Gas storage device using high-specific surface area porous organic material and device for adsorptively absorbing chemical species

A technology of porous organic materials and high specific surface area, applied in the direction of gas/liquid distribution and storage, through adsorption, other chemical processes, etc., to achieve high chemical and physical stability and the effect of stabilizing the porous structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

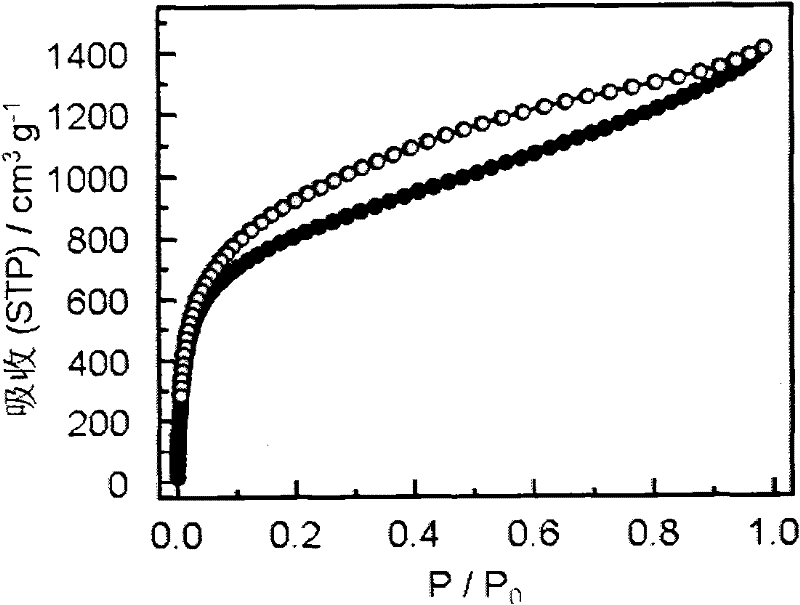

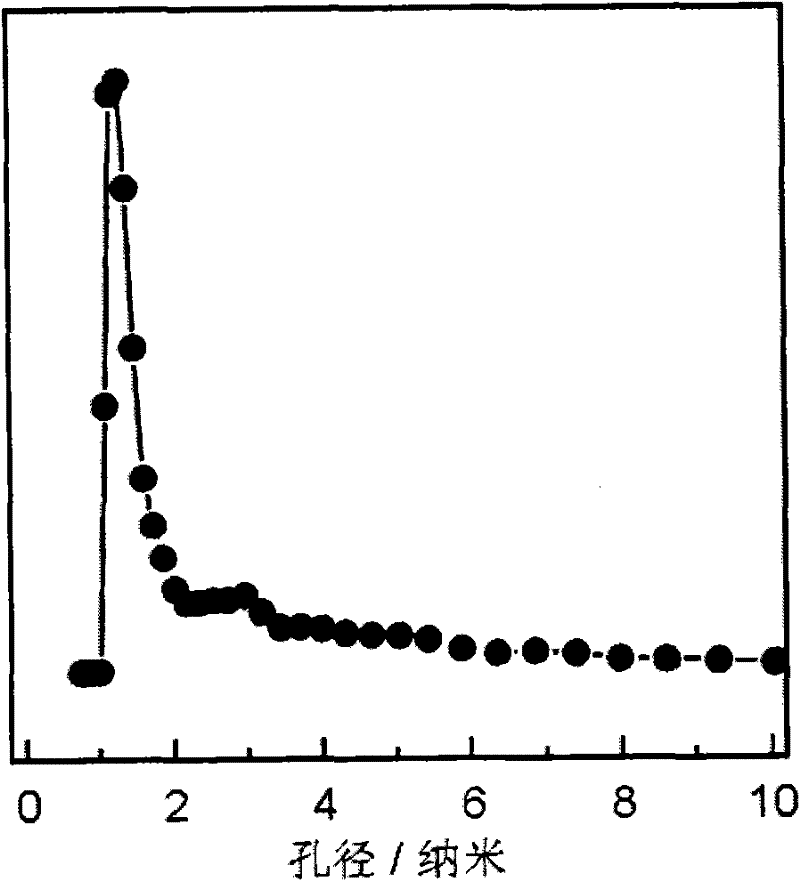

[0065] Low pressure (0-1 atmosphere) argon adsorption measurement of polytetraphenylene silicon and polytetraphenyl germanium at 87K:

[0066] The polytetraphenyl silicon and polytetraphenyl germanium samples were soaked in chloroform and stirred, filtered after half an hour, replaced with new chloroform, and reciprocated four times to remove the solvent and aerosol included in the pores of the material during synthesis. starting material. Load the processed material into an ampoule, then heat it to 80-200°C for 4-40 hours under an oil pump (vacuum degree less than 10-3 mmHg) and vacuumize for 4-40 hours, and backfill the sample with nitrogen to exclude the adsorption of argon Moisture sorption prior to measurement.

[0067] The provided polytetraphenylsilicon and polytetraphenylgermanium have functionalized pores and high specific surface area, which in this example act as adsorbents for argon. Unlike nitrogen, because argon is an inert molecule and is spherical, this kind ...

Embodiment 2

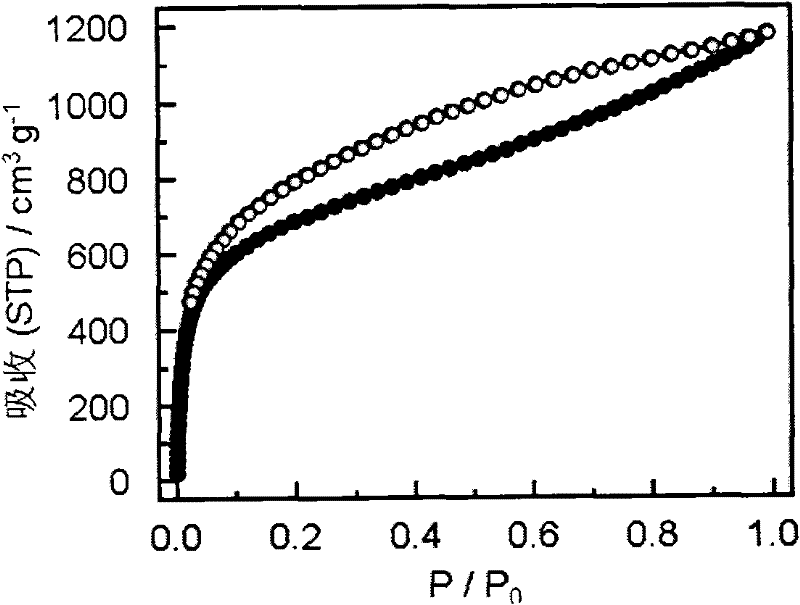

[0071] Low pressure (0-1 atm) hydrogen adsorption measurements on polytetraphenylene silicon and polytetraphenyl germanium at 77K and 87K:

[0072] Polytetraphenylsilicon and polytetraphenylgermanium samples were immersed in chloroform and stirred, filtered after half an hour, replaced with new chloroform, and reciprocated four times to remove the solvent and starting material included in the pores of the material during synthesis. Material. Load the processed material into an ampoule, then heat to 80-200°C under an oil pump (vacuum degree less than 10-3 mmHg) and vacuumize for 4-40 hours, and backfill the sample with nitrogen to exclude it from the hydrogen adsorption measurement previous moisture adsorption.

[0073] Polytetraphenylsilicon and polytetraphenylgermanium sample activation steps:

[0074] 50 milligrams of polytetraphenylsilicon or polytetraphenylgermanium utilize the pretreatment device of ASAP 3020 specific surface area and pore size analyzer to test the sample...

Embodiment 3

[0076] Low pressure (0-1 atm) carbon dioxide gas adsorption measurements on polytetraphenylene silicon and polytetraphenyl germanium at 298K and 273K:

[0077] Polytetraphenylsilicon and polytetraphenylgermanium samples were immersed in chloroform and stirred, filtered after half an hour, replaced with new chloroform, and reciprocated four times to remove the solvent and starting material included in the pores of the material during synthesis. Material. Load the processed material into an ampoule, then heat to 80-200°C under an oil pump (vacuum degree less than 10-3 mmHg) and vacuumize for 4-40 hours, and backfill the sample with nitrogen to exclude the carbon dioxide adsorption measurement previous moisture adsorption.

[0078] Polytetraphenylsilicon and polytetraphenylgermanium sample activation steps:

[0079] 50 milligrams of polytetraphenylsilicon or polytetraphenylgermanium utilize the pretreatment device of ASAP 3020 specific surface area and pore size analyzer to tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com