Method and device for rapidly filling vertical TSV hole with liquid alloy

A filling method, liquid alloy technology, applied in gaseous chemical plating, metal material coating process, semiconductor/solid-state device manufacturing, etc., can solve the problem of toxic electrolytes and additives, hours to tens of hours, and low filling efficiency, etc. problems, to achieve the effect of improving wettability, improving production efficiency, and fast filling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

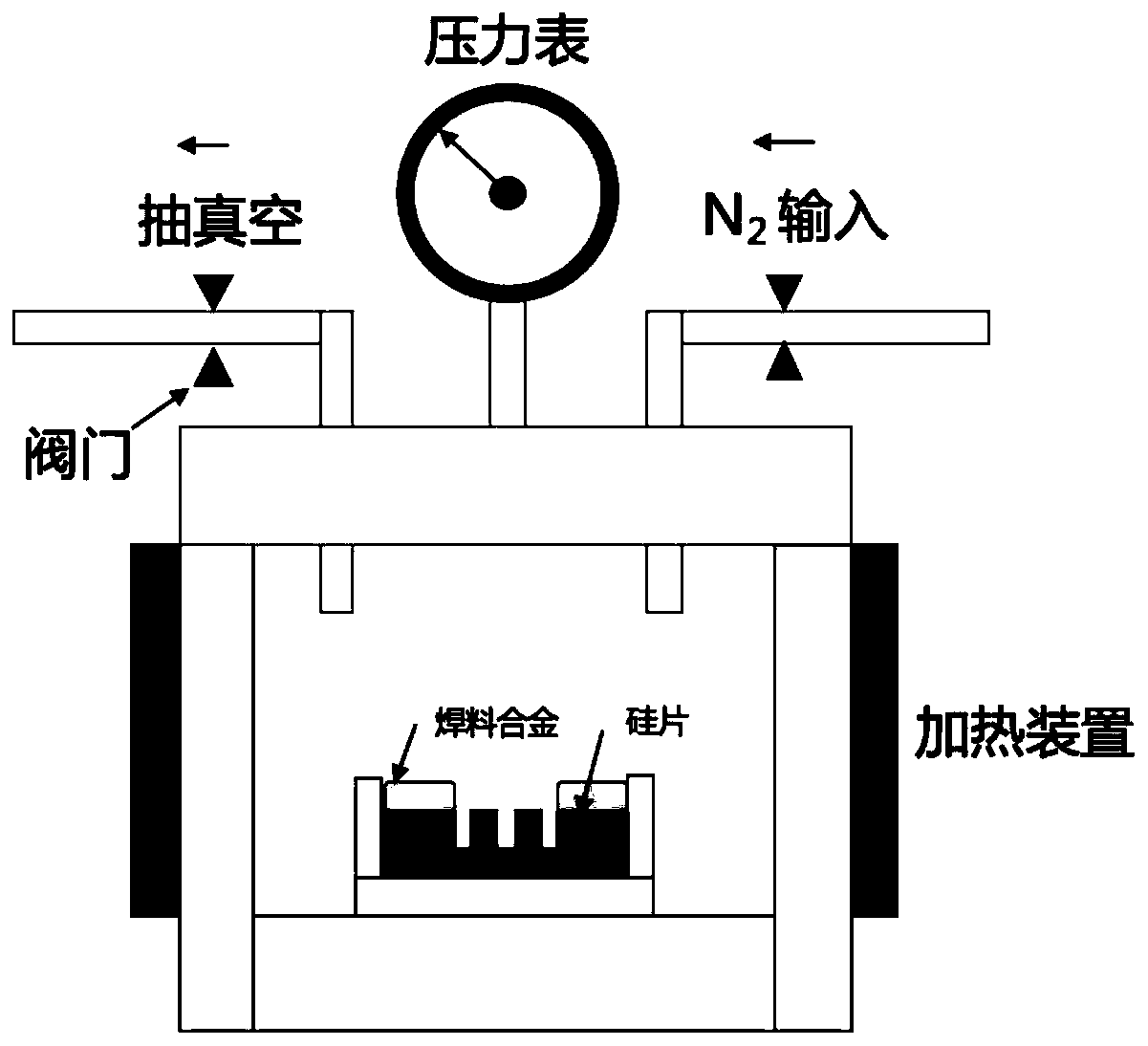

[0038] The alloy provided by the present invention fills the fast filling device of TSV, such as image 3 As shown, sealed reaction chamber, vacuum pump, nitrogen input device, vacuum outlet control valve, nitrogen inlet control valve, filling tank, heating device, temperature sensor.

Embodiment 2

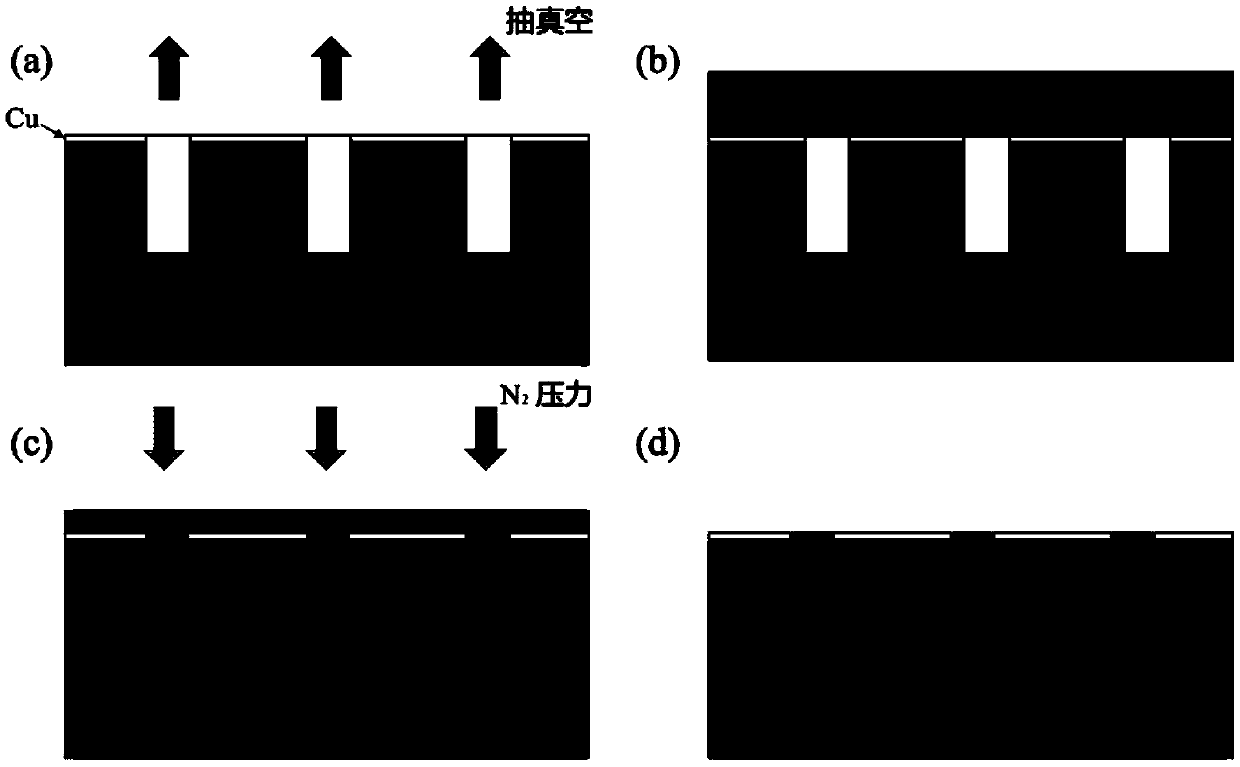

[0040] The TSV fast filling method provided in this embodiment includes the following steps:

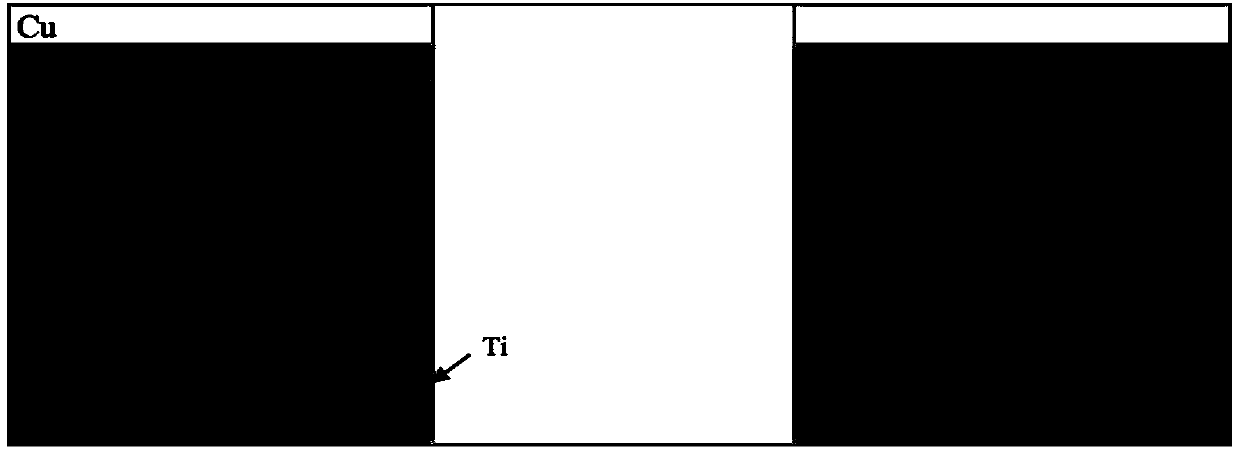

[0041] Step 1: The sample selected in this example is a copper-plated TSV blind hole silicon wafer with a diameter of 10 μm, a depth of 100 μm, and an aspect ratio of 10. The silicon wafer is cut into small pieces of 5mm*5mm by laser, and the cut out small pieces into 20% HNO 3 Soak in the solution for 20s, then take it out with tweezers, put it into a beaker filled with absolute ethanol, and clean it with an ultrasonic cleaner for 10 minutes.

[0042] Step 2: Polish the Sn3.0Ag0.5Cu solder alloy with sandpaper to remove the surface oxide film, then put it into a beaker filled with absolute ethanol and ultrasonically clean it to remove surface impurities and then dry it

[0043] Step 3: Place the sample tank containing the solder alloy and the sample in the reaction chamber of the filling device, and seal the reaction chamber. At this time, the valves at the vacuum outlet and the ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com