Preparation method of high voltage resistant polymer solid electrolyte membrane and preparation method of lithium ion battery

A solid electrolyte membrane and polymer technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, solid electrolytes, etc., can solve problems such as differences in initial charge and discharge capacity, achieve electrochemical stability and improve mechanical properties, and have wide application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1 of the present invention is a method for preparing a high-voltage polymer solid electrolyte membrane. Add functionalized HO-PPG500-OH and crosslinking agent NCO-PPO2300-NCO to chloroform, react for the first preset time, and pour Cross-linked into a film in the mold.

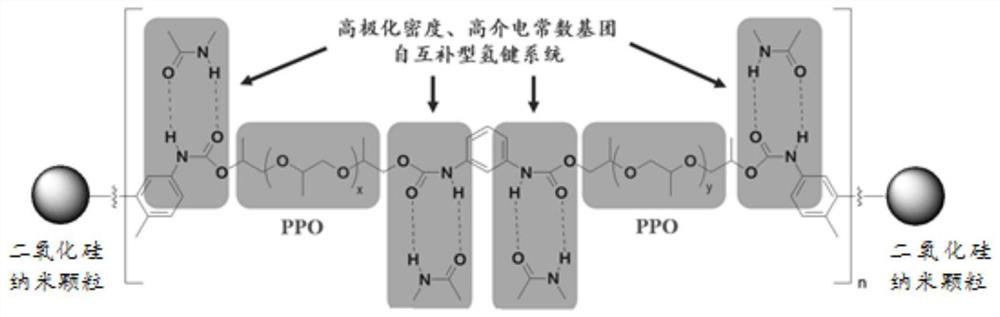

[0039] Such as figure 1 As shown, a highly cross-linked polymer solid electrolyte membrane was synthesized, and the carbamate group -NHCOO- formed by the reaction of -NCO and -OH was introduced into the polymer solid electrolyte membrane, and the carbamate group -NHCOO -With high dielectric constant and polarization density, and a strong hydrogen bond system formed in the entire polymer solid electrolyte membrane system, the electrochemical stability window of the electrolyte made of this polymer solid electrolyte membrane can reach 5V, and the electrochemical The stability and mechanical properties have been significantly improved, and it has broad application prospects in the field of lithium...

Embodiment 2

[0040] Example 2 of the present invention is a method for preparing a high-voltage polymer solid electrolyte membrane. On the basis of Example 1, the preparation method specifically includes the following steps:

[0041] Step 1, react functionalized HO-PPG500-OH with a type of silane coupling agent to generate silanized polypropylene glycol PPG500; wherein, a type of silane coupling agent such as: 3-isocyanopropyltriethoxysilane IPTS;

[0042]Step 2, cross-linking the silanized polypropylene glycol PPG500 with silica sol to generate silicon dioxide-based polypropylene glycol PPG500;

[0043] Step 3, adding the silicon dioxide-based polypropylene glycol PPG500 and the cross-linking agent NCO-PPO2300-NCO into chloroform, reacting for the first preset time, and then pouring into a mold to cross-link to form a film.

Embodiment 3

[0044] Example 3 of the present invention is a method for preparing a high-voltage resistant polymer solid electrolyte membrane. On the basis of Example 2, the step 1 is specifically: dissolving the functionalized HO-PPG500-OH in tetrahydrofuran THF, and sequentially Nitrogen is passed into the tetrahydrofuran THF, the catalyst dibutyltin dilaurate DBTDL is added, and a type of silane coupling agent is added to react to generate silanized polypropylene glycol PPG500.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com