Single-phase oxide multiferroic ceramic with exchange bias effect and preparation method thereof

A technology of multiferroic ceramics and bias effect, which is applied in the field of magnetoelectric mutual control nonvolatile storage, can solve problems such as restricting magnetoelectric coupling performance, and achieve the effect of low cost and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention also provides a corresponding preparation method for the above-mentioned multiferroic ceramic material, comprising the following steps: A) mixing titanate compounds, bismuth source compounds, iron source compounds and cobalt source compounds in a solvent according to the ratio of metal ions, and The mixture is mixed, evaporated to dryness and burned into powder, and the powder is obtained after pre-calcination;

[0029] B) Pressing the powder into tablets and sintering to obtain the multiferroic ceramics.

[0030] In order to clearly illustrate the present invention, the experimental processes of step A and step B are described in detail below respectively.

[0031] The step A is specifically: dissolving the bismuth source compound, iron source compound, cobalt source compound and titanate compound in the solvent according to the molar ratio of metal ions, adding a complexing agent, mixing and stirring to obtain a clear solution, heating and evapor...

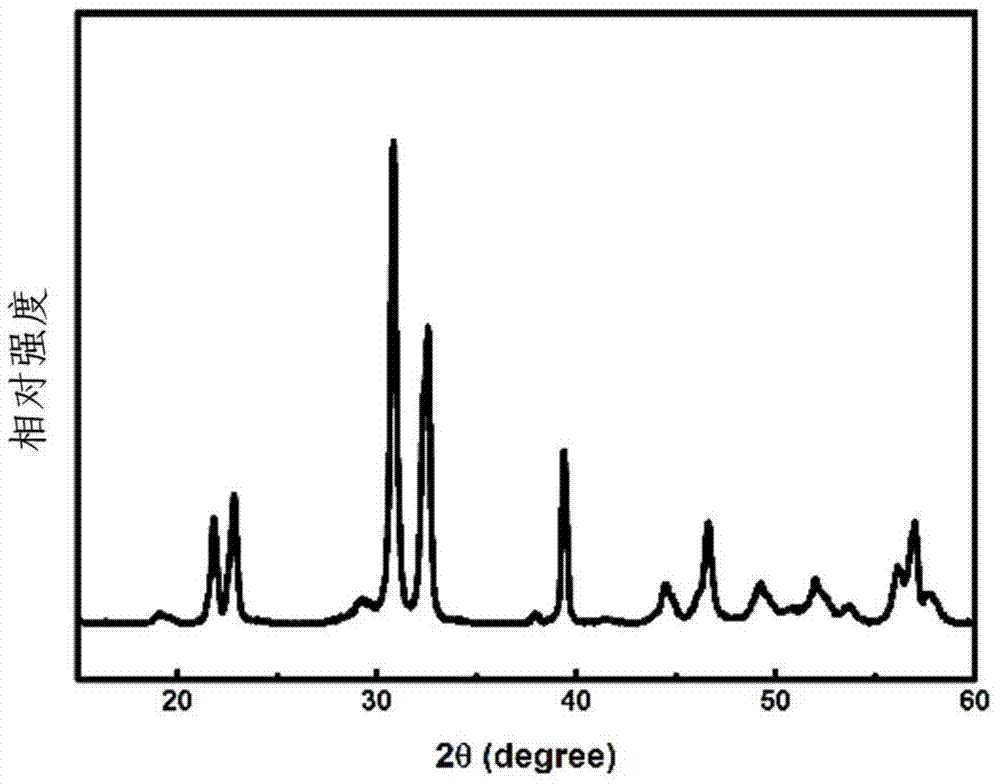

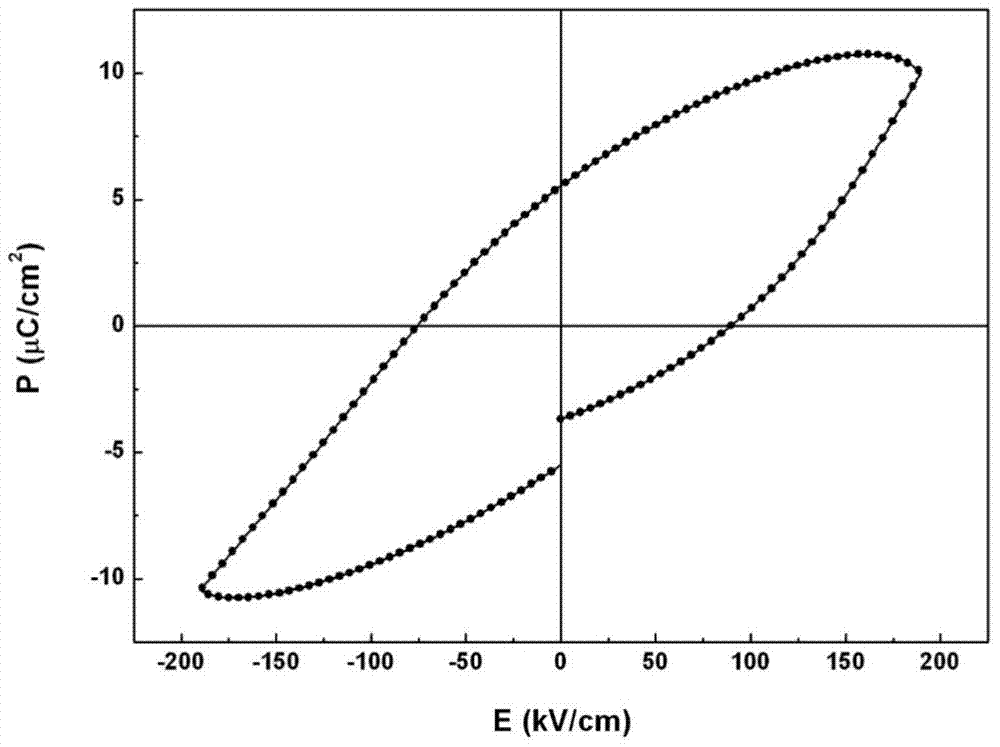

Embodiment 1

[0044] According to the purity of each raw material listed in Table 1 and its weighing amount, get chemically pure n-butyl titanate (C 16 h 36 o 4 Ti), analytically pure bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O), analytically pure ferric nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O) and analytically pure cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 (0) is raw material, after being accurately weighed according to molar ratio 3:10:5.9:0.1, be dissolved in 100mL mass percent concentration and be 80% nitric acid aqueous solution, add the complexing agent that is made up of ethylenediaminetetraacetic acid and citric acid, its The amount to be added is such that the molar ratio of ethylenediaminetetraacetic acid and citric acid in the complexing agent to the metal ions contained in the solution is 0.6:1:1, and stirred at a constant speed until a clear solution is formed.

[0045] Prepare Bi in the embodiment 1 of table 1 10 Fe 5.9 co 0.1 Ti 3 o 30 Raw materials a...

Embodiment 2

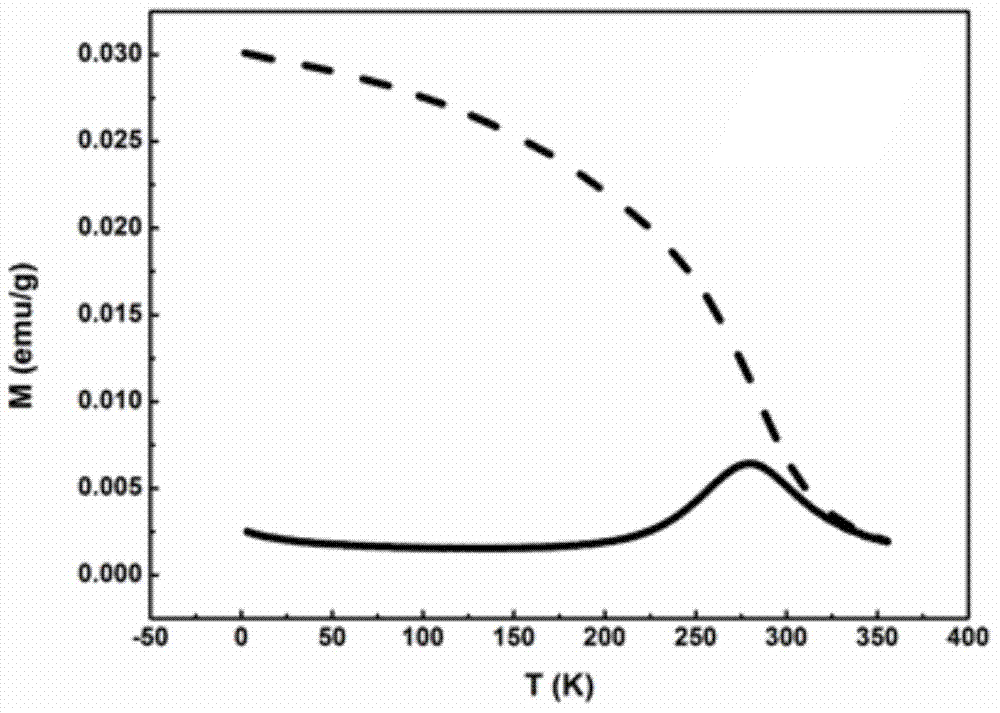

[0054] Using the same preparation method and experimental conditions in Example 1, synthesize Bi 10 Fe 5.9 co 0.1 Ti 3 o 30 sample.

[0055] The hysteresis loops of samples cooled to 100K in zero field and 100K in a magnetic field of 2 kOe were measured by Dynacool comprehensive physical property measurement system (PPMS) produced by Quantum Design Company in the United States. Under the cooling of the magnetic field of 2kOe, the hysteresis loop of the sample shifted, which has the effect of exchange bias. The exchange bias field is H E =1115Oe, the coercive field is H C =2019Oe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| remanent polarization | aaaaa | aaaaa |

| remanent polarization | aaaaa | aaaaa |

| remanent polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com