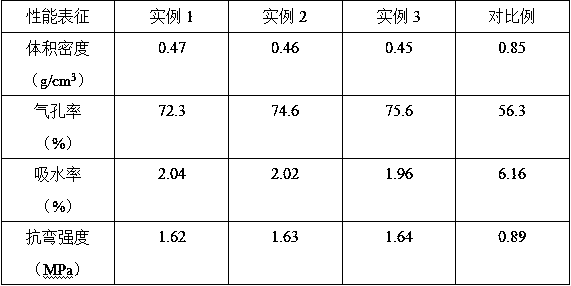

Examples

Embodiment Construction

[0021] Take 60-80g fly ash, 10-20g high-titanium blast furnace slag, 15-20g quartz sand, 12-15g feldspar, 12-15g borax, 3-4g sodium nitrate, 3-3.5g cryolite, 0.5-0.8g Sodium fluorosilicate, 2.5~3.0g calcium fluoride, 4.0~4.5g sodium carbonate, put into a ball mill and mill for 2~3 hours, after the ball milling, put it into an alumina crucible, heat-preserve and melt at 1200~1300℃ for 1~2 hours , and then pour the molten liquid into deionized water for water quenching, take out the water-quenched particles and place them in a drying oven, dry them at 200-240°C for 2-3 hours, put them into a grinder and grind them, and pass through a 120-mesh sieve to obtain a glass-based Material powder, take 90-95g glass base powder, 1-2g calcium carbonate, 4-6g sodium phosphate, put them into a ball mill and mill for 20-30min to obtain a composite material, take 3-5g alumina, 2-3g quartz sand, 1.2-1.5g red mud, 1.0-1.2g montmorillonite, 0.5-1.0g deionized water, mix evenly and apply on the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com