Patents

Literature

264results about How to "High filling accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

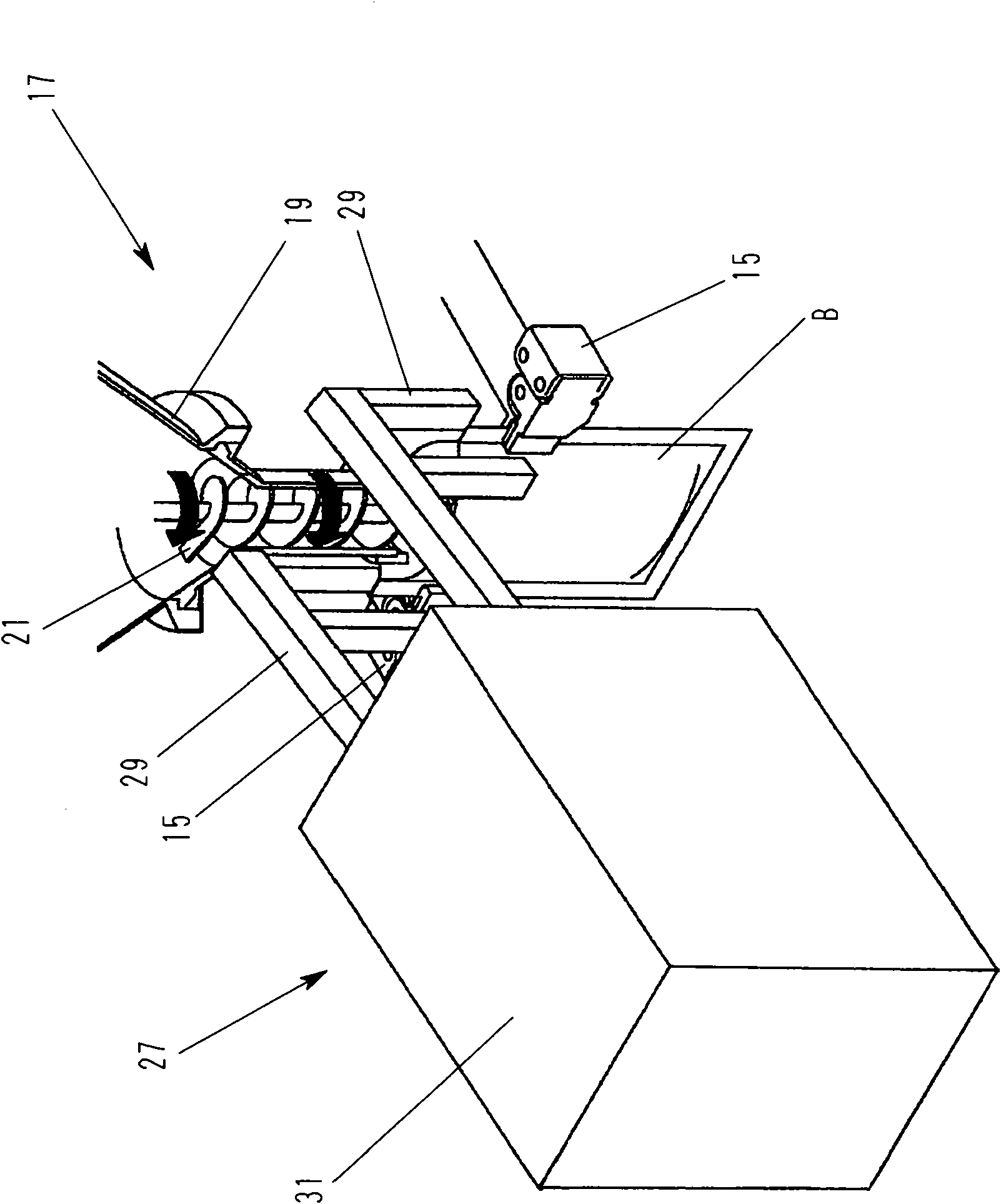

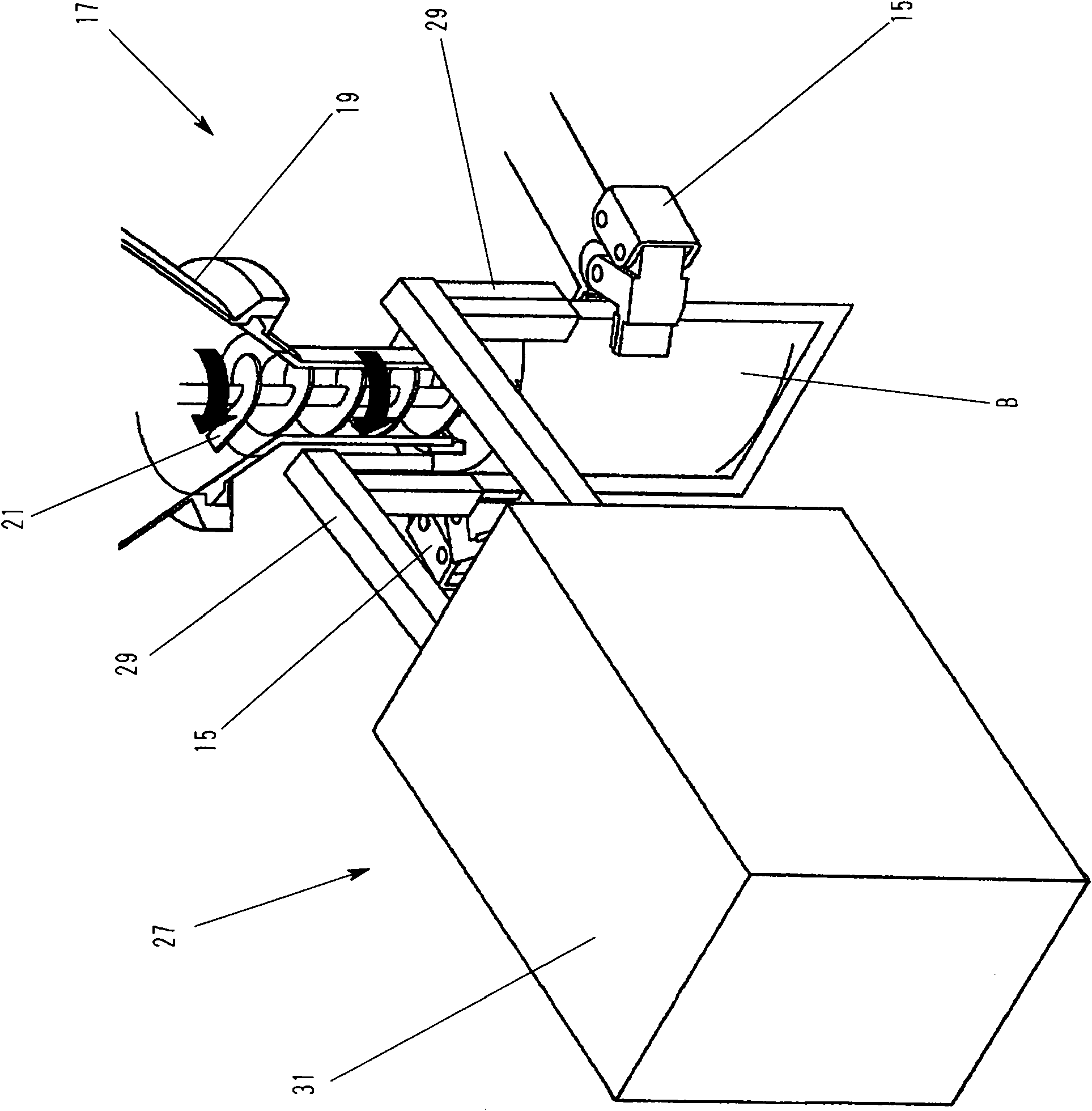

Filling device and filling method for objects to be packed of filling and packing machine

ActiveCN102211671AEfficient fillingHigh filling accuracySolid materialPackaging automatic controlProduction rateInstrumentation

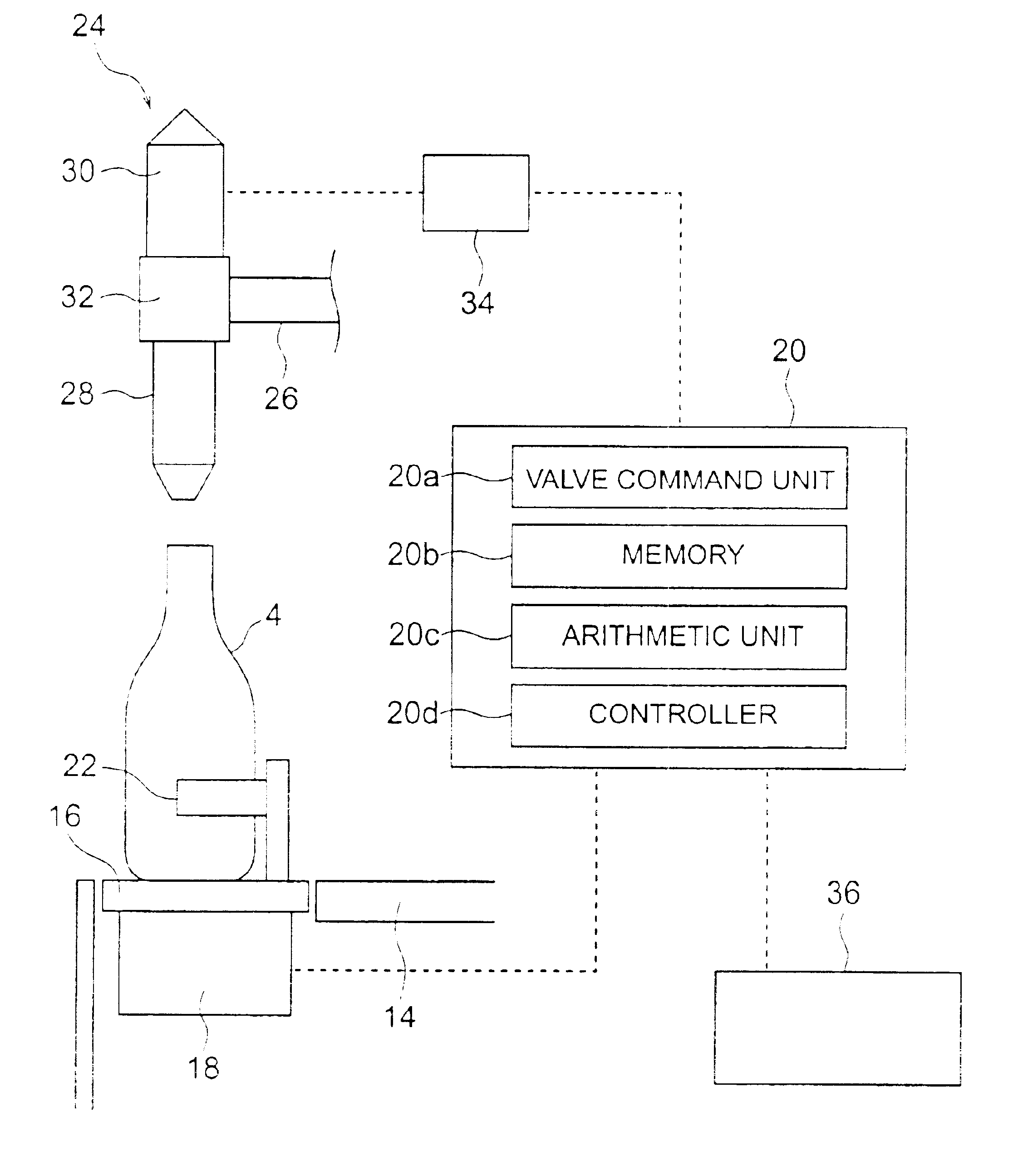

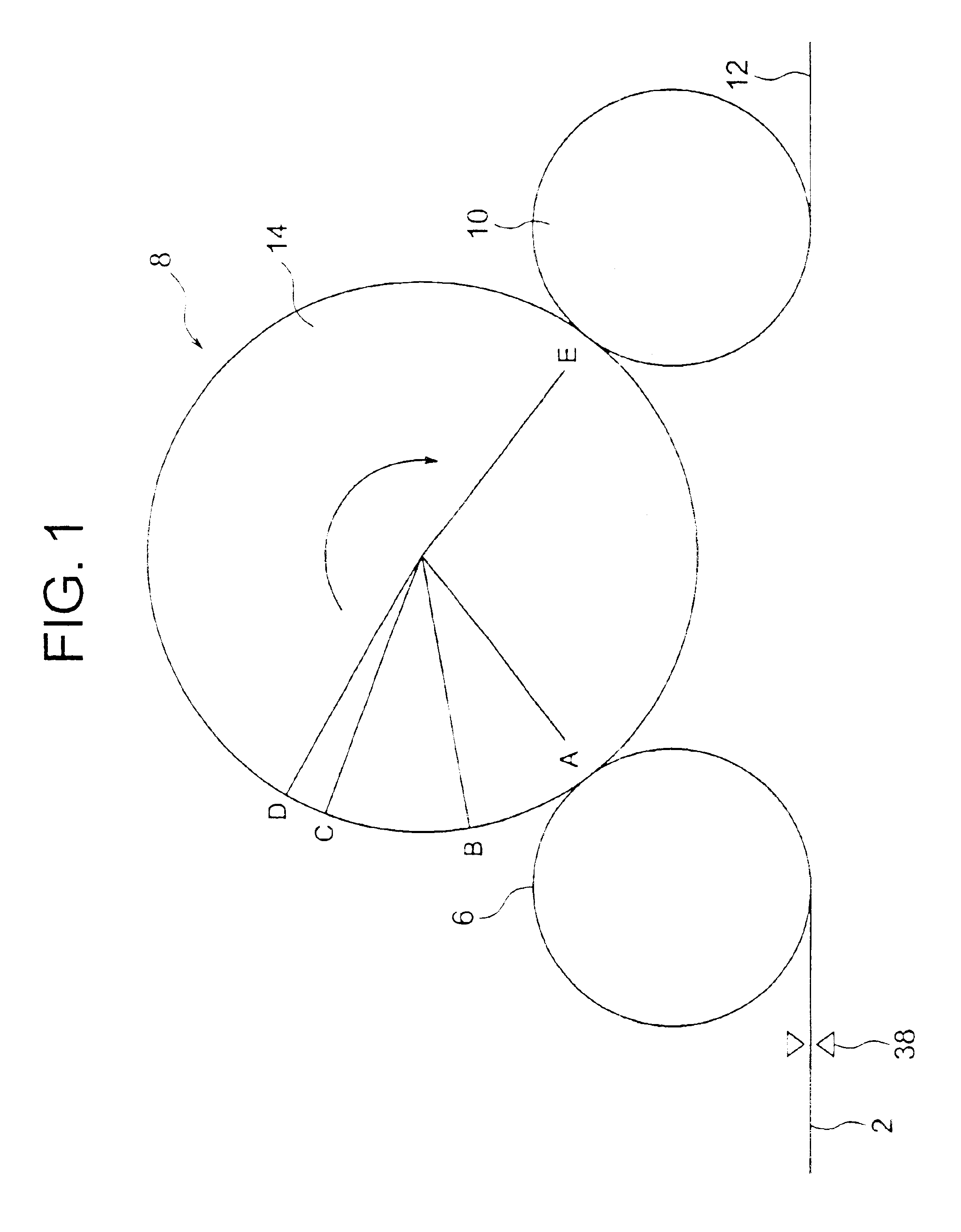

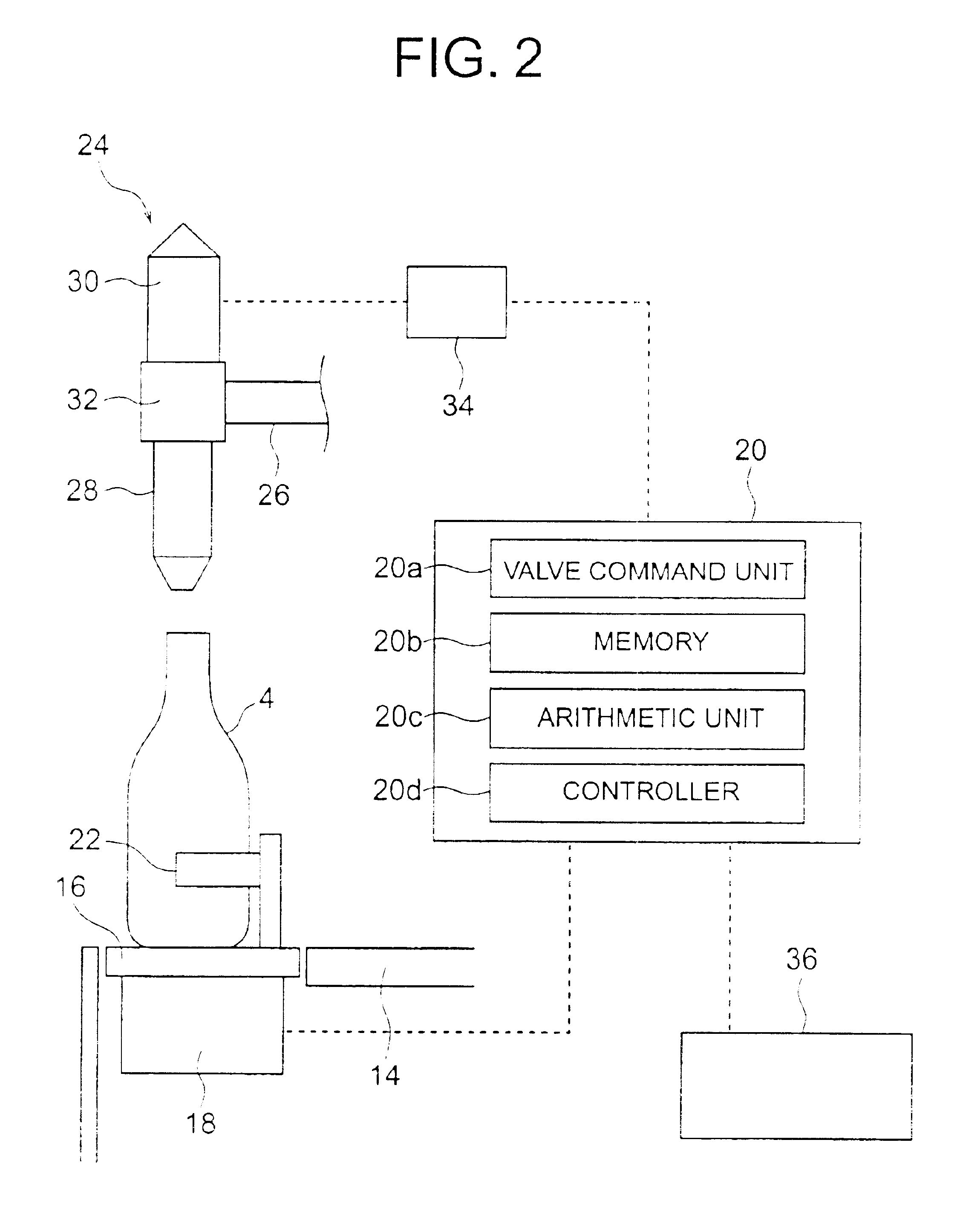

The invention provides a filling device and a filling method for objects to be packed of a filling and packing machine, wherein the balance between a high-accuracy filling process and an improved productivity is realized by correspondingly switching between a weight-type control and a pulse-type control according to the description of the object to be packed. An intermittent conveying type vertical filling and packaging machine comprises a plurality of groups of clamps on a rotary table and a filling station is equipped with a spiral type filling device, a clamping head and a first clamp-changing and metering device of a metering instrument. The metering station is equipped with a clamping head and a second clamp-changing and metering device of the metering instrument. When the weight of a bag calculated by the second clamp-changing and metering device is within a pre-determined range, the first clamp-changing and metering device is not driven. The filling amount of the bags on the filling station is controlled by the pulse number generated by a servo motor. When the weight of a bag calculated by the second clamp-changing and metering device is not within a pre-determined range, the first clamp-changing and metering device is driven. The real filling amount is calculated by the metering instrument.

Owner:TOYO JIDOKI CO LTD

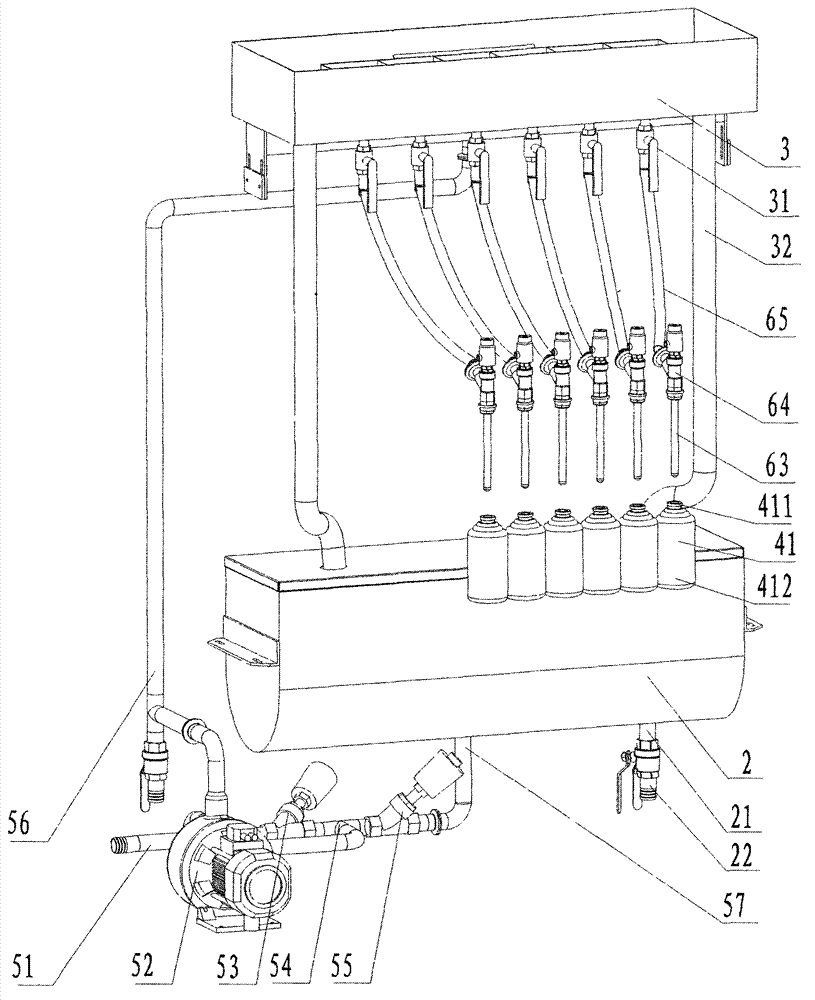

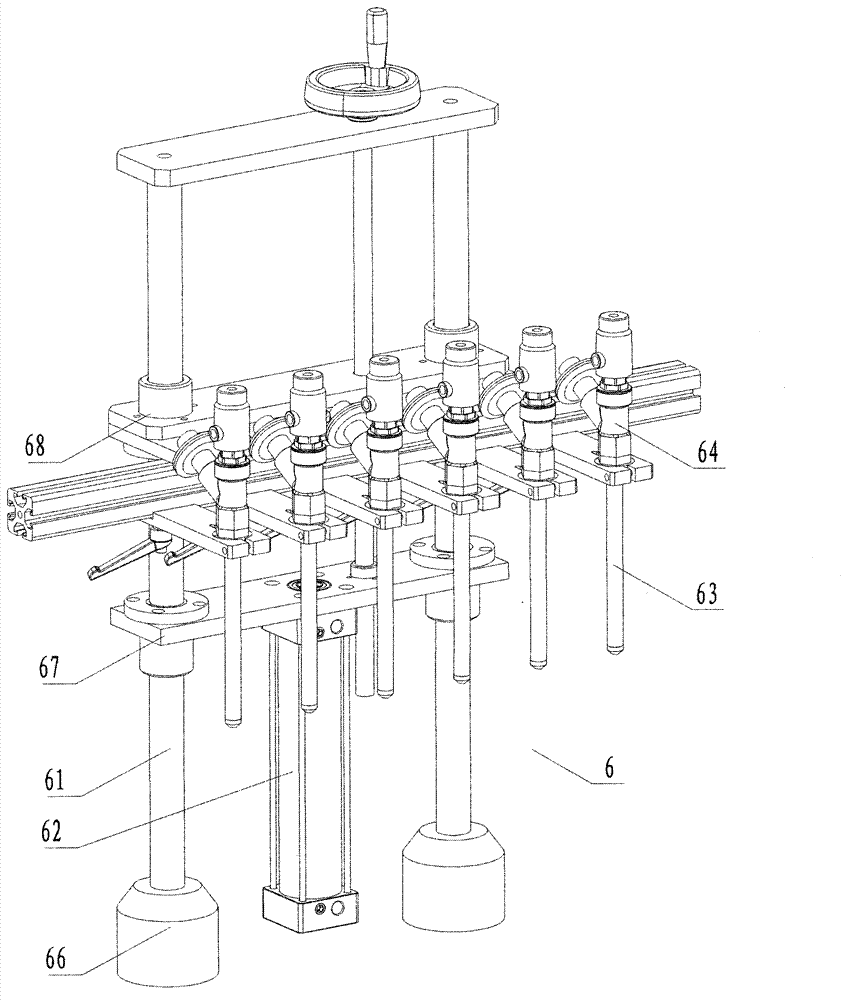

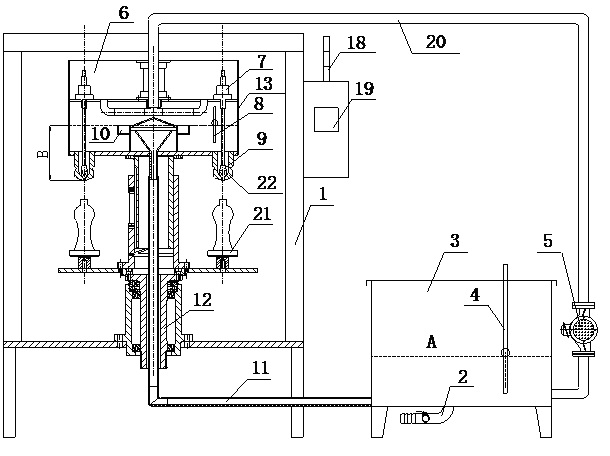

Filling machine

The invention discloses a filling machine which comprises a filling pump system, a liquid storage tank and a liquid transition stabilizing tank, wherein the liquid transition stabilizing tank is located above the liquid storage tank and connected with the liquid storage tank; the filling pump system is connected with the liquid storage tank and the liquid transition stabilizing tank; the liquid transition stabilizing tank is internally provided with a liquid inlet groove and a filling groove, which are communicated with each other; the liquid inlet groove is connected to the filling pump system; the liquid transition stabilizing tank is further internally provided with an overflowing groove allowing the liquid level of the liquid transition stabilizing tank to keep stable; and the overflowing groove is connected to the liquid storage tank. The filling machine can improve the filling accuracy of the filling machine, and is easy to clean.

Owner:广州市冠浩机械设备有限公司

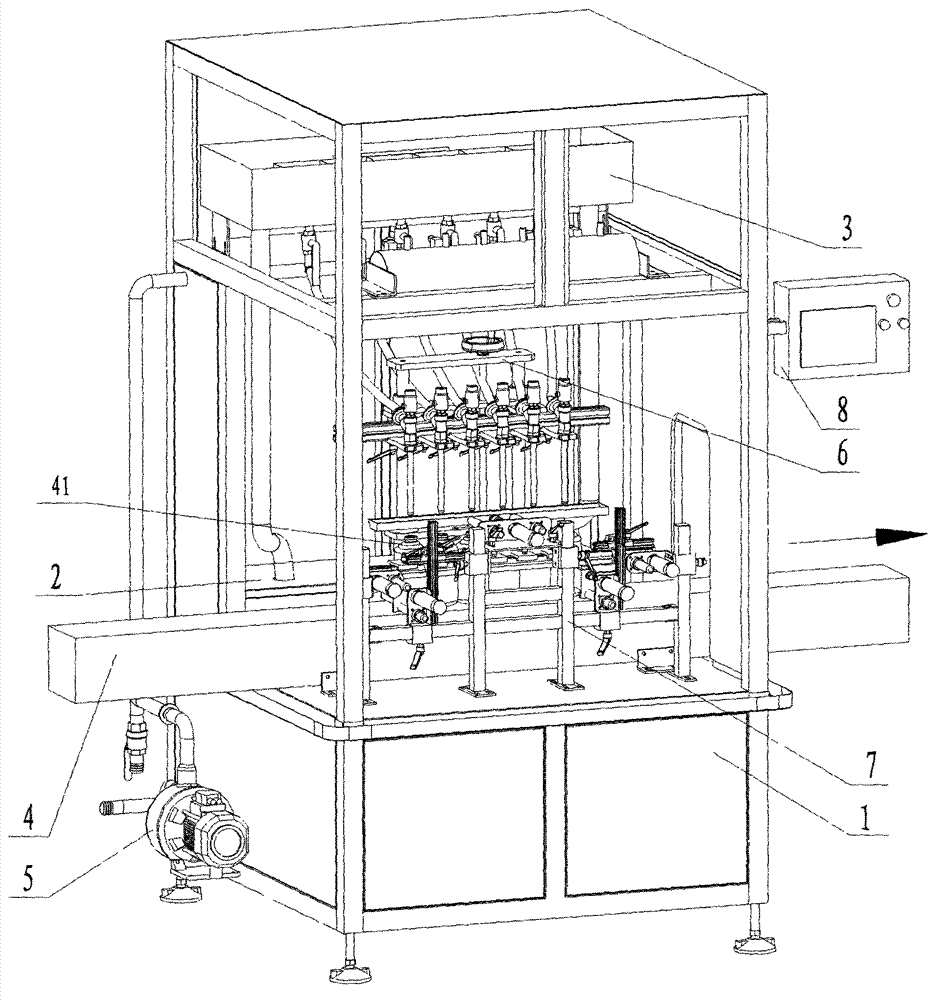

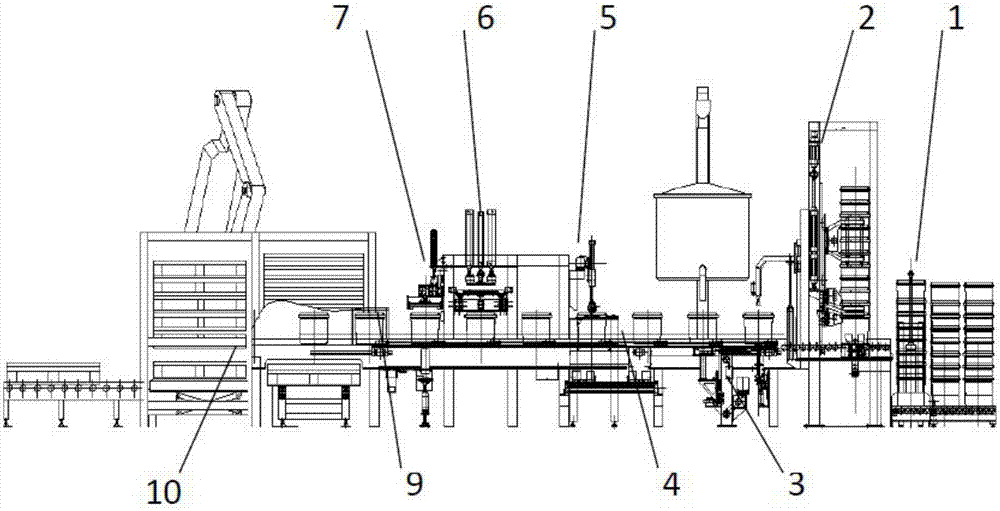

Anti-corrosion and anti-explosion full-automatic multihead filling packaging line

ActiveCN105502259ASatisfy anti-corrosionFulfil requirementsSynchronising machinesControl systemEngineering

The invention discloses an anti-corrosion and anti-explosion full-automatic multihead filling packaging line. The anti-corrosion and anti-explosion full-automatic multihead filling packaging line comprises a filling machine capable of conducting filling on bottles, a control system which is provided with a touch screen and adopts a PLC, a stopper sealing machine capable of installing a stopper in each bottle, a stopper installing detection photoelectric sensor, a stopper installing bottle blocking baffle, a stopper installing pneumatic mechanism, an outer cover installing machine capable of installing an outer cover on each bottle, an outer cover installing detection photoelectric sensor, an outer cover installing bottle blocking baffle, an outer cover installing pneumatic mechanism, a cover screwing machine capable of screwing the outer covers, a labeling machine, a labeling detection photoelectric sensor, an automatic inkjet printing machine and an inkjet printing detection photoelectric sensor. A transport mechanism runs through the whole anti-corrosion and anti-explosion full-automatic multihead filling packaging line and is responsible for transport of the bottles.

Owner:ZHUHAI YUZHOU ENVIRONMENTAL PROTECTION TECH CO LTD

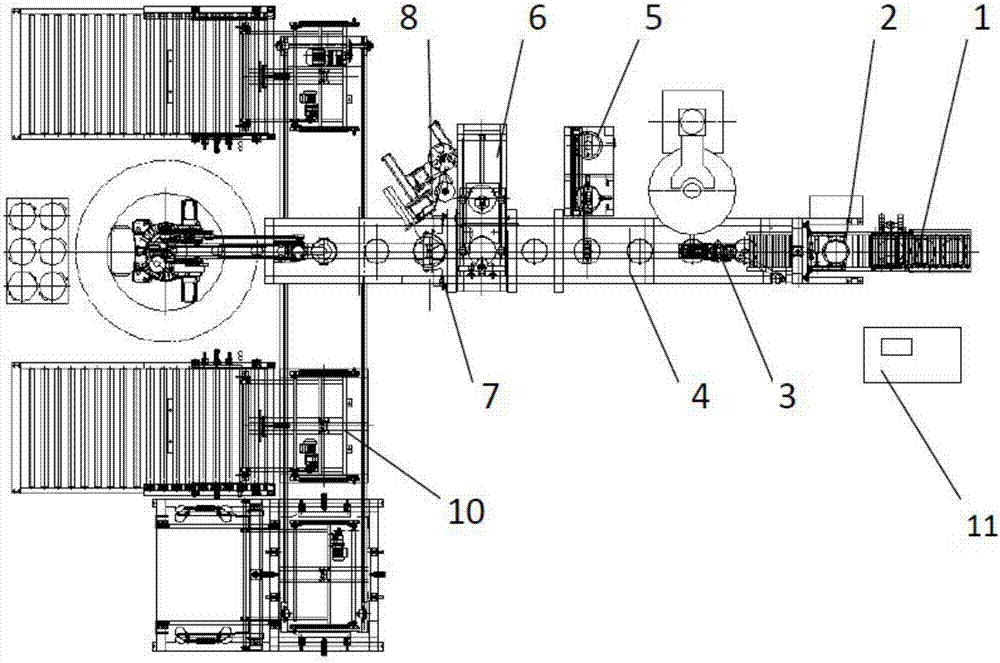

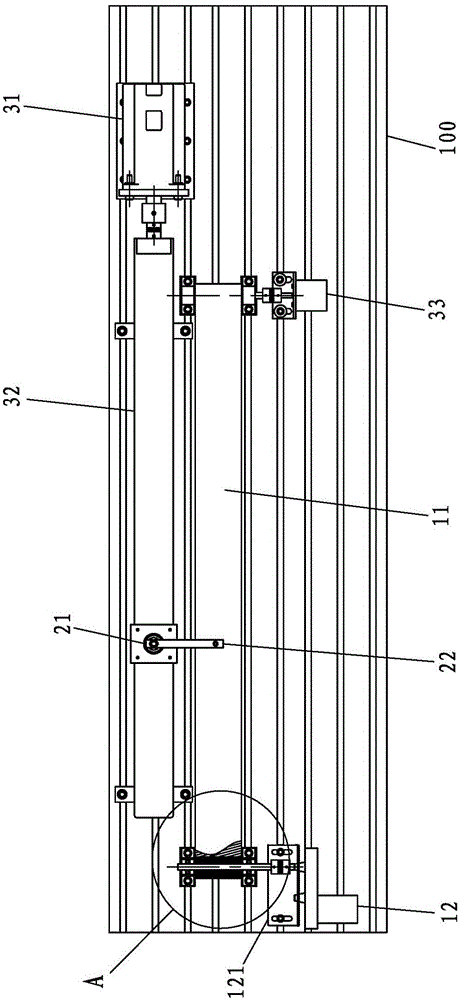

Full-automatic printing ink filling assembly line

PendingCN107298191AHigh degree of automationCompact structureLiquid materialPackaging machinesEngineeringAssembly line

The invention relates to a full-automatic printing ink filling assembly line. The full-automatic printing ink filling assembly line is characterized in that an automatic barrel distributing device is arranged at the rear of an automatic barrel loading device and is connected with an automatic filling device by a stepping line, and an integral pile of plastic barrels can be automatically separated from one another one by one along the perpendicular direction by an automatic barrel distributing machine by the aid of a barrel distributing cylinder and can be sequentially conveyed to the stepping line; filled barrels can be conveyed to an automatic film covering device by the stepping line, and a plastic film can sucked by the automatic film covering device by the aid of vacuum suckers and covers the surface of printing ink in the filled barrels; the filled barrels covered with the plastic films can be conveyed onto an automatic barrelhead loading and compressing device on a barrelhead compressing station by the stepping line, and barrelheads can be automatically extracted by the automatic barrelhead loading and compressing device and can tightly cover the barrels by the automatic barrelhead loading and compressing device; a barrelhead screwing and labeling station is arranged beside the automatic barrelhead loading and compressing device, an automatic barrelhead screwing device and an automatic labeling machine are arranged on the barrelhead screwing and labeling station, the barrelheads can be screwed by the automatic barrelhead screwing device, and bodies of the filled barrels can be labeled by the automatic labeling machine. The full-automatic printing ink filling assembly line has the advantage that the plastic barrels can be automatically filled with the printing ink with different colors.

Owner:SHANGHAI HENGTUO IND DEV

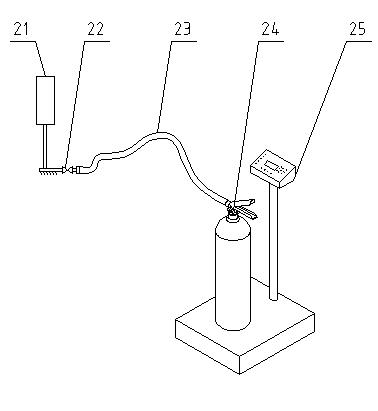

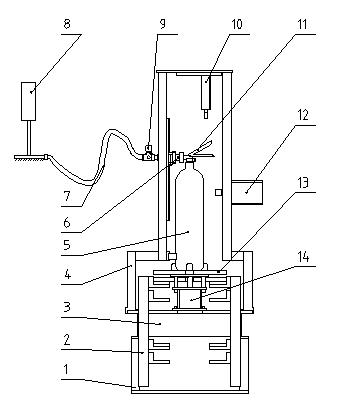

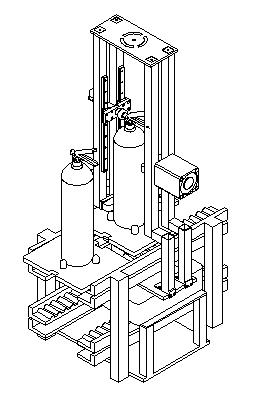

Liquid CO2 extinguisher filling device

InactiveCN102141192AHigh filling accuracyImprove efficiencyContainer filling under pressureGas cylinderAssembly line

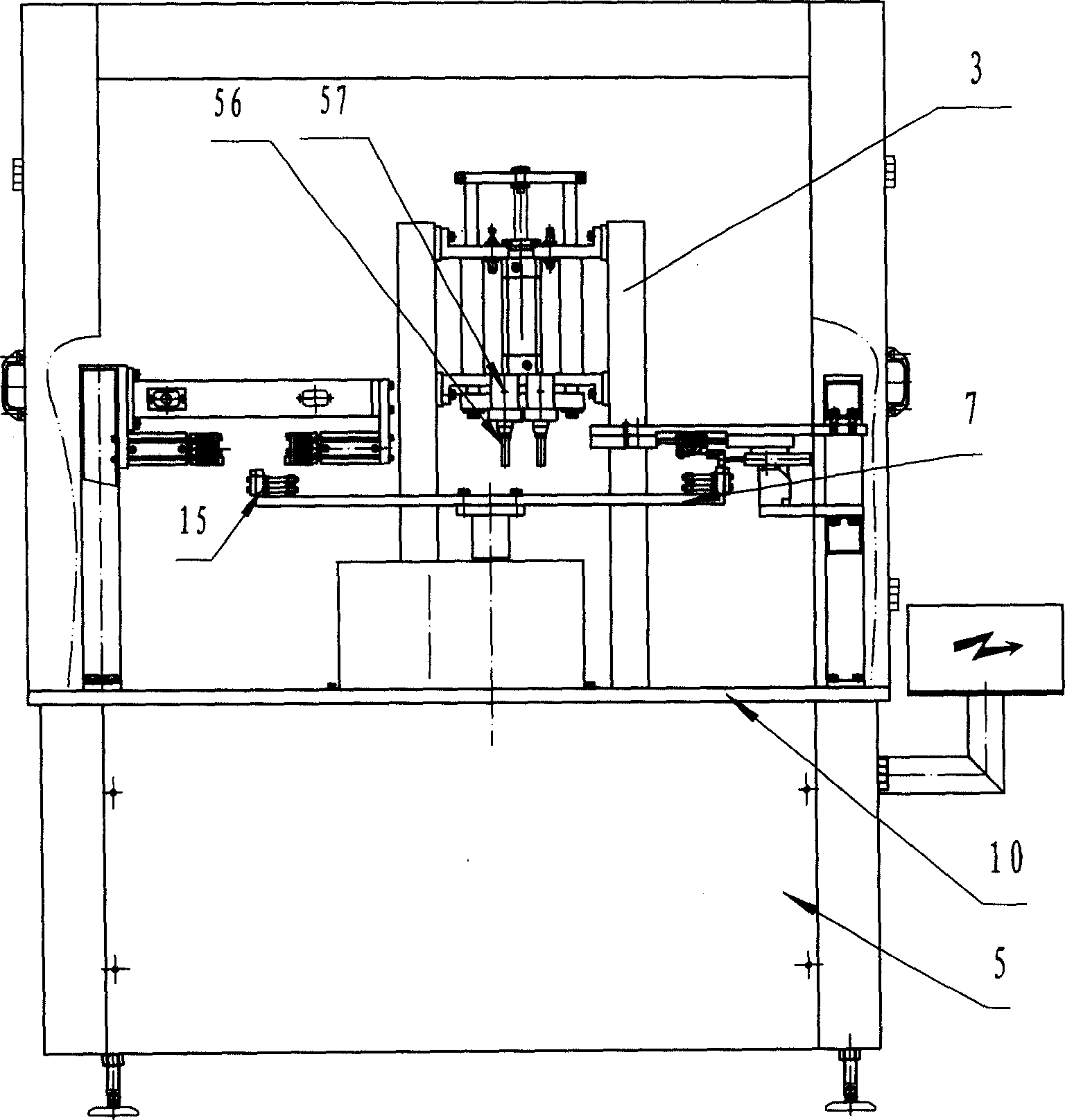

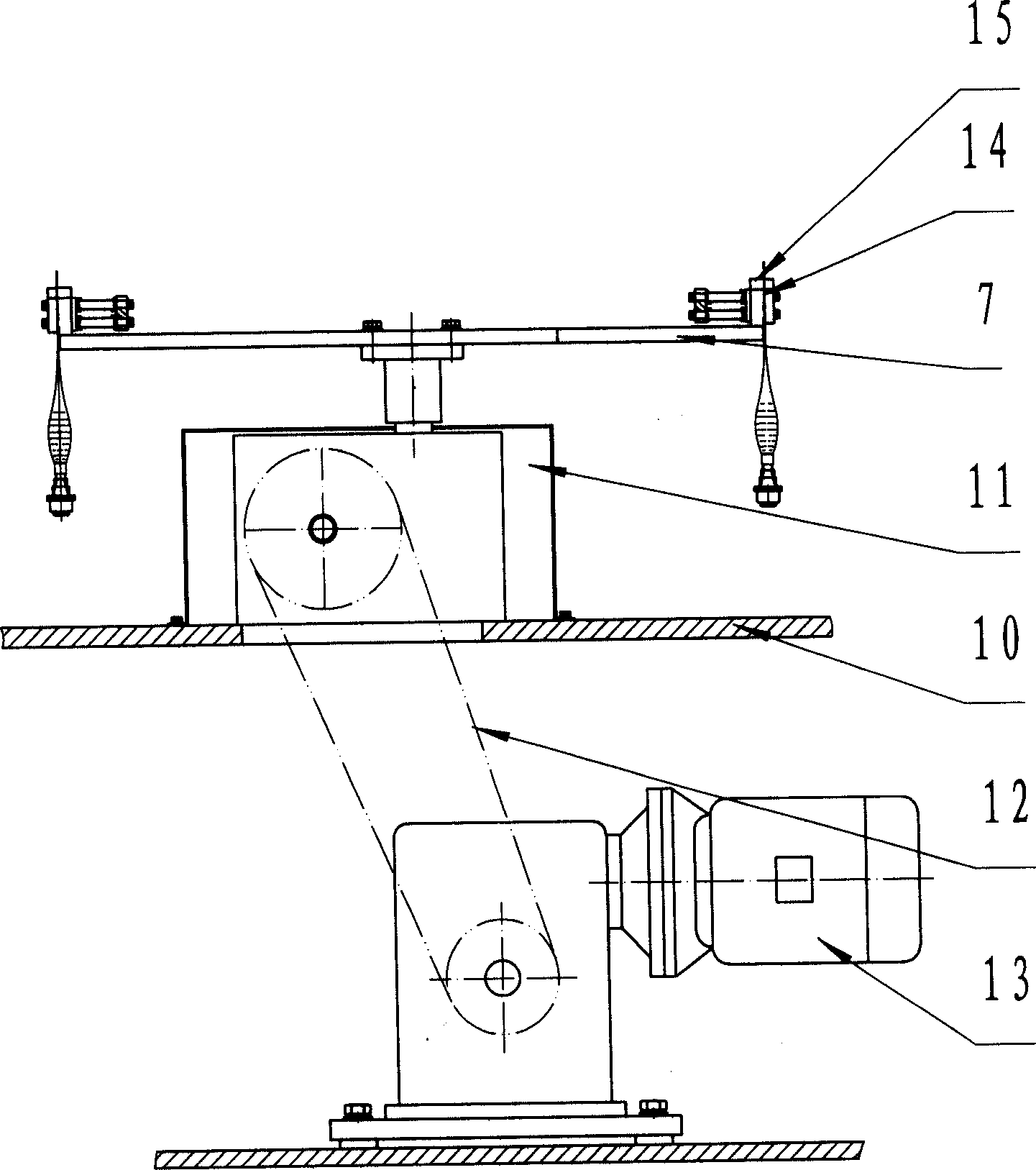

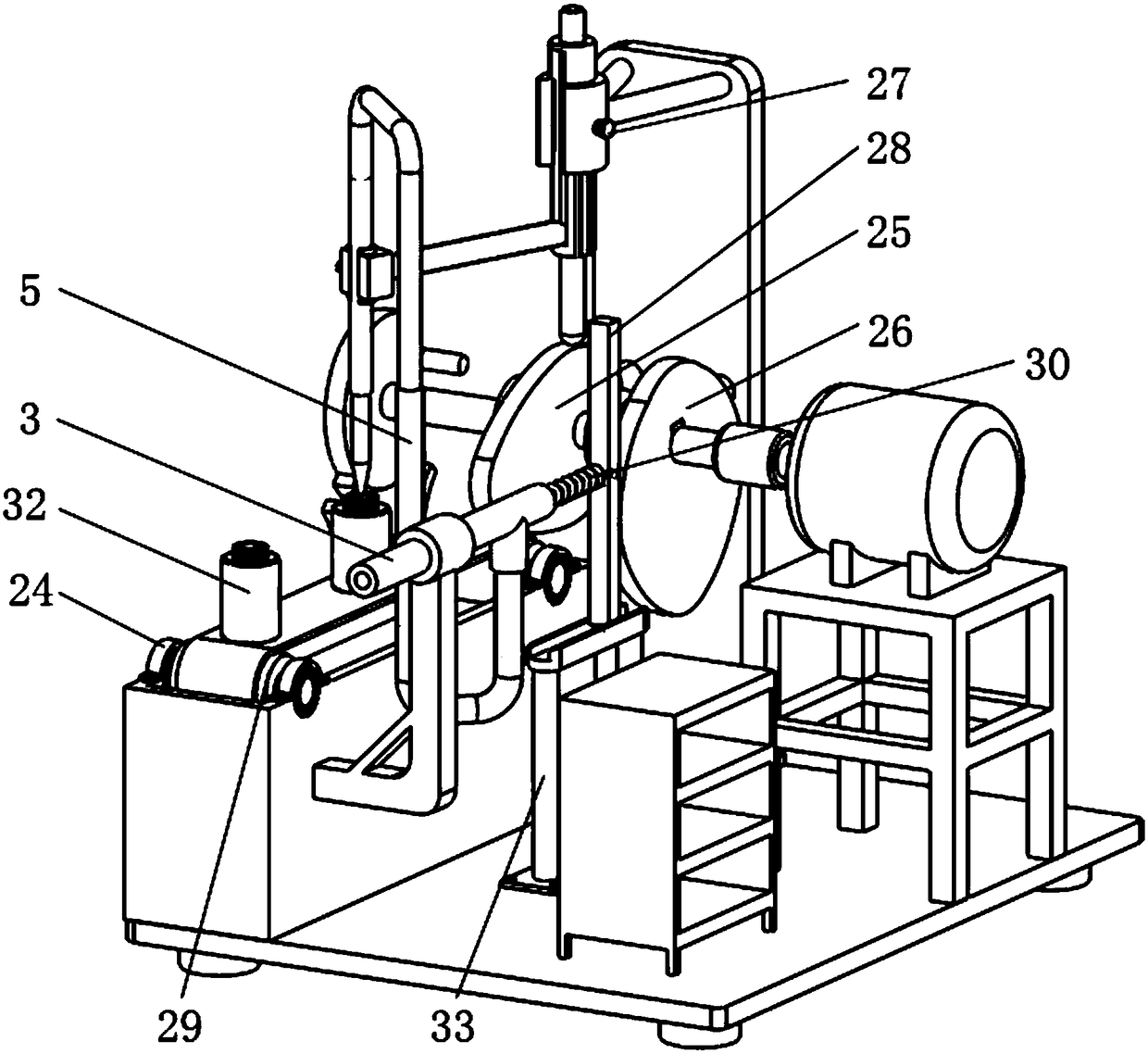

The invention relates to a liquid CO2 extinguisher filling device, wherein a PLC (Programmable Logic Controller) control system is adopted. The liquid CO2 extinguisher filling device is characterized in that a production line traverses a main body of the device, the main body of the device is arranged on a weighing sensor and a base is arranged under the weighing sensor; the production line comprises a machine frame, a positioning control device is arranged on the machine frame, a transmission roller chain is arranged in the middle of the machine frame and a tool plate used for placing a CO2 extinguisher gas bottle is arranged on the transmission roller chain; and the upper part of the main body of the device is of a frame structure, a bottle supporting cylinder is arranged at the midpoint on the weighing sensor at the lower part of the main body of the device, one side of the frame of the main body of the device is provided with an aeration component capable of moving along with a guide rail and the other side of the frame is provided with a clamping cylinder. Under high-pressure and low-temperature CO2 filling conditions, the liquid CO2 extinguisher filling device provided by the invention has the advantages of high filling precision, high efficiency, little waste, and safety and convenience for operation and is suitable for batch assembly line work.

Owner:ZHEJIANG ORIENTX FIRE SAFETY EQUIP

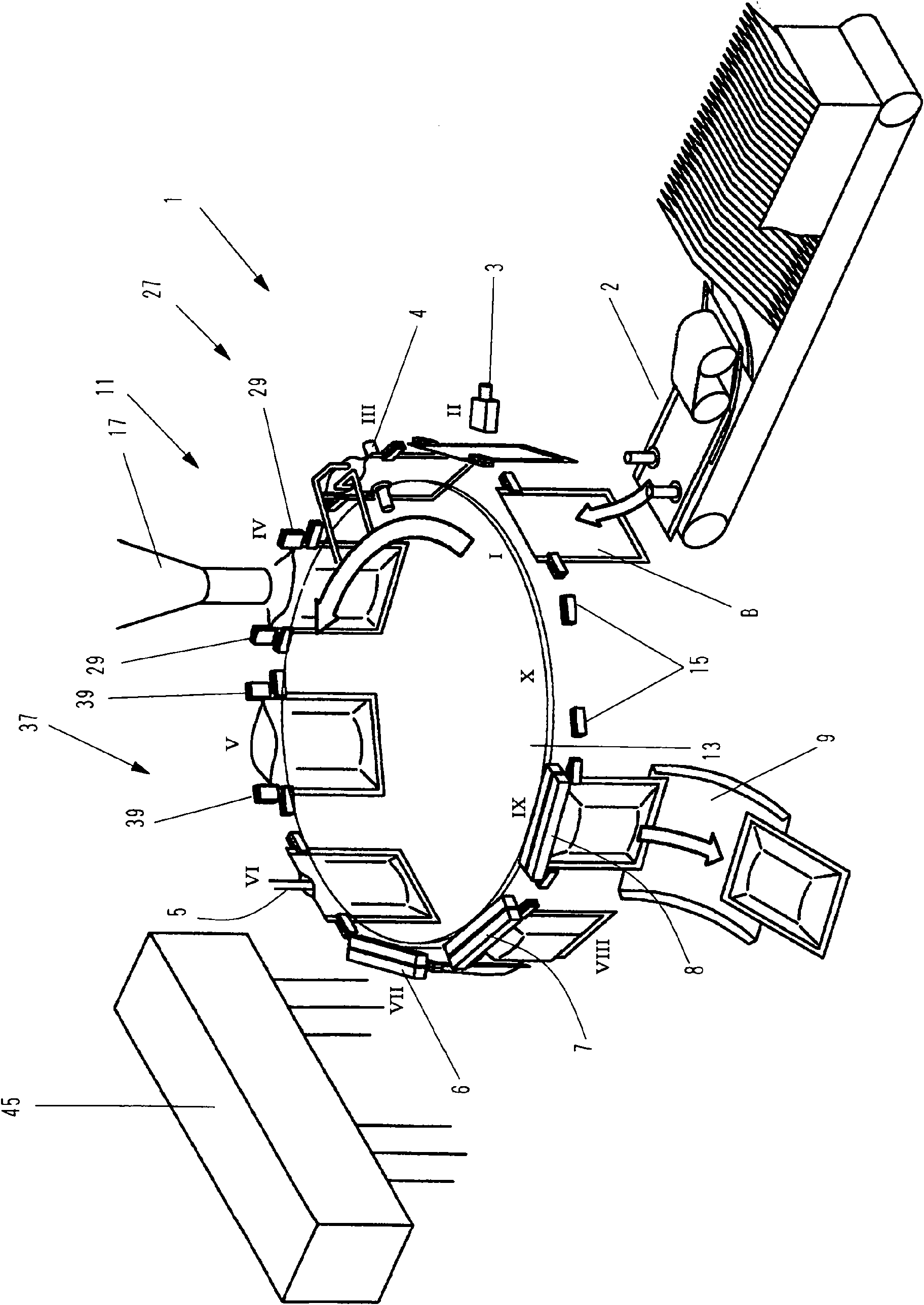

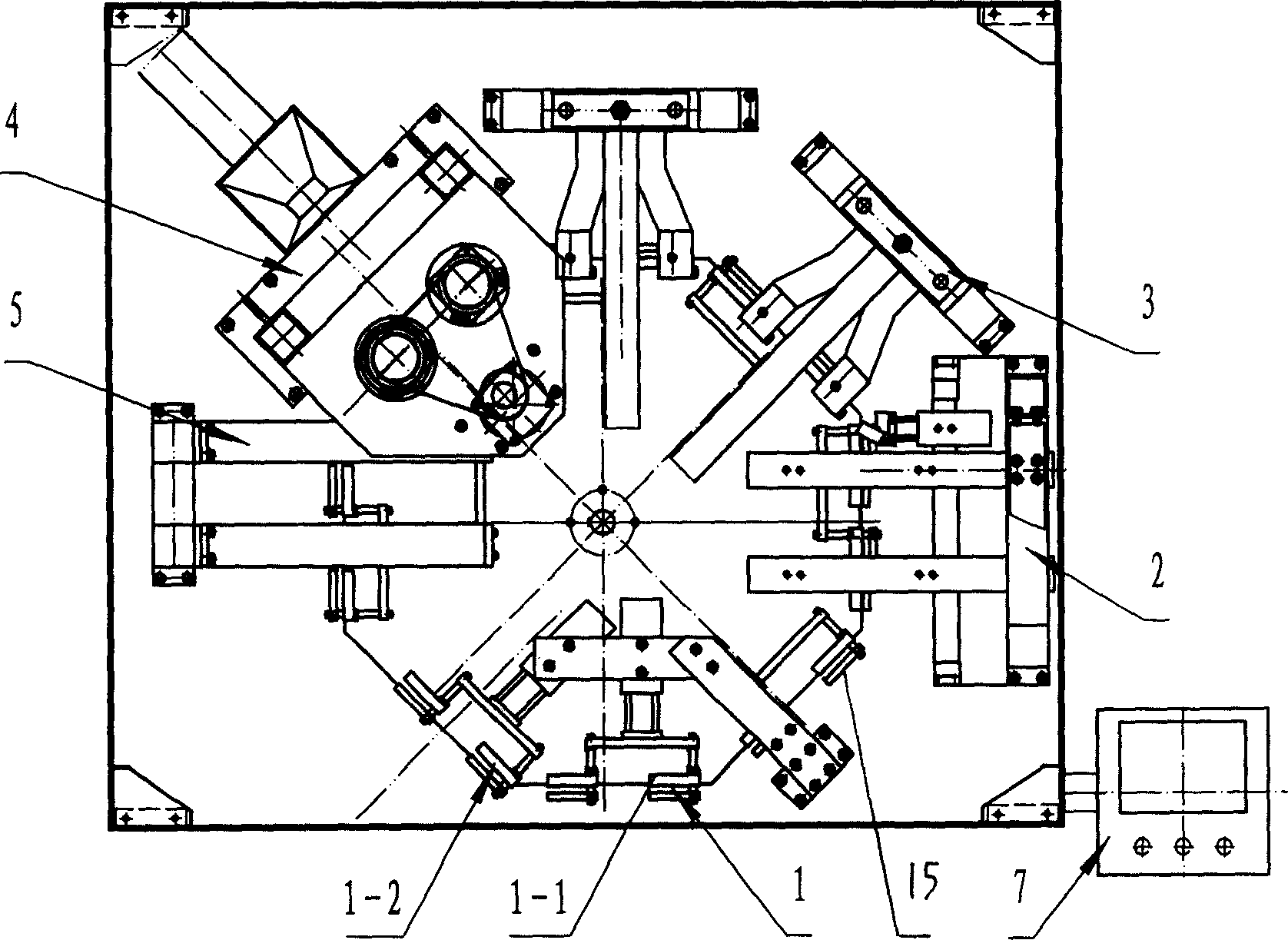

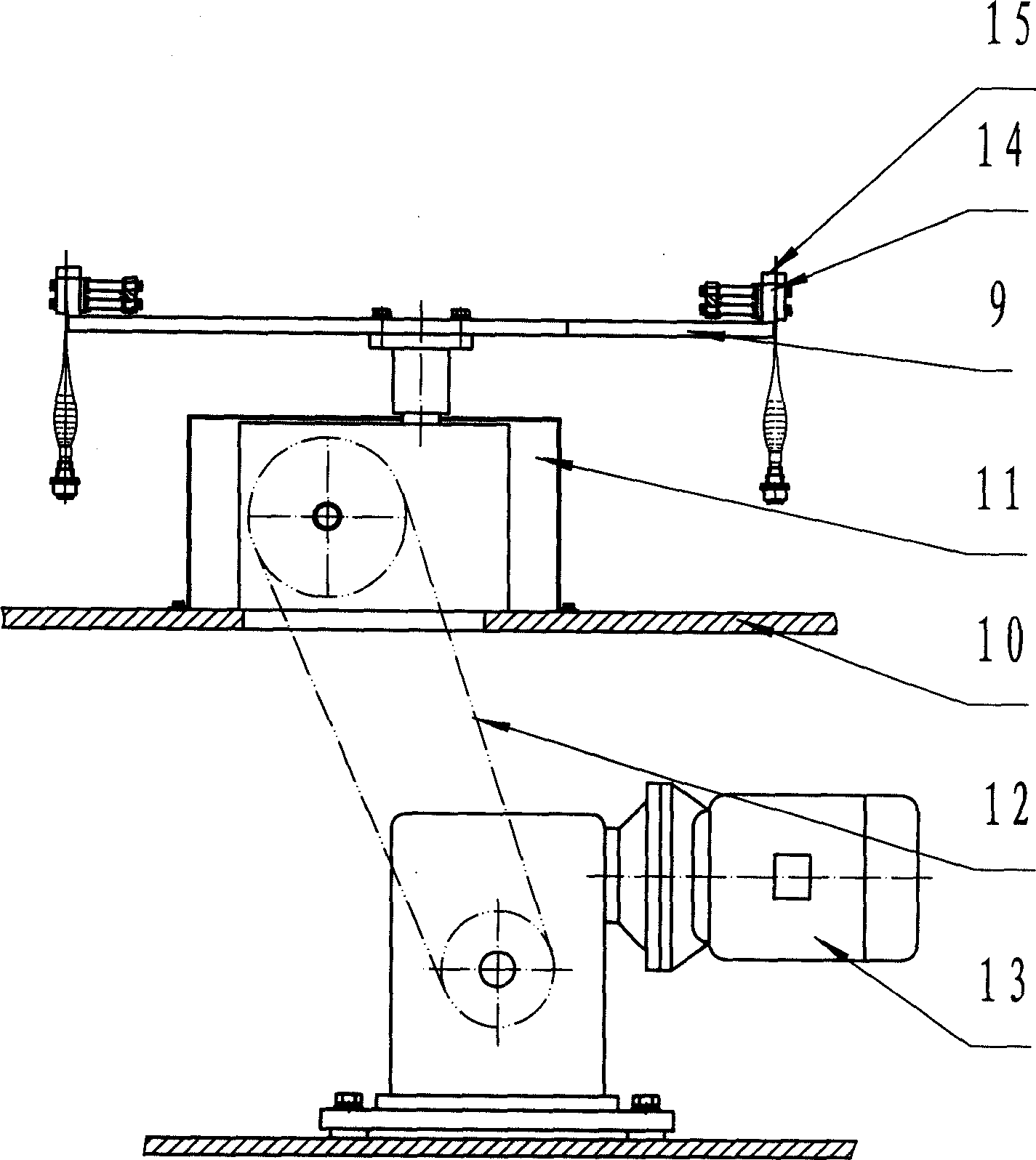

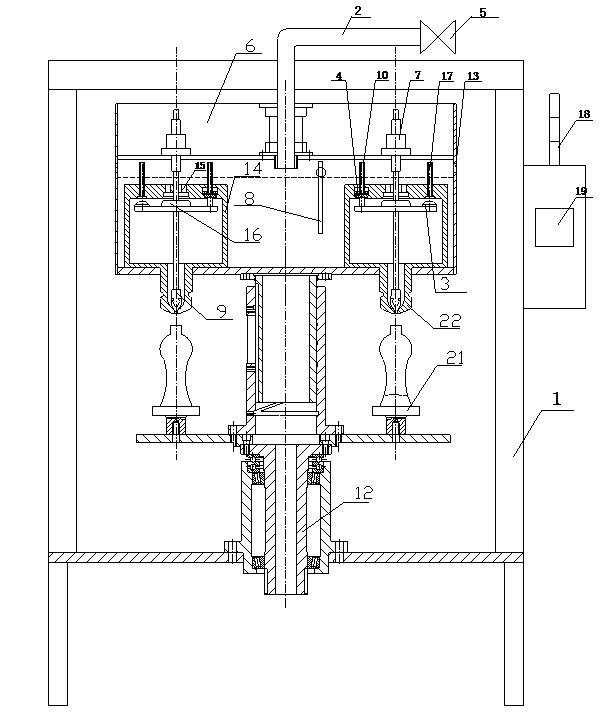

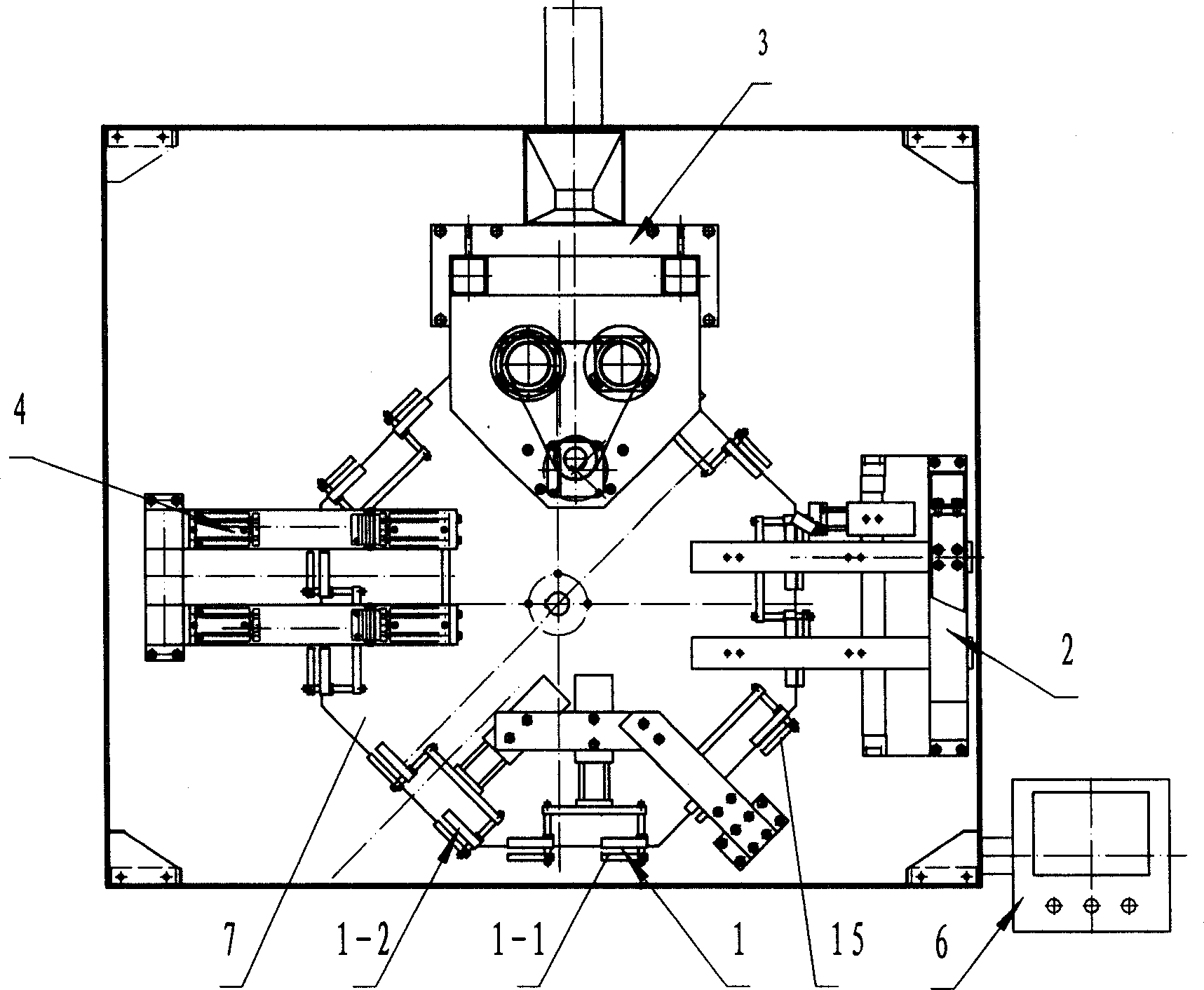

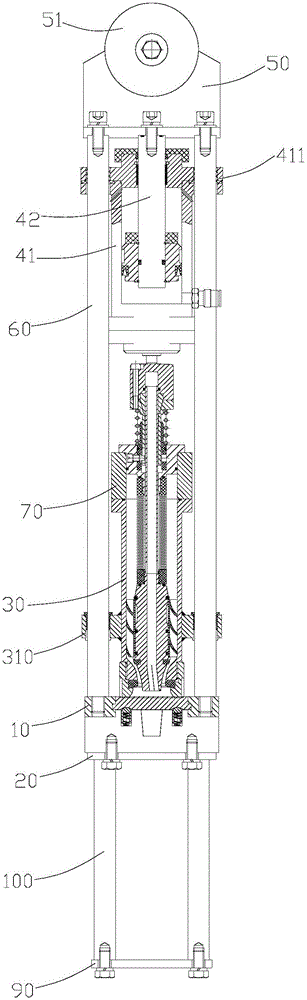

Intermittent rotary non-PVC large infusion soft-bag solid drug filling machine

ActiveCN1743232AChange the way the medicine is dispensedChange middle linkPharmaceutical product form changeWrapper supporting apparatusNitrogenEngineering

The solid medicine filling machine comprises power drive component, central dial, take-in and take-out component, bag-cutting part, part for filling clean air, part for filling nitrogen, thermal sealing part, rack and electric control cabinet. The parts above are set on the side of the center dial that connects with the power drive component and are supported by the rack to layout in turn. Around the central dial is fitted with a bag holder for hanging infusion bag.

Owner:HUNAN CHINASUN PHARMA MASCH CO LTD

Liquid filling machine

InactiveCN102180430AHigh metering and filling accuracyEasy to processLiquid bottlingLiquid tankFloat switch

The invention discloses a liquid filling machine and belongs to the field of filling equipment. The liquid filling machine comprises a liquid inlet pipe and a filling machine liquid storage pot, wherein the liquid inlet pipe passes through the upper end of a stander and is directly connected with the upper end of the filling machine liquid storage pot; and a filling machine liquid storage pot floating switch and a plurality of groups of air cylinders are arranged in the filling machine liquid storage pot. In the liquid filling machine, one air cylinder controls one filling head; an equal height counting mode of the inner liquid level of the liquid storage pot is not required; a constant liquid level cup type stable liquid level is adopted, so one filling head needs only one air cylinder, and the counting and filling precision is high; the filling machine is easy to process and the number of output points of an industrial control computer is small, so the cost can be reduced by over 1 / 2; the liquid filling machine is durable, the liquid level is easy to control, and the reliability is enhanced; backflow control is not needed, so the power is saved; the liquid filling machine is easy in maintenance, good in sealing property and safe; liquid is hard to volatilize during filling; the filling precision is enhanced and the filling speed is high; and the liquid filling machine can be widely applied to rotary gas-free liquid filling machines, discharging gas-free liquid filling machines and the like.

Owner:LUZHOU JIANGXU MACHINERY MFG

Passion fruit linear type filling machine

The invention discloses a passion fruit linear type filling machine. The passion fruit linear type filling machine comprises a conveying mechanism, a stirrer, a filling mechanism and metering cylinders. The conveying mechanism is installed on the transverse front side of the upper end of a base, and a bottle opening limiting mechanism and the filling mechanism are installed on the front side and the rear side of the middle of the conveying mechanism. The filling mechanism is connected to the discharging ends of the metering cylinders through pipelines, and the feeding ends of the metering cylinders are connected to the bottom of the stirrer. The stirrer is fixedly connected to the rear side of the base through a supporting frame, piston rods of the metering cylinders are connected with a metering adjusting mechanism, and the metering adjusting mechanism is installed on the base. The metering adjusting mechanism in the passion fruit linear type filling machine adjusts the stir uniform feeding of the stirrer and the discharging operation of the metering cylinders and controls the feeding operation of the metering cylinders, and after the metering cylinders are filled with passion fruit juice, the filling mechanism is controlled to multiple filling bottles conveyed by the conveying mechanism to conduct discharging and filling operation. The bottle opening limiting mechanism is adopted to conduct automatic quick limiting, the bottles are pushed to the filling positions to be subjected to quick filling, and therefore the bottle output waiting time is shortened, and the production efficiency is improved.

Owner:GUIZHOU UNIV

Intermittent rotary solid-drug-chargeable non-PVC infusion bag solid-drug filling machine

ActiveCN1743233AChange the way the medicine is dispensedChange middle linkPharmaceutical product form changeWrapper supporting apparatusEngineeringElectric control

The solid medicine-filling machine comprises power drive component, central dial, take-in and take-out component, bag-cutting part, thermal-sealing part, rack and electric control cabinet. The parts above are set on the side of the center dial that connects with the power drive component and are supported by the rack to layout in turn. Around the central dial is fitted with a bag holder for hanging infusion bag. On the filling part can be provided with a protective gas inlet.

Owner:HUNAN CHINASUN PHARMA MASCH CO LTD

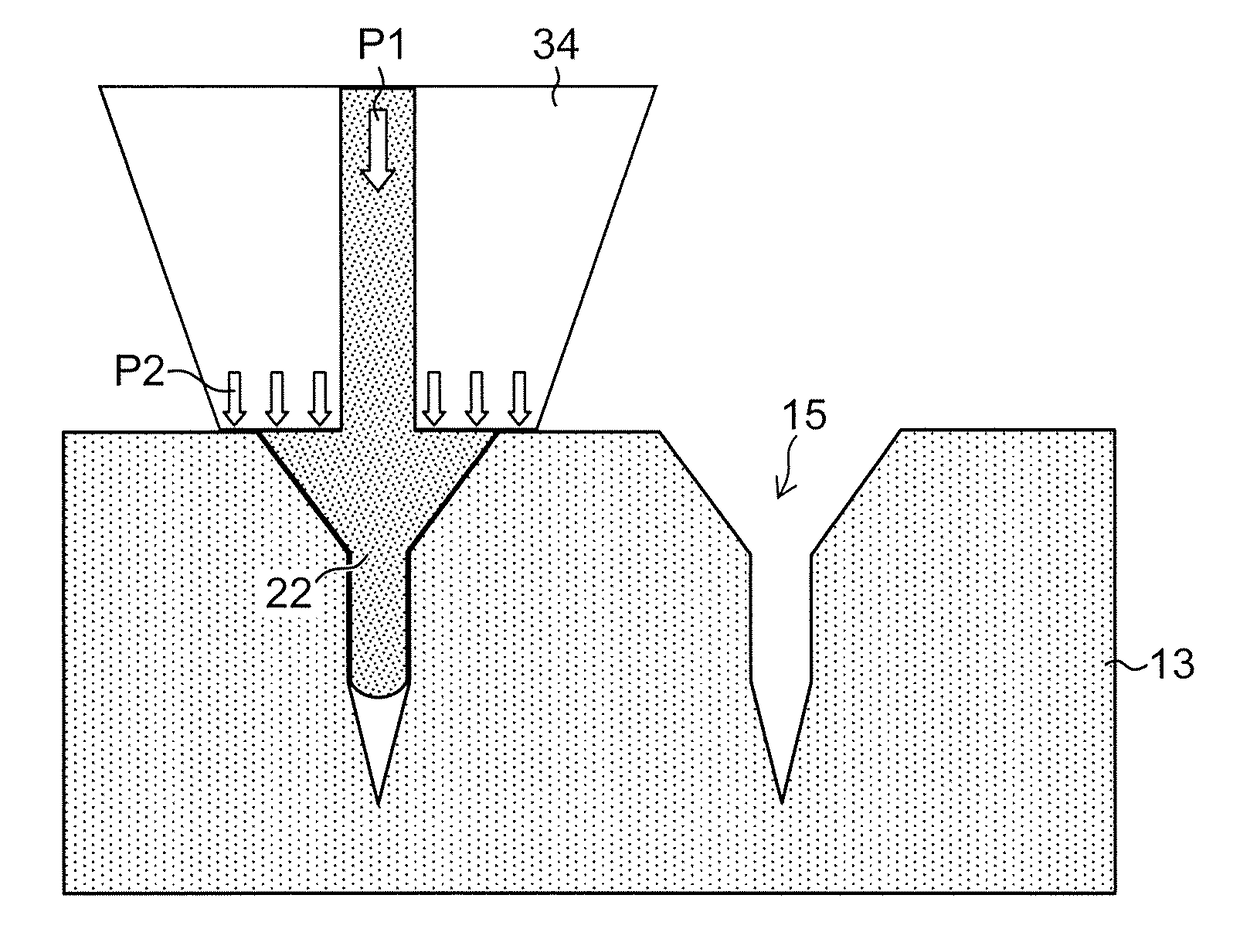

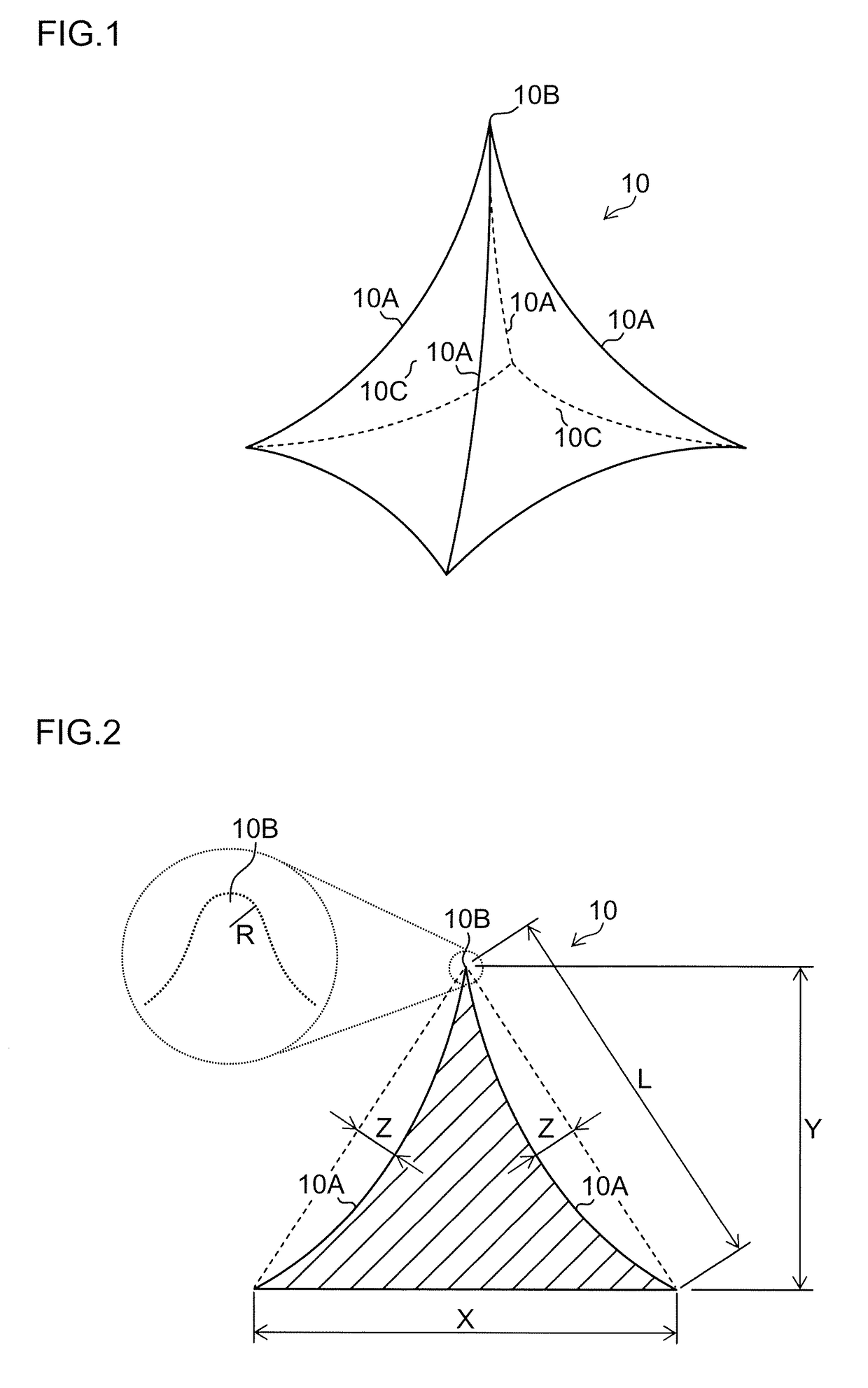

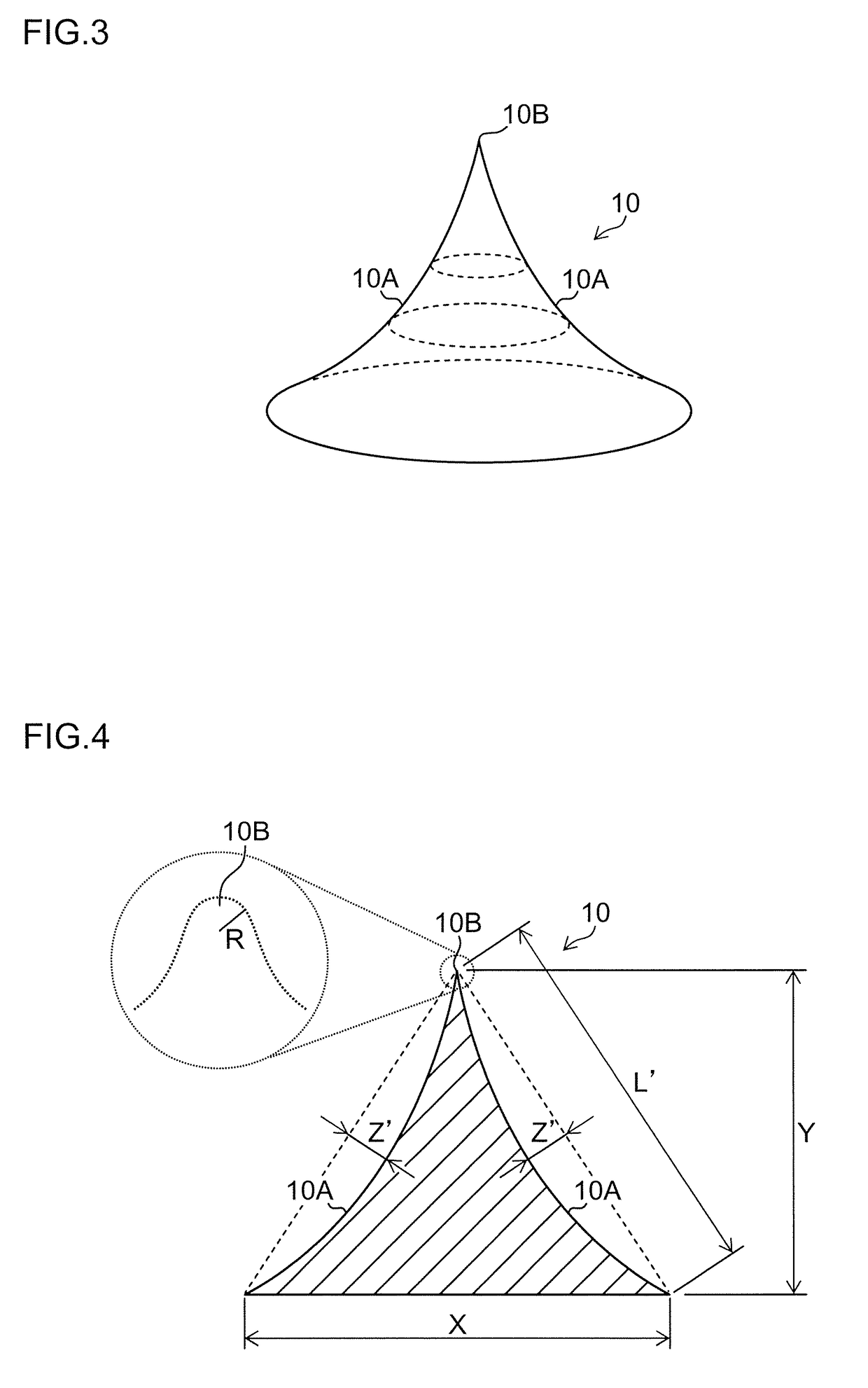

Manufacturing method of sheet having needle-like protruding portions

InactiveUS20170282417A1Avoid deformationHigh filling accuracyMicroneedlesFlat articlesYoung's modulusHardness

The manufacturing method of the sheet having the needle-like protruding portions includes: preparing a mold including needle-like recessed portions, and a solution supply device including a slit-like opening formed at a nozzle distal end portion; supplying a solution from the solution supply device to the mold in a state that the nozzle distal end portion is pressed to a front surface of the mold, and filling the solution in the needle-like recessed portions; and moving the solution supply device relatively to the mold in a state that the nozzle distal end portion is brought into contact with the front surface of the mold, and, as a hardness distribution in a thickness direction of the mold, an average value of a Young's modulus at a part within 40 μm from the front surface of the mold is 1.9 MPa or higher and 100 MPa or lower.

Owner:FUJIFILM CORP

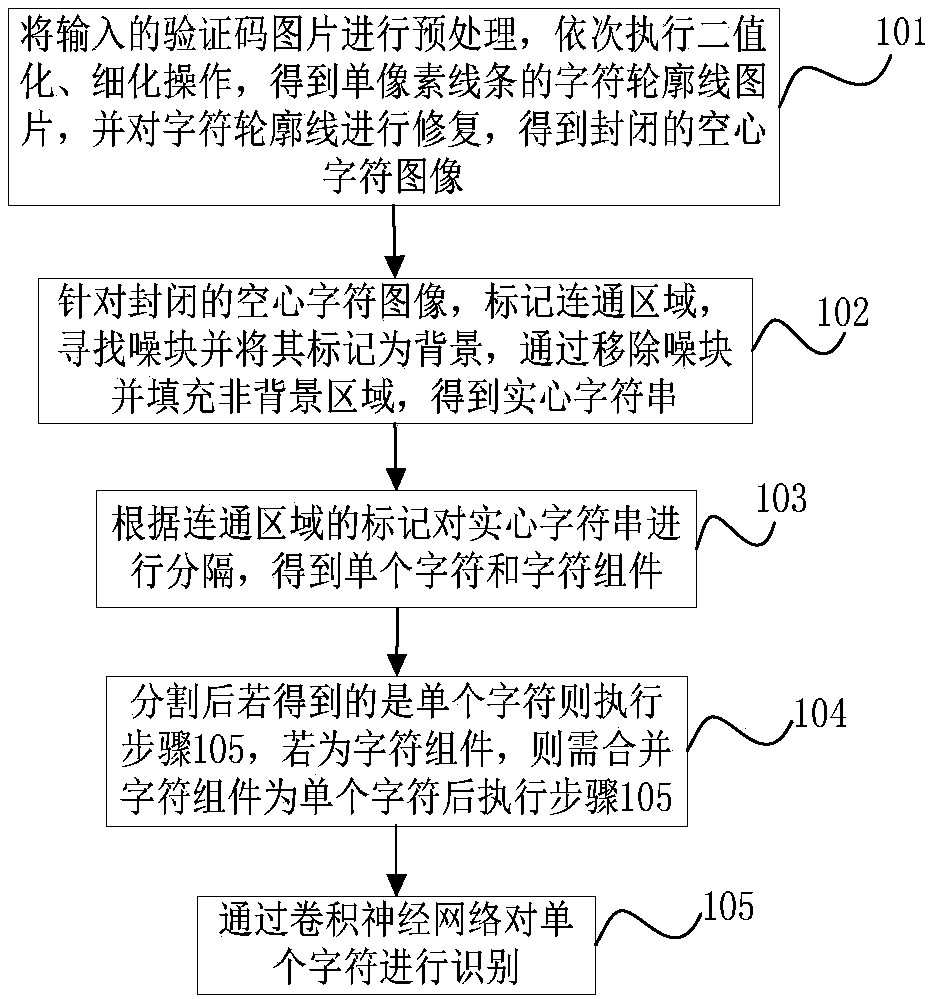

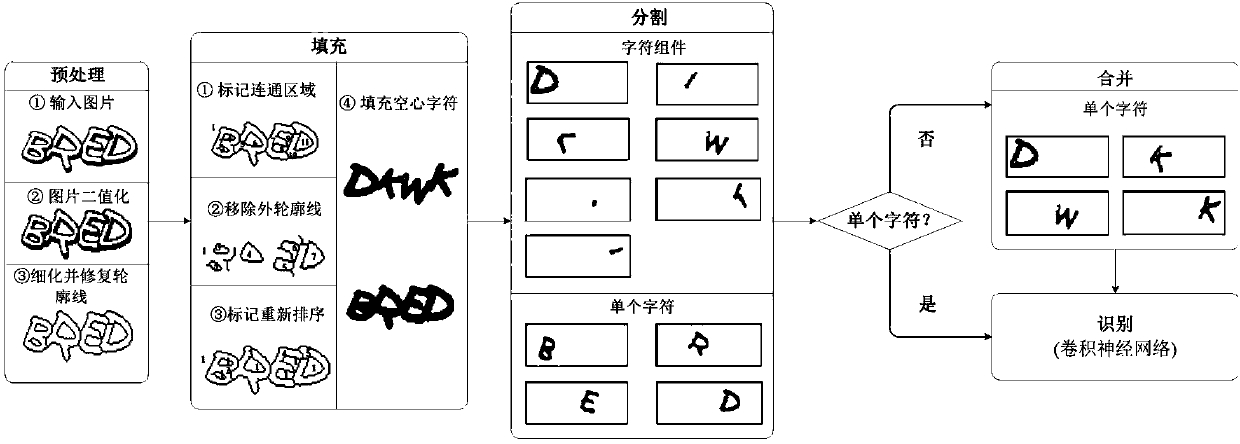

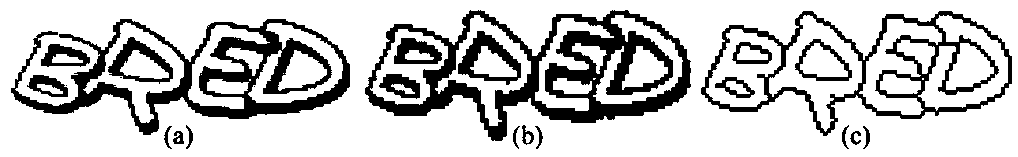

Method for rapidly identifying hollow verification code

ActiveCN108038484AQuick identificationAccurate identificationNeural architecturesNeural learning methodsRapid identificationNear neighbor

The invention belongs to the technical field of a verification code, and in particular relates to a method for rapidly identifying a hollow verification code. The method comprises the steps of firstly, thinning a character contour line of the verification code in a preprocessing stage; secondly, only filling a character block through inner and outer contour lines to obtain a solid character; thirdly, segmenting the solid character to obtain single characters and character components; fourthly, analyzing structural characteristics and order associations of the character components, and combining the character components by use of a minimum nearest neighbor algorithm to obtain the non-redundant single characters; and finally, identifying the single characters obtained after segmentation andcombination by use of a convolutional neural network to obtain a final deciphering result. According to the method for rapidly identifying the hollow verification code, compared with an existing identification method, not only is an original structure kept from being not damaged, but also breakages of the character contour lines are guaranteed to be accurately repaired, the filling time can be shortened, the filling precision can be improved, accurate acquisition and rapid identification of the hollow identification code are realized, the identification success rate is greatly improved, the applicability is high and better application values are provided.

Owner:PLA STRATEGIC SUPPORT FORCE INFORMATION ENG UNIV PLA SSF IEU

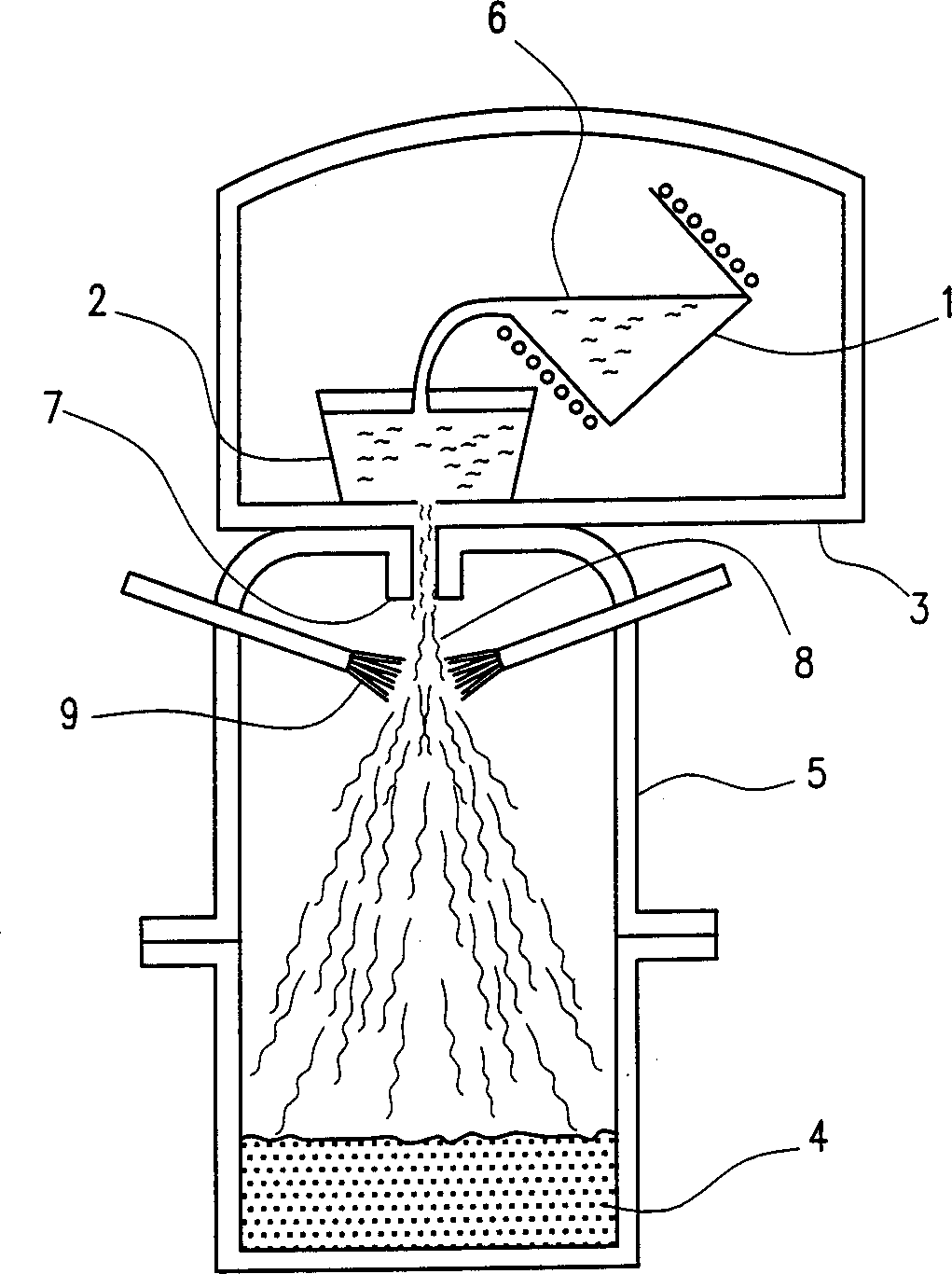

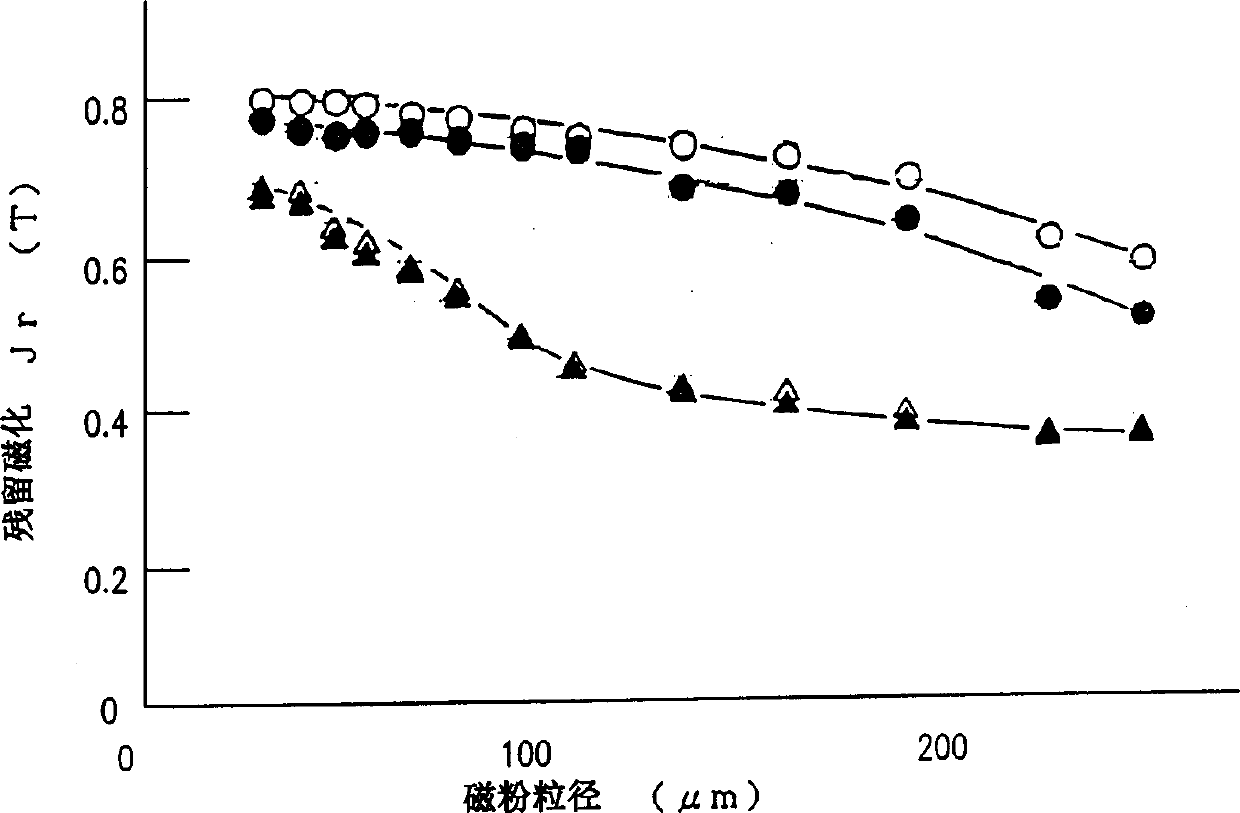

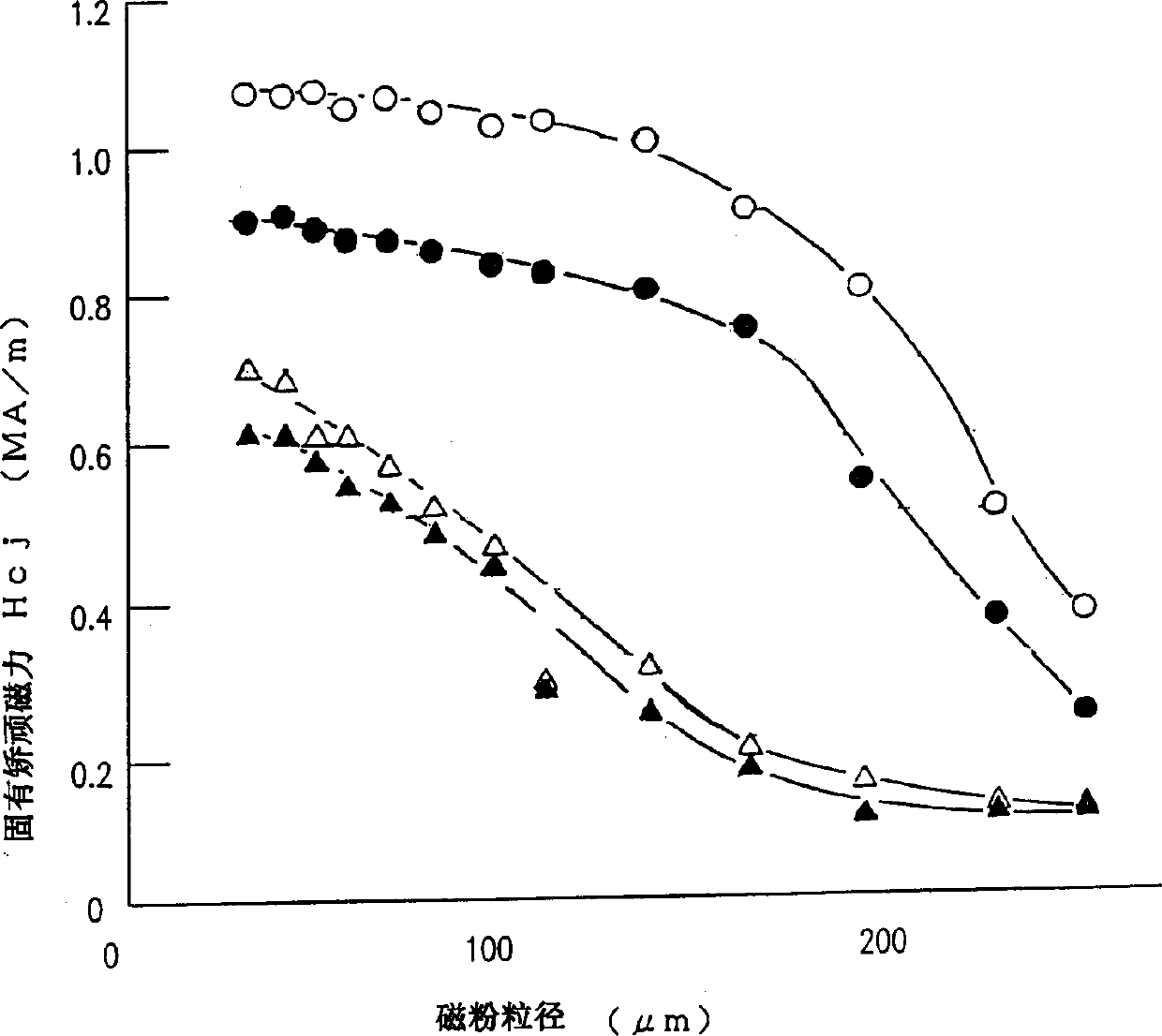

Magnetic alloy powder for permanent magnet and mfg. method thereof

InactiveCN1360316AImprove cooling effectImprove liquidityInorganic material magnetismRare-earth elementNon oxidative

To mass-produce alloyed rare-earth magnetic powder having high coercive force by using the gas atomization method. Spherical powder is formed by spraying molten alloyed pig iron containing R (R is at least one kind of rare-earth elements including Y.) of >=20 wt.% and <=40 wt.%, T (T is a transition metal including Fe as the main component.) of >=60 wt.% and <=79 wt.%, and Q (Q is an element including B (boron) and C (carbon)) of >=0.5 wt.% and <=2.0 wt.%, in the non-oxidative atmosphere, and the shape of particles of the powder is substantially spherical. After that, the spherical powder is heat-treated at a temperature of >=500 deg.C and <=800 deg.C.

Owner:SUMITOMO SPECIAL METAL CO LTD

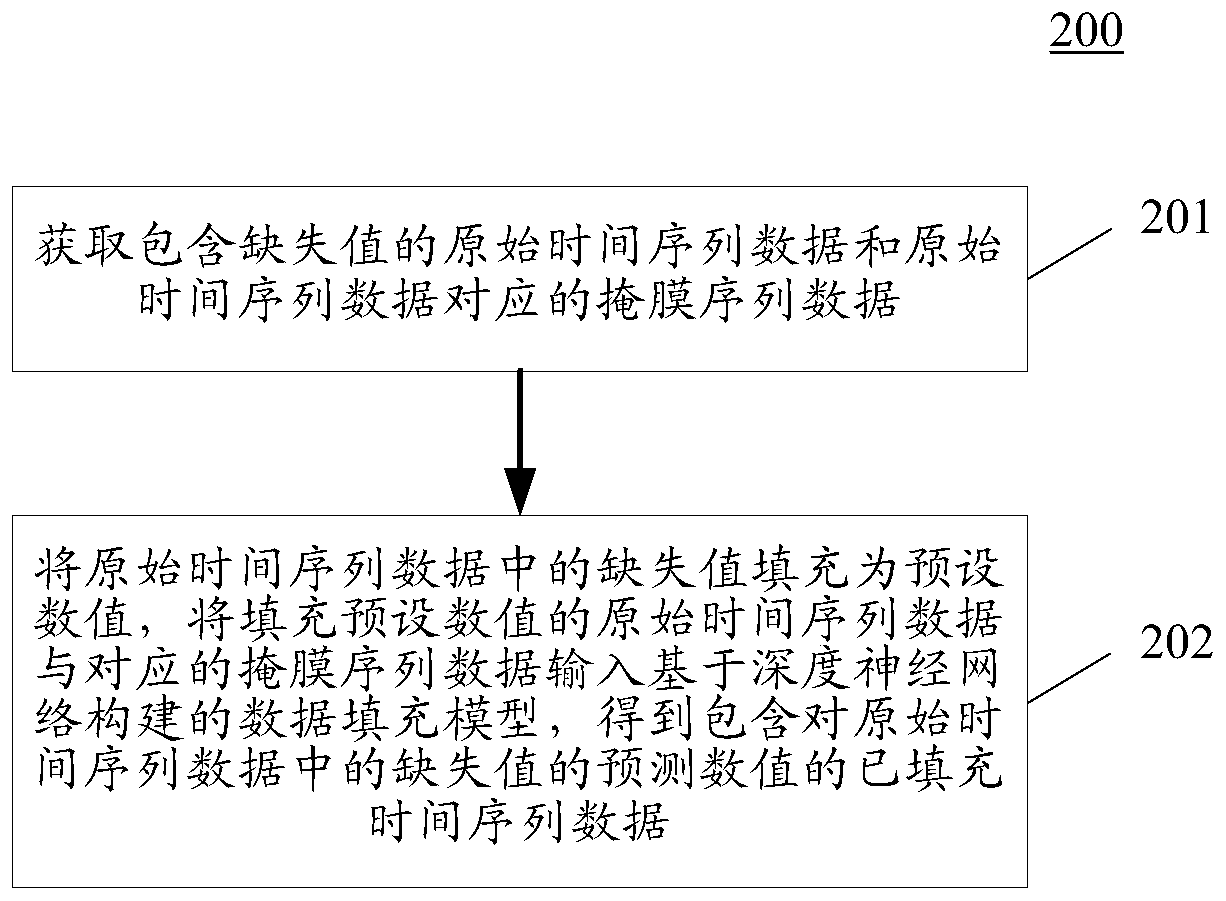

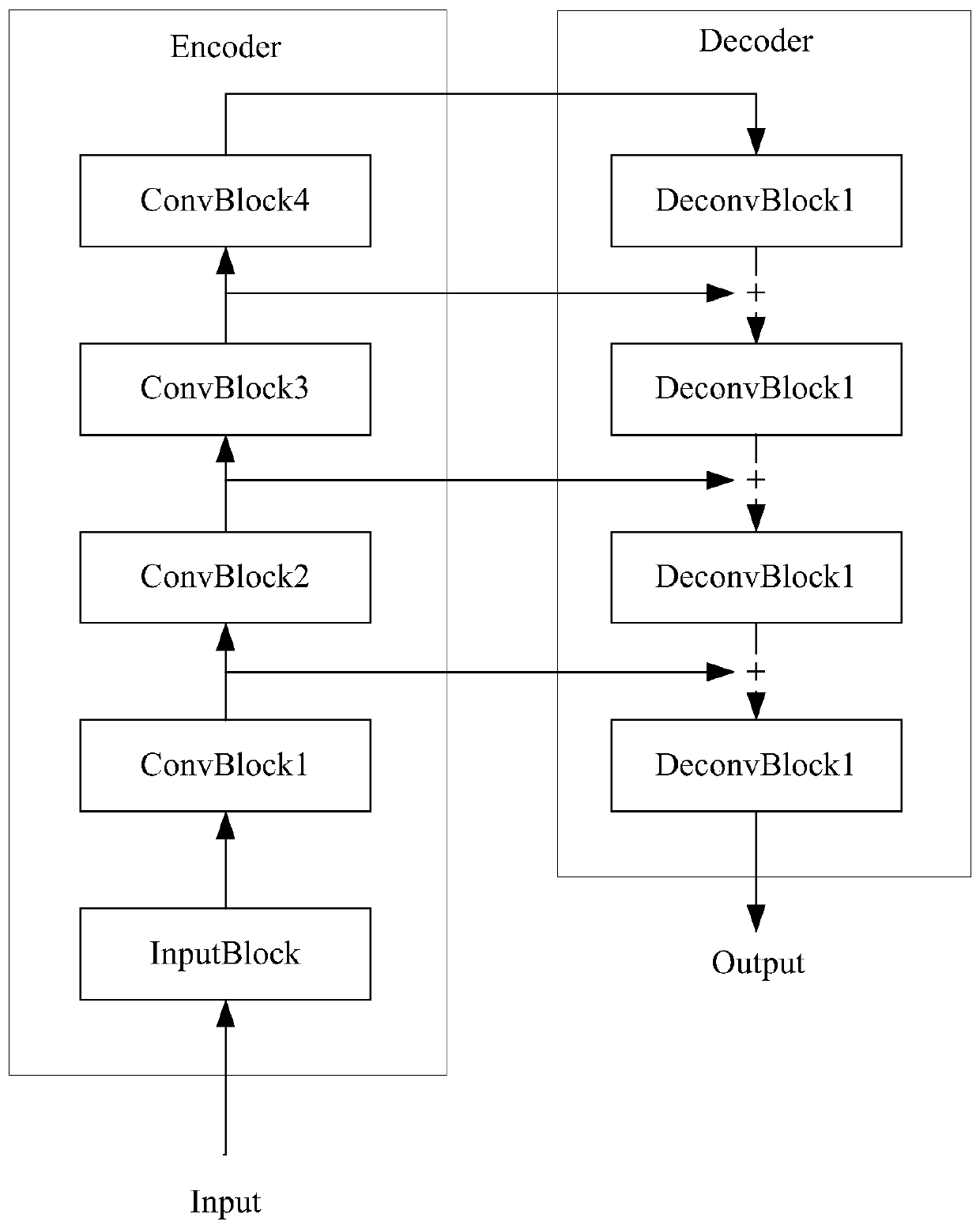

Missing value filling method and device for time series data

ActiveCN111046027AReliable Modeling AnalysisHigh filling accuracyDigital data information retrievalNeural architecturesAlgorithmGenerative adversarial network

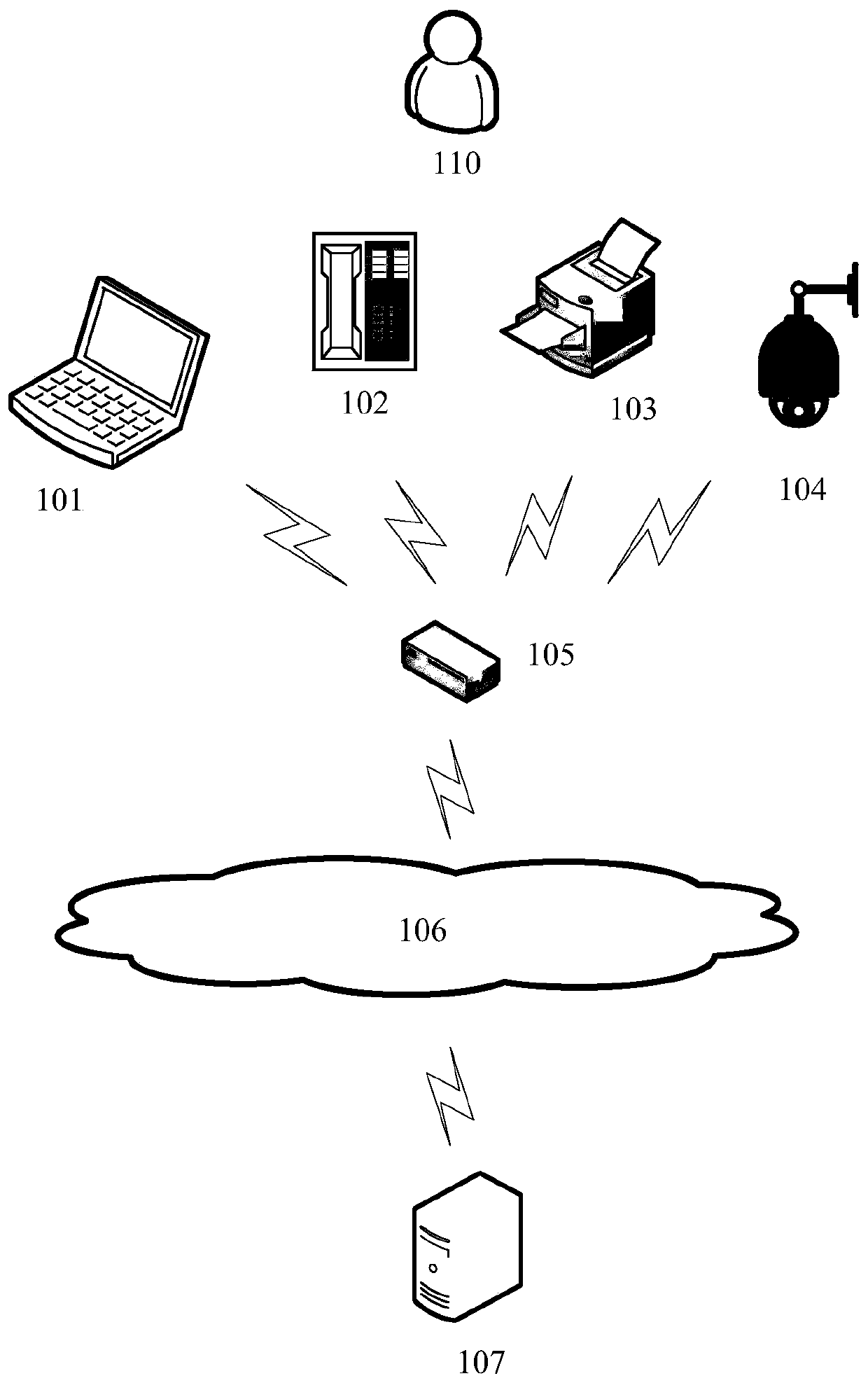

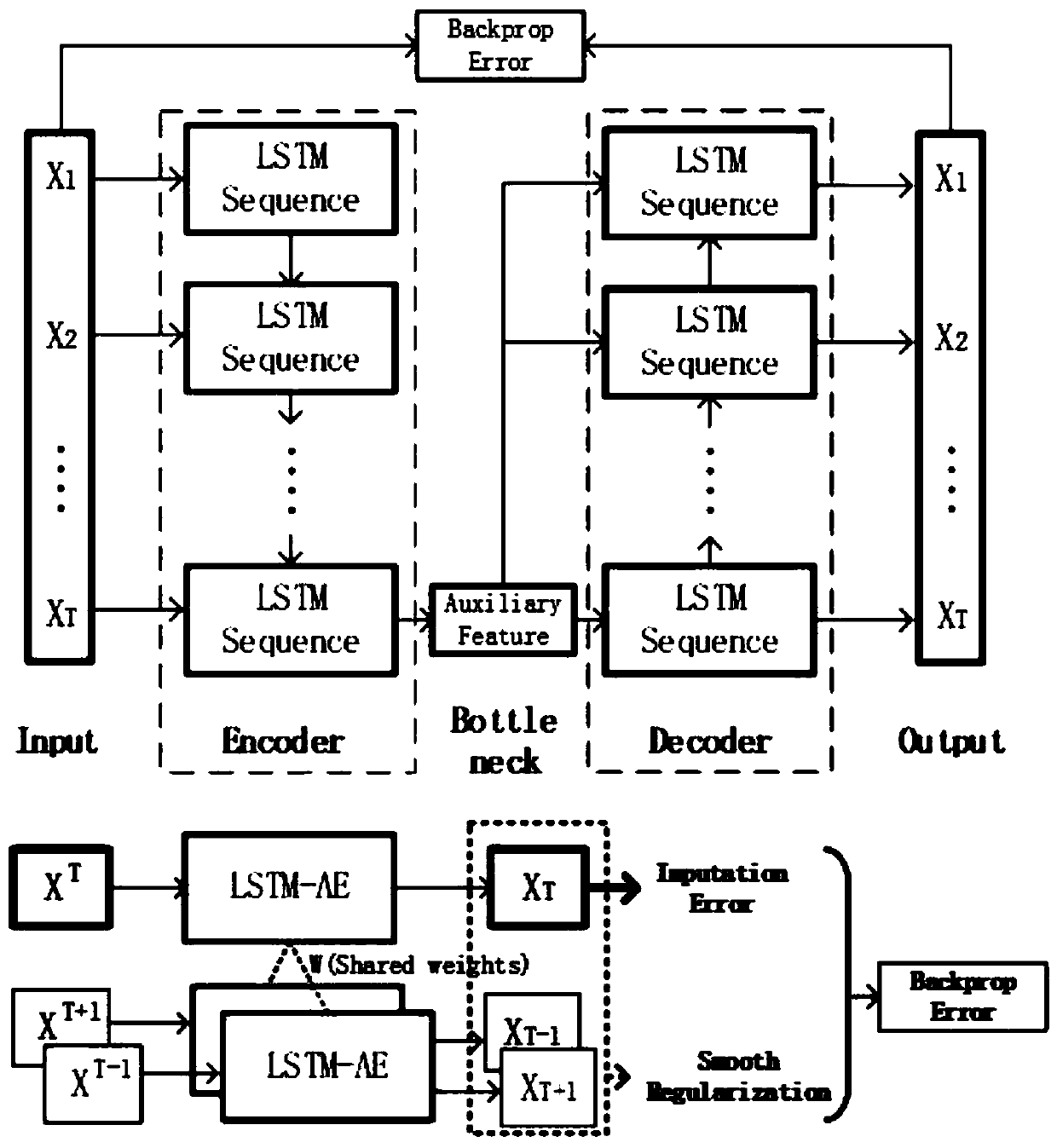

The invention relates to the field of cloud computing. The embodiment of the invention provides a missing value filling method and device for time series data. The method comprises: acquiring originaltime series data containing missing values and mask series data corresponding to the original time series data, wherein the mask series data are used for identifying the positions of the missing values in the original time series data; filling missing values in the original time series data into preset numerical values, and inputting the original time series data filled with the preset numericalvalues and the corresponding mask series data into a data filling model to obtain filled time series data containing prediction numerical values of the missing values in the original time series data,wherein the data filling model comprises a generator in the trained generative adversarial network, and a discriminator in the generative adversarial network is used for discriminating whether the time series data generated by the data filling model is real time series data. According to the method, the filling precision of the missing value of the time series data is improved.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

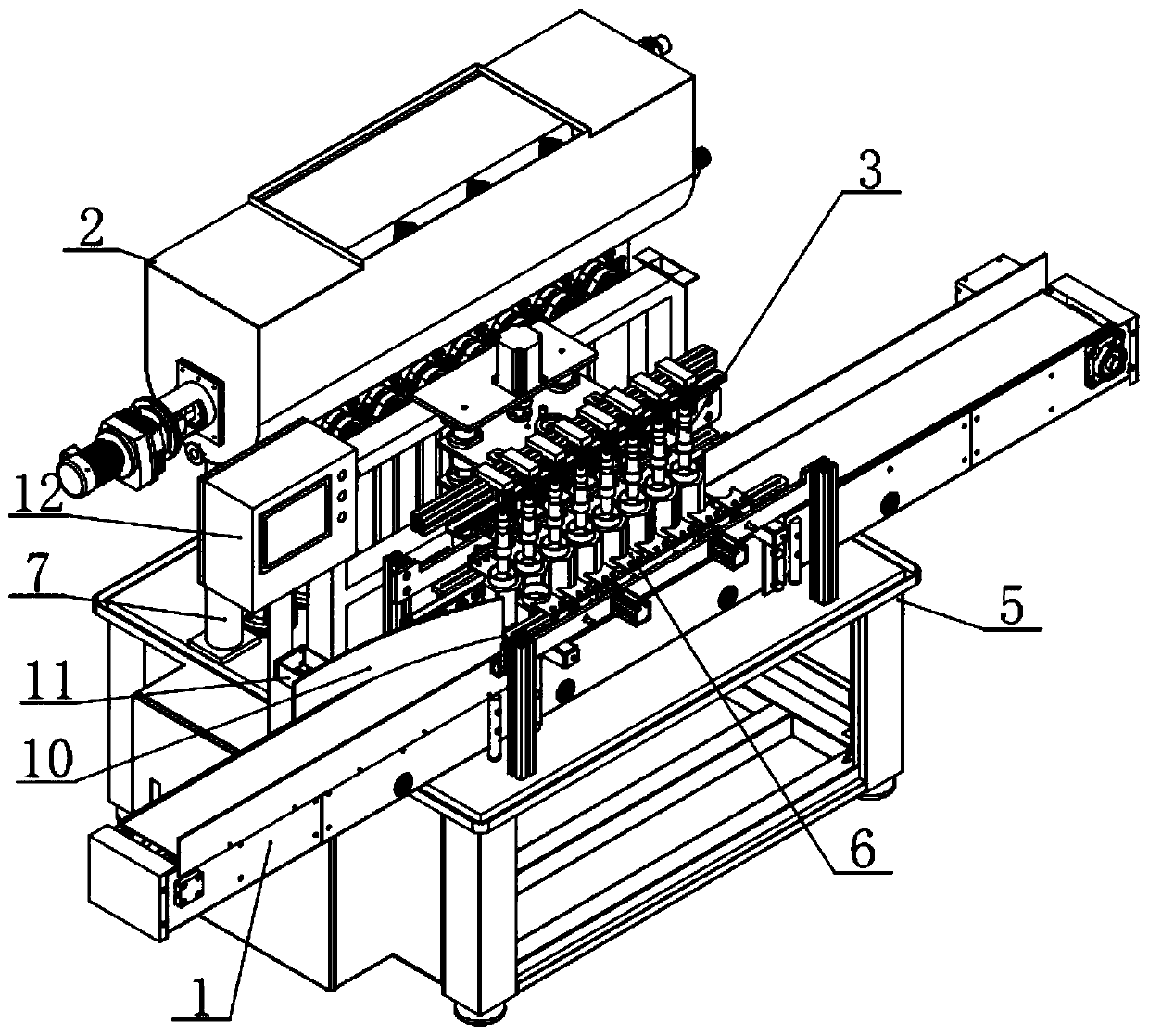

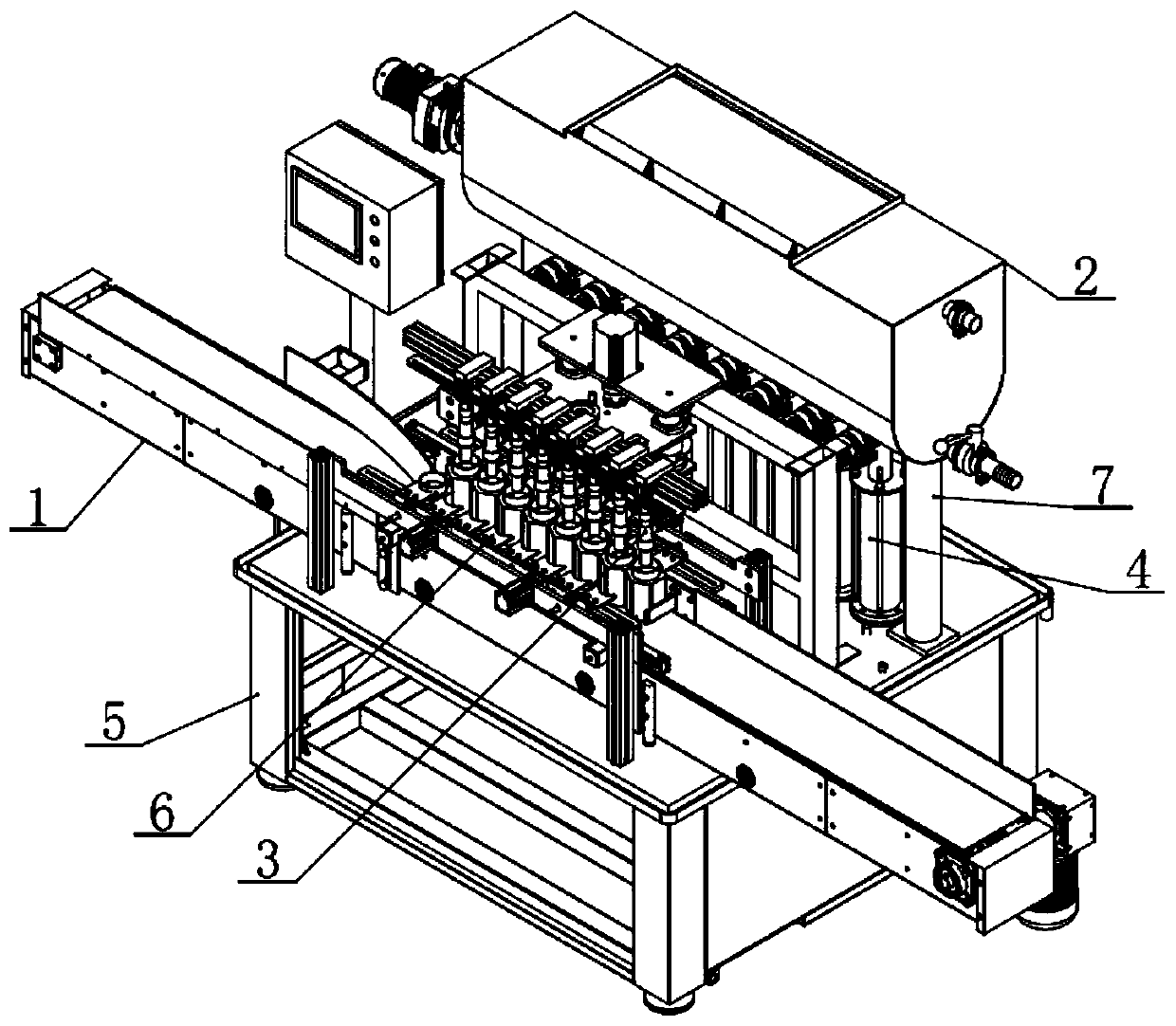

Tracking type self-filling machine and method thereof

InactiveCN105084276AImprove filling efficiencyHigh filling accuracyFilling without pressureEngineeringAssembly line

The invention discloses a tracking type self-filling machine and a method thereof. The self-filling machine comprises an assembly line and a filling mechanism. The assembly line is used for conveying filled bottles. The filling mechanism is arranged on a following mechanism. The filling mechanism is driven by the following mechanism to track the filled bottles on the assembly line and fill the filled bottles in a tracking mode. The tracking type self-filling method comprises the steps that the assembly line carries the filled bottles to run constantly, and the filling mechanism tracks the filled bottles on the assembly line and fills the filled bottles in the tracking mode. According to the tracking type self-filling machine and the method thereof, the filled bottles run on the assembly line constantly and the filling mechanism conducting filling operations is movably installed in a tracking mode, so that tracking filling is achieved when the assembly line keeps running; the filling system is capable of achieving synchronous filling to the filled bottles, so that the filling efficiency and filling precision of the filling system are greatly improved; in addition, the assembly line running constantly is capable of operating stably so that the stability and safety of the system can be ensured.

Owner:XIAMEN UNIV OF TECH

Bottle lifting device for filling machine

The invention relates to a bottle lifting device for a filling machine. The bottle lifting device comprises a false cup, a bottle clamping plate, and a cylinder which is arranged above a filling valve; a roller seat on which a roller is arranged is arranged on a telescopic part of the cylinder; guide rods are respectively arranged at two sides of the roller seat; one end of each guide rod, far away from the roller seat, is connected with the false cup; the bottom end of the false cup is connected with the bottle clamping plate; the false cup is positioned below an opening of the filling valve; axes of the cylinder and the filling valve and a longitudinal center line of the roller are overlapped. According to the bottle lifting device for the filling machine, the roller, the false cup, the bottle clamping plate, the filling valve and the cylinder are connected as a whole structure; the cost is small; when in filling, the cylinder upwards moves under the effect of compacted air, and the bottle clamping plate is driven by the roller seat together with the guide rods to move upwards, so as to prop a bottle opening to the opening of the valve for filling; after the filling, the roller downwards moves, and the bottle clamping plate is driven by the guide rods to downwards move, so as to enable a bottle to be separated from the opening of the valve; the force applied during lifting or lowering is concentrated in the direction of the axis of the filling valve, so that the filling precision can be effectively increased.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

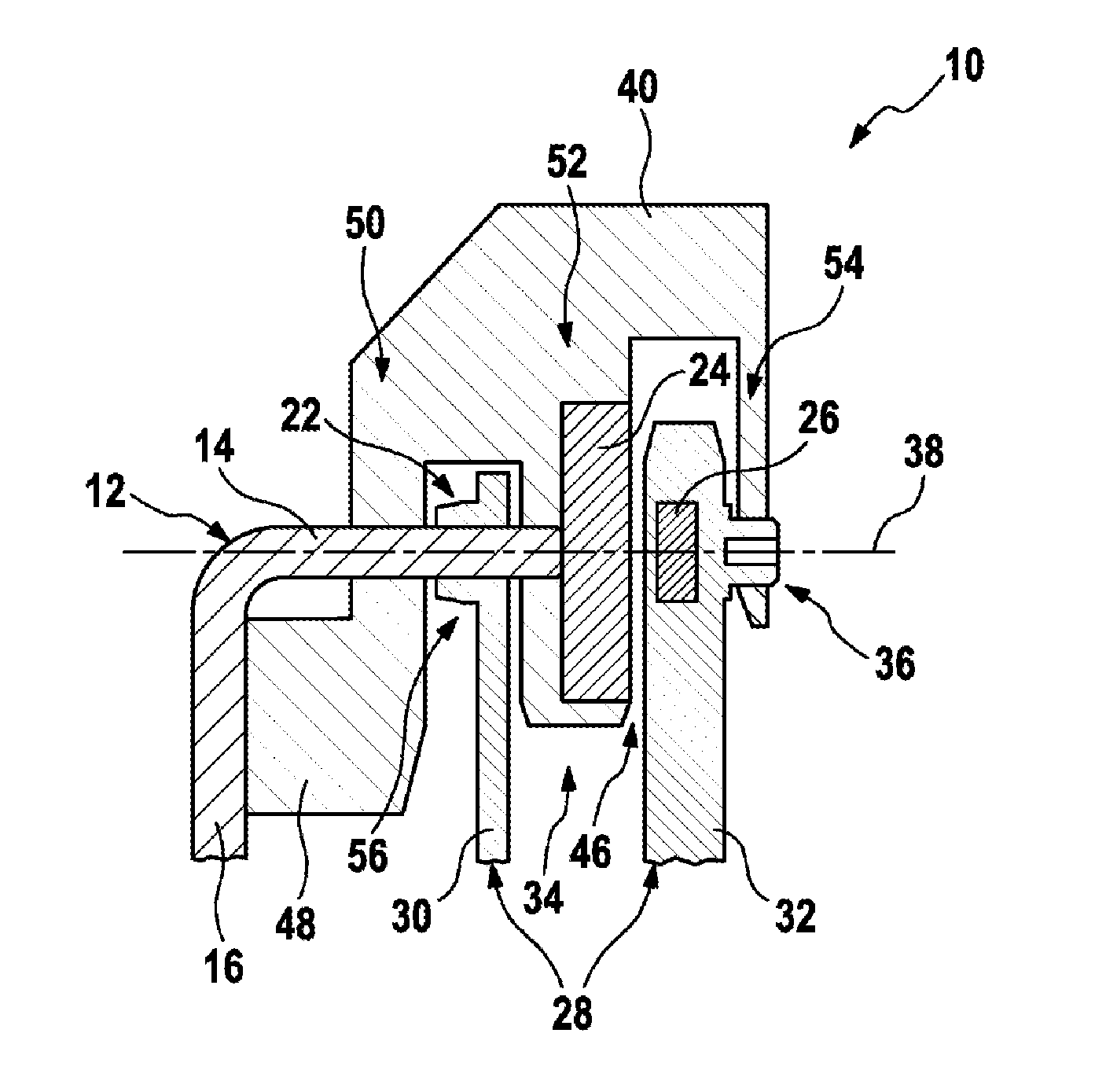

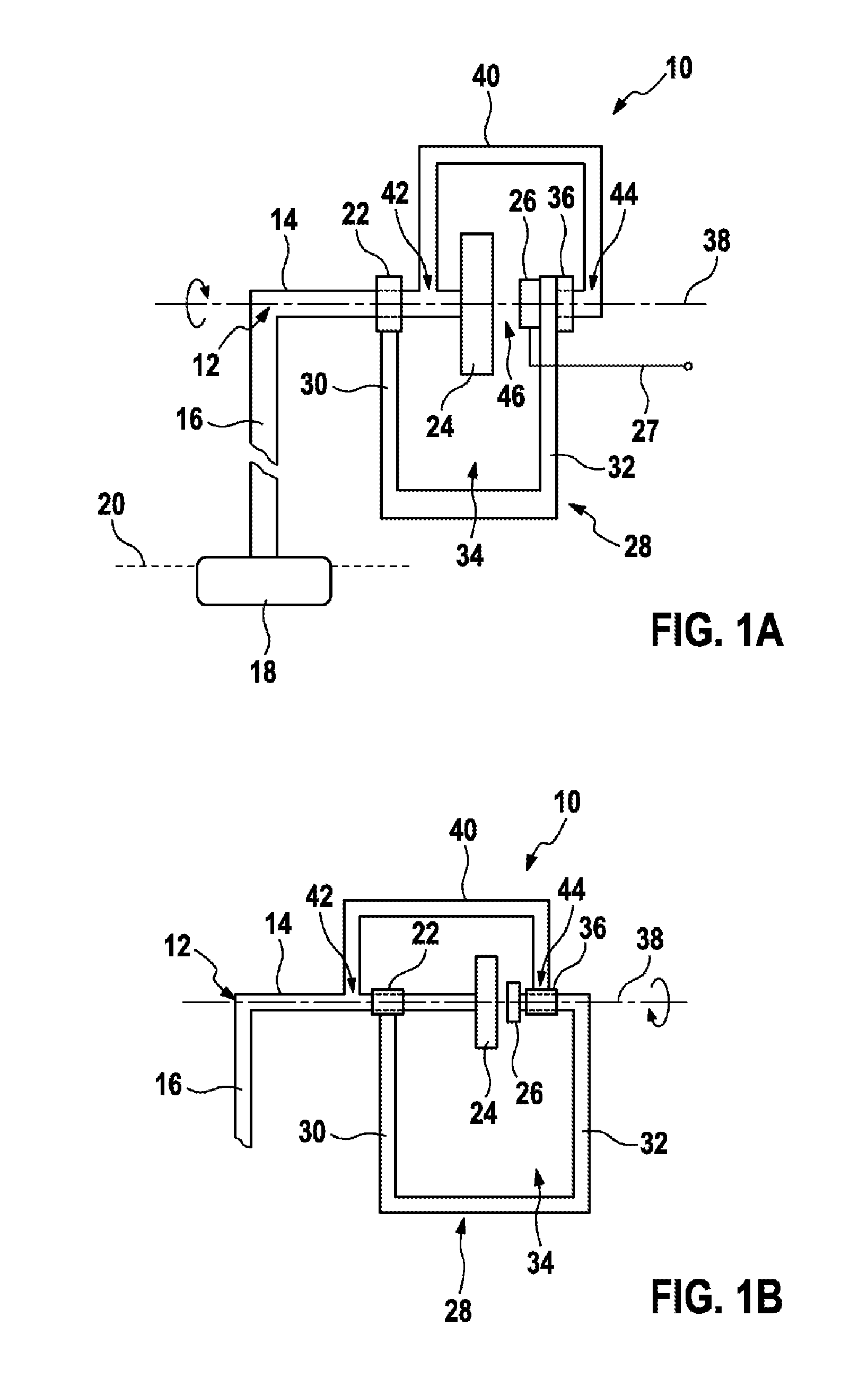

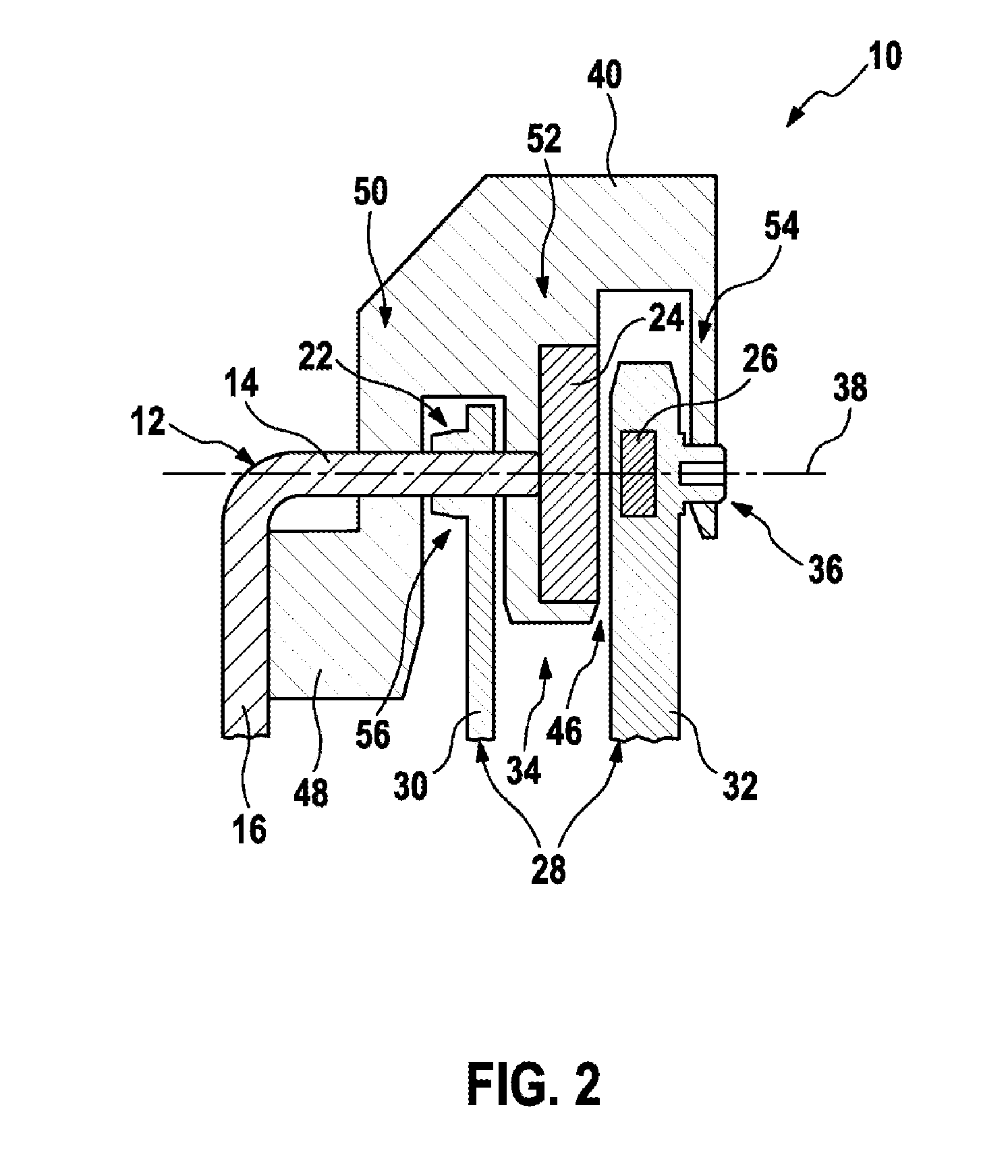

Measuring apparatus for the filling level of a container

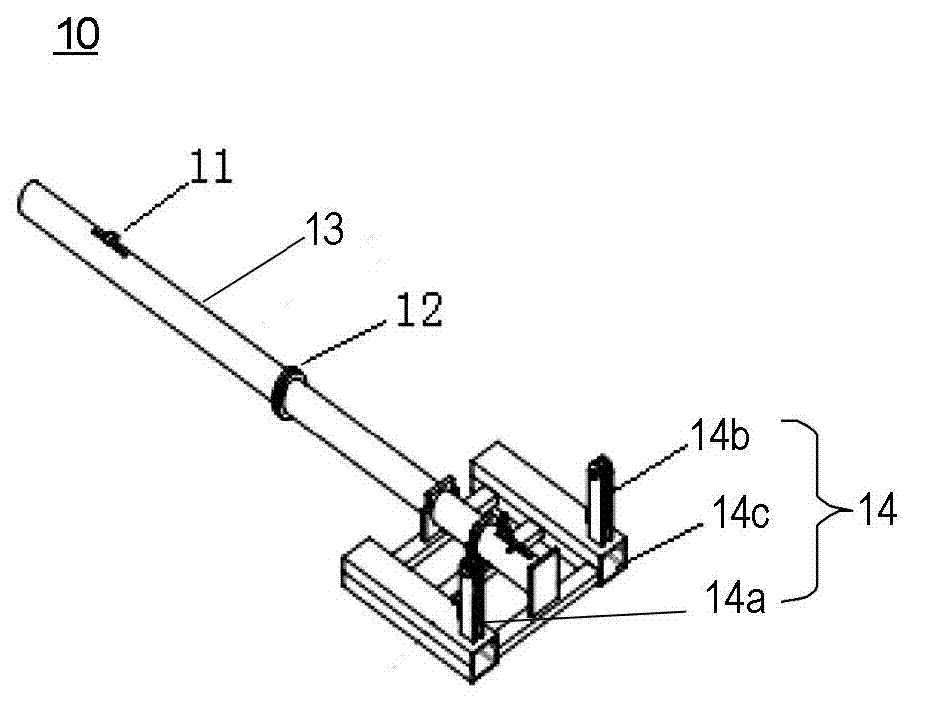

InactiveUS20160178427A1Easy to adaptEasy to implementMachines/enginesLubrication indication devicesEngineeringIntermediate space

The invention relates to a measuring apparatus (10) for measuring a filling level of a container, which measuring apparatus has a measuring arm (12) with a float element (18) which is designed to change its angular position about a rotation axis (38) depending on the filling level. A magnet element (24) is connected to one end of the measuring arm (12) in a rotationally fixed manner. A magnet-sensitive element (26) is designed to output a measurement signal (27) depending on the angular position of the magnet element (24). The measuring apparatus (10) is characterized in that the measuring arm (12) is mounted in a first bearing (22) and additionally in a second bearing (36), wherein the magnet element (24) is arranged in an intermediate space (34) between the first bearing (22) and the second bearing (36).

Owner:ROBERT BOSCH GMBH

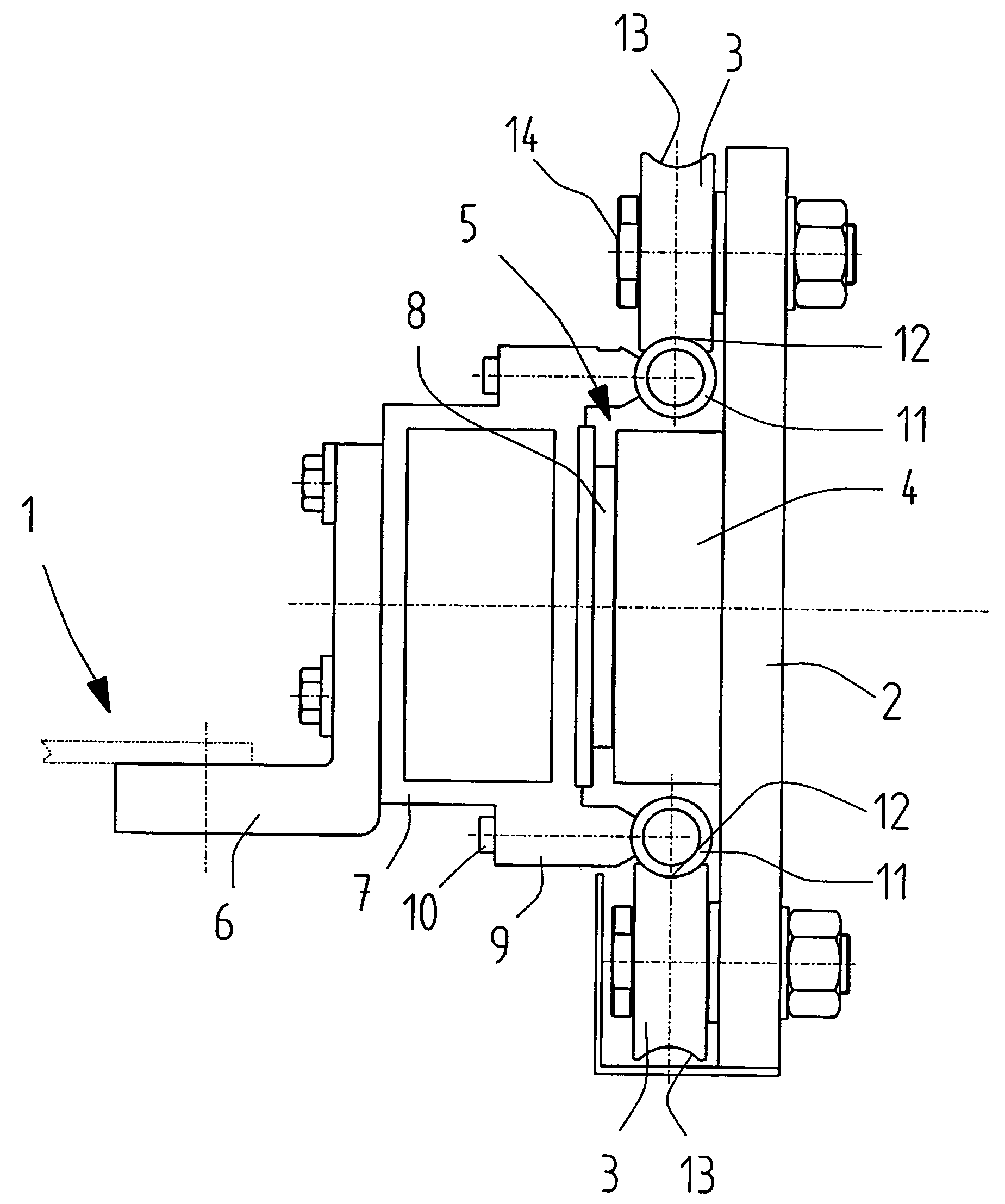

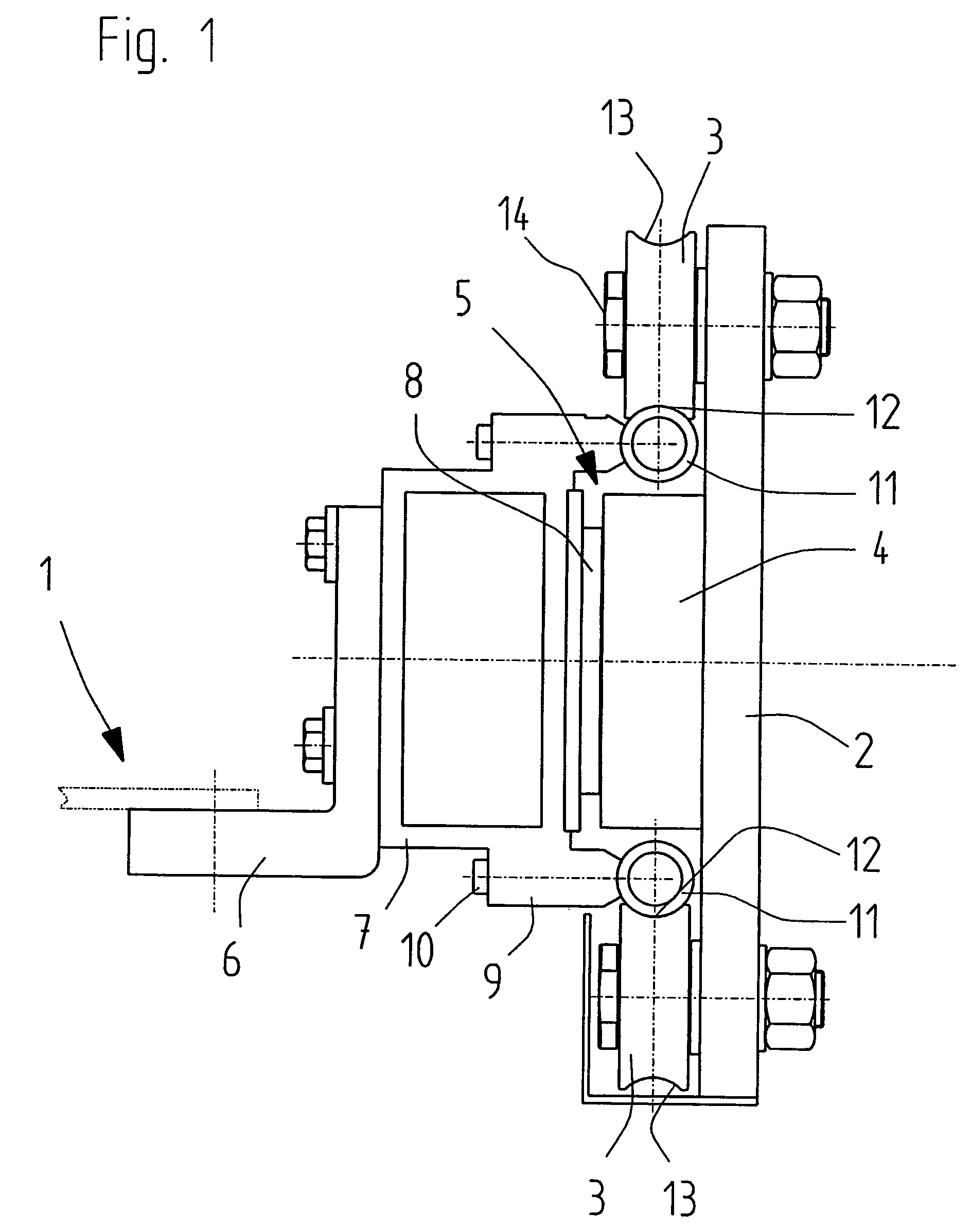

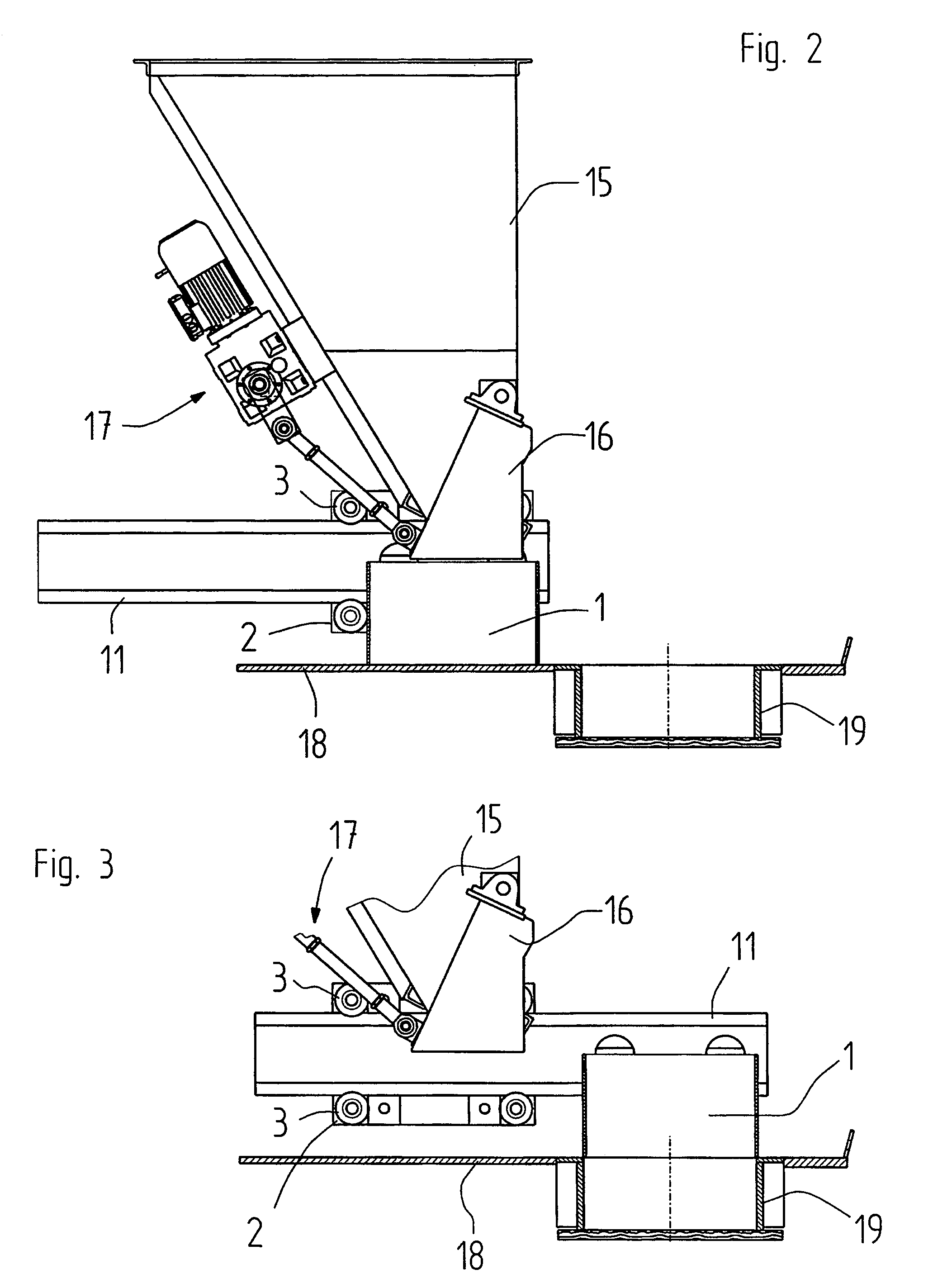

Concrete-block-making machine

The invention relates to a concrete-block-making machine having a part which is displaceable via a linear drive, the linear drive comprising a drive unit and a linear guide for guide rollers, the drive unit comprising at least one linear motor and the linear guide comprising at least one guide rod for the guide rollers, the at least one guide rod and the guide rollers movable relative thereto being hardened, and guide rollers and guide rod being arranged with slight play relative to one another.

Owner:HESS MASCHFAB

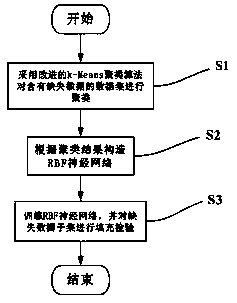

Power missing data filling method based on hybrid strategy

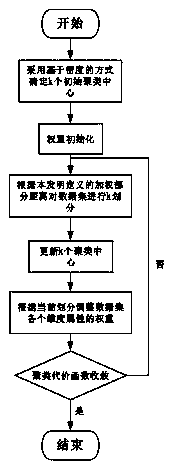

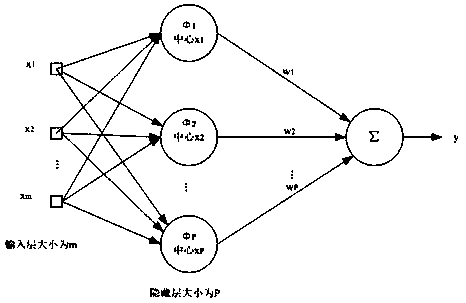

ActiveCN108805193AImprove accuracyReduce the impactCharacter and pattern recognitionNeural learning methodsData setMissing data

The invention relates to the technical field of power data cleaning, in particular to a power missing data filling method based on a hybrid strategy. The method comprises the steps that S1, an improved k-Means clustering algorithm is adopted to perform clustering on a dataset containing missing data; S2, an RBF neural network is improved and constructed according to the clustering result; and S3,the RBF neural network is trained, and filling checking is performed on the missing data. Through the method, clustering of the dataset with missing properties is well realized, and the RBF neural network is designed in combination with the clustering result to perform prediction filling on missing values. Besides, the filling precision of the missing data is improved, implementation is easy and convenient, calculation expenditure is appropriate, and the method has high practical value against the problem that a large amount of data generated in the operation and maintenance process of a powersystem is missed and damaged due to the influences of physical factors, software factors and other factors.

Owner:GUANGDONG POWER GRID CO LTD +1

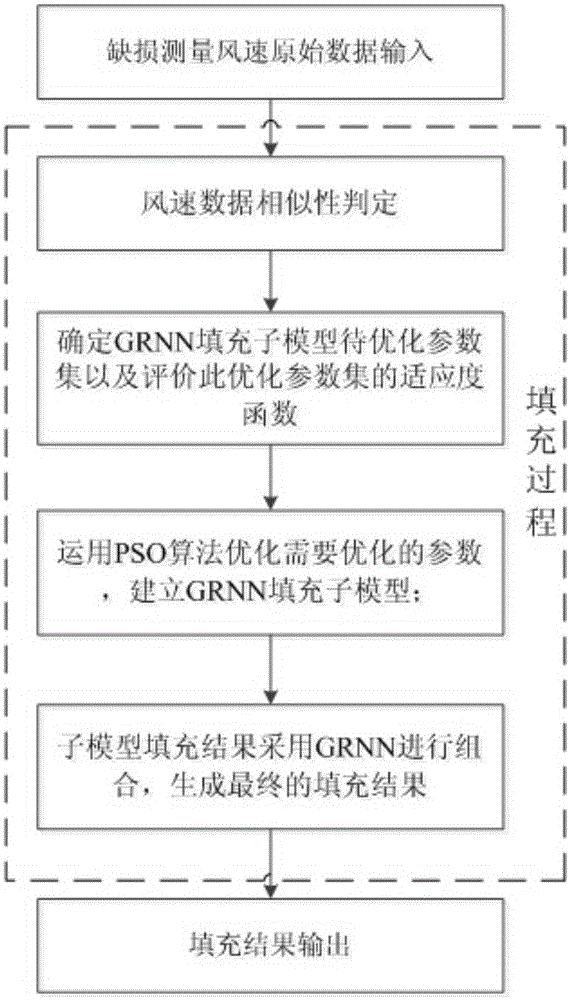

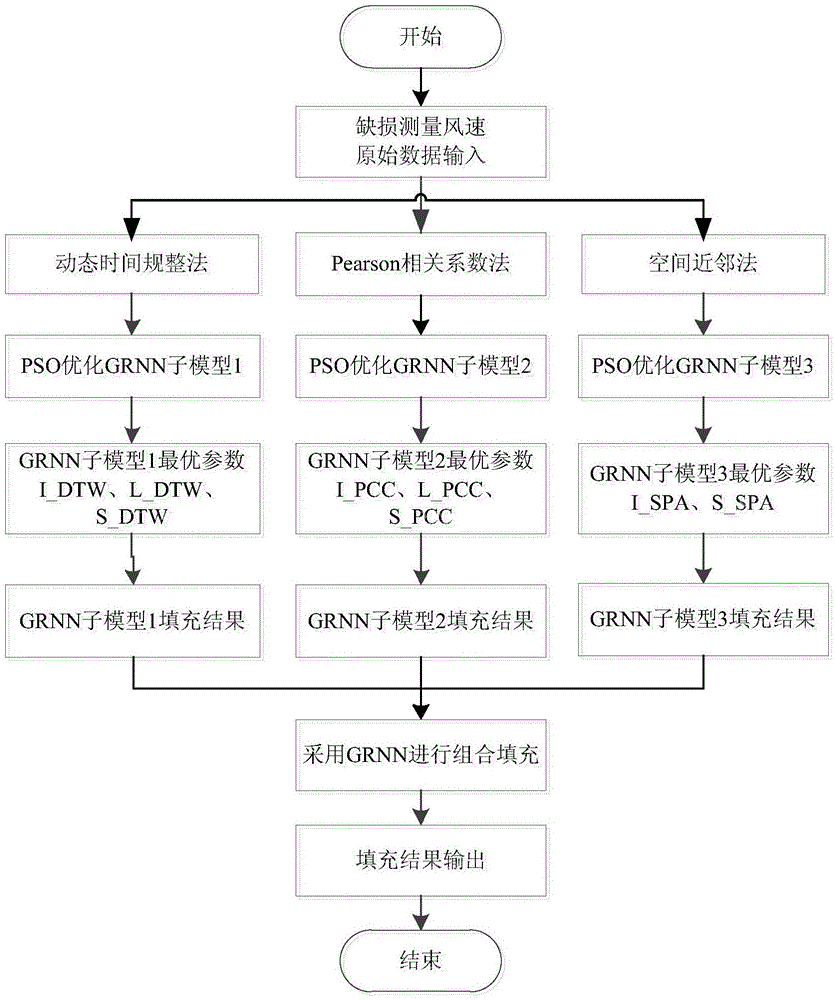

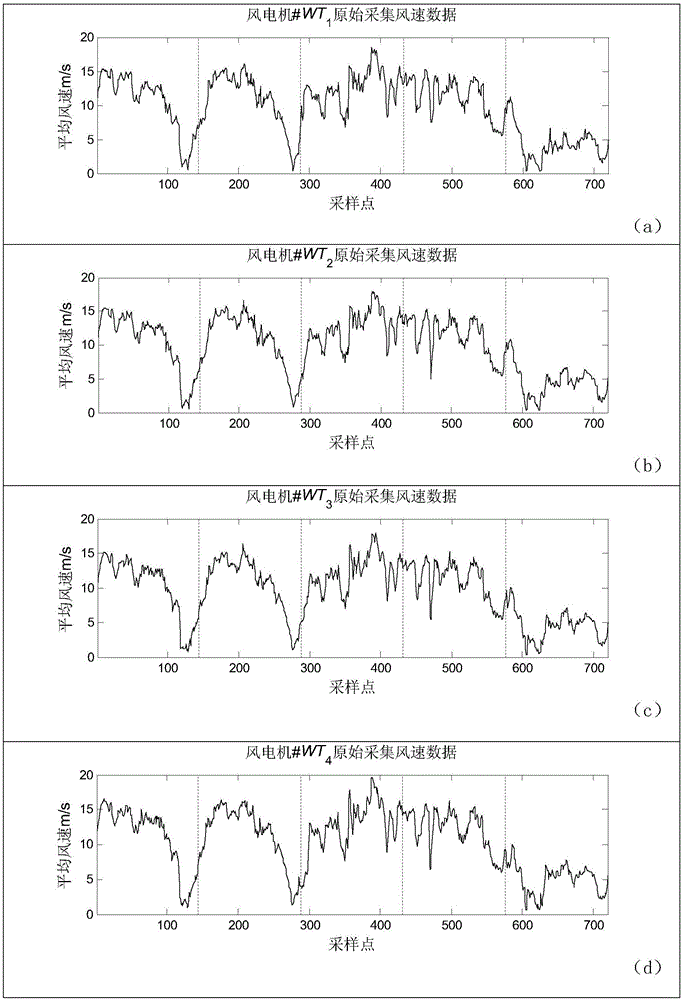

Filling method based on PSO-GRNN (Particle Swarm Optimization-Generalized Regression Neural Network) for defect wind speed values of wind turbines in wind power plant

ActiveCN105138729AHigh filling accuracyHigh precisionSpecial data processing applicationsParticle swarm optimizationEngineering

Owner:墨染微泽软件信息服务(南京)有限责任公司

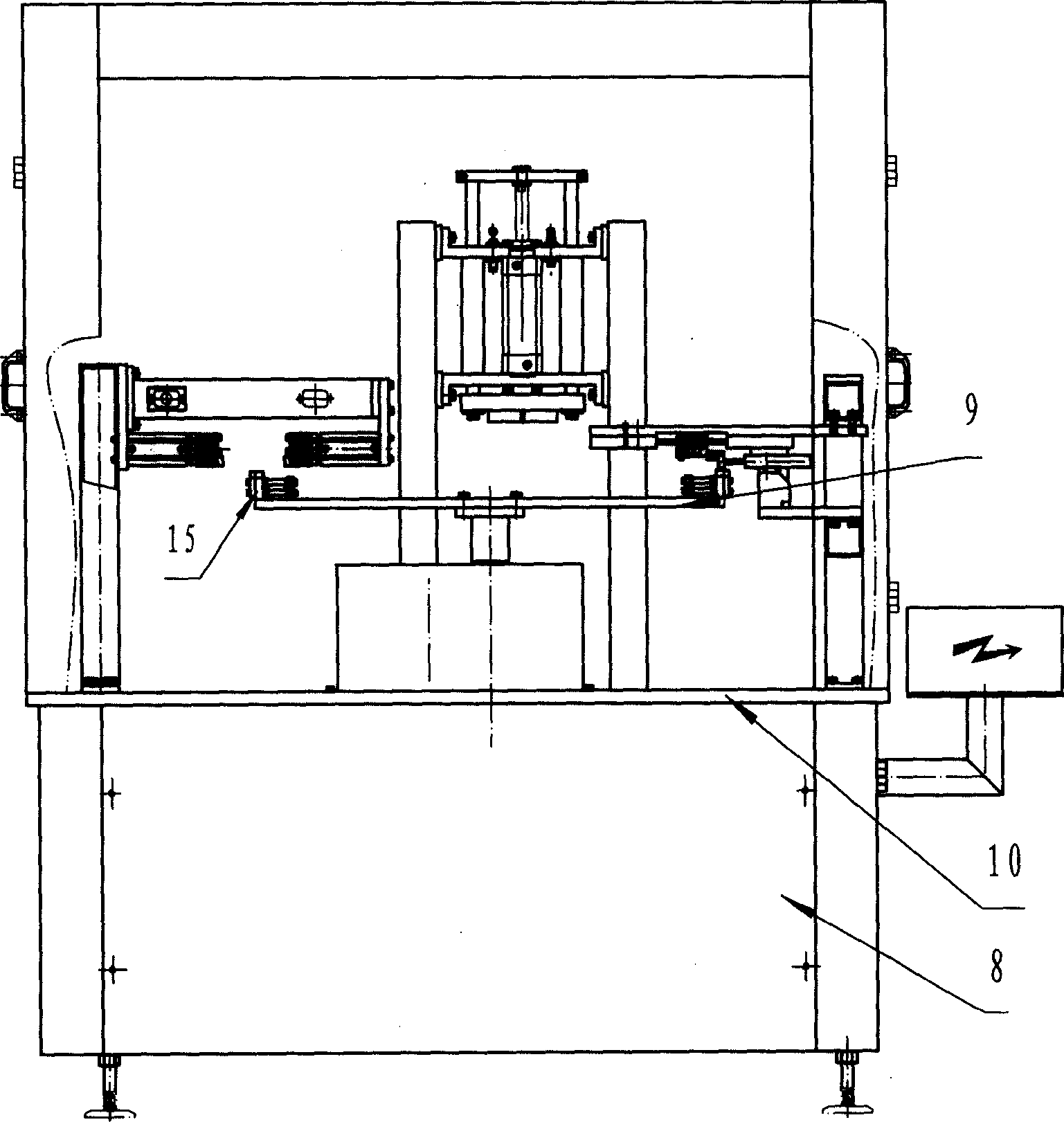

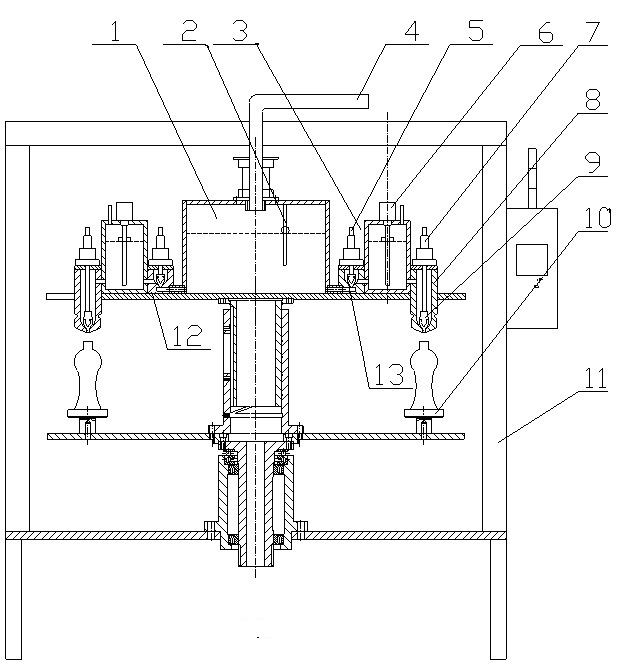

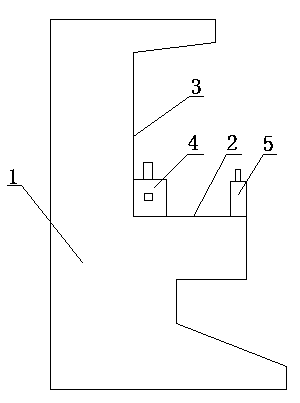

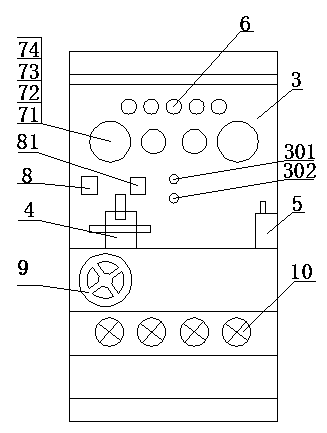

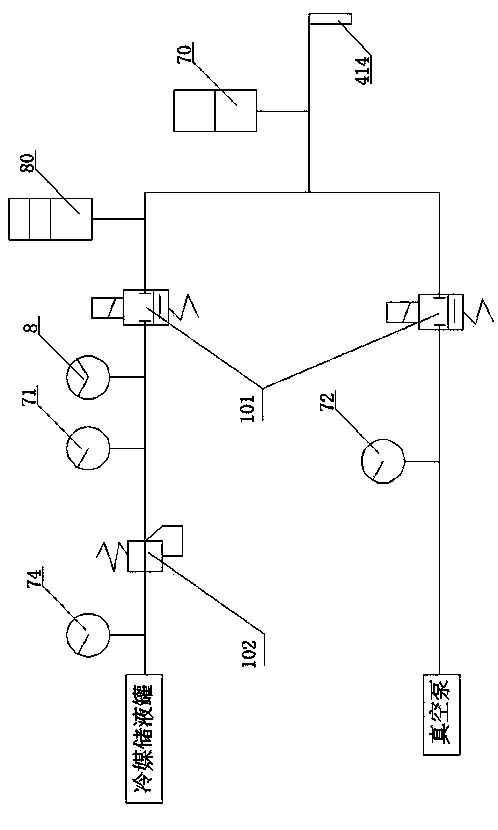

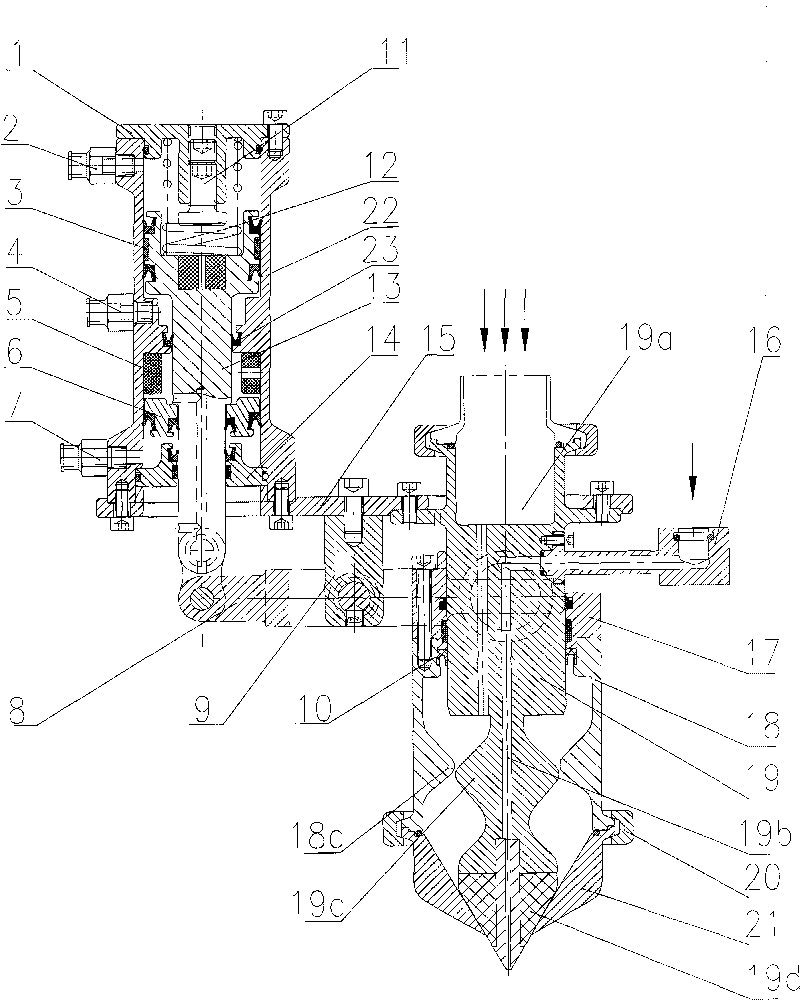

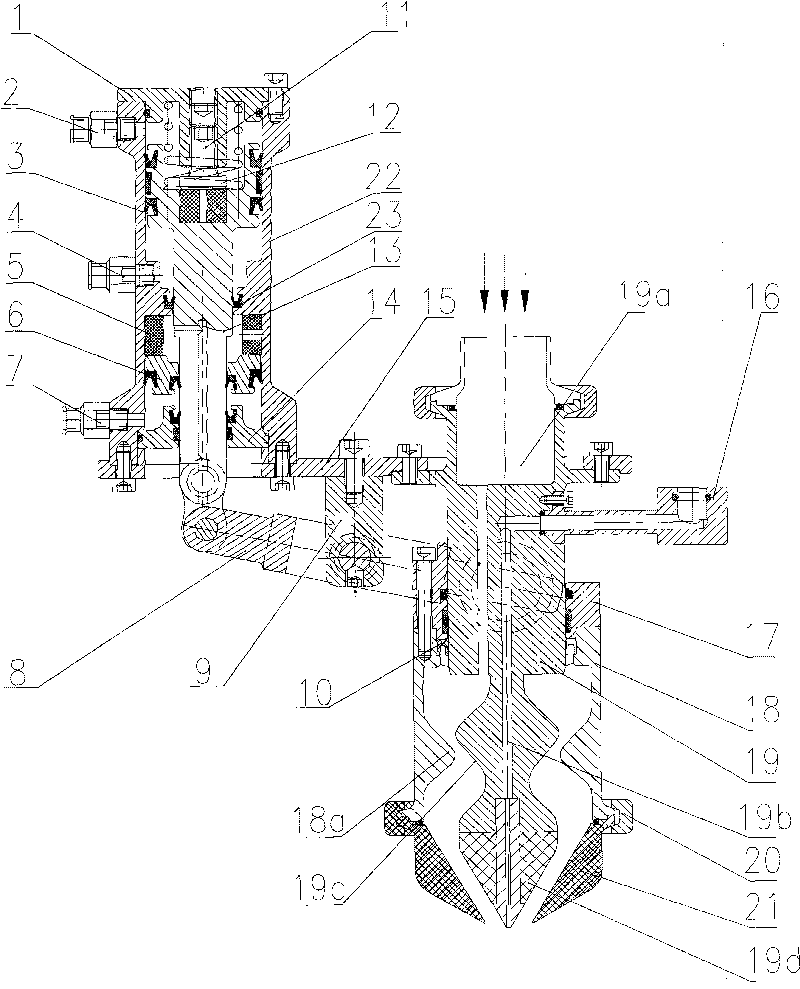

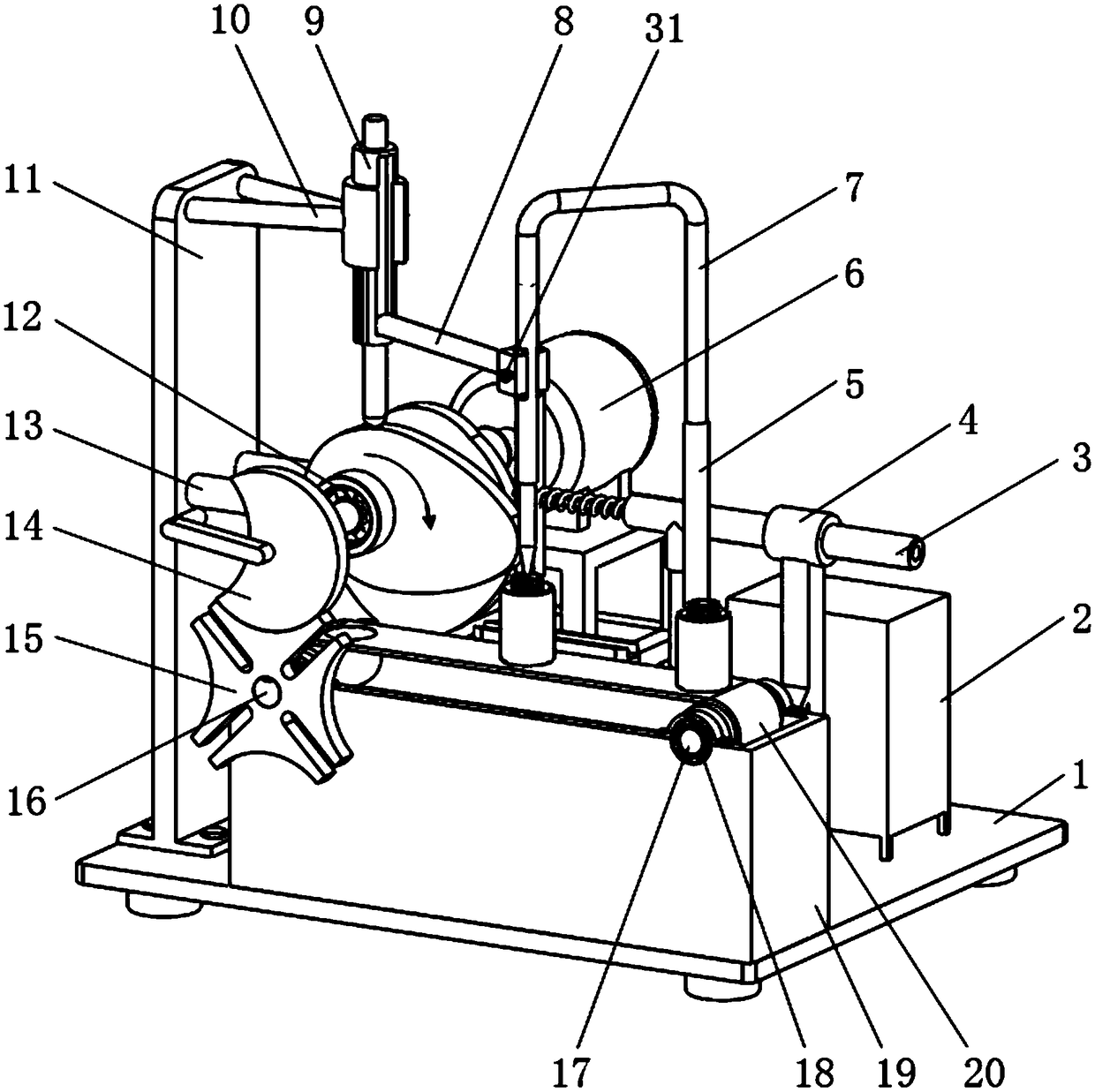

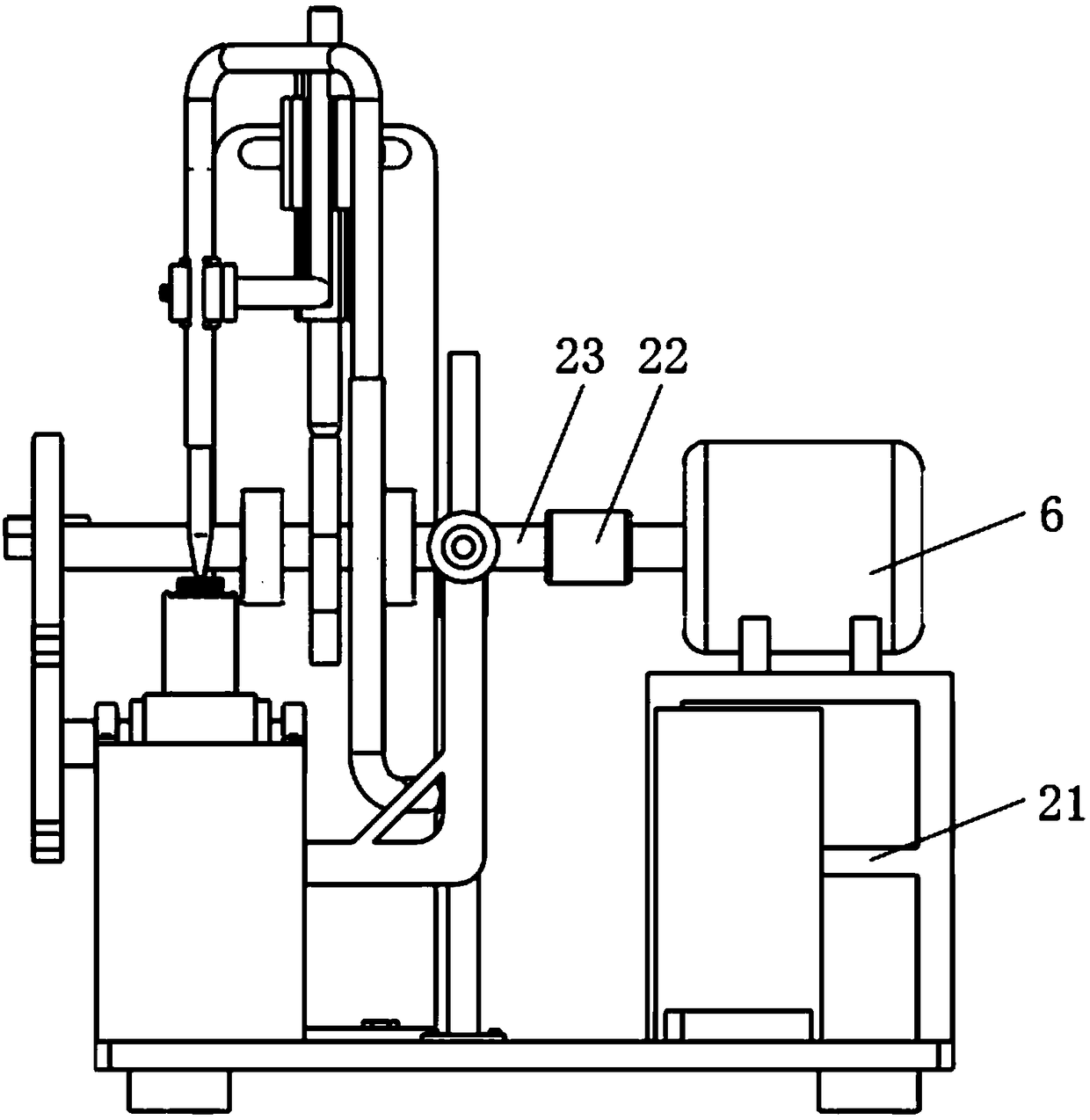

Method and equipment for filling liquid in temperature sensing bulb of thermostatic expansion valve

InactiveCN103388943AImprove sealingExtended service lifeMechanical apparatusFluid circulation arrangementAir compressorVacuum pump

The invention discloses a method and equipment for filling liquid in a temperature sensing bulb of a thermostatic expansion valve. The method comprises the steps of a) vacuumizing the internal part of the temperature sensing bulb of the thermostatic expansion valve; b) filling refrigerant into the temperature sensing bulb of the thermostatic expansion valve; c) flattening the position of the filling end of the capillary tube of the thermostatic expansion valve in a stamping way to enable the filling end to be sealed, wherein the position is approximately 1cm far away from the mouth of the capillary tube; and d) welding and sealing the mouth of the filling end of the capillary tube of the thermostatic expansion valve. The equipment comprises an equipment main body. A worktable and a control panel are arranged on the front side of the equipment main body. A filling tooling and a welding station are arranged on the worktable. A welding machine, a vacuum pump, a refrigerant storage tank and an air compressor which are connected with the filling tooling are arranged in the worktable. Since the filling process disclosed by the invention is added with a capillary tube mouth welding and sealing process relative to the prior art, the product performance is enabled to be more reliable and the product service life is longer; and the structure of the filling equipment is simple, the automation level is high, the equipment is simple to operate and the filling accuracy is high.

Owner:浙江金丰机械设备有限公司

Rotary weight filler

Owner:SHIBUYA IND CO LTD

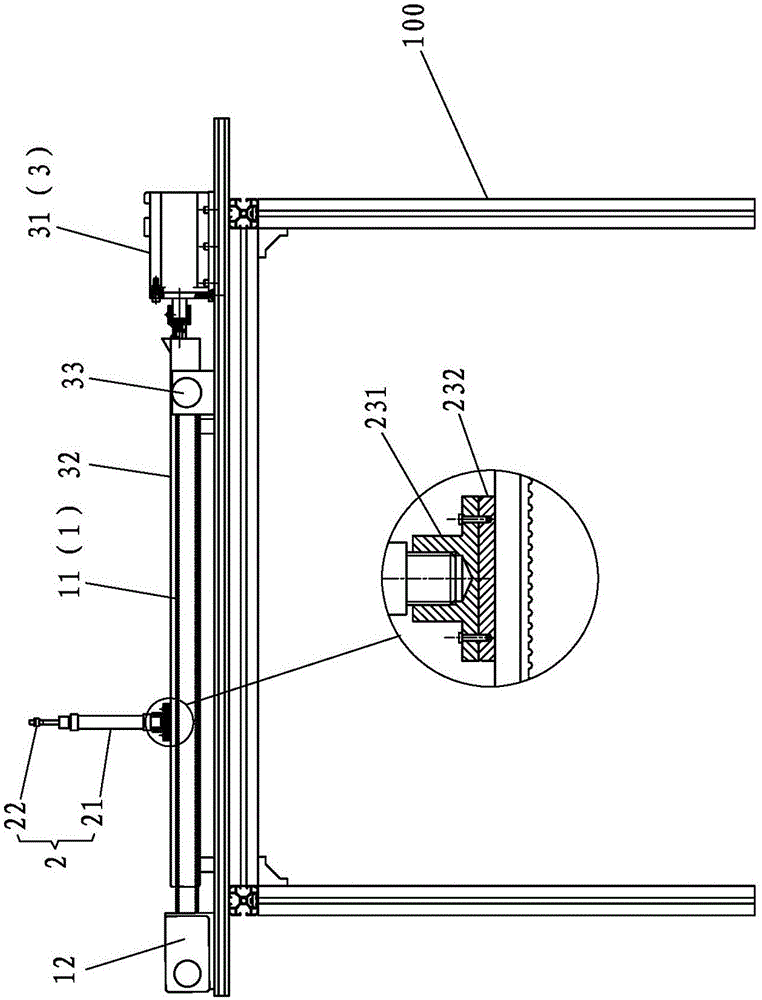

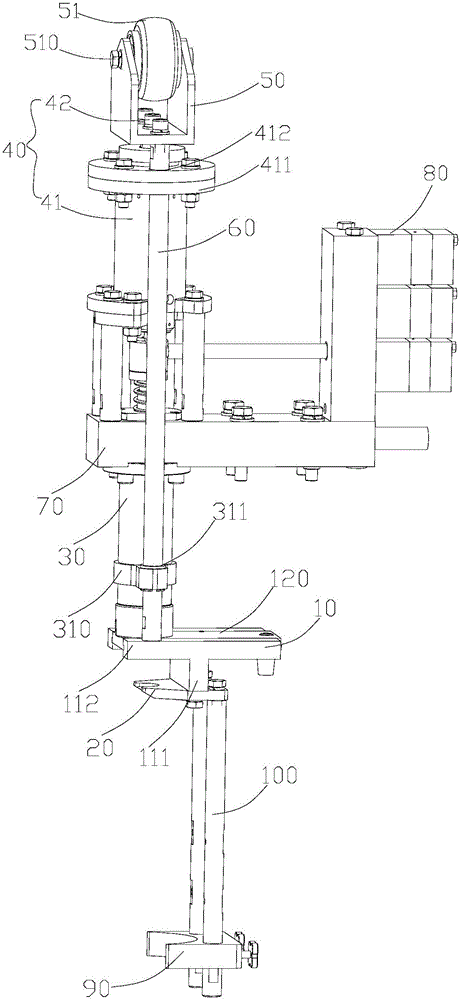

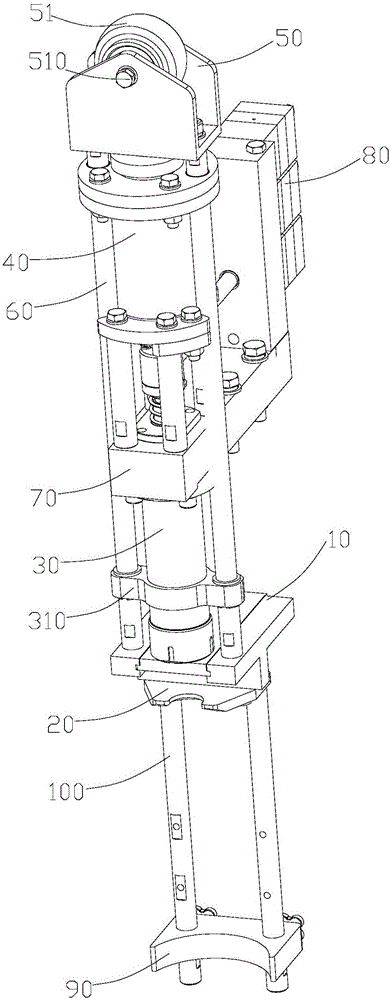

Tap hole replacing device

ActiveCN102899445AChange insertion depthImprove installation accuracyManufacturing convertersInsertion depthElectrical and Electronics engineering

The invention provides a tap hole replacing device. The tap hole replacing device comprises an ejector rod mechanism, and a drive device capable of moving the ejector rod mechanism, wherein the ejector rod mechanism comprises an ejector rod, a blocking part and a limiting part, wherein the exterior of the ejector rod is sleeved with a tap hole; the blocking part and the limiting part are respectively arranged on the outer wall of the ejector rod, the blocking part is at a blocking position or a loosening position along a radial direction of the ejector rod, when the blocking part is at the blocking position, the blocking part and the inner end of a furnace on the tap hole are clamped, when the blocking part is at the loosening position, the inner end of the furnace on the tap hole is loosened by the blocking part, and the limiting part is capable of limiting the motion of the outer end of the furnace on the tap hole so as to prevent the outer end of the furnace from moving to a direction far away from the blocking part. According to the tap hole replacing device, provided by the invention, the insertion depth of the tap hole is changed, the labor intensity is reduced, and the tap hole replacing efficiency is improved.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

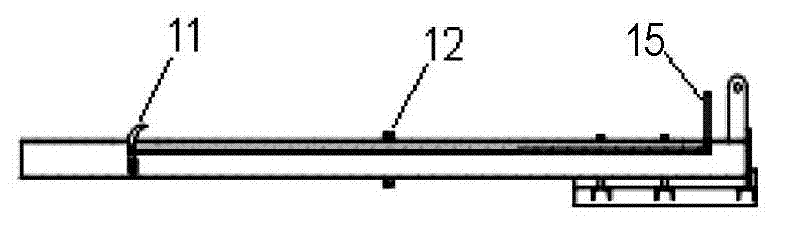

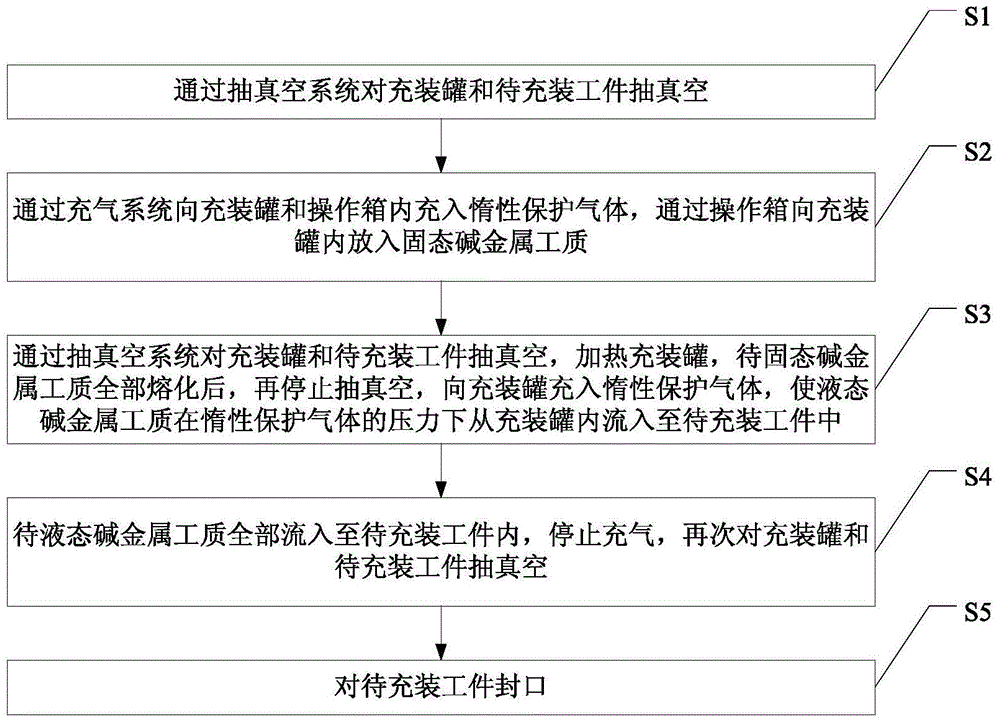

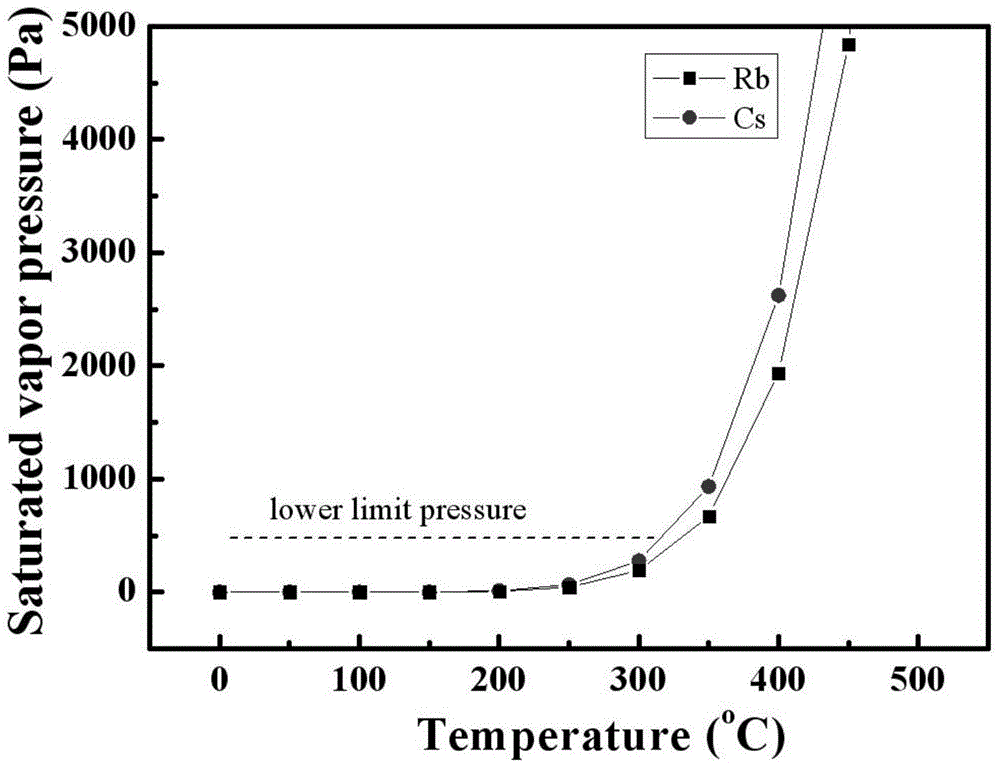

Filling method for low-melting-point alkali metal working mediums

InactiveCN105115328ALow oxidation tendencyReduce quality lossIndirect heat exchangersLiquid stateEngineering

The invention discloses a filling method for low-melting-point alkali metal working mediums. The filling method comprises the following steps: vacuumizing a filling tank and workpieces to be filled through a vacuumizing system; opening a valve, filling the filling tank and an operation box with an inert protection gas through a gas filling system, placing solid-state alkali metal working mediums with a certain mass in the filling tank through the operation box, and closing the valve; vacuumizing the filling tank and the workpieces to be filled through the vacuumizing system, heating the filling tank, and after the solid-state alkali metal working mediums are completely fused, filling the filling tank with the inert protection gas, and enabling the liquid-state alkali metal working mediums to flow into the workpieces to be filled from the filling tank under the pressure of the inert protection gas; stopping the gas filling, and vacuumizing the filling tank and the workpieces to be filled again; and sealing the workpieces to be filled. The filling method disclosed by the invention realizes the filling process by virtue of the inert protection gas, and the oxidation tendency of the low-melting-point alkali metal working mediums is low; and the mass loss is low and the filling accuracy is high.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Liquid filling device with adjustable fill quantity

InactiveCN101759129AReduce Pollution PotentialMeet hygiene requirementsLiquid bottlingNitrogenEngineering

The invention discloses a liquid filling device with adjustable fill quantity, comprising a tapered filling valve fixed on a mounting seat and a driving device, wherein the tapered filling valve comprises a valve casing and a valve core capable of moving in the valve casing relatively to the valve casing, the lower end of the valve core is provided with a tapered valve head, the valve casing is provided with a tapered discharge hole, and the discharge hole is matched with the valve head; the liquid filling device is characterized in that the valve casing or the valve core is connected with the driving device through a lever transmission device. In the invention, a driving cylinder is completely separated with the filling valve, thereby reducing hidden trouble of product pollution; the unique valve-core structure can ensure that the filling products are bunched turbulently under the condition of without a filter screen member, thus being more in accordance with sanitary requirement; in addition, the device has the function of charging nitrogen and can meet the requirement of filling high-grade oils.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

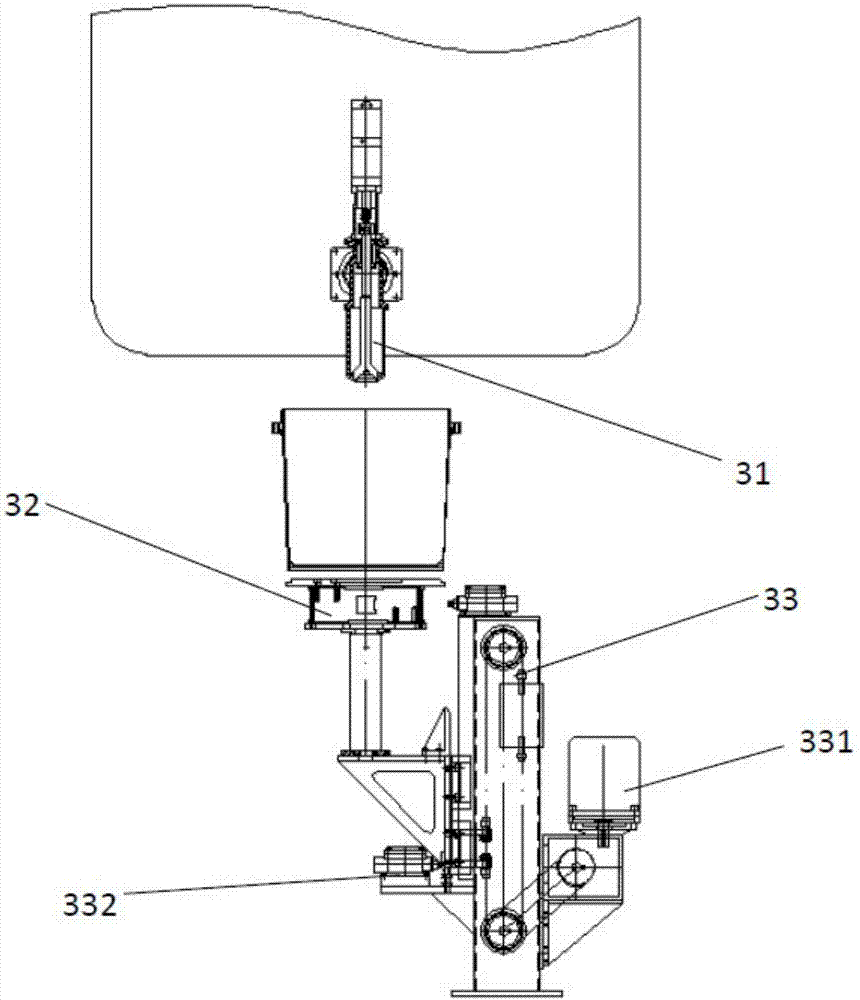

Quantitative filling device for blend oil packing

InactiveCN109264050AControl suction and dischargeHigh filling accuracyLiquid materialMechanical engineeringPiston

The invention relates to a quantitative filling device for blend oil packing. The quantitative filling device comprises a worktable, a mounting plate is arranged above the worktable, the mounting plate is fixed on the worktable through a bearing pole, a bearing box is mounted on the mounting plate, an adjusting screw rod is penetratingly mounted in the bearing box, an adjusting plate is arranged above the mounting plate, an adjusting sleeve is penetratingly mounted on the adjusting plate, an annular oil pool is arranged on the mounting plate, an oil supplying tube is arranged on the annular oil pool in a communicated manner, a plurality of precise quantifying mechanisms are vertically mounted on the mounting plate, every cylinder is vertically and penetratingly mounted on the mounting plate, an upper end of every piston is mounted on the adjusting plate in a threaded manner and fixed on the adjusting plate through a nut, and every inlet tube penetrates through the mounting plate and iscommunicated with the annular oil pool. The quantitative filling device for blend oil packing has the advantage that filling precision is improved.

Owner:CHONGQING ZHIQINGYANG GREASE CO LTD

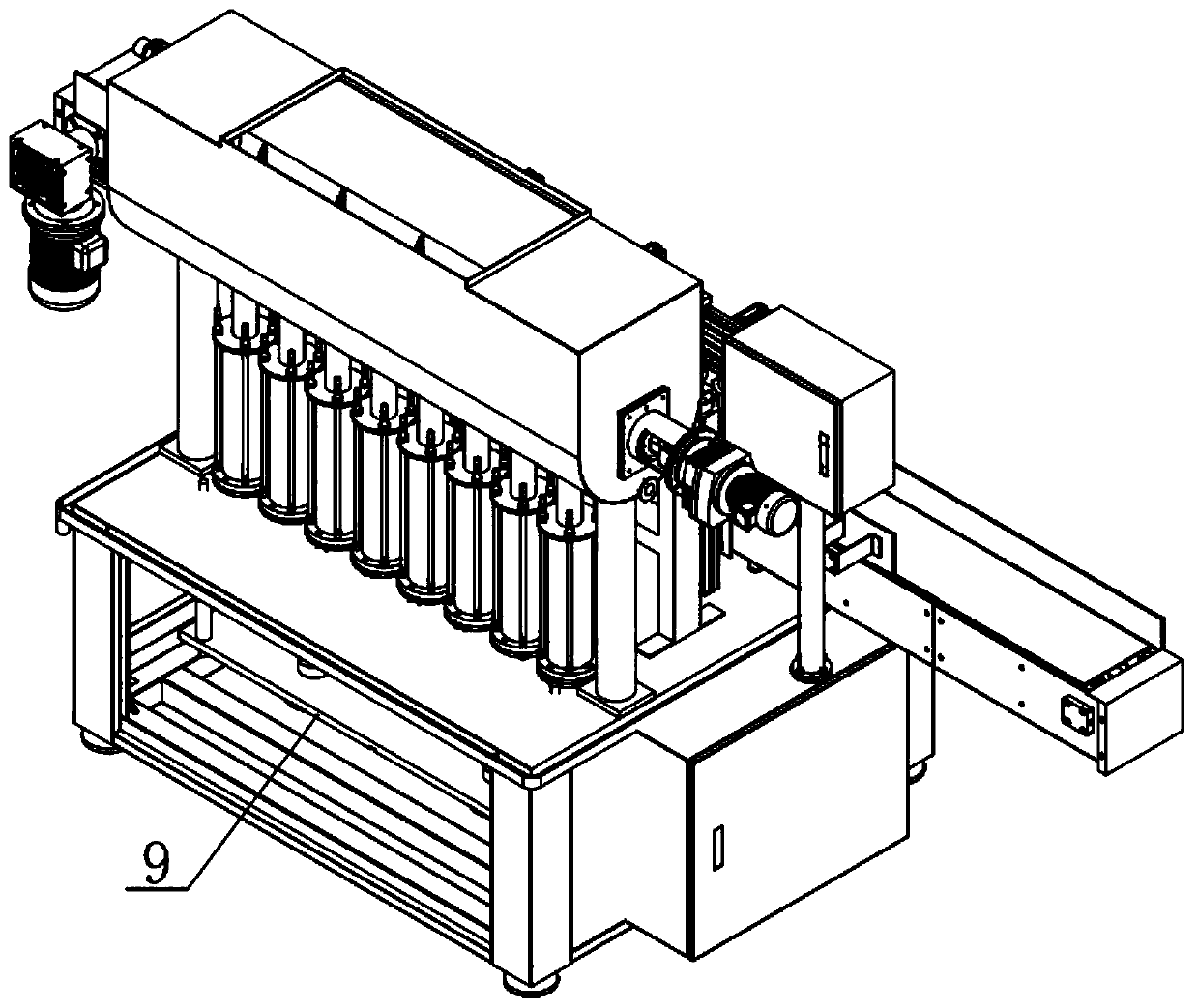

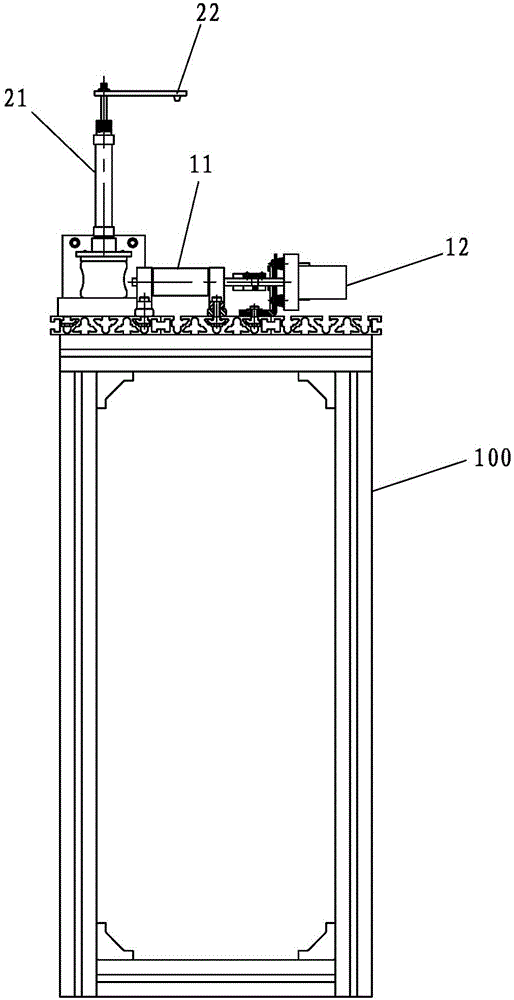

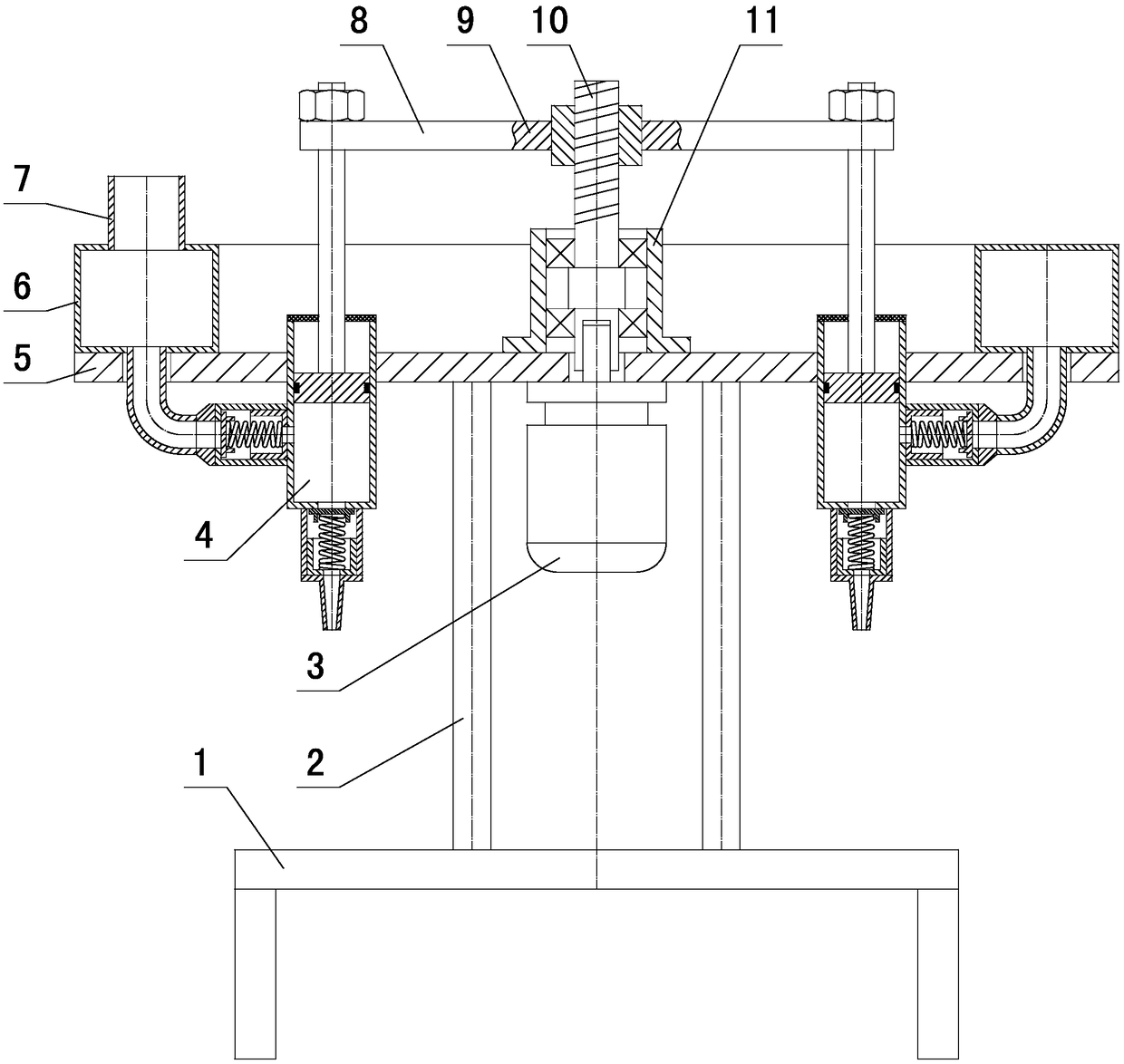

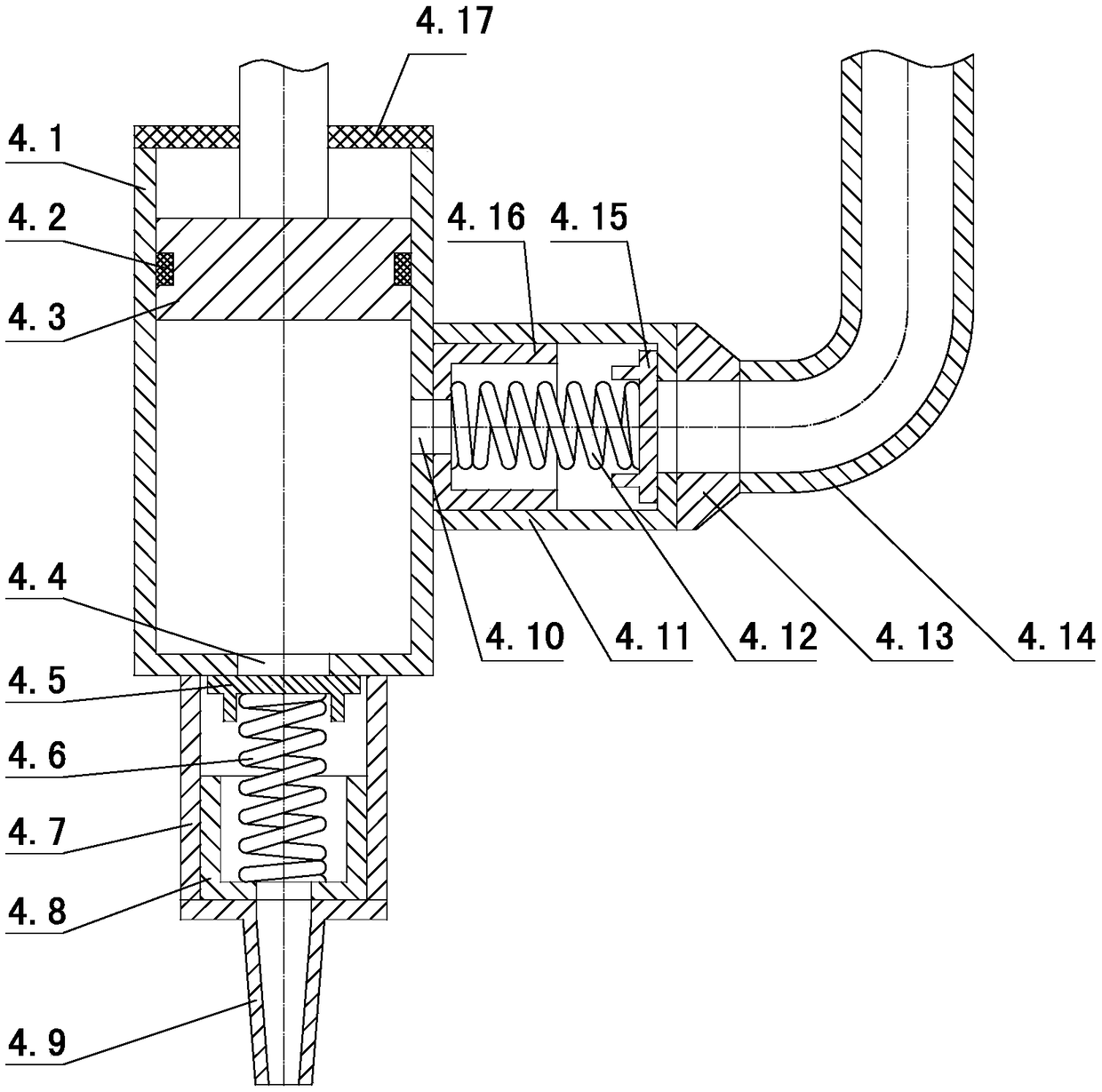

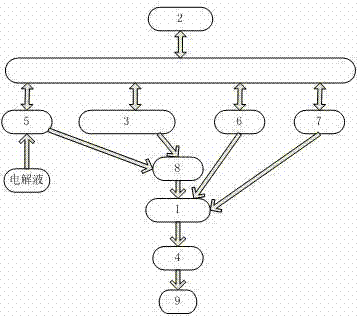

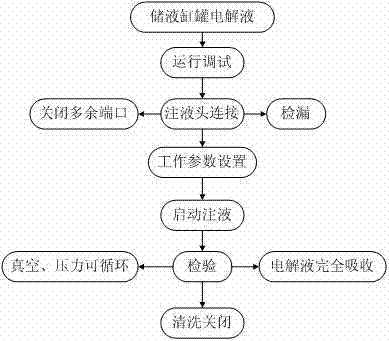

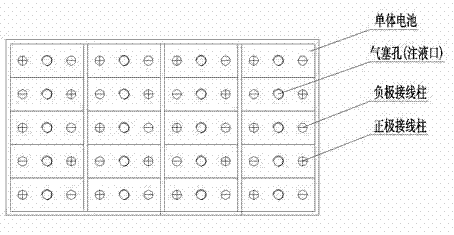

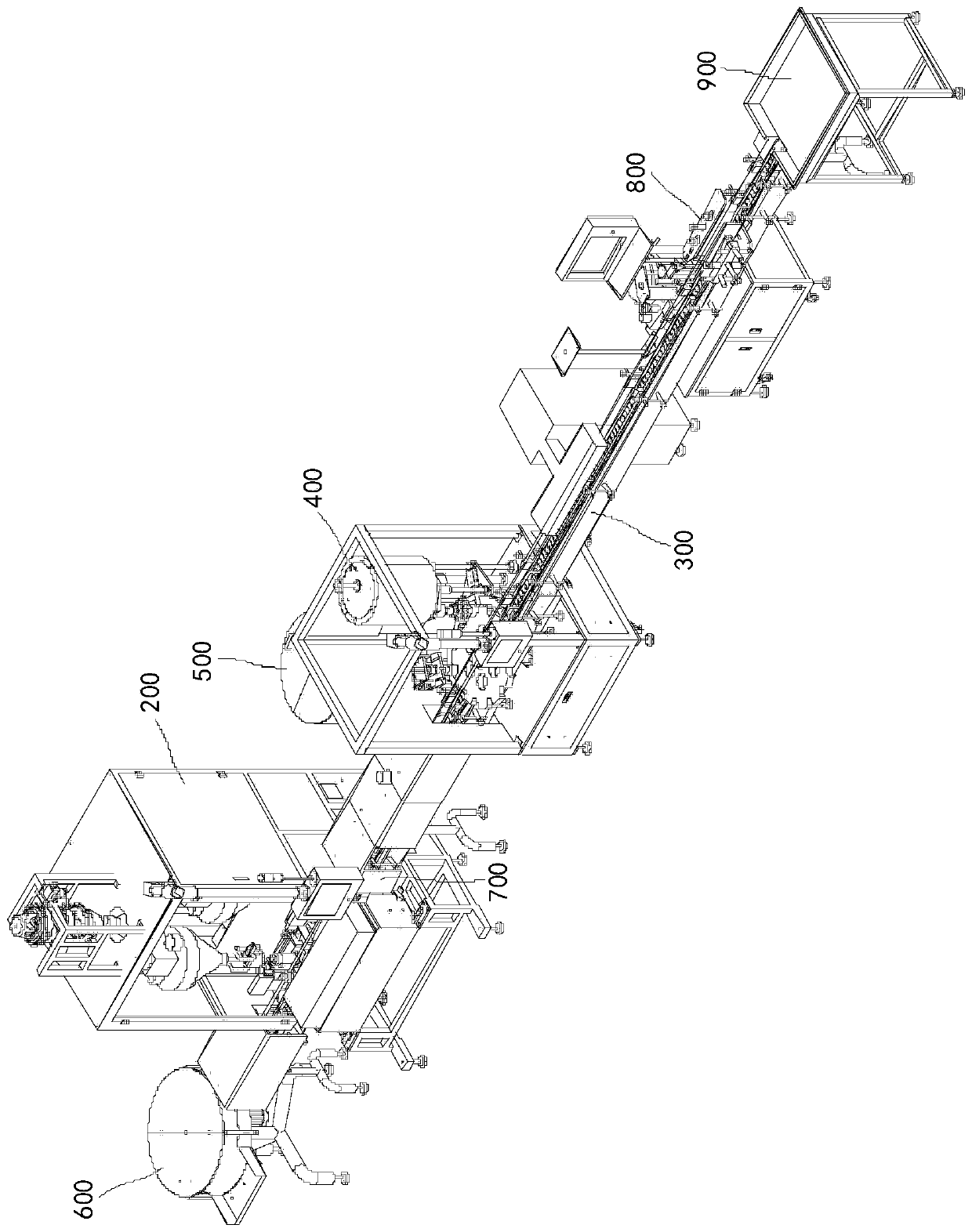

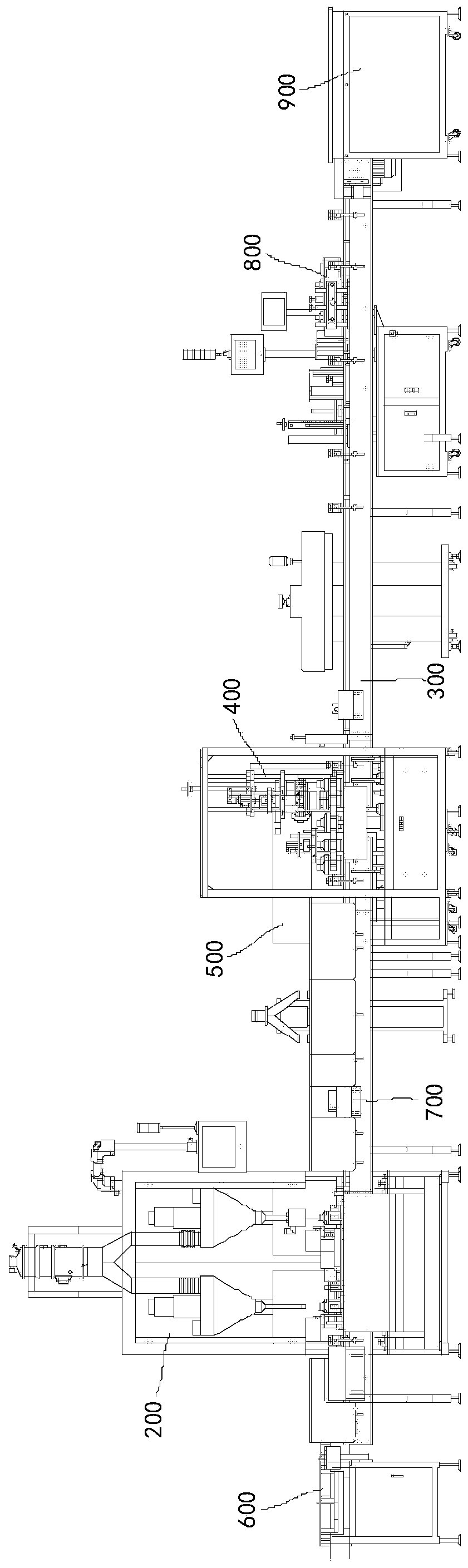

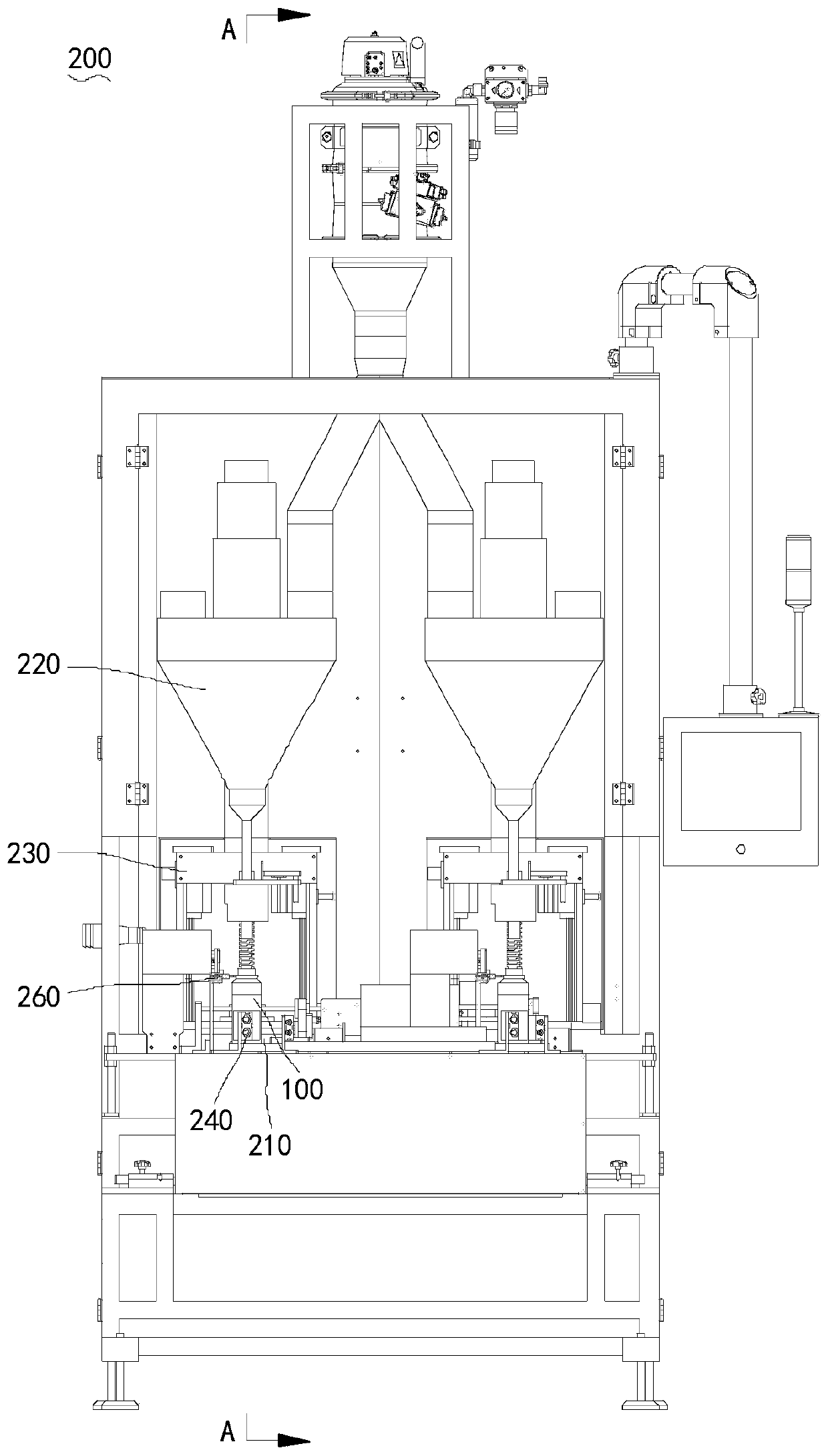

Vacuum automatic charging system of silver-zinc secondary battery electrolyte and method thereof

ActiveCN104518196AHigh filling accuracyPrevent leakageCell component detailsAlkaline accumulators manufactureAir compressorScrew thread

The invention provides a vacuum automatic charging system of a silver-zinc secondary battery electrolyte and a method thereof. The system comprises a cup value module, a transverse stretching module, a mobile servo mechanism, a liquid charge head, a liquid charge pump, a vacuum pump, an air compressor, and a liquid charge needle, wherein the cup value module is connected to the liquid charge head and the liquid charge needle; the liquid charge pump pumps an electrolyte stored in a barrel into the liquid charge needle, and pumps the electrolyte into a liquid storage cylinder; the vacuum pump vacuumizes the whole liquid inlet system including a battery to maintain a liquid inlet process to be in a subatmospheric pressure state or a vacuum state; the air compressor provides pressure for the cup valve module, thus facilitating rapid flowing of the electrolyte; the transverse stretching module controls transverse displacement of the liquid charge needle; the mobile servo mechanism controls vertical movement of the liquid charge needle; and the liquid charge head is connected to a single battery through screw threads. During charging, a vacuumizing automatic charging system is designed according to electrolyte charging characteristics of the silver-zinc secondary battery, and the charging amount is accurately controlled by a digitization manner, so that charging precision is improved. Connecting terminals are in one-to-one correspondence, so that charge missing is effectively prevented, and the charging speed is high.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

Hyaluronic acid powder production line

ActiveCN110921021APrevent escapeHigh filling accuracySolid materialPackaging machinesEngineeringBottle

The invention relates to the technical field of filling production lines and discloses a hyaluronic acid powder production line. The production line comprises a filling machine and a conveying line mechanism, the filling machine comprises a filling platform, a filling head, a lifting assembly, a first pushing assembly and a second pushing assembly, the filling head is located above the filling platform, the lifting assembly is connected with the filling head, the first pushing assembly is located on one side of the conveying line mechanism, and the filling platform and the second pushing assembly are located on the other side of the conveying line mechanism. A bottle body on the conveying line mechanism is pushed to the filling platform through the first pushing assembly; the lifting assembly is used for controlling the filling head to descend until the filling opening of the filling head extends into the bottle through the bottle opening; the bottle body is filled with hyaluronic acidpowder; and finally, the filled bottle body is pushed back to the conveying line mechanism through a second pushing assembly. Thus, it is achieved that the filling opening of the filling machine extends into the bottle for filling, the filling precision is improved, and the filling speed is increased.

Owner:GUANGZHOU V PACK IND CO LTD

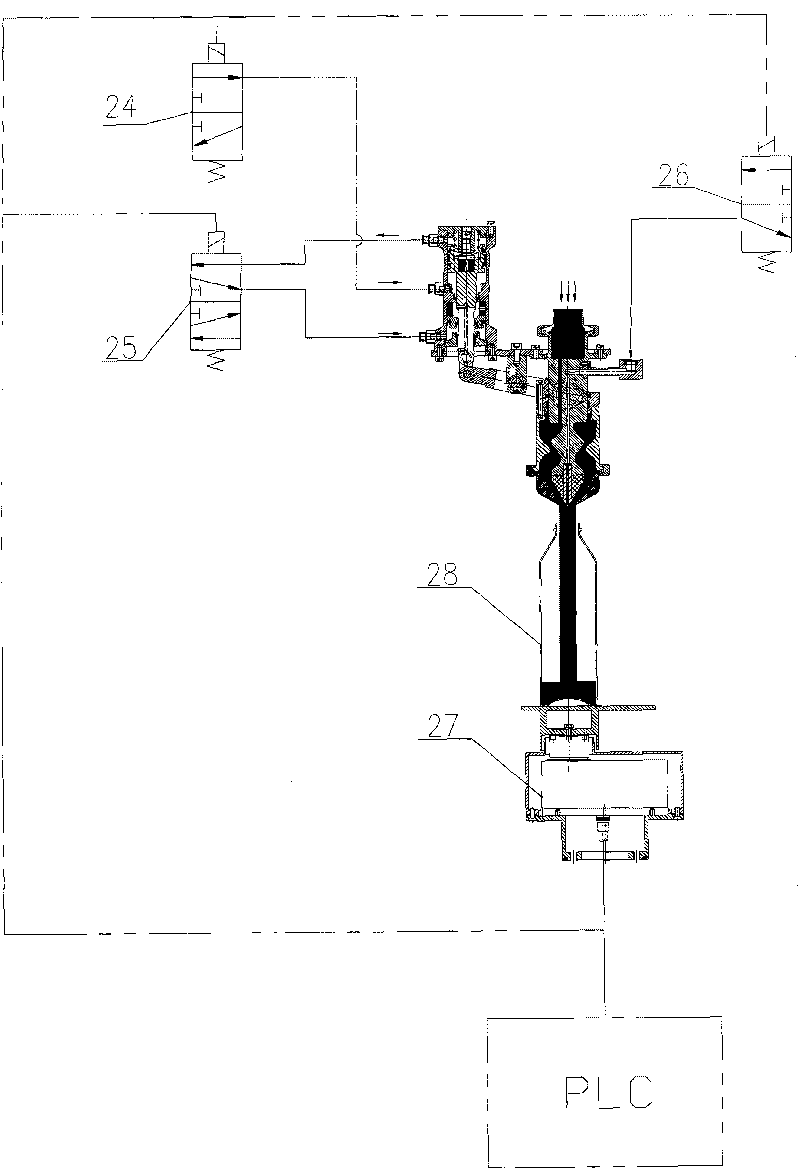

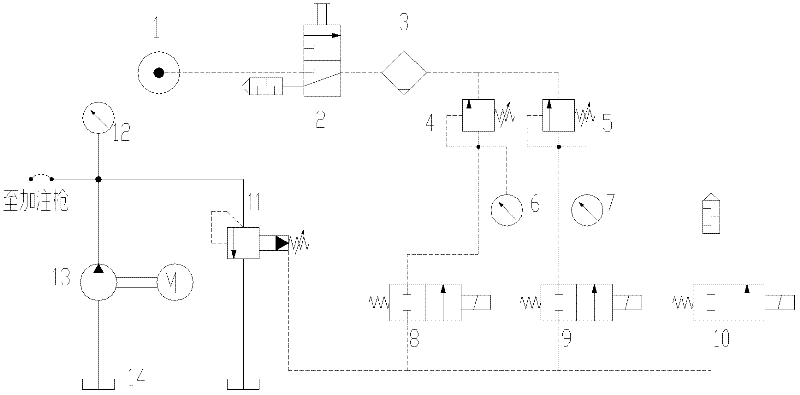

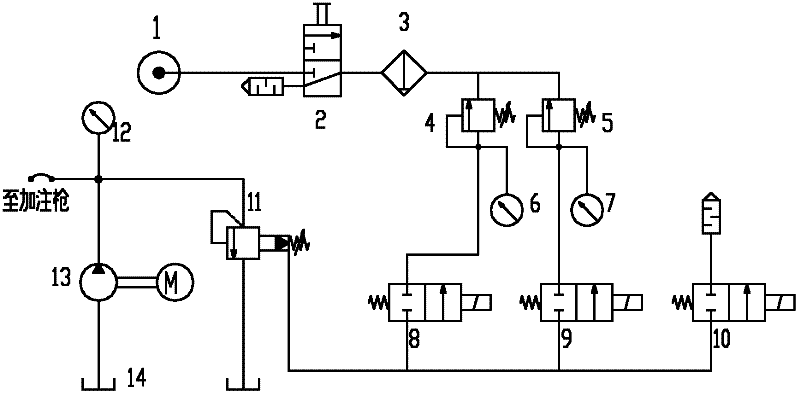

A control loop for variable filling pressure and its control method

ActiveCN102297339AHigh filling accuracyImprove general performancePipeline systemsRemote controlProgrammable logic controller

The invention relates to a control loop capable of changing a filling pressure and a control method thereof. The control loop comprises an air supply, an electromagnetic valve, a pilot overflow valve, a remote pressure regulating valve and a PLC (programmable logic controller), wherein the air supply is connected with the remote pressure regulating valve, and then is connected with a remote control port of the pilot overflow valve through the electromagnetic valve so as to be used for achieving the remote control of the filling pressure; the pilot overflow valve is mounted on a filling loop; an overflow port is connected with a liquid storing tank through a hydraulic pipeline; and the PLC is connected with the electromagnetic valve and can further send an instruction to control the connection, the disconnection and the switching of the electromagnetic valve, so that pressure regulating valves with different pressures are connected with a remote control end of the overflow valve to be used for achieving the automatic switching of a high filling pressure and a low filling pressure.

Owner:CHERY AUTOMOBILE CO LTD

Liquid medicine filling machine

InactiveCN109279558AAccurate filling volumeFilling volume adjustmentLiquid bottlingMotor driveReciprocating motion

The invention relates to the technical field of medicine filling, in particular to a liquid medicine filling machine. A motor drives a dial shaft to rotate through a coupler, a dial, a first cam and asecond cam of the dial shaft are driven to synchronously rotate clockwise; the dial disc rotates to drive a groove wheel to do intermittent periodic rotation, and the groove wheel drives a belt wheelto rotate through a groove wheel shaft so as to drive the belt installed on the belt wheel to move intermittently; the first cam rotates to drive the upper end to make up-and-down reciprocating motion of the ejector rod which is always kept in contact with the high-auxiliary point, and an ejector rod drives a second bent pipe clamped on the ejector rod to do up-and-down reciprocating motion; thesecond cam rotates to push the piston on a top plate mechanism to do reciprocating rectilinear motion, and then opening and closing of the liquid outlet are completed. The liquid medicine filling machine has the beneficial effects that the opening and closing time of the liquid outlet can be changed by adjusting the rotating speed of the motor so as to adjust the filling amount of the medicine; the filling quantity of each medicine bottle is accurate, the medicine is not easy to leak, and the filling precision is higher and the effect is better.

Owner:李乐乐

Filling method of sensor missing value fused with spatio-temporal information

ActiveCN111597175ALower requirementImprove forecast accuracyGeographical information databasesNeural architecturesMissing dataData set

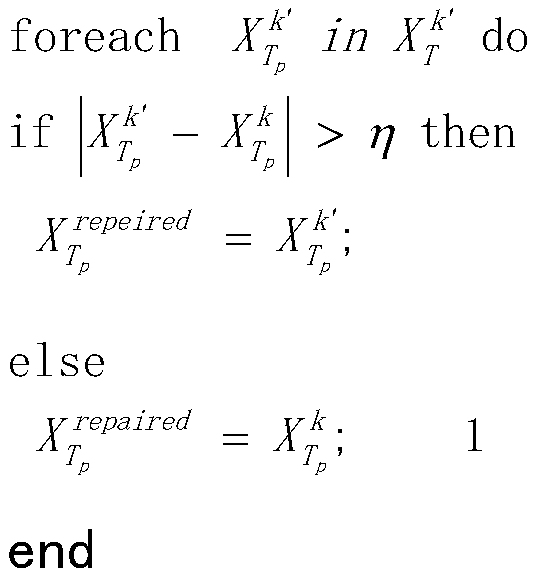

The invention provides a filling method of a sensor missing value fused with spatio-temporal information. The method comprises the following steps of: inputting N pieces of historical data X and M pieces of missing data Xmissing, wherein M and N are greater than the input time sequence length T; filling a threshold eta, and inputting historical data into the trained LSTM-AES, then eta = std (X-X ') so as to obtain the trained model LSTM-AES and the repaired data Xrepaired; dividing the original data into a time series data set; initializing LSTM-AES; then, using the Tensorflow for carrying outnetwork initialization; updating the weight W of the LSTM-AES by using a common back propagation algorithm of the neural network; and carrying out missing value filling. Space-time information is considered at the same time, robustness can be achieved when a large number of sensors are missing at the same time, a single model can be trained to process different types of missing, and the real-timerequirement of sensor missing value filling can be met.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com