Garbage composting energy-saving consumption-reducing and waste gas zero-emission system and method based on zero-emission architecture

A garbage composting and zero-emission technology, applied in the direction of organic fertilizers, fertilization devices, climate sustainability, etc., can solve the problems of reduced processing scale, reduced operating costs, reduced investment costs, etc., to achieve reduced processing scale and lower operating costs The effect of reduction and investment cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention will be further described in detail below in conjunction with the drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the embodiments of the present invention, rather than to limit the embodiments of the present invention. In addition, it should be noted that, for the convenience of description, the drawings only show some but not all structures related to the embodiments of the present invention.

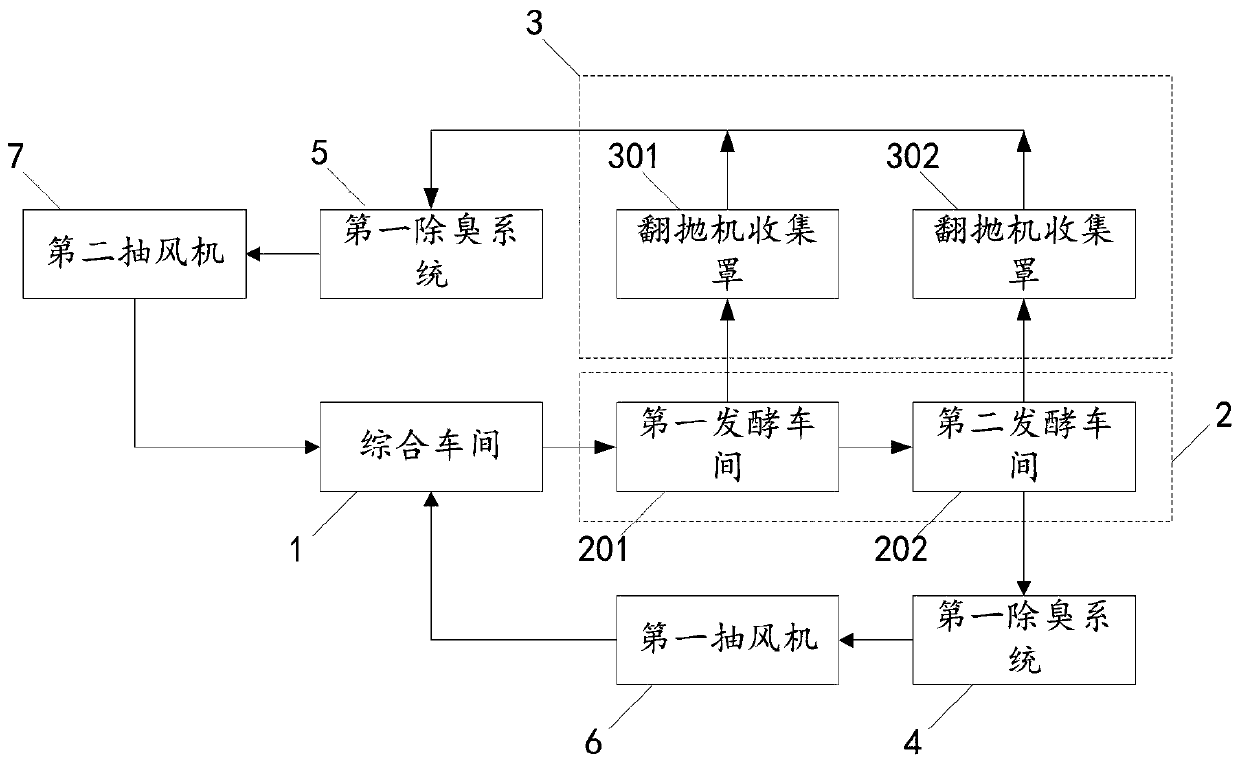

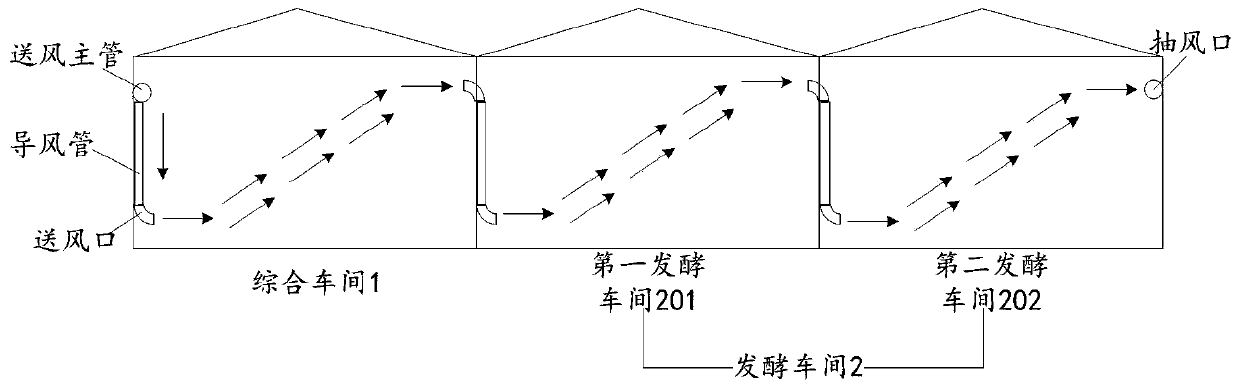

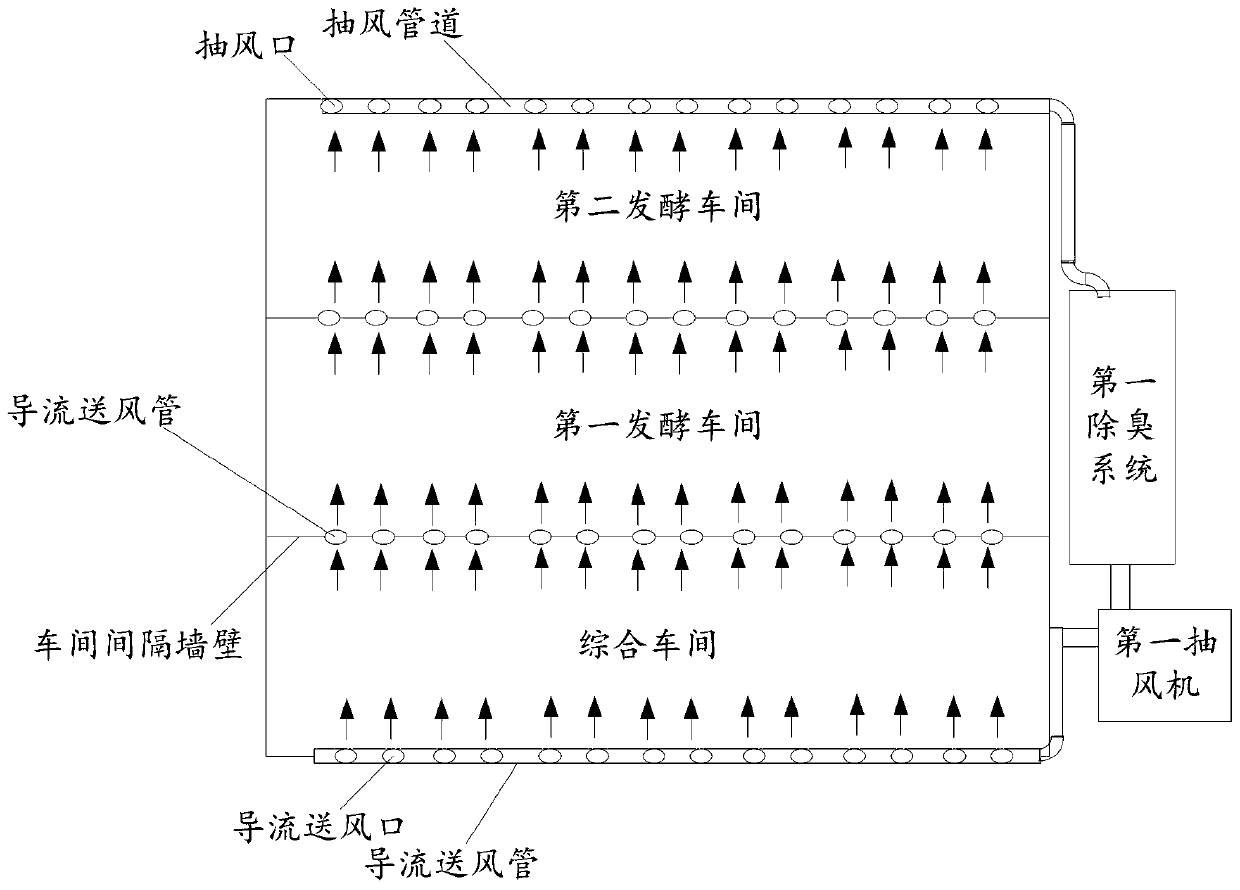

[0034] The exhaust gas generated during the composting process is mainly composed of two parts, one is the odor released from the compost stack to the workshop space, and the other is the large amount of water vapor, odor and dust brought out by the stirring strip stack during the turning operation of the turner Particles, for these two kinds of waste gas, this scheme adopts corresponding waste gas collection and odor purification treatment respectively.

[0035]For ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com