Excitation type high energy power supply apparatus

A power supply device and high-energy technology, applied in circuits, electrical components, lead-acid batteries, etc., can solve the problems of lead-acid battery increase in heat energy, waste of resources, waste of electric energy, etc., achieve uniform distribution of current density, save charging costs, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

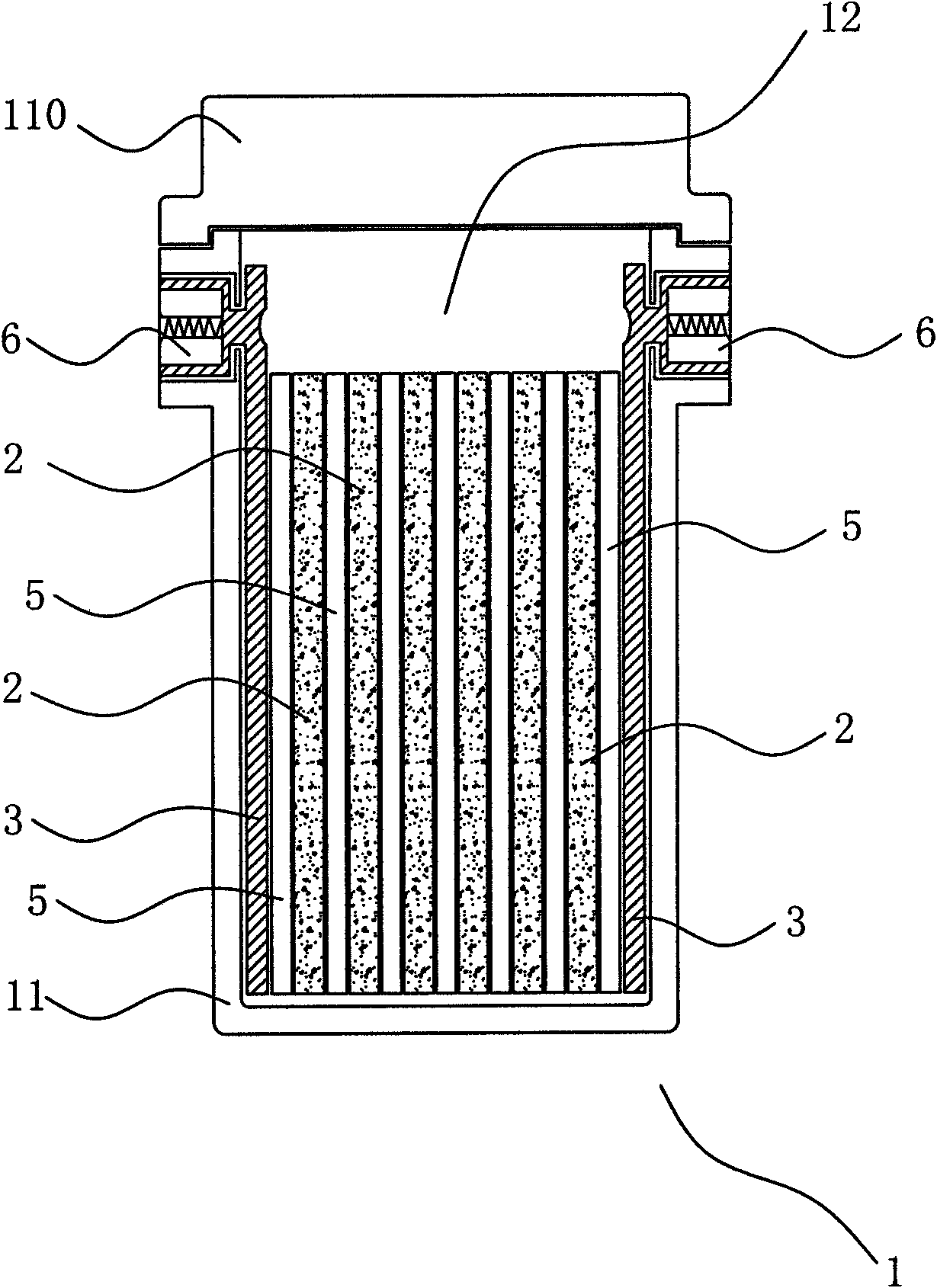

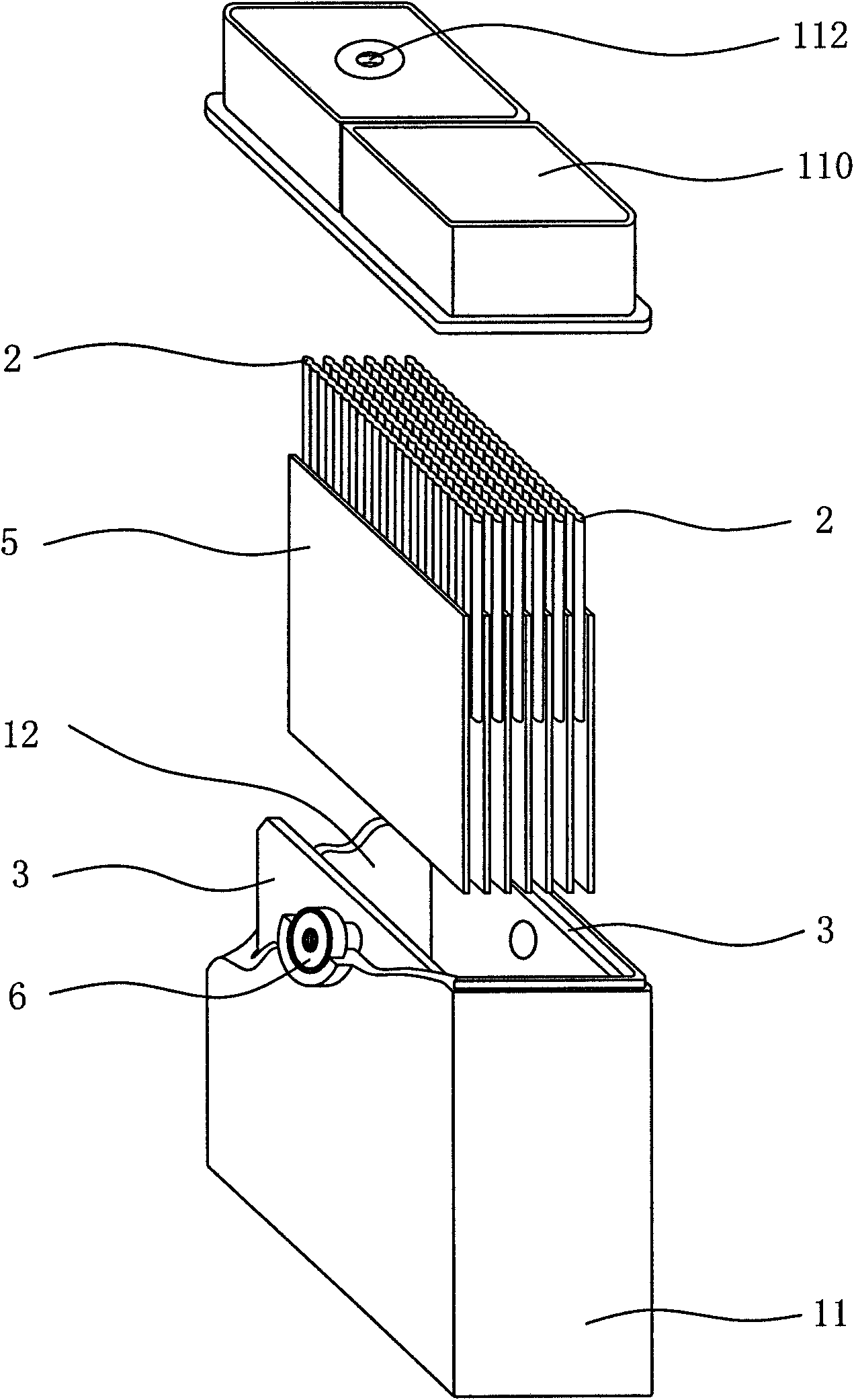

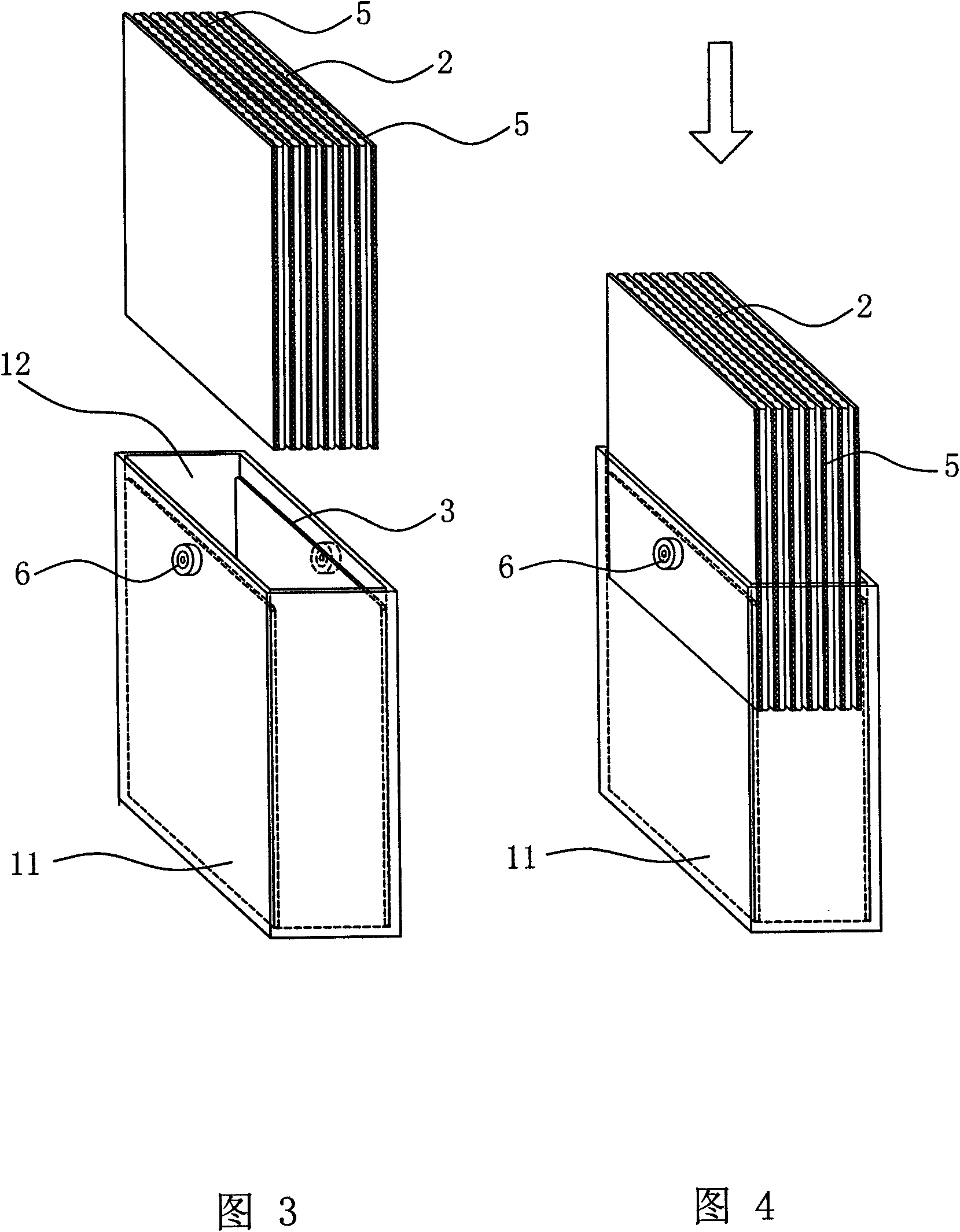

[0117] Referring to all the accompanying drawings, there is an exciting high-energy power supply device, including a storage battery with output negative voltage or positive voltage, and the storage battery with output negative voltage or positive voltage includes a casing, a cover located above the casing, and a At least one battery cell tank, at least two electrical energy bodies, at least one separator, at least two collectors and at least two external terminals filled with electrolyte in the housing, the electrical energy body, separator and collector Located in the cell of the battery cell, the electric energy body is isolated from the electric energy body by the spacer, the current collectors are respectively connected to the external terminals, and the electric energy body is first placed in the formation tank Charging, or charging after the battery is assembled, is usually called formation. The battery in the present invention is discharged directly without internal for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com