Liquid filling device with adjustable fill quantity

A filling device and adjustable technology, applied in liquid bottling, liquid treatment, packaging, etc., can solve problems such as easy to get dirty, inconvenient cleaning of the filter screen, and many wearing parts, and achieve fast filling speed and reduce The hidden danger of product pollution and the effect of high filling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

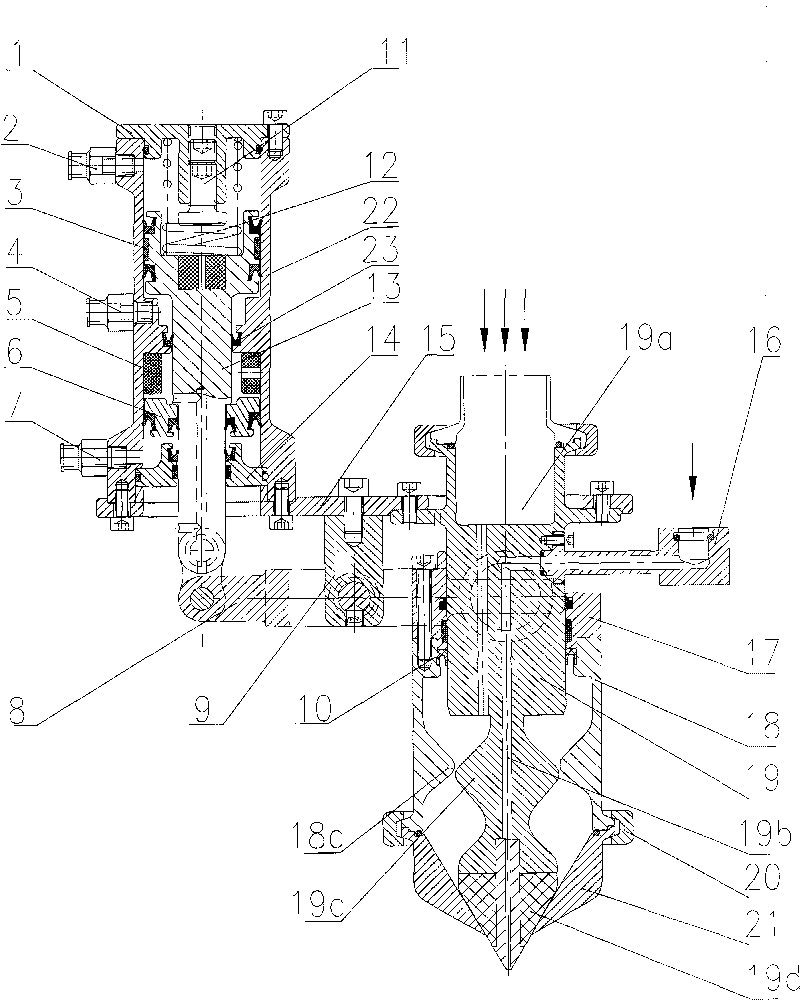

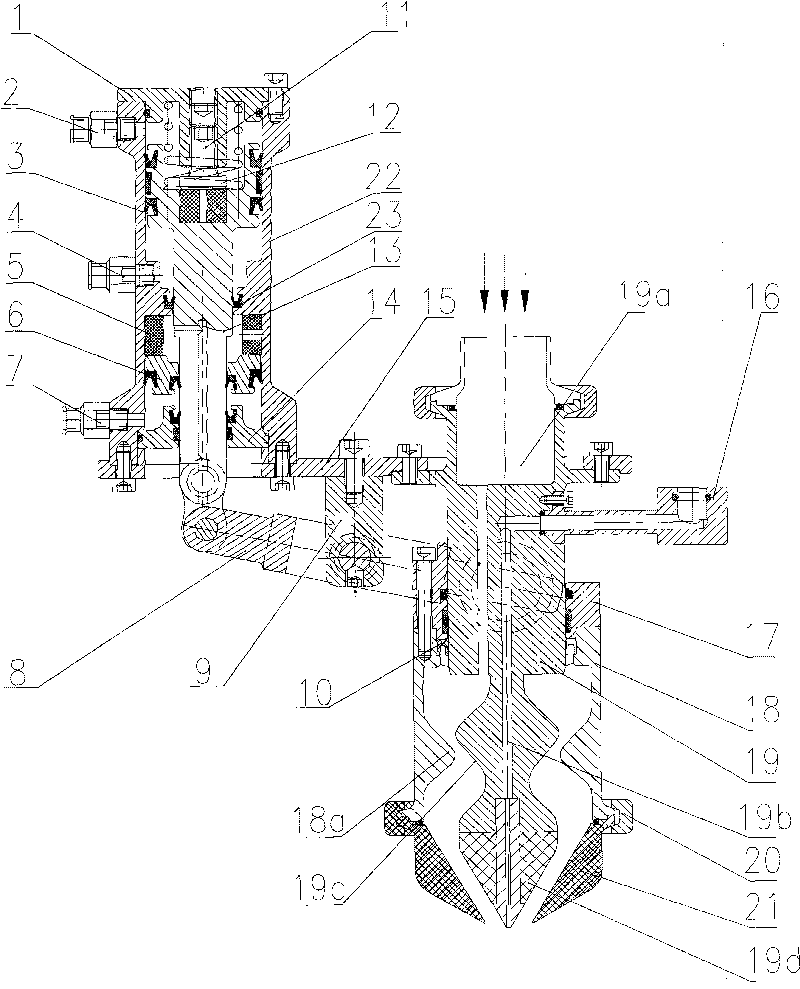

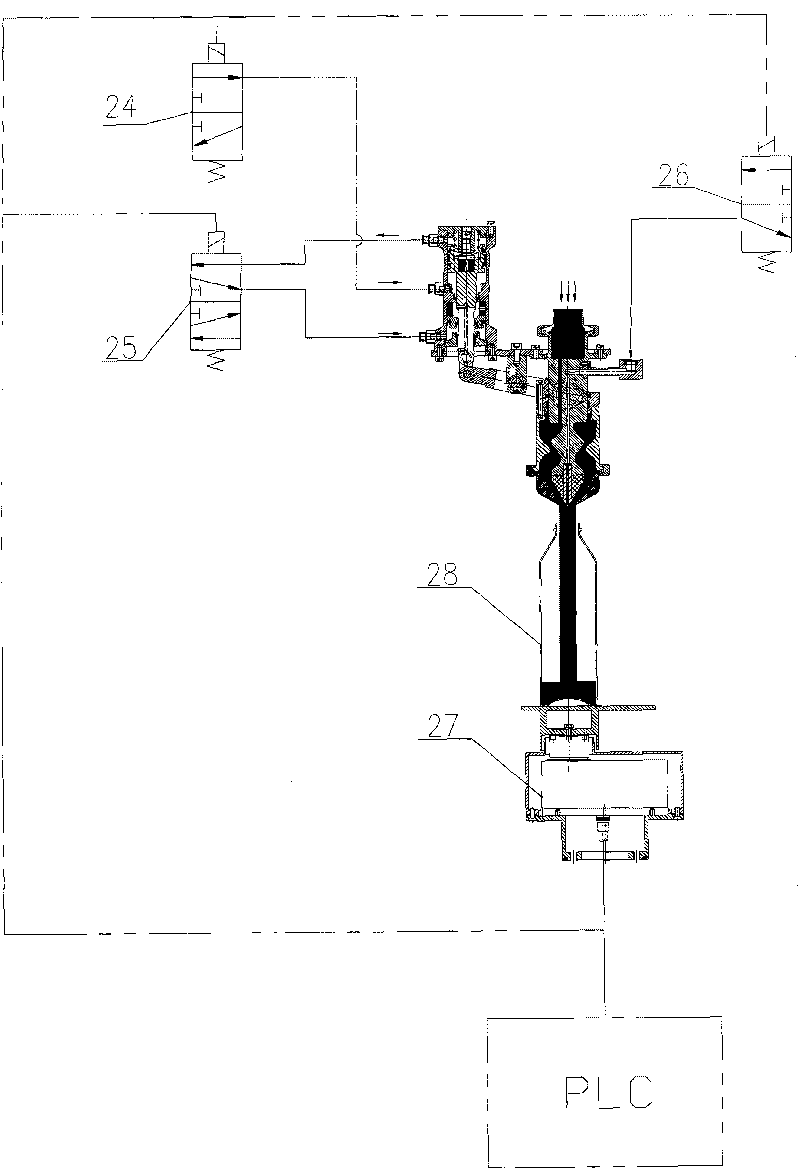

[0020] The embodiments of the present invention will be described in detail below in conjunction with the drawings:

[0021] see figure 1 , figure 2 , The liquid filling device with adjustable filling volume of the present invention is mainly composed of a mounting seat 15 and a cone filling valve installed on the mounting seat 15, a cylinder driving device and a lever transmission device. Among them, the conical filling valve is fixed under the mounting seat 15, and is composed of a valve housing and a valve core 19 installed in the valve housing. The valve housing is composed of an upper sleeve 18 and a lower filling nozzle 21 connected by a connecting piece 20. A first convex ring 18a is provided on the inner wall of the middle of the sleeve 18, and the axial section of the first convex ring 18a is tapered. A tapered discharge port is provided in the center of the filling nozzle 21. The lower end of the valve core 19 is provided with a tapered valve head 19d, which is in a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com