Method for manufacturing high-electrical-property nano generator based on piezoelectric-frictional effect

A technology of nanogenerators and friction effects, applied in the manufacture/assembly of triboelectric generators, piezoelectric/electrostrictive devices, nanotechnology for materials and surface science, etc., to facilitate large-scale production and application, good Effects of durability and processability, easy integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

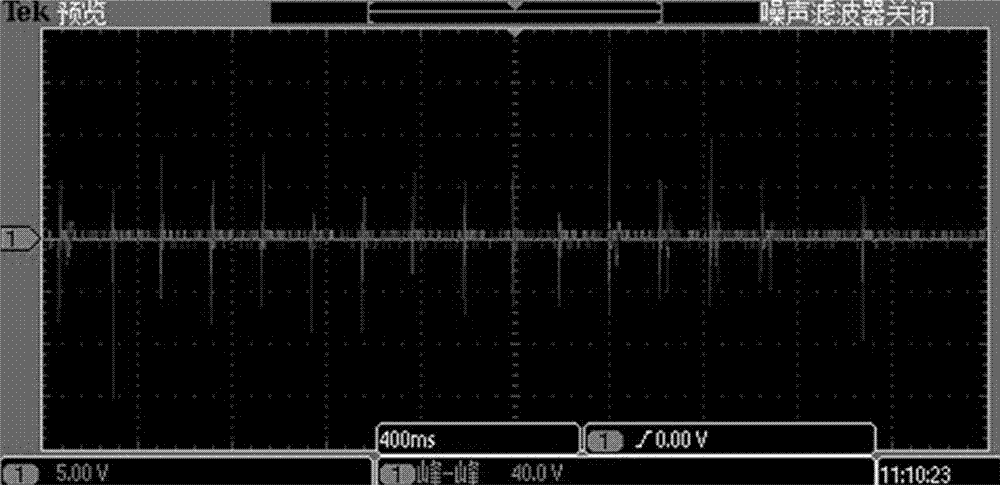

Examples

Embodiment 1

[0023] A method for preparing a nanogenerator with high electrical performance based on the piezoelectric-friction effect, comprising the steps of:

[0024] 1) Preparation of plastic polymers: Take CNT particles and piezoelectric particles and mix them evenly at a mass ratio of 1:12, then put the mixed particles into alcohol for ultrasonic treatment for 20 minutes, then put them in a drying oven to dry for 1.5 hours, and then put the dried The mixed particles are added to the liquid PDMS and stirred evenly, and the air bubbles are removed by vacuuming. The mixed particles and the liquid PDMS are mixed at a mass ratio of 1:8, and finally the plastic polymer is obtained;

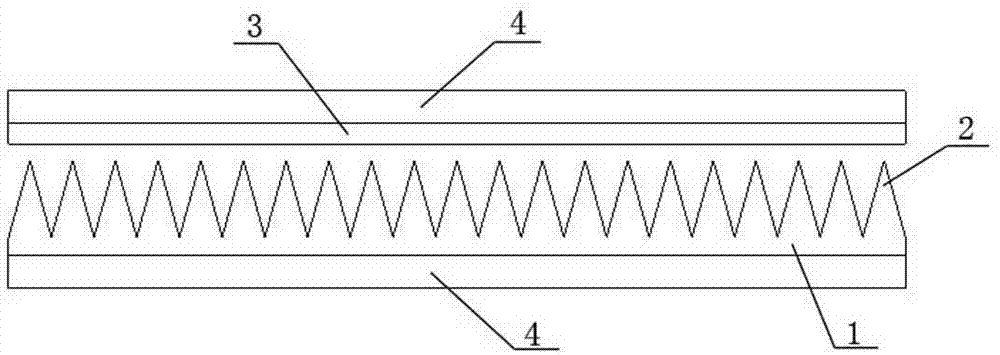

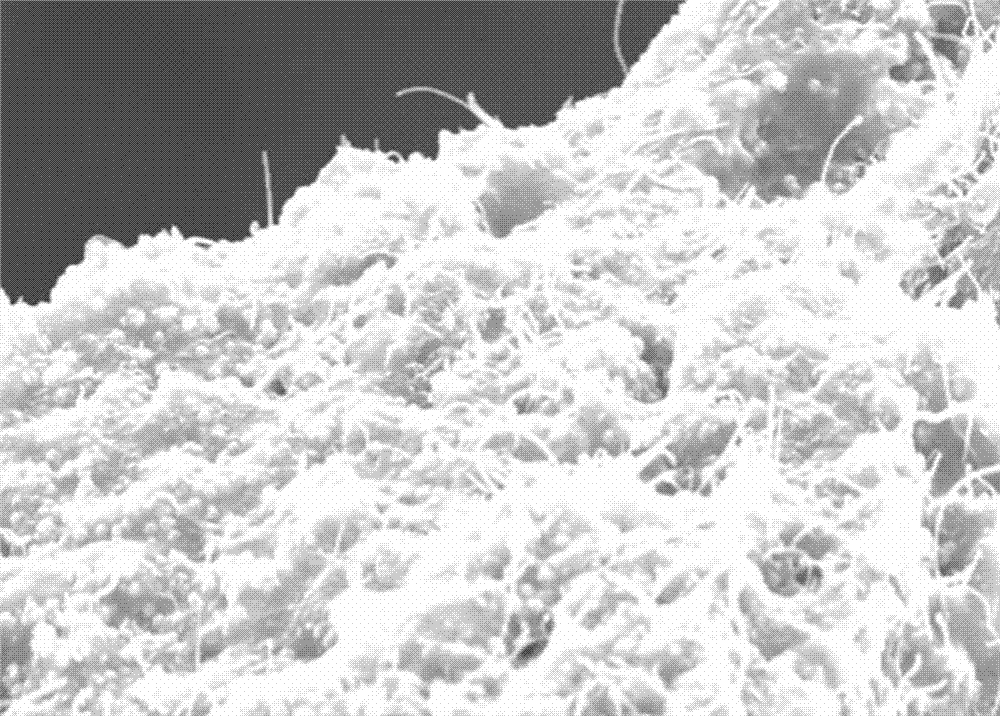

[0025] 2) Preparation of a composite film with a micro-nano concave-convex structure 1: Place the plastic polymer prepared in step 1) on a substrate with a micro-nano concave-convex structure on the surface, and then use a casting box to evenly pull it over the substrate, so that The plastic polymer on the sub...

Embodiment 2

[0030] A method for preparing a nanogenerator with high electrical performance based on the piezoelectric-friction effect, comprising the steps of:

[0031] 1) Preparation of plastic polymers: Take CNT particles and piezoelectric particles and mix them evenly at a mass ratio of 1:14, then put the mixed particles into alcohol for ultrasonic treatment for 17 minutes, then put them in a drying oven to dry for 1.8 hours, and then put the dried Add the mixed particles into the liquid PDMS and stir evenly and vacuumize to remove air bubbles. The mixed particles and liquid PDMS are mixed at a mass ratio of 1:6, and finally the plastic polymer is obtained;

[0032] 2) Preparation of a composite film with a micro-nano concave-convex structure 1: Place the plastic polymer prepared in step 1) on a substrate with a micro-nano concave-convex structure on the surface, and then use a casting box to evenly pull it over the substrate, so that The plastic polymer on the substrate forms a thin f...

Embodiment 3

[0037] A method for preparing a nanogenerator with high electrical performance based on the piezoelectric-friction effect, comprising the steps of:

[0038] 1) Preparation of plastic polymers: Take CNT particles and piezoelectric particles and mix them evenly at a mass ratio of 1:10, then put the mixed particles into alcohol for ultrasonic treatment for 15 minutes, then put them in a drying oven to dry for 1.6 hours, and then put the dried The mixed particles are added to the liquid PDMS and stirred evenly, and the air bubbles are removed by vacuuming. The mixed particles and the liquid PDMS are mixed at a mass ratio of 1:8, and finally the plastic polymer is obtained;

[0039] 2) Preparation of a composite film with a micro-nano concave-convex structure 1: Place the plastic polymer prepared in step 1) on a substrate with a micro-nano concave-convex structure on the surface, and then use a casting box to evenly pull it over the substrate, so that The plastic polymer on the sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com