Method for carrying out thermoelectric chemical oxidation on surface of titanium alloy and electrolyte

A thermoelectrochemical, titanium alloy technology, applied in surface reaction electrolytic coatings, electrolytic coatings, electrolytic processes, etc., can solve problems such as lack of biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

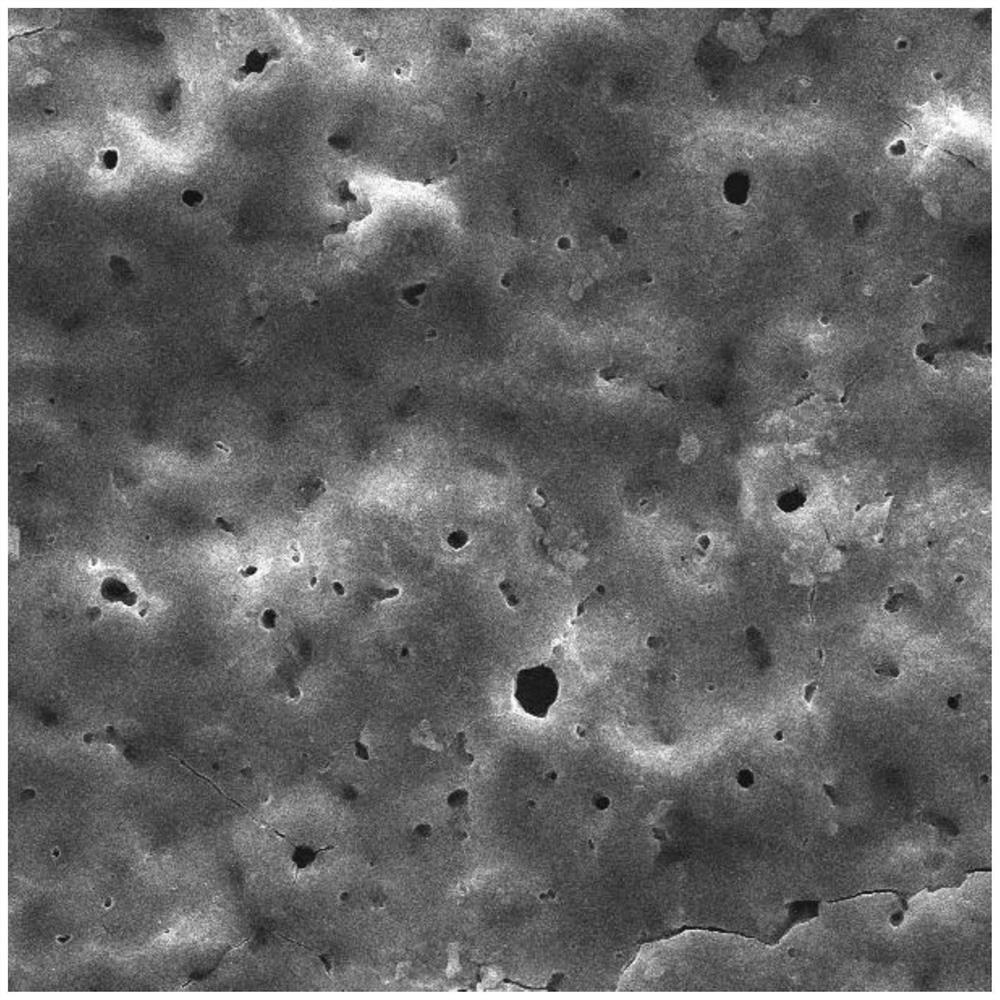

Image

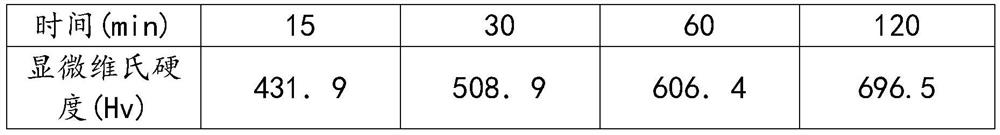

Examples

Embodiment 1

[0037]A method of thermoelectrochemically oxidation on the surface of a titanium alloy surface, and a biochemical oxidation of titanium alloys has a bio-coating having a selenium-containing bio-coating in situ, wherein the electrochemically oxidized electrolyte comprises: Na2SEO3, Glycerin, KOH, NA3PO4NA2SiO3, H2O2And deionized water, thermoelectric chemical oxidation of power supply is a DC pulse power supply, the voltage of the flow pulse power supply is 200V-350V, the frequency is 50 Hz, the current density is 0.1A / DM2-0.4a / dm2The duty cycle is 30%.

[0038]All components of the electrolyte, NA2SEO3The concentration of 1.6 mg / L, the concentration of glycerol was 2 g / L, and the concentration of KOH was 4g / L, NA3PO4The concentration is 4.5g / L, NA2SiO3The concentration is 9 g / l, h2O2The concentration is 6 g / l. The titanium alloy is a low modulus beta titanium alloy, and the osteogenic activity of low modulus β titanium alloy is good. The low modulus titanium alloy is Ti...

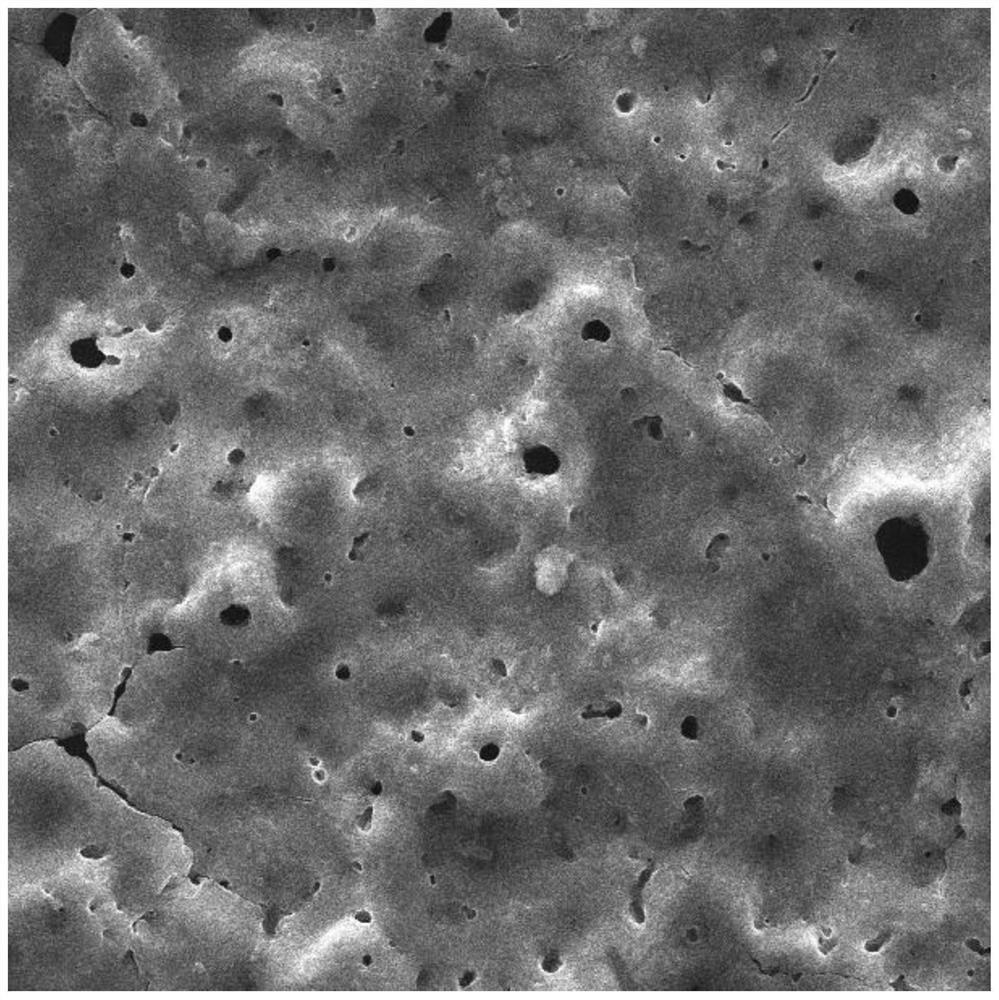

Embodiment 2

[0046]An electrolyte of thermoelectrochemically oxidation of titanium alloy surfaces, including: NA2SEO3, Glycerin, KOH, NA3PO4NA2SiO3, H2O2And deionized water, for the use of thermoelectric oxidation of titanium alloys to grown in the titanium alloy surface in situ having selenium-oriented biocarbon, using the electrolyte to thermoelectrochemically oxidize the titanium alloy, its power supply is 200V-350V, Frequency 50 Hz, current density is 0.1A / DM2-0.4a / dm2, Duty cycle is 30% DC pulse power supply.

[0047]All components of the electrolyte, NA2SEO3The concentration of 1.7 mg / L, the concentration of glycerol was 2.5 g / L, and the concentration of KOH was 4g / L, NA3PO4The concentration is 4.5g / L, NA2SiO3The concentration is 9.2g / L, h2O2The concentration was 6.5 g / L. The titanium alloy is a low modulus beta titanium alloy, and the osteogenic activity of low modulus β titanium alloy is good. The low modulus titanium alloy is Ti-35NB-7ZR-5TA.

[0048]When the thermoelectric ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com