Patents

Literature

193 results about "Polarization density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In classical electromagnetism, polarization density (or electric polarization, or simply polarization) is the vector field that expresses the density of permanent or induced electric dipole moments in a dielectric material. When a dielectric is placed in an external electric field, its molecules gain electric dipole moment and the dielectric is said to be polarized. The electric dipole moment induced per unit volume of the dielectric material is called the electric polarization of the dielectric.

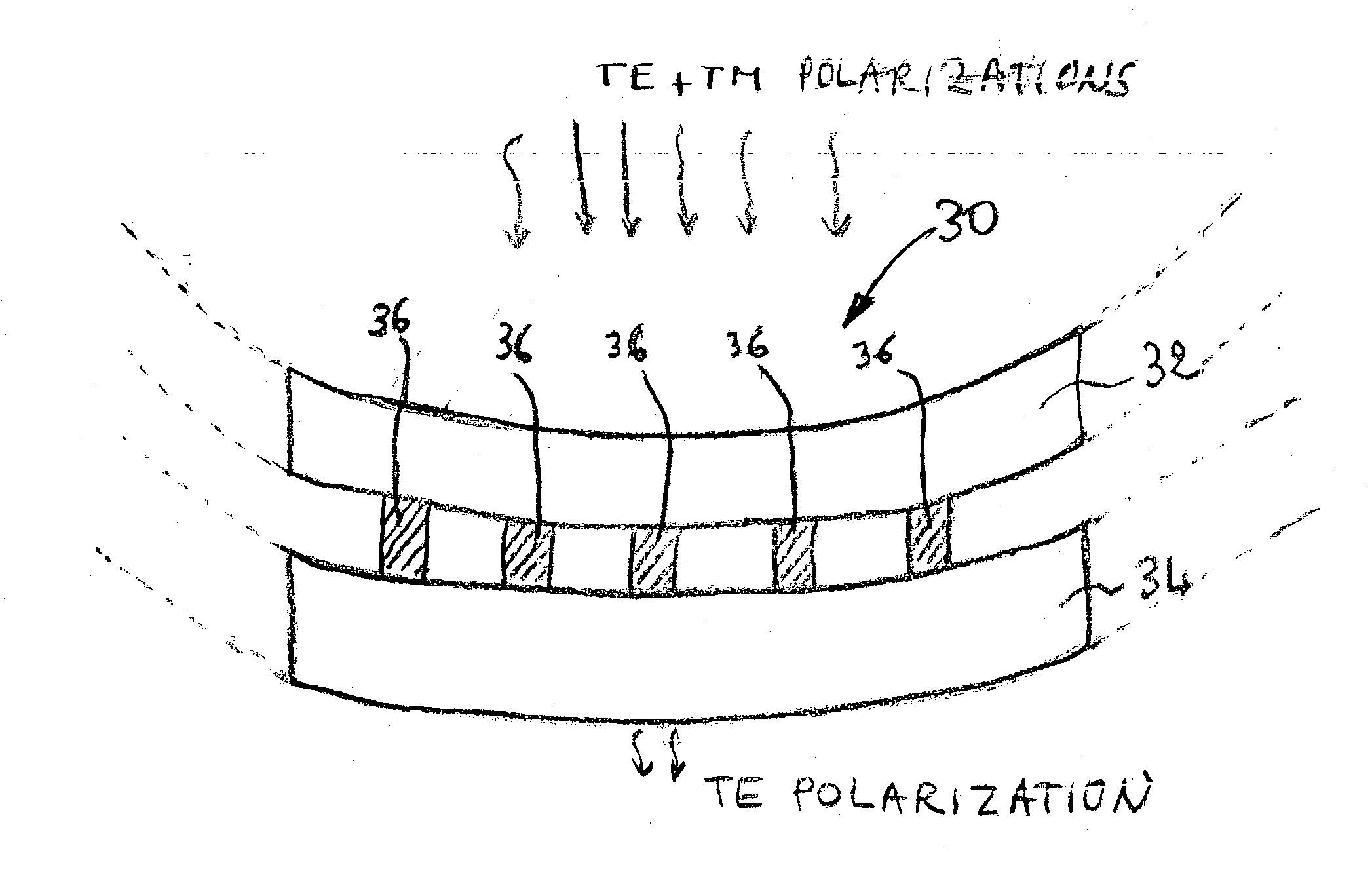

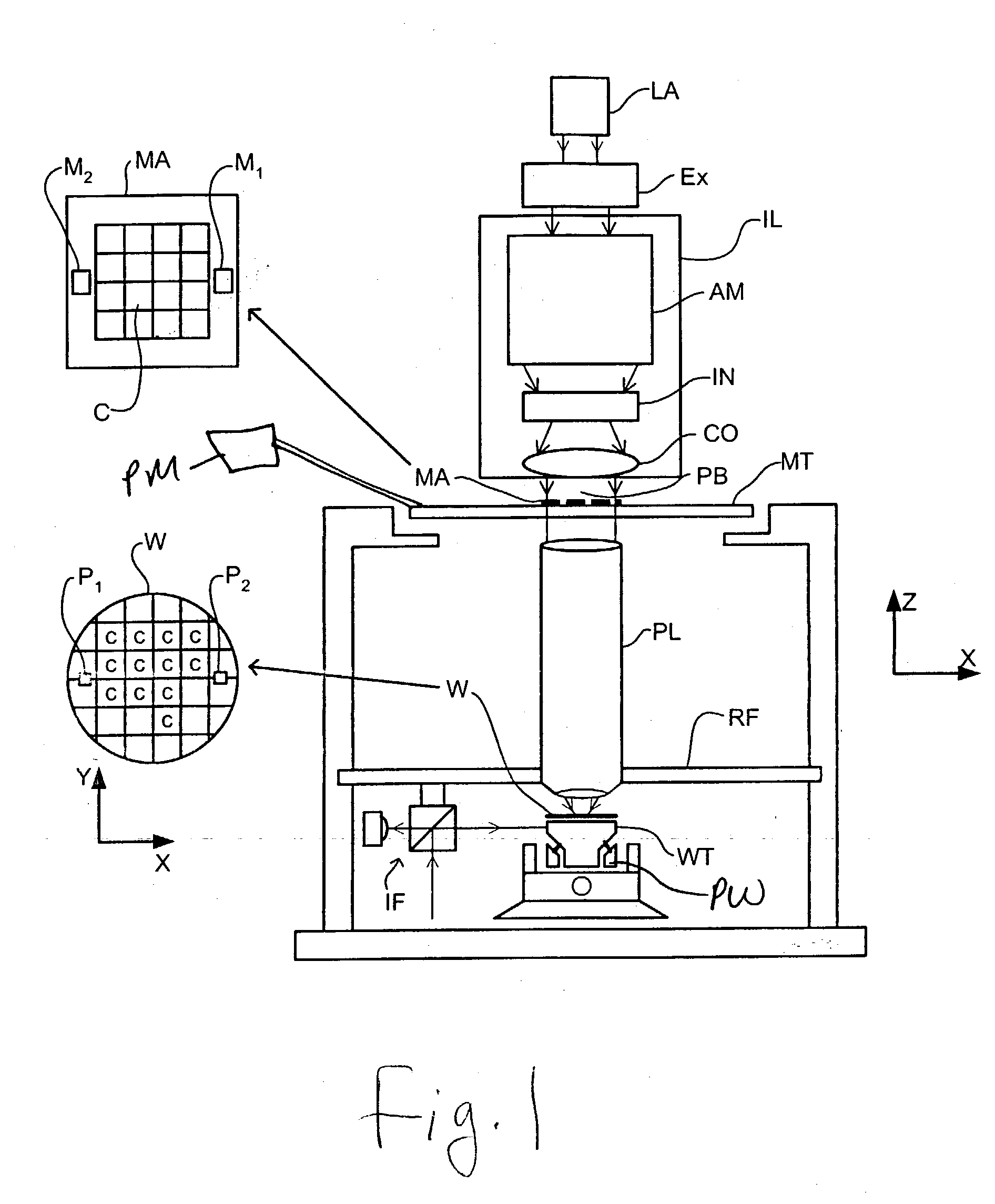

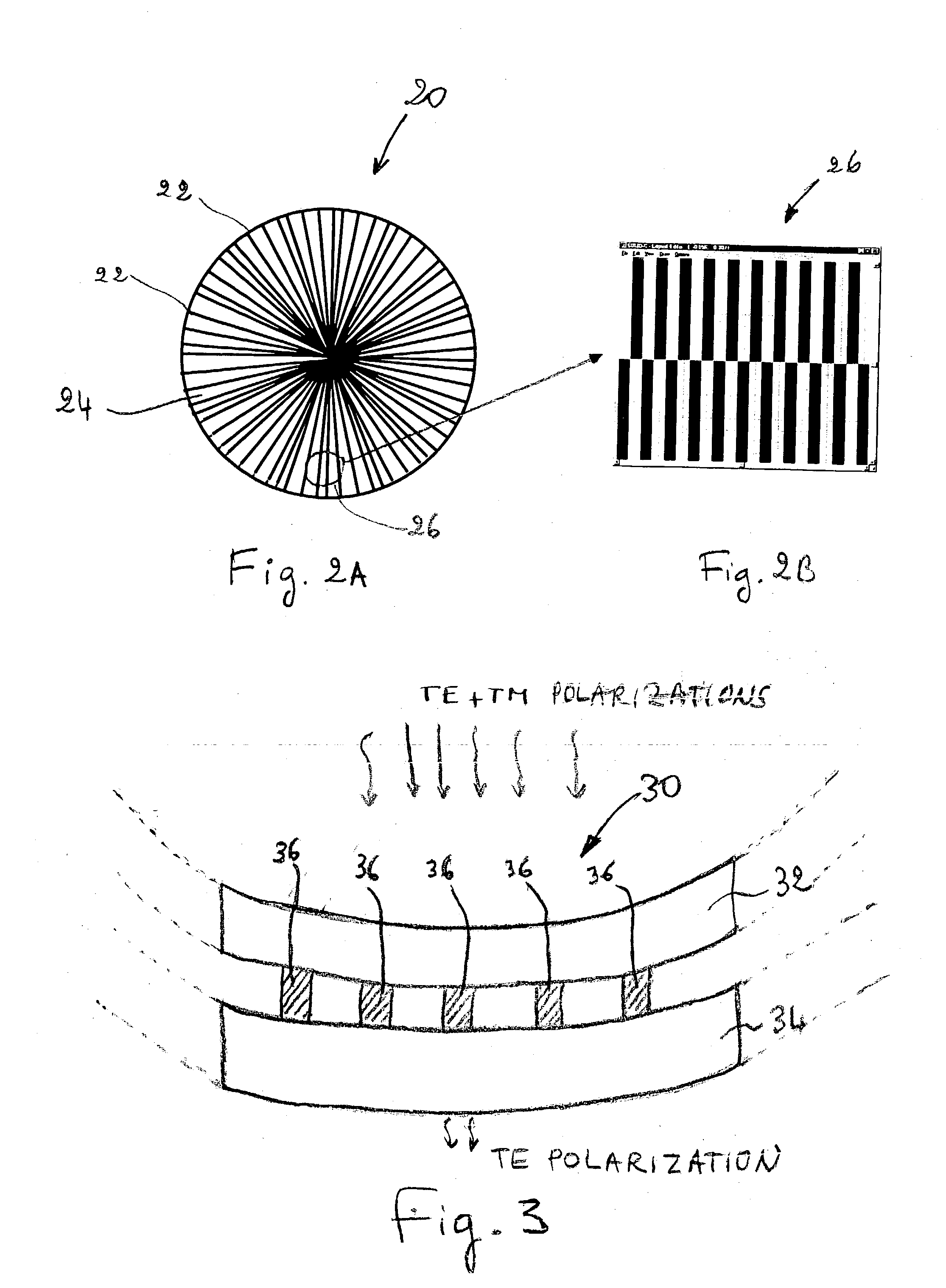

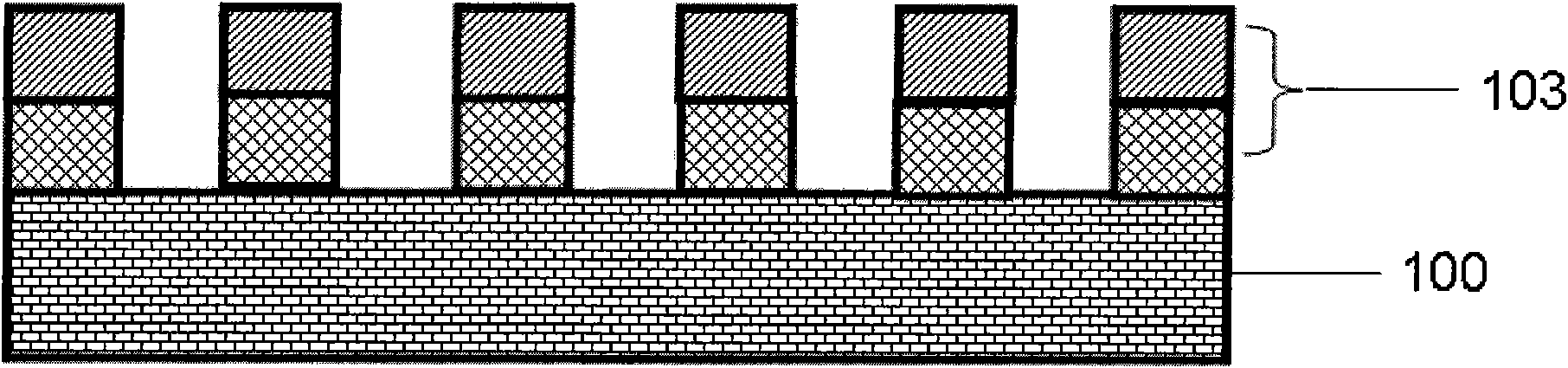

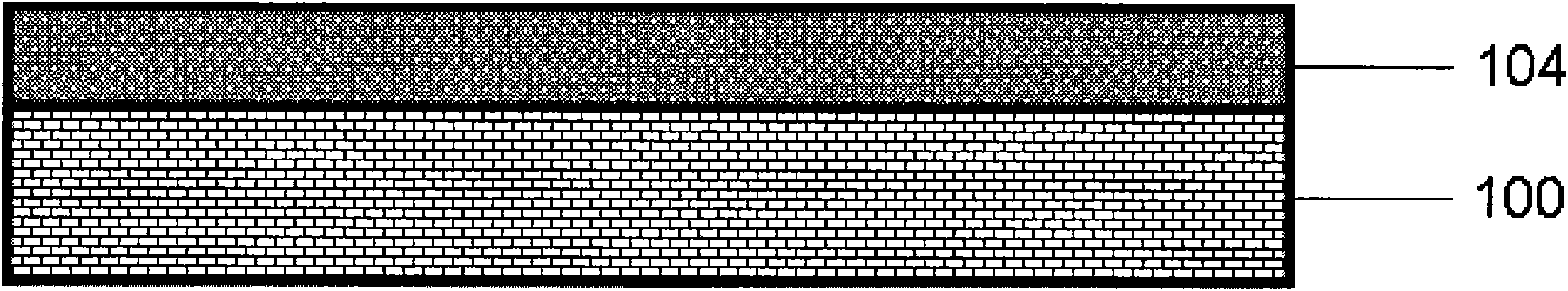

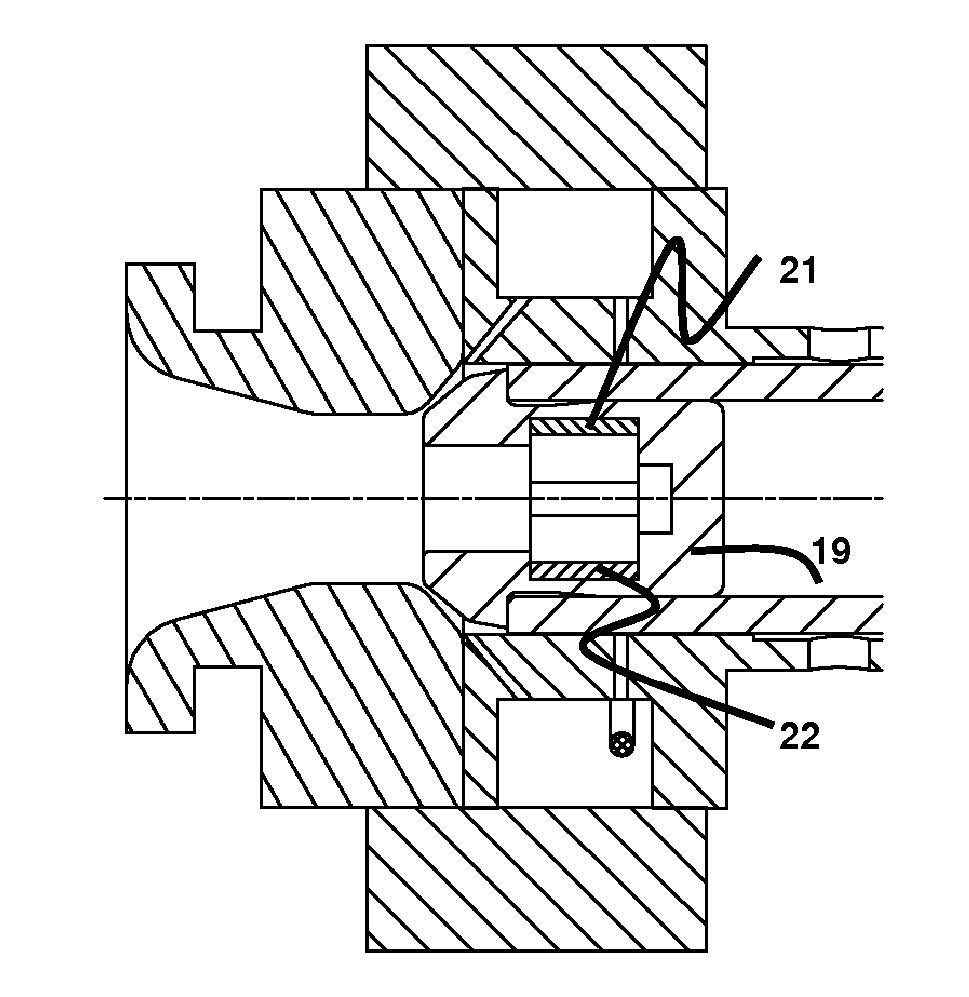

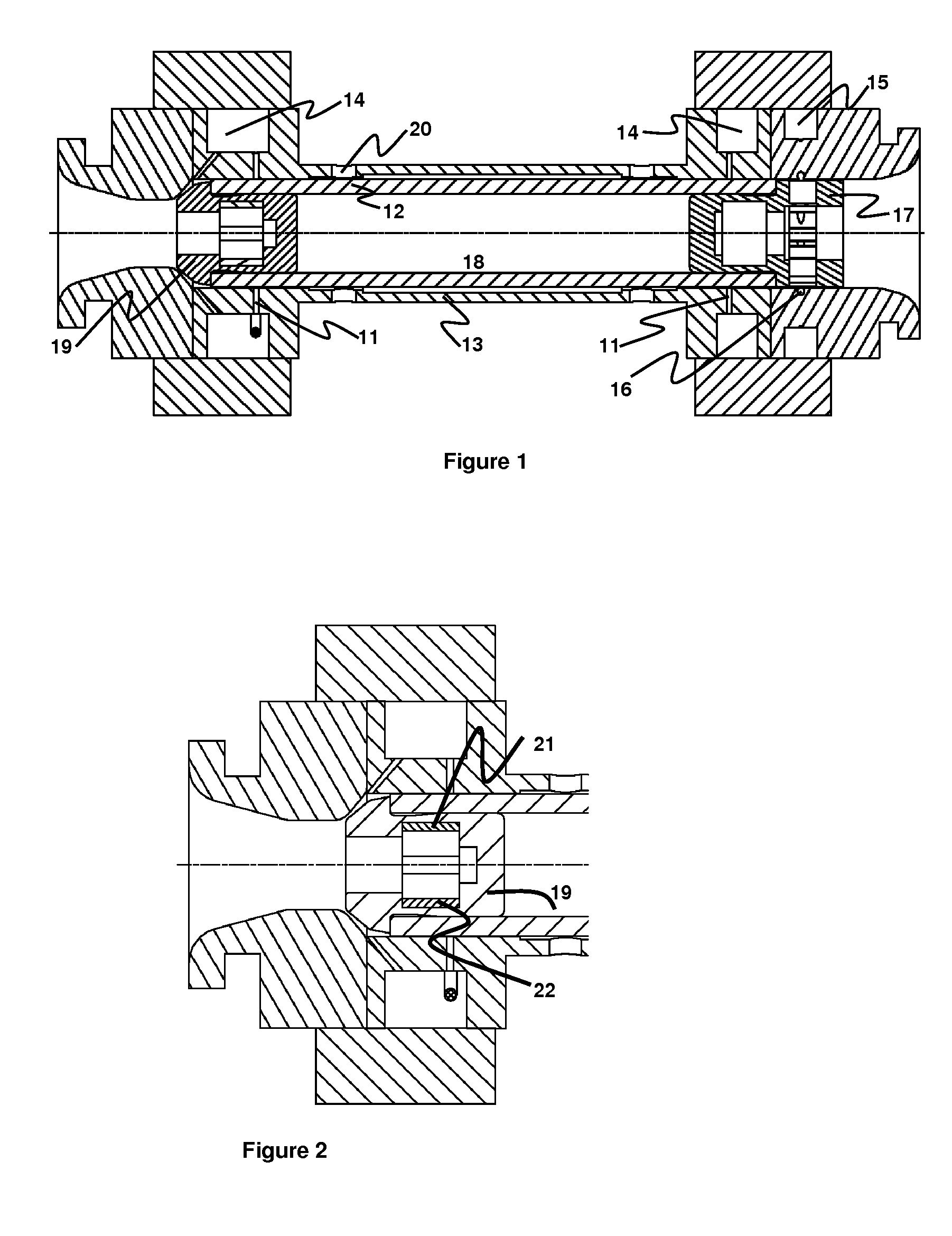

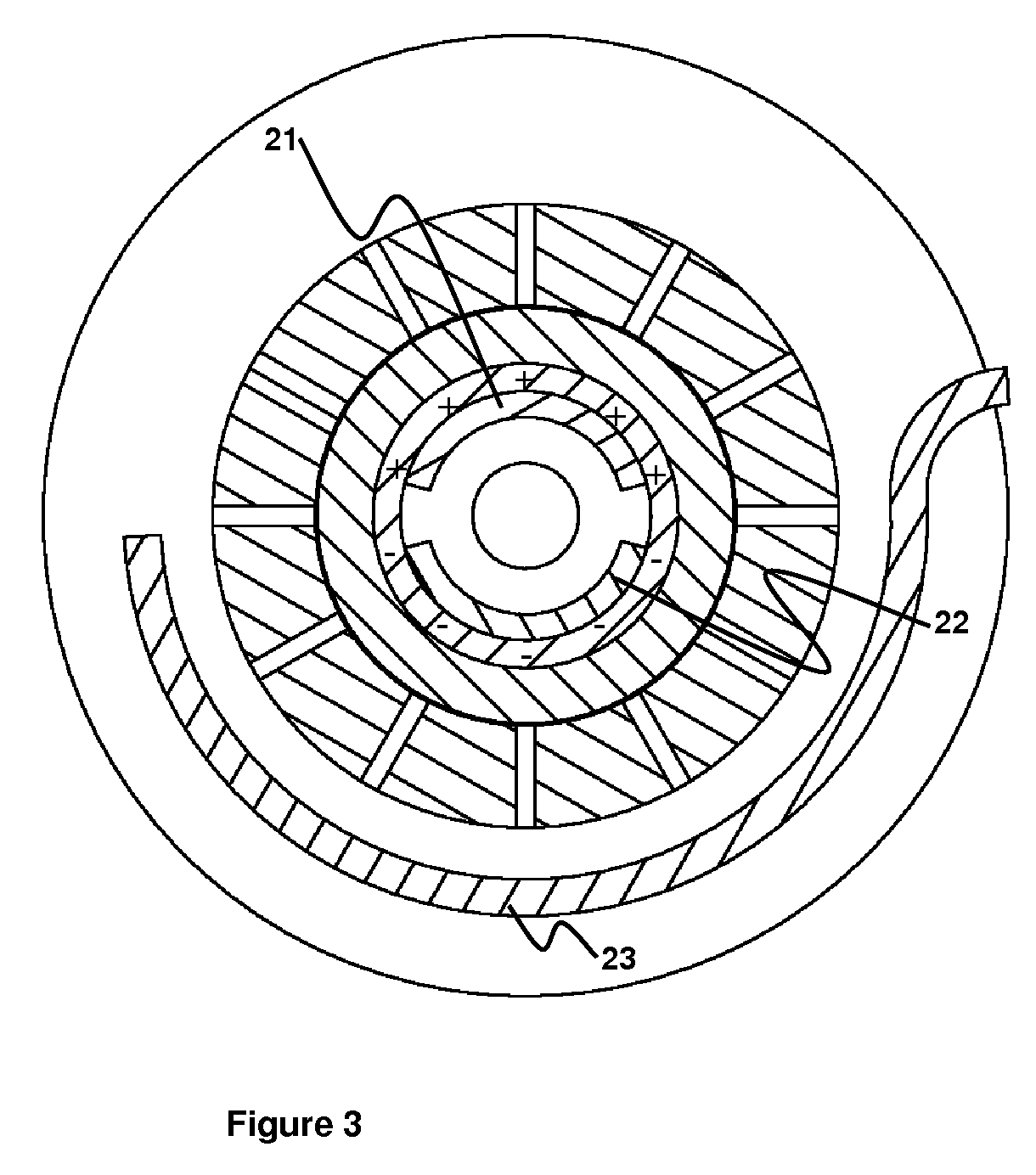

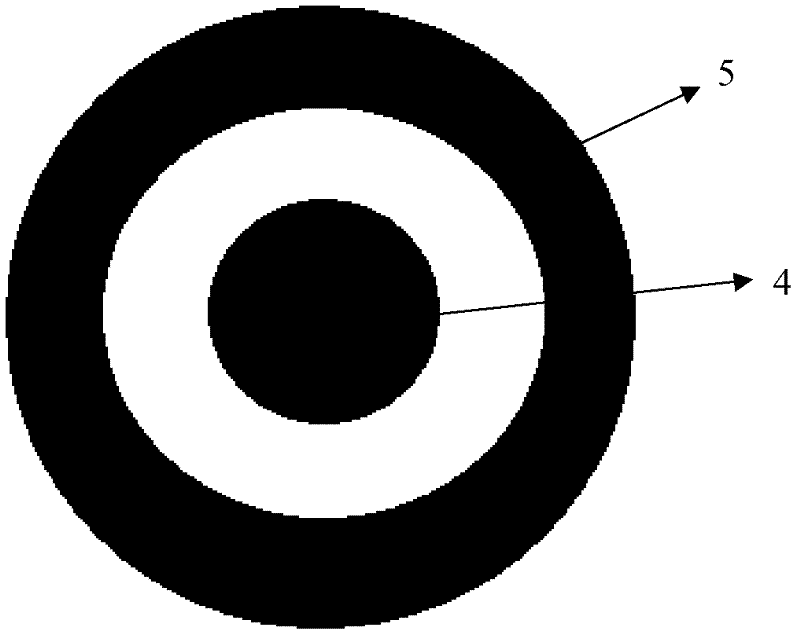

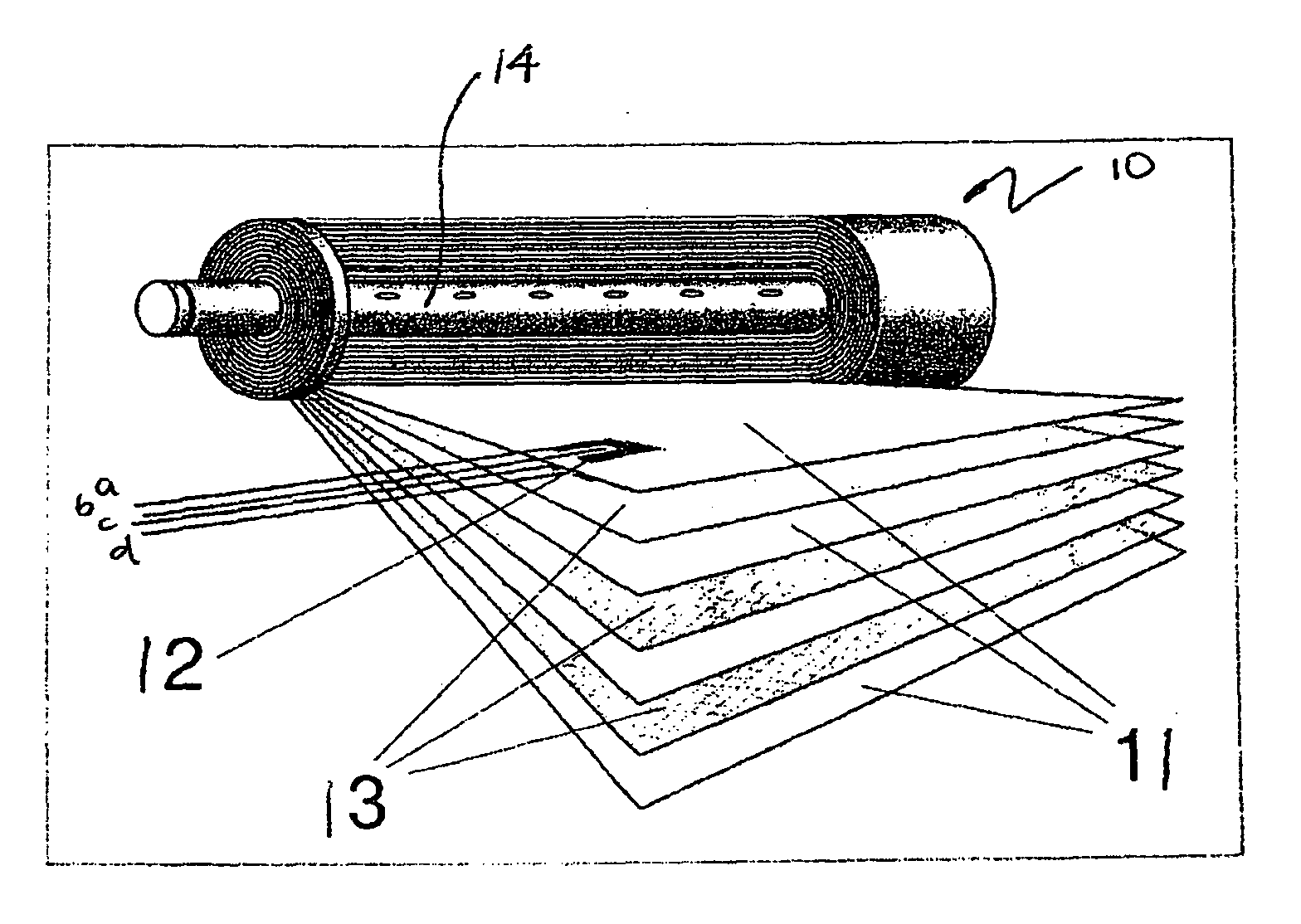

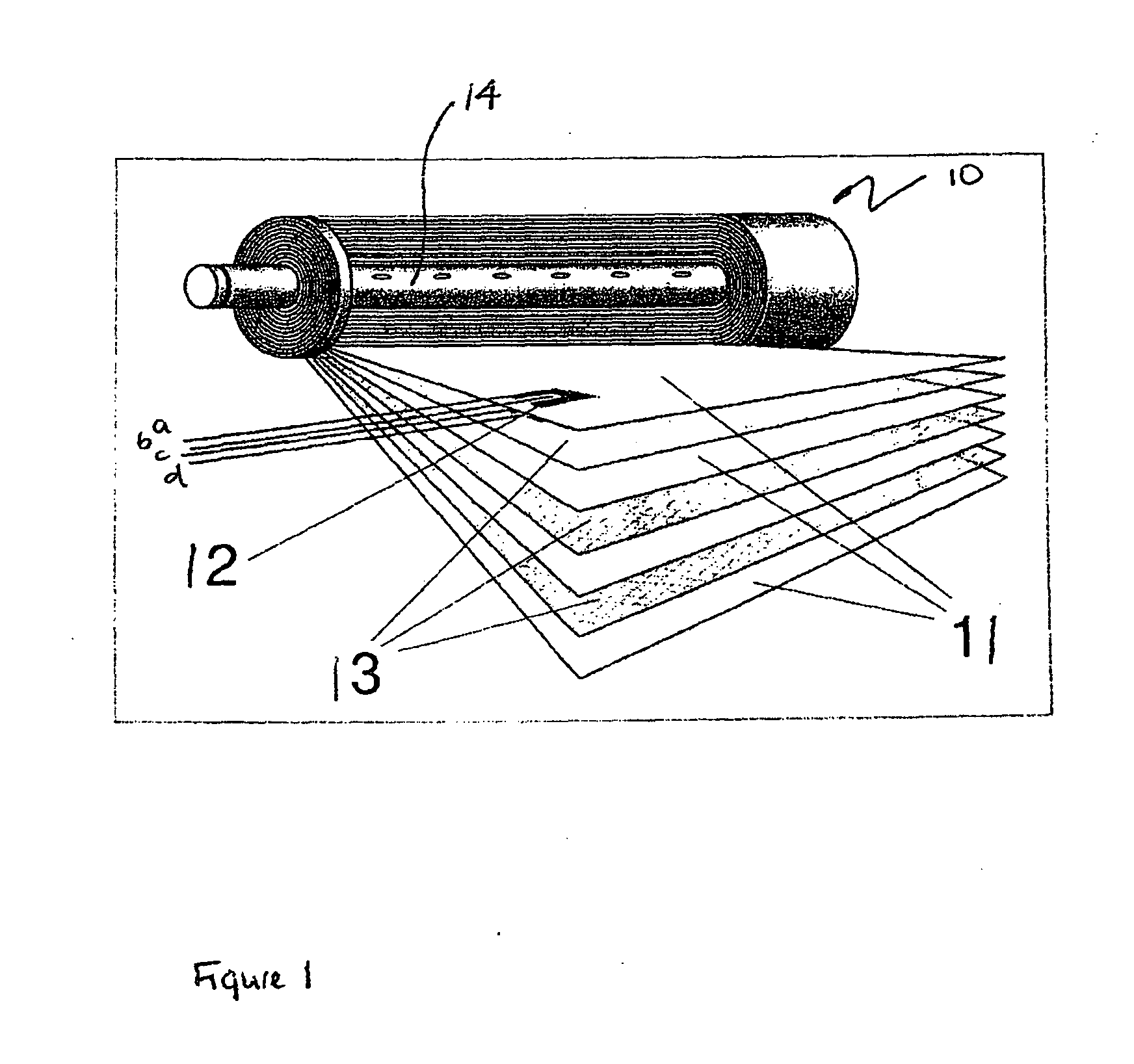

Stationary and dynamic radial transverse electric polarizer for high numerical aperture systems

InactiveUS20040169924A1Polarising elementsSemiconductor/solid-state device manufacturingHigh numerical apertureClassical mechanics

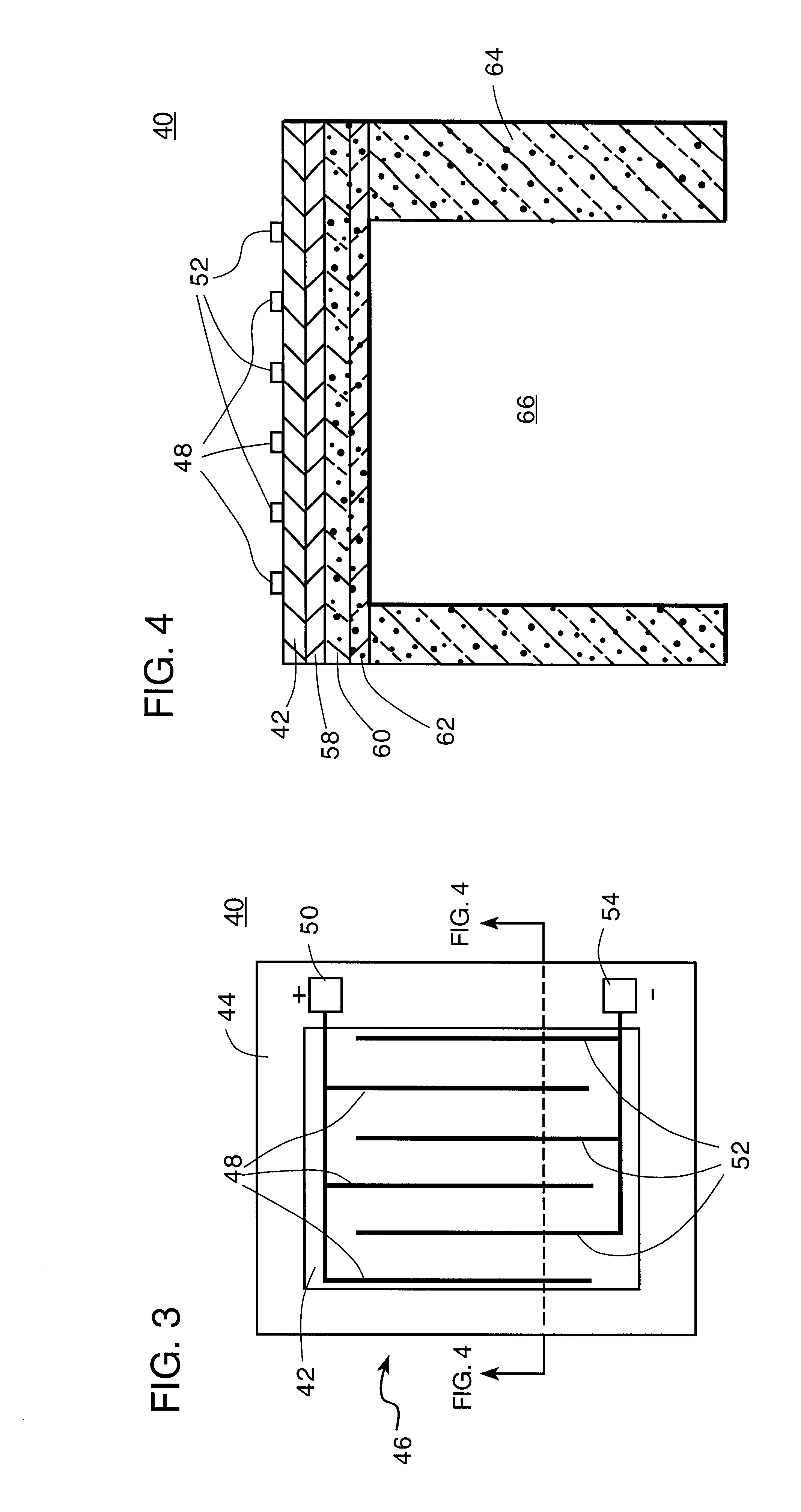

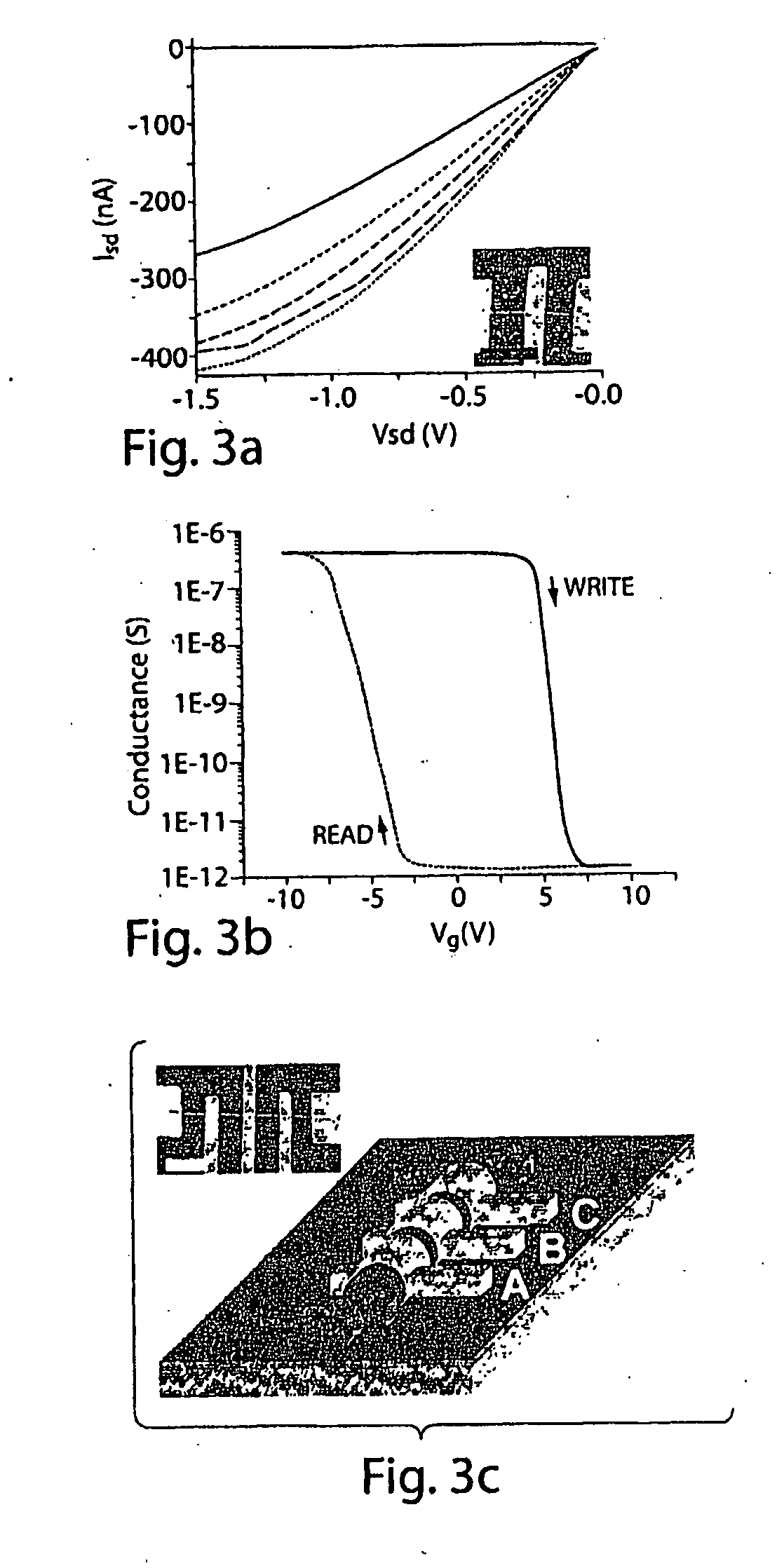

A radial transverse electric polarizer device is provided. The device includes a first layer of material having a first refractive index, a second layer of material having a second refractive index, and a plurality of elongated elements azimuthally and periodically spaced apart, and disposed between the first layer and the second layer. The plurality of elongated elements interact with electromagnetic waves of radiation to transmit transverse electric polarization of electromagnetic waves of radiation. One aspect of the invention is, for example, to use such polarizer device in a lithographic projection apparatus to increase imaging resolution. Another aspect is to provide a device manufacturing method including polarizing a beam of radiation in a transverse electric polarization.

Owner:ASML NETHERLANDS BV

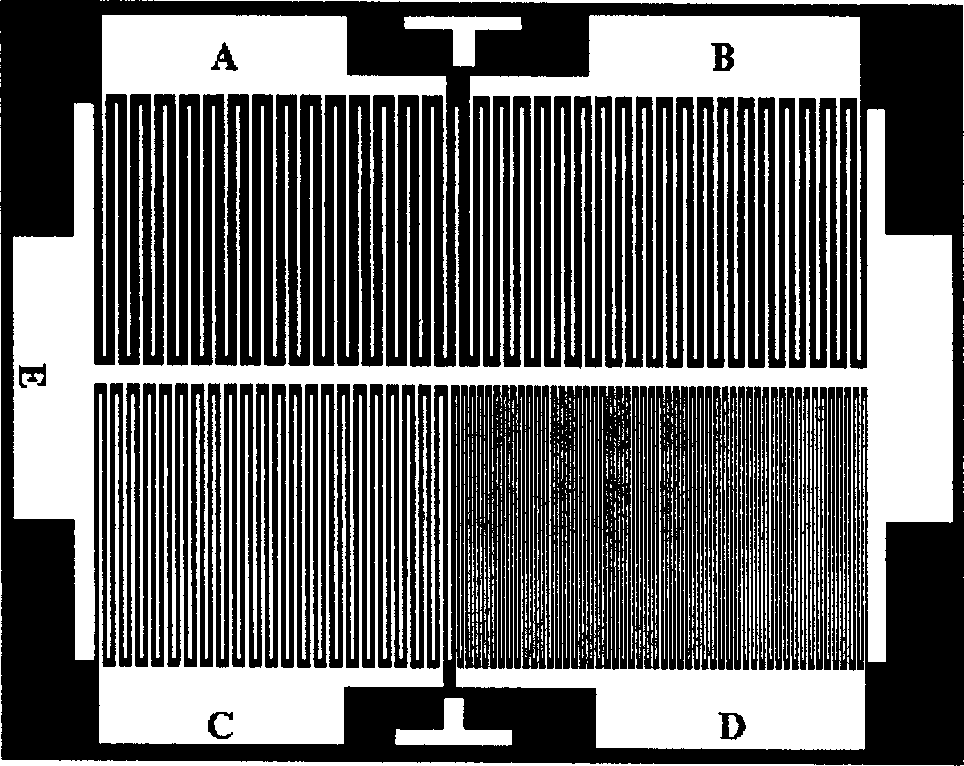

Ferroic transducer

InactiveUS6323580B1High sensitivityIncrease spacingThermoelectric device with dielectric constant thermal changePiezoelectric/electrostriction/magnetostriction machinesTransducerInterdigitated electrode

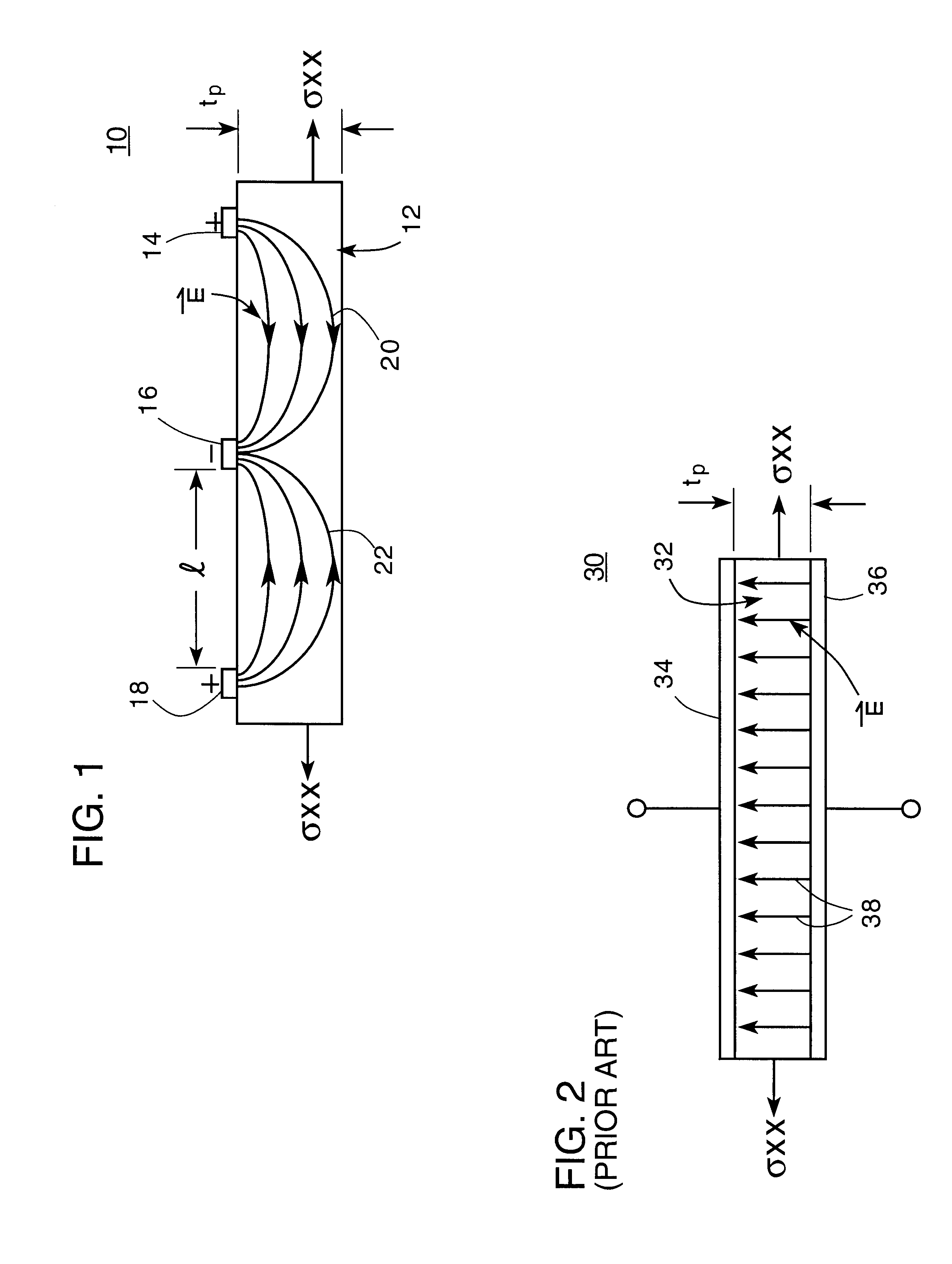

An interdigitated electrode ferroic transducer includes a film of ferroic material electrically polarized substantially in the plane of the film; and a set of interdigitated electrodes including at least two electrodes spaced from one another on the same side of the film and disposed at the termini of the polarization field.

Owner:CHARLES TARK DRAPER LAB INC THE

A film LED chip part based on compound low-resistance buffer structure and its making method

ActiveCN101241963APadding achievedTo achieve electrical connectionSemiconductor devicesEngineeringMetal

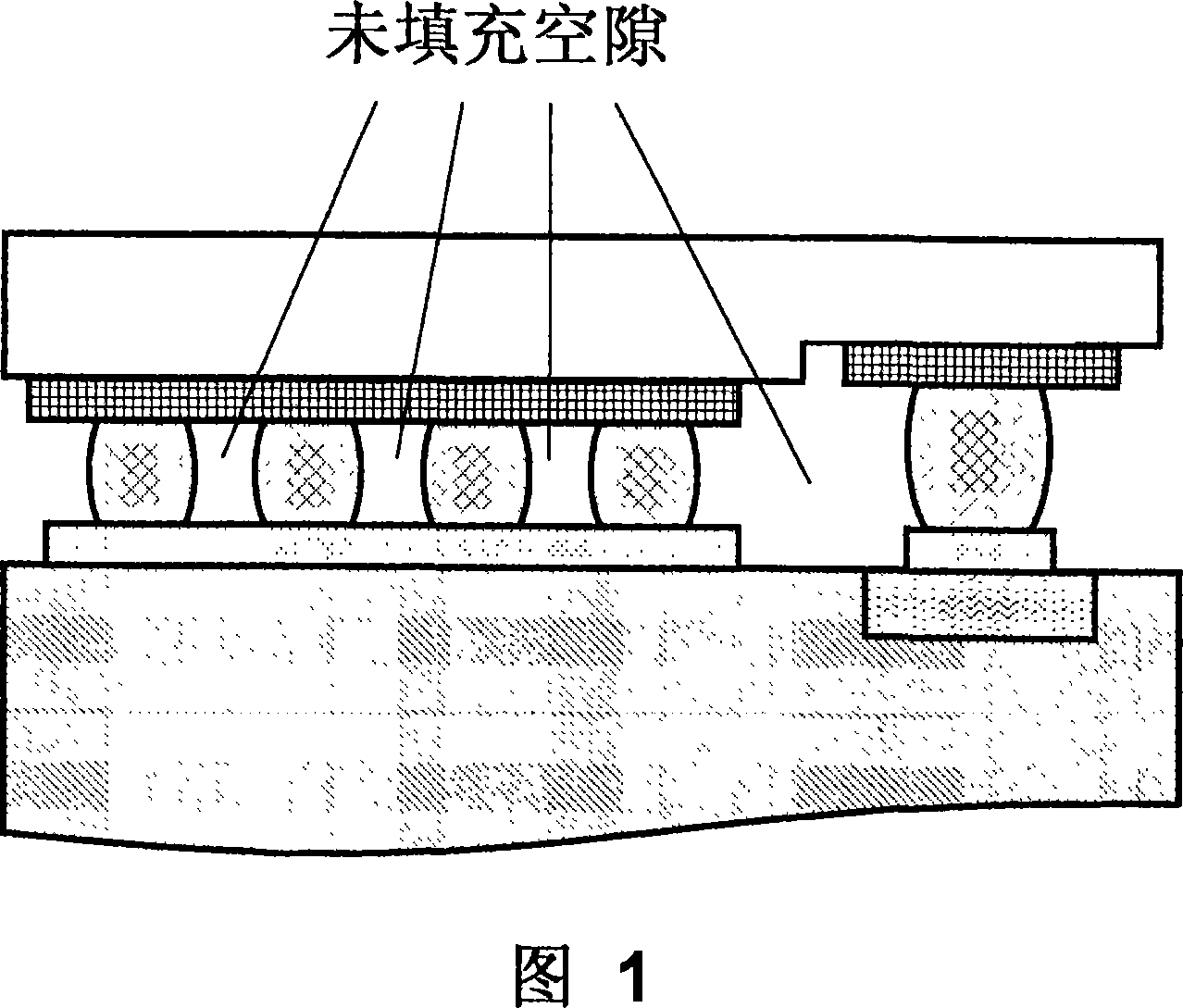

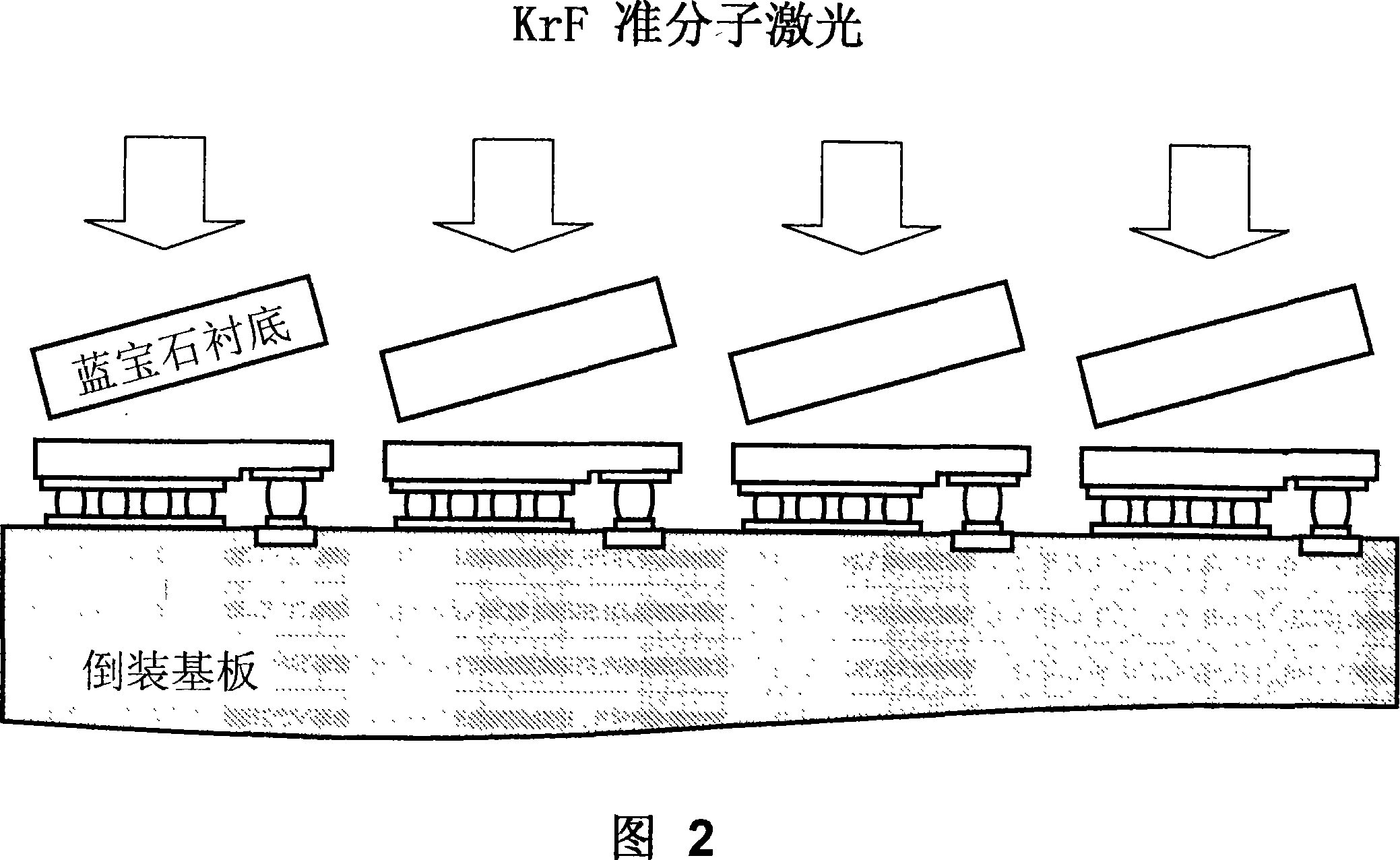

The present invention provides a film LED chip device basing on the combined low-resistance buffer structure and the manufacturing method thereof, the insulating buffer film is packaged on side wall of all metal structures and is filled in all non-electrical connected areas, with filling in insulating buffer film between all metal convex points which connects the GaN base illuminating device and the electric polarized substrate, the filling-in thickness is a little under or even with the height of the metallic convex points, and with directly liking the GaN base illuminating device crystal disc with the whole surface of the electric polarized inversely mounted substrate with the mode of whole surface linking of the wafer, the metallic convex point of the conductive supporting thick metal layer and the insulating buffer film form the combined low-resistance buffer structure of the invention together, not only the electric connection between the GaN base illuminating device and the electric polarized inversely mounted substrate is realized, but also the buffer layer filling is realized thereby reducing the wafer rupture incidence rate of the subsequent laser stripping technique in order to increase the good product ratio, besides the stripped sapphire substrate disc which can execute finishing to the sapphire substrate and is obtained after stripped operation can be recovered for reusing, the production cost is reduced.

Owner:XIAMEN SANAN OPTOELECTRONICS TECH CO LTD

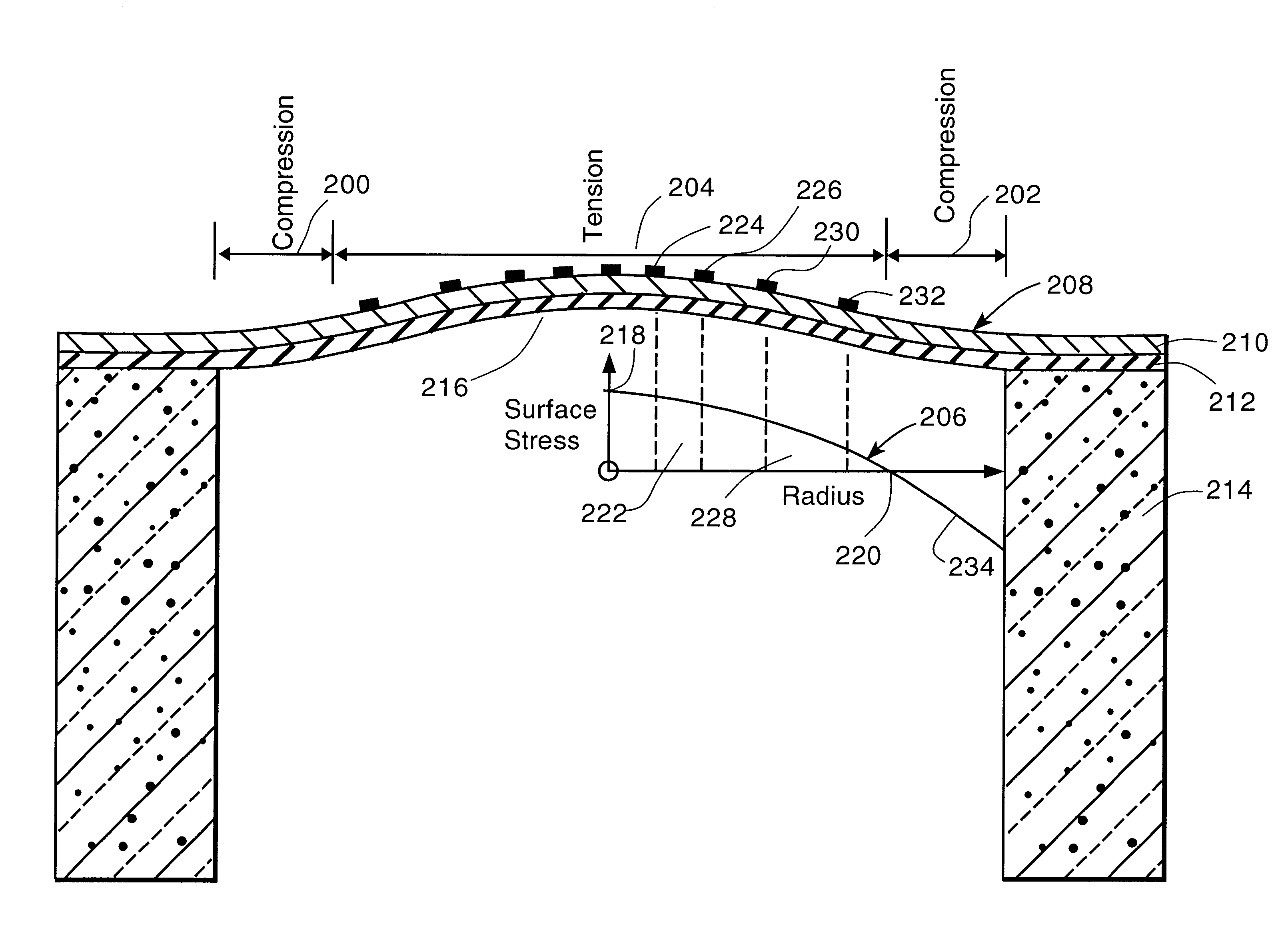

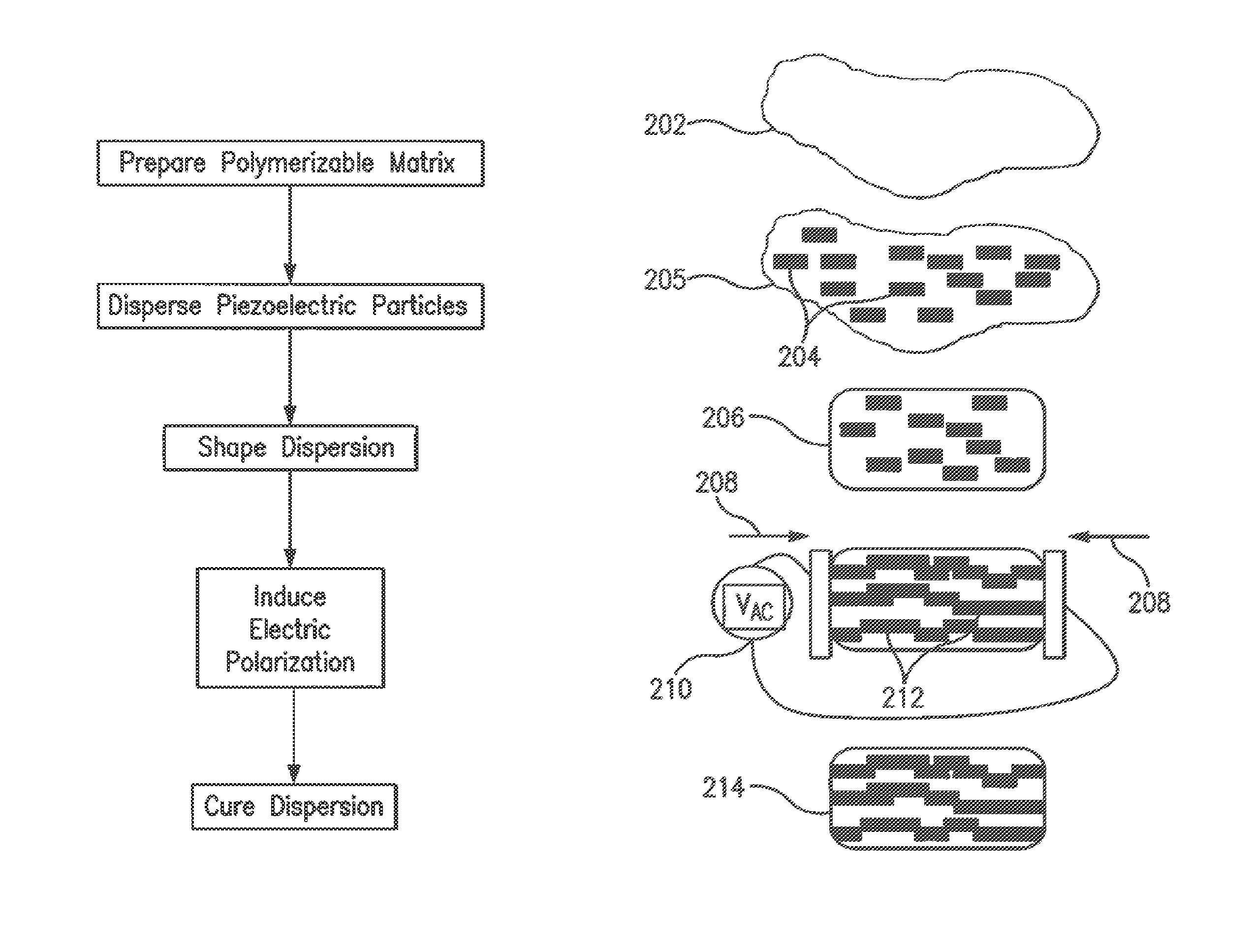

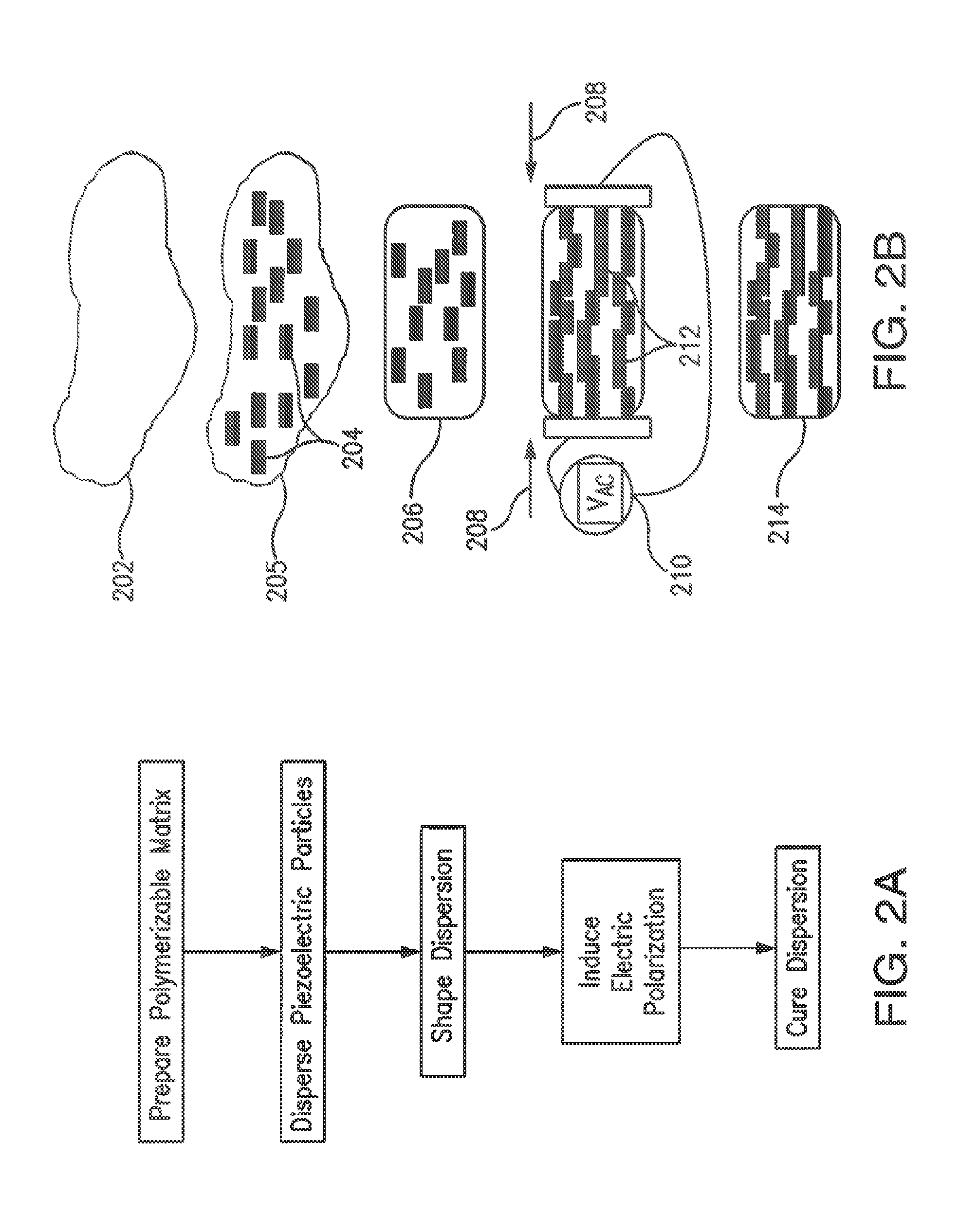

Piezoelectric composites and methods of making

InactiveUS20150134061A1Bone implantPiezoelectric/electrostrictive device material selectionThermoplasticMedicine

There is a need for methods that can produce piezoelectric composites having suitable physical characteristics and also optimized electrical stimulatory properties. The present application provides piezoelectric composites, including tissue-stimulating composites, as well as methods of making such composites, that meet these needs. In embodiments, methods of making a spinal implant are provided. The methods suitably comprise preparing a thermoset, thermoplastic or thermoset / thermoplastic, or copolymer polymerizable matrix, dispersing a plurality of piezoelectric particles in the polymerizable matrix to generate dispersion, shaping the dispersion, inducing an electric polarization in the piezoelectric particles in the shaped dispersion, wherein at least 40% of the piezoelectric particles form chains.

Owner:UNIVERSITY OF KANSAS

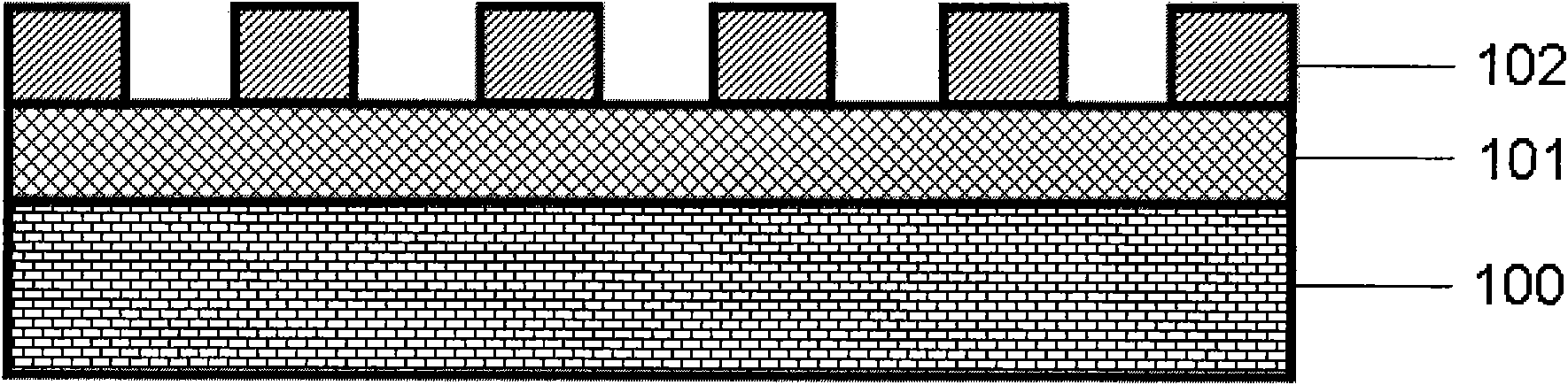

One-phase ferroelectric film and preparing method thereof as well as effective resistance regulation mode

InactiveCN102157682AWith ferroelectricityWith semiconductor performanceElectrical apparatusVacuum evaporation coatingLead zirconate titanateSputtering

The invention discloses a one-phase ferroelectric film capable of regulating effective resistance by ferroelectric polarization, a preparing method of the one-phase ferroelectric film and an effective resistance regulation mode. The one-phase ferroelectric film comprises B-bit-doped Bal-xSrxTil-yByO3, Pb(Fe1-yBy)O3, Pb(Co1-yBy)O3, (Pb1-xAx)(ZryTi1-y)O3, A-bit-doped Y1-xAxMnO3, Bil-xAxFeO3, and Bi4-xAxTi3O12. The one-phase ferroelectric film is prepared by using film preparing methods, such as pulsed laser deposition (PLD), laser molecular beam epitaxy (LMBE) and magnetron sputtering. The prepared ferroelectric film is 0.4-1000 nanometer in the thickness and has larger conductance and leakage current, as well as ferroelectricity and semiconductor performance. The invention provides a method for improving the antifatigue performance of the one-phase ferroelectric film. Turning frequency (x) of the ferroelectric polarization in the method can be increased to 102-1010; and the ferroelectric polarization is turned to regulate the effective resistance of the one-phase ferroelectric film.

Owner:NANJING UNIV OF SCI & TECH

Magnetic recording medium based on multiferroic film and write-in method thereof

The invention relates to a magnetic recording medium based on a multiferroic film, comprising a substrate and a medium layer growing on the substrate. The medium is characterized in that the medium layer comprises a ferroelectric structure unit formed by a ferroelectric material and a ferromagnetic structure unit formed by a ferromagnetic material. The write-in method comprises the following steps: an electric signal generated by a signal source is applied to two ends of the ferroelectric structure unit; an impulse voltage signal generated by the signal source changes the polarized state of a ferroelectric layer; through a magnetoelectric coupling effect, changes of the polarized state can further change the magnetization direction in the ferroelectric structure unit so as to record the state of an electric signal and complete information storage. Compared with the prior art, the invention provides the novel magnetic recording medium of the multiferroic composite material and several structures for recording the medium based on the traditional magnetic recording medium; and the medium using the multiferroic materials for recording can realize the magnetic recording method for electric write-in, and has wide application prospect for novel multifunctional devices with high density storage.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

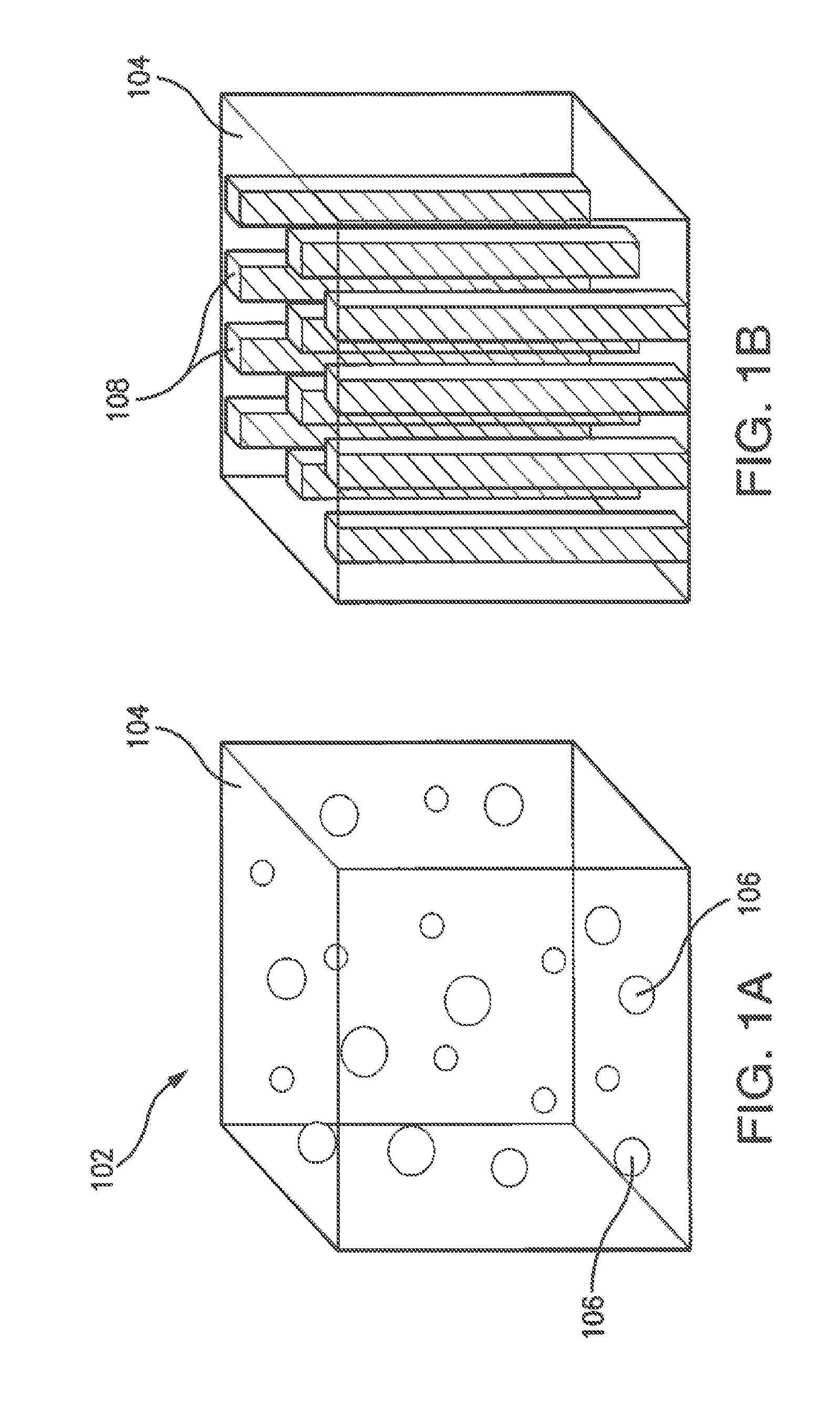

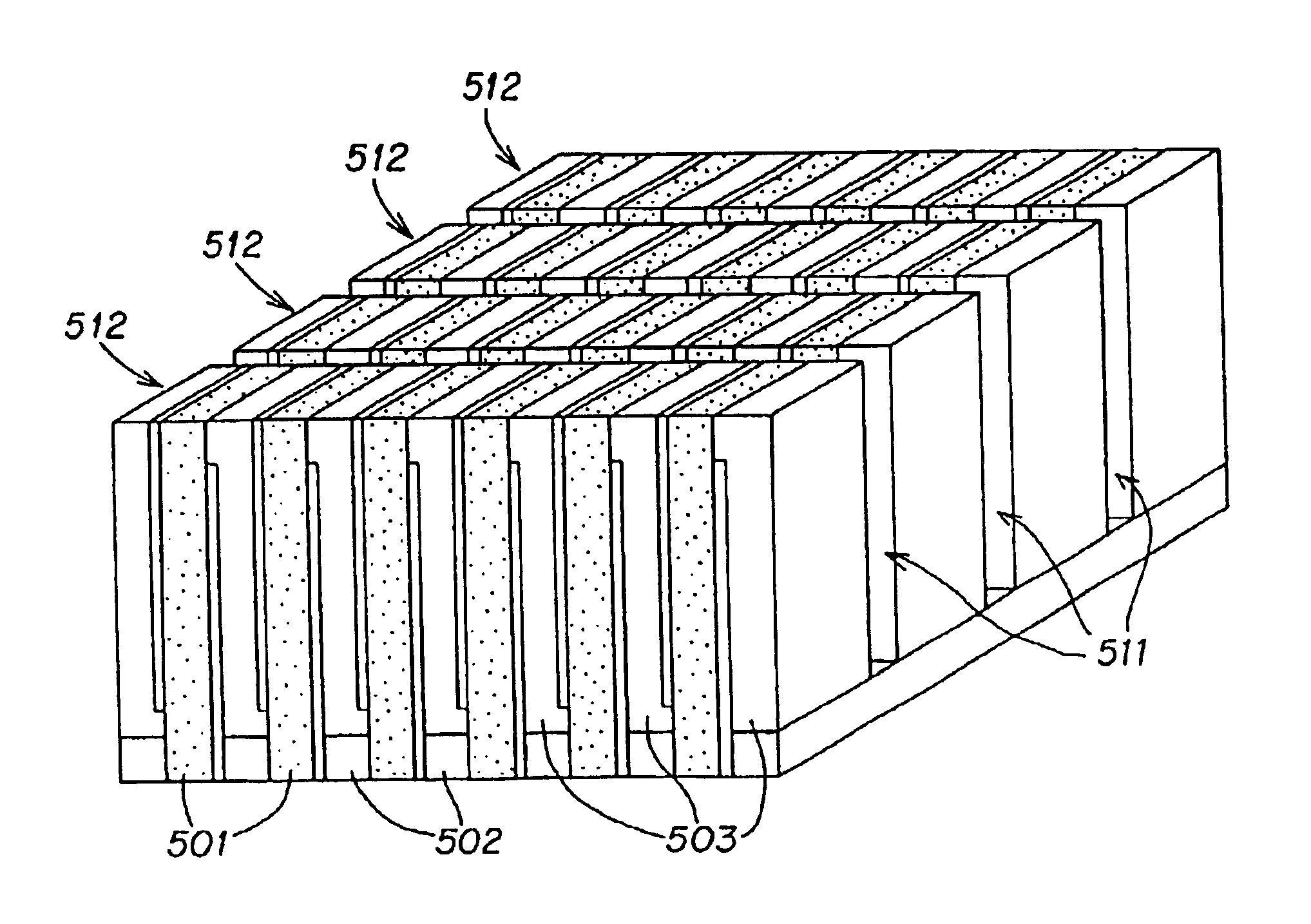

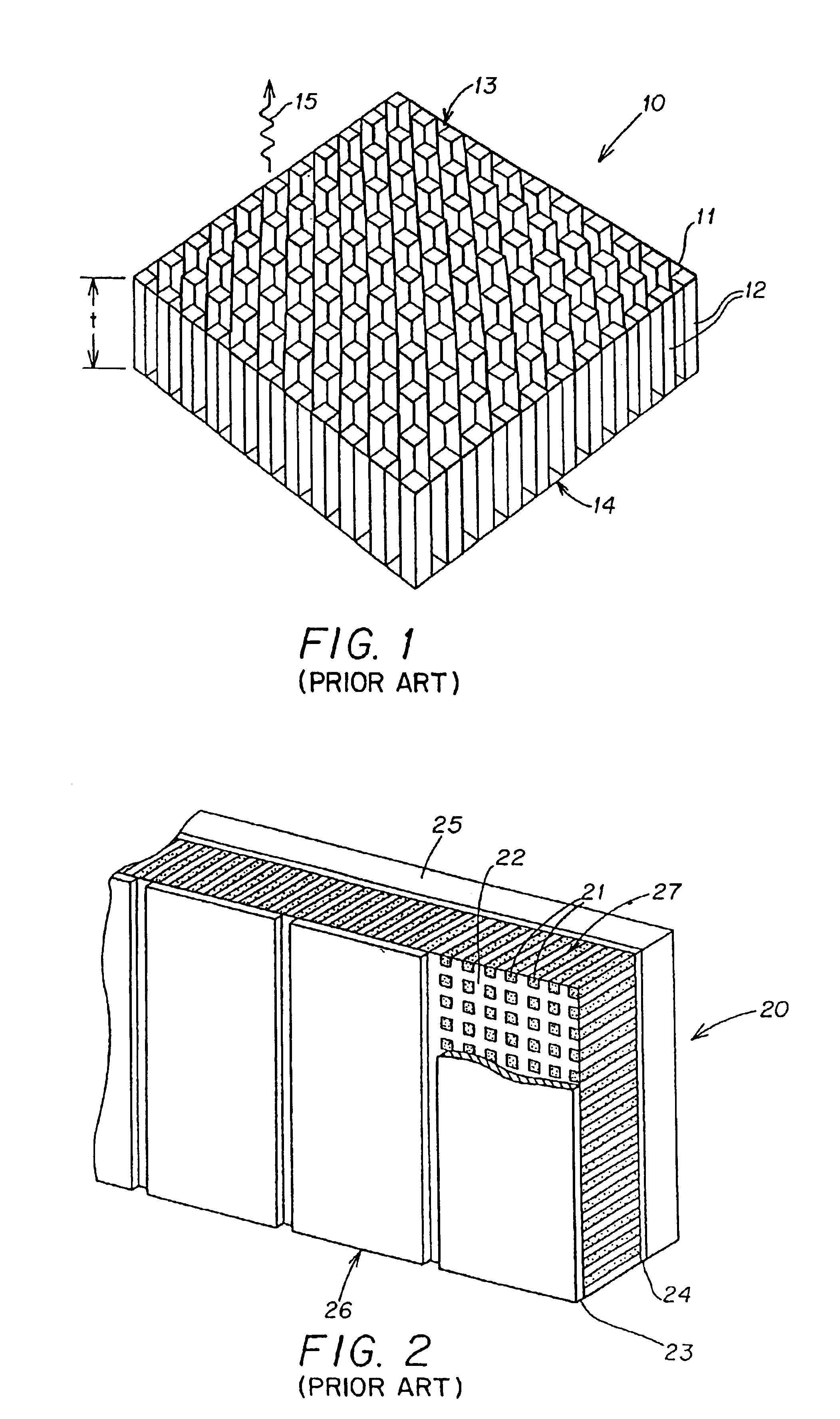

Method for making a transducer

InactiveUS6868594B2Decrease open-circuit sensitivityDecreased open-circuit sensitivityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesTransducerPolymer

A method for producing transducers having a 1-3 composite structure. The transducer element includes a plurality of thin piezoceramic wafers which are electroded on opposing major surfaces. The spaced wafers are separated by a passive polymer layer in a composite structure and the electrodes on the opposing major surfaces are connected to different ones of top and bottom electrode surfaces.

Owner:GUARDIAN IND CORP

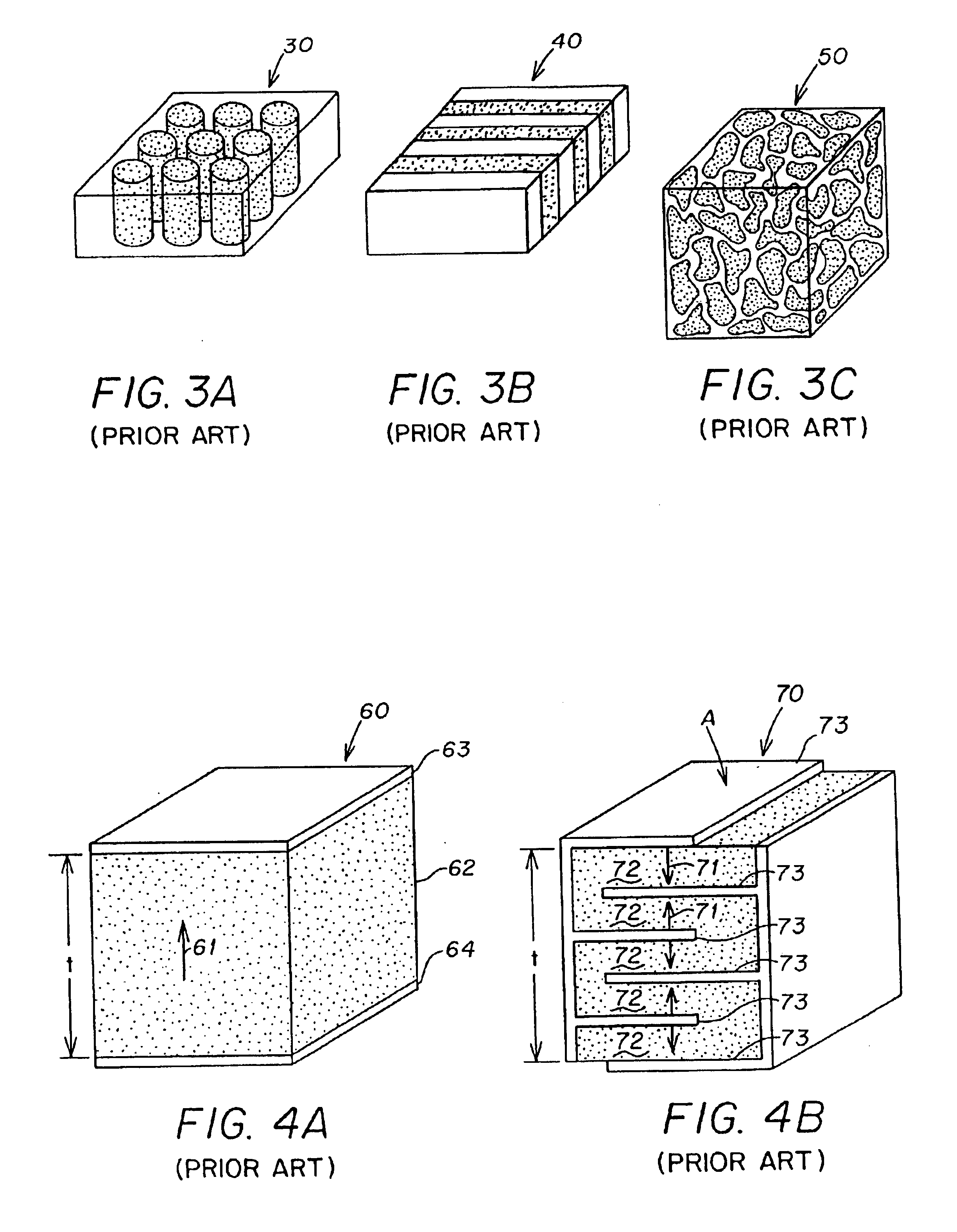

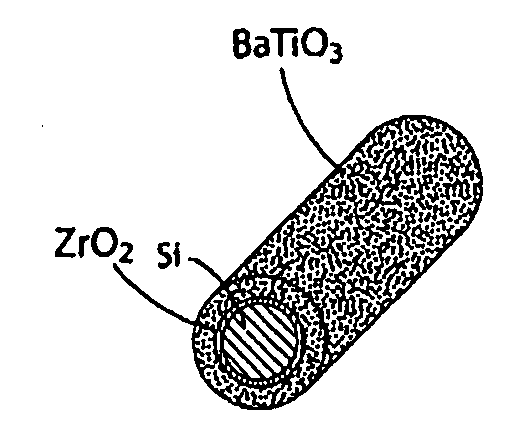

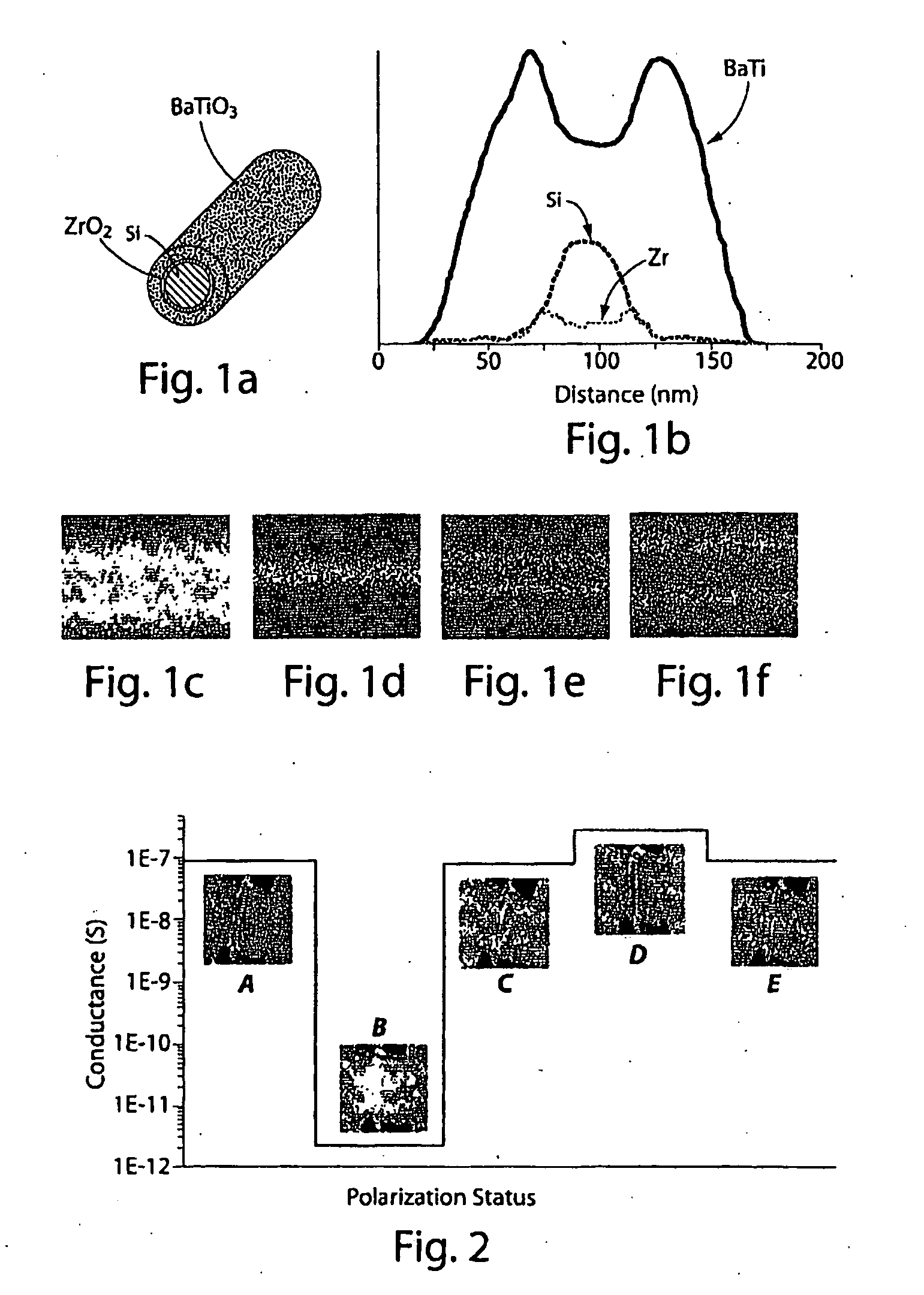

Nanoscale Wire-Based Data Storage

The present invention generally relates to nanotechnology and submicroelectronic devices that can be used in circuitry and, in some cases, to nanoscale wires and other nanostructures able to encode data. One aspect of the invention provides a nanoscale wire or other nanostructure having a region that is electrically-polarizable, for example, a nanoscale wire may comprise a core and an electrically-polarizable shell. In some cases, the electrically-polarizable region is able to retain its polarization state in the absence of an external electric field. All, or only a portion, of the electricallypolarizable region may be polarized, for example, to encode one or more bits of data. In one set of embodiments, the electrically-polarizable region comprises a functional oxide or a ferroelectric oxide material, for example, BaTiO3, lead zirconium titanate, or the like. In some embodiments, the nanoscale wire (or other nanostructure) may further comprise other materials, for example, a separation region separating the electricallypolarizable region from other regions of the nanoscale wire. For example, in a nanoscale wire, one or more intermediate shells may separate the core from the electricallypolarizable shell.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

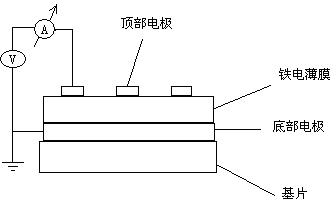

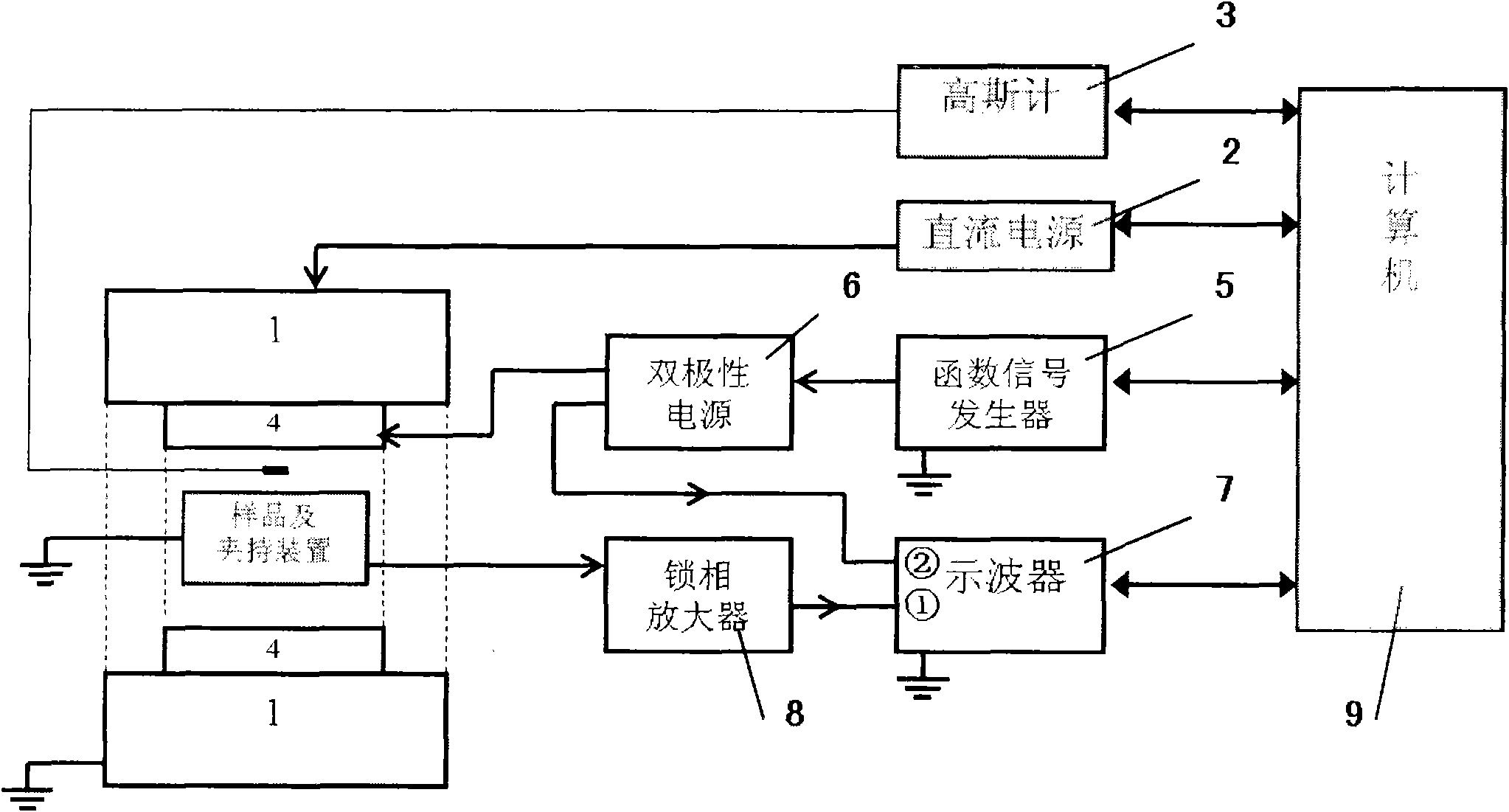

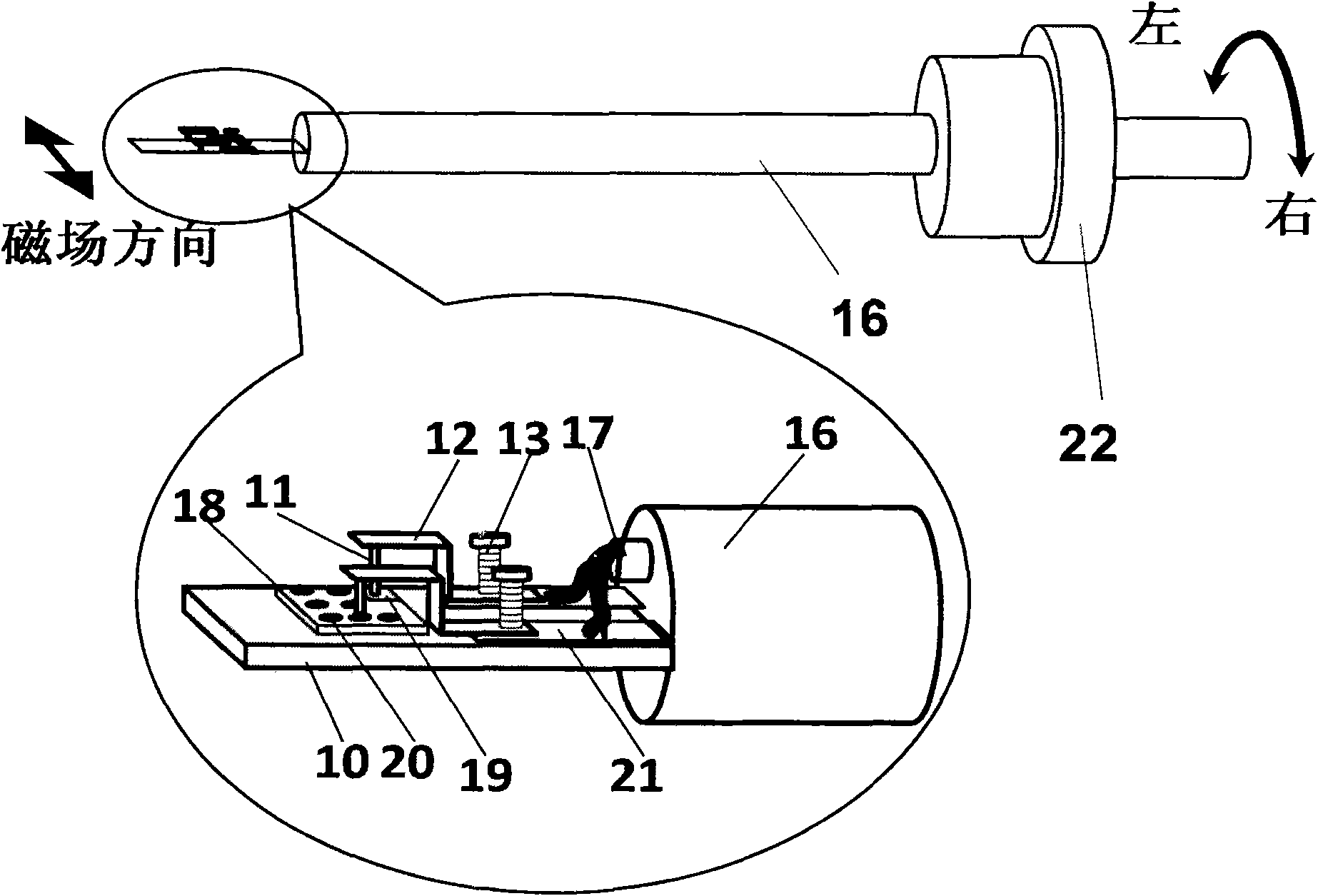

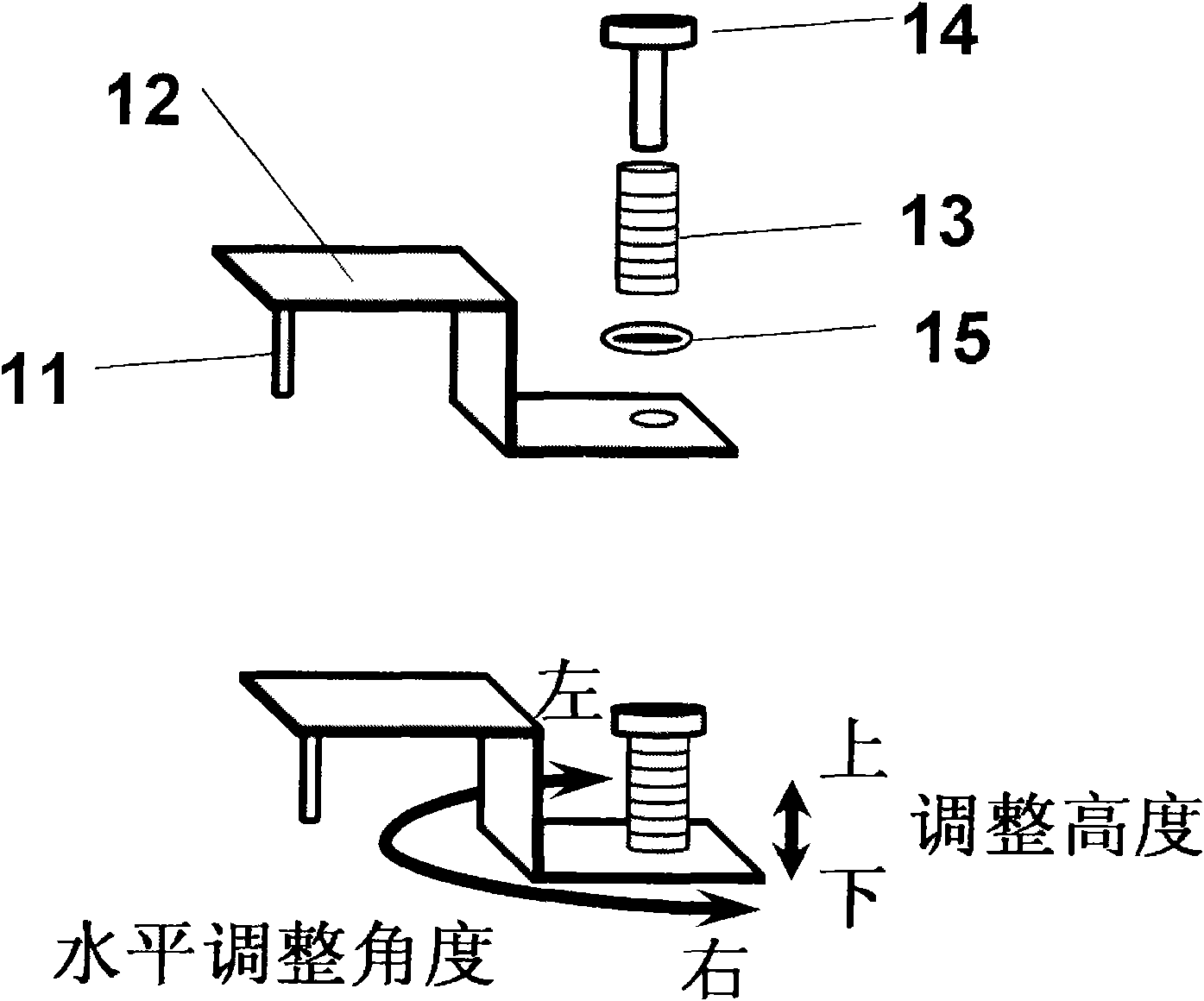

System and method for testing magnetoelectricity property of multiferroic thin-film material

The invention relates to a system and a method for testing magnetoelectricity property of a multiferroic thin-film material, belonging to the field of property tests of materials. The system is characterized by comprising a DC bias magnetic field generating device, an AC magnetic field generating device, a thin-film sample probe holding device and a micro signal acquiring and amplifying device. The invention also provides a method for testing magnetoelectricity property of the multiferroic thin-film material. The invention can recognize the difference of an electromagnetic inductive interference signal and a multiferroic magnetoelectricity responding signal by accurately testing a thin-film micro electric responding signal so as to obtain a real amplitude of a magnetoelectricity coefficient of the multiferroic thin-film material under different frequencies and bias magnetic fields and also obtain the change law of thin-film sample polarization with an alternating magnetic field.

Owner:TSINGHUA UNIV

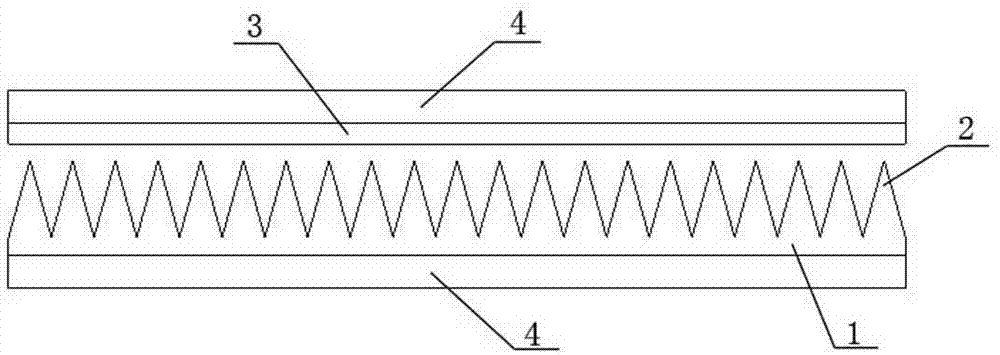

Method for manufacturing high-electrical-property nano generator based on piezoelectric-frictional effect

ActiveCN103490005AExtended service lifeIncrease production capacityMaterial nanotechnologyPiezoelectric/electrostrictive device manufacture/assemblyMicro nanoConvex structure

The invention discloses a method for manufacturing a high-electrical-property nano generator based on a piezoelectric-frictional effect. The small-area high-output-voltage nano generator is manufactured on the basis of the piezoelectric effect and the frictional effect. According to the method, CNT particles and piezoelectric particles in a certain proportion are mixed into liquid PDMS to be manufactured into a composite film, a micro-nano concave-convex structure with rules is manufactured on the surface of the composite film through a micro-processing method, finally electric polarization is carried out on the composite film, and an electrode is arranged in a clamping mode. The method combines the advantages of piezoelectricity and friction, and the manufactured piezoelectric-frictional nano generator with the small area, high sensitivity and high voltage output is low in manufacturing cost and simple in process, has good durability and workability, enables large-scale production and application to be carried out conveniently, and can be easily blended in the design of other products. Self-powered and self-driven equipment is provided for personnel electronic products, environmental monitoring, medical science and the like, and huge commercial and practical potentials are achieved.

Owner:ZHONGBEI UNIV +1

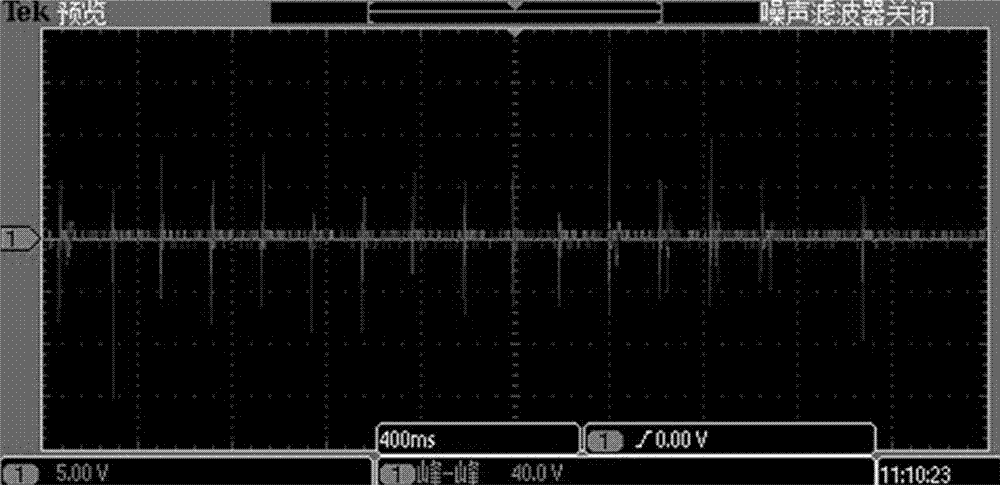

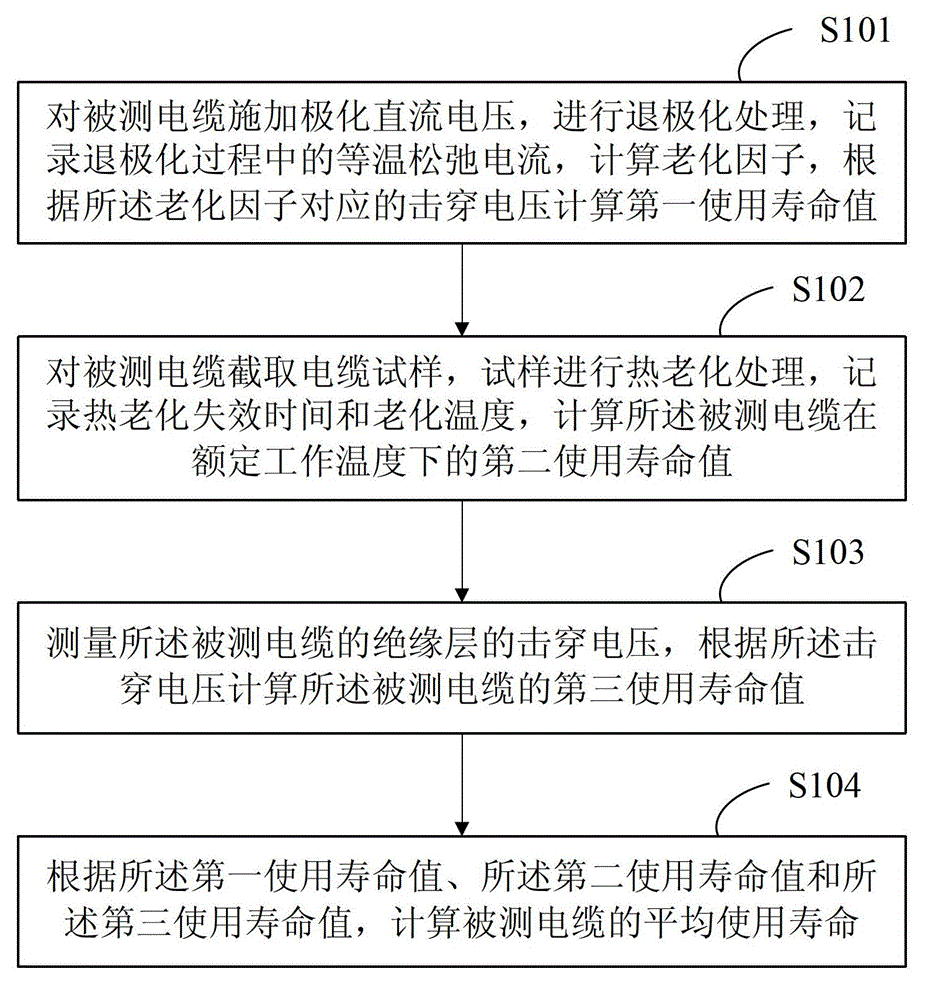

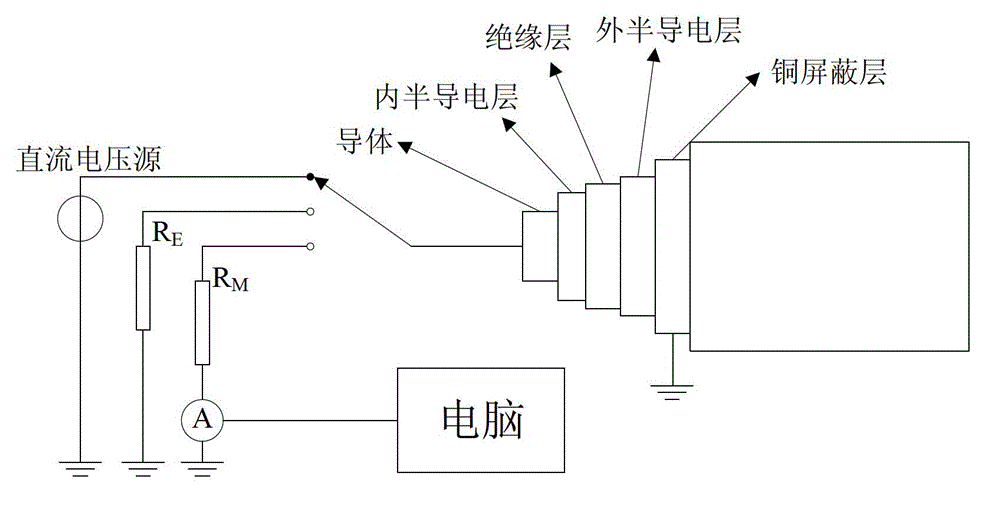

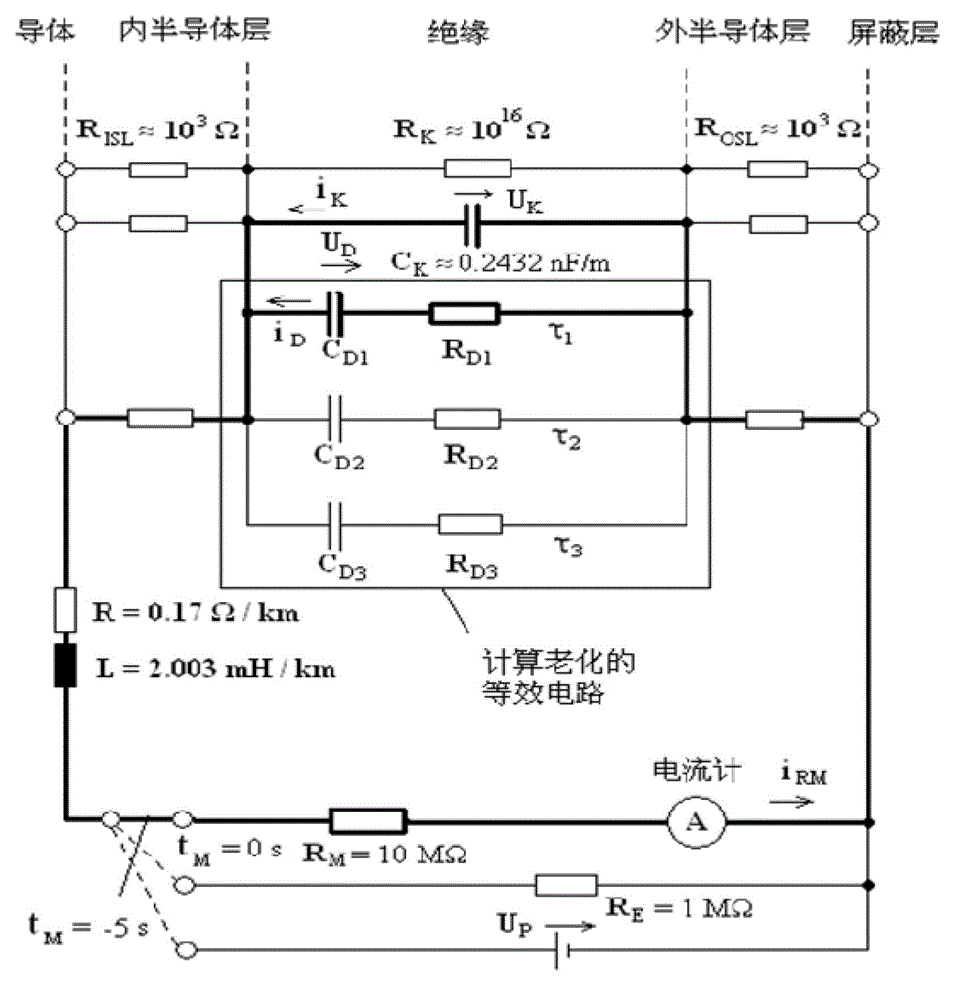

Method for detecting service life of cable

Owner:GUANGZHOU POWER SUPPLY CO LTD +1

NMR MAS electret spin rate detection

InactiveUS7196521B2High sensitivityImprove stabilityMagnetic measurementsElectric/magnetic detectionHigh resistivityCharge generation

A material having a permanent external diametrical electric field is included within an NMR MAS spinner. Such materials include ferroelectret porous films, in which the electric polarization arises from opposite mono-polar charges on separated surfaces within a structured material containing voids. Rotation of electrically polarized material produces a time-dependent electric field, modulated at the rotational frequency, so that a simple antenna achieves high sensitivity and phase stability in spin rate detection. The electrically polarized material is also of sufficiently high resistivity that modulation of the external NMR polarizing magnetic field B0 is negligible.

Owner:DOTY SCI

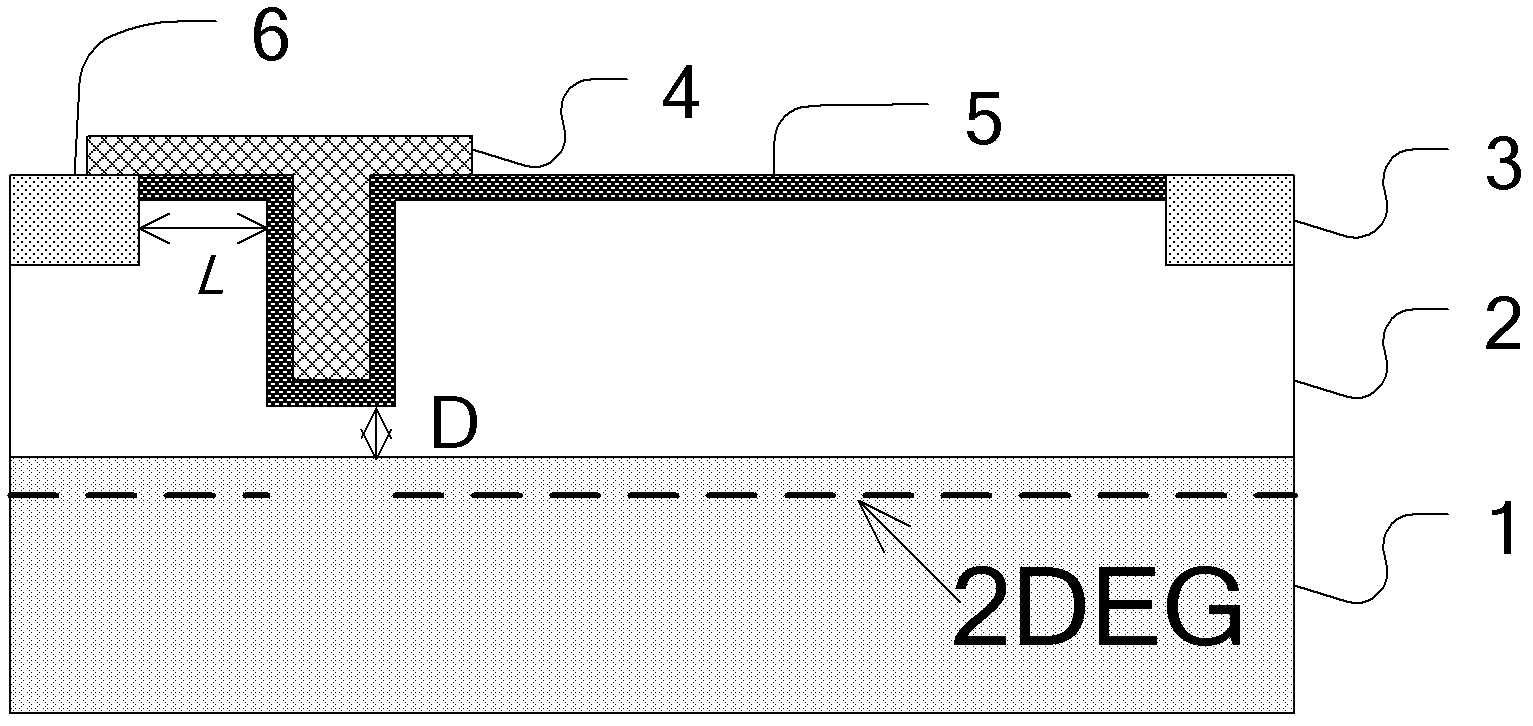

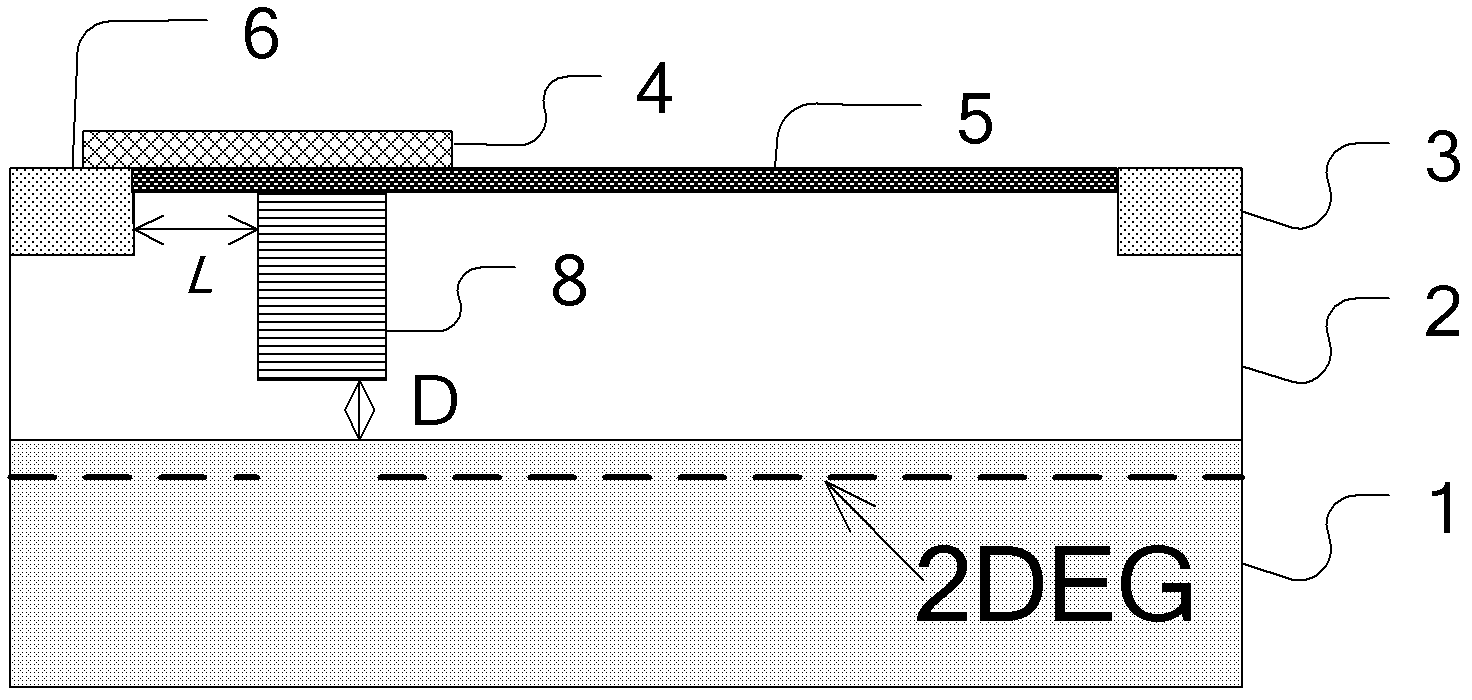

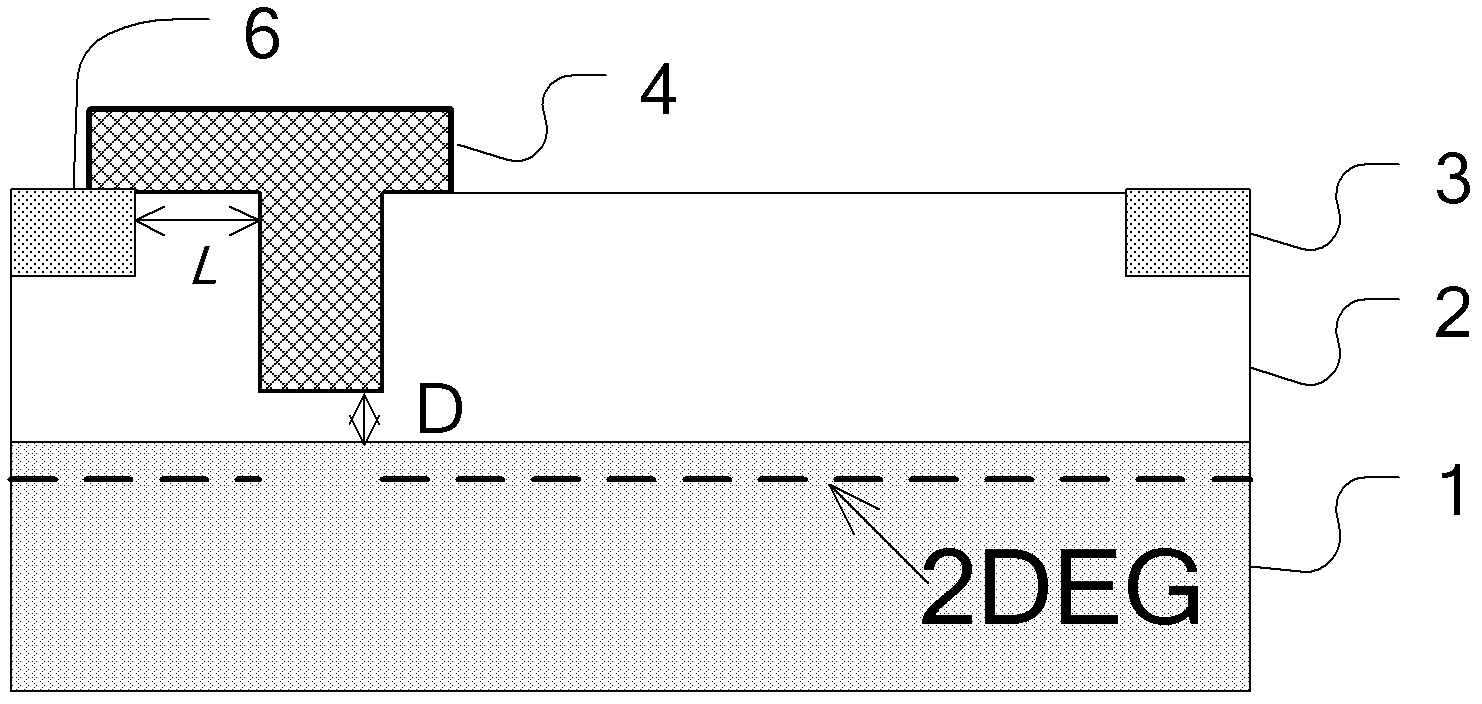

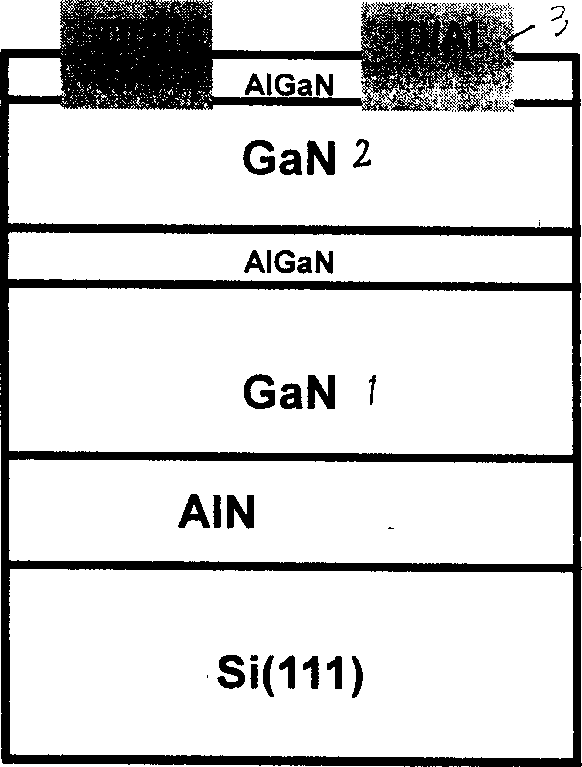

Normally-off field-controlled channel gan heterojunction diode

InactiveCN102280494AImplement field control featuresEfficient use ofSemiconductor devicesControl channelPositive power

A normally-off type field-controlled channel GaN heterojunction diode belongs to the technical field of semiconductor devices. The invention adopts the technology of combining insulating layer-groove, modulation doping and groove-modulation doping to change the conductive channel structure of the existing GaN heterojunction diode, and convert the original normally-on spontaneously polarized GaN heterojunction The junction conductive channel is changed into a normally-off field-controlled conductive channel combining spontaneous polarization and piezoelectric polarization in the present invention, which realizes the field-controlled characteristics of the GaN heterojunction diode conductive channel and reduces the forward conduction resistance and enhanced reverse cut-off capability. The invention has lower forward conduction resistance and power consumption, stronger reverse cut-off ability, and is compatible with AlGaN / GaN HEMT power switching device technology, which is beneficial to the application of the device.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

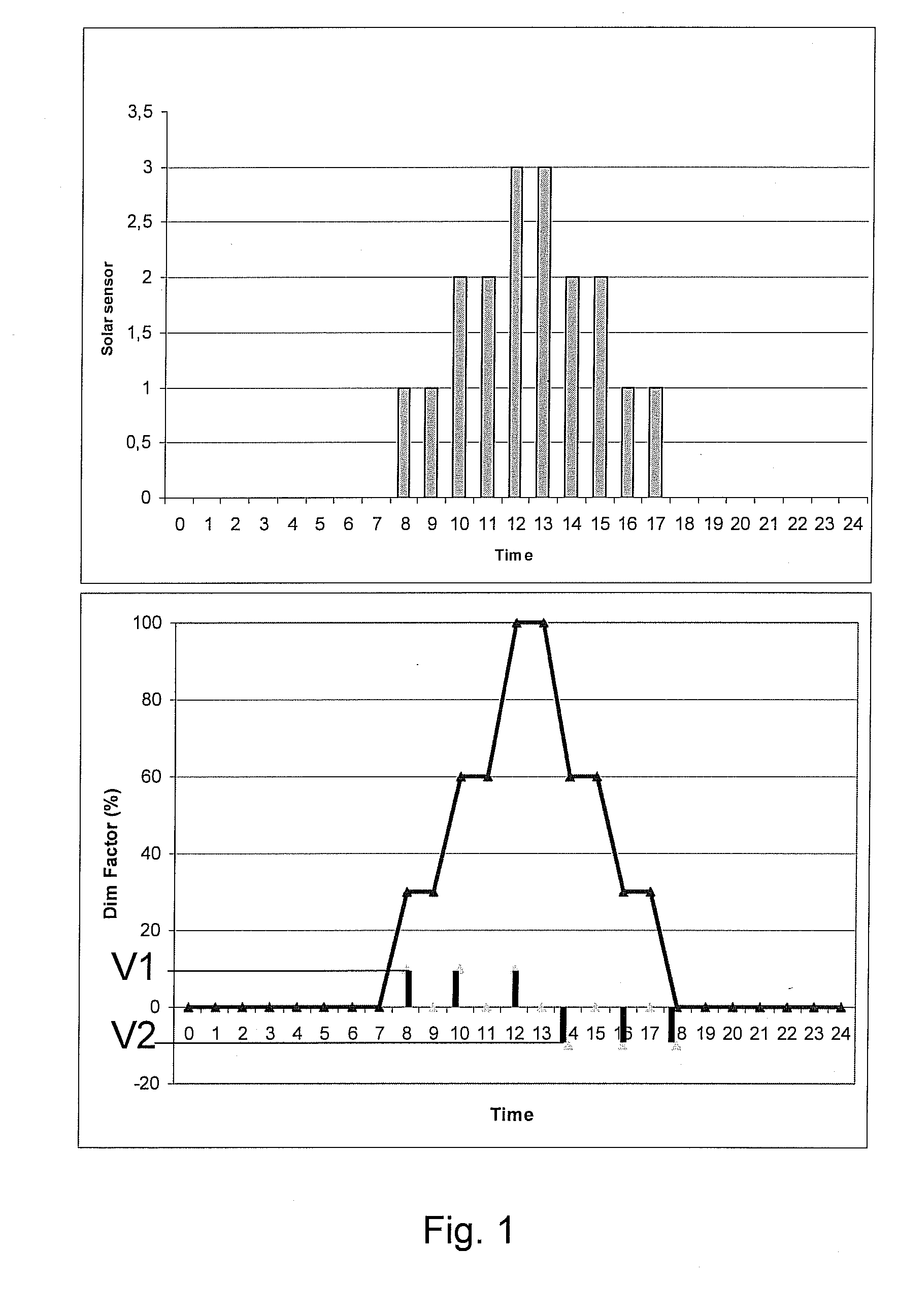

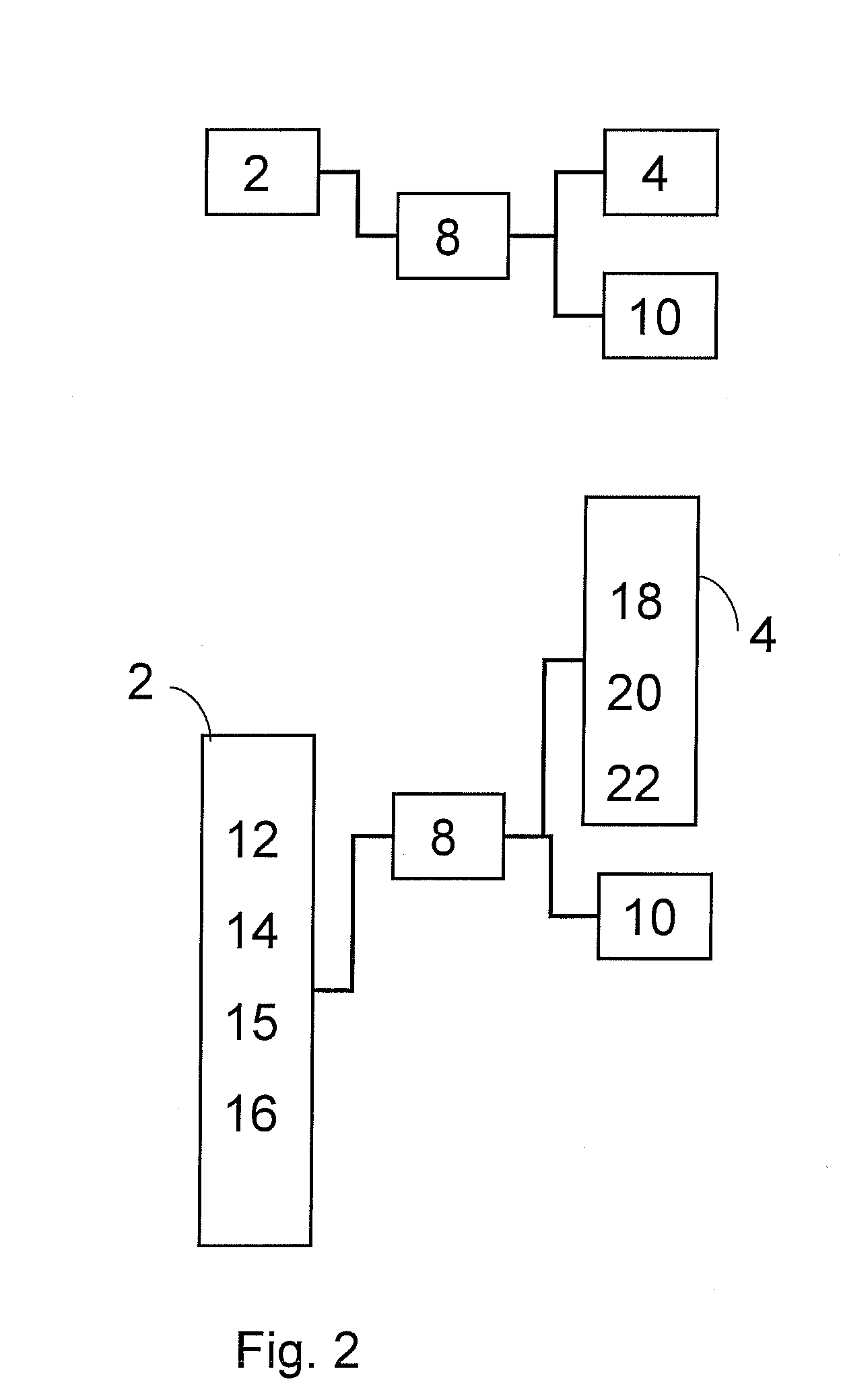

Climate control system

InactiveUS20090187287A1Reduce power consumptionAntiglare equipmentTemperatue controlVoltage pulseConductive polymer

The invention is related to a climate control system with one dimmable device capable of variably reducing the transmission of radiation through a window, and a climate control unit coupled to and adapted to control the dimmable device. The dimmable device includes at least one inherent conductive polymer and at least one ionic liquid. The dimmable device is controlled to change colours and / or dimming levels by applying a voltage pulse of a first electrical polarisation for darkening and a second reverse polarized voltage pulse for bleaching.

Owner:SMR PATENTS S A R L

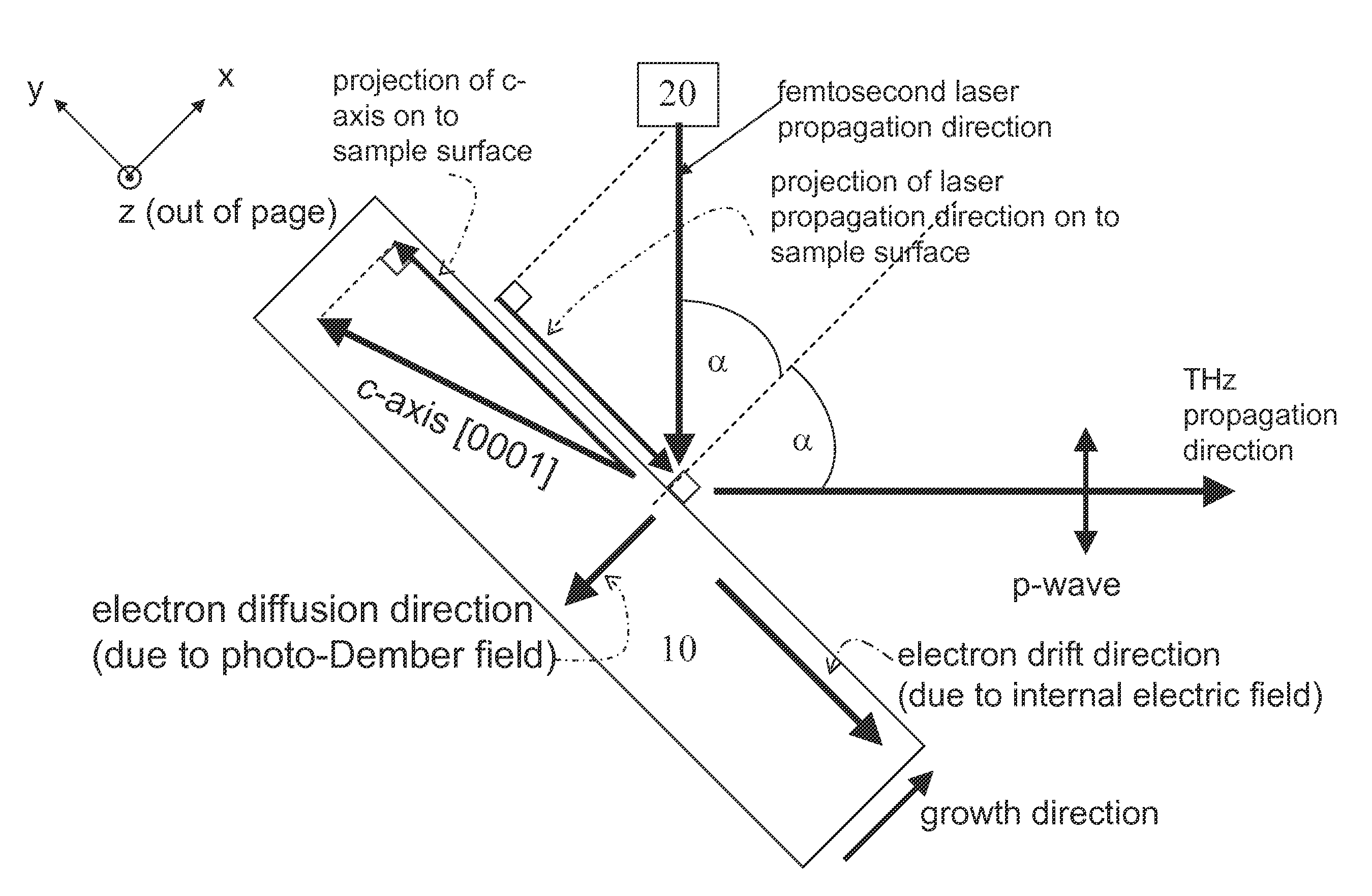

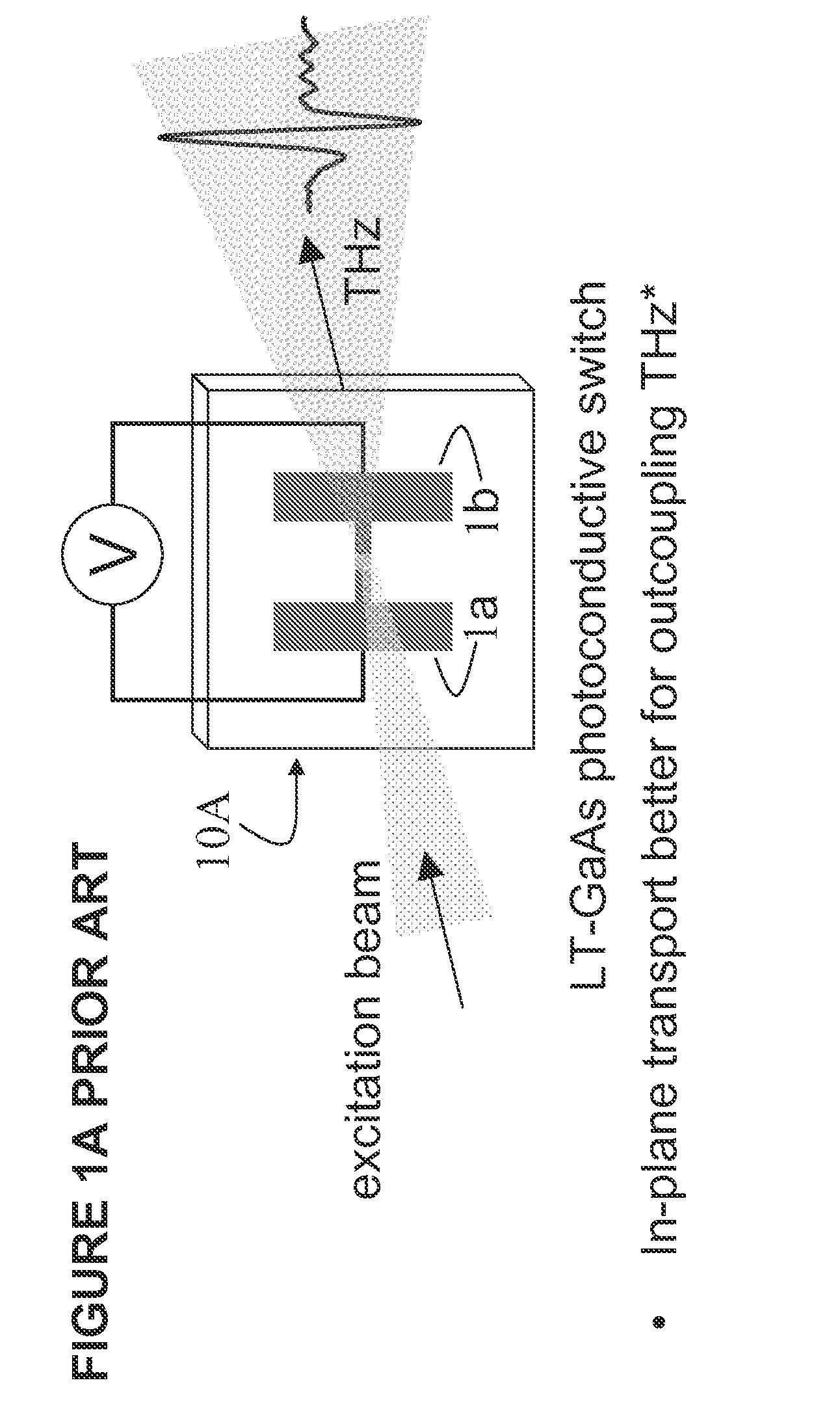

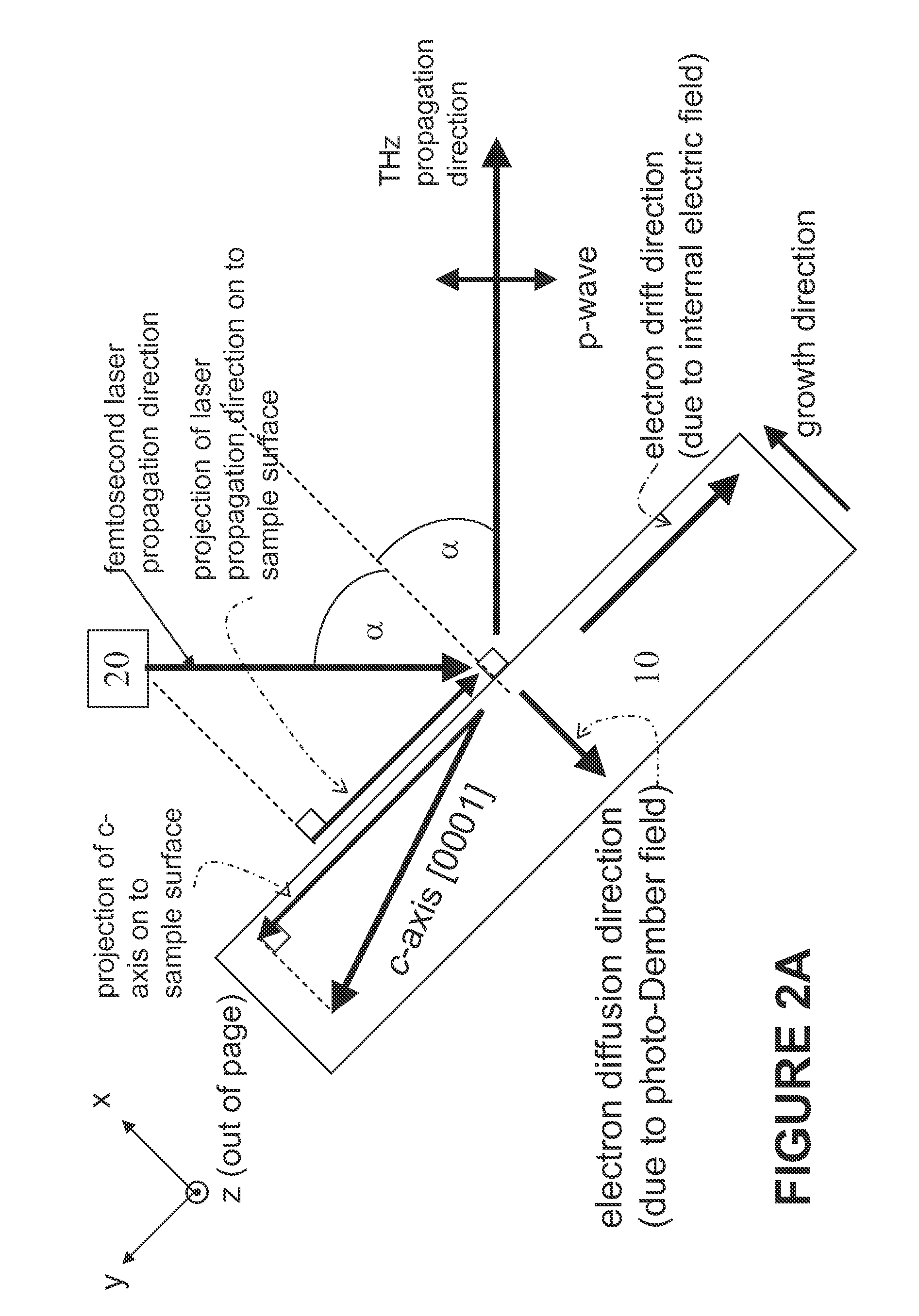

Method and Apparatus for Enhanced Terahertz Radiation from High Stacking Fault Density

ActiveUS20100006780A1Enhanced levelImprove efficiencyRadiation pyrometrySolid masersStacking faultTerahertz radiation

A method and device for generating terahertz radiation comprising a polar crystal material layer operative to emit terahertz radiation; the polar crystal material layer comprising a plurality of stacking faults; the stacking faults lying substantially perpendicular to the polar axis and forming boundaries at which the internal electric polarization terminates leading to charges accumulating at the boundaries, and creation of internal electric fields oriented along the polar axis; a pulsed radiation source for creating photogenerated carriers in the polar crystal material; whereby the photogenerated carriers accelerate in the internal electric fields associated with the termination of the internal electric polarization by the stacking faults to thereby generate terahertz radiation.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Photovoltaic UV detector

InactiveUS20130026382A1Solid-state devicesSemiconductor/solid-state device manufacturingElectricitySchottky barrier

A photovoltaic UV detector configured to generate an electrical output under UV irradiation. The photovoltaic UV detector comprises a first layer comprising an electrically polarized dielectric thin layer configured to generate a first electrical output under the UV irradiation; and a second, layer configured to form an electrical energy barrier at an interface between the second layer and the first layer so as to generate a second electrical output under the UV irradiation, the second electrical output having a same polarity as the first electrical output, the electrical output of the photovoltaic UV detector being a sum of at least the first electrical output and the second electrical output. The electrically polarized dielectric thin layer may be a ferroelectric thin film, which may comprise PZT or PZLT. The second layer may be a metal and the electrical energy barrier may be a Schottky barrier.

Owner:AGENCY FOR SCI TECH & RES

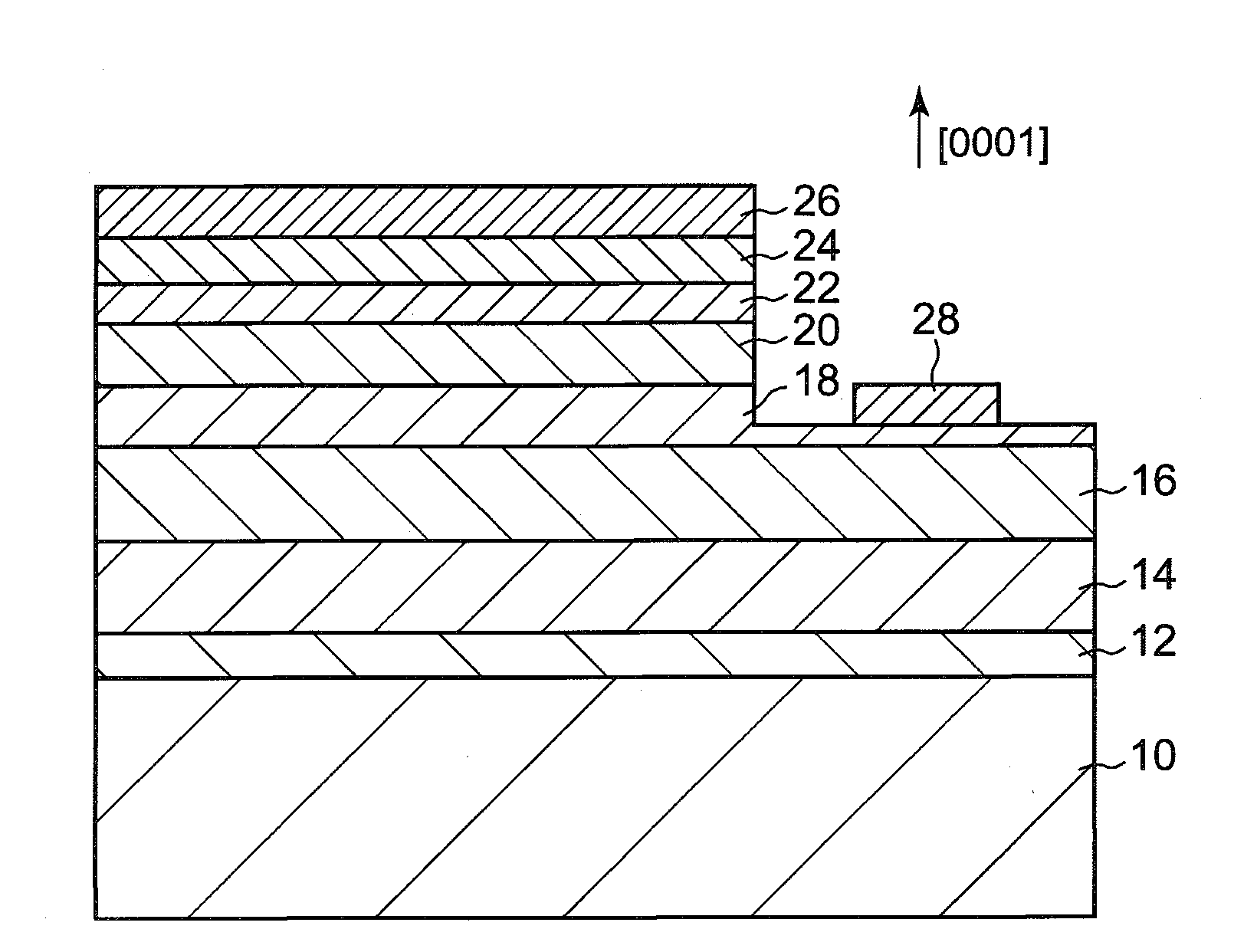

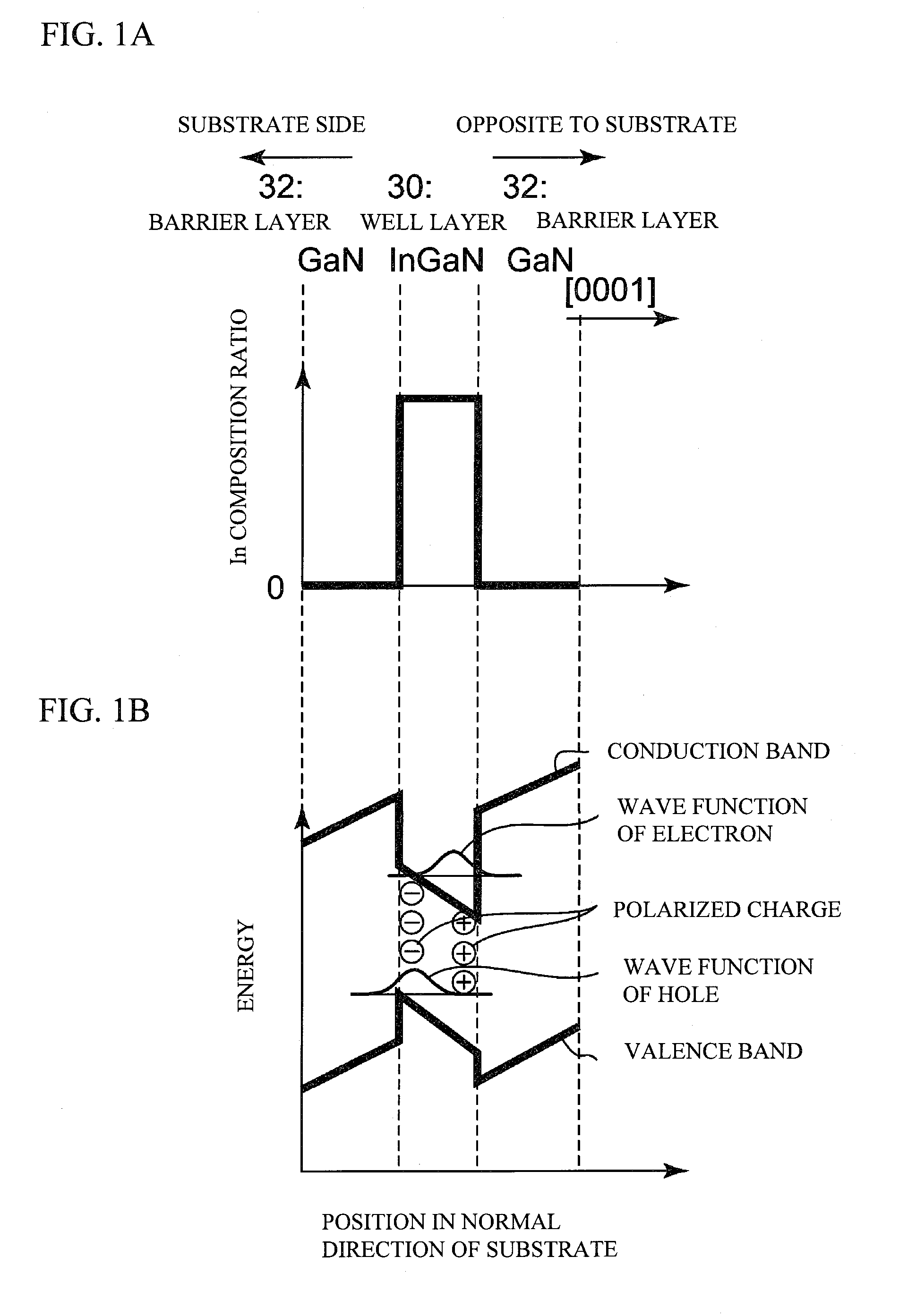

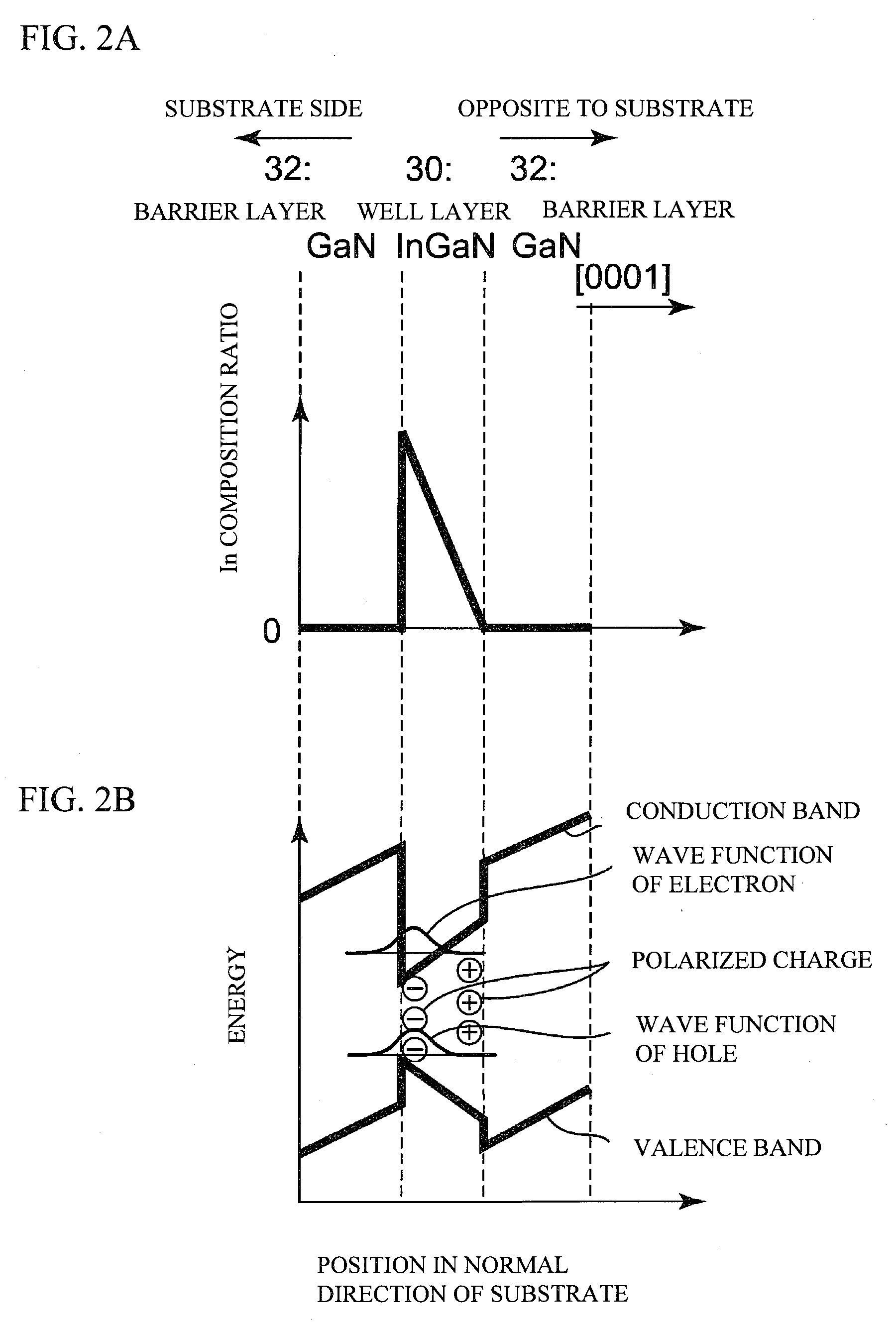

Semiconductor light emitting device

InactiveUS20080283822A1Improve efficiencyPositional separationSemiconductor devicesQuantum wellActive layer

A semiconductor light emitting device includes a substrate and a quantum well active layer. The quantum well active layer has a plurality of barrier layers made of GaN-based semiconductor and a well layer made of GaN-based semiconductor sandwiched between the barrier layers and has polarized charge between the barrier layer and the well layer caused by piezo polarization. The well layer has a composition modulation so that a band gap is minimum at an interface between the well layer and one of the barrier layers more far from the substrate than the other.

Owner:SUMITOMO ELECTRIC DEVICE INNOVATIONS

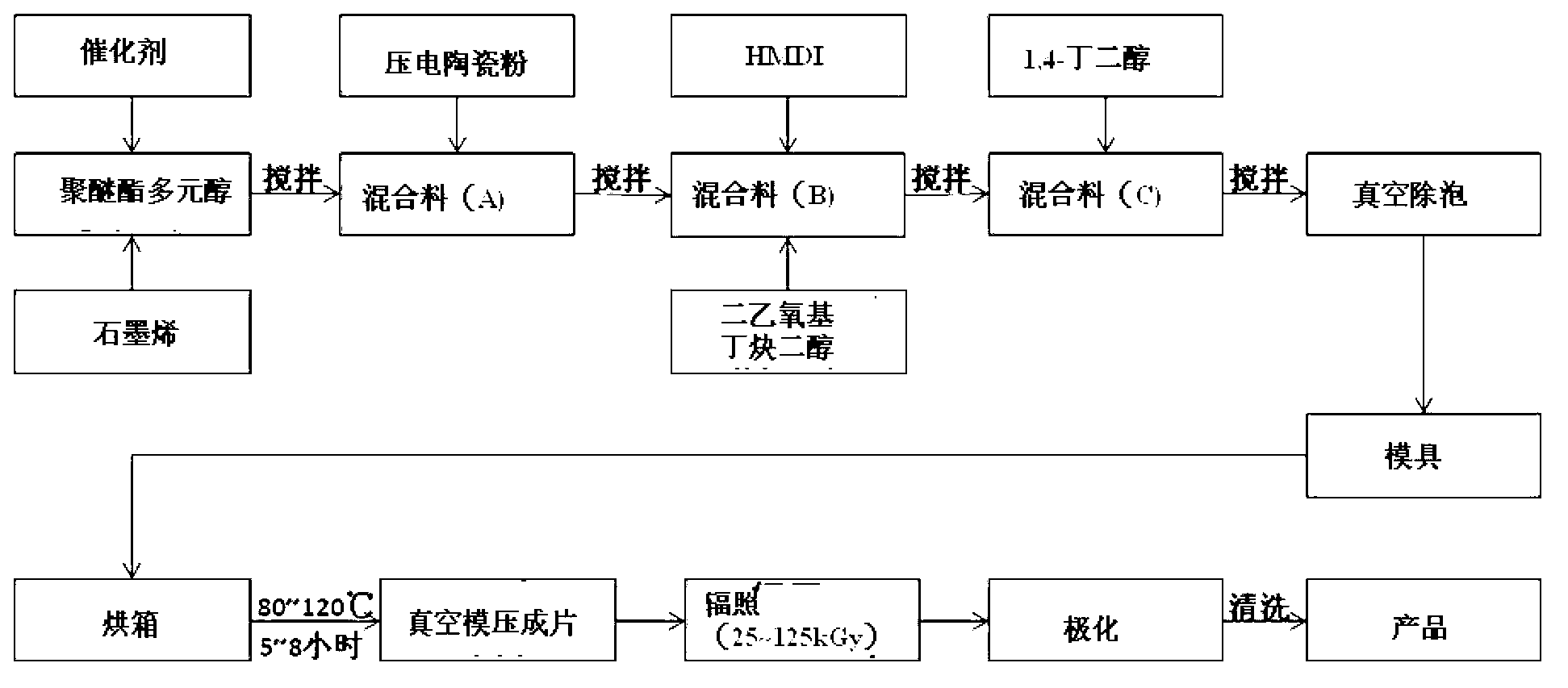

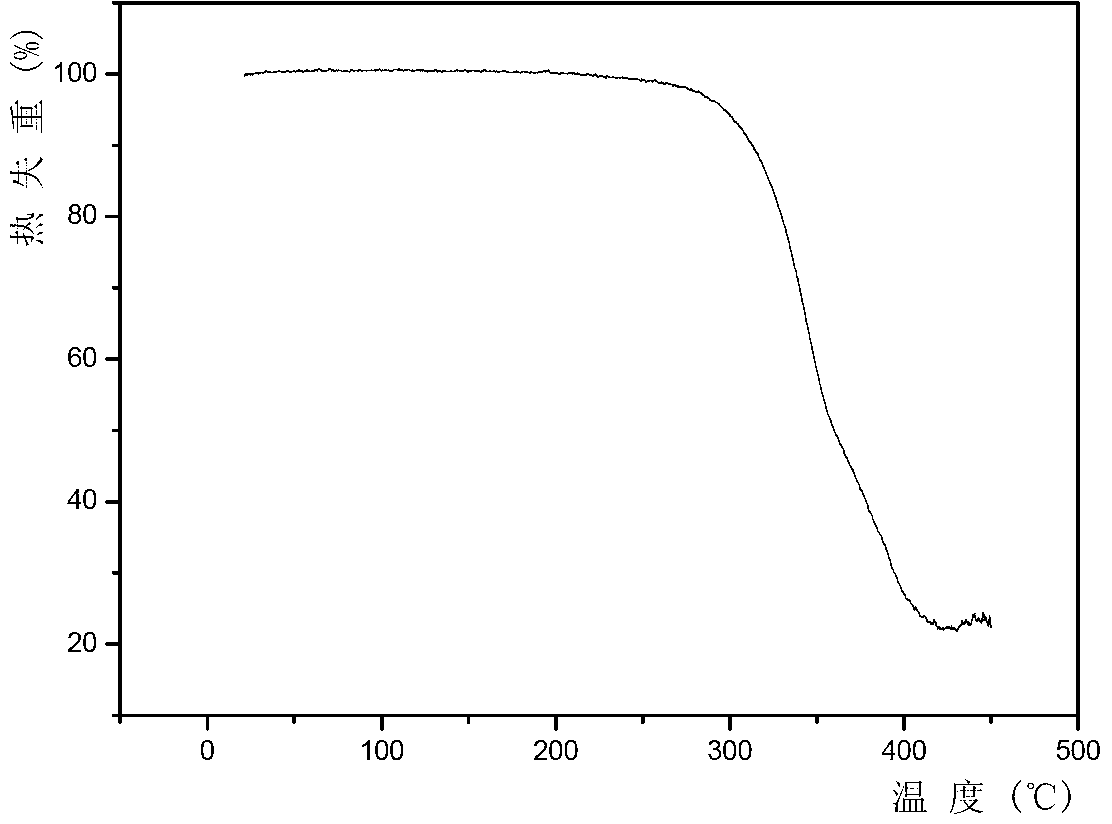

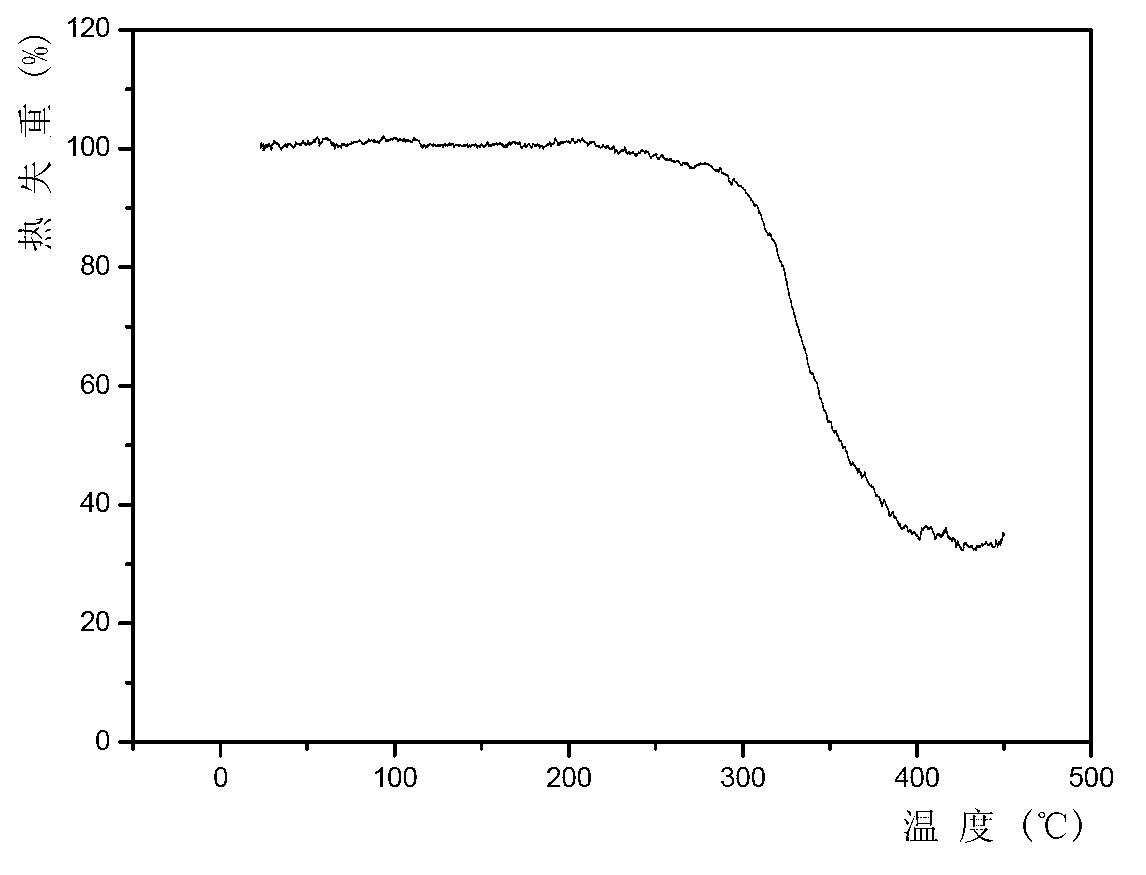

Irradiation-modified polyurethane piezoelectric damping material with conductive channel prepared from graphene and preparation method for same

The invention discloses an irradiation-modified polyurethane piezoelectric damping material with a conductive channel prepared from graphene and a preparation method for the same. The method comprises the following steps of: (1) mixing polyether ester polyol, 4,4'-dicyclohexyl methylene diphenyl diisocyanate, a catalyst, graphene, piezoelectric ceramic powder, dioxethyl butynediol and 1,4-butanediol to obtain a mixed material, performing vacuum defoaming on the mixed material, then pouring the mixed material in a mould, and sheeting via tape-casting to obtain sheets; (2) thermally curing the sheets, and then performing vacuum mould pressing to obtain a plate; and (3) irradiating the plate, and then performing electric polarization treatment to obtain the product. According to the method disclosed by the invention, via the introduction of the graphene conductive channel, the dielectric constant of the material is greatly increased, and the damping performance of the material is greatly improved. According to the method disclosed by the invention, crosslinking treatment is performed on the material via irradiation, so that the mechanical performance of the material is improved under the action of irradiation; and simultaneously, the post-curing time of the material is reduced, the production process is simplified, and the damping performance of the material is good.

Owner:BEIJING RADIATION APPL RES CENT

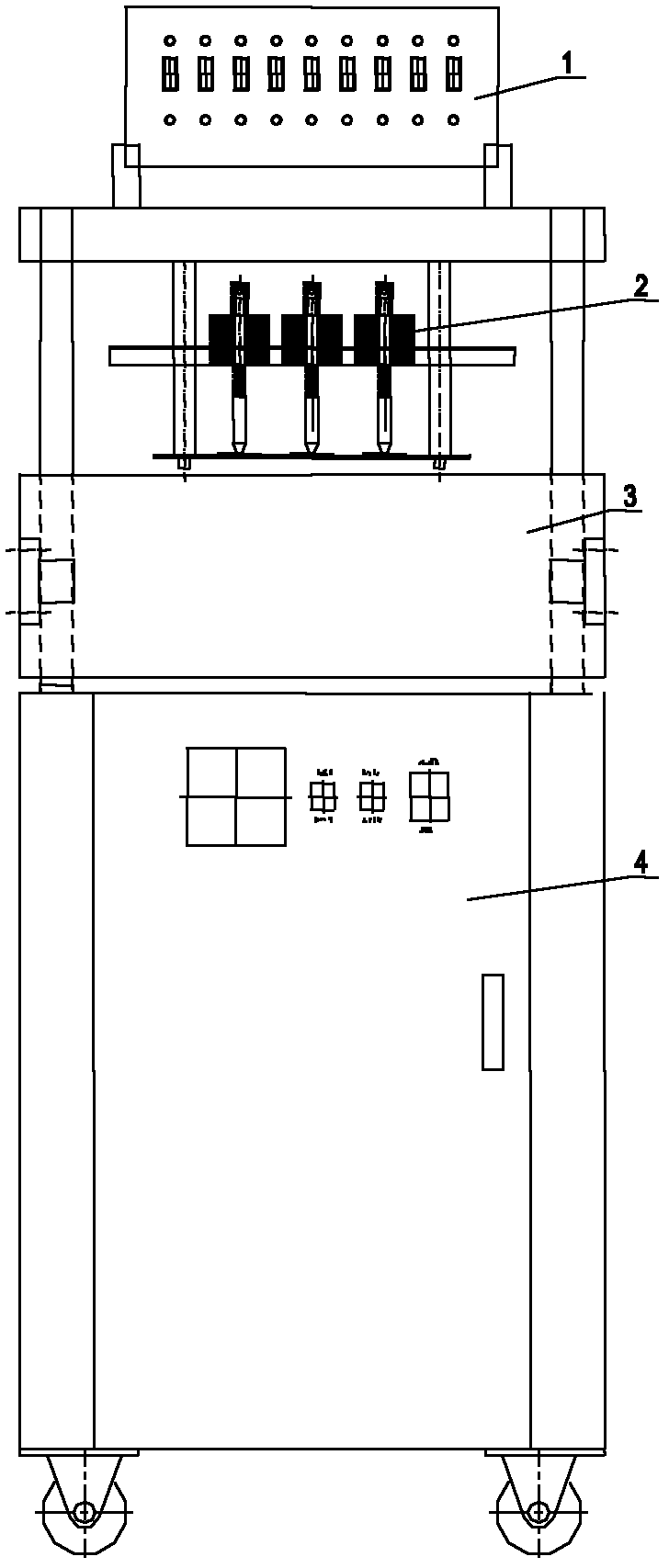

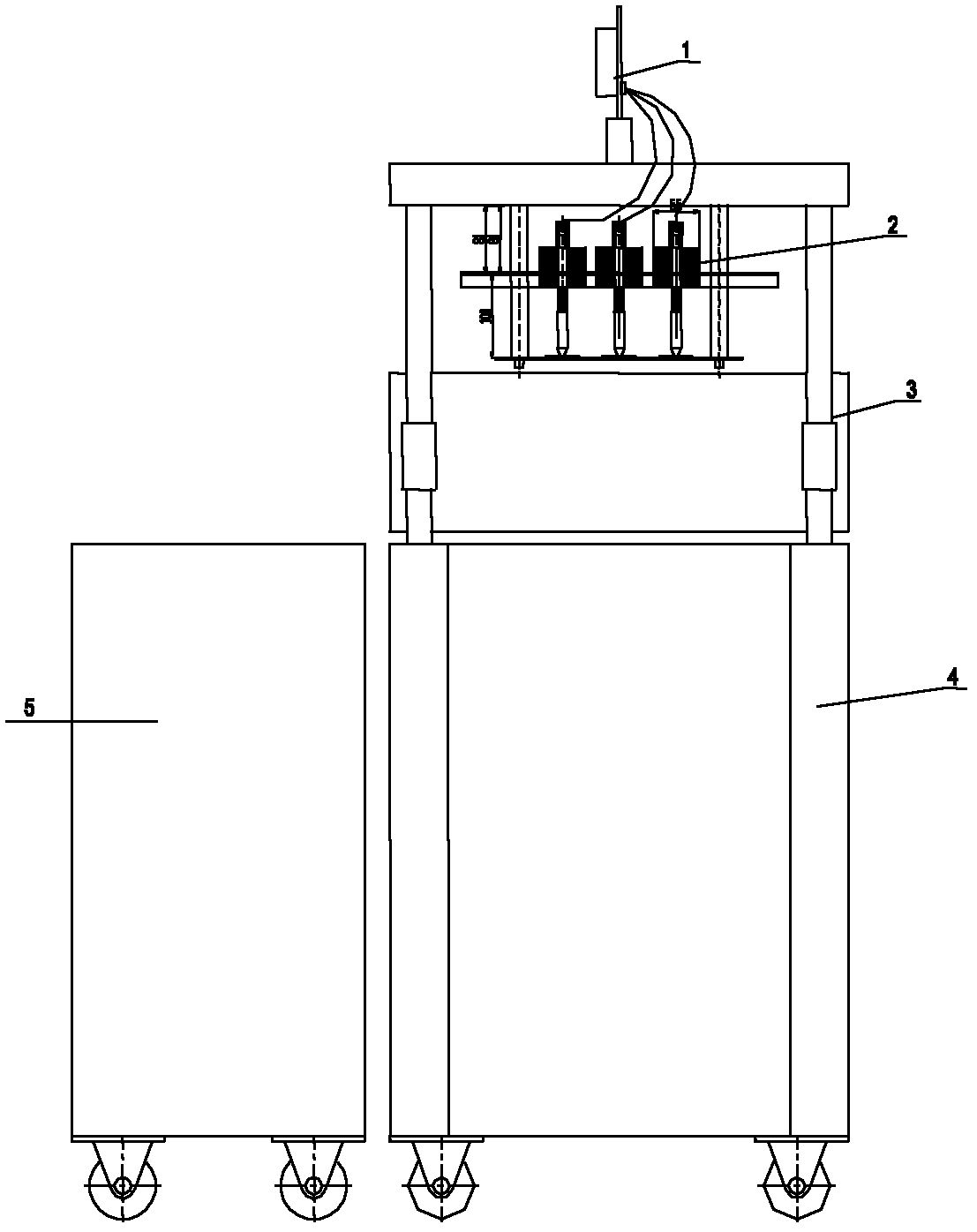

Piezoelectric polarization device and method

InactiveCN102610741AAvoid unsafe factorsEnsure safetyPiezoelectric/electrostrictive/magnetostrictive devicesElectricityRemote control

The invention relates to a polarization technology of piezoelectric ceramic materials and aims at providing a piezoelectric polarization device and a piezoelectric polarization method. The device comprises a polarization host machine, wherein a polarization oil tank is arranged at the upper part of an electric control box and is connected to a motor through a lifting device, an electric heater is arranged in the polarization oil tank, a plurality of polarization electrodes are arranged under an upper side cover plate of the polarization oil tank, the lower ends of the polarization electrodes are provided with clamps used for clamping test pieces to be polarized, a 50KW high-voltage direct current power supply is connected to a remote high-voltage control instrument through a cable, the electric control box is connected to a remote polarization control instrument through a cable, and the remote high-voltage control instrument and the remote polarization control instrument are arranged beyond a distance being at least 1.5meters from the polarization host machine. Operators can operate the polarization host machine in a safe range in a remote control way, so unsafe factors of the operators are avoided. Polarization on a new test piece can be immediately carried out without long-time temperature rise, and the characteristics of energy saving and high efficiency are realized.

Owner:ZHEJIANG UNIV

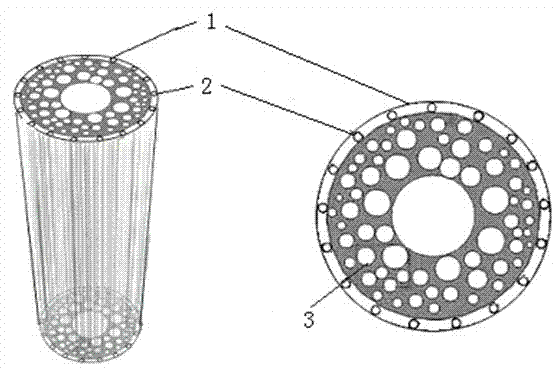

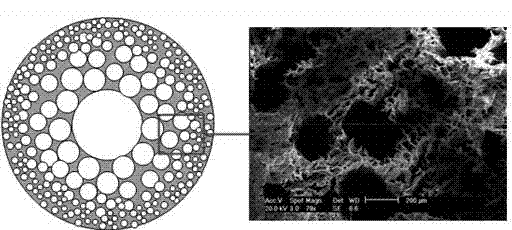

Construction and preparation of three-dimensional bionic electropolarized gradient pore nerve conduit

InactiveCN102727931ASolving Control Release IssuesGuaranteed effective current problemProsthesisPeripheral neuronPeripheral nerve

The invention provides construction and preparation of a three-dimensional bionic electropolarized gradient pore nerve conduit. The nerve conduit is an electropolarized beta-tricalcium phosphate / polylactic acid / hyaluronic acid / chitosan / nerve growth factor nerve conduit, and is prepared by the steps of: preparing a uniformly dispersed electropolarized beta-tricalcium phosphate and polylactic acid core material by using polylactic acid as a substrate material and adding the electropolarized beta-tricalcium phosphate; and preparing a three-dimensional bionic electropolarized gradient pore nerve conduit with component and pore structure double gradient by attaching the hyaluronic acid, the chitosan and the nerve growth factor to the surface of the core material by virtue of electrostatic self-assembly and coupling crosslinking, wherein the length is between 10 and 100mm, the inner diameter is between 1 and 6mm, the wall thickness is between 0.5 and 2mm, and the outer tube wall is of a three-dimensional network structure. The nerve conduit is applied to repairing of a peripheral nervous system, induction of peripheral nerve regeneration and in-vitro culture of nerve cells in tissue engineering. The three-dimensional bionic electropolarized gradient pore nerve conduit has the advantages of simple preparation method, low cost, environmental friendliness and high economical benefit, and is applicable to industrial production.

Owner:武汉渝联生物科技有限公司

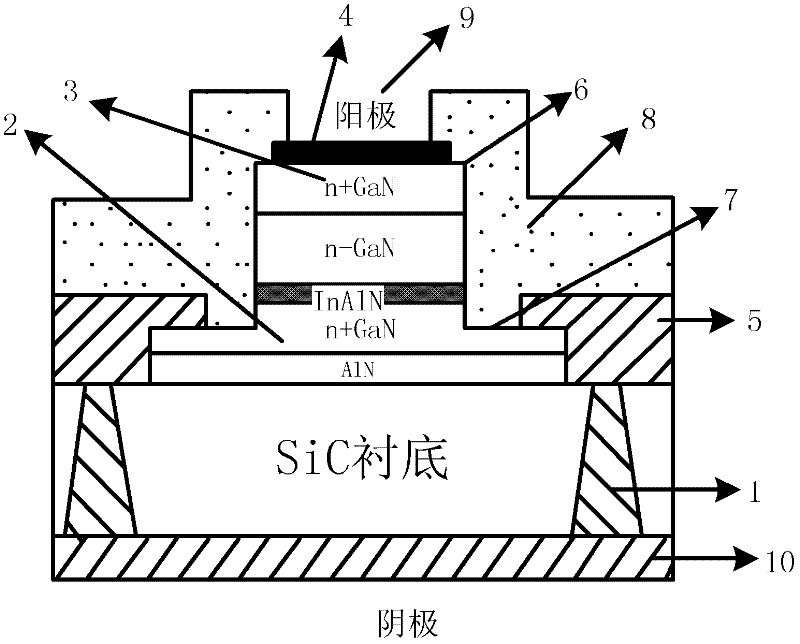

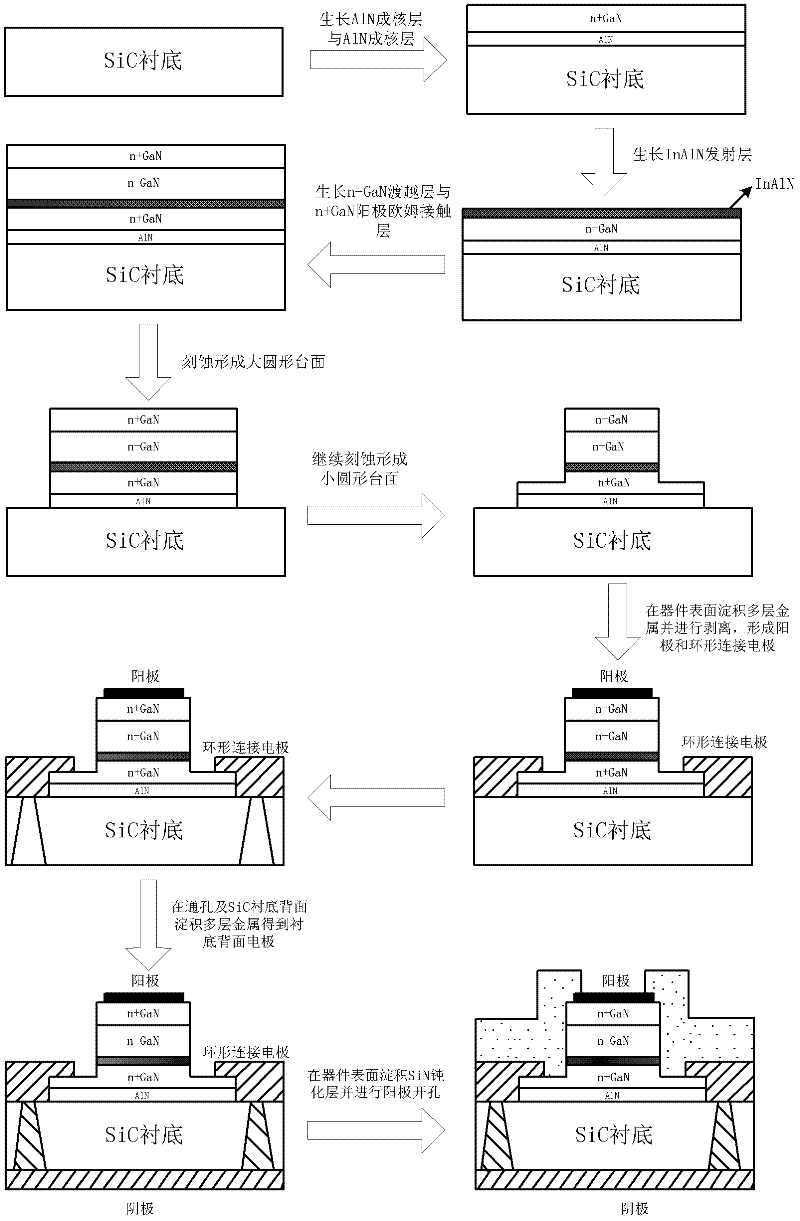

Terahertz GaN Gunn diode based on SiC substrate and manufacturing method thereof

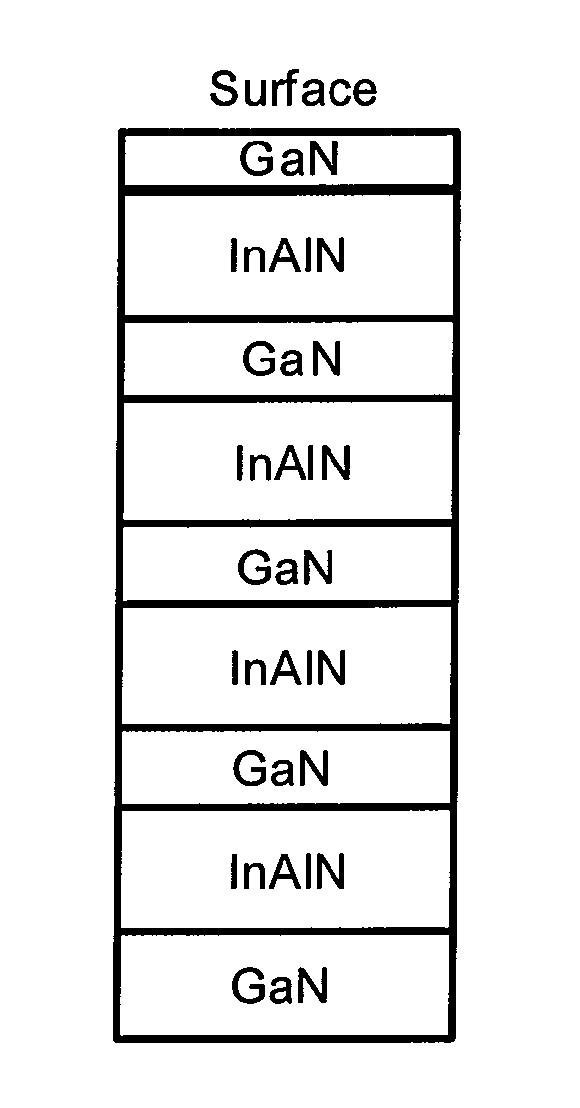

ActiveCN102522502AIncrease powerHigh frequencyBulk negative resistance effect devicesOhmic contactActive layer

The invention discloses a terahertz GaN Gunn diode based on an SiC substrate and a manufacturing method thereof, which are used for mainly solving the problems of low output power, poor heat radiation performance and the like in the traditional Gunn device structure. The diode respectively comprises the SiC substrate, an AlN nucleating layer, an n+GaN ohmic contact layer, an electron emitting layer, an n-GaN active layer and an n+GaN ohmic contact layer from bottom to top and is characterized in that the electron emitting layer is made of an InAlN material with 14-22% of an In component and has the thickness of 80-200 nm; a through hole (1) is etched in the SiC substrate; metals Ti / Al / Ni / Au are deposited at the bottom of the substrate; and the metals are connected with an annular electrode (5) through the through hole, so that a longitudinal device structure is formed. The terahertz GaN Gunn diode disclosed by the invention is capable of eliminating a piezoelectric polarization effect and obviously reducing interface dislocation and the length of a Dead Zone, has the advantages of high output power and working frequency, and is applied to working in terahertz frequency bands.

Owner:云南凝慧电子科技有限公司

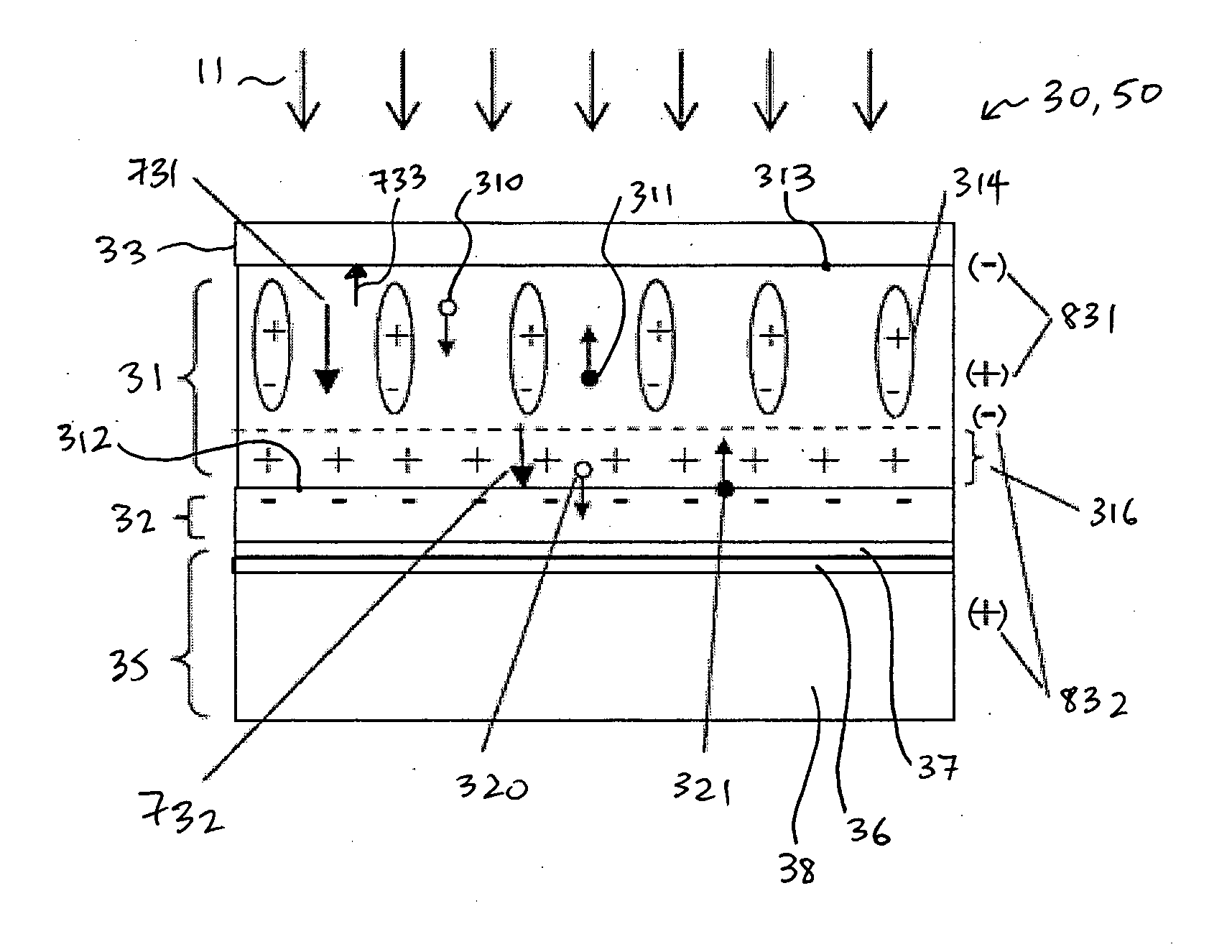

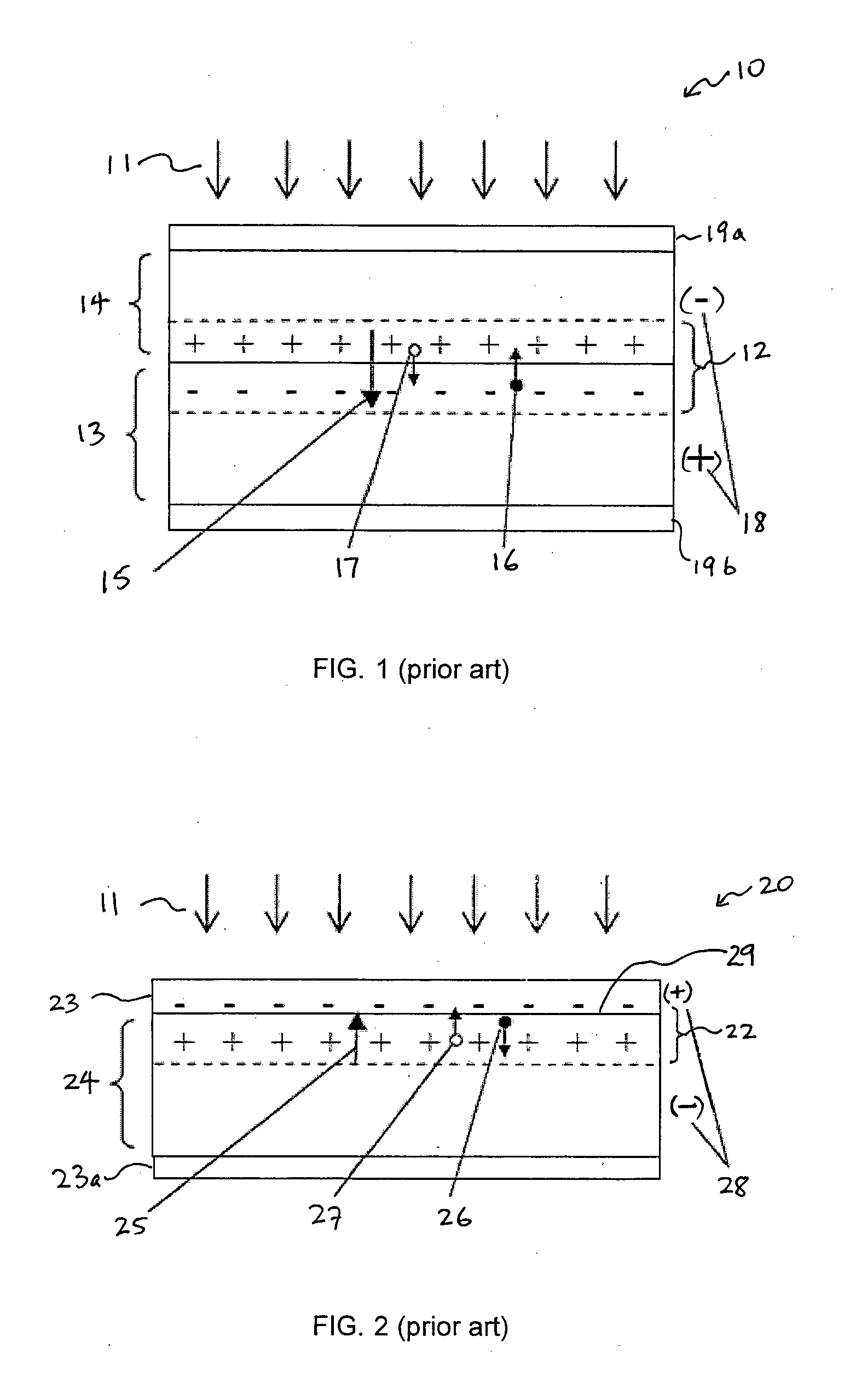

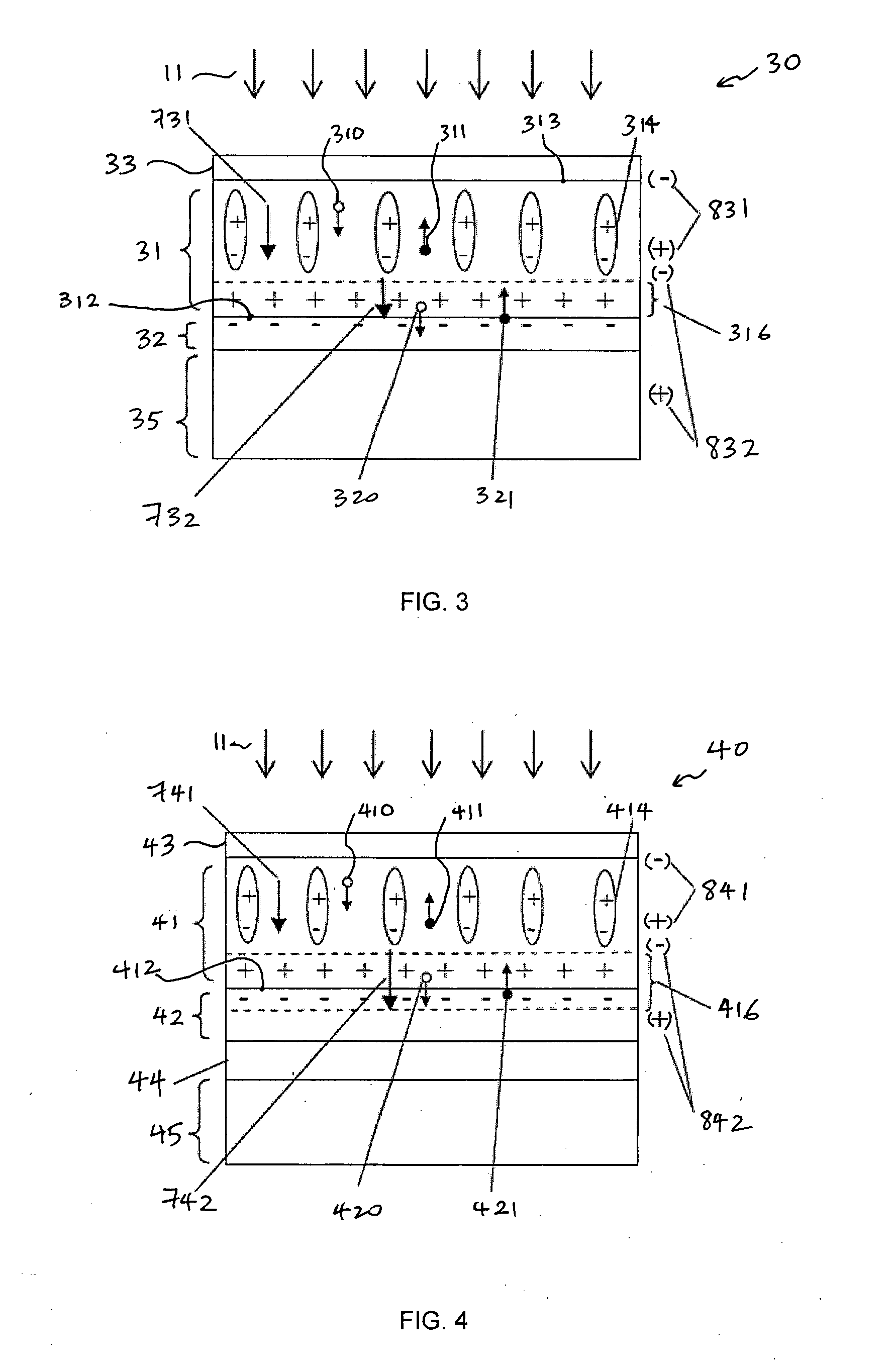

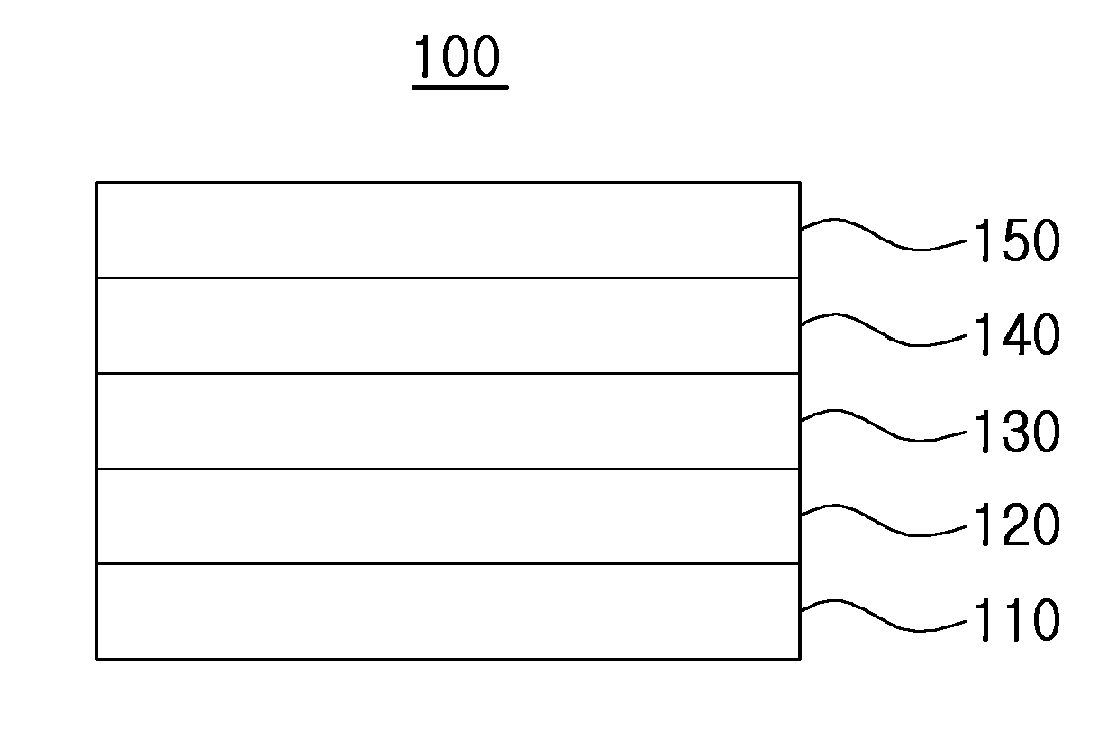

Solar cell and method of manufacturing therefor

ActiveUS20150287848A1Improve photoelectric conversion efficiencyEasy to collectFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringPhotoelectric conversion efficiency

The present invention relates to a structure of a solar cell for improving photoelectric conversion efficiency of the solar cell, and a manufacturing method therefor. One aspect of the solar cell according to the present invention relates to a solar cell having a light-absorbing layer formed between two electrodes arranged to face each other, wherein an electrical polarization layer comprising an electrical polarization material forming an inner electrical field is formed between the electrodes and the light-absorbing layer.

Owner:JUN YOUNG KWON

Electro-optic phase modulator and modulation method

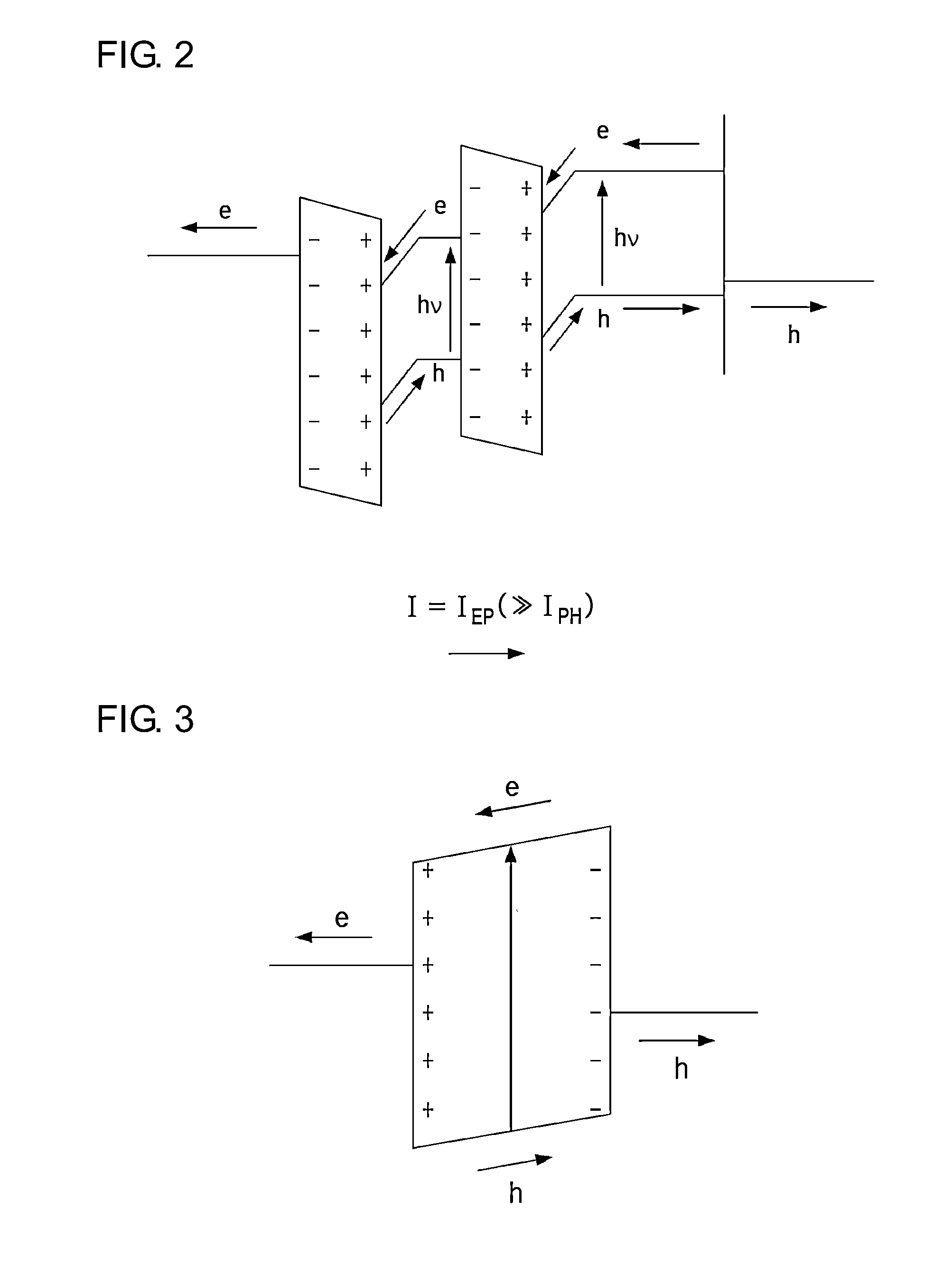

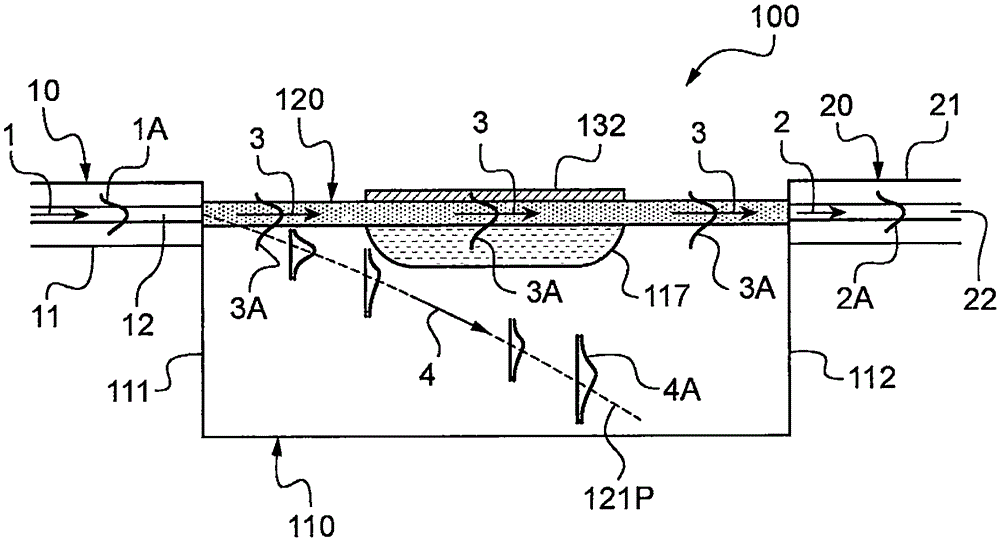

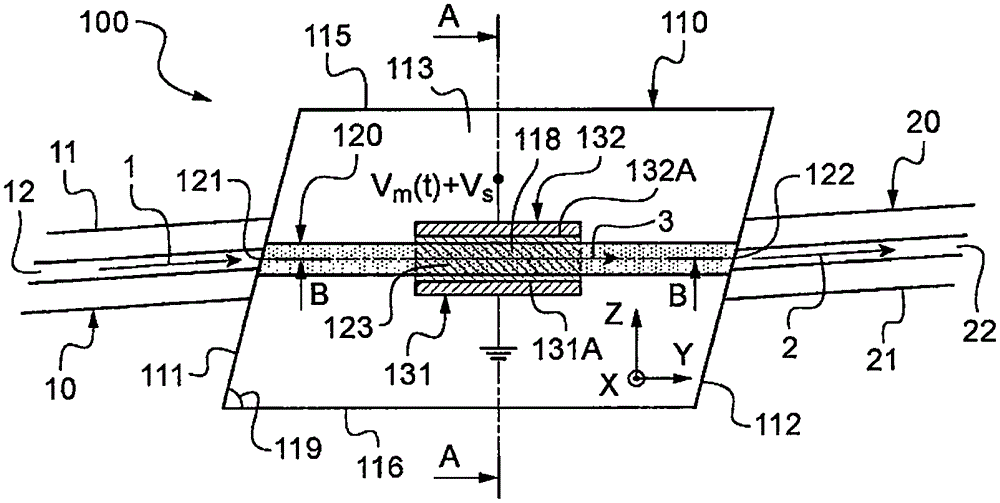

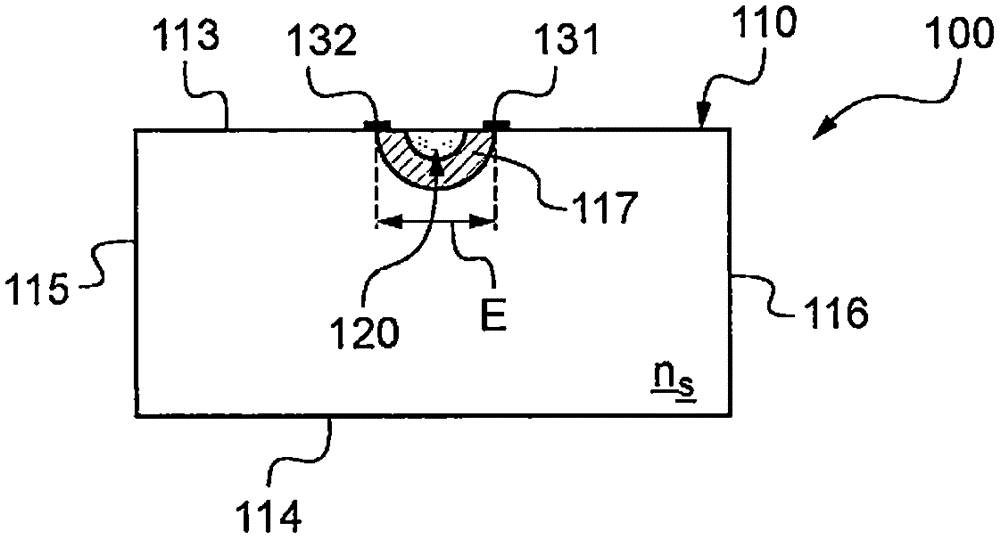

The electro-optic phase modulator intended to modulate the optical phase of a lightwave incident on the modulator, includes an electro-optic substrate having an entrance face and an exit face, an optical waveguide of refractive index (ng) higher than that (ns) of the substrate, continuously rectilinear from a guide entrance end located on the entrance face to a guide exit end located on the exit face, and which is adapted to guide the incident lightwave partially coupled in the waveguide into a guided lightwave propagating along the optical path of the waveguide between the guide entrance end and exit end, and at least two modulation electrodes arranged parallel to the waveguide, so as, when a modulation voltage (Vm(t)) is applied between these modulation electrodes, to introduce a modulation phase-shift, function of the modulation voltage, in the guided lightwave. The phase modulator further includes elements for the electric polarization of the substrate.

Owner:IXBLUE

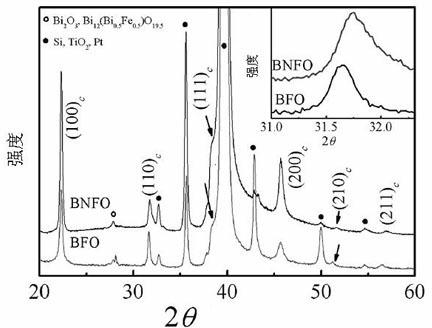

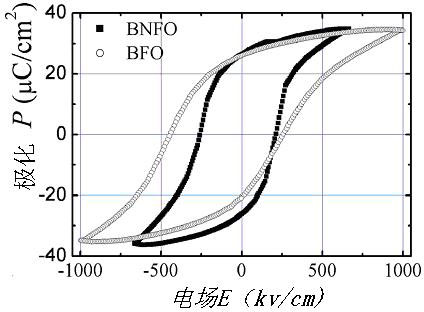

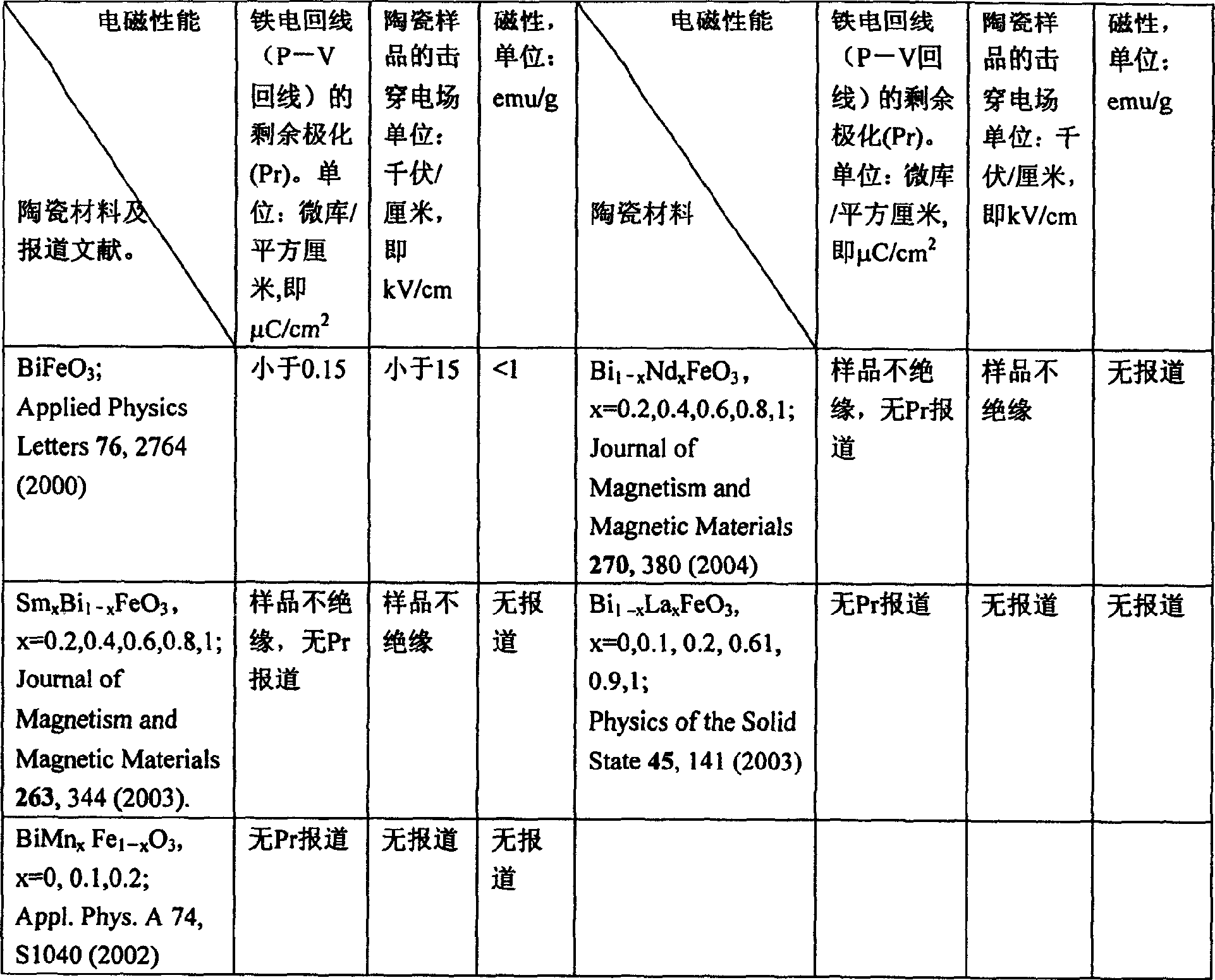

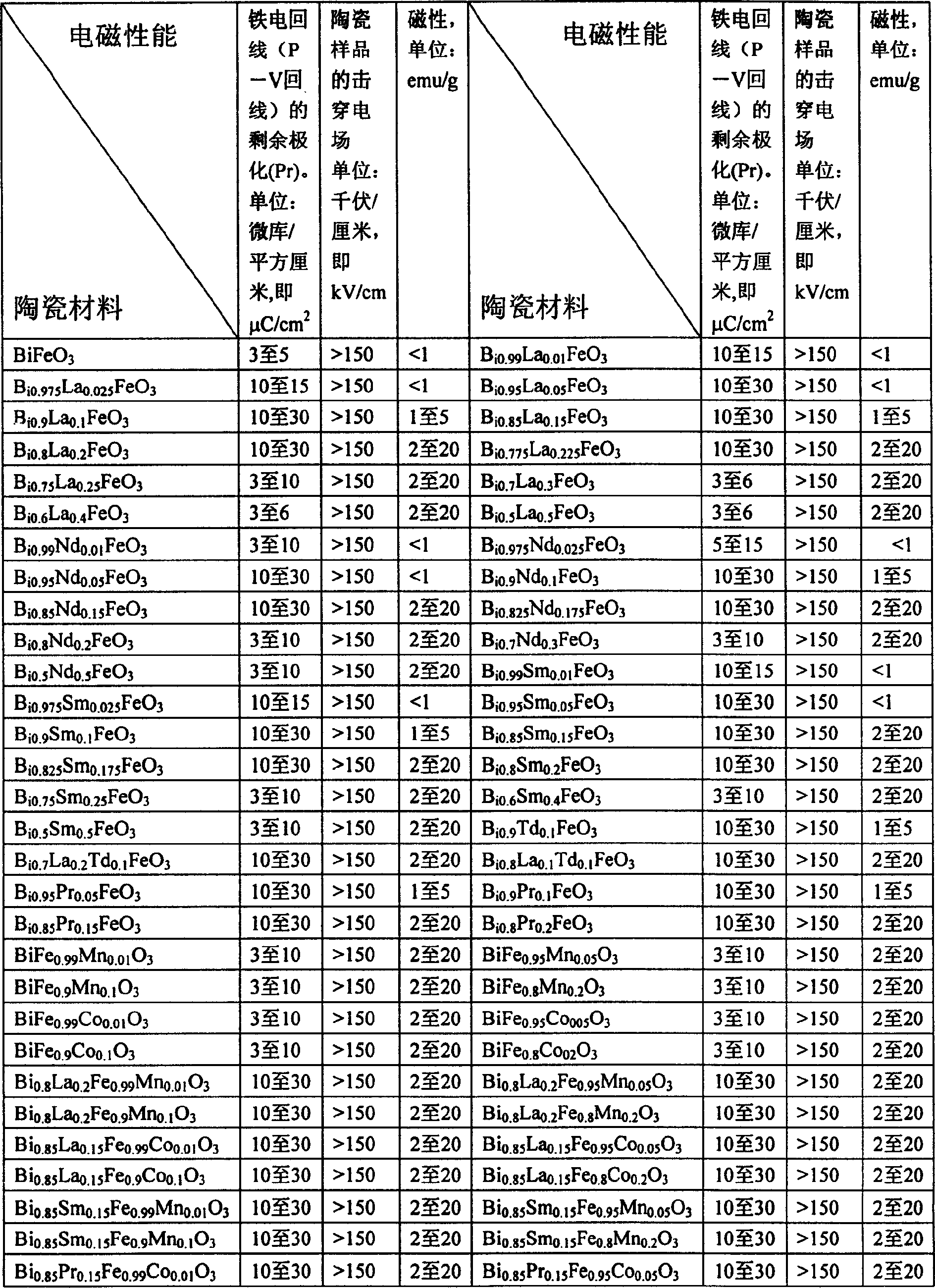

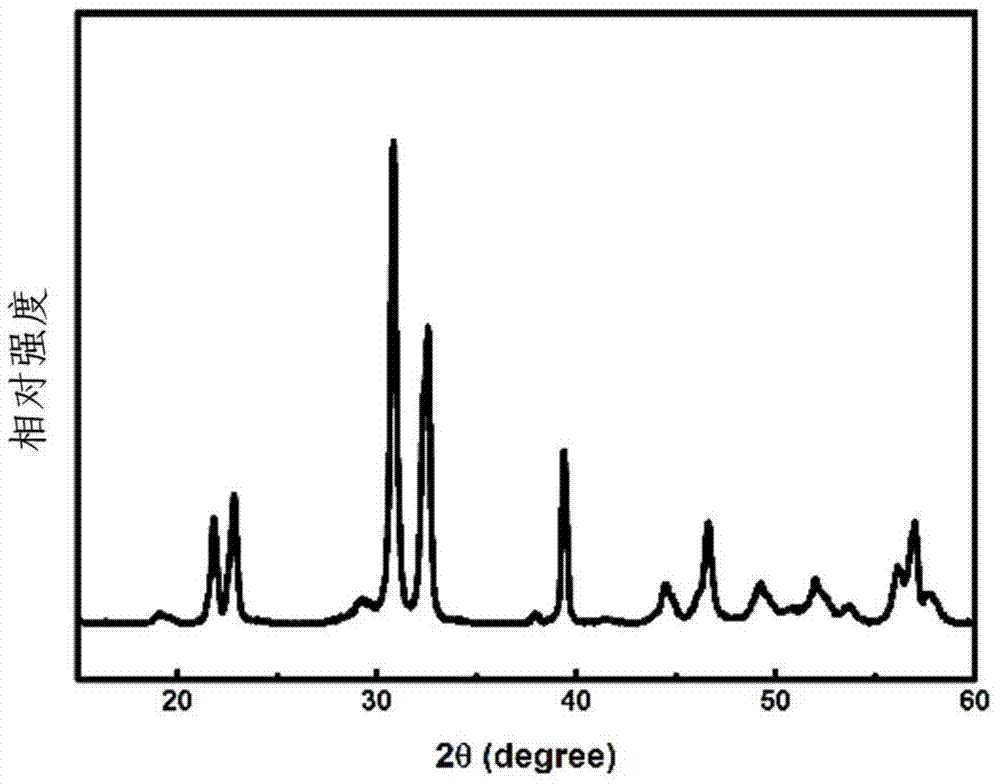

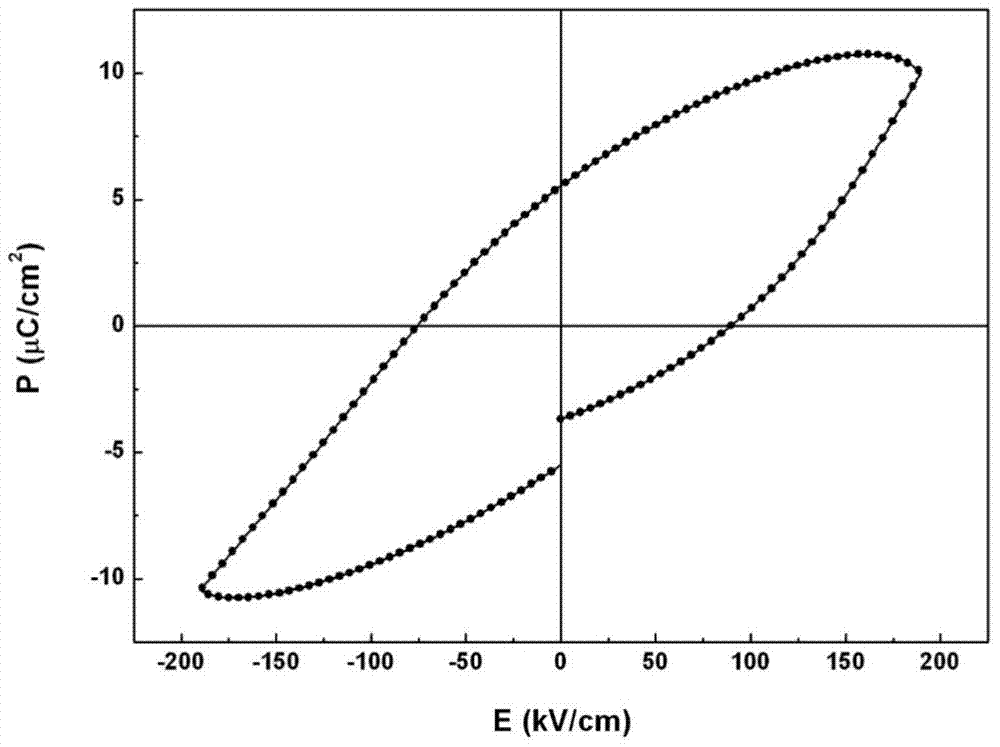

Magneto-electric coupled ceramic materials and preparing method thereof

The invention discloses a magneto-electric coupling ceramics material. Its chemical formula is (Bi1-xAxFe1-yByO3), and 0<=x<0.5, 0<=y<0.2, x, y can not equal 0 in the same time. an is trivalency rare earth metal ion selected one or two kinds from La, Nd, Td, Sm and Pr. B is a transition metal ion Mn or Co. The material has following physical property: breakdown electric field is over 150kV / cm, its breakdown electric field is between 3 microcoulomb per square centimeter to 30 microcoulomb per square centimeter. Meanwhile, the invention discloses the method to produce the material. Its feature is when sintering, temperature would increase at the speed of 30 degree per second and stabilizing between 850 degree centigrade and 940 degree centigrade, then cooling quickly.

Owner:NANJING UNIV

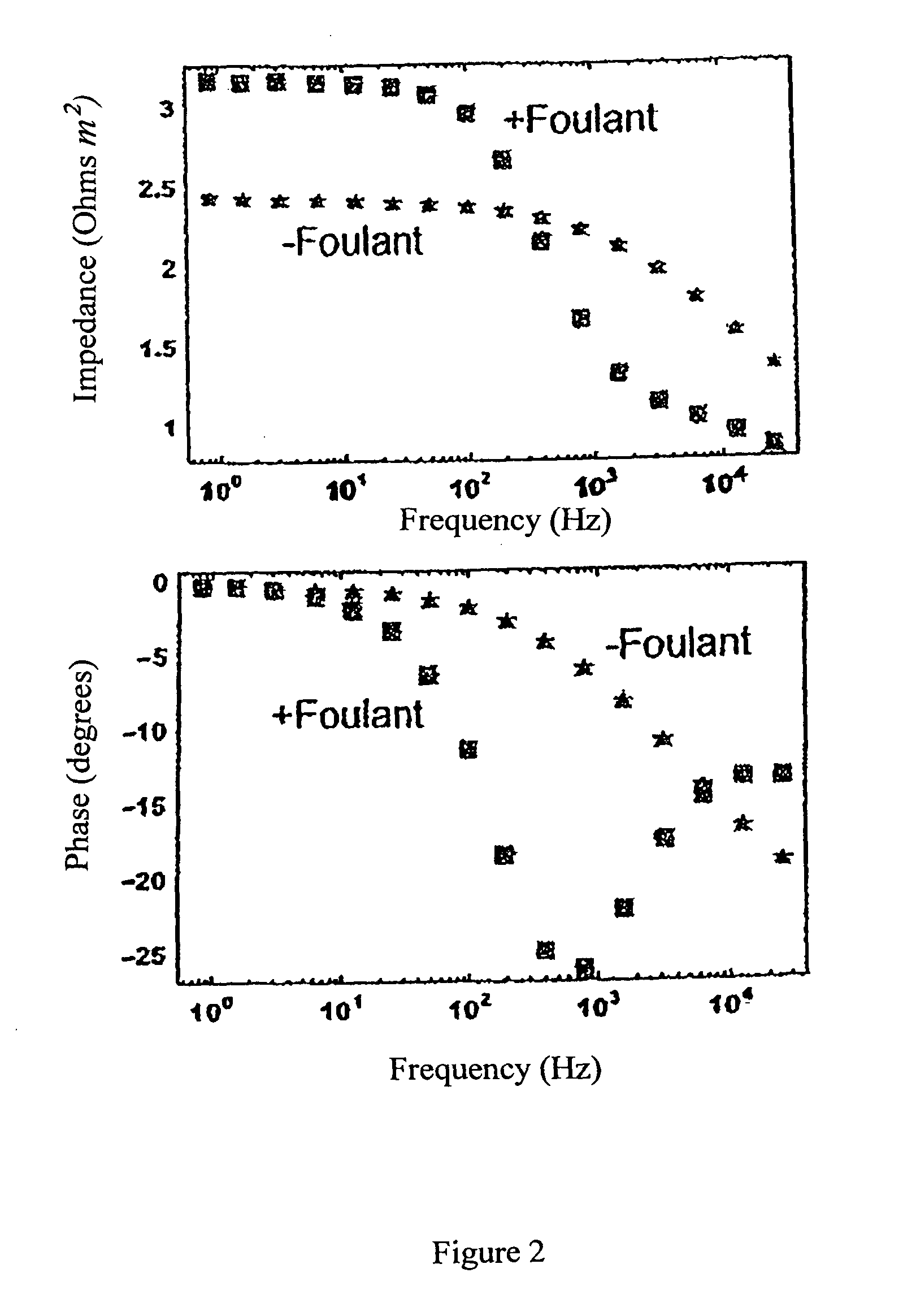

In situ membrane monitoring

InactiveUS20100308842A1Precise cuttingVibration measurement in solidsMembranesElectricityStimulus current

Owner:INPHAZE AUSTRALIA PTY LTD

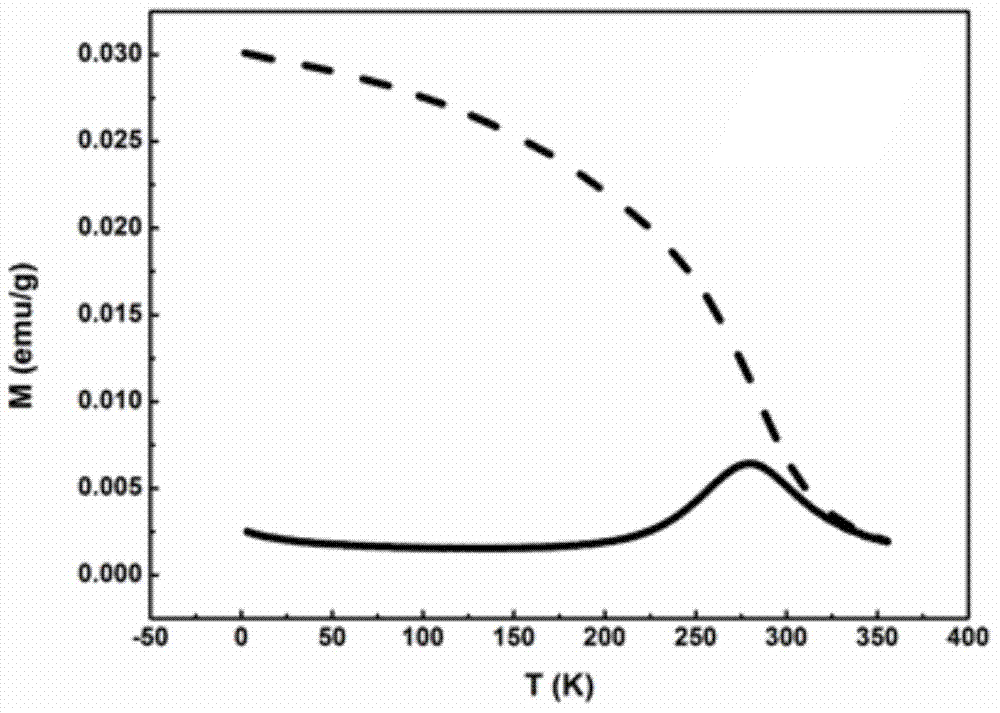

Single-phase oxide multiferroic ceramic with exchange bias effect and preparation method thereof

The invention provides a single-phase oxide multiferroic ceramic with exchange bias effect. The single-phase oxide multiferroic ceramic is as shown in the formula (I): Bi10Fe5.9Co0.1Ti3O30 (I). The single-phase oxide multiferroic ceramic has high Curie temperature, has ferroelectricity and ferromagnetism under the room temperature at the same time, and has intrinsic exchange bias effect. Not only a magnetic field can be regulated and controlled, but also an electric field can be regulated and controlled, the possibility of encoding storage information through the adoption of electric polarization and magnetic polarization at the same is provided, and then a magneto-electric mutual-control nonvolatile storage magnetic medium with ultrahigh storage density becomes possible.

Owner:UNIV OF SCI & TECH OF CHINA

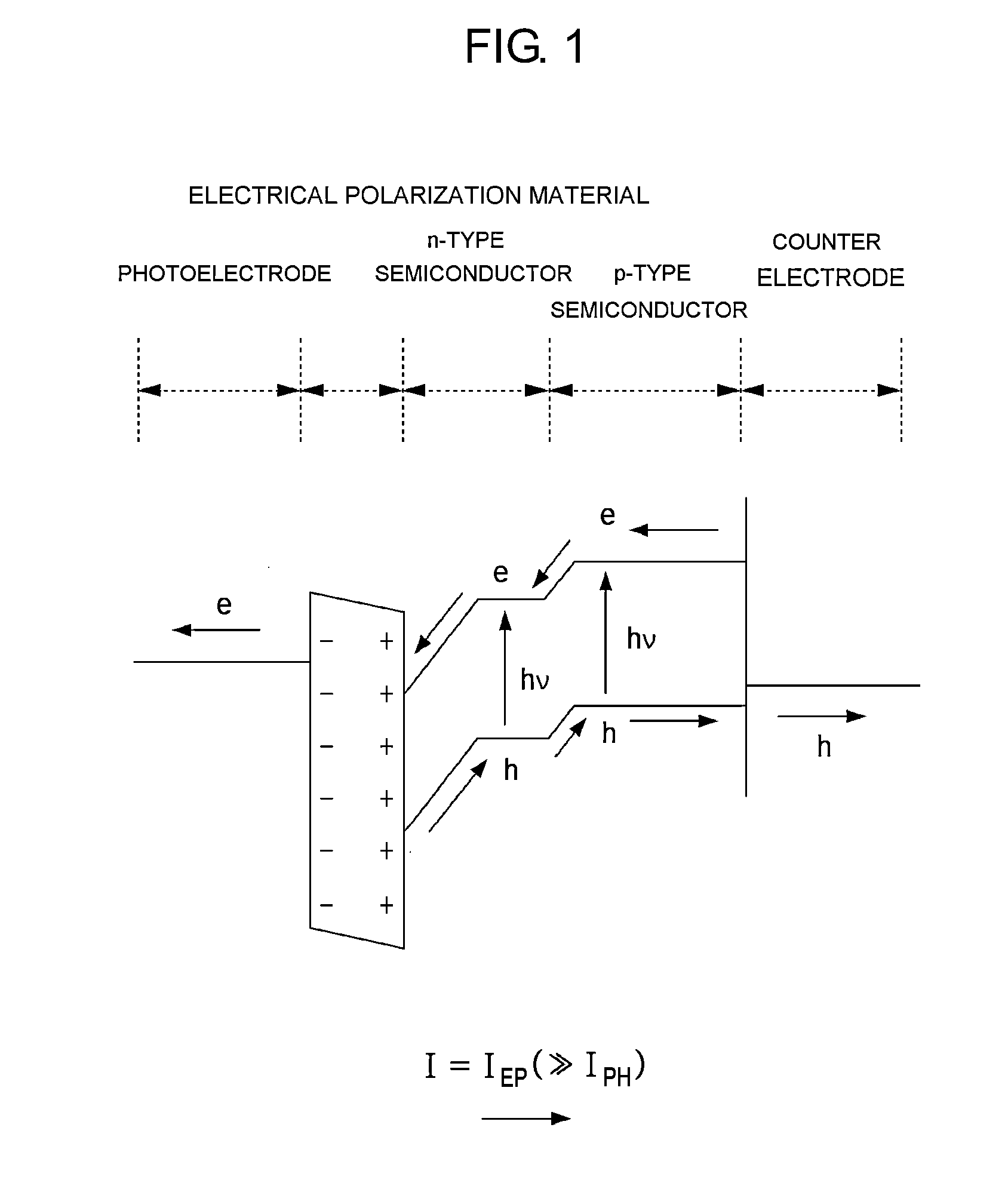

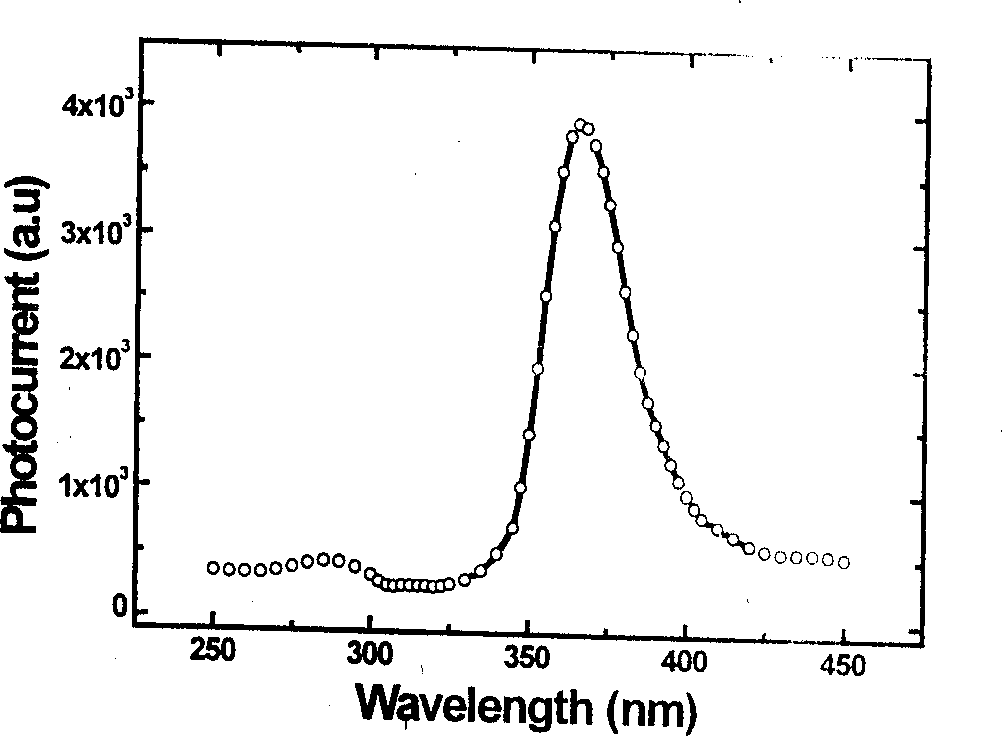

High-responsivity photoelectronic detector based on the polarization effect of III family nitride heterojunction structure

InactiveCN1371133AImprove responsivenessEffective space separationPhotometrySolid-state devicesMetal electrodesSapphire

An optical detector has the following strain alloplasm materials on the silicon or sapphire gemstone substrate: with AIN as the buffer layer strain alloplasm structure GAN is grown extendedly. Polarized electric field arisen from the self-piezoelectric polarization effect especially for the strain alloplasm structure can effectively separate optical-electron-cavity couple to lower the direct complex lose to increase the lift of optical-carrier. Alloying metal electrode extends to the inner part of GAN from surface to reduce the surface complex loss of the carrier to raise the collective efficiency.

Owner:NANJING UNIV

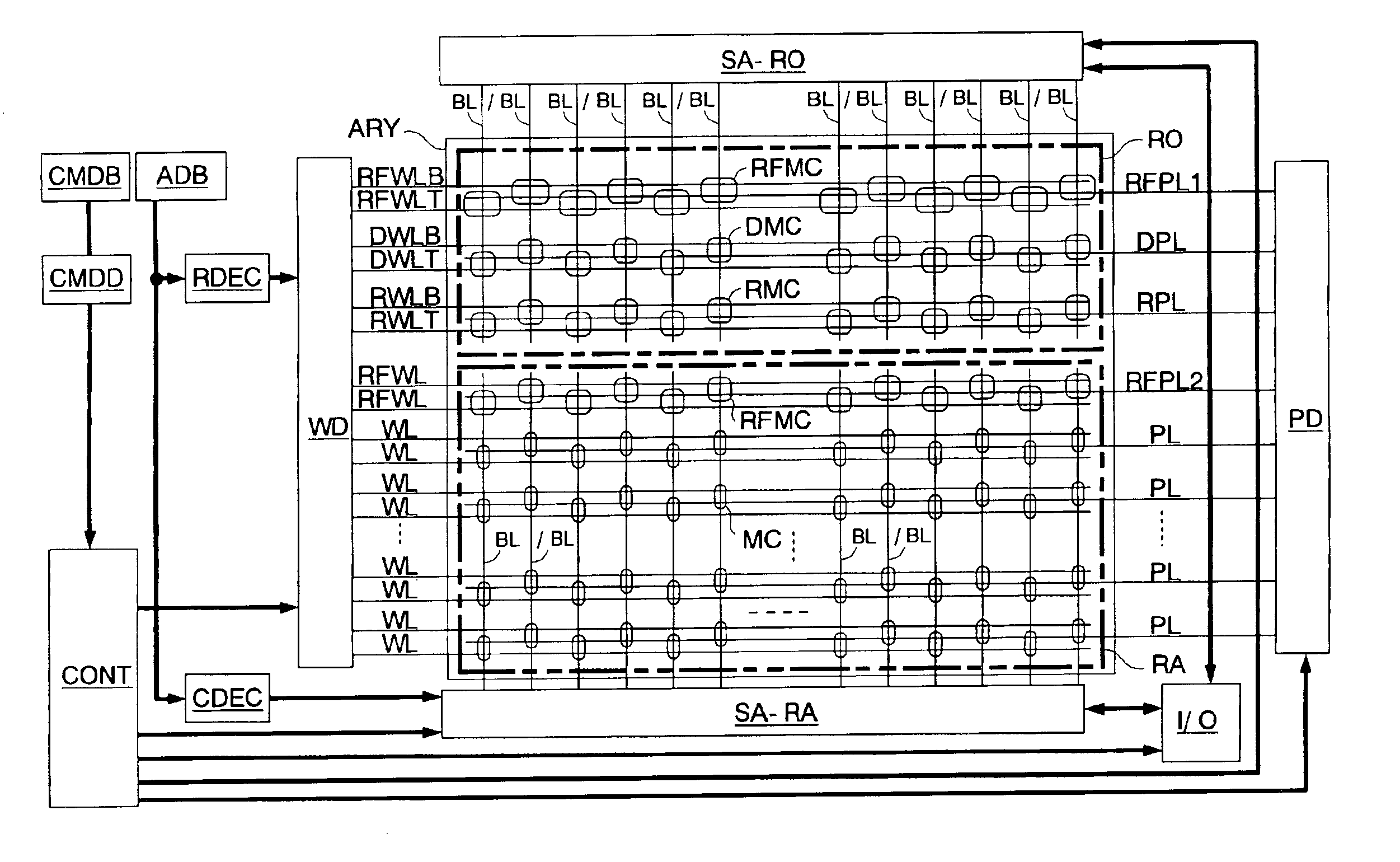

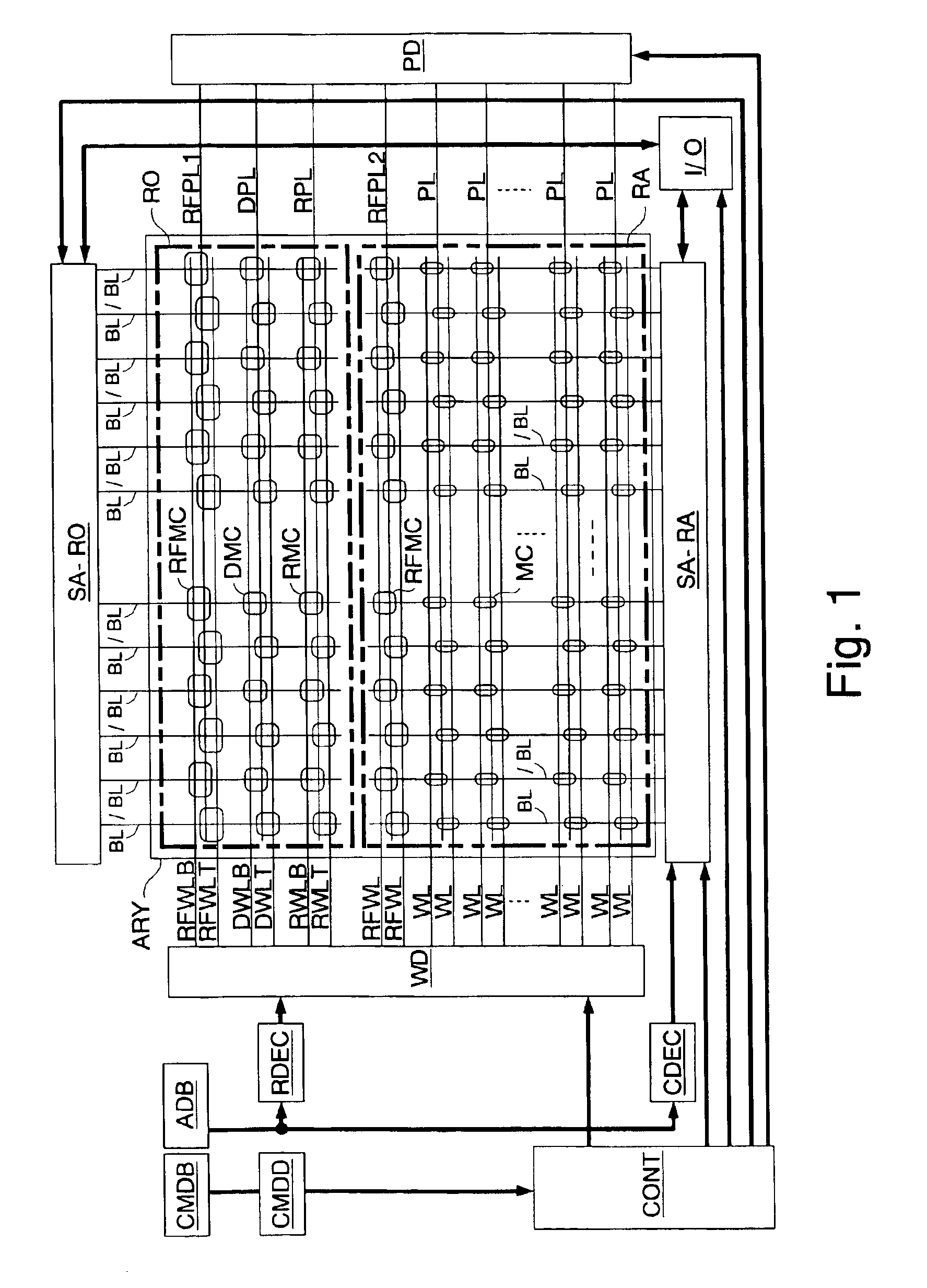

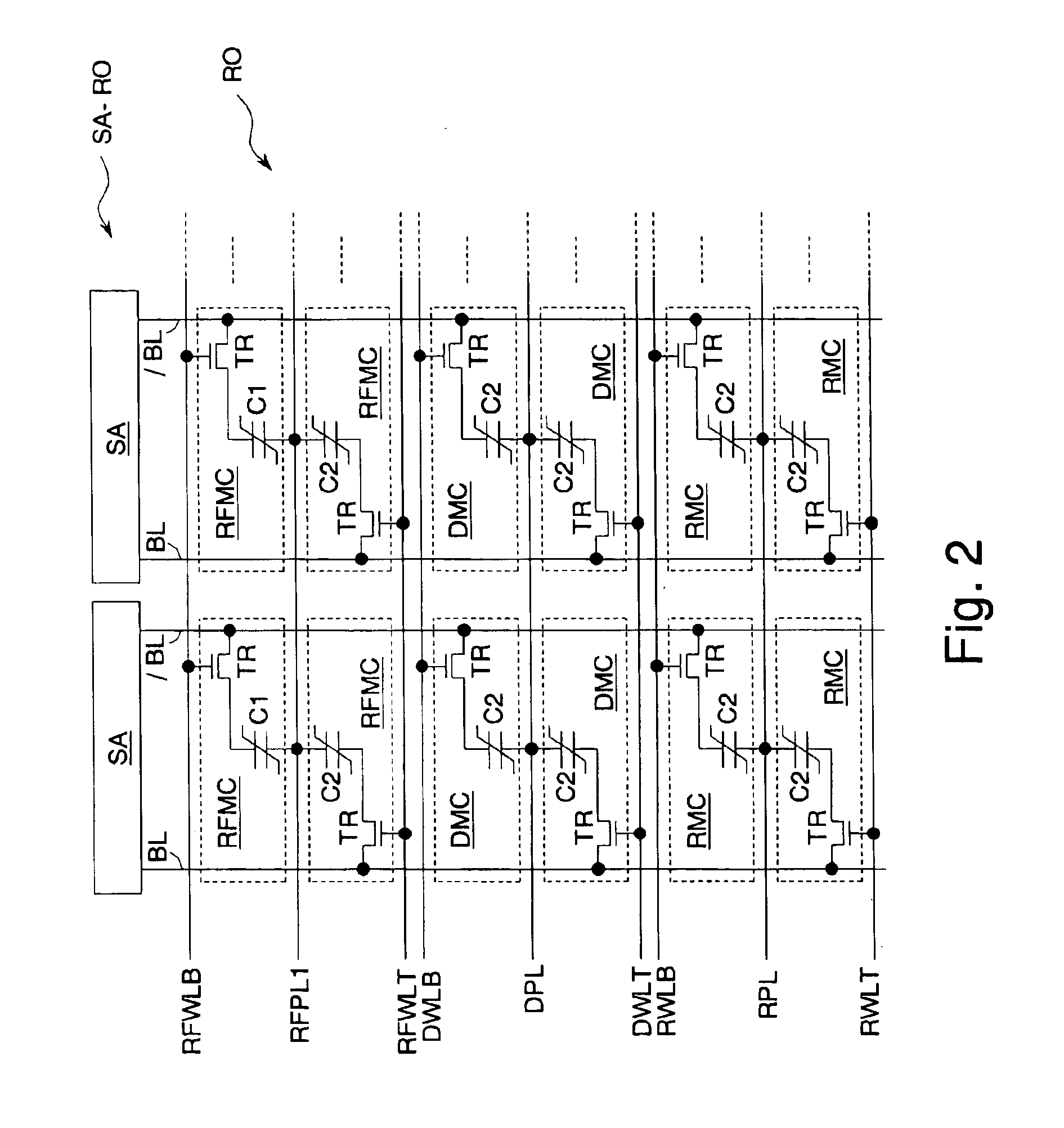

Ferroelectric memory and method of reading data in the same

InactiveUS6847539B2Reduced residual dielectric polarization valueSmall sizeRead-only memoriesDigital storageComputer architectureReference memory

Prior to the first read operation for reading data from real memory cells, the second read operation for reading data from dummy memory cells is carried out using reference memory cells. A reduced residual dielectric polarization values of ferroelectric capacitors of the reference memory cells due to heat treatment and the like in manufacturing process, is recovered by the second read operation to an original value before the read access to the real memory cells. Therefore, data in the real memory cells is properly read out in the subsequent first read operation. As a result, it is possible to certainly read data from a ROM area in a ferroelectric memory to which data is written in advance in a test process of the manufacturing process, for example.

Owner:FUJITSU LTD

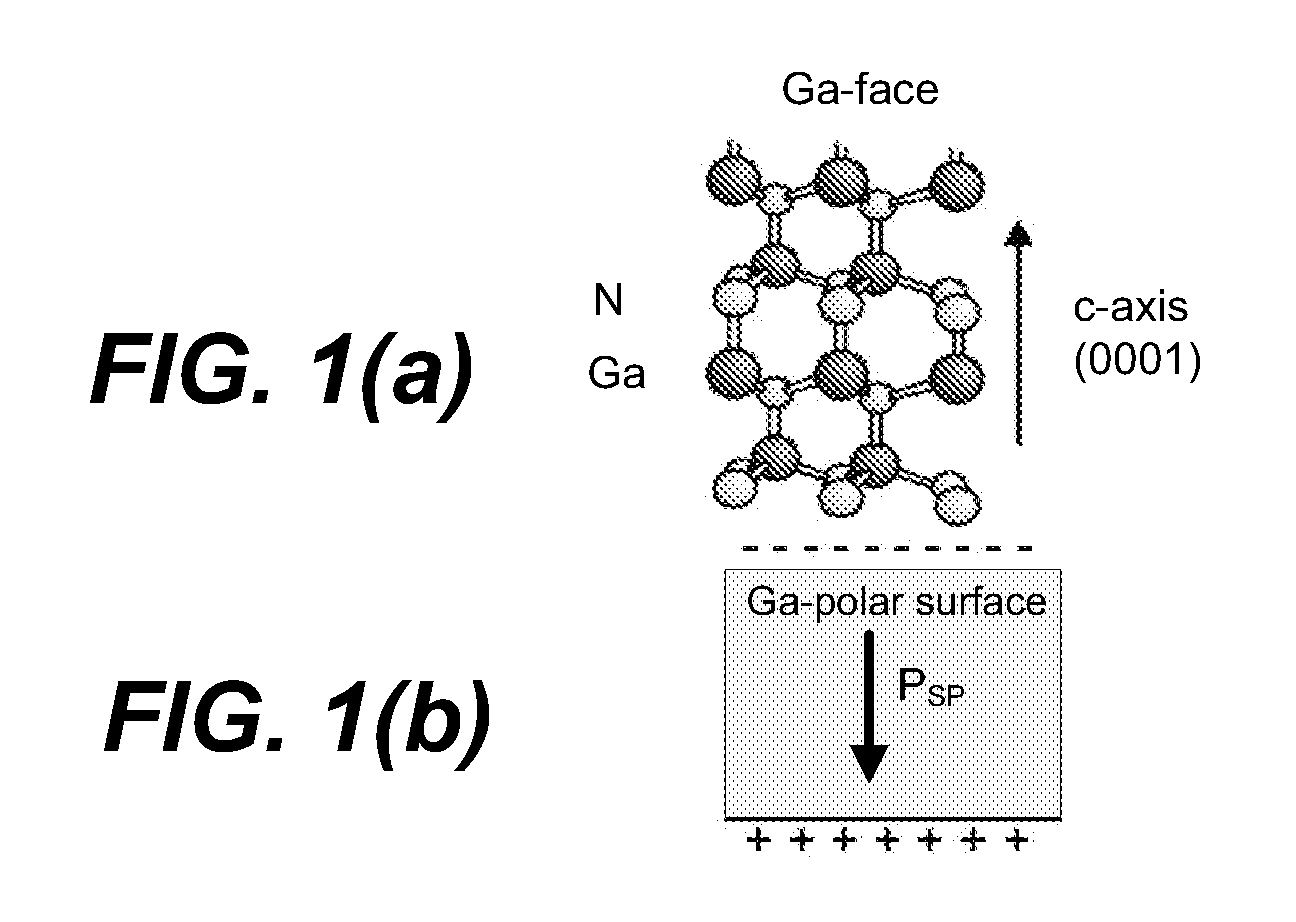

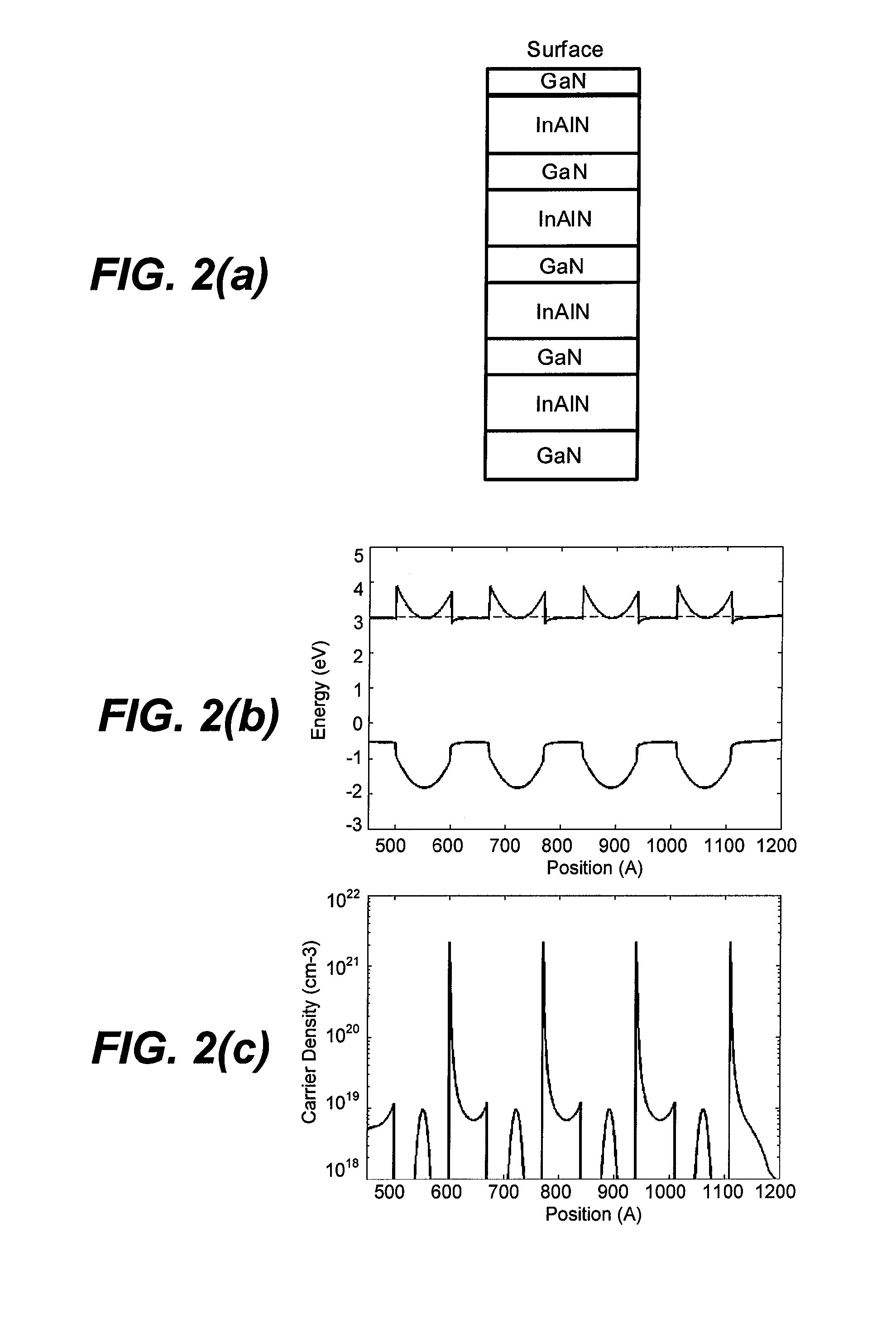

Enhancement of thermoelectric properties through polarization engineering

InactiveUS20140318592A1Improve thermoelectric performanceLow thermal conductivityPolycrystalline material growthThermoelectric device manufacture/treatmentNanostructurePhonon

A method for enhancement of thermoelectric properties through polarization engineering. Internal electric fields created within a material are used to spatially confine electrons for the purpose of enhancing thermoelectric properties. Electric fields can be induced within a material by the presence of bound charges at interfaces. A combination of spontaneous and piezoelectric polarization can induce this interfacial charge. The fields created by these bound charges have the effect of confining charge carriers near these interfaces. By confining charge carriers to a channel where scattering centers can be deliberately excluded the electron mobility can be enhanced, thus enhancing thermoelectric power factor. Simultaneously, phonons will not be affected by the fields and thus will be subject to the many scattering centers present in the majority of the structure. This allows for simultaneous enhancement of power factor and reduction of thermal conductivity, thus improving the thermoelectric figure of merit, ZT. This approach is also compatible with other strategies for reducing thermal conductivity, for example the inclusion of nanostructures.

Owner:RGT UNIV OF CALIFORNIA

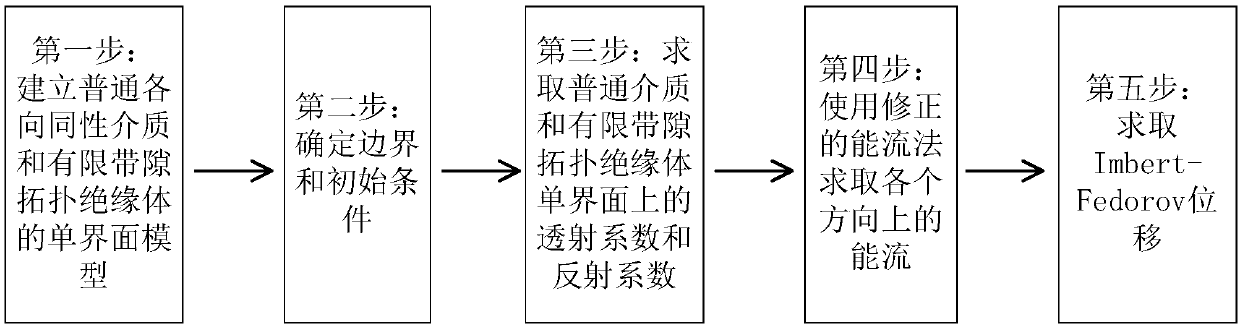

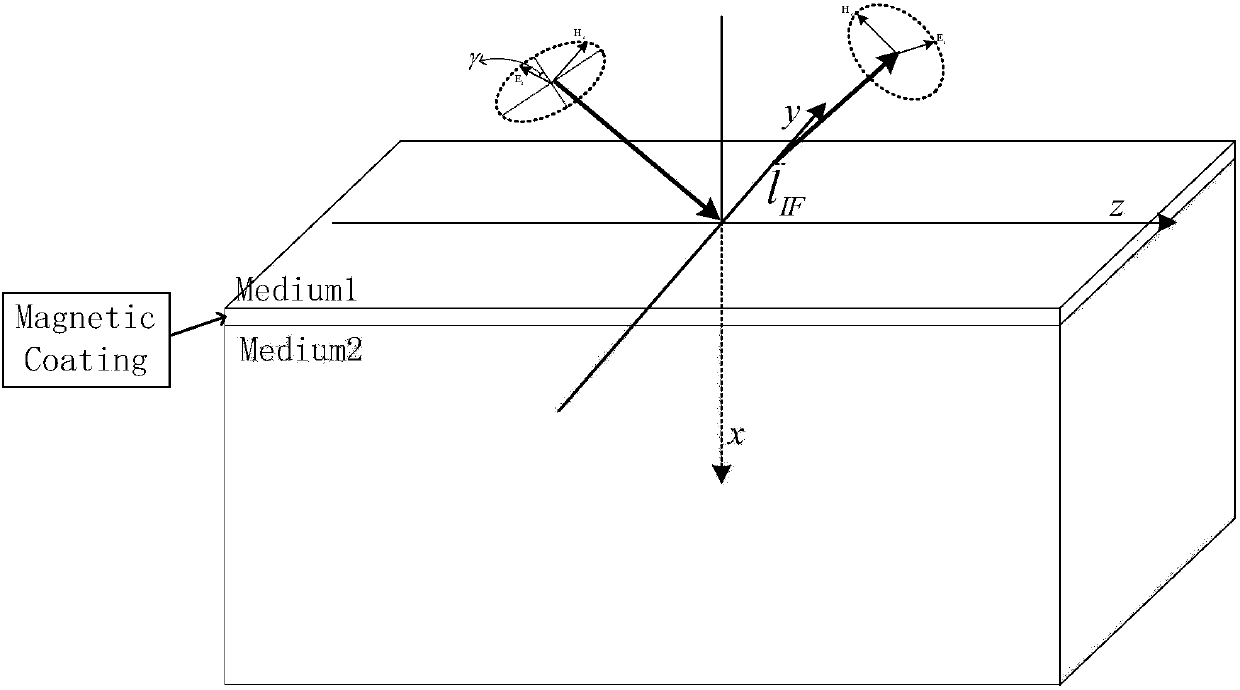

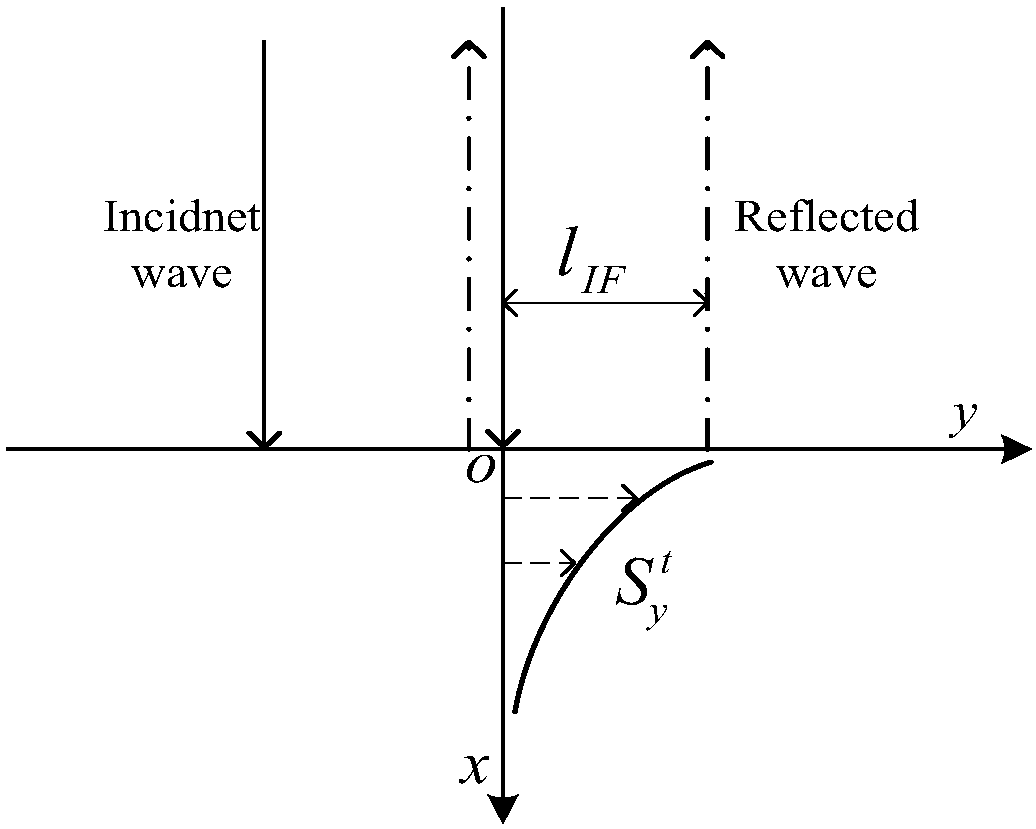

Finite surface band gap topologic insulator-based material interface light beam IF displacement system

ActiveCN108614911AAccurate analysisDesign optimisation/simulationSpecial data processing applicationsEnergy fluxDisplacement control

The invention discloses a method for calculating Imbert-Fedorov displacement of reflected light beam on a topologic insulator of a finite surface band gap based on an energy flux method. The method comprises the following steps of 1: building single interface models of a general isotropic medium and the isotropic finite band gap topologic insulator; 2: determining boundary and initial conditions;3: calculating transmission coefficients and reflection coefficients on single interfaces of the general medium and a chiral medium; 4: calculating energy fluxes in all directions by using a correctedenergy flux method; and 5, calculating the Imbert-Fedorov (IF) displacement. The transverse displacement characteristics of the single interface models of the general medium and the finite band gap topologic insulator can be accurately analyzed; the topologic insulator of the finite surface band gap is relatively close to a theoretical model of an actual topologic insulator material, and has relatively high application values as a test model; a new way is provided for IF displacement control; and an optical method is provided for measuring topologic magnetoelectric polarization properties.

Owner:HANGZHOU DIANZI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com