U-shaped pipe underground fluid multilayer sampling device

A technology for underground fluids and sampling devices, which is used in wellbore/well components, earth-moving drilling, etc., and can solve the problems of inability to obtain representative water samples, limited application depth, limited plastic materials and pressure resistance of pneumatic joints, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Hereinafter, a U-tube underground fluid multi-layer sampling device of the present invention will be described in detail with reference to the accompanying drawings.

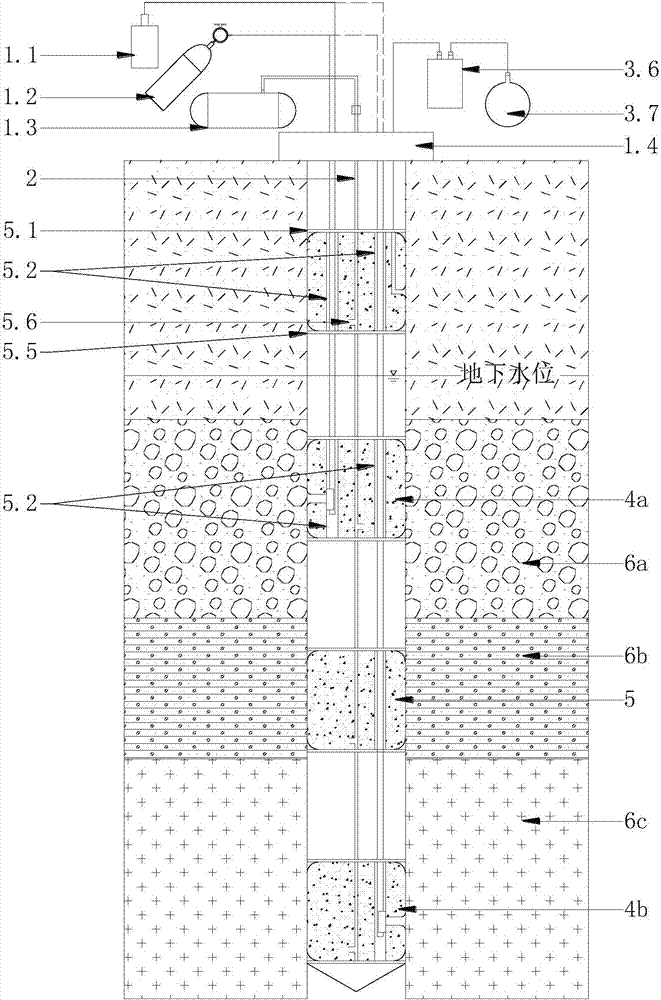

[0057] figure 1 It is a structural schematic diagram of a U-shaped tube underground fluid multi-layer sampling device according to an embodiment of the present invention. In this embodiment, only the case of one layer for gas intake and two layers for water intake and two aquifers will be described, and the number of sampling units used can be freely assembled according to actual monitoring needs.

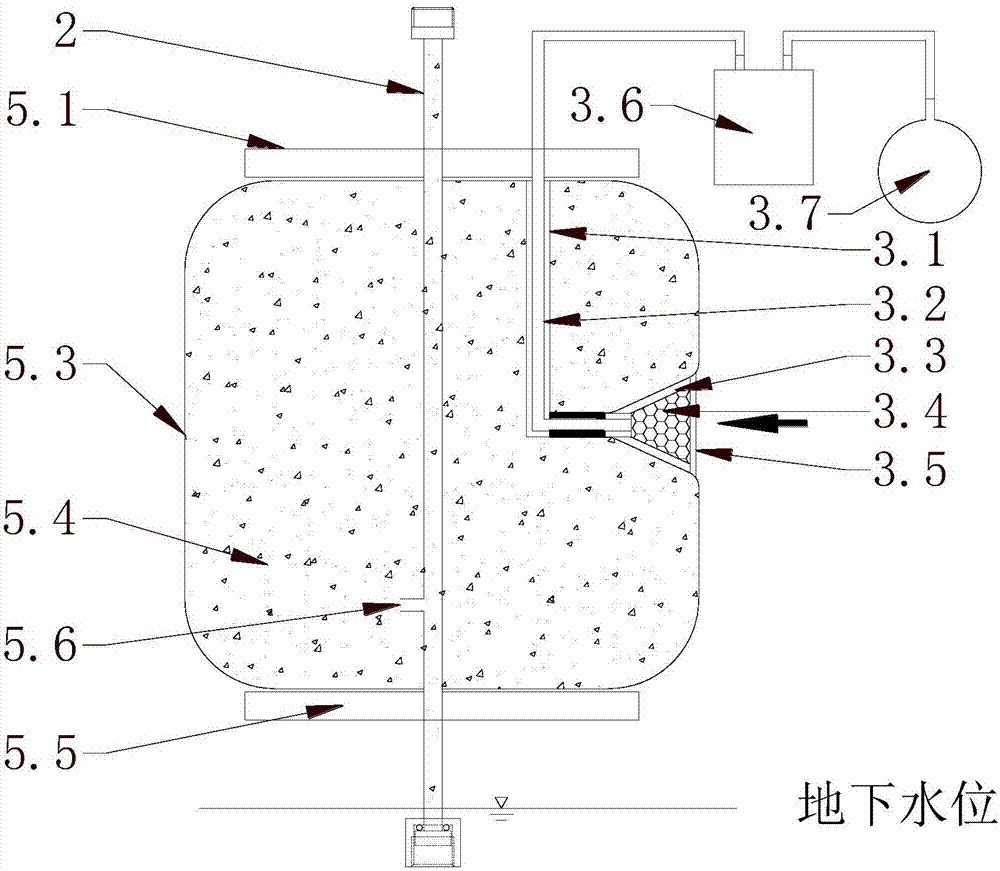

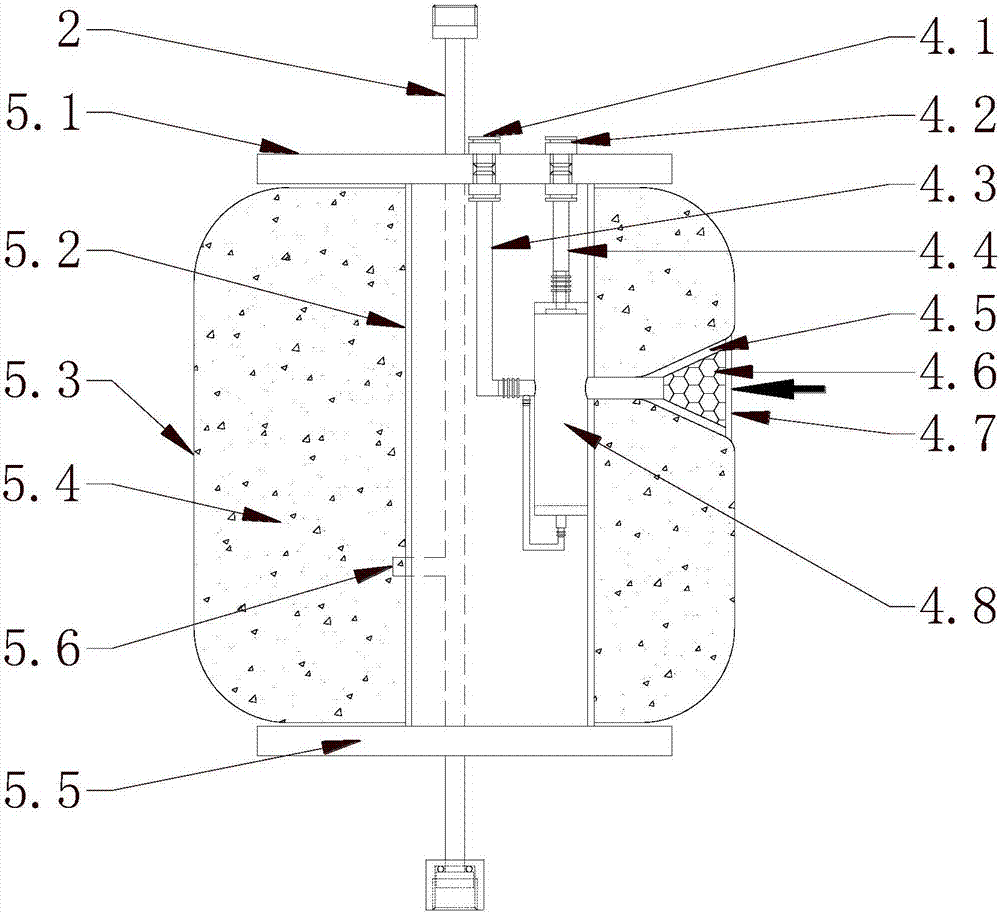

[0058] Such as figure 1 As shown, a U-shaped pipe underground fluid multi-layer sampling device of the present invention includes: a ground auxiliary system 1, a support system 2, an air extraction unit 3, a water extraction unit 4a, 4b and an interlayer packer 5. Among them, the ground auxiliary system 1 includes: a water sample bottle 1.1, a high-pressure gas source 1.2, a grouting machine 1.3 and a well h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com