Microhole filling paste for circuit board, preparation method and application thereof

A technology of circuit boards and micro-holes, which is applied in the manufacture of printed circuits, circuits, printed circuits, etc., can solve problems affecting the development of circuit boards, and achieve the effects of dense holes, good electrical conductivity, and improved toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

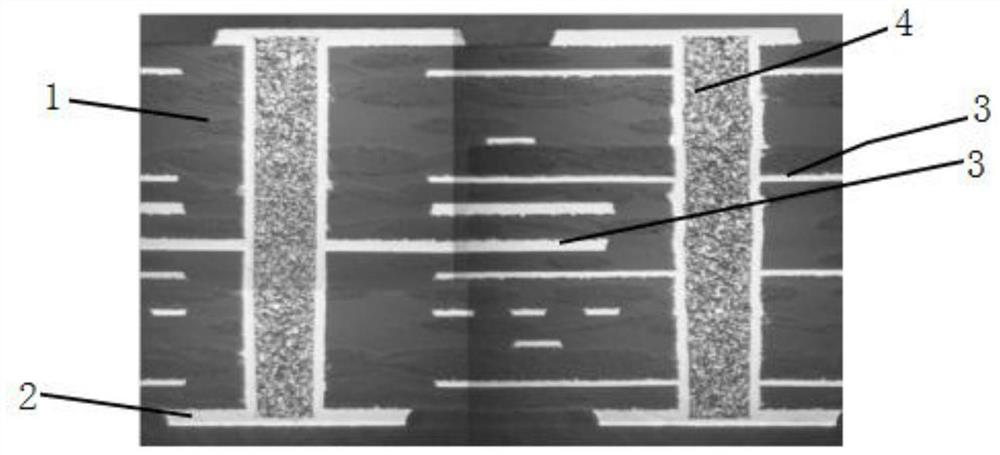

[0028] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

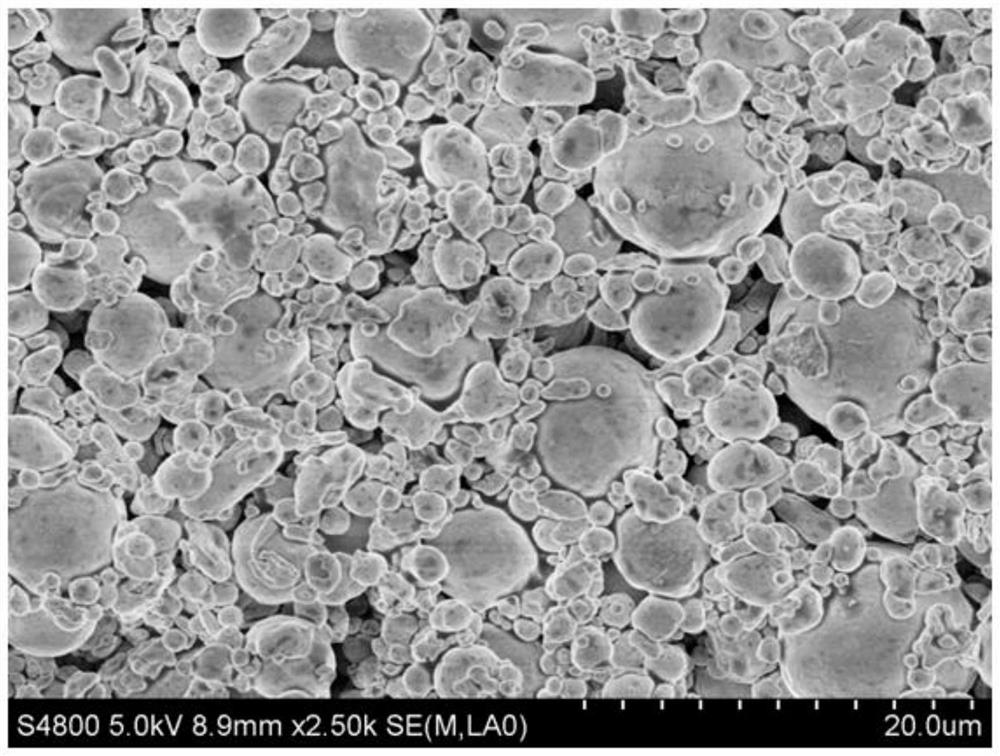

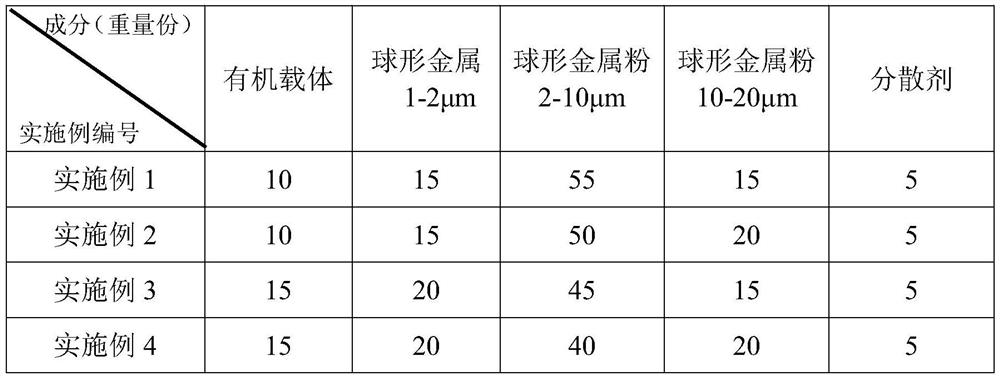

[0029] A micropore filling slurry for circuit boards, comprising the following raw materials in parts by weight: 5-20 parts of organic carrier, 15-30 parts of spherical metal powder with a particle size of 1-2 μm, and spherical metal powder with a particle size of 2-10 μm. 30-60 parts of powder, 10-20 parts of spherical metal powder with a particle size of 10-20 μm and 1-5 parts of dispersant.

[0030] Wherein, the organic vehicle includes the following raw materials in parts by weight: 70-90 parts of epoxy resin, 1-5 parts of curing agent, 5-10 parts of DBE solvent, 5-10 parts of liquid crystal polymer material, 1-5 parts of curing accelerator 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com