Patents

Literature

60results about How to "Padding achieved" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

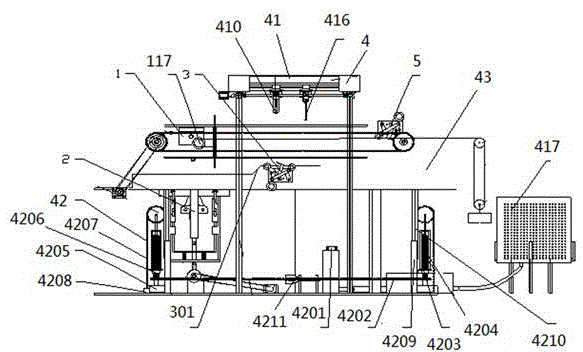

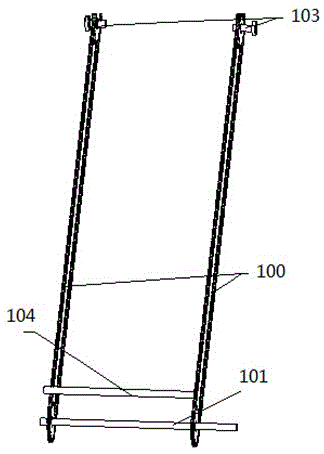

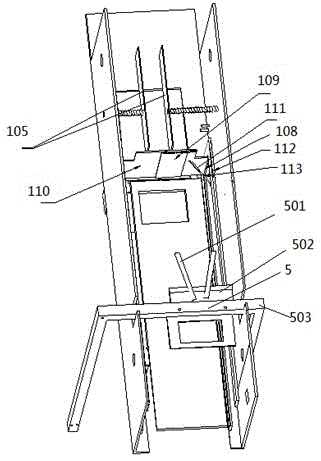

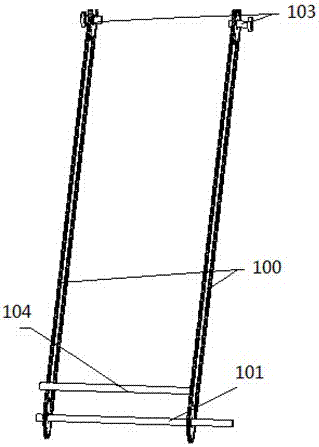

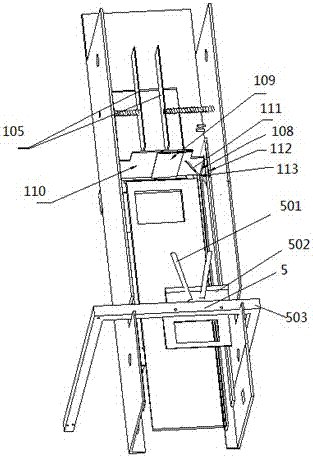

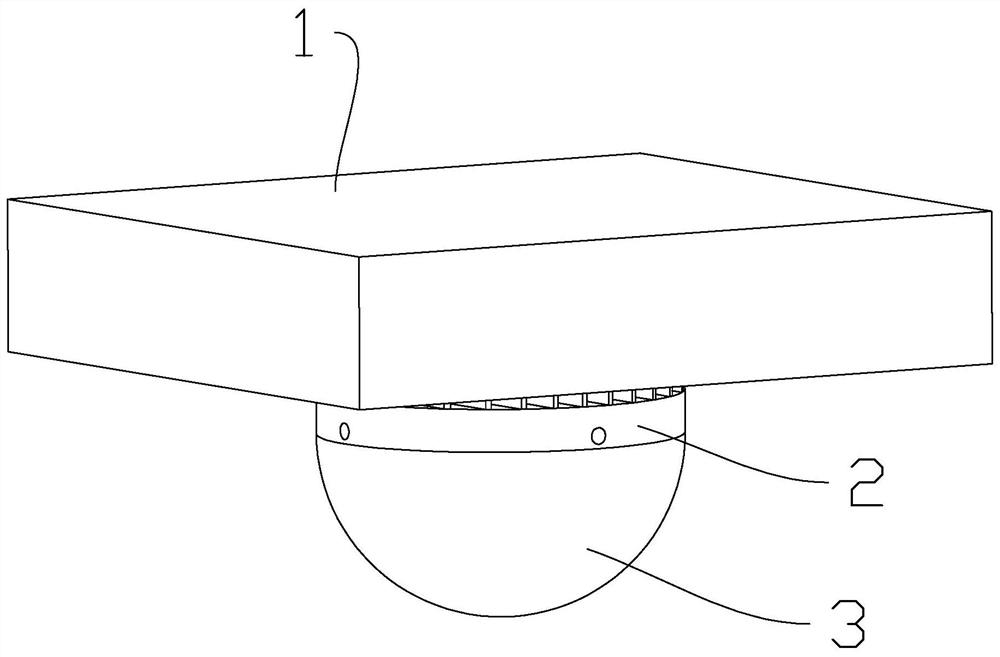

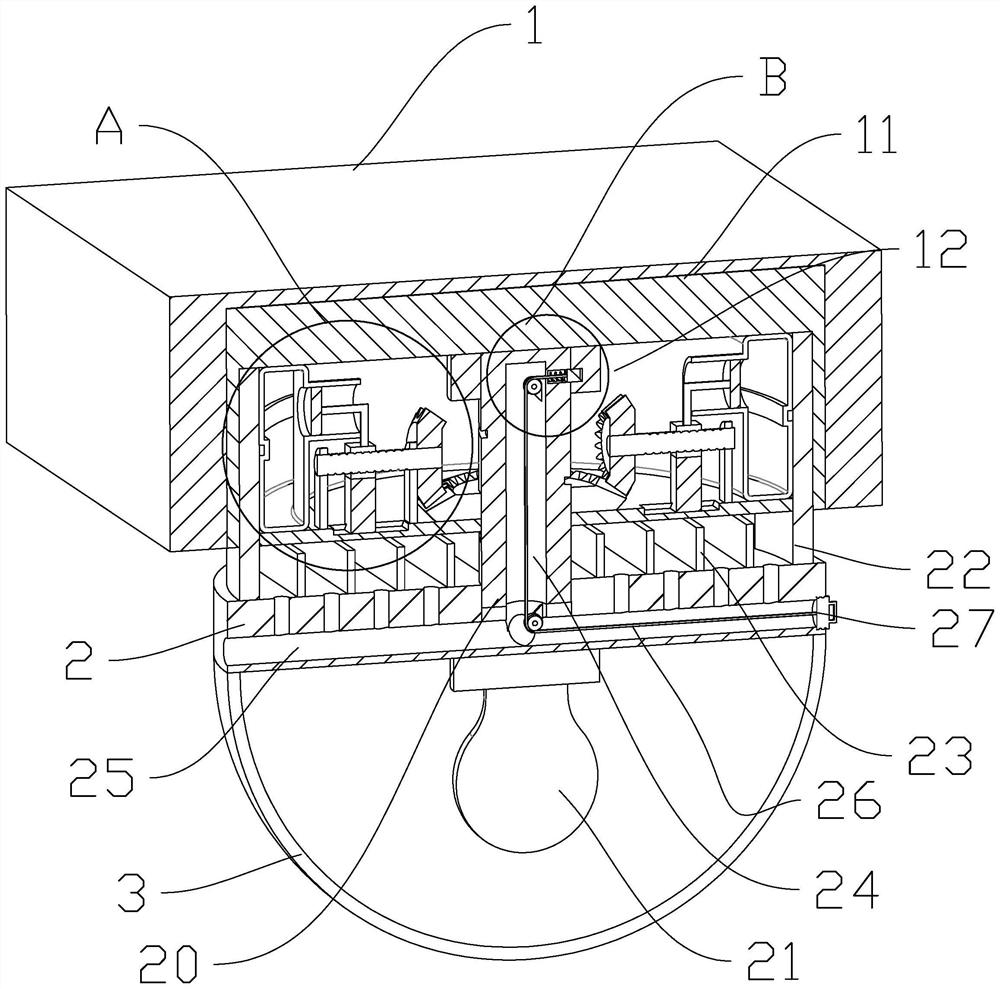

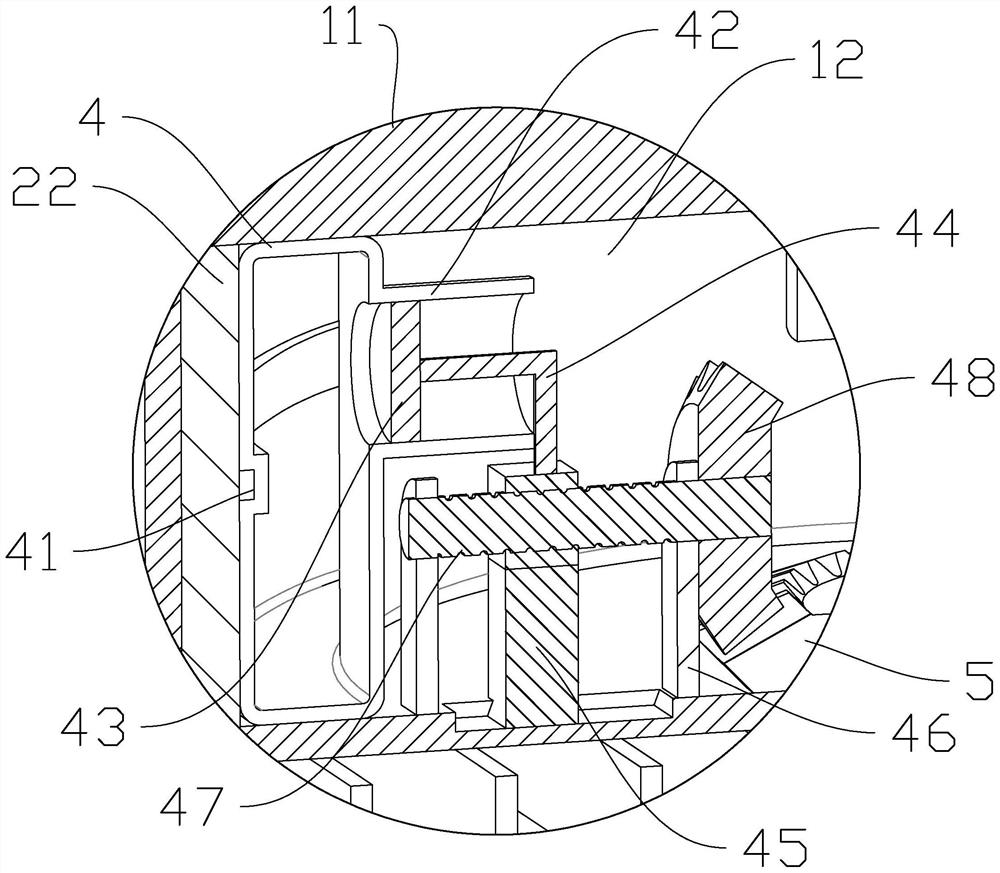

Rapid packaging equipment

The invention provides rapid packaging equipment which comprises a flexible box opening device, a six-claw bottom folding device, a gluing device, a 3D printing foam filling device and a box sealing mechanism. After a carton box passes through the devices, the packaging process of the whole carton box is completed. According to the rapid packaging equipment, after an operator places the carton box in a designated position of the equipment, the equipment can automatically achieve packaging of objects which are made of various materials and in various shapes, so that the production efficiency is substantially improved, and labor cost is reduced.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

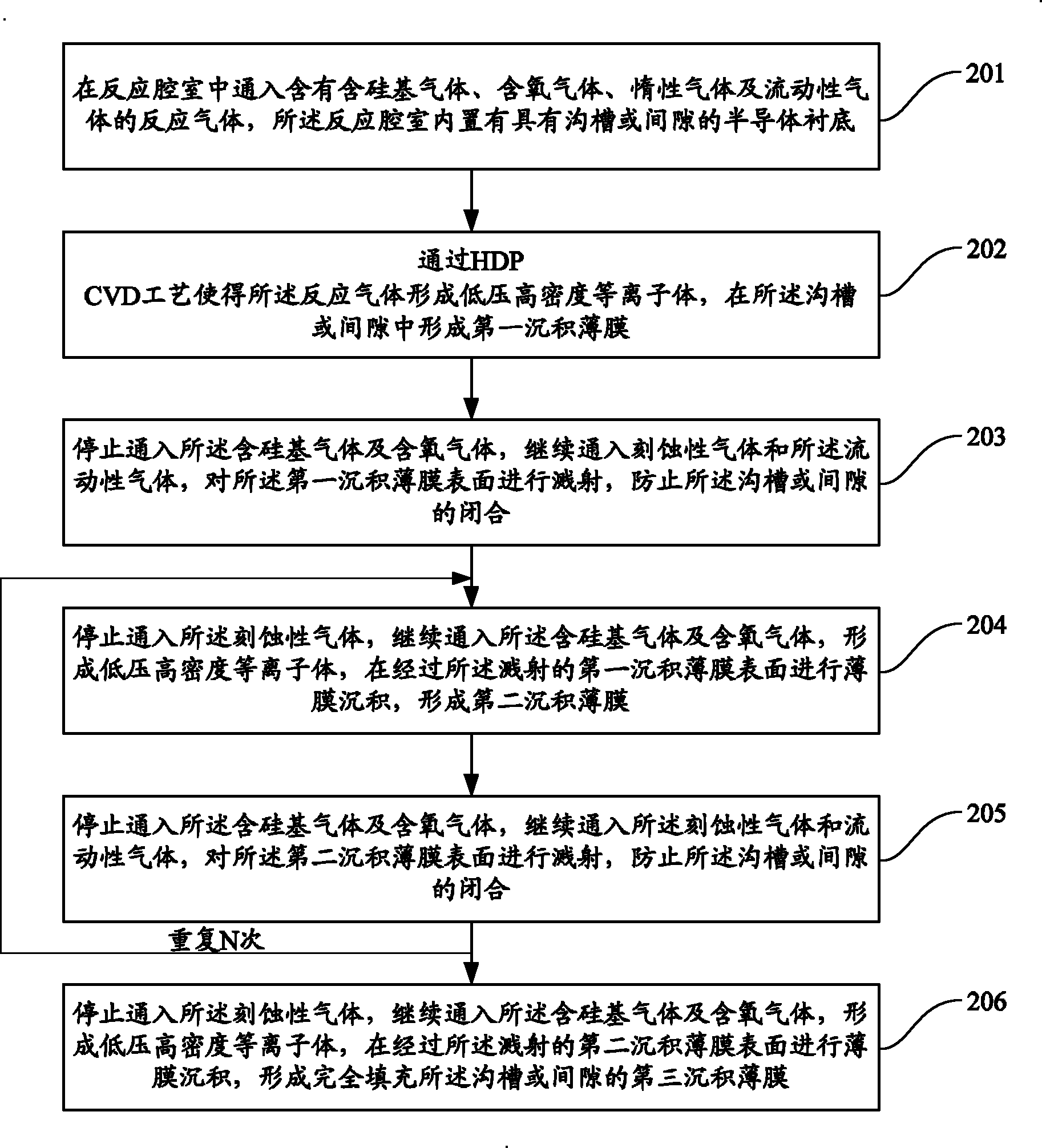

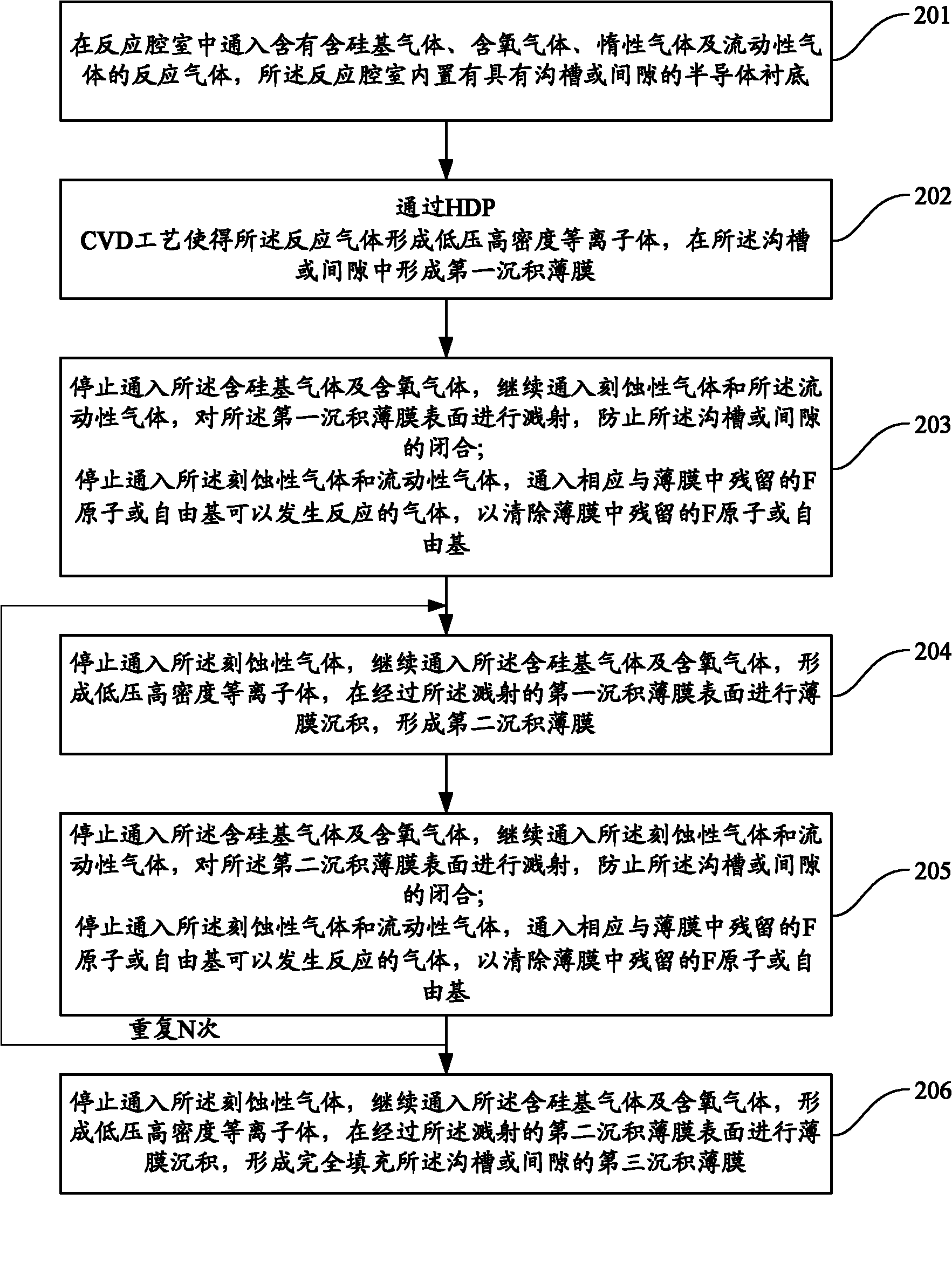

Thin film filling method

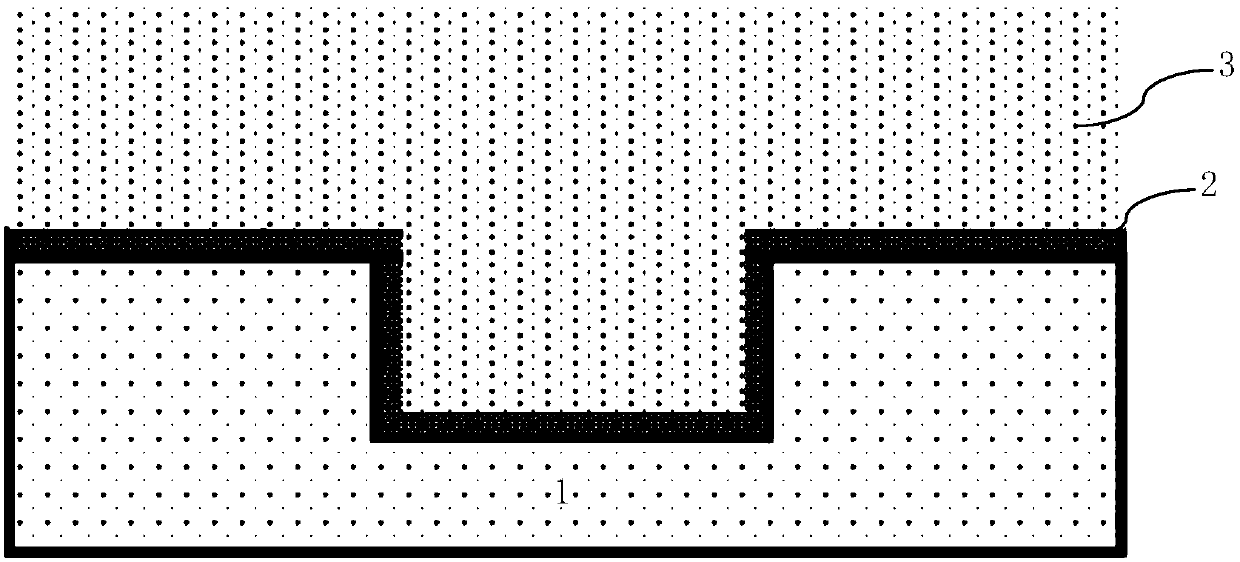

InactiveCN102693931APrevent closurePadding achievedSemiconductor/solid-state device manufacturingChemical vapor deposition coatingOxygenTwo step

The invention discloses is a thin film filling method which comprises the following steps of: firstly supplying reaction gases containing a silicon-containing gas, an oxygen-containing gas, an inert gas and a flowability gas into a reaction chamber; forming a first deposition film in the channels or gaps through an HDP CVD process; stopping supplying the silicon-containing gas and the oxygen-containing gas and continuing to supply an etching gas and the flowability gas to sputter a surface of the first deposition film; stopping supplying the etching gas, continuing to supply the silicon-containing gas and the oxygen-containing gas, and performing film deposition on the sputtered surface of the first deposition film to form a second deposition film; stopping supplying the silicon-containing gas and the oxygen-containing gas and continuing to supply the etching gas and the flowability gas to sputter a surface of the second deposition film; repeating the last two steps, stopping supplying the etching gas, continuing to supply the silicon-containing gas and the oxygen-containing gas, and performing the film deposition on the sputtered surface of the second deposition film to form a third deposition film that completely fills the channels or gaps.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

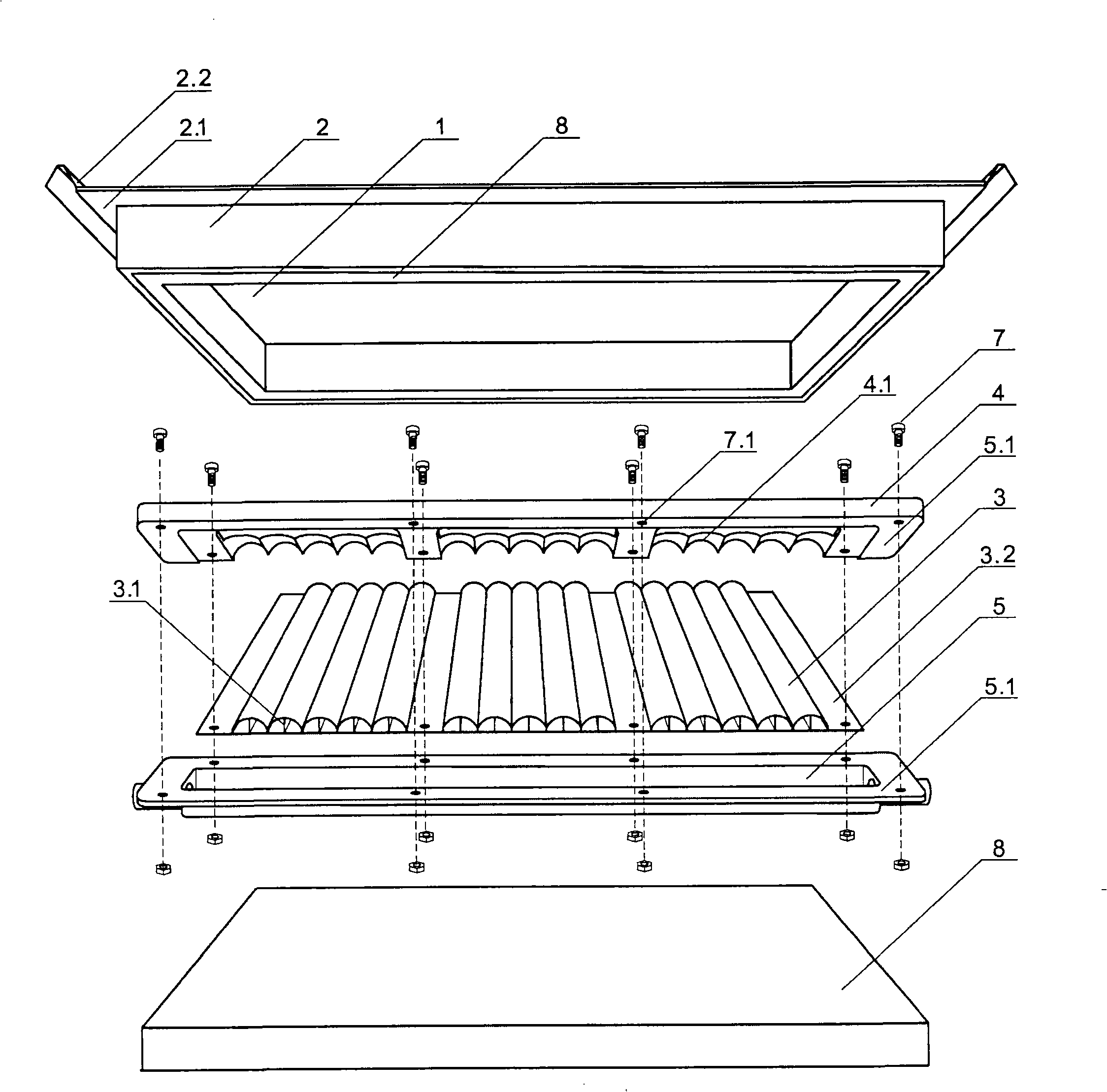

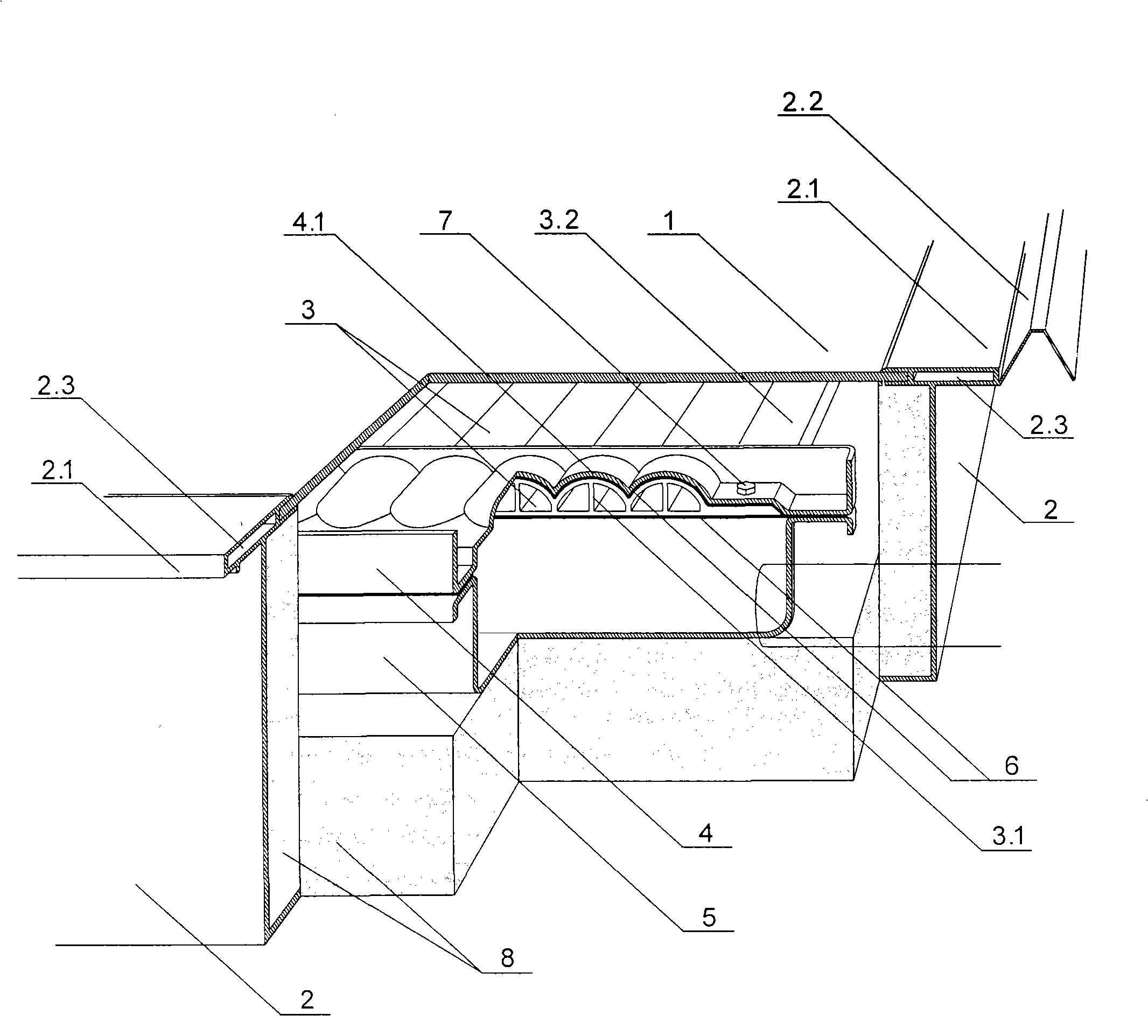

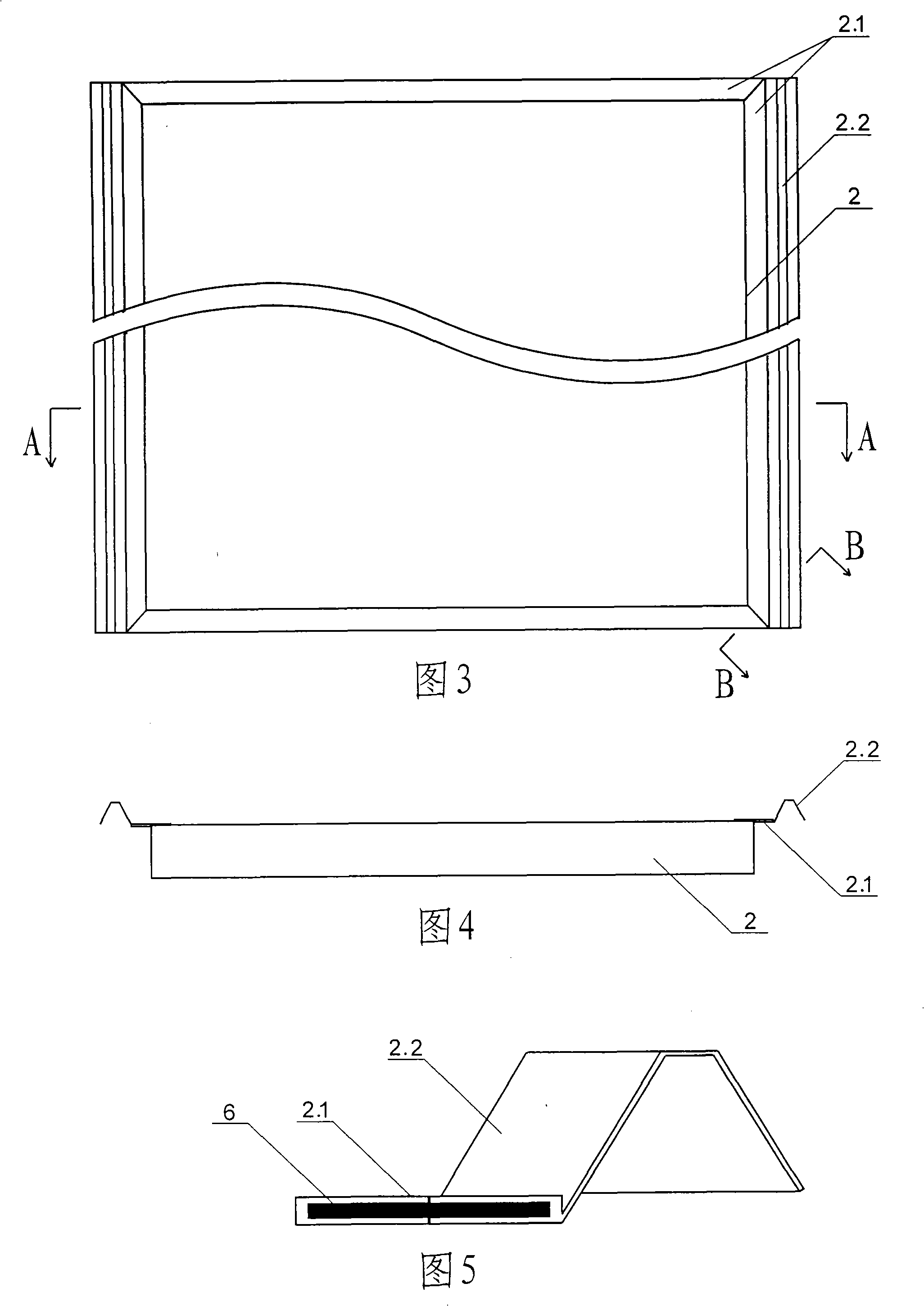

Aluminum alloy non-welding and roof tile solar heat collector

InactiveCN101353923AImprove heat collection efficiencyIncrease absorbanceSolar heating energyRoof covering using slabs/sheetsBuilding integrationSEMI-CIRCLE

The invention discloses an aluminum alloy welding-free and roofing-tile solar collector, wherein, a collecting board is integrated with a heat-exchanging container; the solar collector is a section material with a semi-circle and tubular-shaped transect, the upper part of which is cambered and the lower part of which is flat, and connected with a plurality of aluminum alloy pipes which are connected with each other in parallel; the sunny side of the solar collector is coated with a selective heat absorption coating; water pipes which are arranged at the two sides of the solar collector and connected with the pipe section material are metal water pipes that are divided into an upper part and a lower part and has a pipe section material interface; the pipe section material and the water pipe are connected firmly by bolts and sealed by a sealant, and the upper part and the lower part of the water pipe are connected firmly by the bolts and sealed by the sealant; a glass cover plate is arranged on the pipe section material and the water pipe; a thermal insulation layer is arranged below the pipe section material and the water pipe; borders enclose the solar collector into a sealed whole at the periphery and extend out of regulas in all directions on the plane of the glass cover plate; the regulas on the left and right rise upwards so that the solar collection has the function of a large insulation roofing tile. The solar collector has the advantages of high heat collection efficiency, low price and long service life, basically requiring no maintenance, and being integrated with buildings and beneficial to scale production.

Owner:范东杰

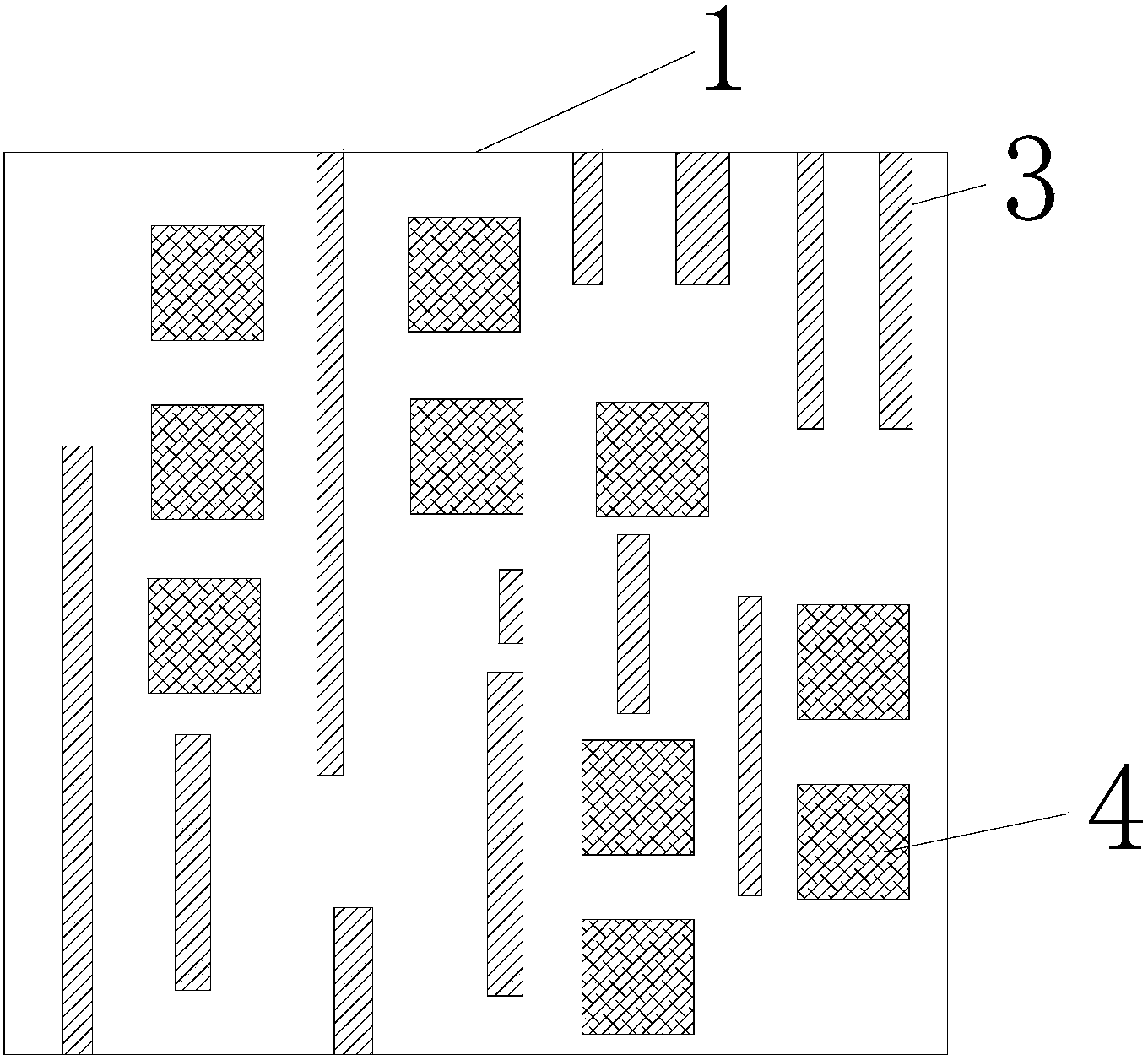

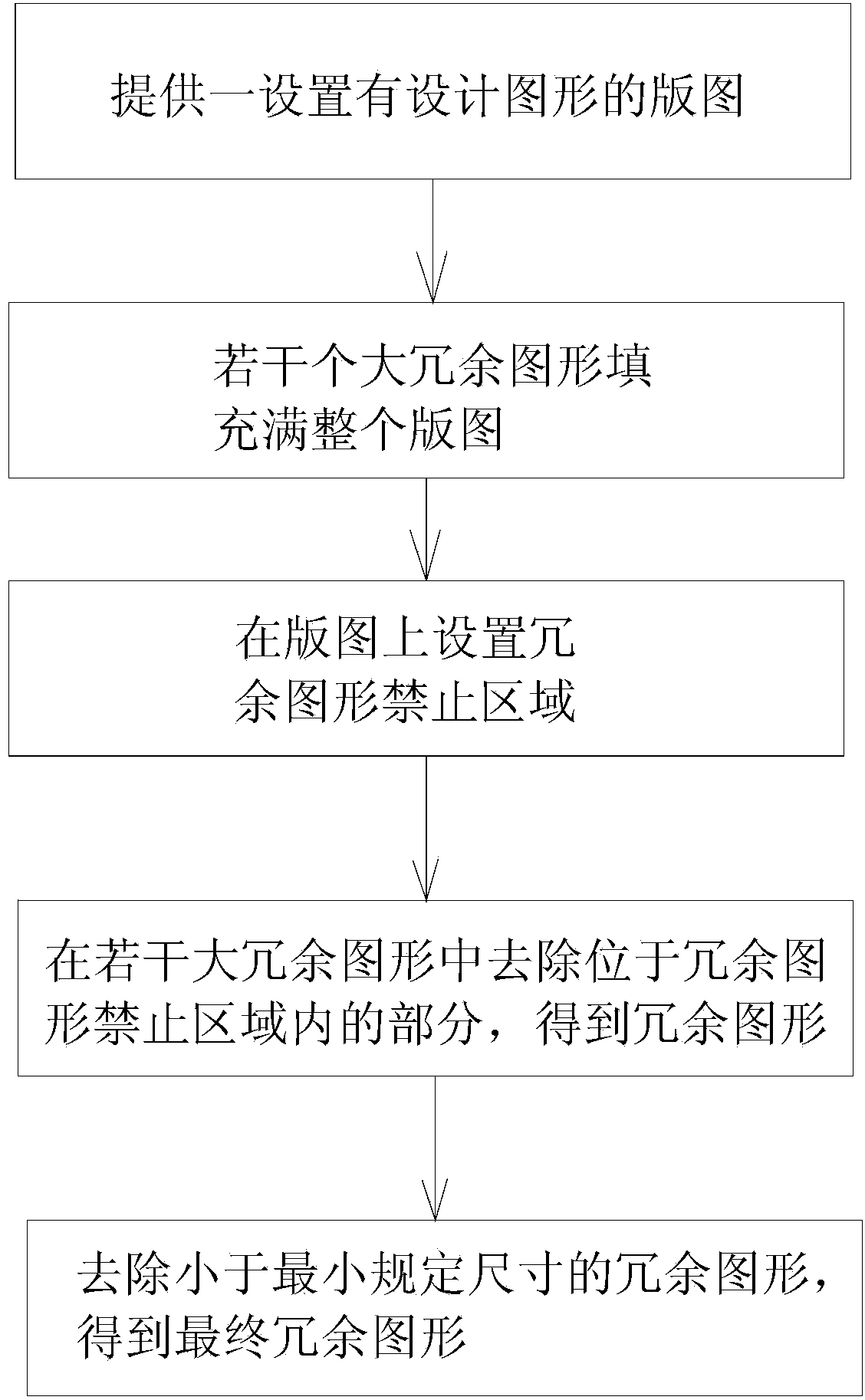

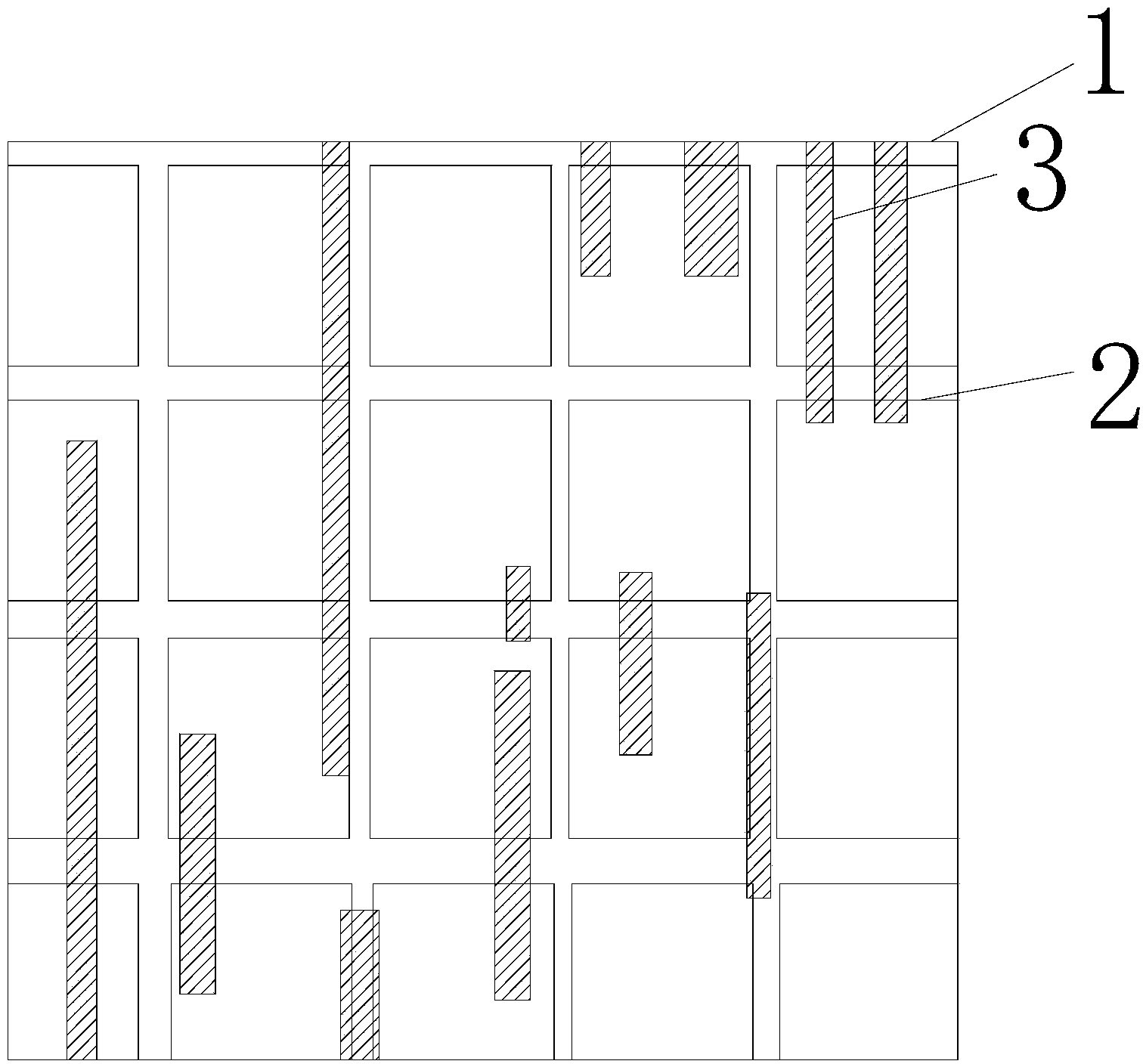

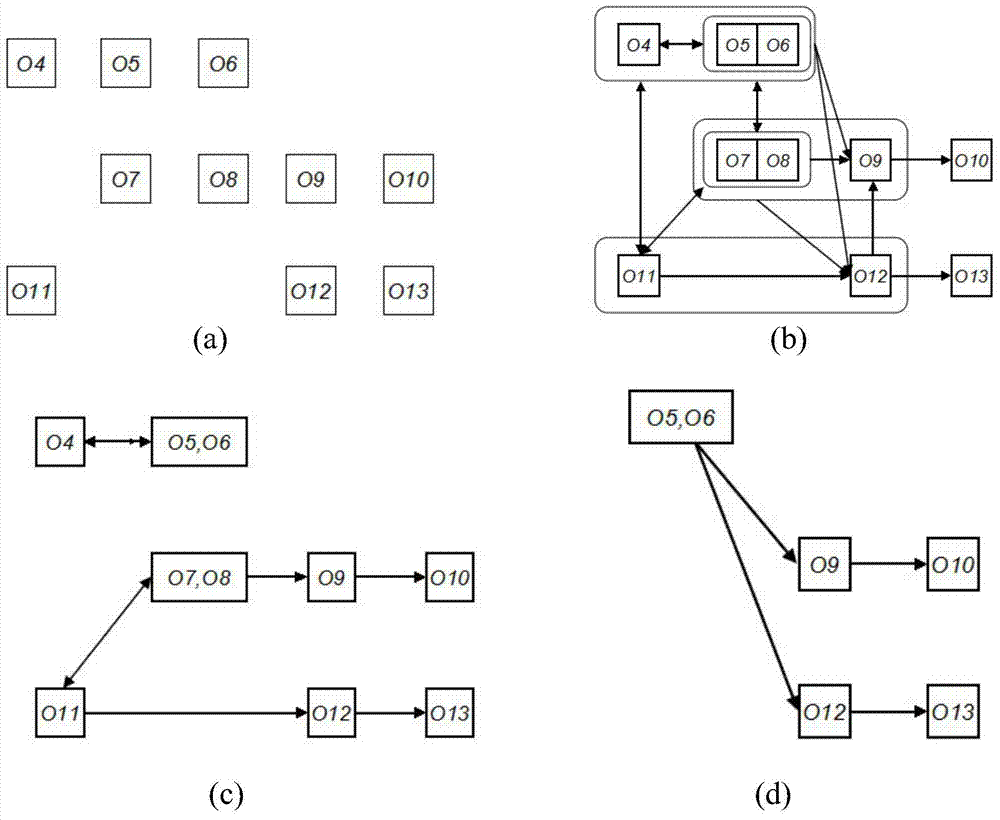

Filling method for redundancy graph

InactiveCN103886150APadding achievedIncrease graphics densitySpecial data processing applicationsGraphicsA domain

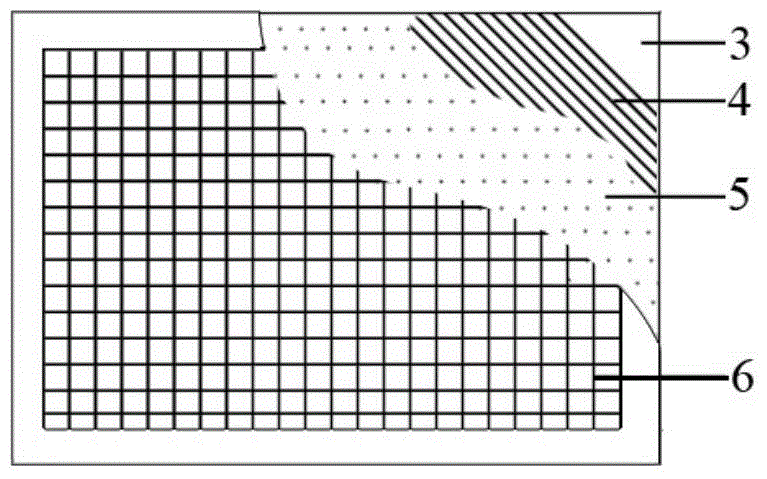

The invention provides a filling method for a redundancy graph. Through software for filling the redundancy graph, firstly, the whole area of a domain is filled with the redundancy graph; secondly, a prohibited area of the redundancy graph is selected; thirdly, the redundancy graph located in the prohibited area is removed through the Boolean operation. By means of the method, filling of the redundancy graph with the larger area can be achieved, the graph density of the whole domain is improved, and therefore line width uniformity of a wafer after the wafer is etched and flatness of the wafer after chemical machinery grinding are improved.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

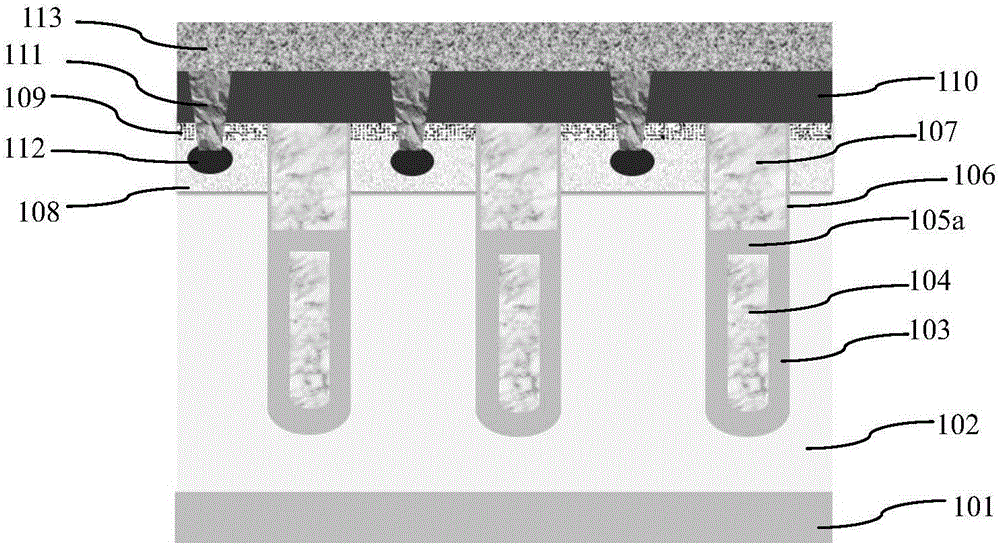

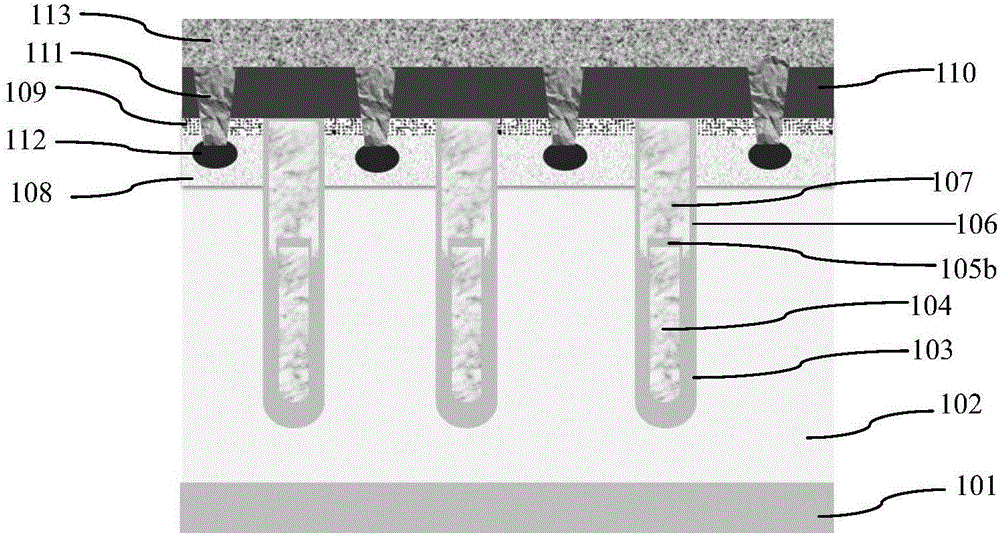

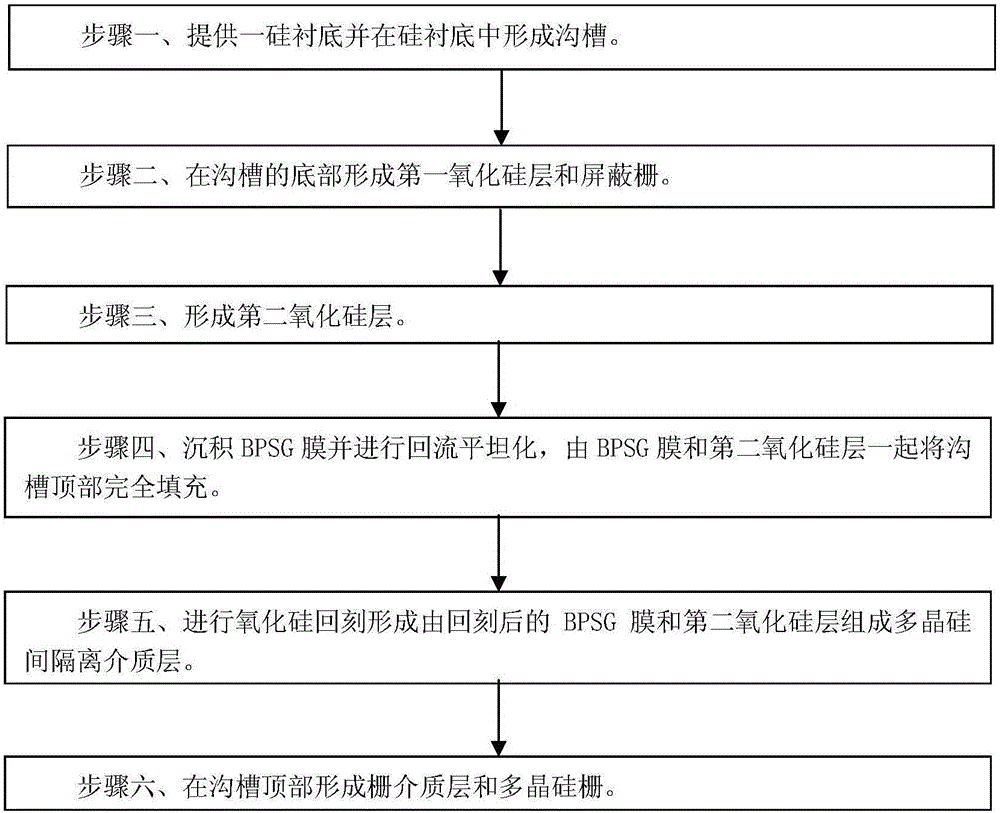

Method for manufacturing trench gate power devices with shielded gate

InactiveCN105957811APadding achievedGood filling effectSemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricLow voltage

The invention discloses a method for manufacturing a trench gate power device with a shield gate, which comprises the following steps: step 1, providing a silicon substrate and forming a trench in the silicon substrate; step 2, forming a trench at the bottom of the trench The first silicon oxide layer and the shield gate; Step 3, forming a second silicon oxide layer; Step 4, depositing a BPSG film and performing reflow planarization, and completely filling the top of the trench with the BPSG film and the second silicon oxide layer; Step 5 1. Etching back the silicon oxide to form an isolation dielectric layer between polysilicon composed of the etched back BPSG film and the second silicon oxide layer; step 6, forming a gate dielectric layer and a polysilicon gate on the top of the trench. The invention can reduce the unit structure size of the device and obtain a thin grid dielectric layer, thereby reducing the conduction voltage drop of the device and realizing low-voltage application.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

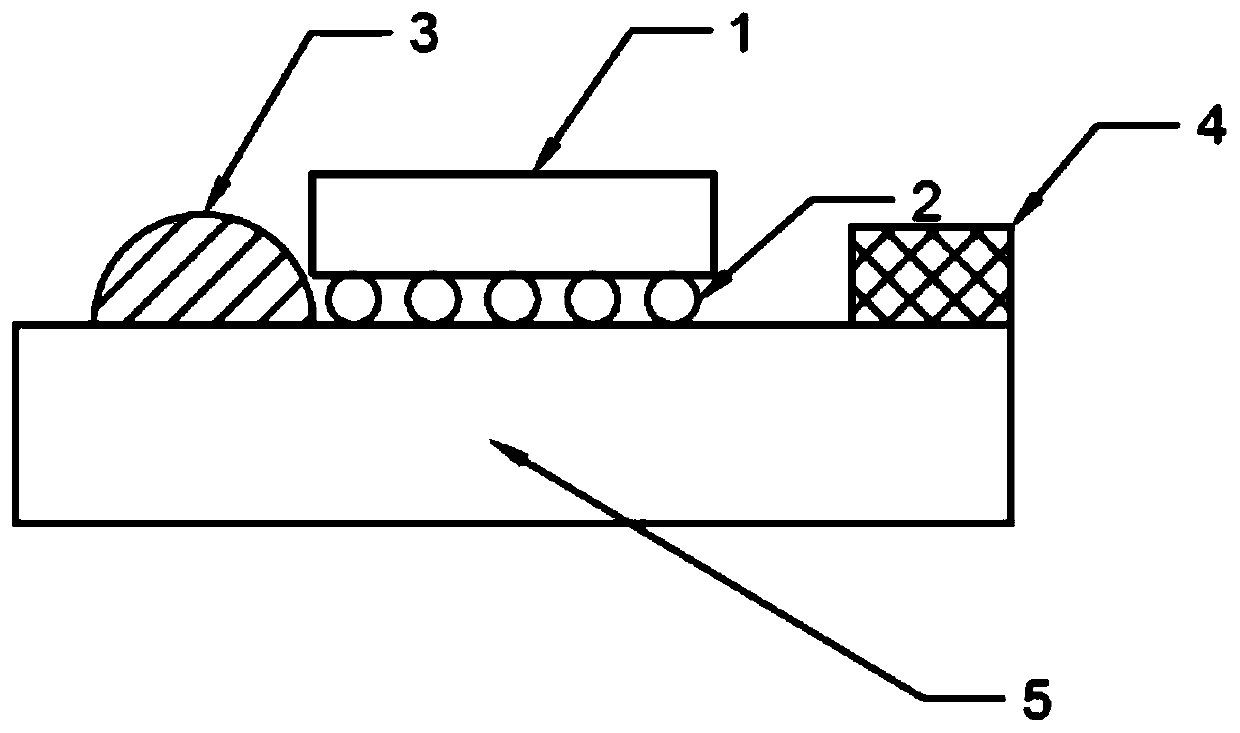

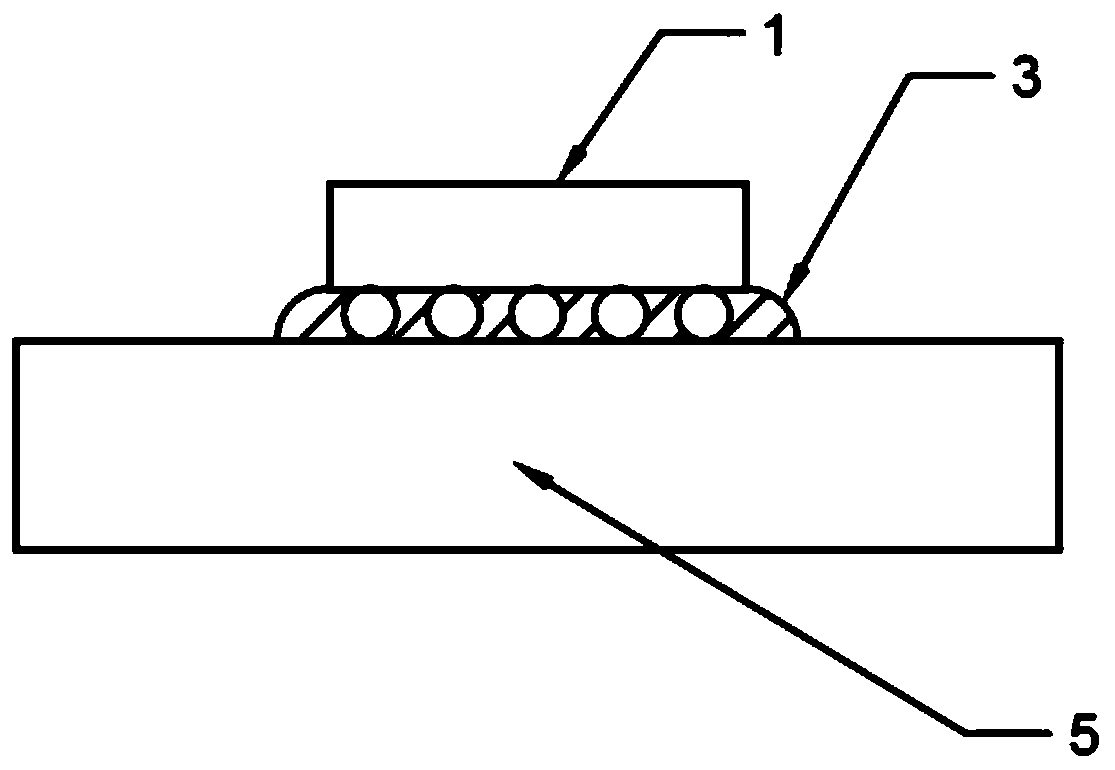

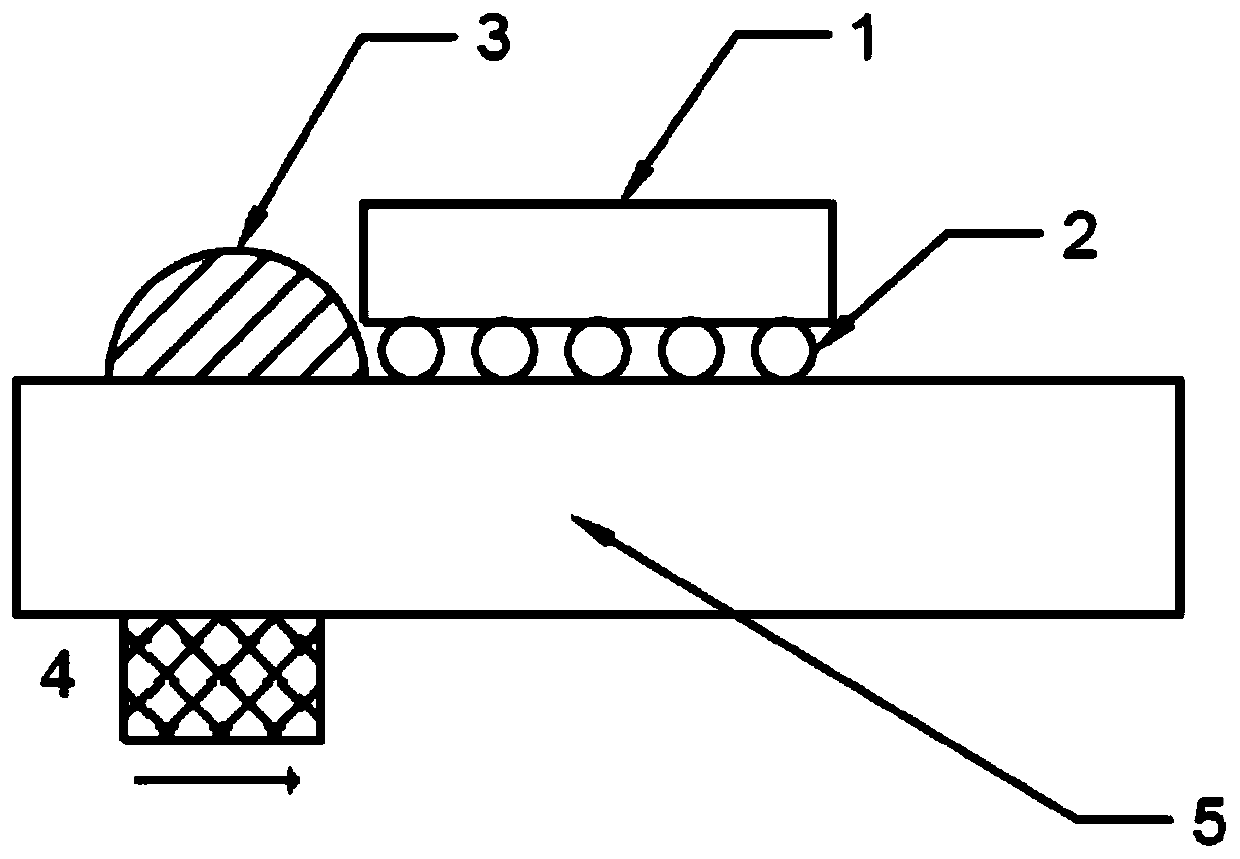

Electronic packaging device and underfilling method

InactiveCN110429066AImprove reliabilityImprove structural strengthSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageThermal expansion

The invention belongs to the technical field of semiconductor packaging, and particularly relates to application of magnetic materials as a bottom glue filling filler in an electronic packaging device, an electronic packaging device and an underfilling method thereof. The magnetic materials are taken as the bottom glue filling filler to achieve the filling of small gaps, reduce stress impact caused by large difference of the thermal expansion coefficient between a substrate and a chip and / or between a base and a mother board, improve the reliability, structural strength and the auto-dropping performance of the electronic package device.

Owner:SHANGHAI XIANFANG SEMICON CO LTD

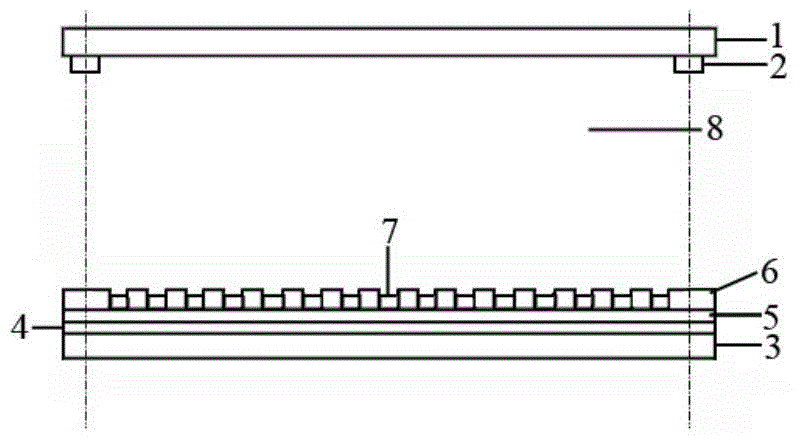

Ink filling equipment and ink filling method for electrofluidic displays

The invention discloses a piece of ink filling equipment and an ink filling method for electrofluidic displays. Ink is applied to a lipophilic and hydrophobic carrier to at least form a to-be-transferred oil film of which the size matches the size of a display area of a display substrate, wherein the lipophilicity of the carrier is weaker than that of a hydrophobic layer in a pixel grid; and the to-be-transferred oil film of the carrier is made to correspondingly contact a part, with a pixel grid, of the display substrate so as to enable the ink applied to the carrier to transfer to the pixel grid, thus completing oil filling. By adopting the method to carry out ink filling on an electrofluidic display, oil filling is uniform, the controllability is good, and the filling speed is high. The equipment and the method are suitable for mass production.

Owner:SOUTH CHINA NORMAL UNIVERSITY +2

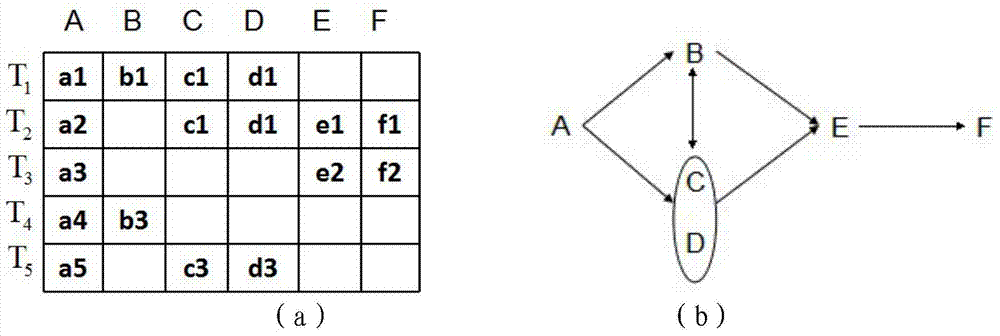

Data filling method and data filling system based on quality control

ActiveCN104881487AHigh filling accuracyPadding achievedNatural language data processingSpecial data processing applicationsQuality controlConfidence interval

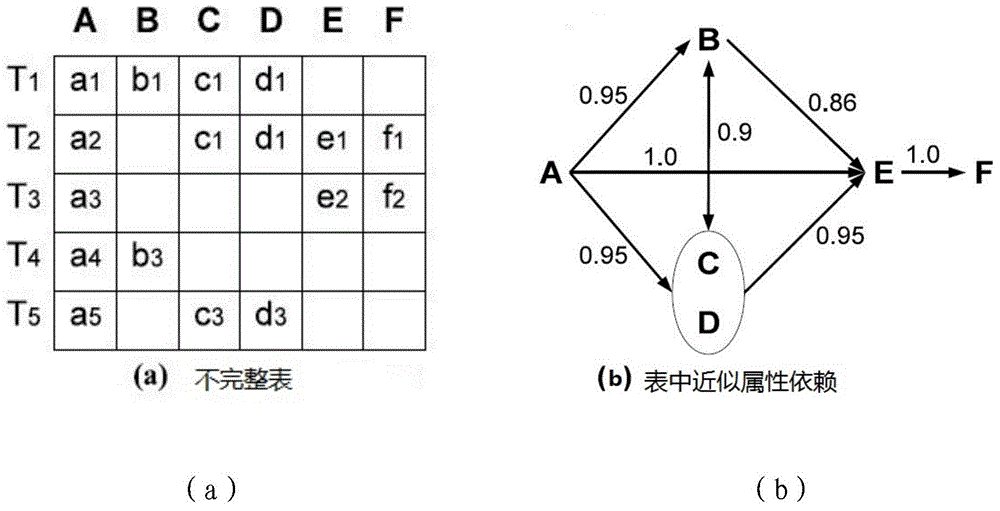

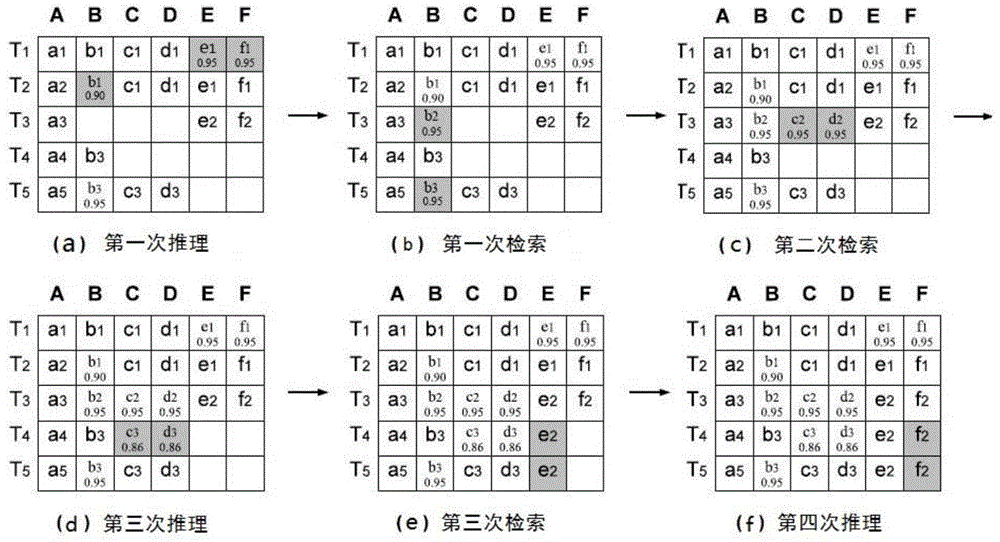

The invention discloses a data filling method and a data filling system based on quality control. The data filling method includes the steps of determining missing data according to existing data of a database; establishing a data dependency relationship of the database, and determining a dependency confidence level of the data dependency relationship; determining deducible data and at least one group of non-deducible data in the missing data according to the existing data and the data dependency relationship; determining one group of to-be-retrieved data from the groups of non-deducible data according to a preset rule; deducing the deducible data according to the existing data and the data dependency relationship, and calculating a deduction confidence level according to the dependency confidence level; when the deduction confidence level is higher than a preset threshold value, filling the deducible data, retrieving the to-be-retrieved data from external resources, and calculating a retrieving confidence level according to the dependency confidence level; when the retrieving confidence level is higher than a preset threshold value, filling the to-be-retrieved data. The data filling method and the data filling system based on quality control have the advantages that by means of executing deducing and retrieving alternately, high filling accuracy can be guaranteed at small cost, and the confidence level is enabled to be high due to the fact that the dependency confidence level of the data dependency relationship is taken into consideration.

Owner:苏州大数据有限公司 +2

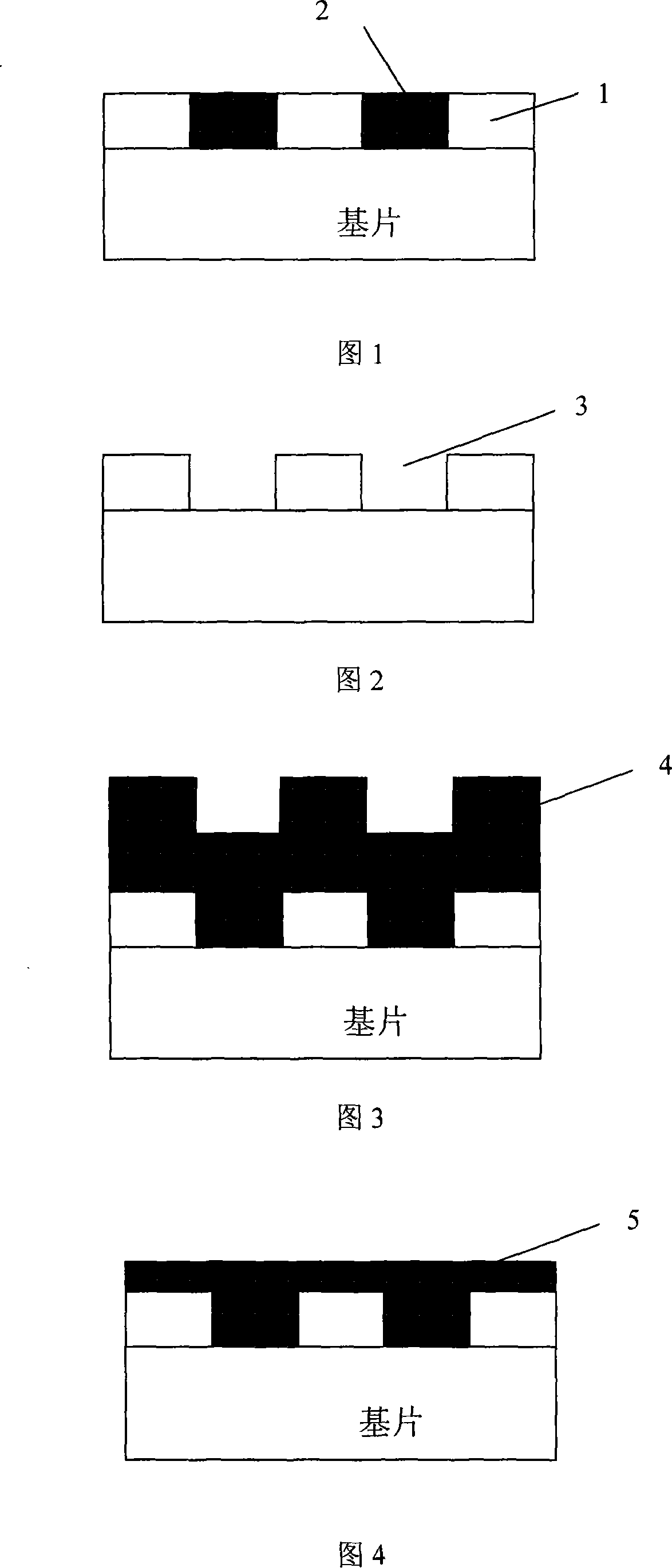

Preparation method of filling type sub-wavelength guide mode resonance optical filter

InactiveCN101178454AReduce difficultyPadding achievedOptical filtersPhotomechanical apparatusGratingWavelength

The invention relates to a production method of a filling type subwavelength guided mode resonance light filtering piece. The initial air filling type subwavelength grating is produced by adopting methods of plate covering light charactering and reaction ion beam etching, then film plating and etching are proceeded by taking the air filling type subwavelength grating as the base piece. The invention is characterized in that: a) a film plating uses a method of physics vacuum sediment, the material of the film is the material being filled in a grating groove and the thickness of the film is 2 times of the depth of the subwavelength grating groove; b) the reaction ion beam is used for etching the light filtering piece being plated, the etching thickness is 2 times of the depth of the subwavelength grating groove. The invention fills the material, the thickness of which has the exactitude to the nanometer grade in the grating groove with nanometer yardstick and which no doubt is one of the production in the light filtering pieces with the most difficult. The invention combines the plating technique and the etching technique to provide a practical and feasible etching production method; the method used can conveniently produce filling type subwavelength guided mode resonance light filtering pieces.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

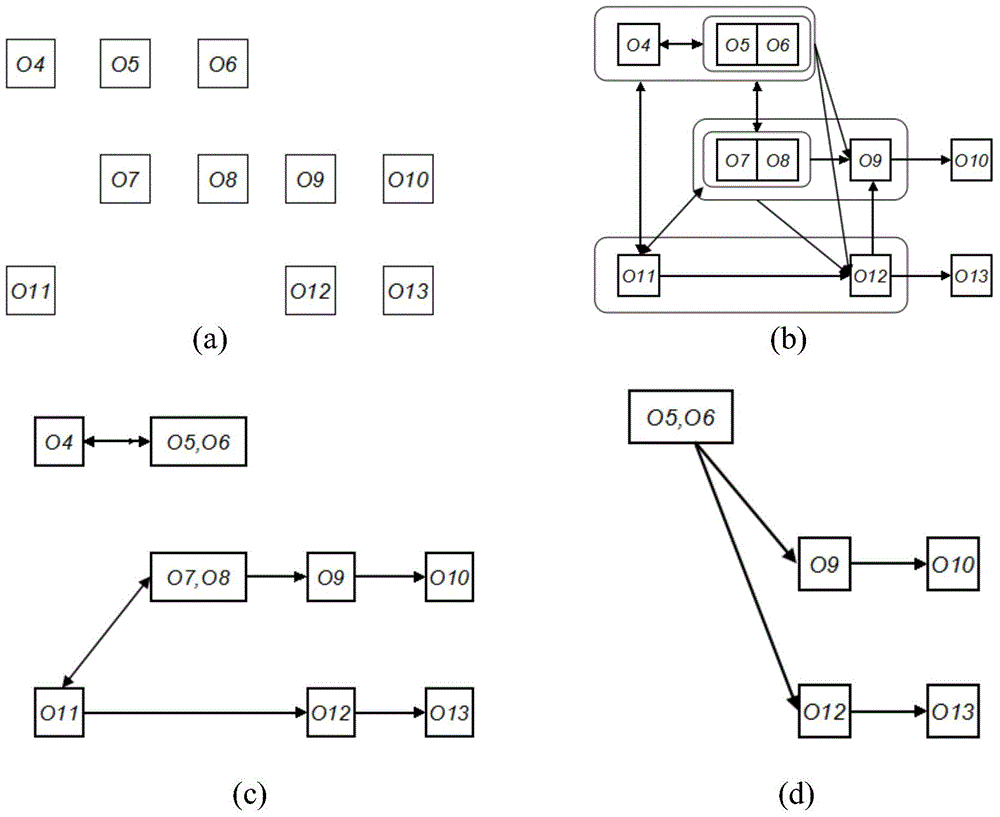

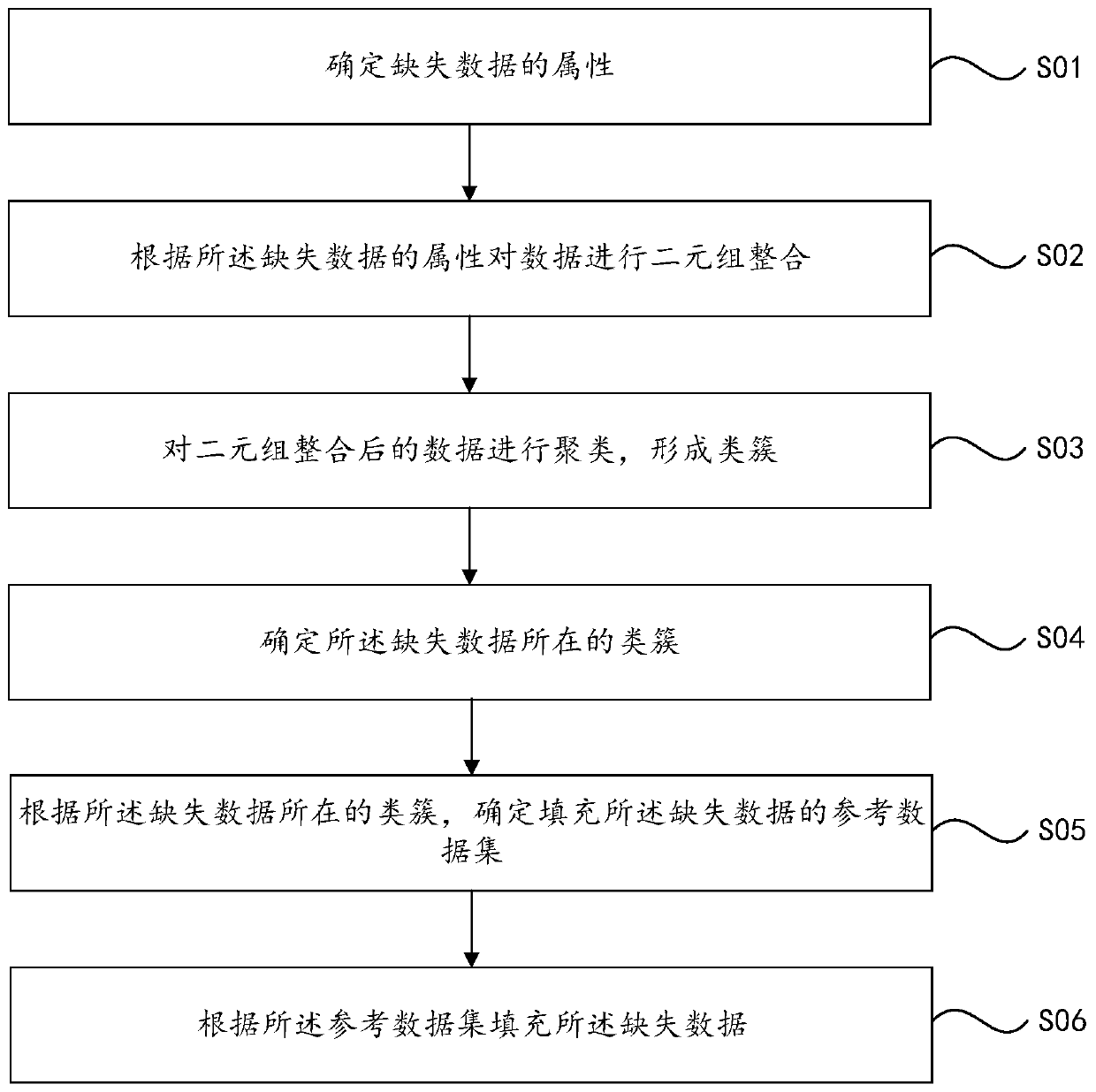

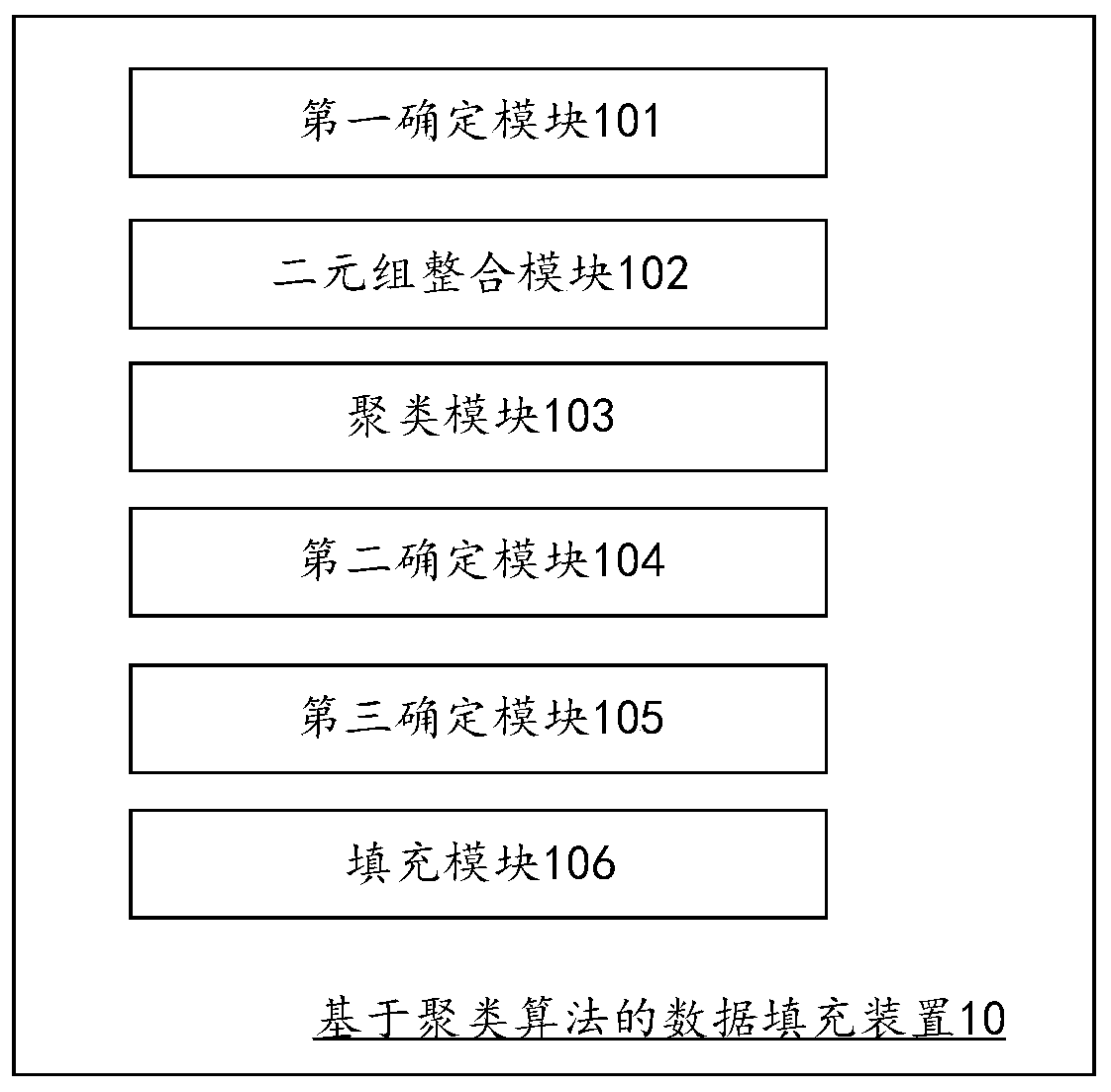

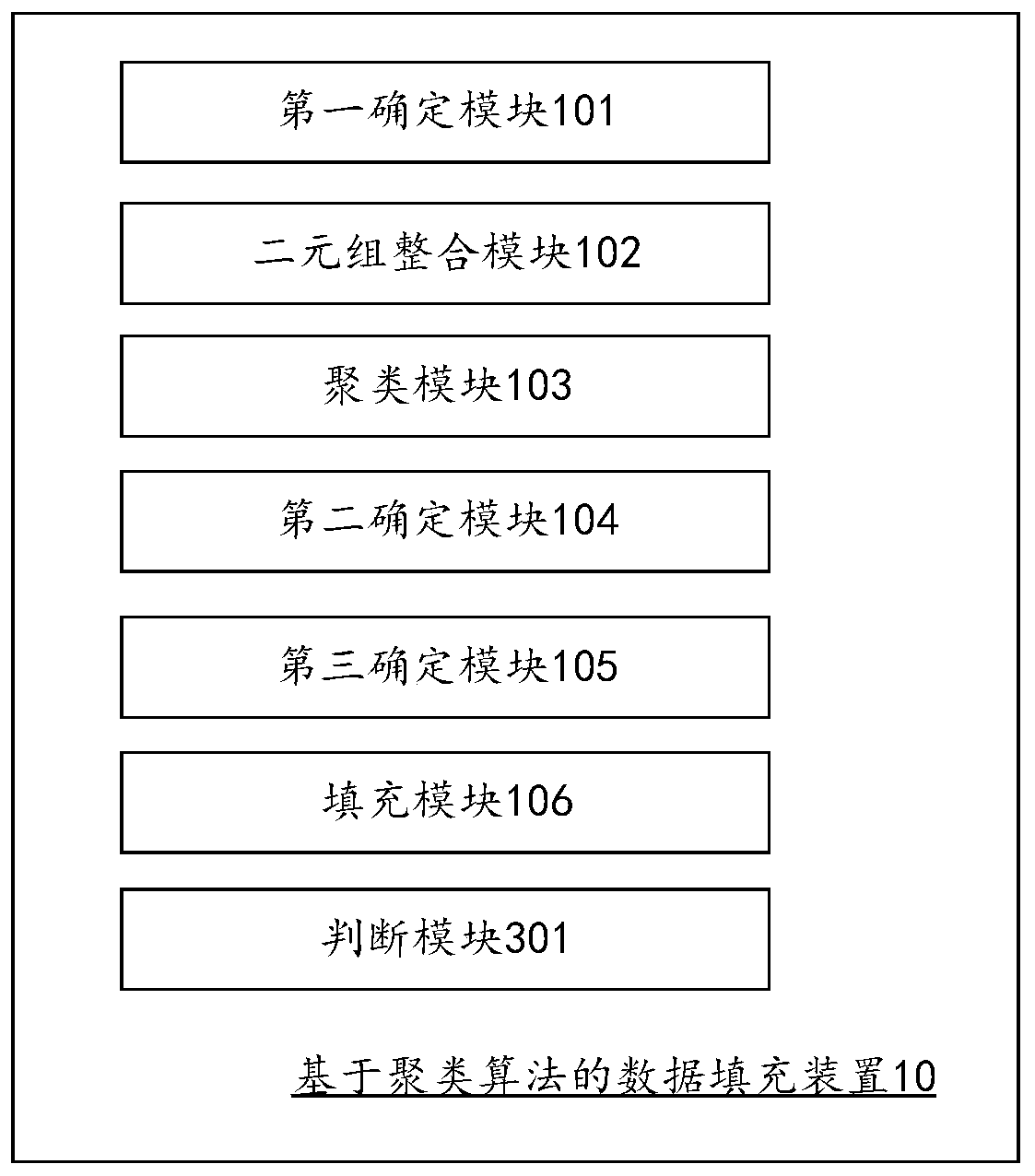

Data filling method and device based on clustering algorithm and computer equipment

PendingCN110659268APadding achievedGuaranteed accuracyDigital data information retrievalCharacter and pattern recognitionCluster algorithmData set

The invention provides a clustering algorithm-based data filling method and device, and a computer device. The method comprises the steps of determining attributes of missing data; performing two-tuple integration on the data according to the attributes of the missing data; clustering the data after the two-tuple integration to form a class cluster; determining a class cluster where the missing data is located; determining a reference data set for filling the missing data according to the class cluster where the missing data is located; and filling the missing data according to the reference data set. According to the method, the missing data can be filled, the accuracy of the filled missing data is ensured, and a basis is provided for the accuracy of data mining and analysis.

Owner:CHINA PING AN PROPERTY INSURANCE CO LTD

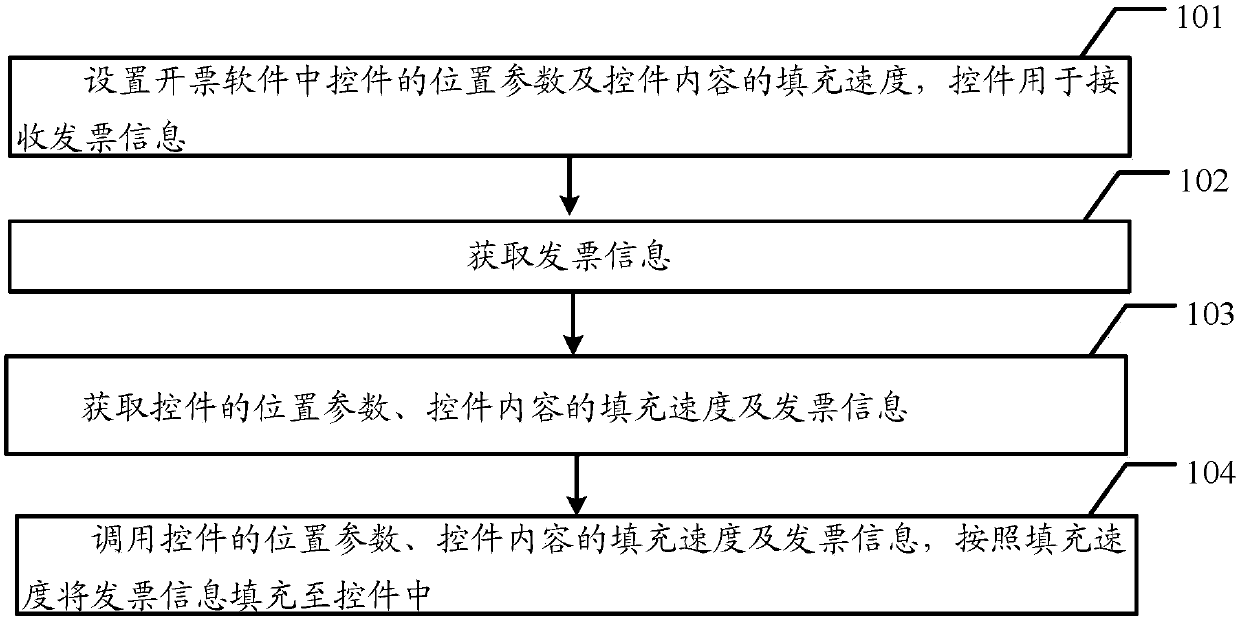

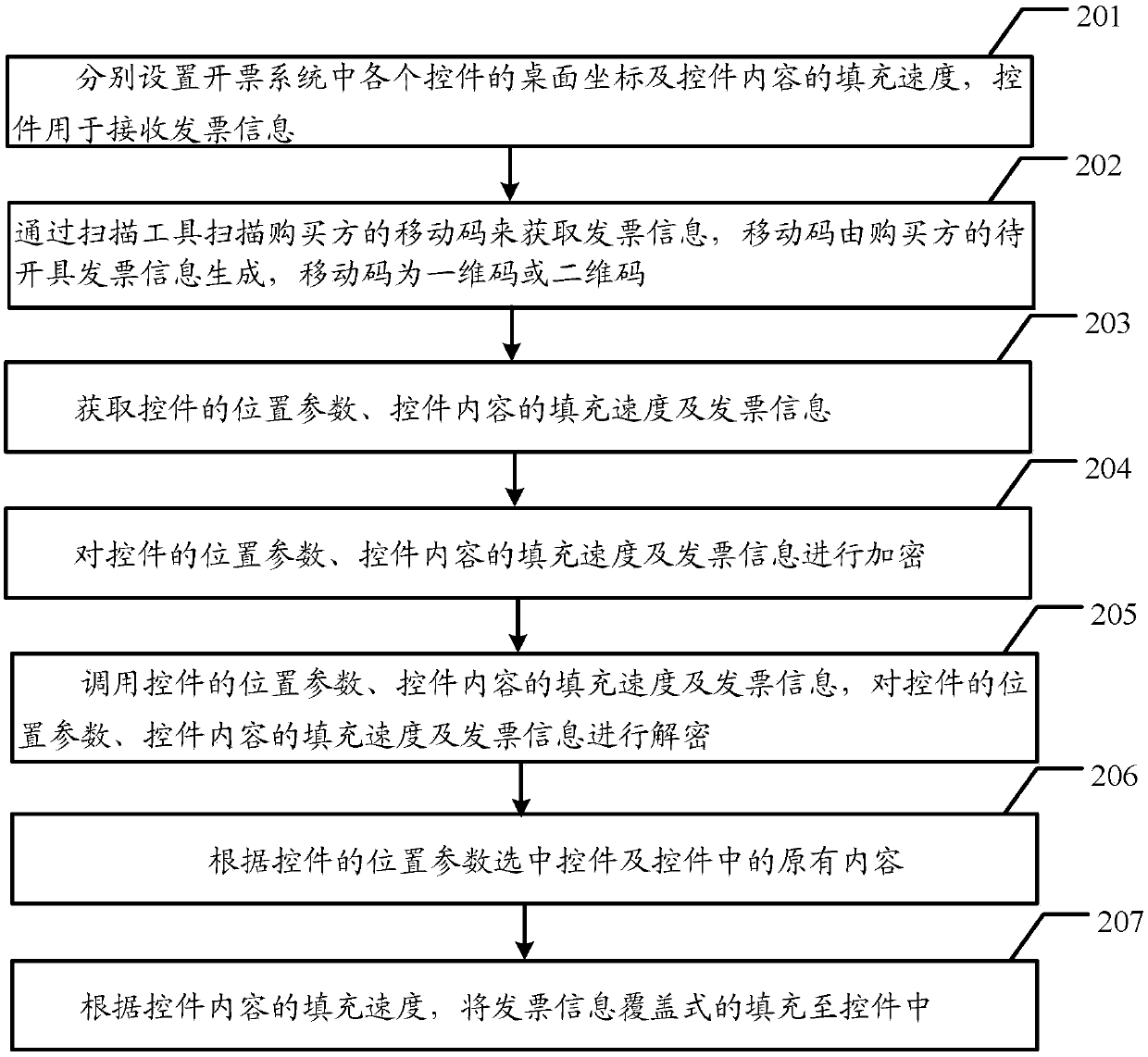

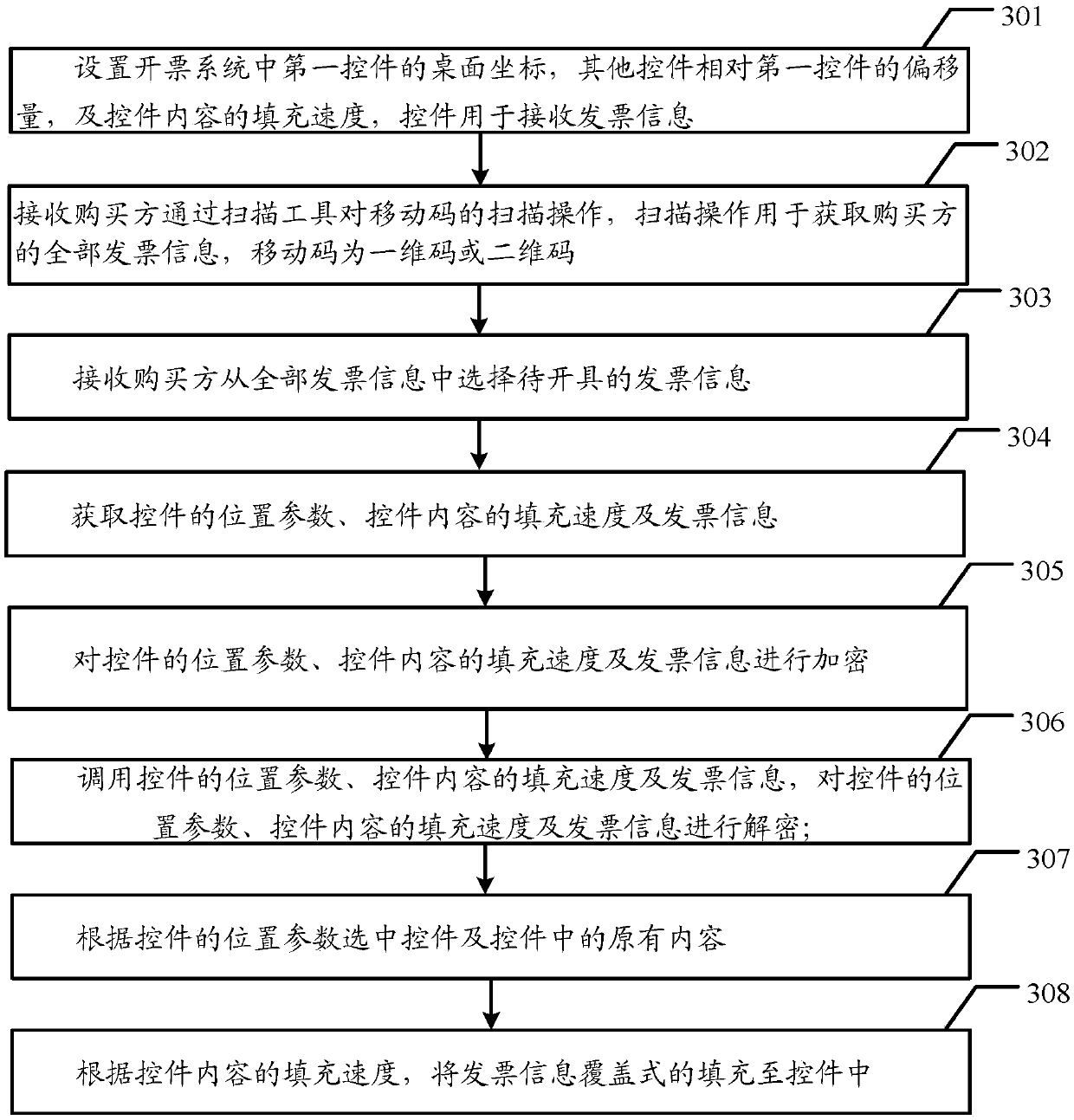

Invoice title filling method and system

InactiveCN107832284AAchieve positioningPadding achievedCharacter and pattern recognitionNatural language data processingInvoiceComputer science

Embodiments of the invention disclose an invoice title filling method and system, and aims at filling invoice title information for handle-free invoicing systems. The method comprises the following steps of: setting a position parameter of a control in an invoicing system and a filling speed of control content, wherein the control is used for receiving invoice information; obtaining the invoice information; obtaining the position parameter of the control, the filling speed of the control content and the invoice information; and calling the position parameter of the control, the filling speed of the control content and the invoice information, and filling the invoice information into the control according to the filling speed. The invention furthermore provides the invoice title filling system which is used for filling invoice title information for handle-free invoicing systems.

Owner:国信电子票据平台信息服务有限公司

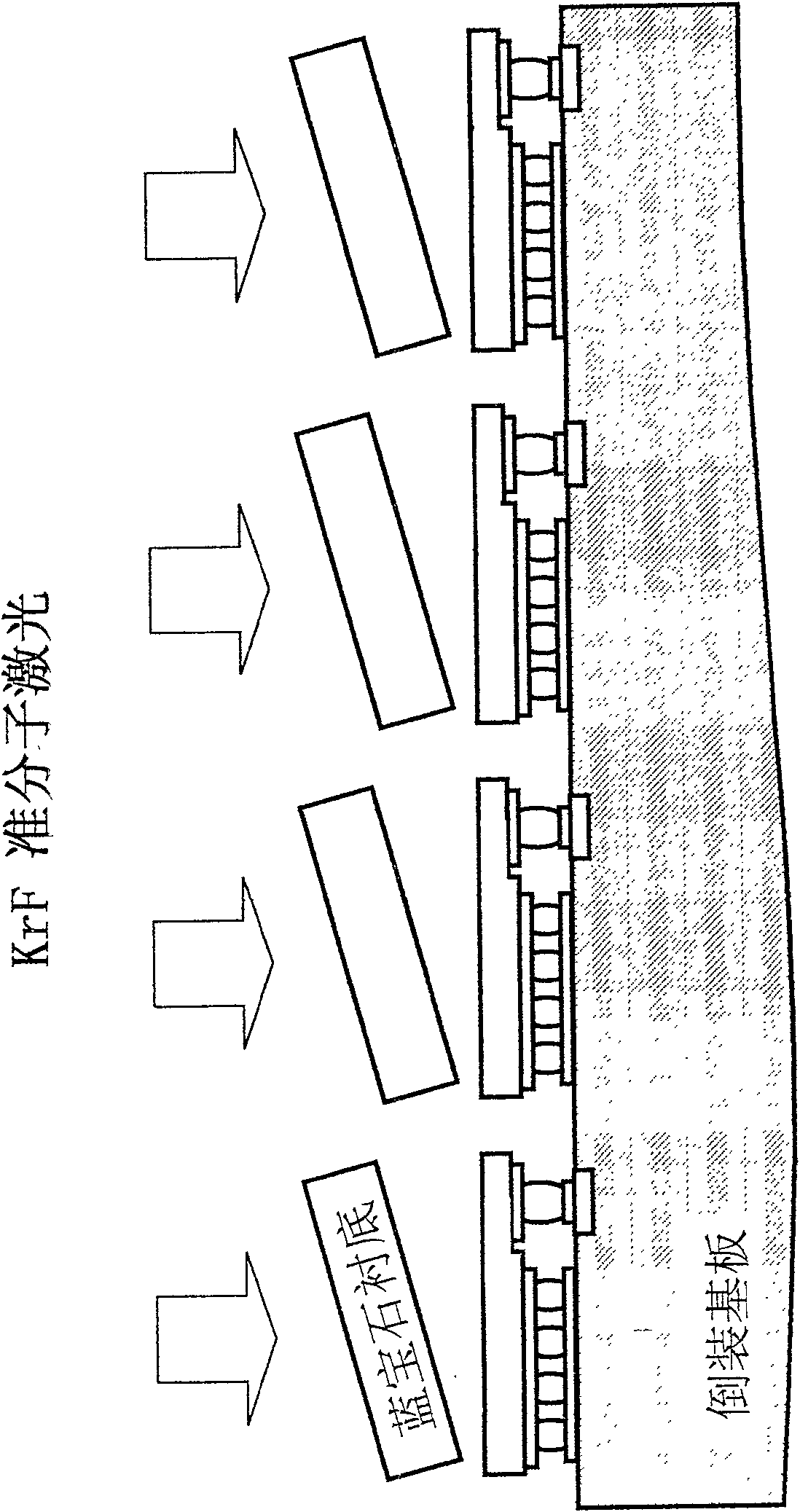

Film LED chip device based on compound low-resistance buffer structure and its making method

ActiveCN100580965CPadding achievedTo achieve electrical connectionSemiconductor devicesEngineeringLow resistance

The present invention provides a film LED chip device basing on the combined low-resistance buffer structure and the manufacturing method thereof, the insulating buffer film is packaged on side wall of all metal structures and is filled in all non-electrical connected areas, with filling in insulating buffer film between all metal convex points which connects the GaN base illuminating device and the electric polarized substrate, the filling-in thickness is a little under or even with the height of the metallic convex points, and with directly liking the GaN base illuminating device crystal disc with the whole surface of the electric polarized inversely mounted substrate with the mode of whole surface linking of the wafer, the metallic convex point of the conductive supporting thick metal layer and the insulating buffer film form the combined low-resistance buffer structure of the invention together, not only the electric connection between the GaN base illuminating device and the electric polarized inversely mounted substrate is realized, but also the buffer layer filling is realized thereby reducing the wafer rupture incidence rate of the subsequent laser stripping technique in order to increase the good product ratio, besides the stripped sapphire substrate disc which can execute finishing to the sapphire substrate and is obtained after stripped operation can be recovered for reusing, the production cost is reduced.

Owner:QUANZHOU SANAN SEMICON TECH CO LTD

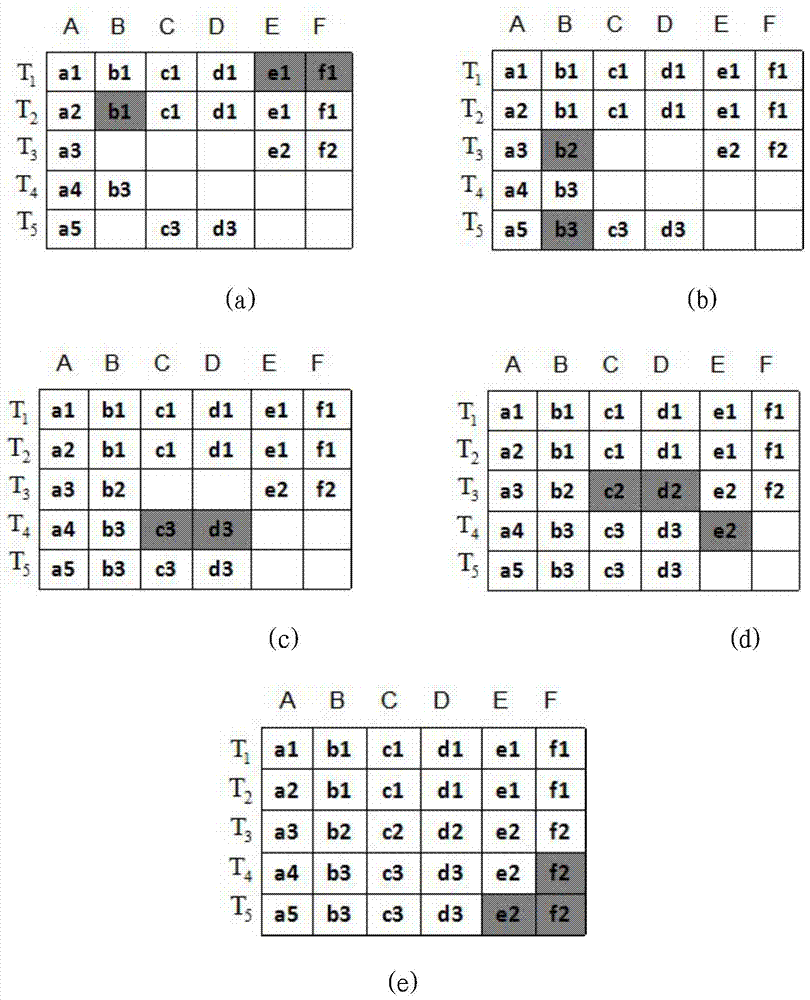

Data filling method and system

ActiveCN104850658AHigh filling accuracyPadding achievedRelational databasesSpecial data processing applicationsMissing dataData filling

The invention discloses a data filling method. The data filling method includes determining missing data of database according to existing data in the database and setting up data dependence relation among all data in the database; repeating the following steps until all the missing data of the database is filled up, determining deducible data and at least one group non-deducible data in the missing data of the database according to the existing data of the database and the data dependence relation, determining a group of data to be retrieved from the non-deducible data according to the preset rules, deducing and filling the deducible data according to the existing data of the database and the data dependence relation, and retrieving the external resource of the database and filling the data to be retrieved. Thus, by alternating executing deduction and retrieval, the missing data of the database can be filled up in high efficiency and high quality, and high data filling accuracy can be obtained under low system cost.

Owner:ZHANGJIAGANG INST OF IND TECH SOOCHOW UNIV +1

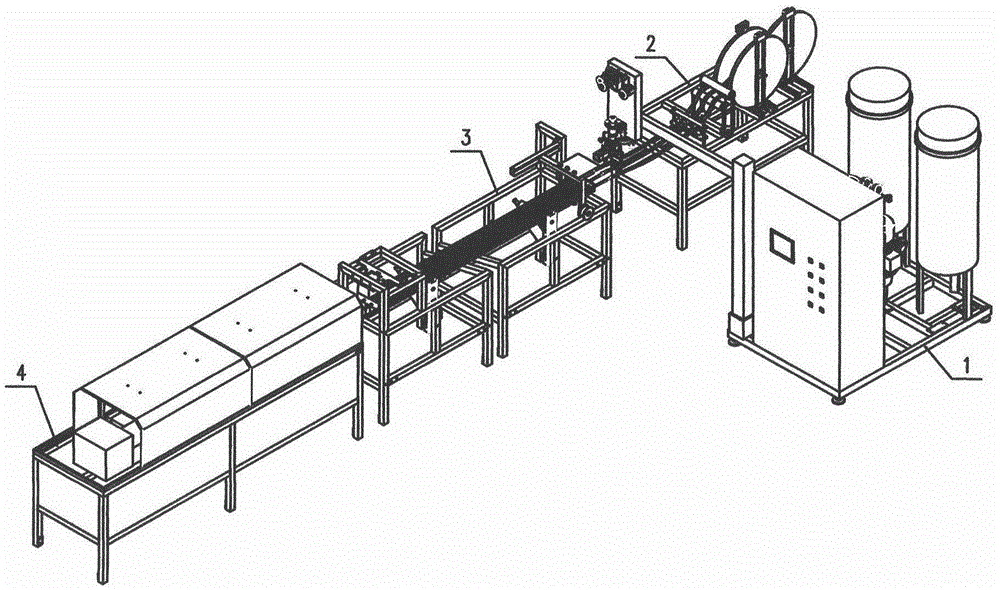

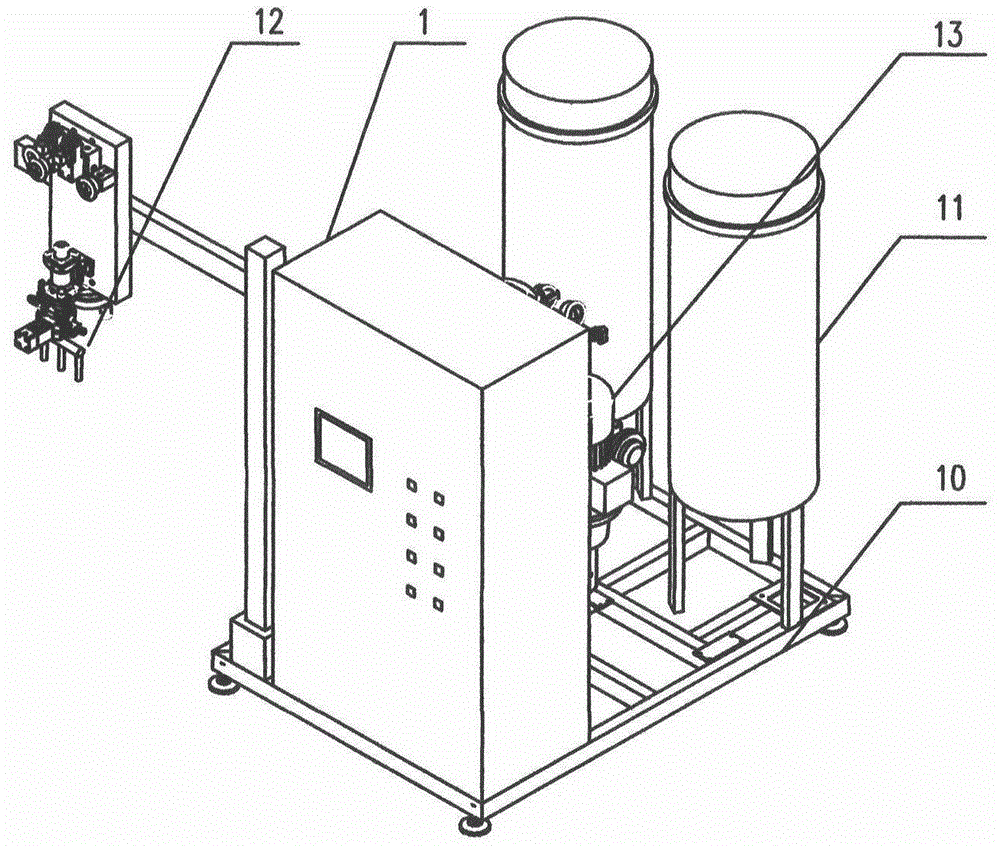

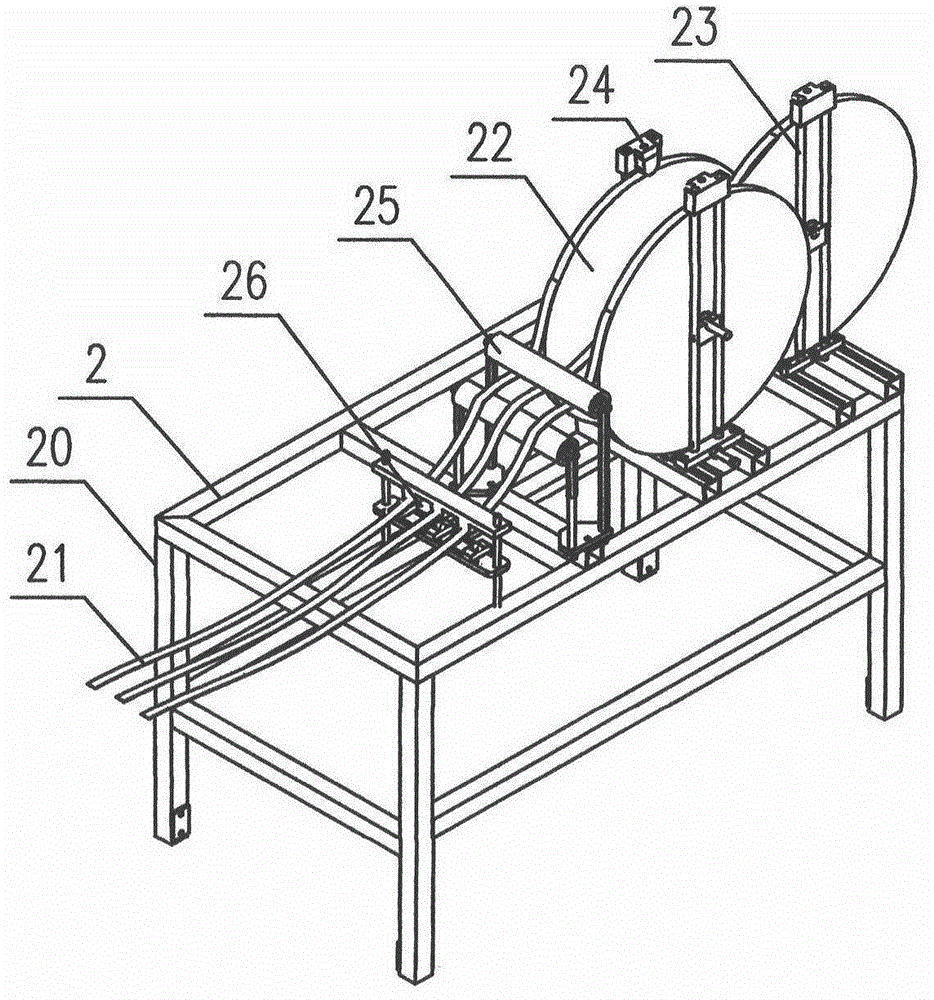

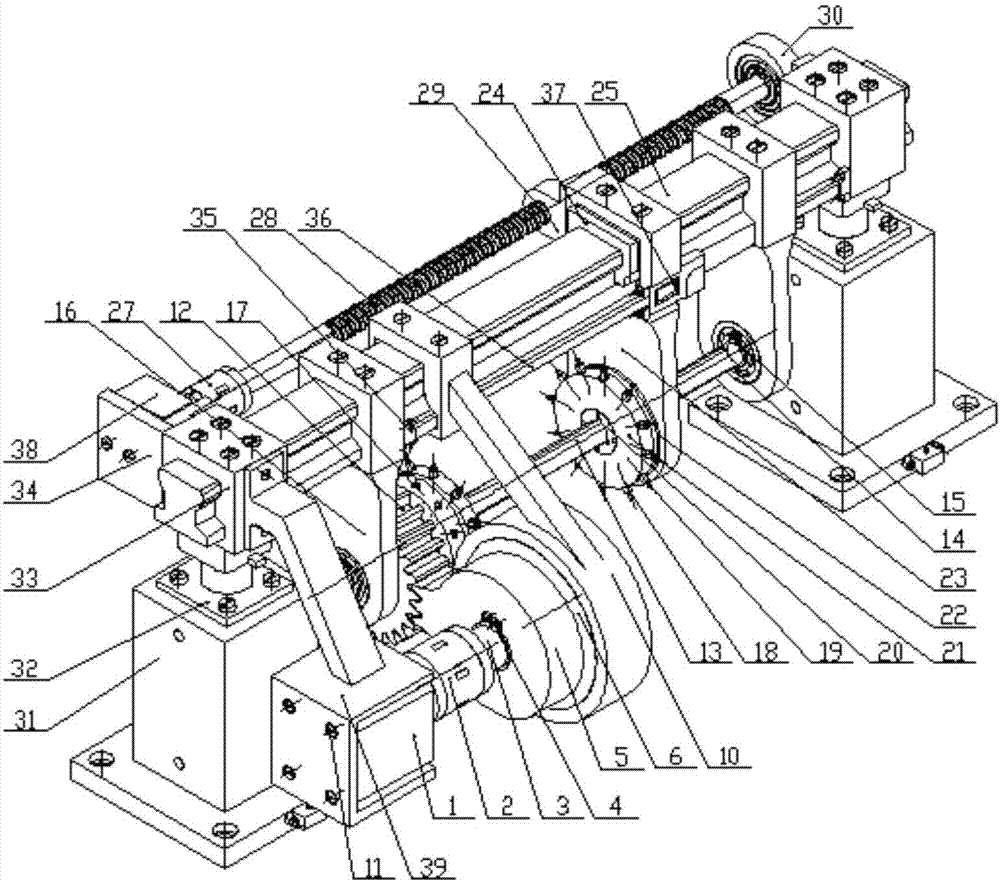

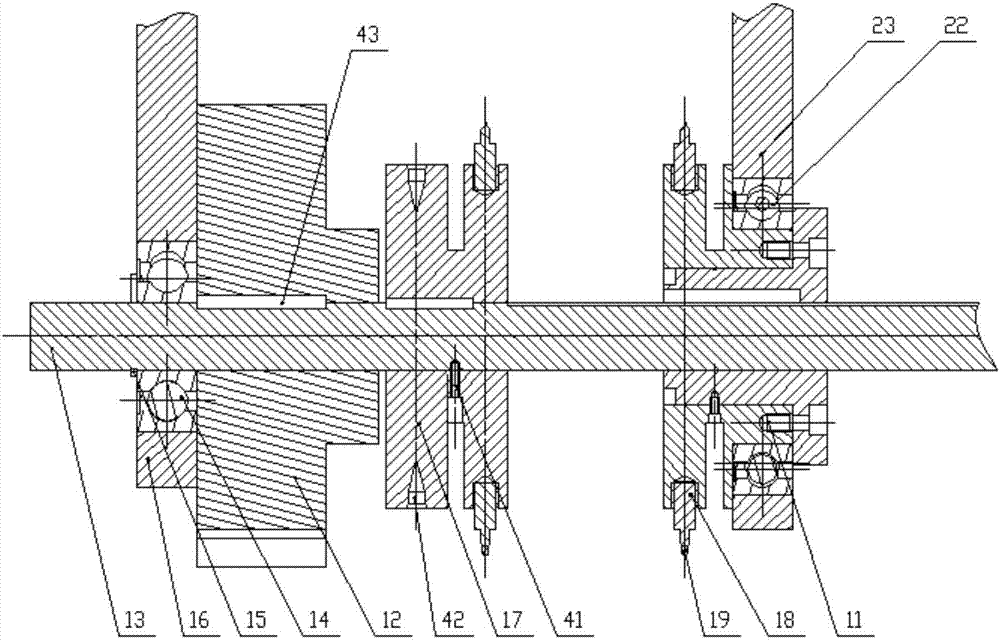

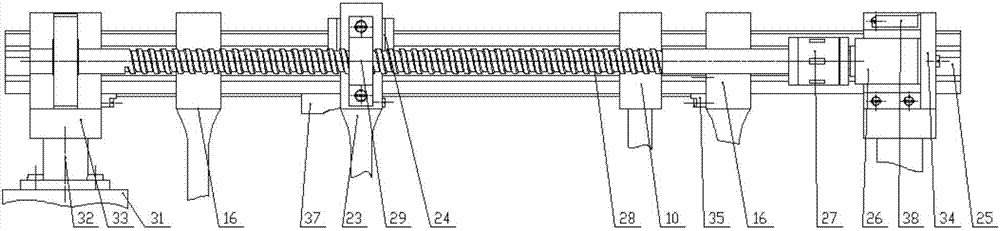

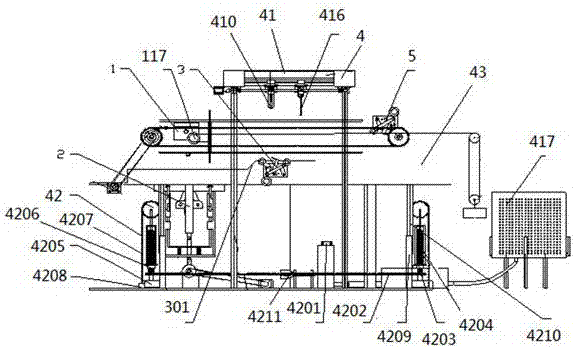

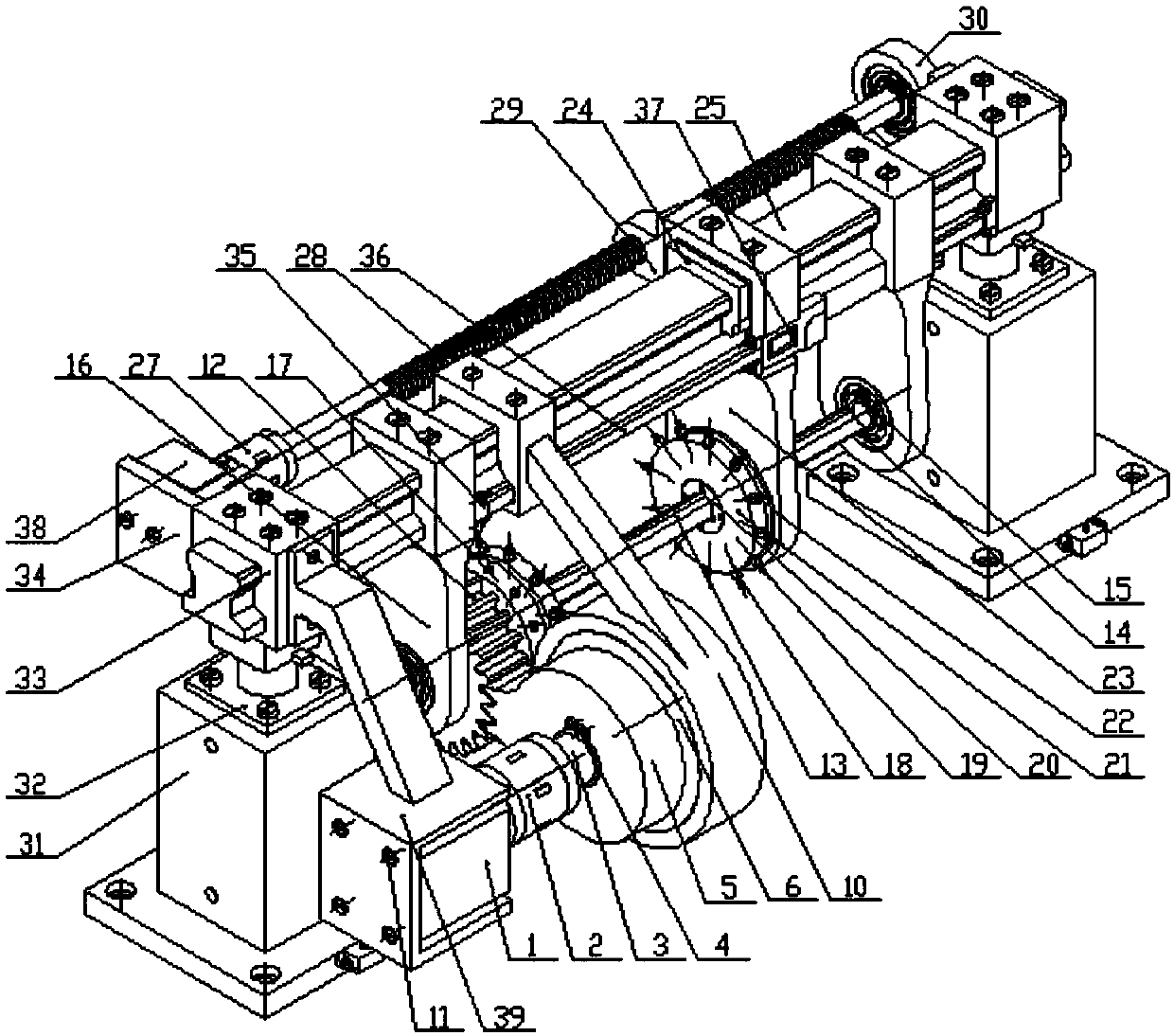

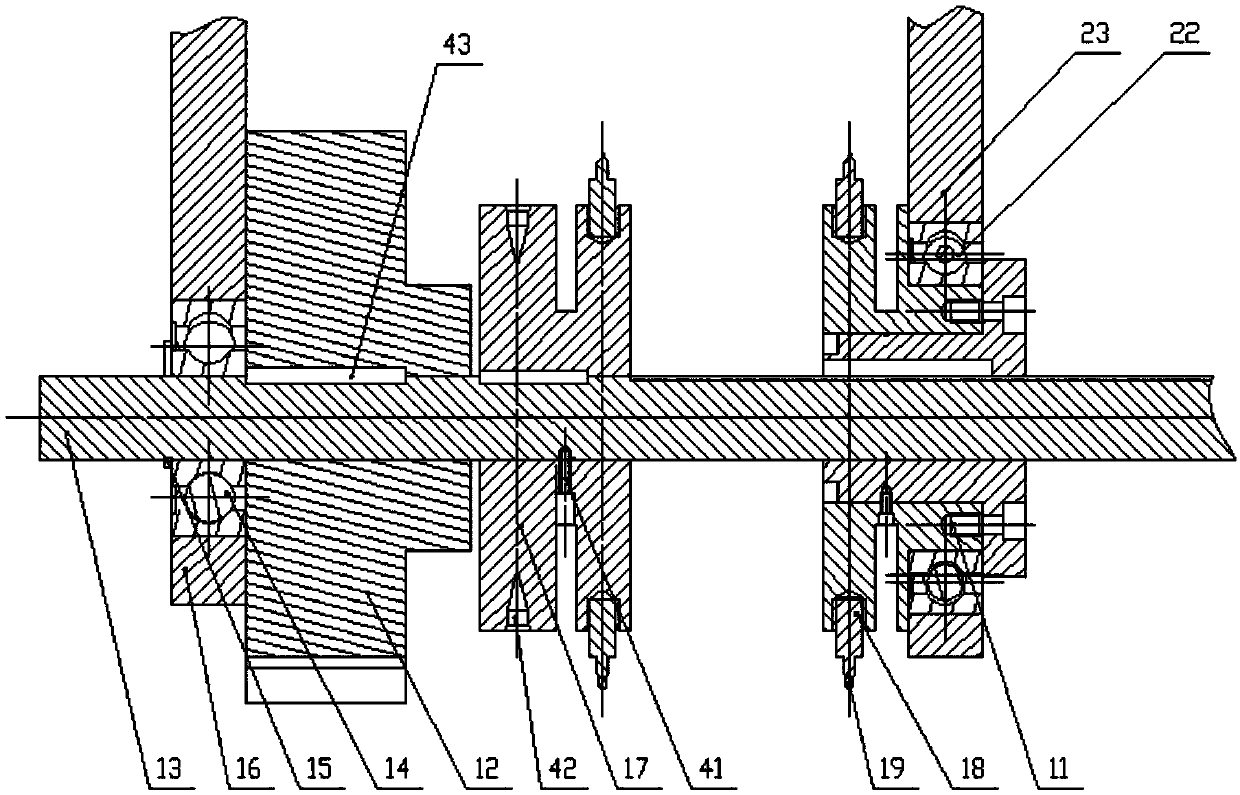

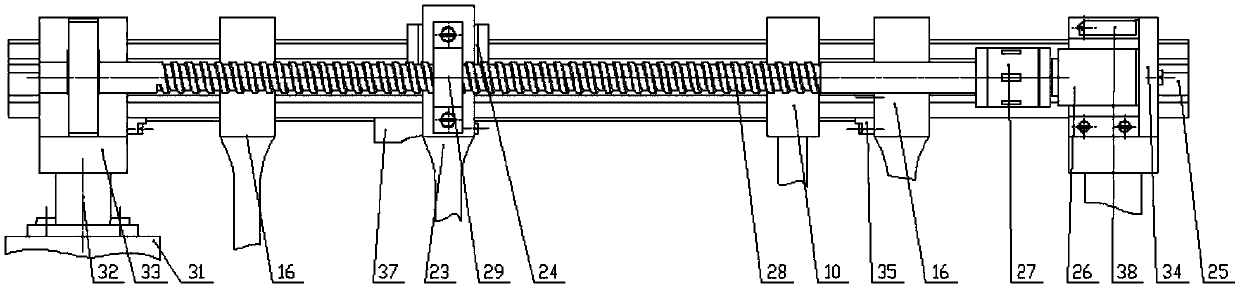

Material perfusion and filling device and process for narrow and long space

The invention relates to a material perfusion and filling device and process for narrow and long space. The device includes a perfusion host, a carrier zigzag conveying portion, a section bar positioning portion and a carrier traction portion. The carrier zigzag conveying portion is arranged at the left end of the perfusion and filling device; the section bar positioning portion is arranged in the middle of the perfusion and filling device; the carrier traction portion is arranged on the right end of the perfusion and filling device; the perfusion host is arranged on the external side of the junction of the carrier zigzag conveying portion and the section bar positioning portion; the perfusion host includes a base, a material storage container, a discharge port and a transfer pump; the material storage container, the discharge port and the transfer pump are fixedly disposed on the base, and the transfer pump t is respectively connected to the discharge port and the material storage container through the feed tubes. The device is capable of efficiently and quickly realize rapid and full material filling in workpiece with narrow filling space, greatly improves production efficiency, reduces waste and production costs and ensures quality and consistency of perfusion filling product, so that automated streamline production operation of that kind of perfusion and filling is possible.

Owner:京华派克邯郸机械科技有限公司

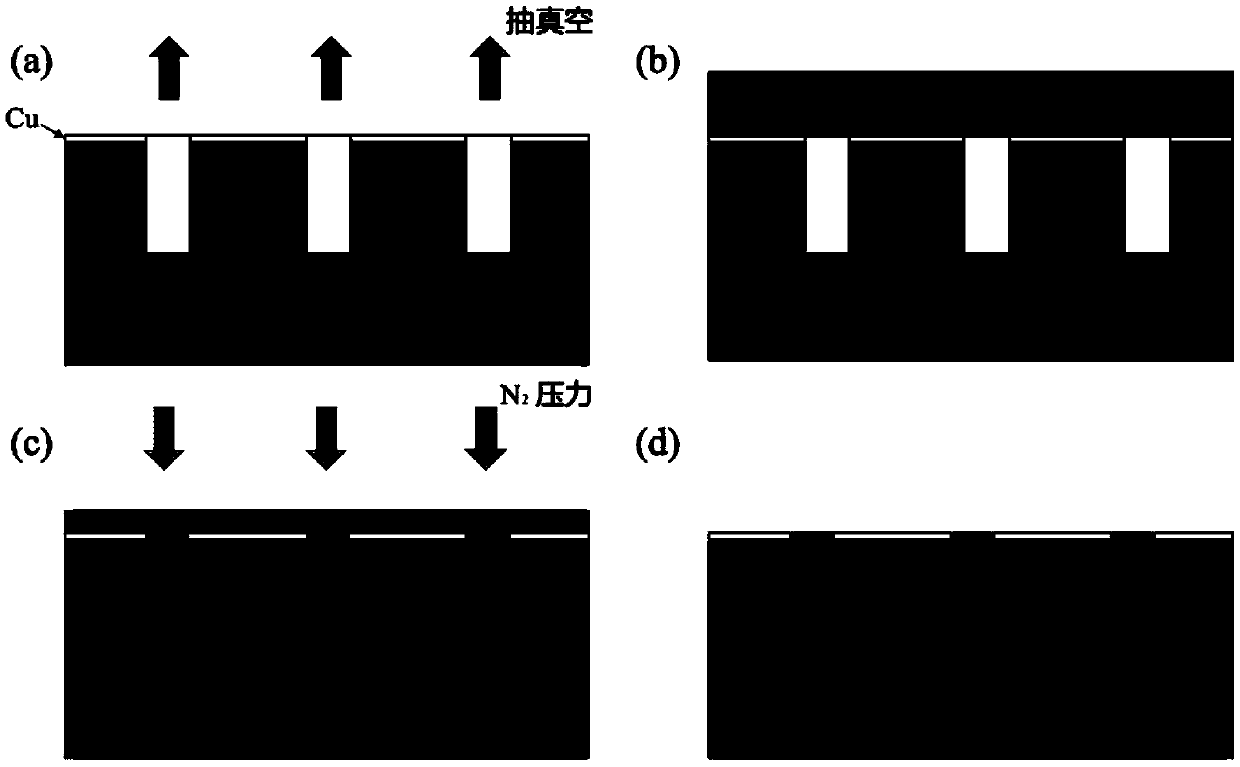

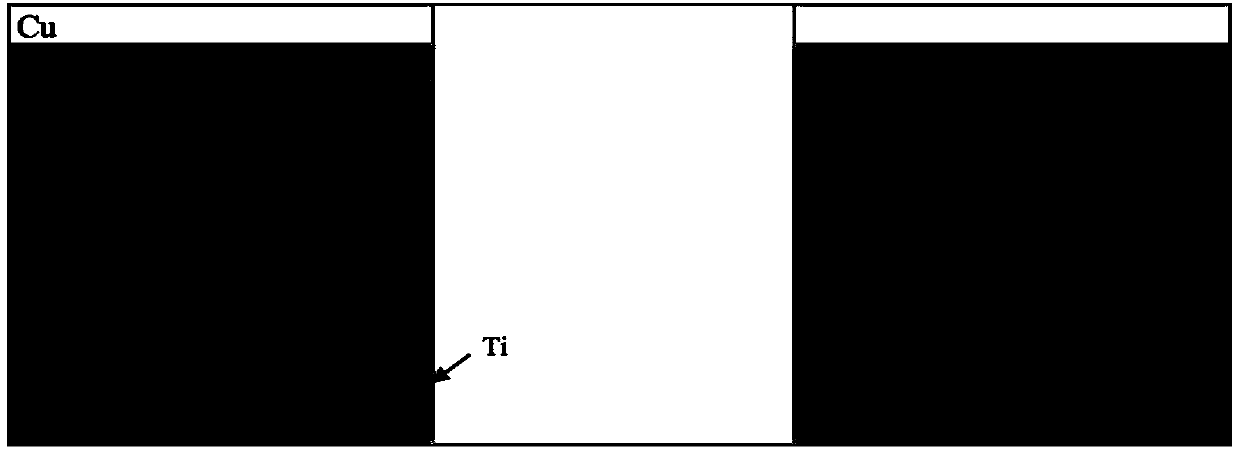

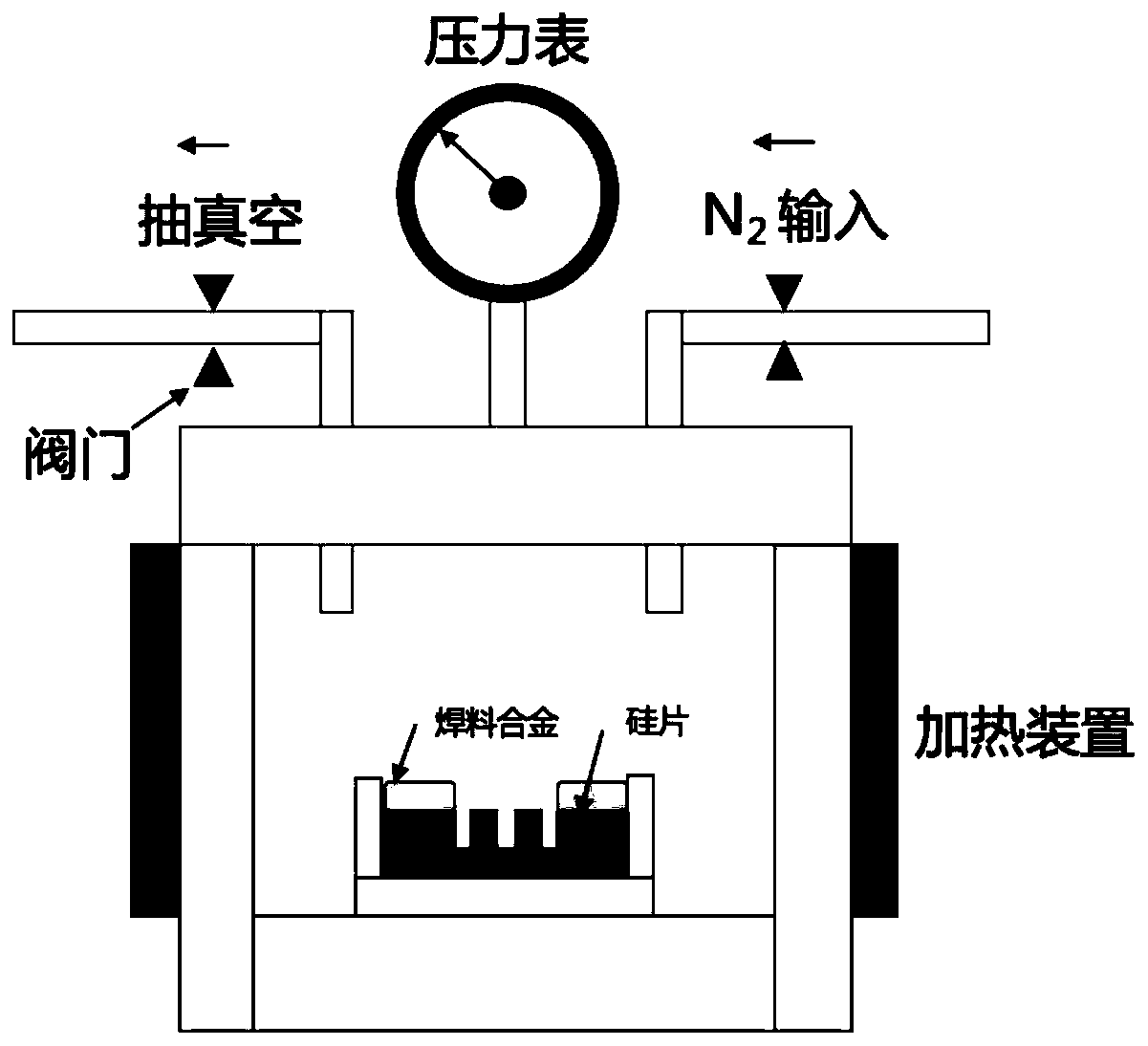

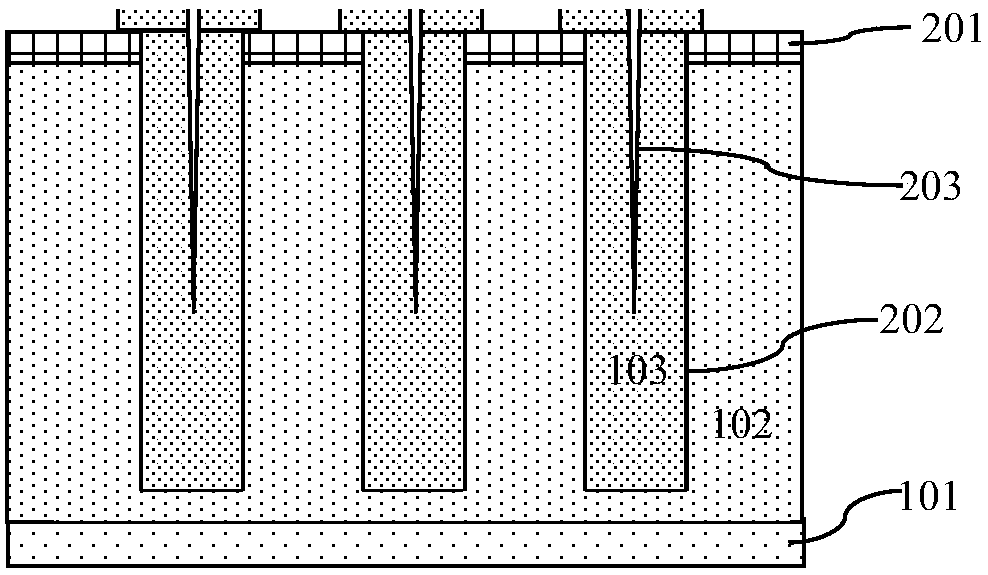

Method and device for rapidly filling vertical TSV hole with liquid alloy

ActiveCN110791746ANot affectedImprove wettabilityVacuum evaporation coatingSputtering coatingInsulation layerDisplay device

The invention provides a method and device for rapidly filling a vertical TSV hole with liquid alloy, and relates to the field of microelectronic packaging. With solder alloy as a filling material, asilicon dioxide insulation layer is deposited on the surface of a TSV silicon wafer and in a blind hole in advance through chemical vapor deposition, a titanium barrier layer is deposited on the wallof the hole through physical vapor deposition, and finally, a copper layer is electroplated on the surface of the silicon wafer deposited with silicon dioxide to serve as a wet layer; and the obtainedwafer is placed in a vacuum chamber, the alloy is heated to be molten, the silicon wafer is pressurized when completely making contact with the molten alloy due to the wettability of the solder alloyand copper, the pressure in the vacuum chamber is maintained after pressurization, and filling is completed after the temperature is decreased. By the adoption of the method and device, the filling efficiency of the TSV hole can be improved, and imporous filling of a high-depth-wide-ratio TSV blind hole with the solder alloy is completed. The alloy and the wall of the TSV hole are firmly bonded together, and the filling process is simple. The TSV hole filling device comprises a vacuum outlet, a nitrogen inlet, a pressure gauge, a reaction chamber, a heating device and a temperature display device, wherein the vacuum outlet and the nitrogen inlet are controlled through valves.

Owner:BEIJING UNIV OF TECH

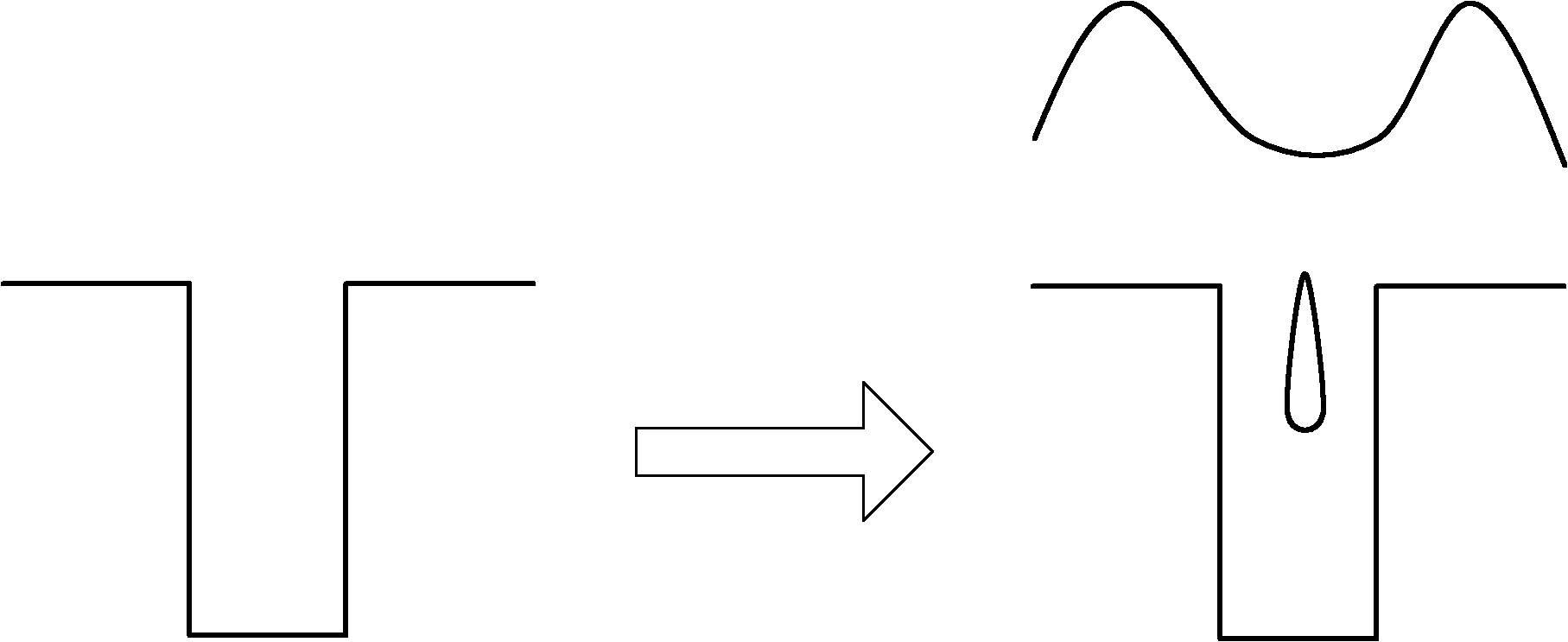

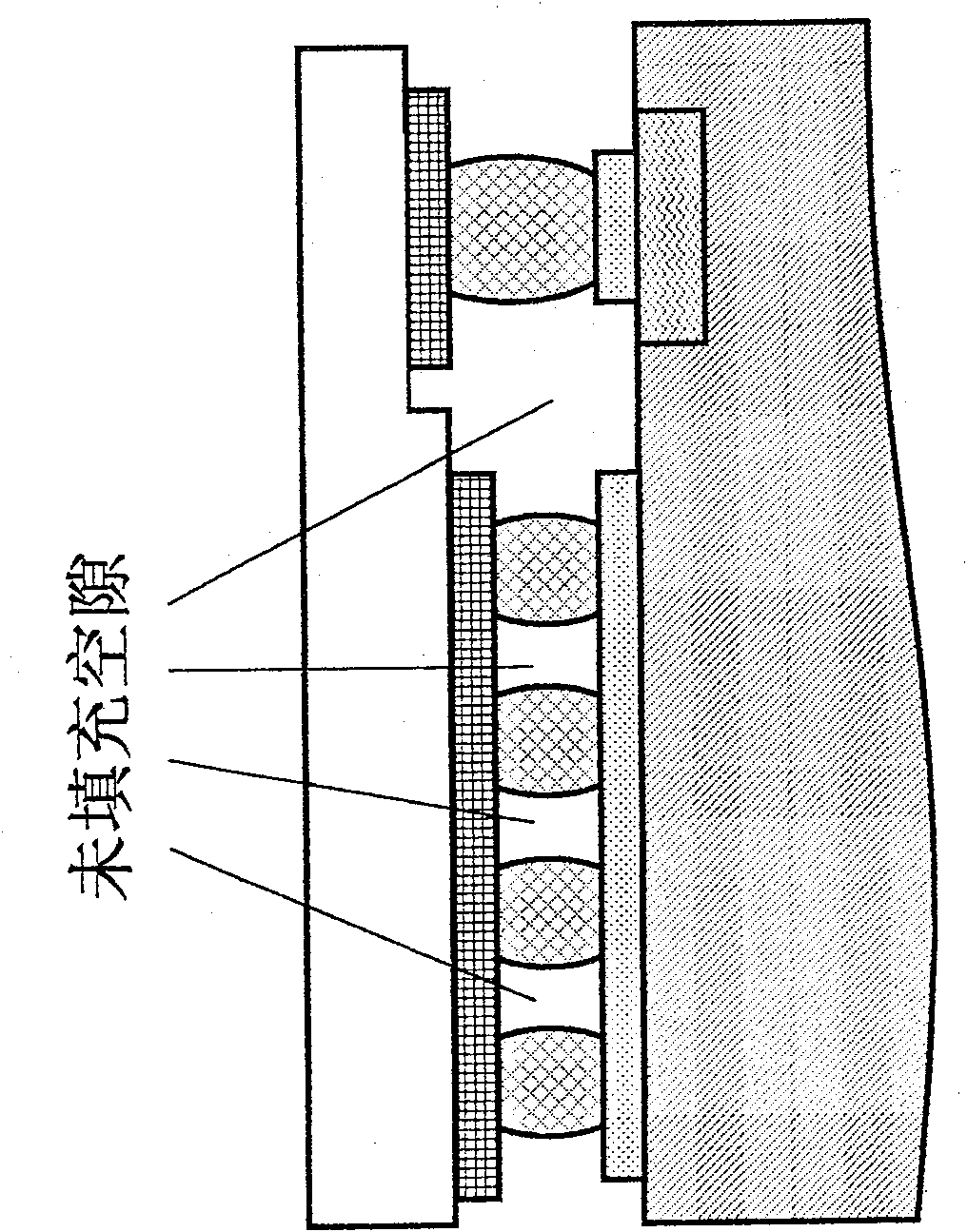

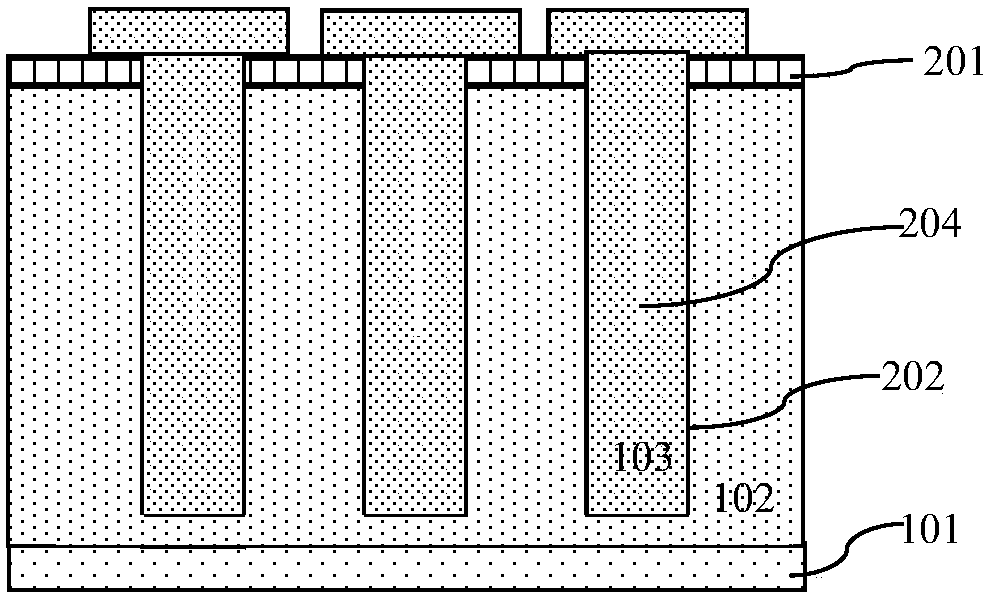

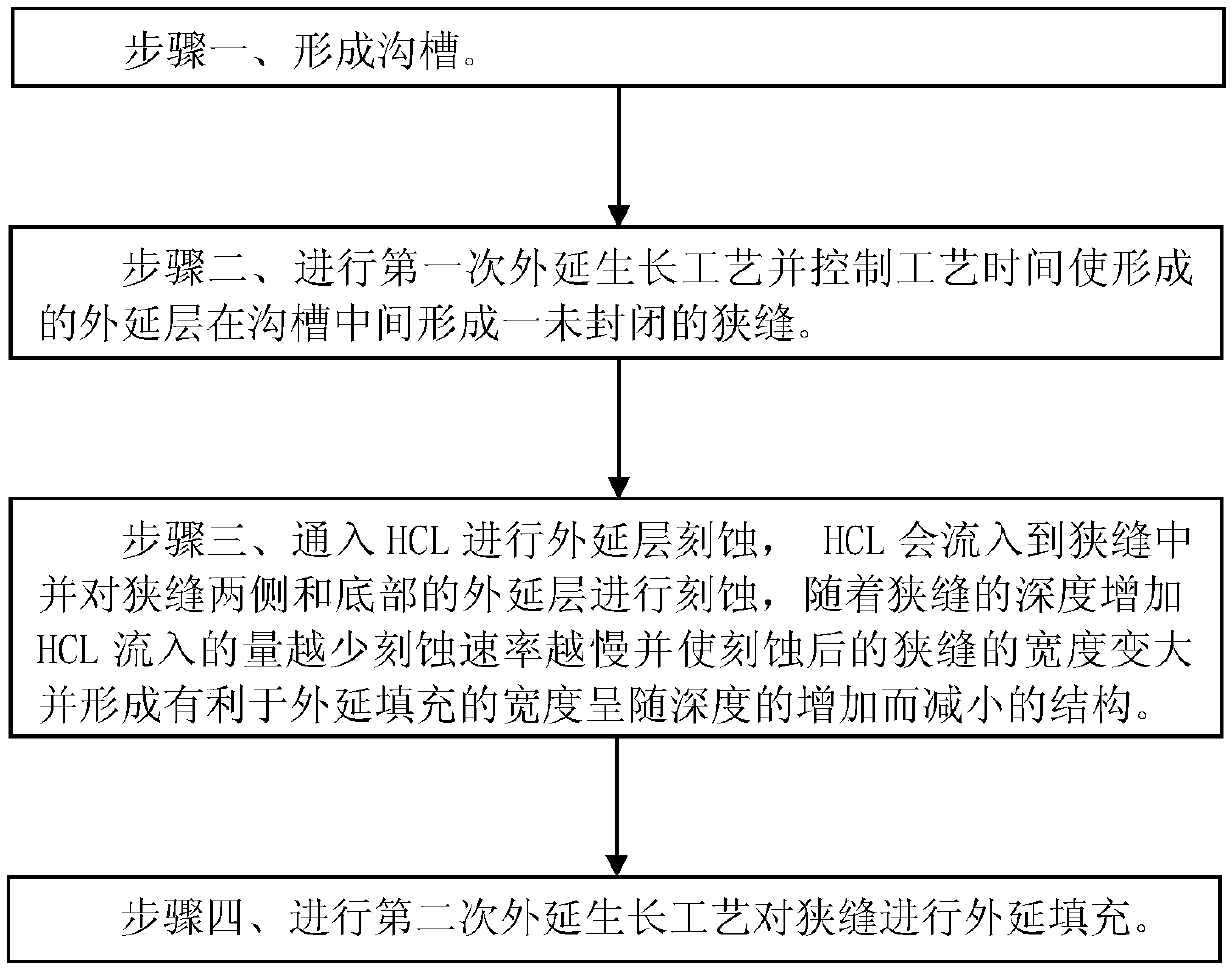

Epitaxial filling method for groove

InactiveCN107611080AEasy inflowIncrease widthSemiconductor/solid-state device manufacturingDevice failureEtching rate

The invention discloses an epitaxial filling method for a groove. The method comprises the following steps of (1) forming a groove; (2) carrying out first epitaxial growth process and controlling theprocess time to form an unclosed slot in the middle of the groove through formed epitaxial layers; (3) introducing HCL for epitaxial layer etching, wherein the HCL flows into the slot and etches the epitaxial layers at two sides and the bottom of the slot, the inflow amount of the HCL is reduced and the etching rate is reduced along with a depth increase of the slot, the width of the etched slot is increased and a structure of facilitating reduction of the epitaxial filling width along with the depth increase is formed; and (4) carrying out second epitaxial growth process for epitaxial fillingon the slot. By using the structure of reducing the width of the slot along with the depth increase, a process gas in the second epitaxial growth process smoothly reaches the bottom of the slot, thereby achieving void-free filling. According to the epitaxial filling method, void-free filling can be achieved, a device failure generated by a void can be prevented and the yield of a product can be improved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

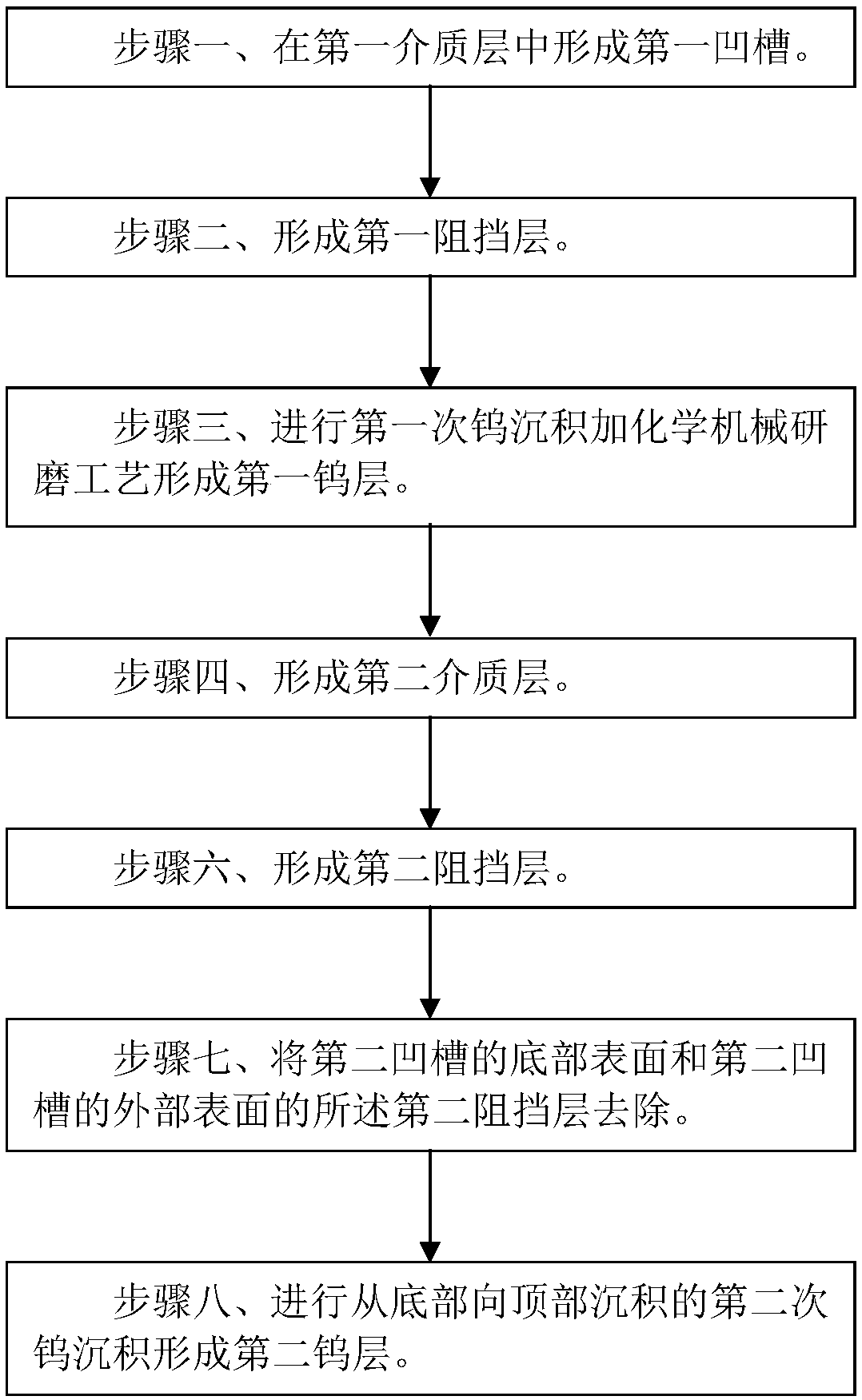

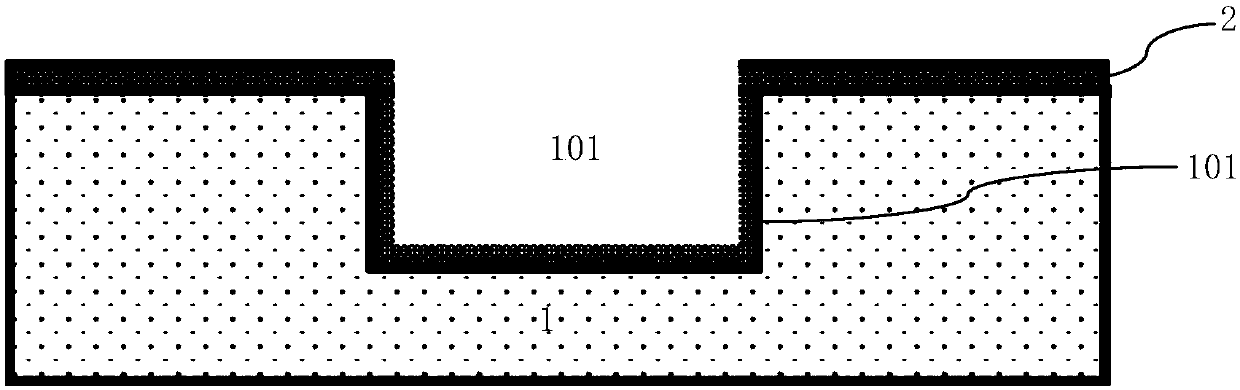

Method of filling groove structure with tungsten

ActiveCN109545741AImprove filling qualityEliminate gap-forming defectsSemiconductor/solid-state device manufacturingTungstenCompound (substance)

The invention discloses a method of filling a groove structure with tungsten, which comprises the following steps: S1, forming a first groove in a first dielectric layer; S2, forming a first barrier layer; S3, carrying out a first tungsten deposition and chemical mechanical grinding process to form a first tungsten layer; S4, forming a second dielectric layer; S5, forming a second groove superimposed directly above the first groove; S6, forming a second barrier layer; S7, removing the second barrier layer from the bottom surface of the second groove and the outer surface of the second groove;and S8, carrying out second tungsten deposition from bottom to top to form a second tungsten layer. By using the method of the invention, seamless filling of tungsten can be realized, and the qualityof a tungsten-filled groove structure can be improved.

Owner:SHANGHAI HUALI INTEGRATED CIRCUTE MFG CO LTD

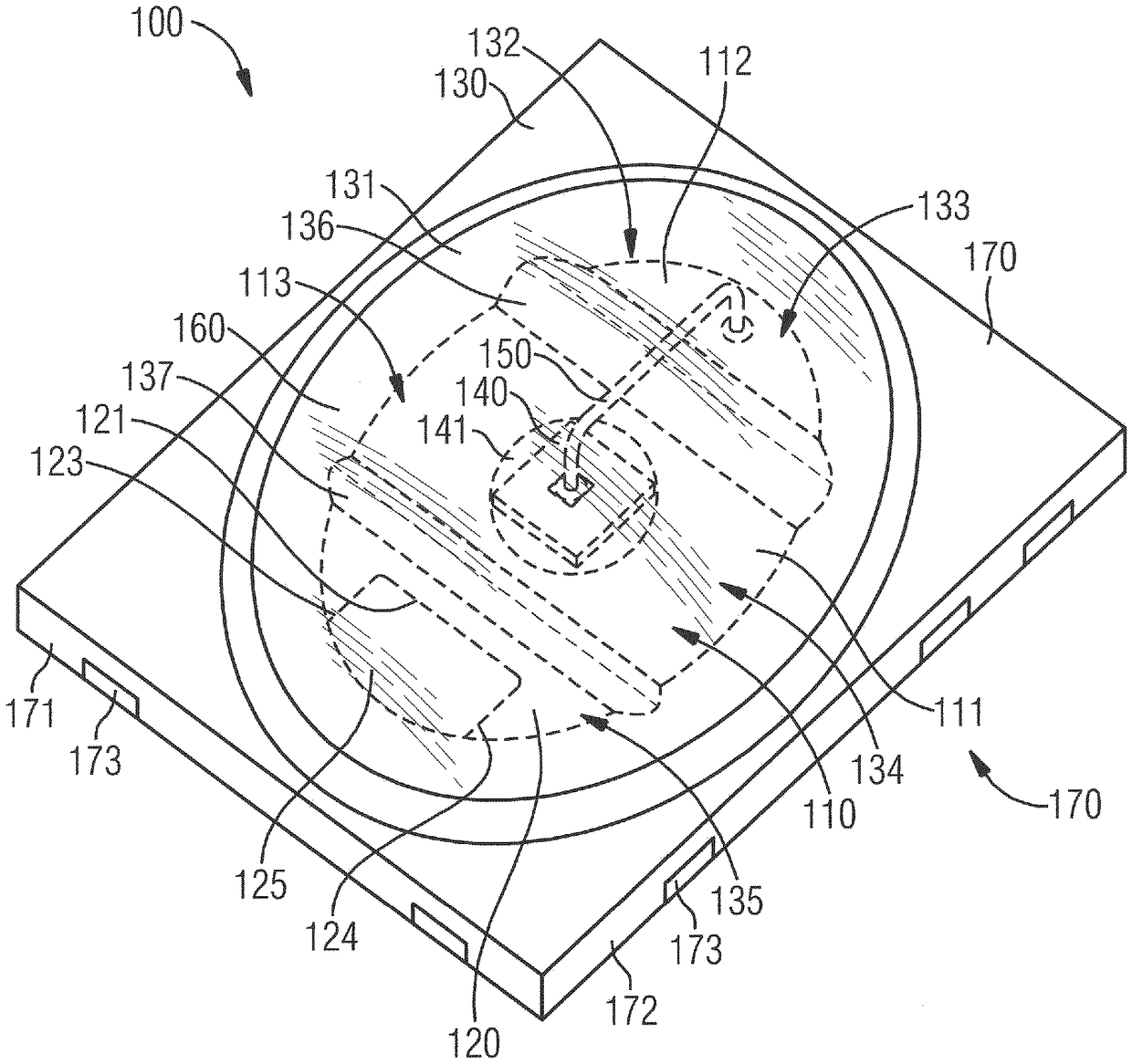

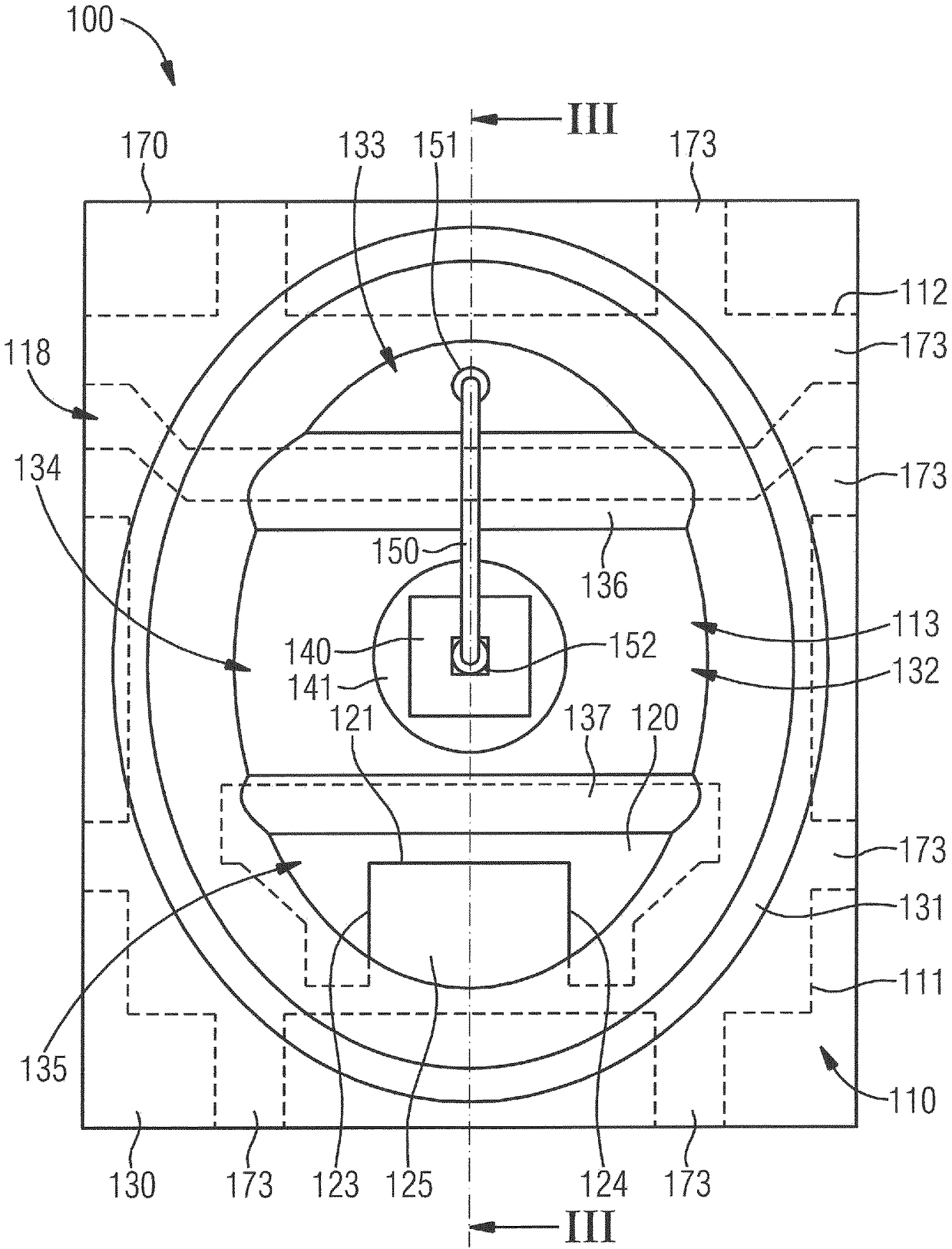

Filling device and method for filling microstructural pit with solid lubricating material

ActiveCN107461597AEasy to processGuaranteed alignmentLubricant transferSupporting systemControl system

The invention provides a filling device and method for filling a microstructural pit with a solid lubricating material. The device comprises a supporting system, a filling system, a multi-station die rotating system, a locking system, a die head spacing adjusting system and a control system. According to the device, the multi-station die rotating system and the die head spacing adjusting system enable continuous processing; and moreover, the requirement on filling different-size and different-spacing structures is met; the solid lubricating material can be directly pressed into the microstructure of a workpiece surface, and such filling method is a purely physical filling method which does not change the performances of a workpiece; in addition, the filling device is simple to operate and small in requirements on working conditions, and has the advantages of being high in efficiency, low in cost, and easy to realize automation.

Owner:JIANGSU UNIV

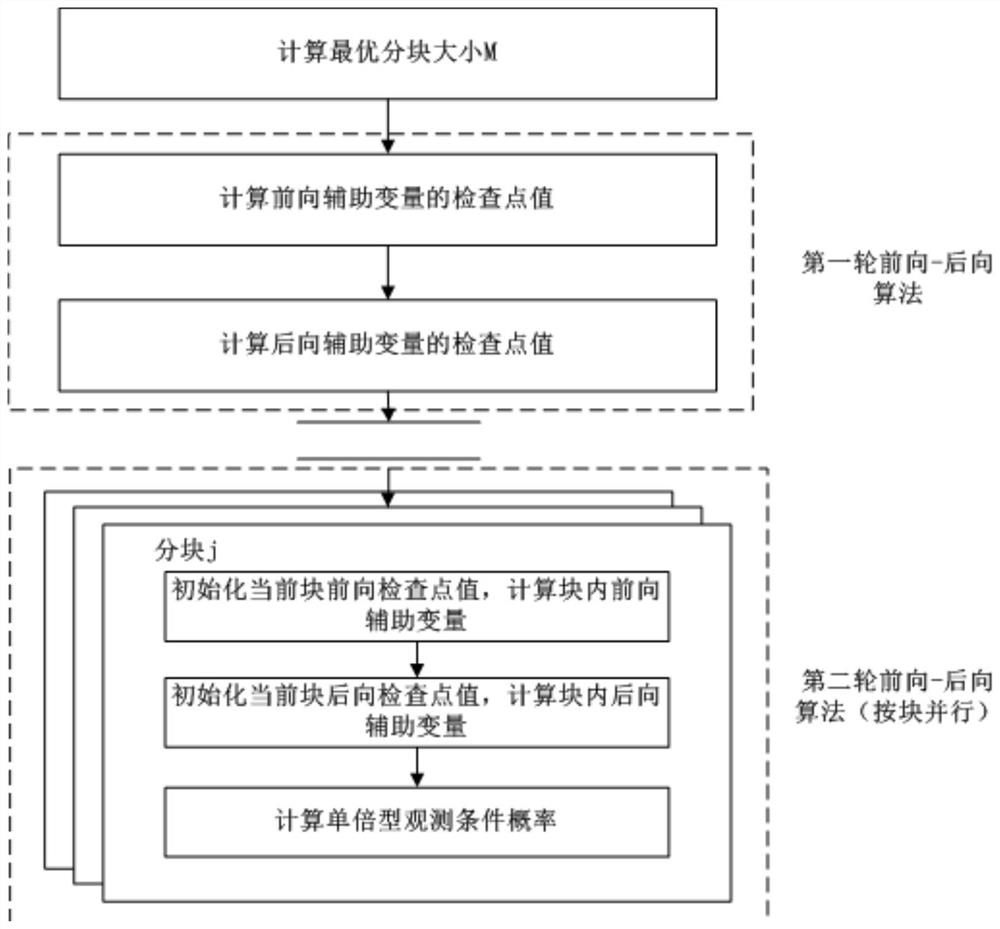

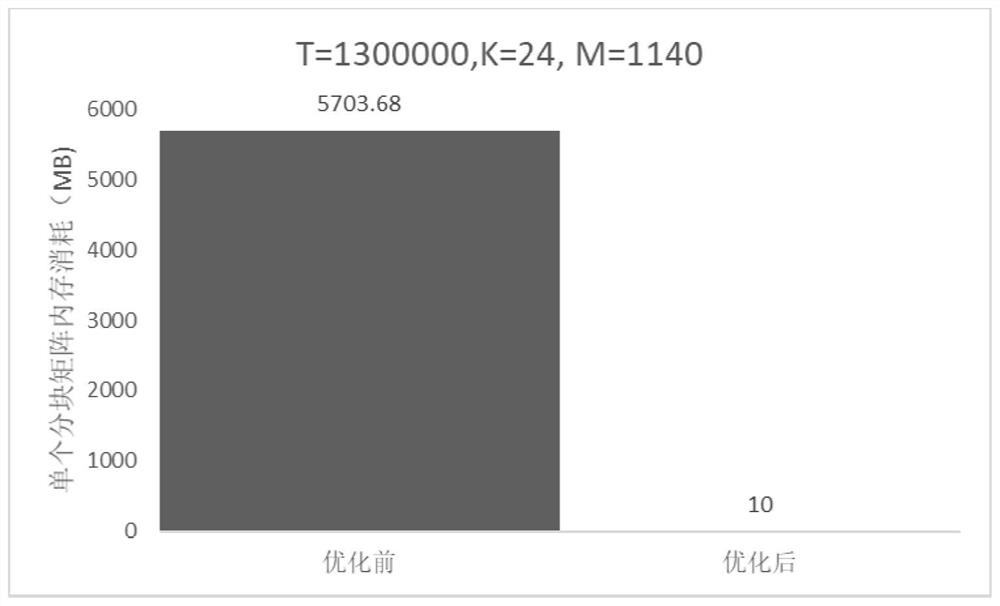

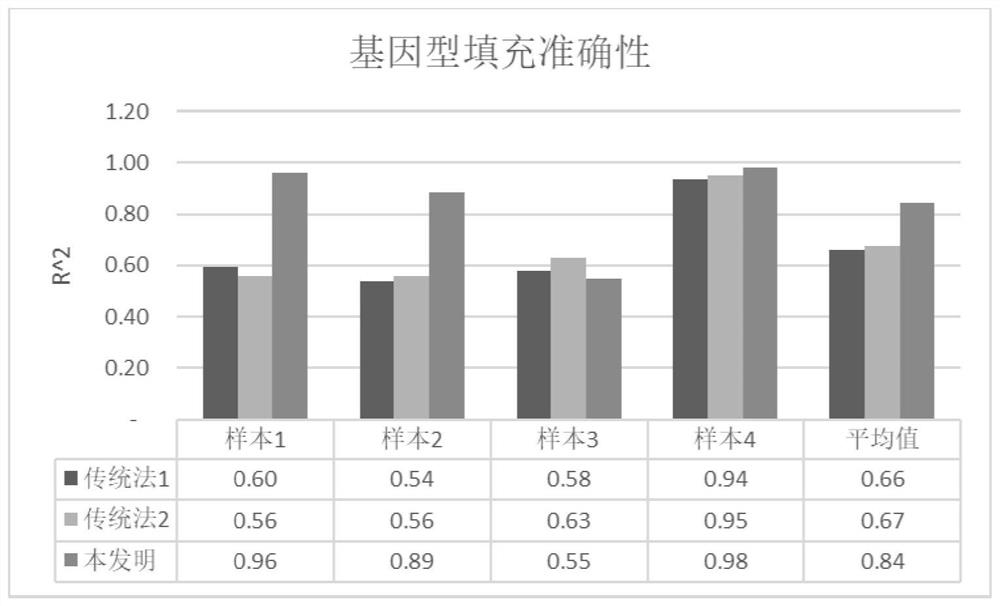

Low-depth sequencing population genotype filling calculation memory optimization method

PendingCN113742070AReduce memory consumptionEliminate data dependenciesResource allocationProteomicsDeep sequencingNucleotide

The invention discloses a low-depth sequencing population genotype filling calculation memory optimization method, which comprises the following steps of: partitioning single nucleotide polymorphism (SNP) sites, and setting check point values according to the blocks; calculating a forward auxiliary variable and a backward auxiliary variable by blocks according to the set check point values, and calculating a haplotype observation condition probability. The method has the advantages that the principle is simple, calculation memory consumption can be effectively reduced, and genotype filling efficiency is improved.

Owner:GENETALKS BIO TECH CHANGSHA CO LTD

A kind of rapid packaging equipment

The invention provides rapid packaging equipment which comprises a flexible box opening device, a six-claw bottom folding device, a gluing device, a 3D printing foam filling device and a box sealing mechanism. After a carton box passes through the devices, the packaging process of the whole carton box is completed. According to the rapid packaging equipment, after an operator places the carton box in a designated position of the equipment, the equipment can automatically achieve packaging of objects which are made of various materials and in various shapes, so that the production efficiency is substantially improved, and labor cost is reduced.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

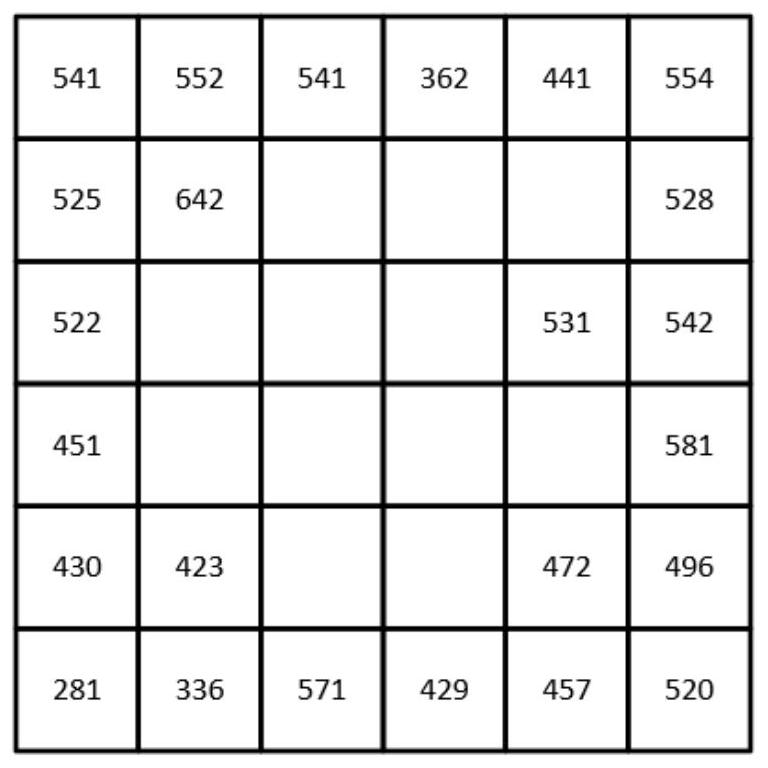

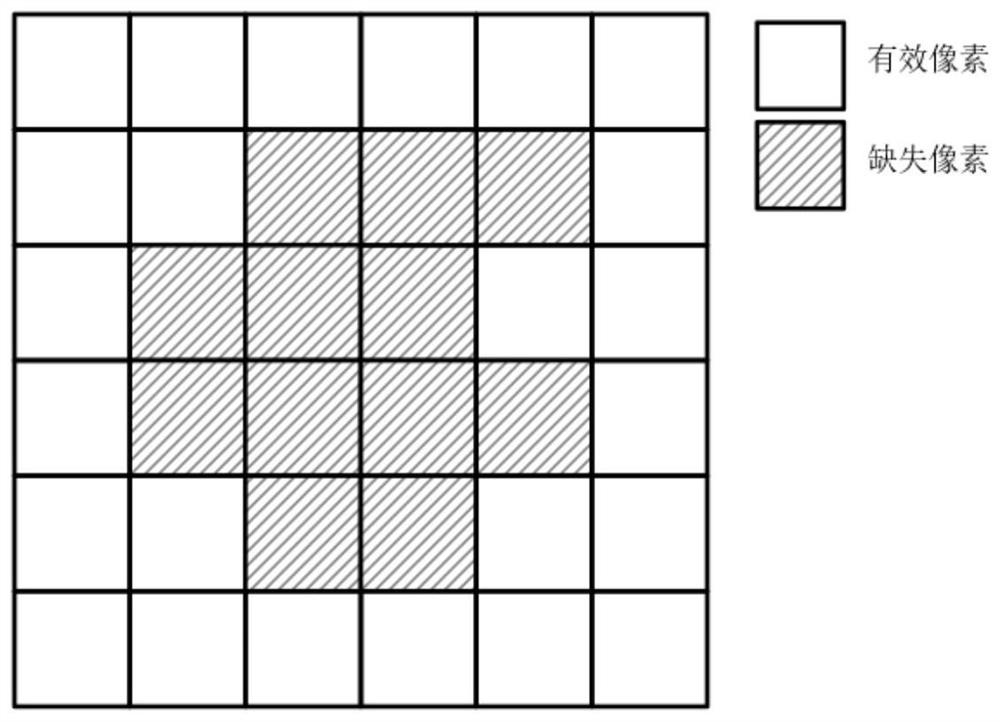

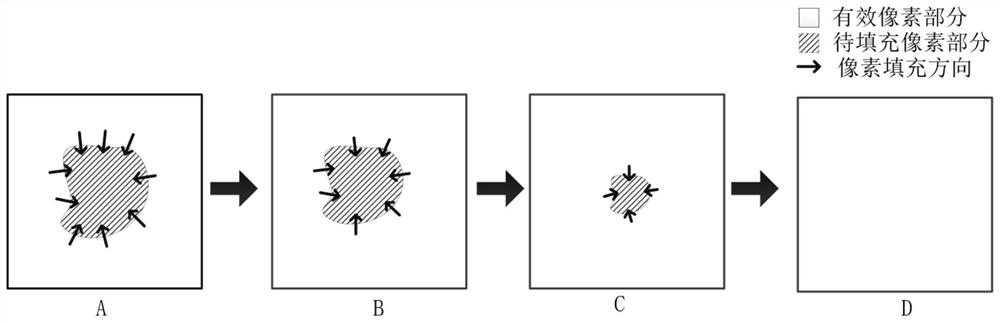

Filling method and device for missing pixels of depth image

The invention provides a filling method and device for missing pixels of a depth image. The method comprises the steps of determining a to-be-filled pixel region, a strip-shaped region and an effective pixel region according to the data effectiveness of the depth image, wherein the to-be-filled pixel region comprises a missing pixel part and / or a pixel invalid part caused by noise; obtaining a mapping value from an effective pixel to a boundary distance in the strip-shaped region to form a priority queue; when the number of the pixels in the priority queue is greater than zero, obtaining the pixels of the priority queue, and adding the pixels to the effective pixel region; acquiring four neighborhood pixels of the pixel, dividing the region where the four neighborhood pixels are located, when the number of the pixels in the priority queue is equal to zero, obtaining a depth image which is completely filled, achieving the quick and effective filling of the depth image, setting a regionneeding to be filtered as an invalid pixel region while the missing pixels are filled, and achieving the filling of the invalid pixels in the filtering region.

Owner:BEIJING LUSTER LIGHTTECH

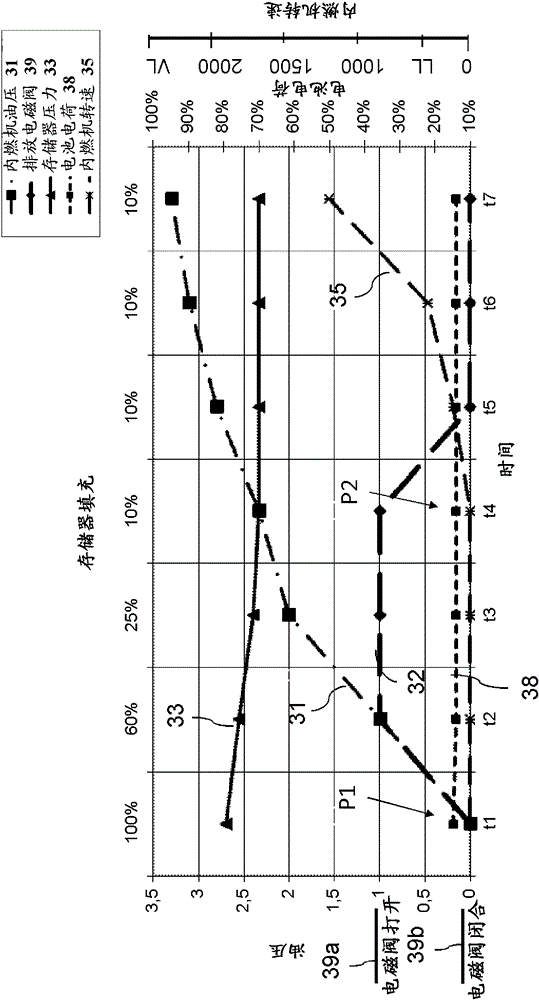

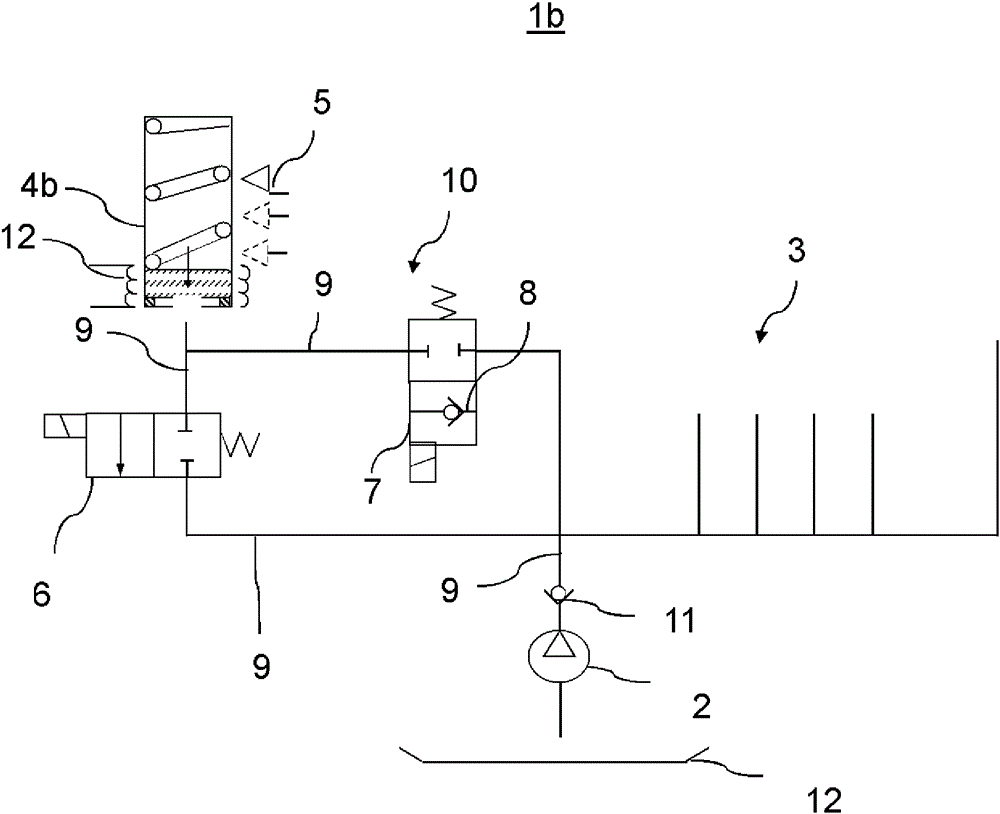

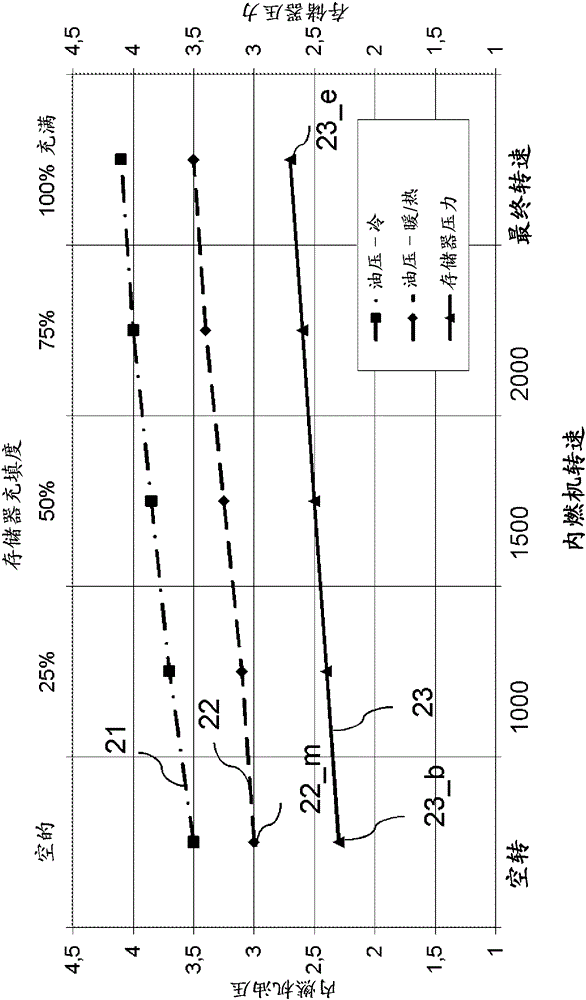

Assembly for supplying lubrication to the bearings of a combustion engine of a motor vehicle

ActiveCN105275537AGuaranteed fillingSustainablePressure lubrication with lubrication pumpLubrication pressure controlCombustionInternal combustion engine

The invention relates to an assembly for supplying the lubrication to the bearings of a combustion engine of a motor vehicle. The assembly includes a lubricant pump (2) and a lubricant-pressure accumulator (4) via which the bearings of the internal combustion engine can be supplied in an engine starting phase and / or an engine stop switching phase, regardless of the lubricant pump (2) with the lubricant.

Owner:MAN TRUCK & BUS AG

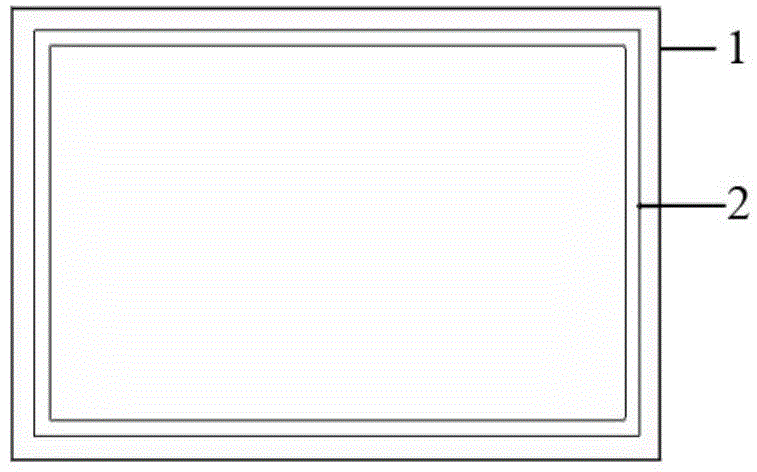

Stone-like coating

The invention discloses a stone-like coating and belongs to the technical field of wall building materials. The stone-like coating comprises, by weight, 10 to 20 parts of an emulsion, 10 to 20 parts of water, 60 to 80 parts of modified natural colored sand, 0.3 to 0.5 parts of a film-forming aid, 6 to 10 parts of an agar solution, 0.1 to 0.3 parts of a thickener, 0.1 to 0.2 parts of a defoaming agent, 0.2 to 0.6 parts of a bactericide, 0.8 to 1.5 parts of an antifreezing agent and 0.03 to 0.05 parts of a pH buffer agent. The modified natural colored sand is prepared through homogenizing natural colored sand and lichen, carrying out refrigeration, carrying out illumination constant-temperature constant-humidity culture circulation and carrying out carbonization and quenching. The stone-likecoating can form a compact film on the base surface, prevent permeation of inner water and outer water and effectively improve the water bleaching resistance of the product.

Owner:常州杰轩纺织科技有限公司

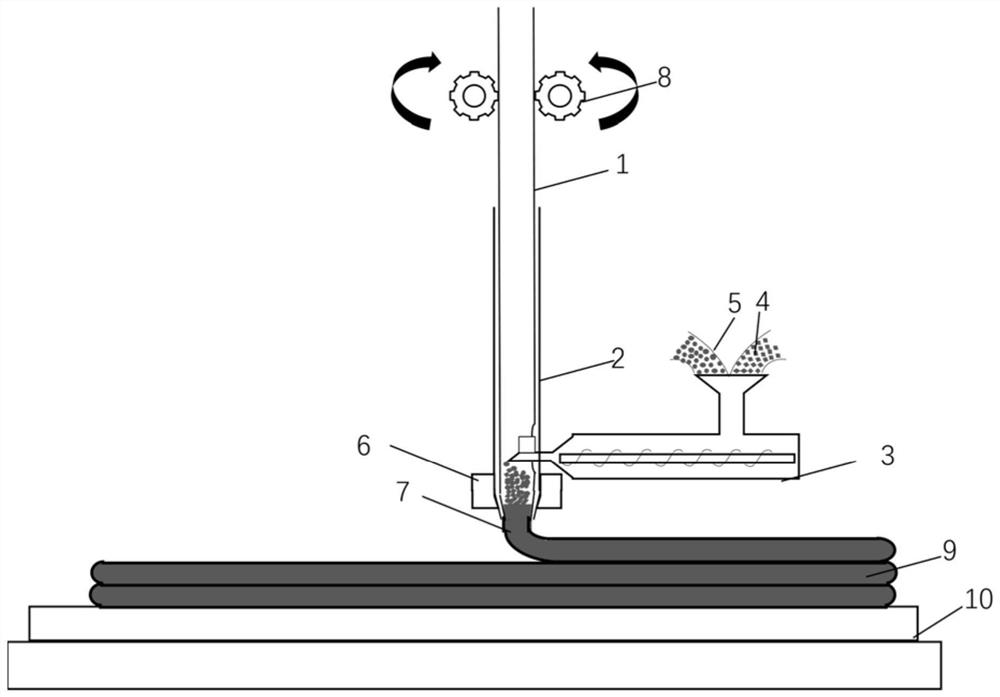

Multifunctional additive manufacturing device and method for hollow filling composite wires

ActiveCN112976567ARealize sub-regional manufacturingFacilitates real-time preparationAdditive manufacturing apparatus3D object support structuresKnife bladesMaterials science

The invention discloses a multifunctional additive manufacturing device and method for hollow filling composite wires. The multifunctional additive manufacturing device comprises a wire feeding pipe, the diameter of the upper section of the wire feeding pipe is uniform, the diameter of the lower section of the wire feeding pipe is gradually reduced, a heating block is arranged on the outer side of the diameter-gradually-reduced section of the wire feeding pipe, and a hollow base material is inserted into the wire feeding pipe in a penetrating mode; and the hollow base material extends into the wire feeding pipe through guiding of a wire guide wheel, the multifunctional additive manufacturing device further comprises an automatic filling device, the automatic filling device comprises a material mixing cavity, a feeding port and a discharging port are formed in the material mixing cavity, the discharging port is inserted into the junction of the diameter uniform section and the diameter gradually-reduced section of the wire feeding pipe in a penetrating mode, and a blade capable of splitting the side wall of the hollow base material is arranged at the upper part of the discharge port. According to the requirements of materials in different areas, the hollow base material can be filled with materials, and when the different areas are printed, the types and proportions of the materials are flexible and controllable.

Owner:XI AN JIAOTONG UNIV

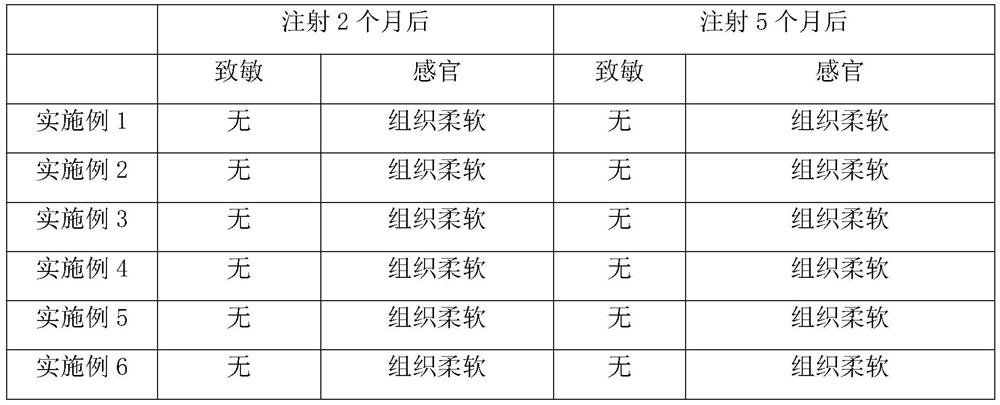

Facial injection filling agent for cosmetic plastic surgery and preparation method of facial injection filling agent

InactiveCN113559322APadding achievedGood compatibilityPharmaceutical delivery mechanismProsthesisTri calcium phosphateCollagenan

The invention discloses a facial injection filling agent for cosmetic plastic surgery. The facial injection filling agent is prepared from the following raw materials: 4 to 6 ml of hyaluronic acid, 0.3 to 0.6 g of beta-tricalcium phosphate, 0.1 to 0.3 g of collagen powder, 0.3 to 0.5 g of an excipient, 0.1 to 0.3 g of vitamin powder and 6 to 8 ml of water for injection. According to the facial injection filling agent disclosed by the invention, the hyaluronic acid and beta-tricalcium phosphate particles are mixed to form suspension; the collagen powder, the excipient and the vitamin powder are added, so that the facial injection filling agent has very high compatibility and no sensitization is generated after injection; and meanwhile, the hyaluronic acid is selected and is mixed with the beta-tricalcium phosphate particles, so that filling of different parts of a face can be realized and the application range is relatively wide.

Owner:张广利

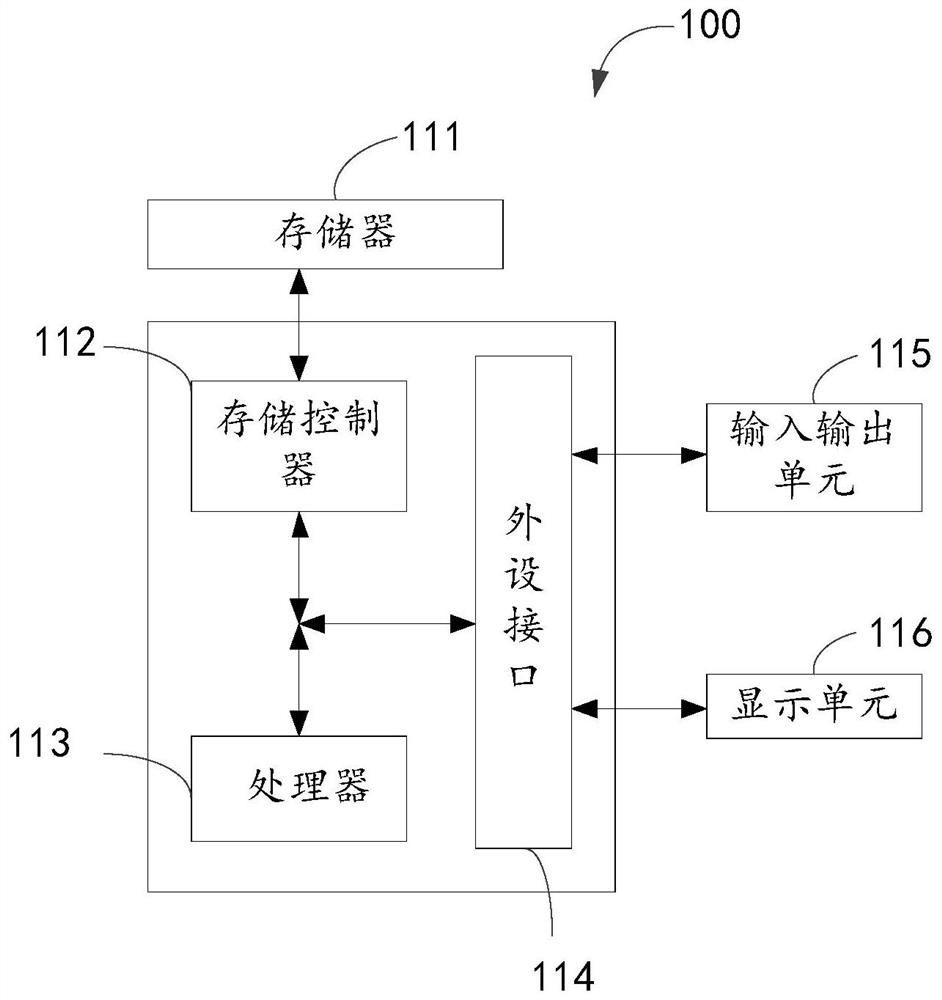

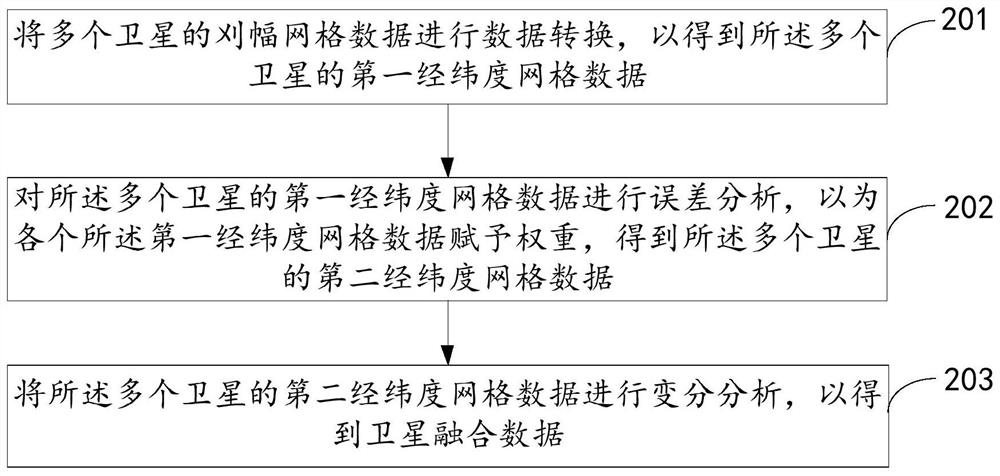

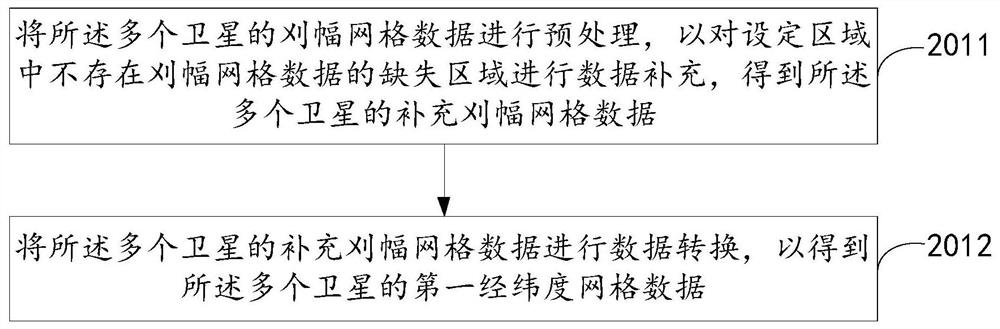

Satellite data fusion method and device and electronic equipment

ActiveCN111611731AEasy to coverAccurate representationDesign optimisation/simulationCAD numerical modellingSatellite dataData transformation

The invention provides a satellite data fusion method and device and electronic equipment, and the method comprises the steps: carrying out the data conversion of the swath grid data of a plurality ofsatellites, so as to obtain the first longitude and latitude grid data of the plurality of satellites; performing error analysis on the first longitude and latitude grid data of the plurality of satellites, and endowing each piece of first longitude and latitude grid data with a weight to obtain second longitude and latitude grid data of the plurality of satellites; and performing variational analysis on the second longitude and latitude grid data of the plurality of satellites to obtain satellite fusion data.

Owner:NAT SATELLITE OCEAN APPL SERVICE +2

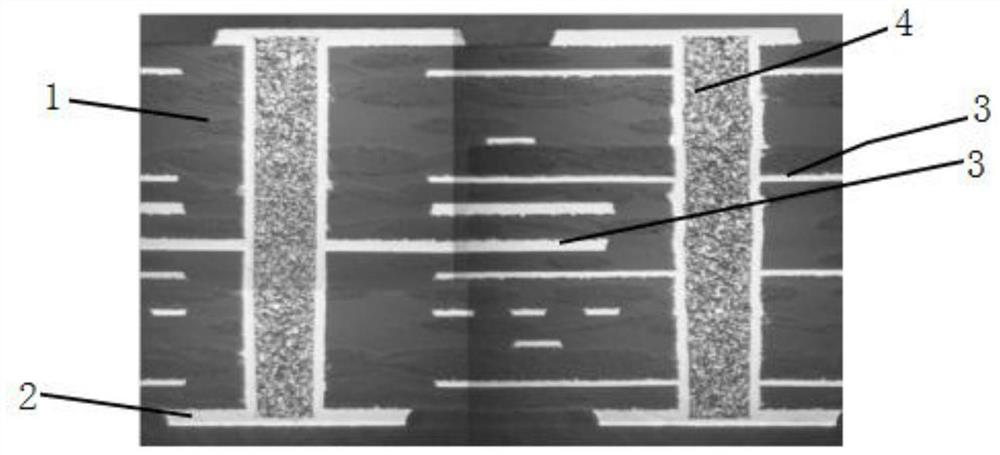

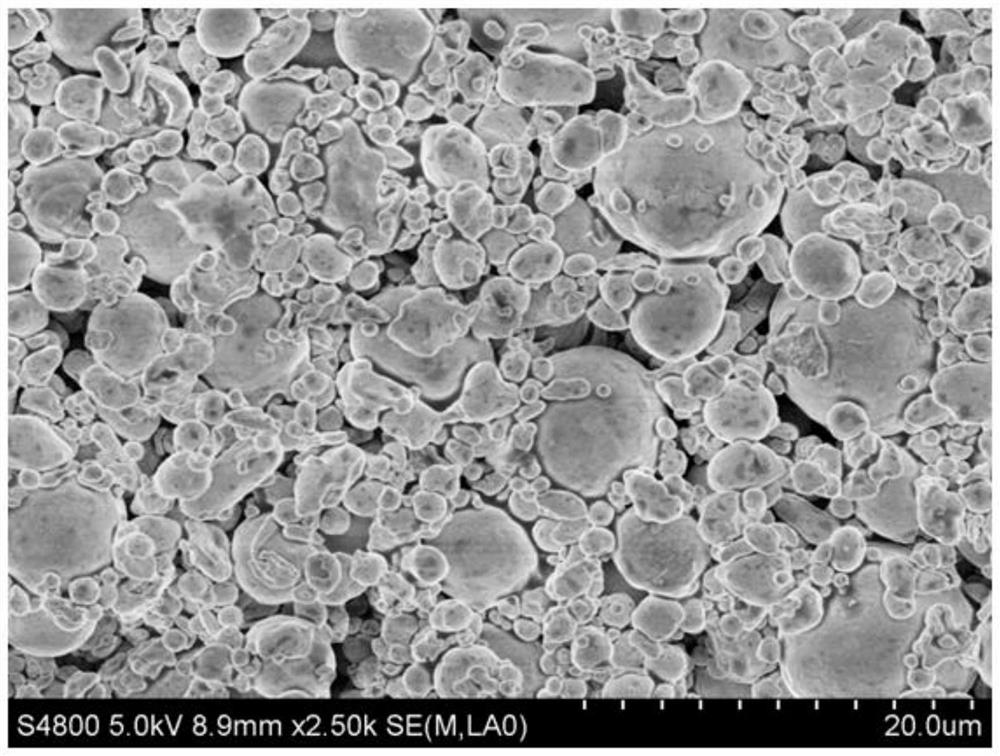

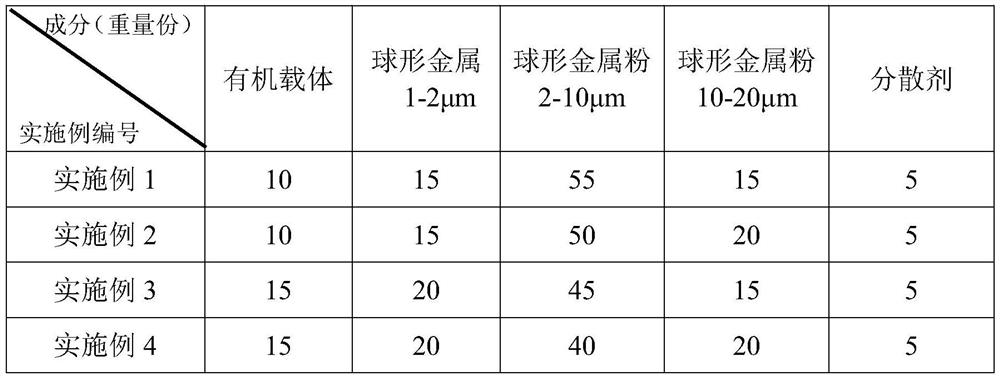

Microhole filling paste for circuit board, preparation method and application thereof

ActiveCN110493952BImprove toughnessImprove heat resistancePrinted circuit aspectsNon-conductive material with dispersed conductive materialSlurryMetal powder

Owner:SEMITEL ELECTRONICS

A kind of energy-saving lamp for indoor use

ActiveCN111878740BAchieve positioningEasy to fixLighting support devicesLighting heating/cooling arrangementsAirbagMaterials science

Owner:深圳市元本室内建筑设计有限公司

A filling device and method for filling solid lubricating materials in micro-textured pits

ActiveCN107461597BEasy to processGuaranteed alignmentLubricant transferSupporting systemControl system

The invention provides a filling device and method for filling a micro-texture with a solid lubricating material. The device comprises a supporting system, a filling system, a multi-station mold rotation system, a locking system, a mold head spacing adjustment system, and a control system. By application of the multi-station mold rotation system and the mold head spacing adjustment system, continuous processing can be implemented, and filling requirements of different sizes and different pitch textures can be satisfied. The device can directly press solid lubricating material into a micro-texture of a workpiece surface, which is a purely physical filling method, without modifying properties of the workpiece. Moreover, the filling device is easily operated, has low requirements on working conditions, is efficient and low-cost, and can be easily automated.

Owner:JIANGSU UNIV

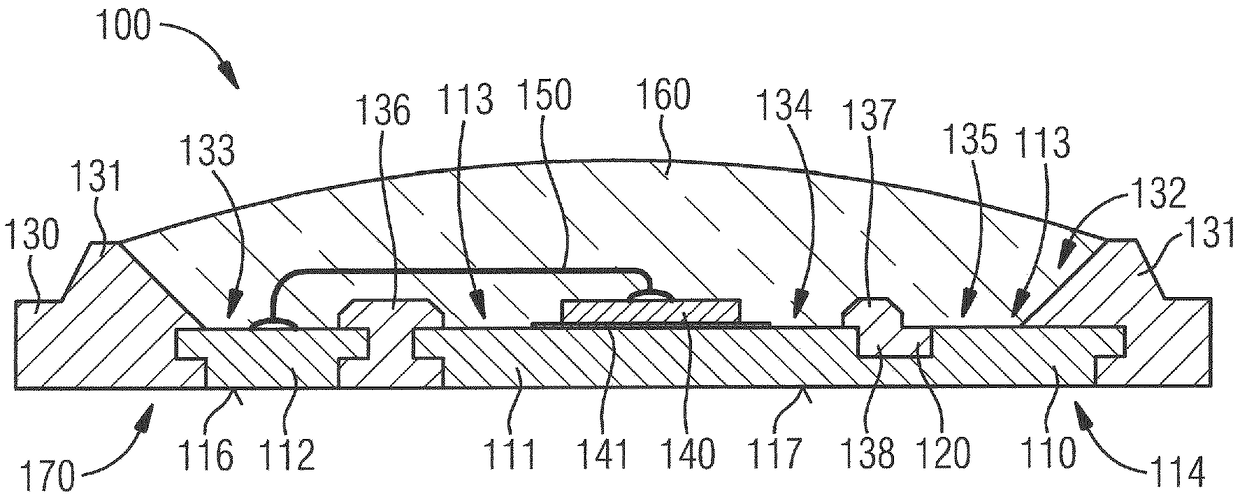

Optoelectronic components and methods for their manufacture

ActiveCN105765743BPadding achievedSolid-state devicesSpeech recognitionSemiconductor chipEngineering

Owner:OSRAM OPTO SEMICON GMBH & CO OHG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com