Patents

Literature

34results about How to "Reduce Pollution Potential" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

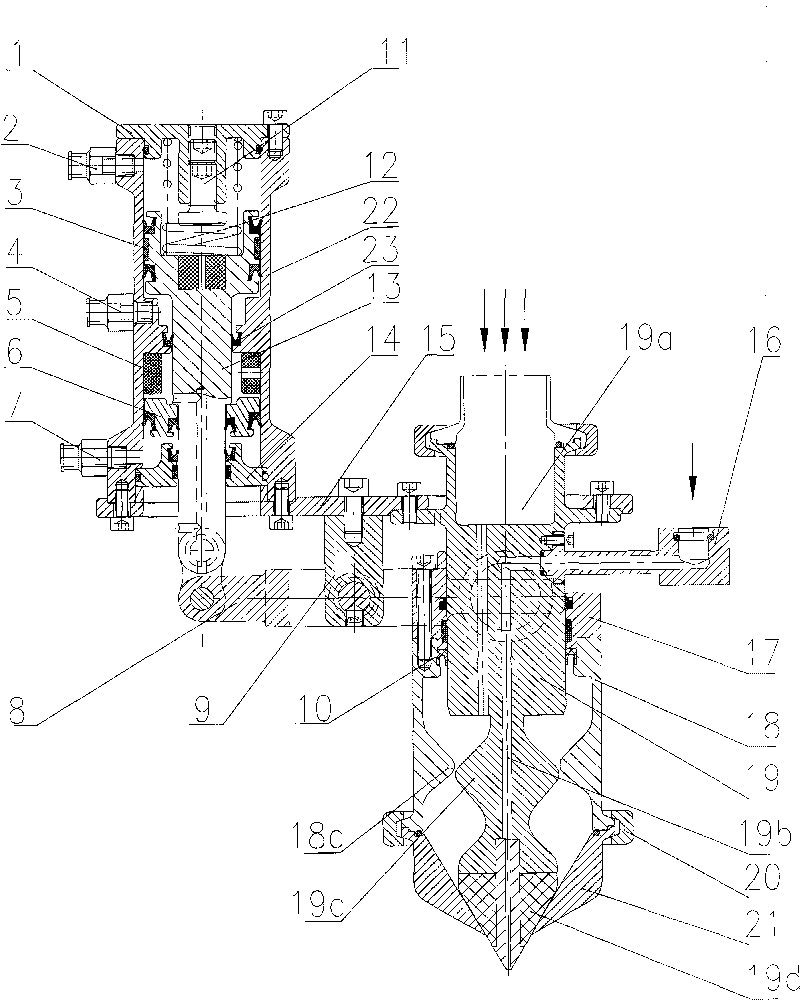

Nucleic acid extractor

PendingCN108441423ASimple extraction processReduce the impactBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringNucleic acid

The invention discloses a nucleic acid extractor which is provided with an operation space. A magnetic rod-magnetic rod sleeve module and a driving transmission mechanism are arranged in the operationspace, the driving transmission mechanism enables the magnetic rod-magnetic rod sleeve module to reciprocate or move, a cracking area and a pretreatment area are included in the operation space and are independent from each other, and the magnetic rod-magnetic rod sleeve module reciprocates in the cracking area and the pretreatment area. The nucleic acid extractor is simpler in extraction step, short in extraction time, higher in nucleic acid extraction rate and has little nucleic acid extraction loss.

Owner:SHAOXING INGENIGEN BIOTECH CO LTD

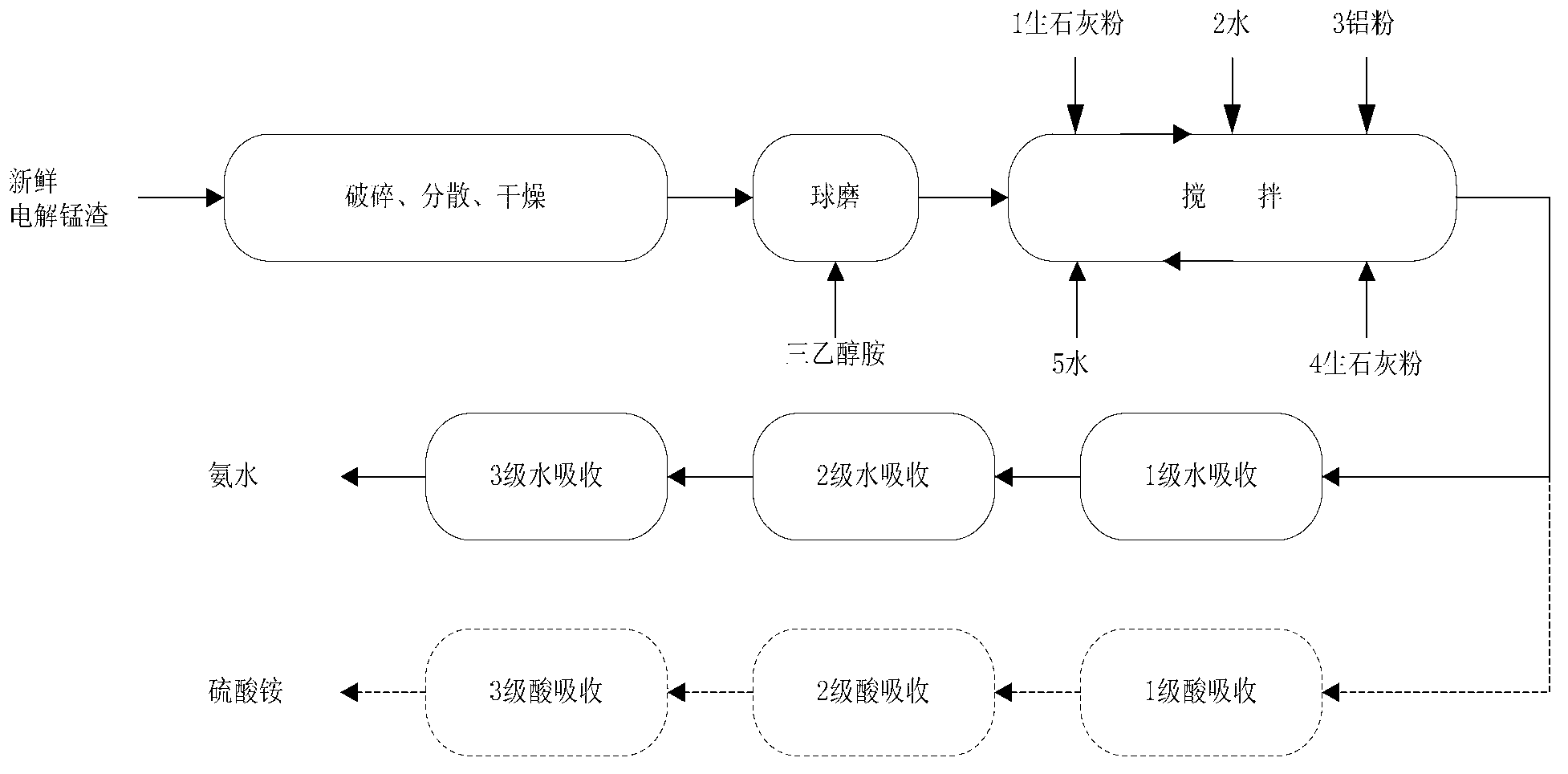

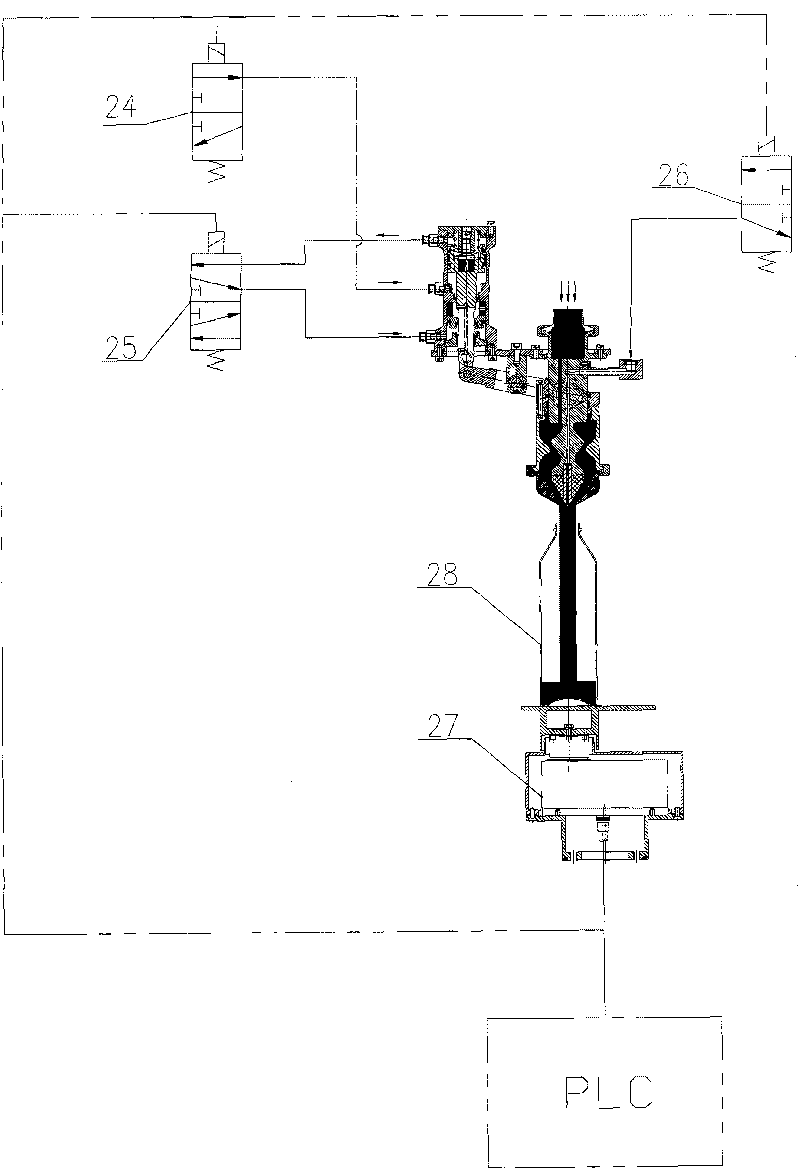

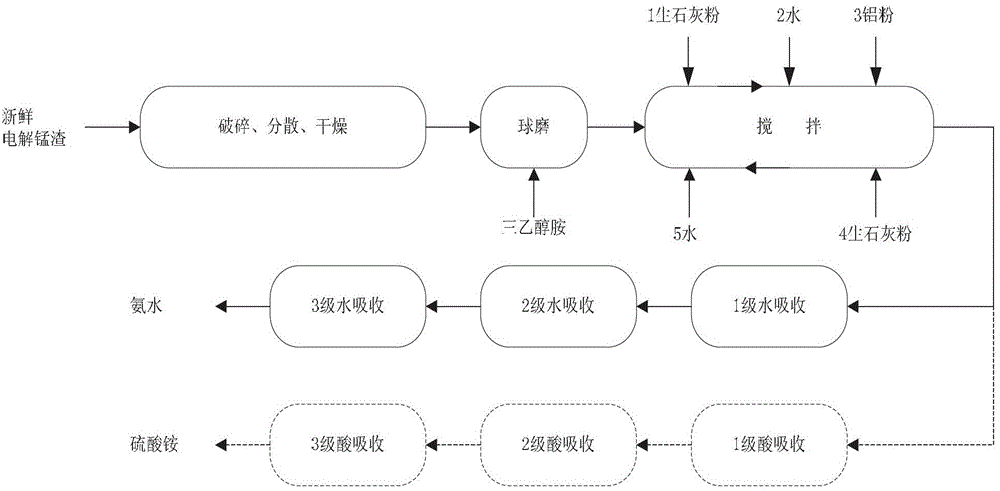

Novel method for direct extraction recovery of ammonia nitrogen from electrolyzed manganese slag

InactiveCN102795641AReduce Pollution PotentialRealize extraction and utilizationSolid waste disposalAmmonium sulfatesRecovery methodElectrolysis

The invention discloses a novel method for direct extraction recovery of ammonia nitrogen from electrolyzed manganese slag. The novel method comprises the following steps of directly adding an alkaline preparation and a foaming agent into fresh manganese slag subjected to crushing, dispersion, drying and ball-milling so that a pH value and humidity in an electrolyzed manganese slag environment are changed and transformation of a solid phase and a liquid phase into a gas phase is promoted, and introducing released NH3 gas into a multistage absorption device by a negative-pressure suction device cover located above a mixer so that the released NH3 gas is absorbed by water or dilute sulphuric acid and then is transformed into ammonia water or ammonium sulfate. The novel method for direct extraction recovery of ammonia nitrogen from electrolyzed manganese slag solves the problem that the existing extraction recovery methods have high water consumption, high energy consumption and complex processes, greatly reduces environmental pollution hidden troubles of ammonia nitrogen in manganese slag, and realizes extraction and utilization of an ammonia nitrogen resource well.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Composition of hydraulic fluid and process for the preparation thereof

InactiveUS20070060486A1Reduce pollution potentialExcellent miscibilityWork treatment devicesLiquid carbonaceous fuelsDefoamerLubrication

The present invention provides a composition of hydraulic fluid that mainly contains alkyl benzenes. In addition to alkyl benzenes, the composition also contains an antioxidant, an antifoaming agent, a pour point dispersant, a corrosion inhibitor and a detergent-dispersant additive, an extreme pressure additive, a lubrication additives, comprising of the following steps (I) removing of insoluble matter from the base stock, (II) tailoring the base stock by vacuum distillation and blending, (IV) removing the oxidized matters by adsorption, (V) addition of performance additives and homogenizing the mixture. The product of this invention has utility as an general purpose hydraulic fluid.

Owner:COUNCIL OF SCI & IND RES

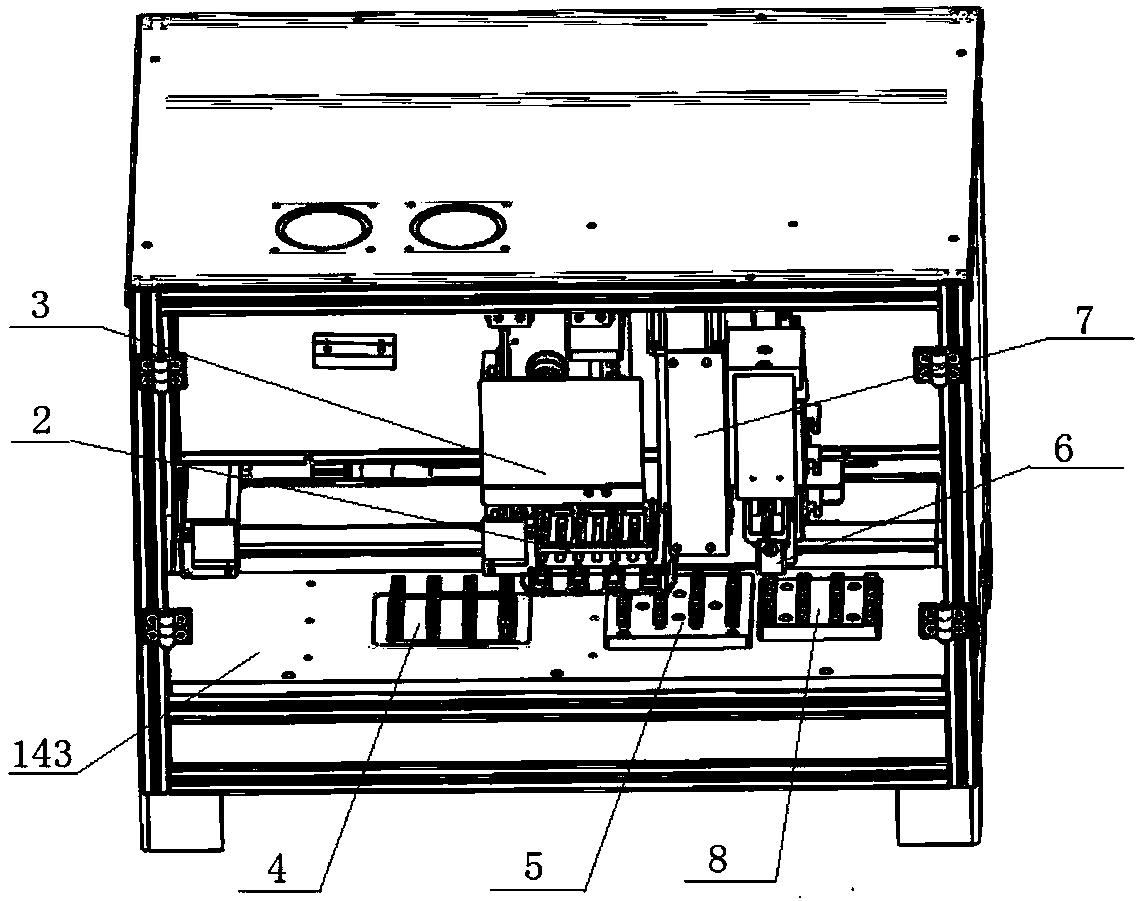

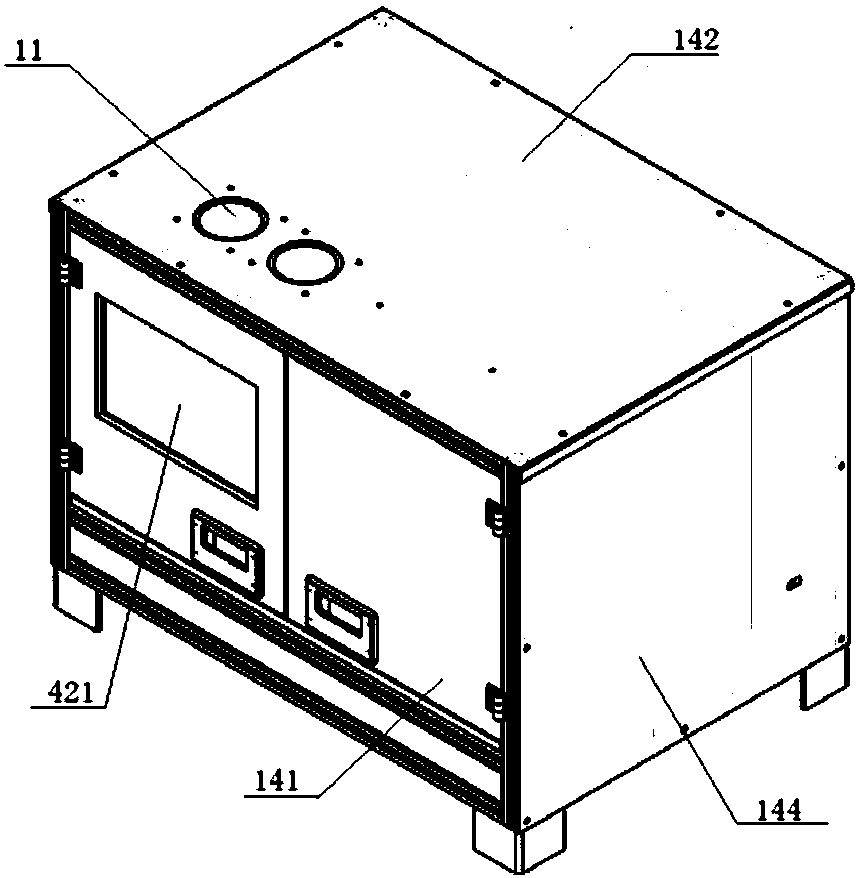

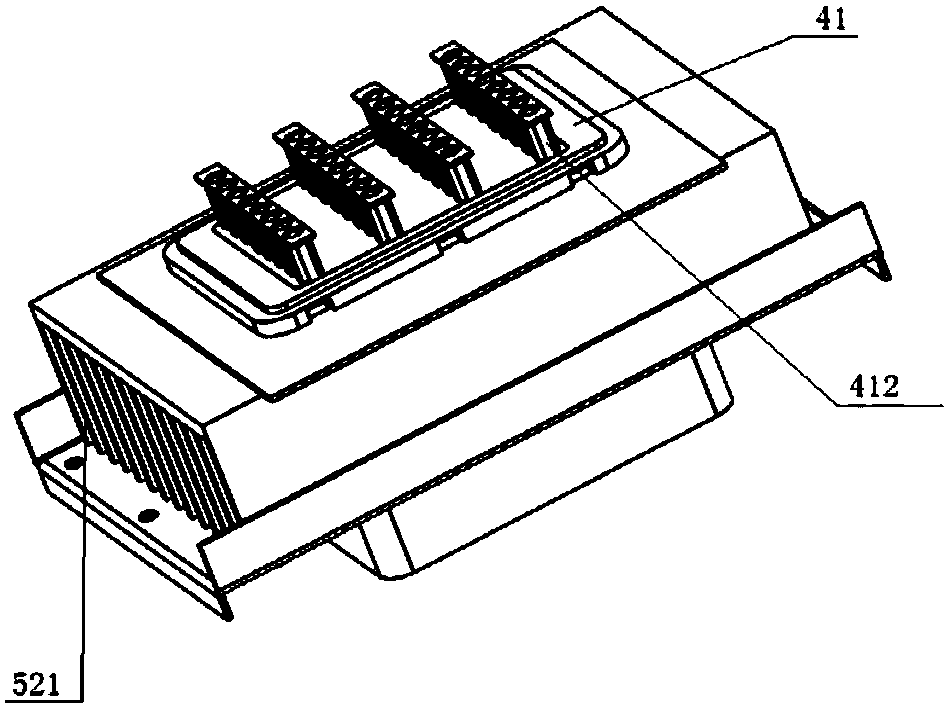

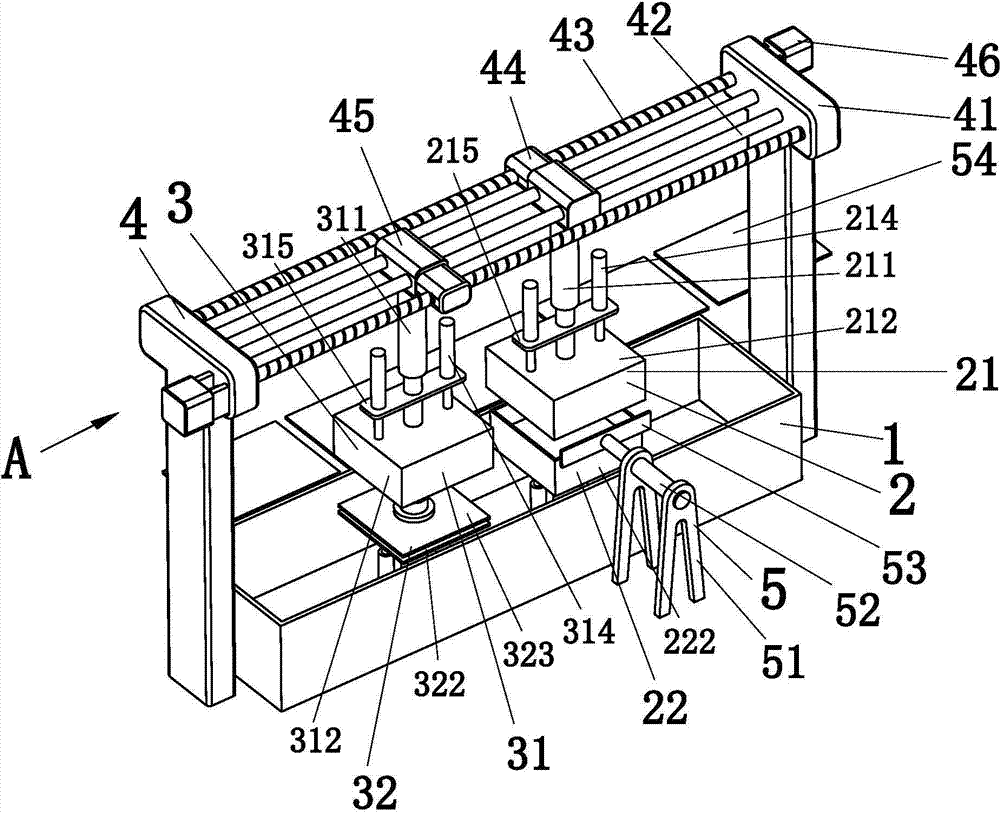

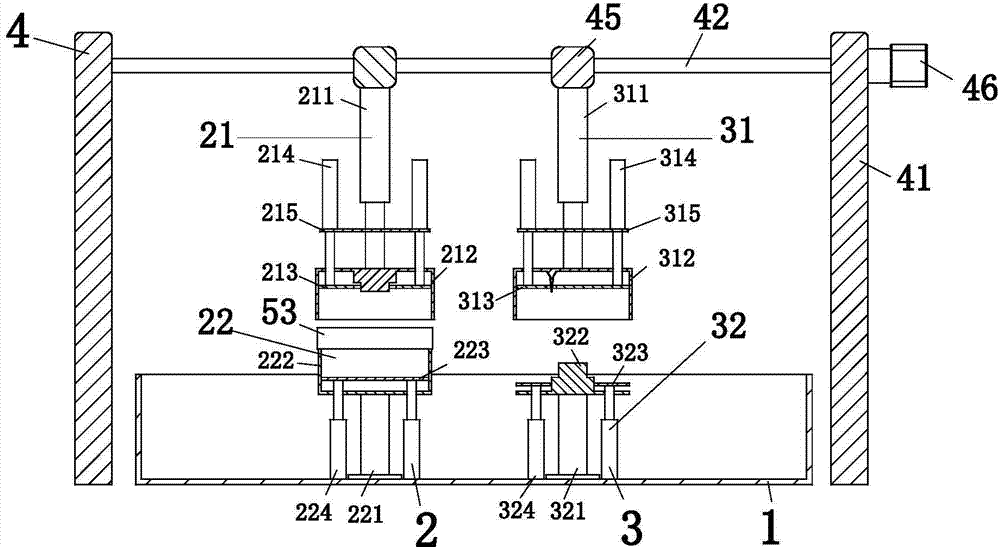

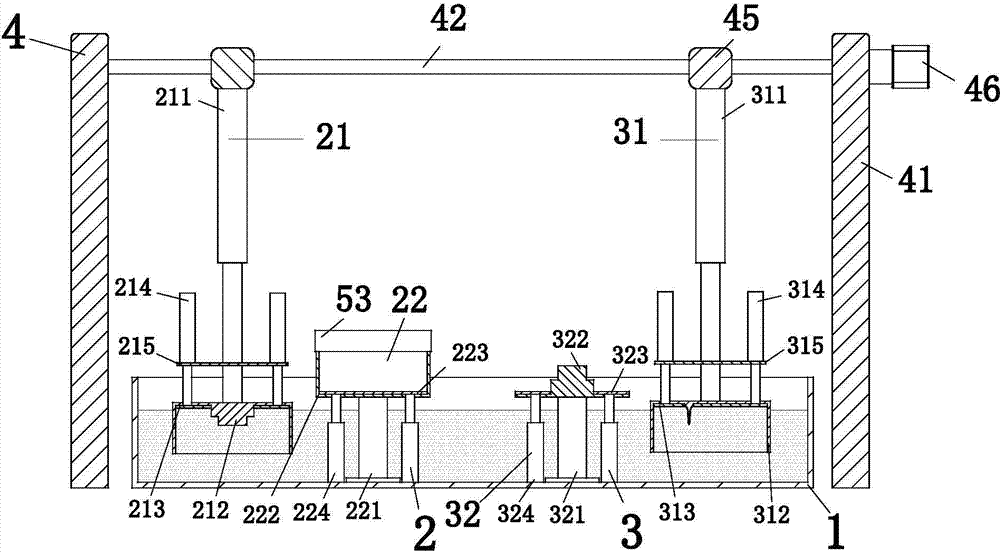

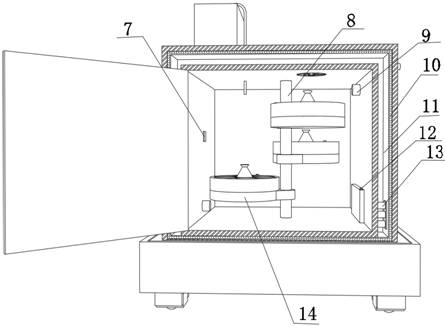

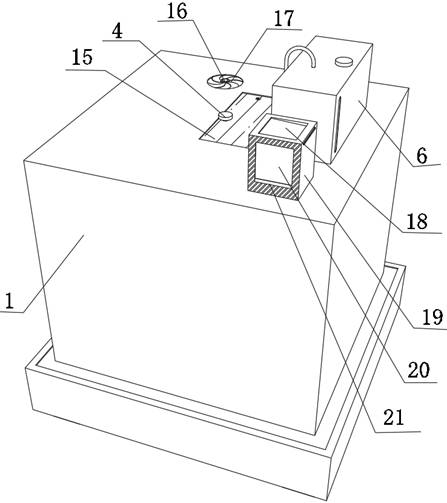

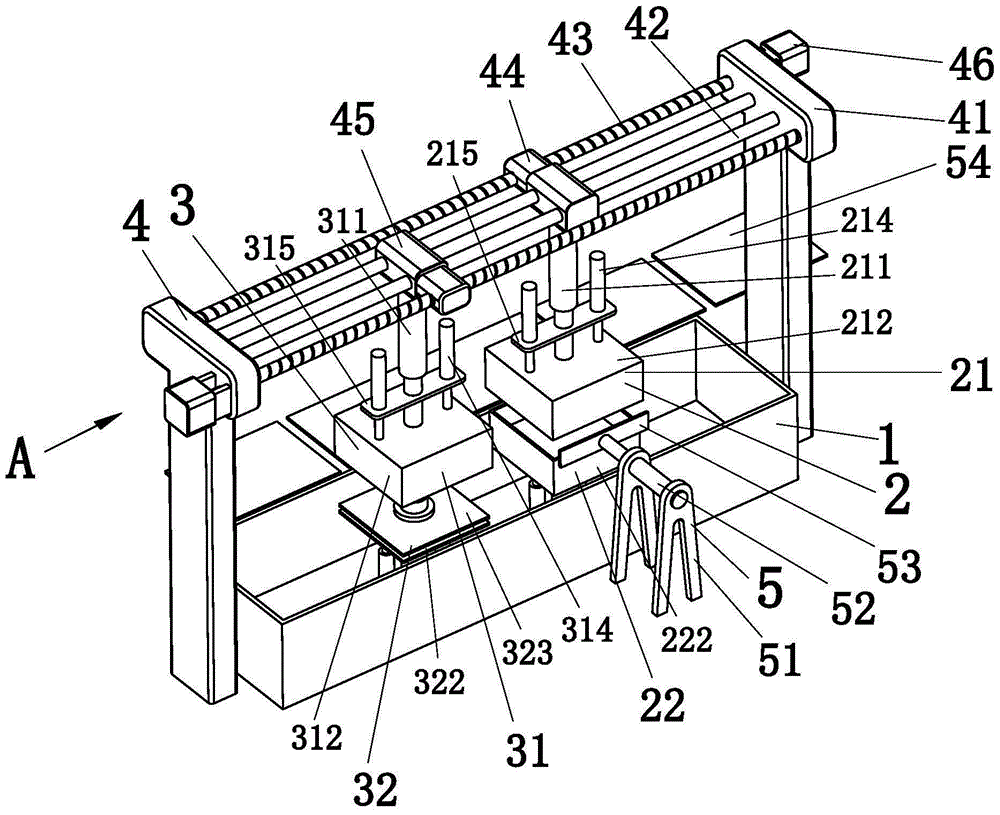

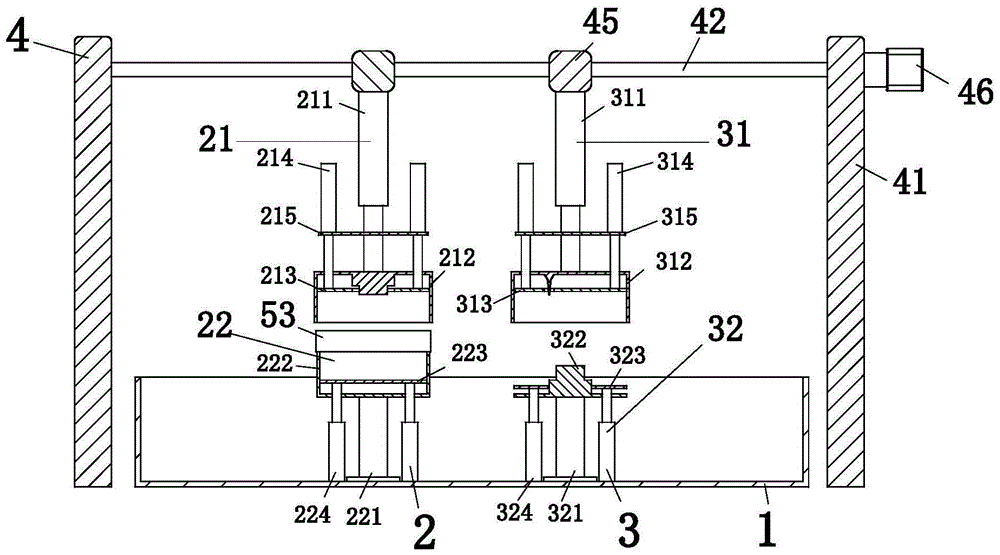

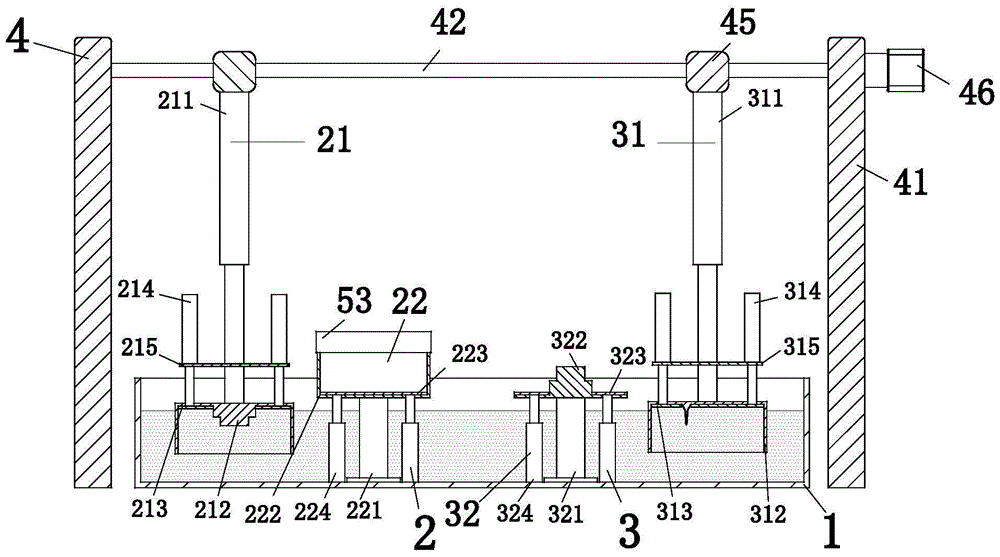

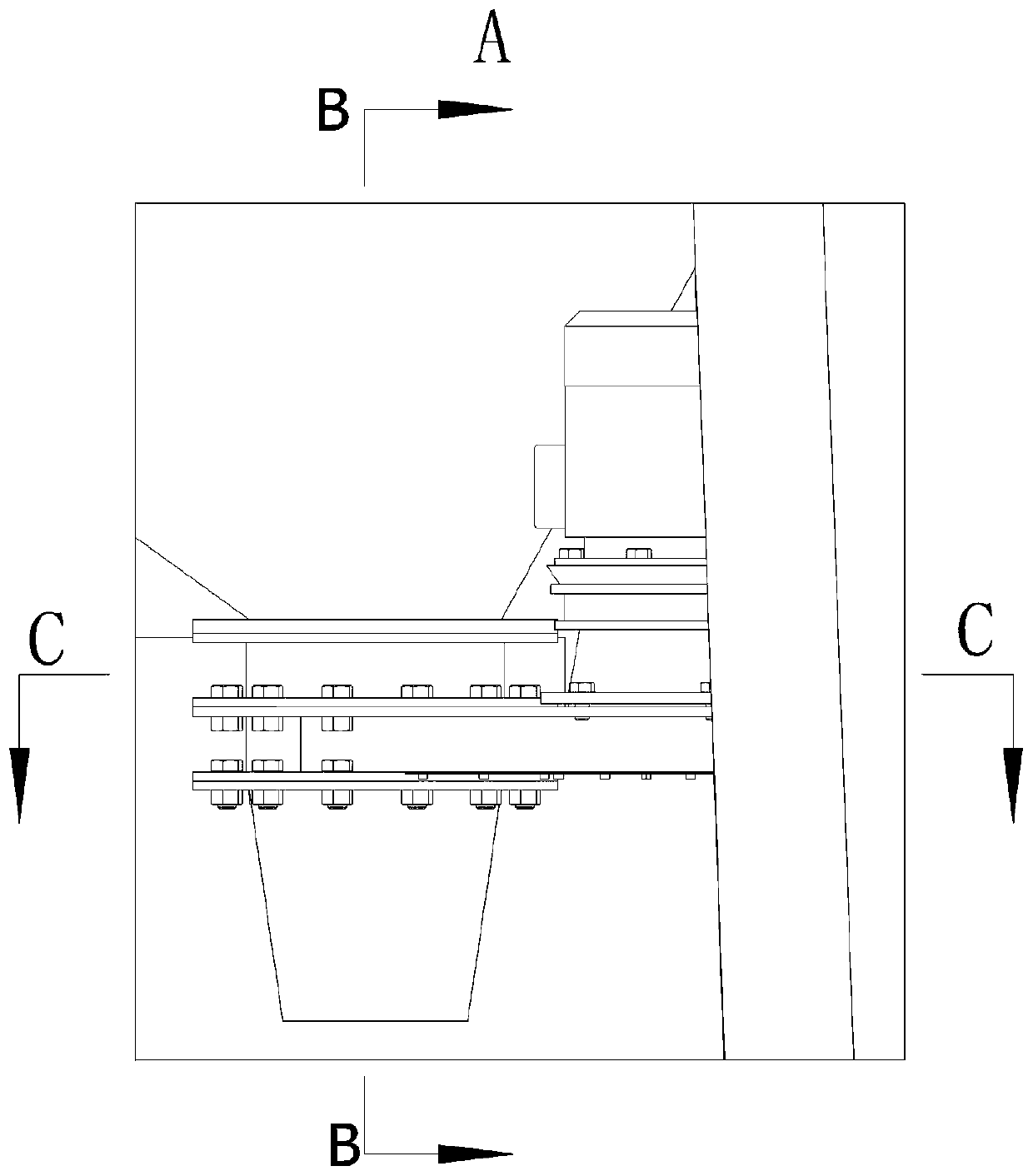

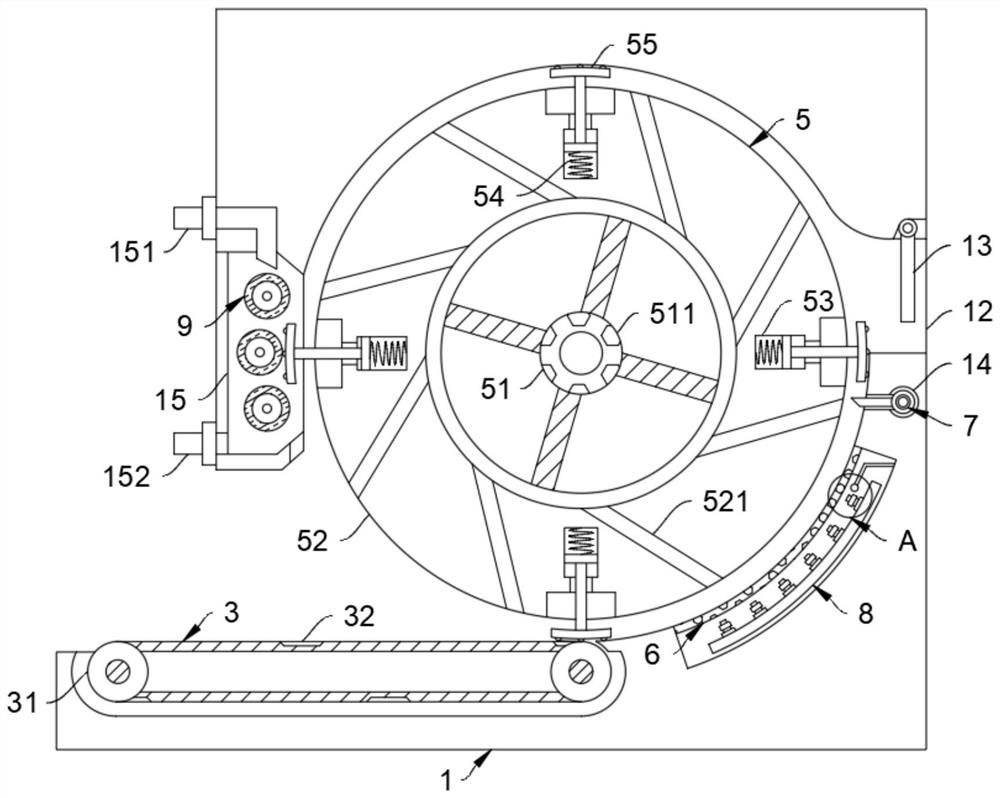

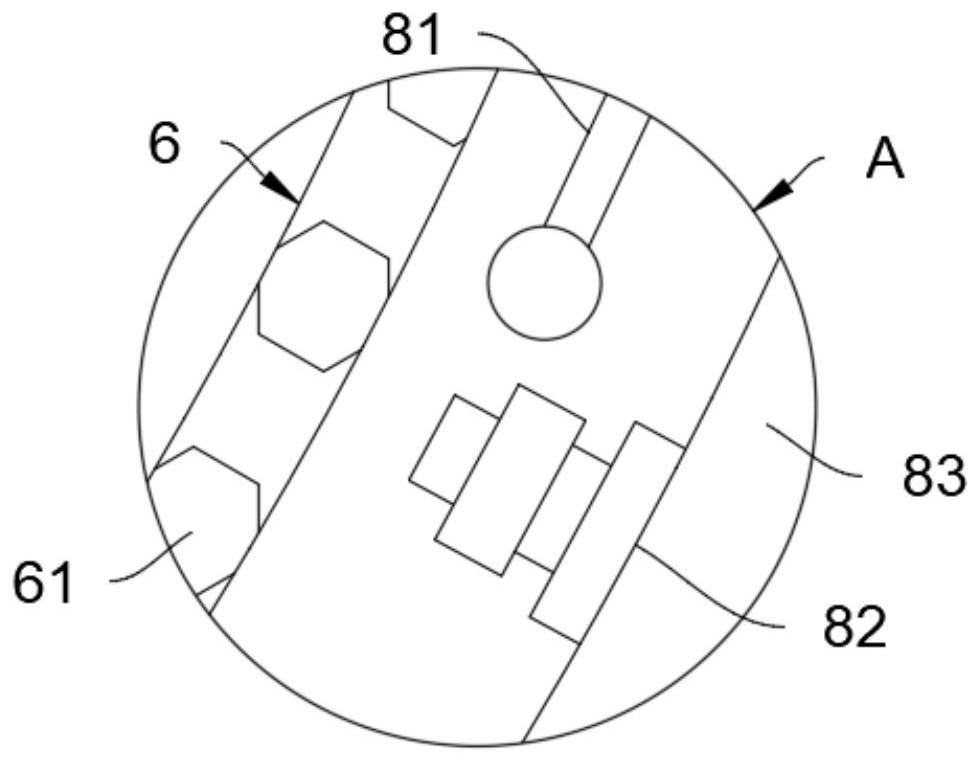

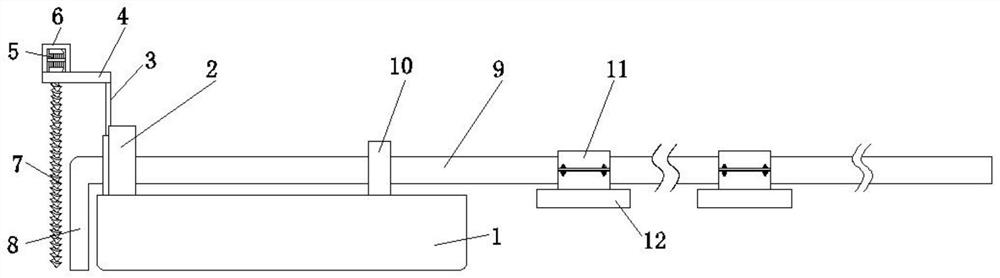

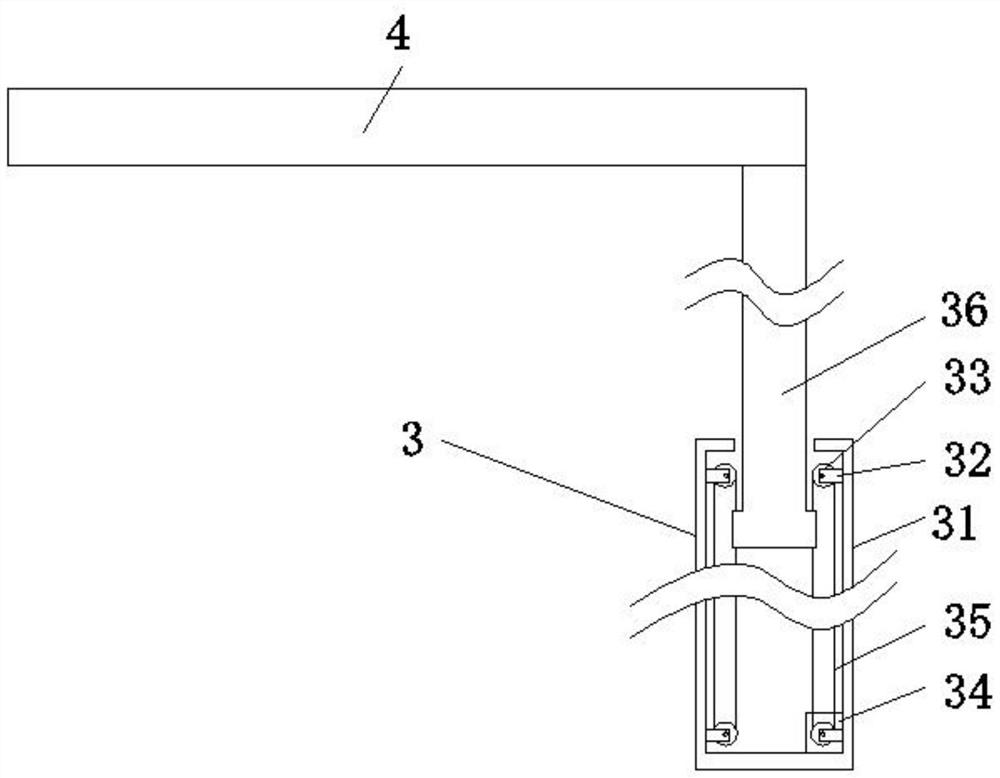

Box division molding machine

ActiveCN104841890ARealize automated productionIncrease productivityMoulding machinesMolding machineEngineering

The invention relates to the technical field of sand mold casting, and concretely relates to a box division molding machine. The box division molding machine comprises a sandbox, a lower box molding device, an upper box molding device, a walk device and a push device, and the sandbox is a rectangular box body; the lower box molding device and the upper box molding device are positioned in the sandbox, the lower box molding device is positioned at the left side of the sandbox, and the upper box molding device is positioned at the right side of the sandbox; the walk device is positioned above the sandbox, the upper ends of the walk device and the lower box molding device are connected with the upper end of the upper box molding device, and the walk device is used for moving the lower box molding device and the upper box molding device; and the push device is positioned just behind the lower box molding device, and the push device is used for sending box closed sand mold to a conveyer belt and allowing the box closed sand mold to enter a next process. The box division molding machine adopting a manual coal beating machine principle realizes automatic production of box division castings, and also has the advantages of simple structure, low manufacturing cost and high production efficiency.

Owner:河北中和铸造有限公司

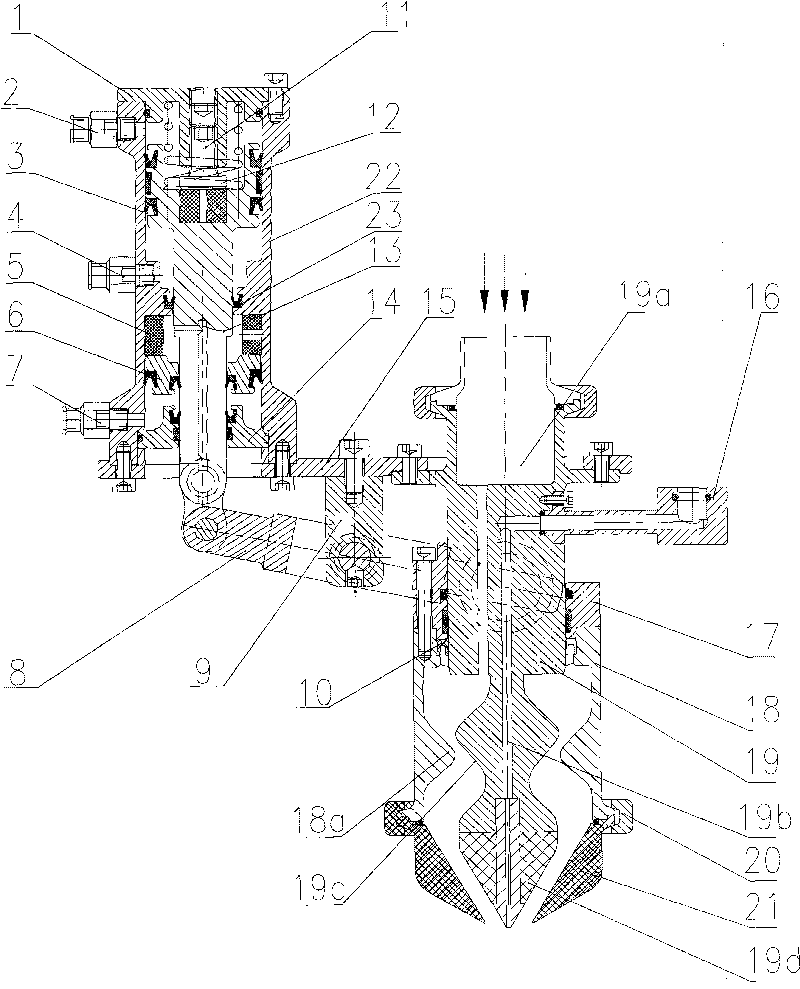

Liquid filling device with adjustable fill quantity

InactiveCN101759129AReduce Pollution PotentialMeet hygiene requirementsLiquid bottlingNitrogenEngineering

The invention discloses a liquid filling device with adjustable fill quantity, comprising a tapered filling valve fixed on a mounting seat and a driving device, wherein the tapered filling valve comprises a valve casing and a valve core capable of moving in the valve casing relatively to the valve casing, the lower end of the valve core is provided with a tapered valve head, the valve casing is provided with a tapered discharge hole, and the discharge hole is matched with the valve head; the liquid filling device is characterized in that the valve casing or the valve core is connected with the driving device through a lever transmission device. In the invention, a driving cylinder is completely separated with the filling valve, thereby reducing hidden trouble of product pollution; the unique valve-core structure can ensure that the filling products are bunched turbulently under the condition of without a filter screen member, thus being more in accordance with sanitary requirement; in addition, the device has the function of charging nitrogen and can meet the requirement of filling high-grade oils.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

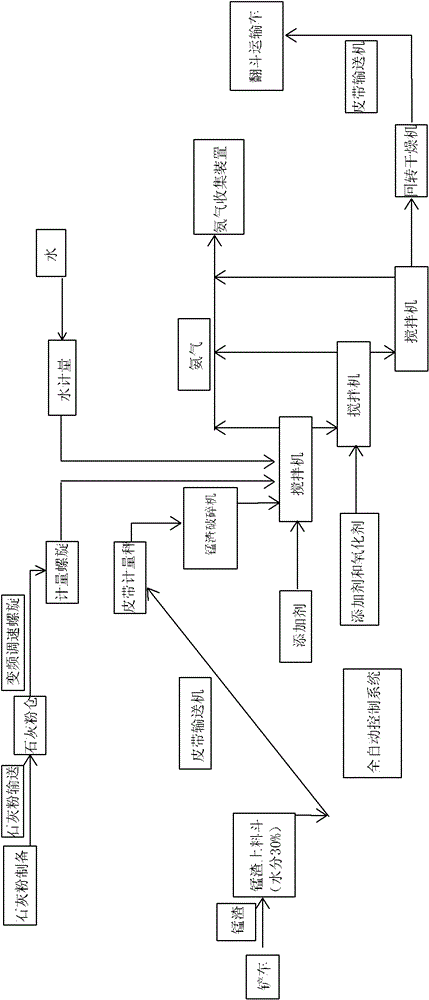

Innocent treatment method of electrolytic manganese slag

The invention discloses an innocent treatment method of electrolytic manganese slag. The method comprises the following steps of: (1) weighing manganese slag accurately with metering equipment and crushing the manganese slag; (2) adding the crushed manganese slag into a blender; adding calcium oxide powder and water into the manganese slag, adding a certain amount of silicate additives into the mixture, stirring the mixture to form a uniform mixed material, and recovering ammonia gas; (3) after unloading the mixed material, transferring the mixed material into another blender, adding a certain amount of water soluble resin sulfosalt additives and ferric chloride, stirring again and recovering the ammonia gas; and (4) after stirring and unloading the material, transferring the material into a third blender, fully stirring, recovering the ammonia gas, drying the material in a turnover dryer, controlling the water content of the mixed material, and performing landfill treatment after drying. The method has a wide raw material source, an excellent treatment effect, a simple technical technology, high product strength and high durability; an environmental potential hazard caused in a manganese slag stacking process is eliminated; and the investment cost of an enterprise is reduced.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

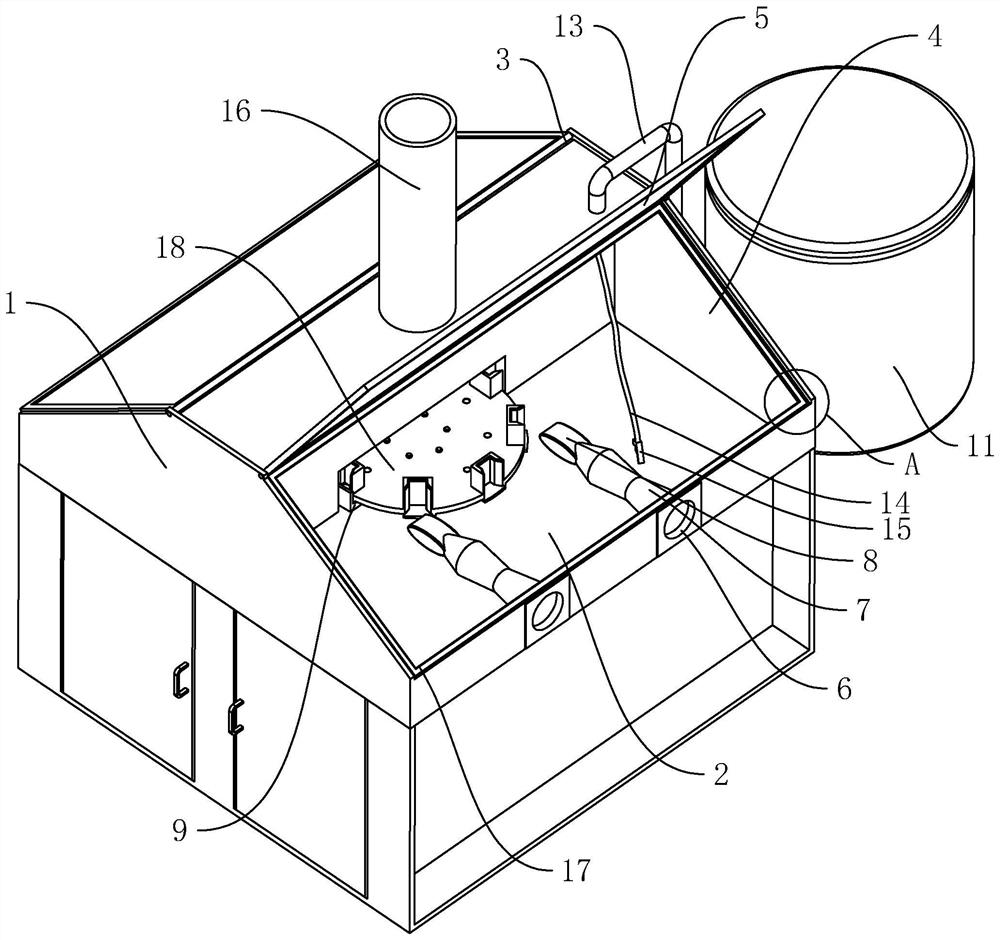

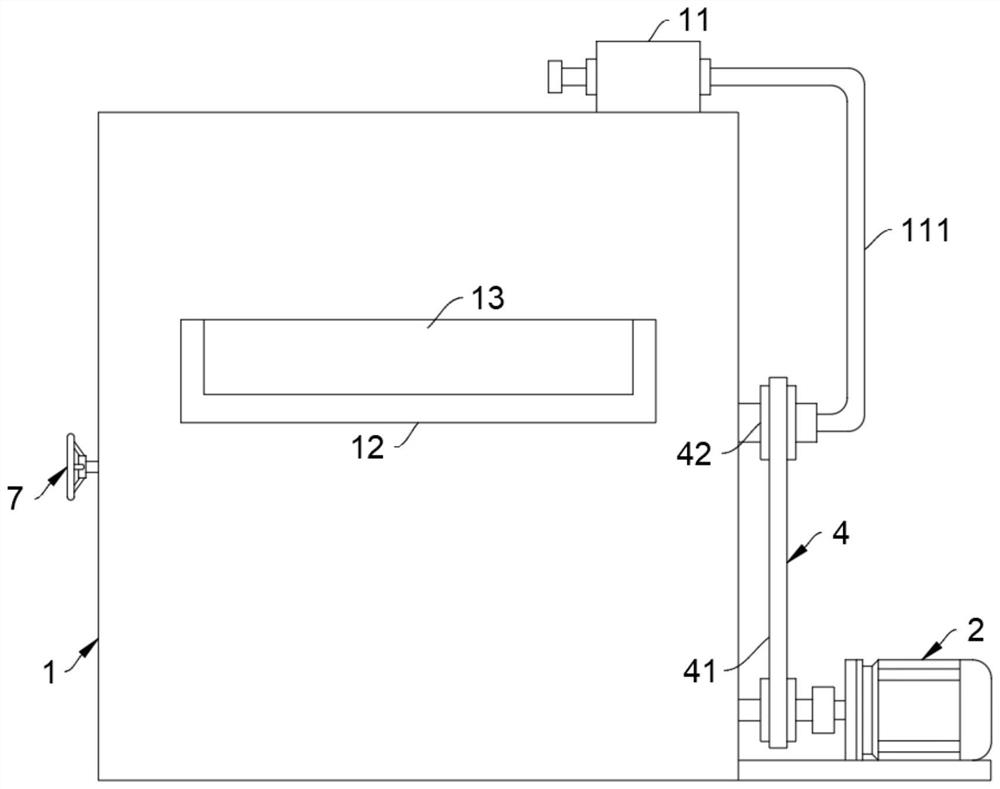

Stem cell culture device and culture method thereof

InactiveCN113136335AEasy to addQuick addBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyAnimal science

The invention discloses a stem cell culture device and a culture method thereof, and relates to the technical field of stem cell culture. The problem that nutrient solution adding efficiency is low is solved. The device comprises a machine body, a liquid box is arranged on the outer wall of the top of the machine body, a liquid conveying pipe is arranged on the outer wall of the top of the liquid box, a one-way valve is arranged on the circumferential outer wall of the liquid conveying pipe, and the other end of the liquid conveying pipe penetrates through the outer wall of the top of the machine body; an adjusting hand is arranged on the outer wall of the top of the machine body, a rotating column is arranged on the inner wall of the top of the machine body, the input end of the rotating column is connected with the output end of the adjusting hand through a transmission shaft, and three connecting bases are arranged on the circumferential outer wall of the rotating column. The culture method of the device comprises the following steps: after culture dishes are sequentially placed on a placing disc, an ultraviolet lamp is turned on to continuously sterilize the organism for 30 to 100 minutes. A nutrient solution is rapidly added, the culture device does not need to be repeatedly opened, pollution hidden dangers are reduced, the culture increase rate is increased, and the working time is greatly saved.

Owner:湖北明德健康科技有限公司

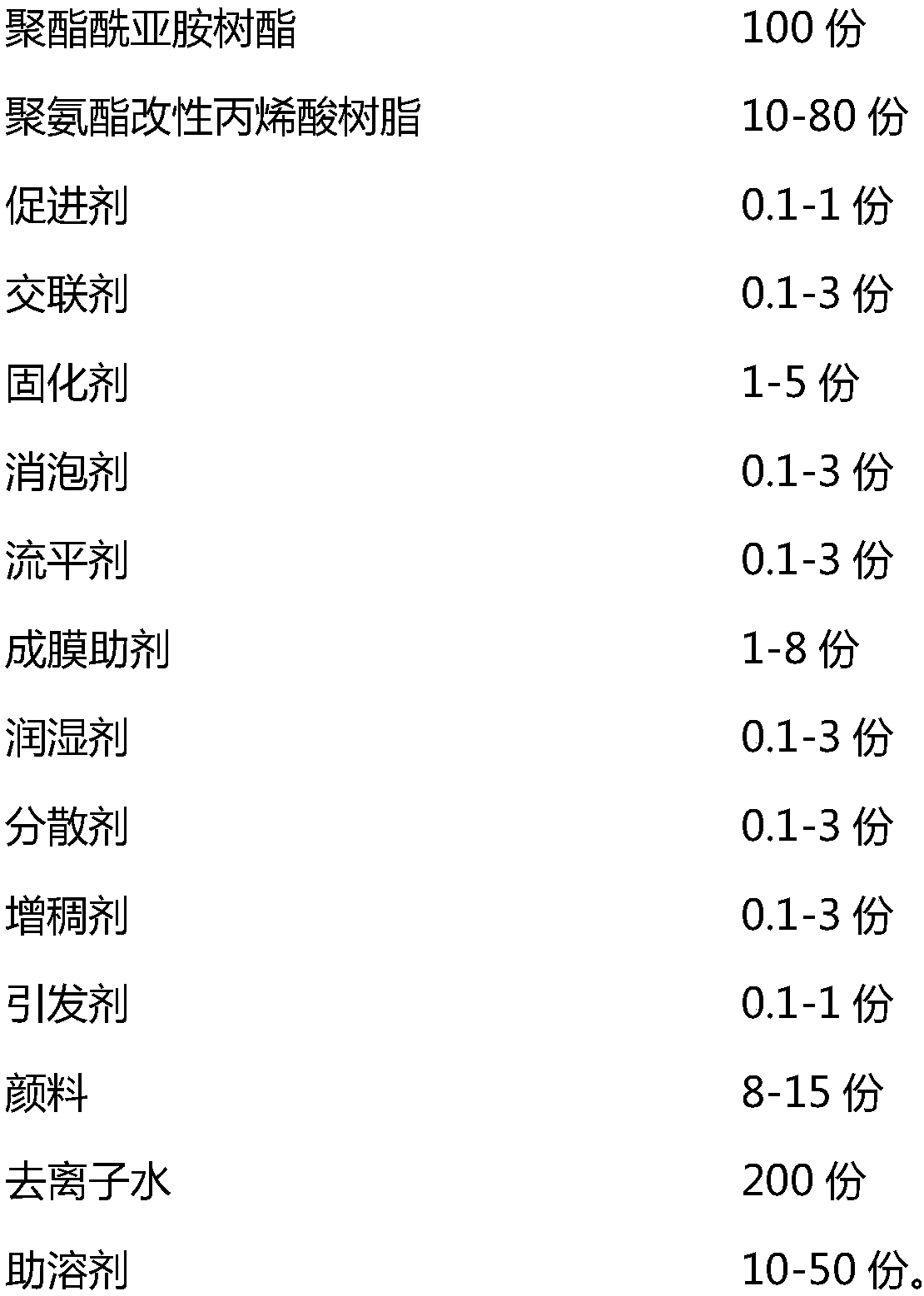

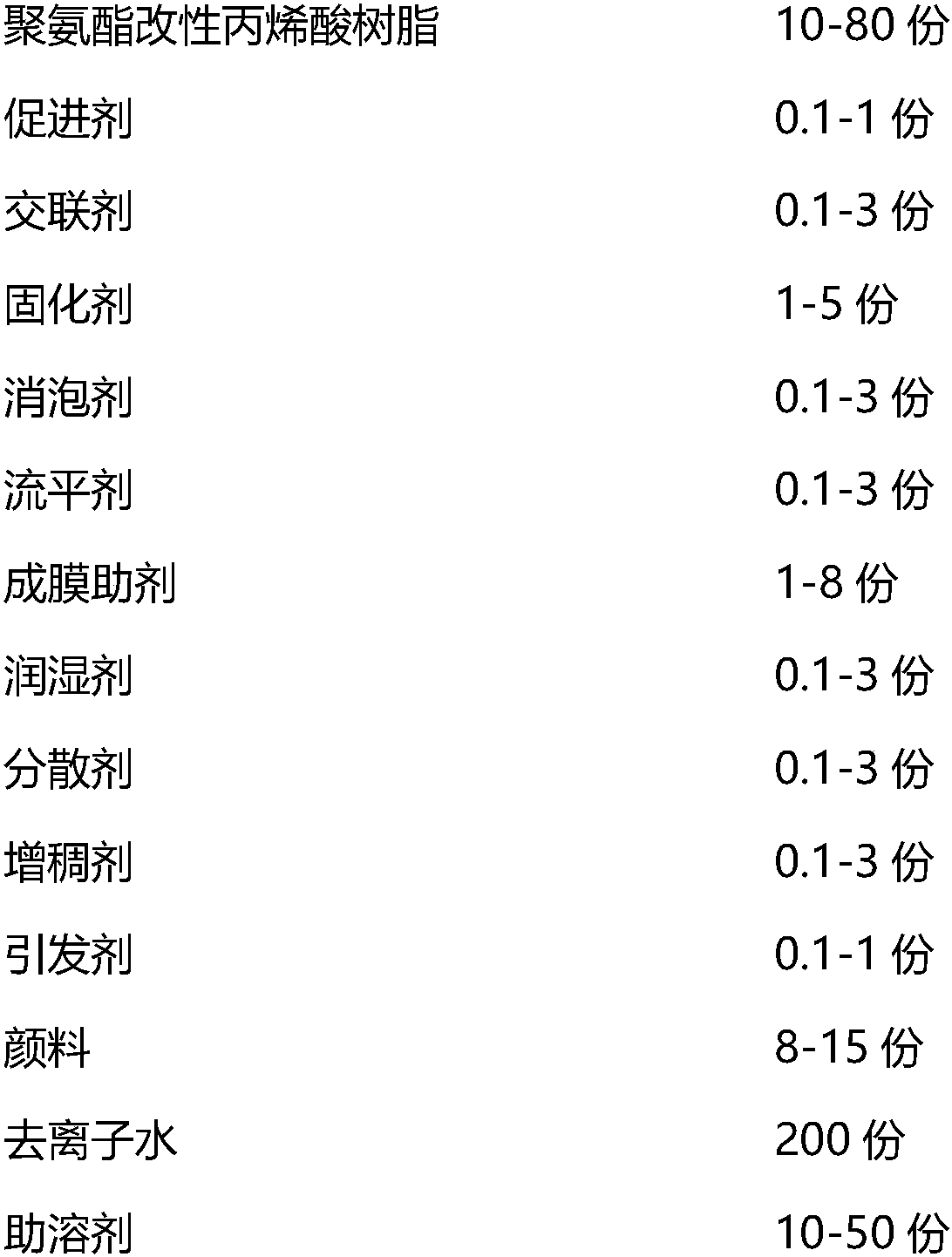

High heat-resistant waterborne coating

InactiveCN108047929AReduce contentReduce manufacturing costFireproof paintsPolyurea/polyurethane coatingsPolyesterAcrylic resin

The invention discloses a high heat-resistant waterborne coating. The high heat resistant waterborne coating is made from a variety of raw materials, the high heat-resistant waterborne coating is prepared from, by weight, 100 parts of polyester imide resin, 10-80 parts of polyurethane modified acrylic resin, 0.1-1part of accelerant, 0.1-3 parts of cross-linking agents, 1-5parts of curing agents, 0.1-3 parts of antifoaming agents, 0.1-3 parts of flatting agents, 1-8 parts of coalescing agents, 0.1-3 parts of wetting agents, 0.1-3 parts of dispersing agents, 0.1-3parts of thickening agents, 0.1-1 part of initiating agent, 8-15 parts of pigments, 200 parts of deionized water and 10-50 parts of cosolvents. The invention further provides a preparation method of the high heat-resistant waterborne coating. The high heat-resistant waterborne coating has good heat resistance, and has a good heat insulation effect, can adapt to a higher temperature environment, the hardness of the coating is increased by adding a small amount of curing agent, and the coating has good high temperature resistance and weather resistance, thus not only the hidden danger of environmental pollution is reduced, andbut also the production cost can be reduced.

Owner:肇庆易涂宝涂料有限公司

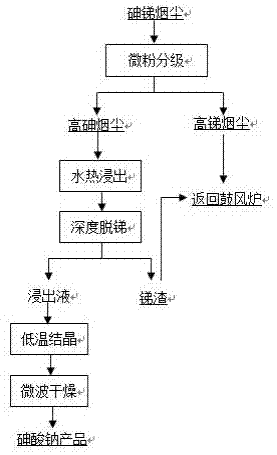

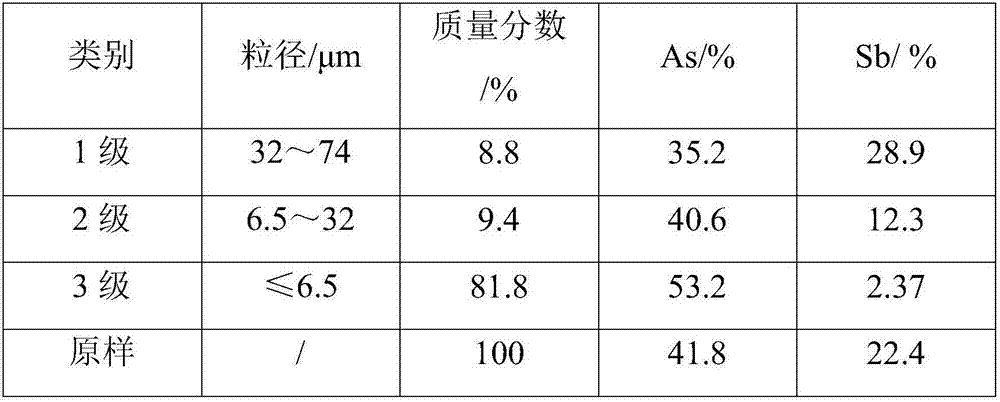

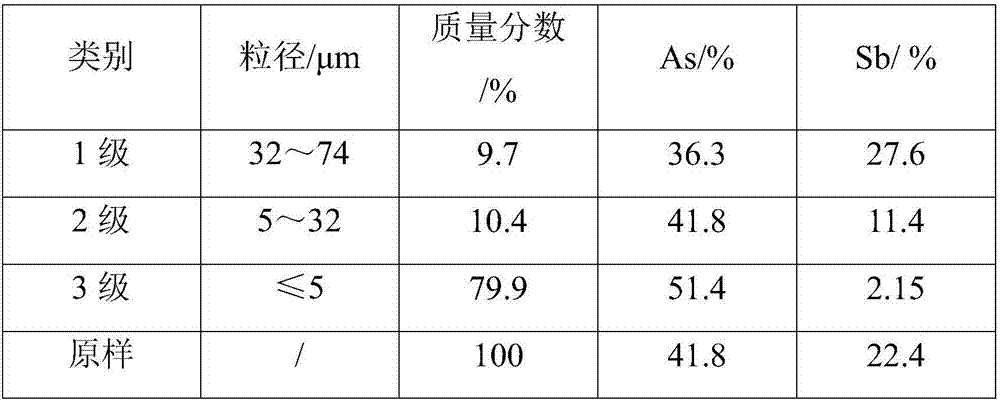

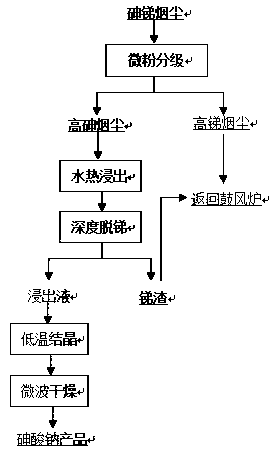

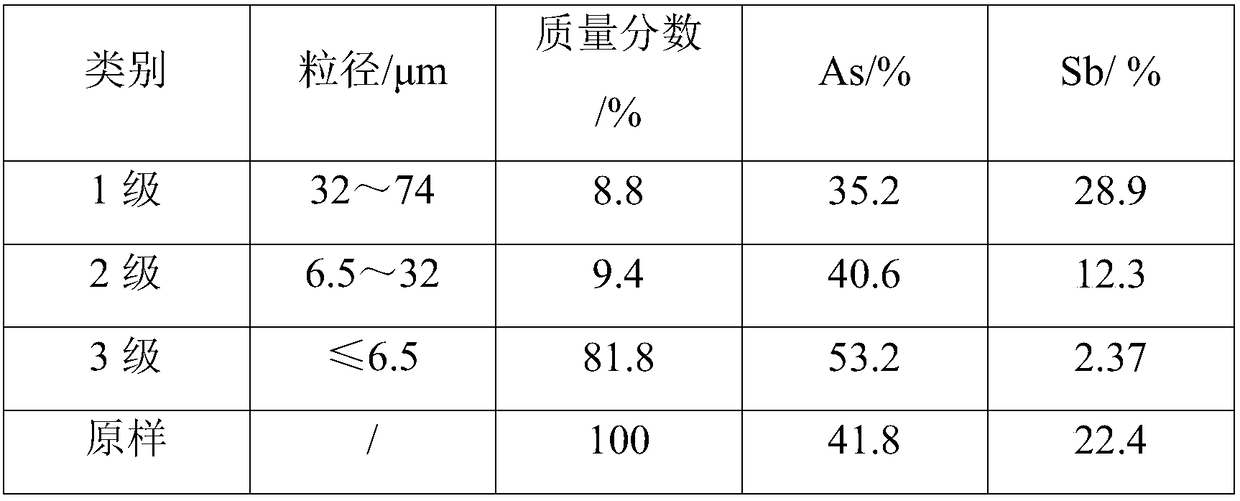

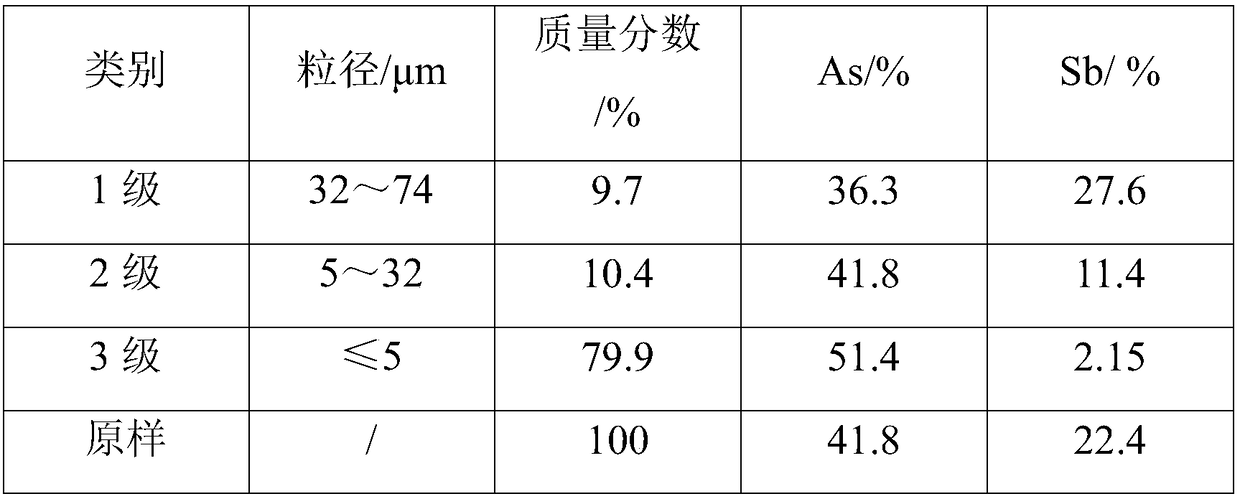

Efficient comprehensive utilization method of arsenic and antimony in arsenic and antimony smoke

ActiveCN107365913AReduce Pollution PotentialEliminate Pollution PotentialProcess efficiency improvementSodium saltArsenic product

The invention relates to an efficient comprehensive utilization method of arsenic and antimony in arsenic and antimony smoke and belongs to the technical field of non-ferrous metallurgy. The method comprises the specific steps that the arsenic and antimony smoke is subjected to stge treatment, fine powder smoke obtained through separation is put into hot water according to the formula that the liquid-solid ratio is 5:1, agitation leaching is conducted for 60 min at the temperature is 85 DEG C, and solid-liquid separation is conducted after leaching; an oxidizing agent is slowly added into leaching liquid, the volume percentage of the oxidizing agent is 3%, stirring is continuously conducted for 60 min, and arsenic-containing leaching post-liquid and antimony-containing leaching residues are obtained after filtering; a sodium salt solution is added into the leaching post-liquid, the mixture is subjected to low-temperature concentration and crystallization under the microwave condition after sufficient stirring, sodium arsenate crystals are obtained after centrifugal filtering, and crystallization mother liquor is used circularly; and the sodium arsenate crystals are sent to microwave drying equipment to be dried, and products are obtained after drying. According to the method, the arsenic and antimony smoke is subjected to stage treatment according to the grain size, enrichment and separation of arsenic and antimony can be achieved, operation is easy, and the cost is effectively reduced; and separated arsenic-enriched smoke is leached, refined and crystallized, arsenic products are formed for export sales, antimony-containing materials return to the procedure, and resource recycling is achieved.

Owner:红河绿地环保科技发展有限公司

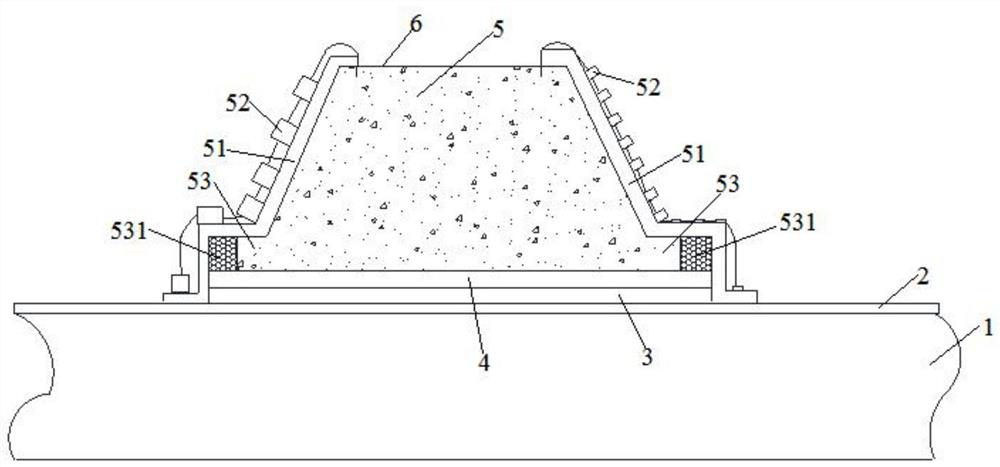

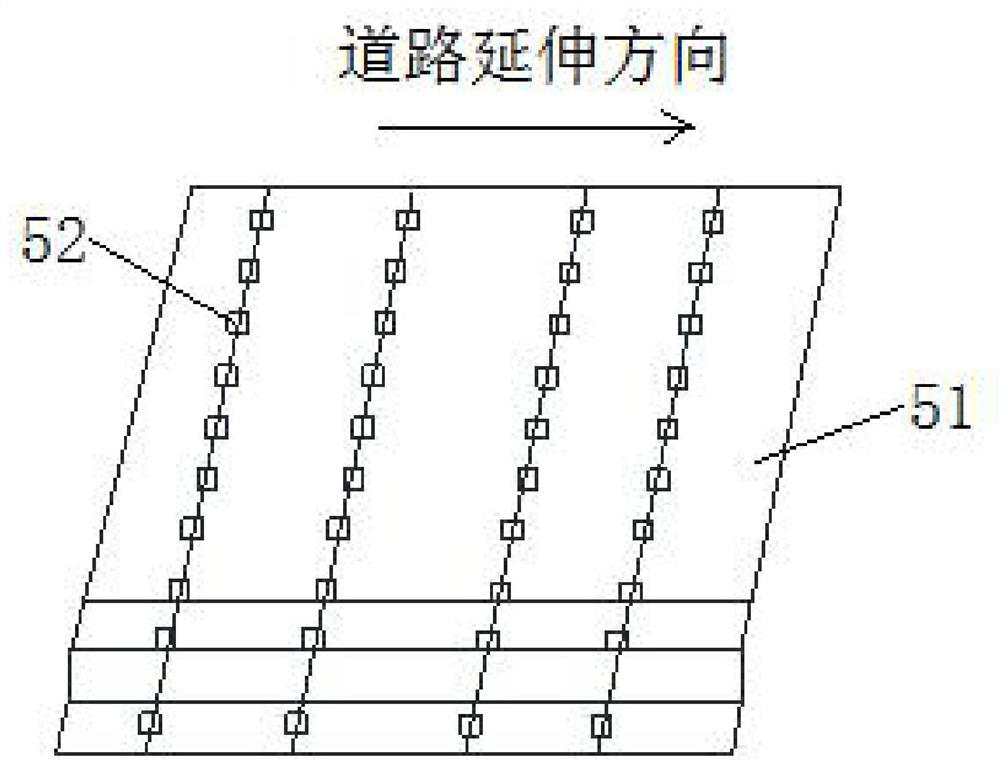

Temporary road structure and construction method thereof

PendingCN112458813AGood road smoothnessAvoid sinking or deformingProtective foundationTemporary pavingsEnvironmental geologyStructural engineering

The invention relates to a temporary road structure and a construction method thereof. The temporary road structure is sequentially paved with a first impermeable film layer, a bentonite waterproof cushion layer and a roadbed body from bottom to top. Wherein the first impermeable film layer is paved above an original impermeable film layer of a garbage heap body; a pavement is arranged at the topend of the roadbed body; the temporary road structure can effectively prevent the impermeable film from being punctured, so that landfill gas and leachate in a garbage heap are prevented from leaking,and the overall stability of the garbage heap is prevented from being influenced; meanwhile, the pavement is good in flatness, the capacity of bearing vertical loads downwards transmitted by the pavement can be achieved in the temporary road period operation period, the loads are effectively diffused, and a garbage heap cannot sink or deform. The roadbed body and the road surface are of a mixed structure comprising soil and gravels.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

Environmentally-friendly size composition for tyre surface of tyre and preparation method thereof

ActiveCN102408589BEasy to useImprove performanceSpecial tyresRolling resistance optimizationStearic acidButadiene-styrene rubber

The invention discloses an environmentally-friendly size composition for a tyre surface of a tyre and a preparation method thereof. The environmentally-friendly size composition comprises natural rubber, butadiene styrene rubber, butadiene rubber, carbon black, zinc oxide, stearic acid, an antiager, C5 resin, insoluble sulfur, environmentally-friendly arene oil, an accelerator and a homogenizing agent and various other components. The environmentally-friendly size can be prepared by the steps of plastifying and mixing the raw materials and the like. The environmentally-friendly size composition for the tyre surface of a tyre and size obtained by using the preparation method have better breaking strength, tensile strength and hardness, meet environmentally-friendly requirement and are prepared from environmentally-friendly raw materials which do not contain harmful substances, wherein arene oil, C5 resin, insoluble sulfur, carbon black and the like belong to the environmentally-friendly materials; and through adopting the environmentally-friendly raw materials coordinated with reasonable composition design, the environment pollution hidden danger caused in the production and use processes is greatly reduced, and the product has wider safety, economy and adaptability.

Owner:SICHUAN YUANXING RUBBER

Brewing technique of reutilizing Vaccinium bracteatum pomace

InactiveCN105567506AIncrease the way of deep processingReduce Pollution PotentialAlcoholic beverage preparationFruit wineNutritive values

The invention discloses a brewing technique of reutilizing Vaccinium bracteatum pomace. The brewing technique comprises the following steps: S1, uniformly mixing 100 to 280 parts by weight of maltose with 200 to 450 parts by weight of water, adding 0.5 to 1.8 parts by weight of multiple microorganisms, and fermenting for 8 to 18 days in a sealing manner to obtain a product A; S2, adding 15 to 30 parts by weight of Vaccinium bracteatum pomace and 1.2 to 3.0 parts by weight of fruit wine distiller yeast into the product A, and fermenting for 10 to 20 days in a sealing manner to obtain a product B; S3, filtering and deactivating the product B to obtain a finished product. By adopting the brewing technique, the Vaccinium bracteatum pomace can be sufficiently utilized; by utilizing the maltose, the cytoderm of the Vaccinium bracteatum pomace cells can be broken, and active substances can be released; by adopting the sectional feeding and compound bacteria fermenting technique, the brewing technique is simplified, and the cost is saved; and the obtained fruit wine product is high in nutritive value.

Owner:梁红昌

Novel method for direct extraction recovery of ammonia nitrogen from electrolyzed manganese slag

InactiveCN102795641BReduce Pollution PotentialRealize extraction and utilizationSolid waste disposalAmmonium sulfatesRecovery methodElectrolysis

The invention discloses a novel method for direct extraction recovery of ammonia nitrogen from electrolyzed manganese slag. The novel method comprises the following steps of directly adding an alkaline preparation and a foaming agent into fresh manganese slag subjected to crushing, dispersion, drying and ball-milling so that a pH value and humidity in an electrolyzed manganese slag environment are changed and transformation of a solid phase and a liquid phase into a gas phase is promoted, and introducing released NH3 gas into a multistage absorption device by a negative-pressure suction device cover located above a mixer so that the released NH3 gas is absorbed by water or dilute sulphuric acid and then is transformed into ammonia water or ammonium sulfate. The novel method for direct extraction recovery of ammonia nitrogen from electrolyzed manganese slag solves the problem that the existing extraction recovery methods have high water consumption, high energy consumption and complex processes, greatly reduces environmental pollution hidden troubles of ammonia nitrogen in manganese slag, and realizes extraction and utilization of an ammonia nitrogen resource well.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

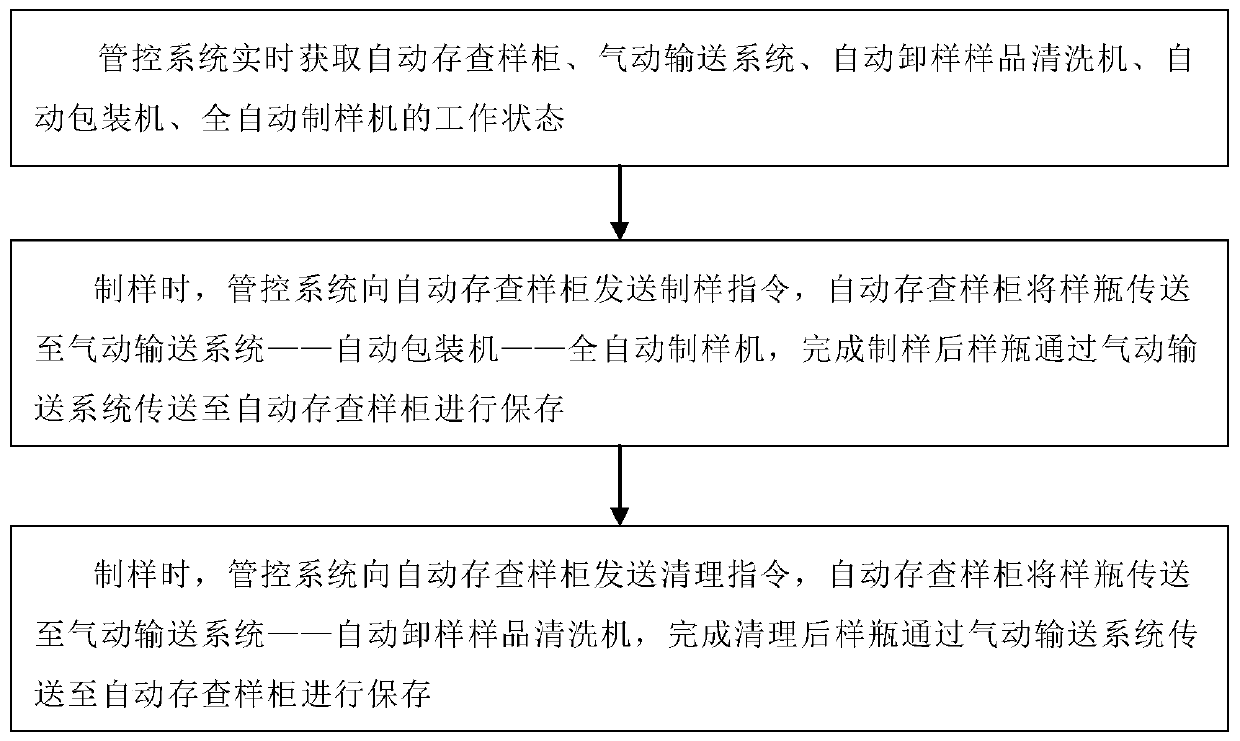

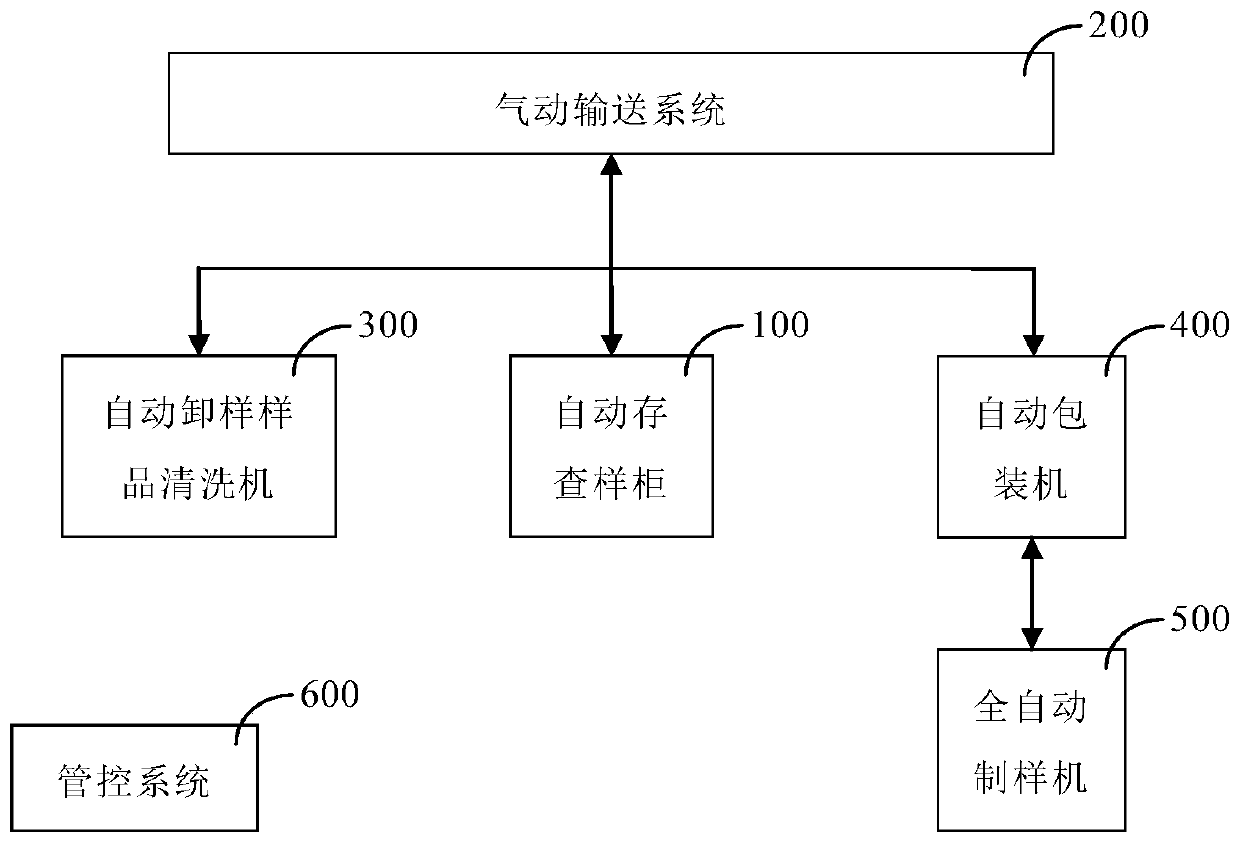

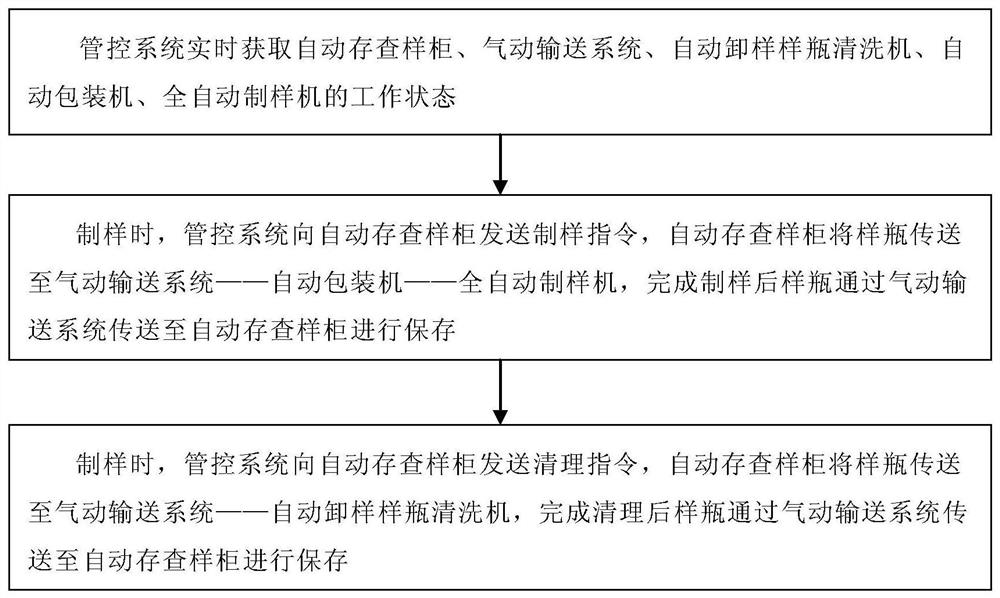

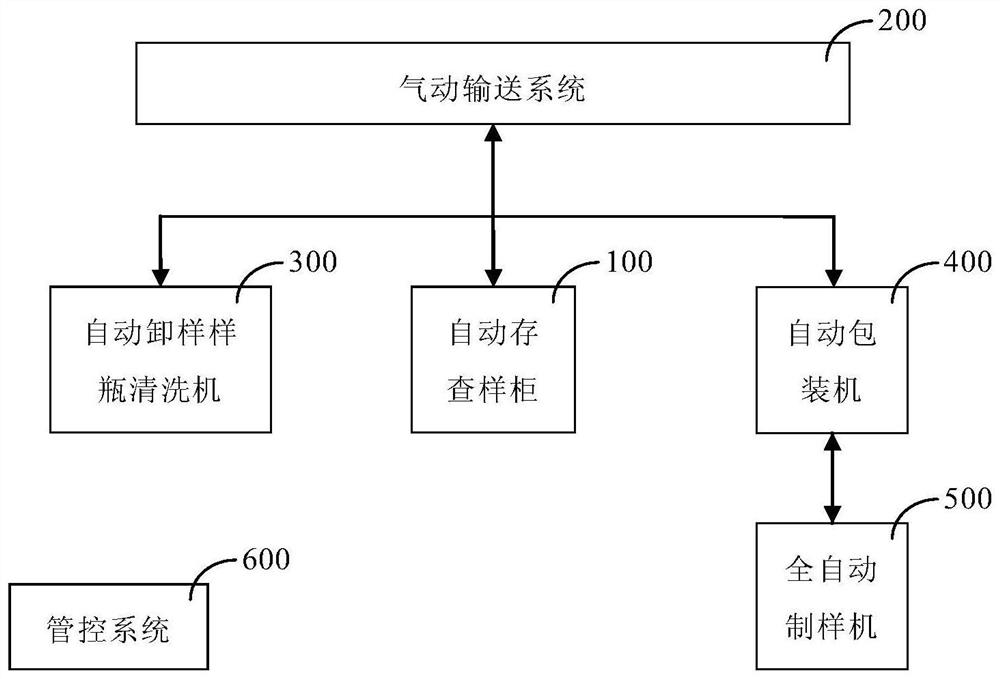

Sample preparation operation control method

ActiveCN111498518AReduce Pollution PotentialRealize unmannedStorage devicesControl systemProcess engineering

The invention discloses a sample preparation operation control method. Operation of a sample preparation operation system comprises the steps of acquiring the working states of an automatic sample storing and checking cabinet (100), a pneumatic conveying system (200), an automatic sample discharging and cleaning machine (300), an automatic packaging machine (400) and a full-automatic sample preparation machine (500) in real time and controlling the sample preparation process, the cleaning process and the cleaning process through instructions by a control system (600). According to the sample preparation operation control method, full-closed automation of samples in the preparation, storage, transportation and cleaning processes can be achieved, manual intervention is avoided, and the accuracy and effectiveness of the samples are improved.

Owner:JIANGXI GUANGMING INTELLIGENT TECH CO LTD

A control method for sample preparation and transport

ActiveCN111498518BReduce Pollution PotentialRealize unmannedStorage devicesMaterial analysisTransport systemControl system

Owner:JIANGXI GUANGMING INTELLIGENT TECH CO LTD

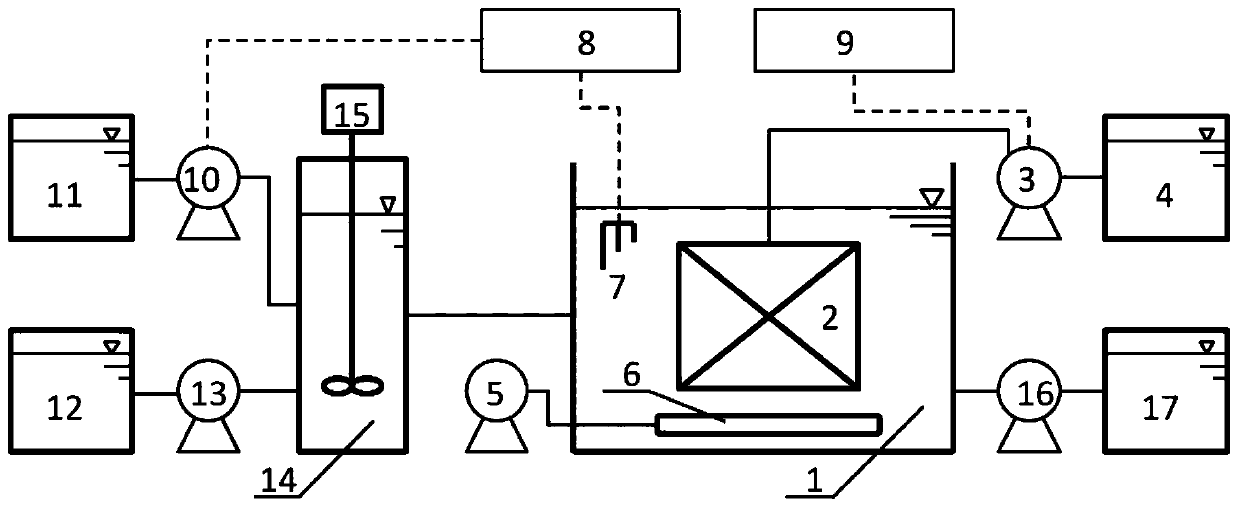

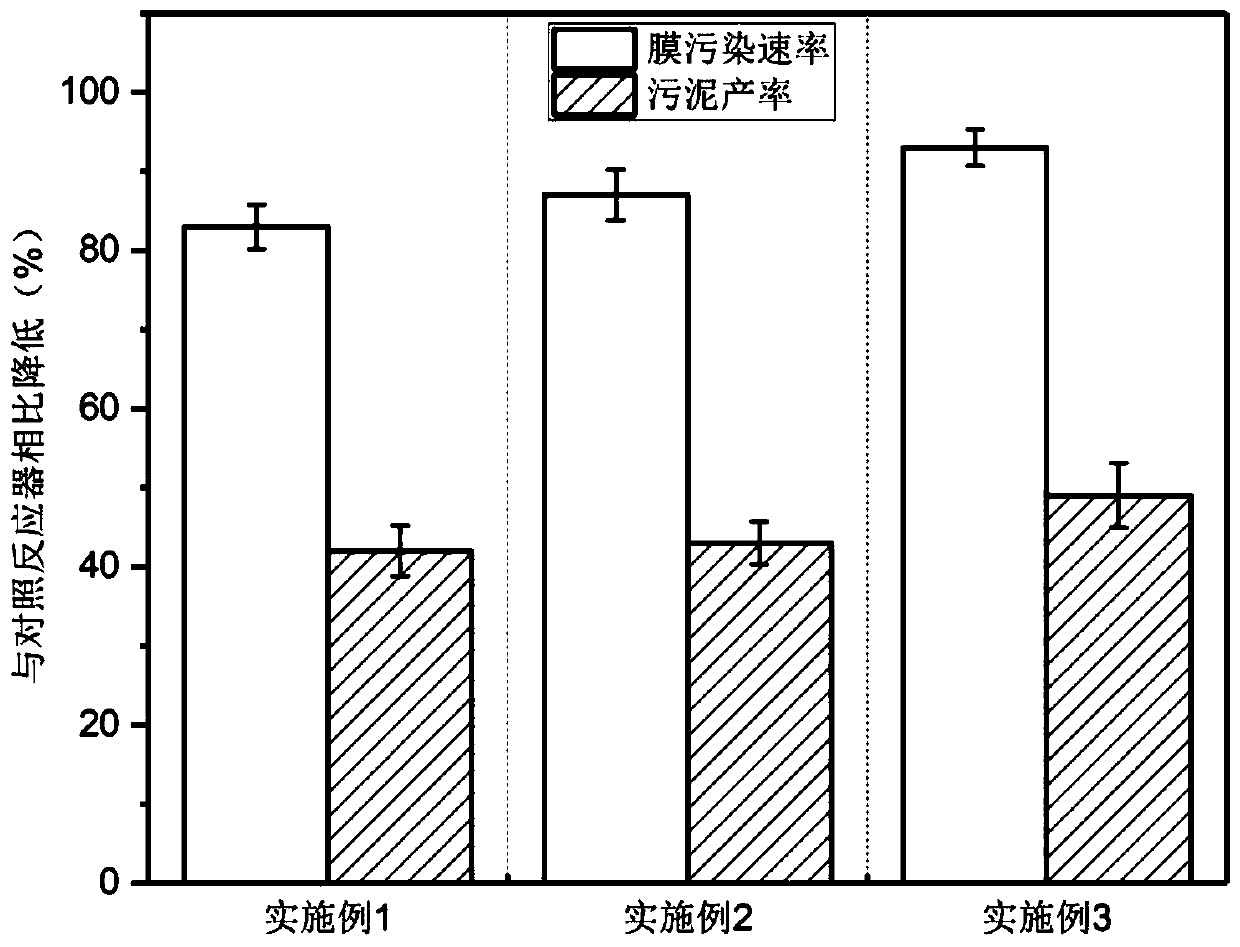

Membrane bioreactor device synergistically regulated by utilizing iron-based water treatment material

PendingCN110746051AGood biocompatibilityReduce pollutionWater contaminantsMultistage water/sewage treatmentUltrafiltrationTreated water

The invention discloses a membrane bioreactor device synergistically regulated by an iron-based water treatment material. The device is structurally characterized in that an ultrafiltration membrane assembly is arranged in a reactor, treated water enters an effluent water tank through a water outlet pump, and the water outlet pump is connected with a time relay to control the operation or stop ofthe water outlet pump. The reactor is provided with a perforated aeration pipe which is connected with an aeration pump. A liquid level contact is arranged at the upper part of the reactor and is connected with a liquid level meter to control the turn-on of a water inlet pump, and the water inlet pump is connected with a raw water tank. A ferrate solution tank is connected with a dosing pump, a medicament enters a pre-oxidation reactor through the dosing pump, and a mechanical stirrer is arranged in the pre-oxidation reactor. A bio-polymeric ferric sulfate dosing pump is arranged at the lowerpart of the reactor and is connected to a bio-polymeric ferric sulfate solution tank. Advanced oxidation and biological flocculation technologies are combined together, so that the problem of biological membrane pollution caused by refractory organic matters can be effectively relieved. The membrane pollution potential of the wastewater can be remarkably reduced, the sludge yield can be effectively reduced by the residual high-valence iron, and the quality of effluent water is improved.

Owner:NORTHEAST DIANLI UNIVERSITY

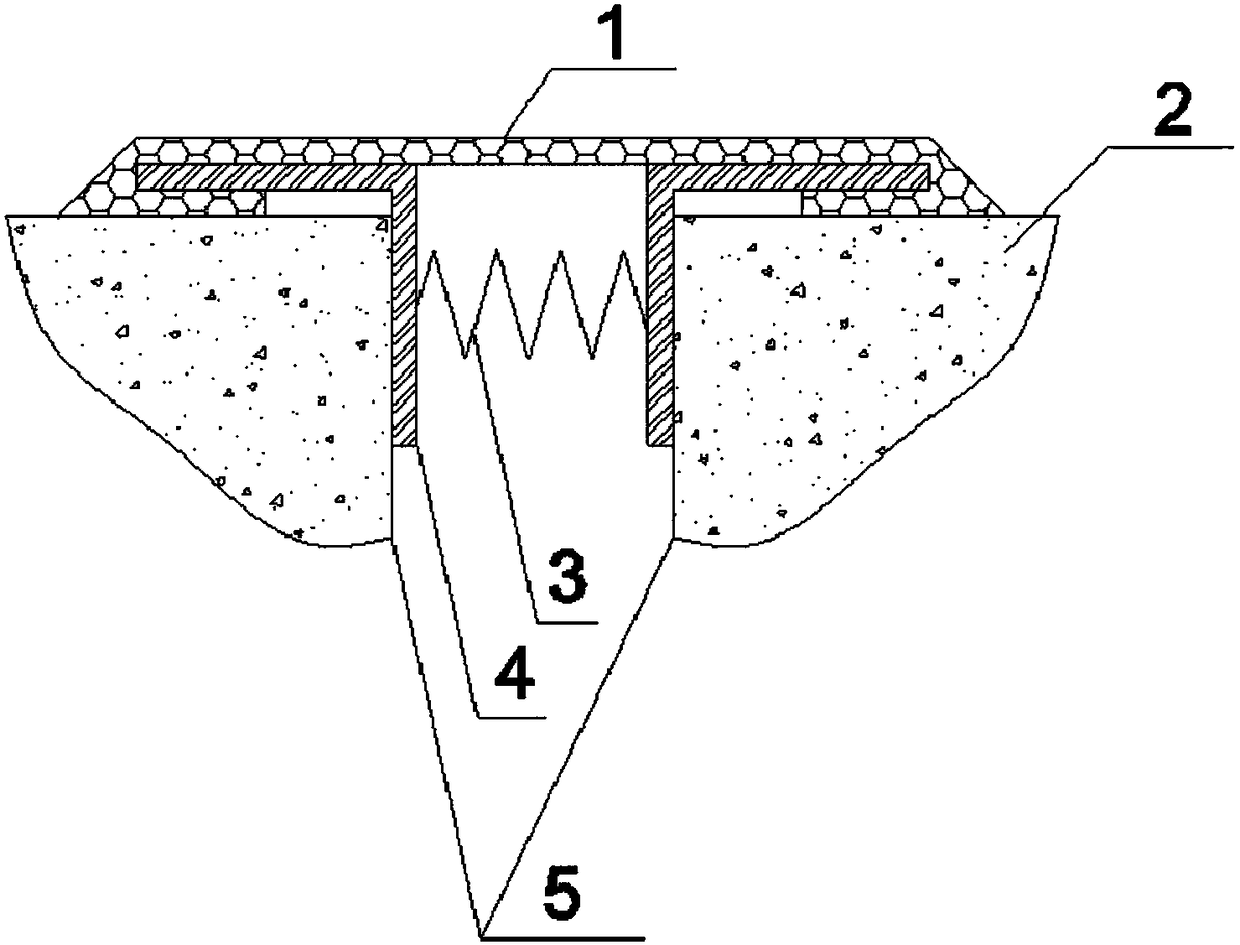

Sealing device for expansion joint of clean workshop

The invention discloses a sealing device for an expansion joint of a clean workshop. The sealing device comprises an abrasion-resistant elastic soft material, an elastic material and steel skeletons;the steel skeletons are tightly attached to floors of the clean workshop; the expansion joint is embedded in the mode of being compressed towards the inner side, and after being embedded, the expansion joint is sealed and compactly embedded through the abrasion-resistant elastic soft material in the horizontal direction. The sealing device has the beneficial effects that customized mass productionprofiles are adopted, the structure is simple, cutting can be conducted for use according to the length of the expansion joint, using is convenient, and the problems that a current expansion joint ofthe clean workshop is filled with a polystyrene foam plate, a wall cracks during stretching out, drawing back and settlement of the clean workshop, and consequently the clean area environment is polluted are solved.

Owner:JIUZHITANG

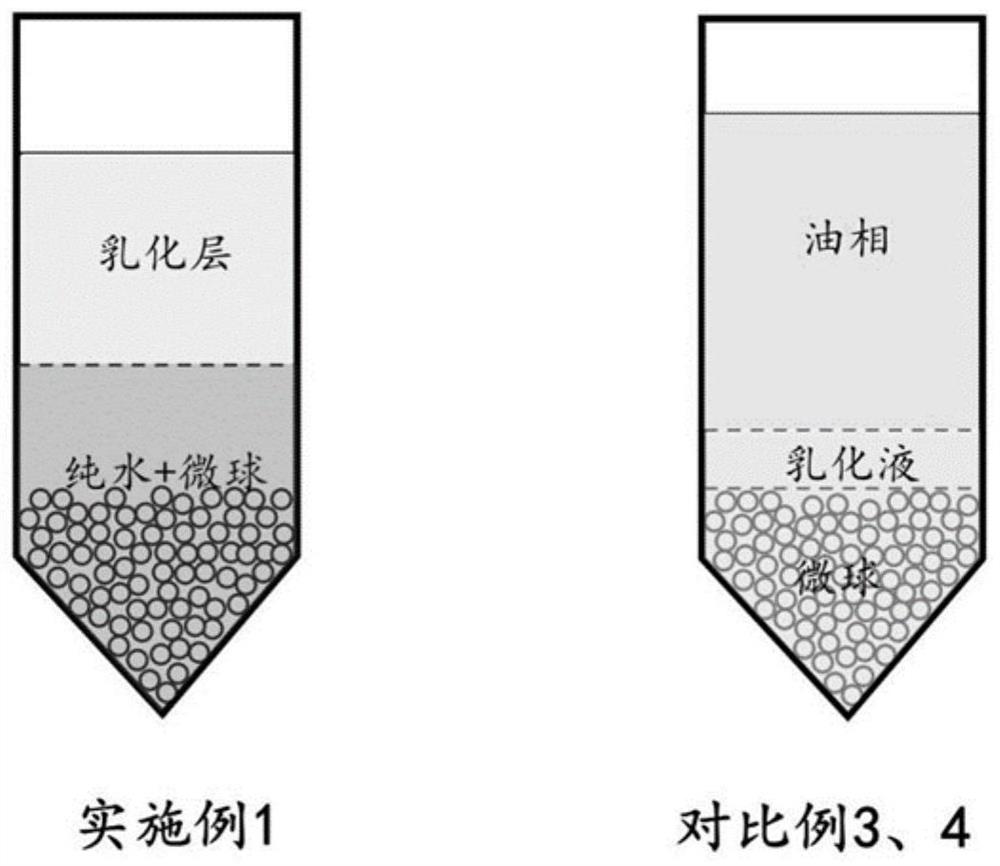

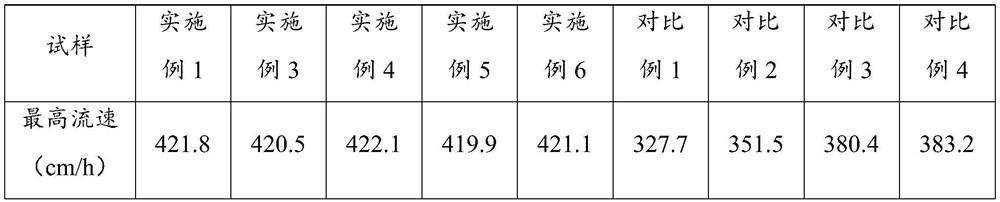

Cleaning method of agarose microspheres

ActiveCN114191848AReduce dosageReduce volumeLiquid separationMicroballoon preparationMicrosphereOil phase

The invention provides a method for cleaning agarose microspheres, which comprises the following steps: standing and layering an agarose microsphere emulsion obtained by an emulsification-cooling method, and separating an upper oil phase to obtain a lower agarose microsphere emulsion layer; adding water into the agarose microsphere emulsion layer, standing for layering, separating to obtain an upper emulsion layer and a lower agarose microsphere water-phase layer, and separating from the lower water-phase layer to obtain agarose microspheres; and repeatedly adding water into the upper emulsion layer for layering separation, mixing the agarose microspheres obtained by each time of separation, and washing with water to obtain the high-purity agarose microspheres. According to the method, firstly, the emulsion is subjected to standing, so that most of oil phases are separated out, and the volume of an emulsion layer to be cleaned is greatly reduced, so that the maximum cleaning amount which can be realized at a time can be increased, and the running cost of equipment is saved; meanwhile, reduction of the volume of the emulsion layer must reduce the dosage of the cleaning liquid, the cleaning cost is further reduced, and the method is suitable for industrial production; the obtained microspheres have good physicochemical properties after the cross-linking reaction is completed.

Owner:WUHAN RUIFA MEDICAL DEVICES CO LTD

Concrete slurry containing magnesium and its preparation process and application thereof

InactiveCN100445233CHigh activityReduce the burden onSolid waste managementFilling materialsPhosphogypsum

Owner:何金星 +1

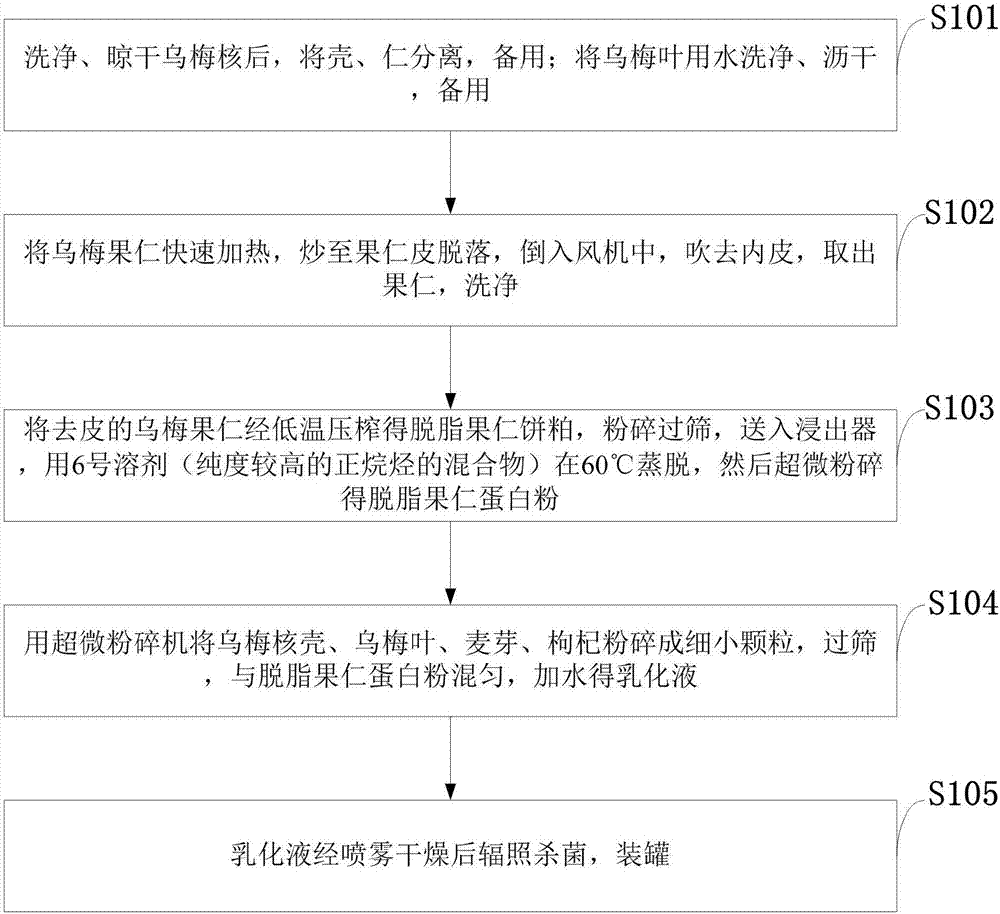

Selenium-enriched dark plum kernel protein powder, energy bars made of same and preparation method

ActiveCN106962943AImprove production efficiencySolve abandoned problemsProtein composition from waste materialsFood ingredient functionsPhysical chemistrySpray dried

The invention belongs to the technical field of food deep-processing and discloses selenium-enriched dark plum kernel protein powder, energy bars made of the same and a preparation method. The selenium-enriched dark plum kernel protein powder is composed of 30-60 parts of dark plum kernel, 20-40 parts of dark plum leaf, 10-30 parts of malt and 10-20 parts of medlar. The preparation method includes: washing and airing the dark plum kernel, and separating shell from kernel for standby use; using water to clean the dark plum leaf, and draining the water for standby use; quickly heating dark plum nutlet, pouring into a fan to blow away inner skin, and taking out nutlet; subjecting skinless dark plum nutlet to low-temperature squeezing to obtain degreased nutlet cake meal, crushing, sieving, feeding into an extractor, evapo-separating at 60 DEG C, and performing superfine grinding to obtain degreased nutlet protein powder; crushing the dark plum kernel and shell, the dark plum leaf, the malt and the medlar into fine particles, sieving, well mixing the fine particles with the degreased nutlet protein powder, and adding water to obtain an emulsion; subjecting the emulsion to spray drying before radiation sterilization, and tinning. By the method, the dark plum kernel and the dark plum leaf are changed into things of value from waste, potential trouble of environment pollution is reduced, and comprehensive production benefit of dark plum is increased effectively.

Owner:XIHUA UNIV

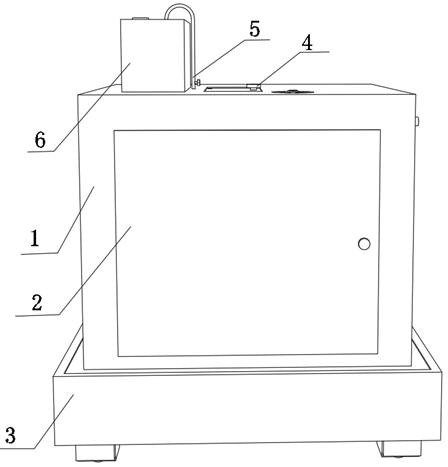

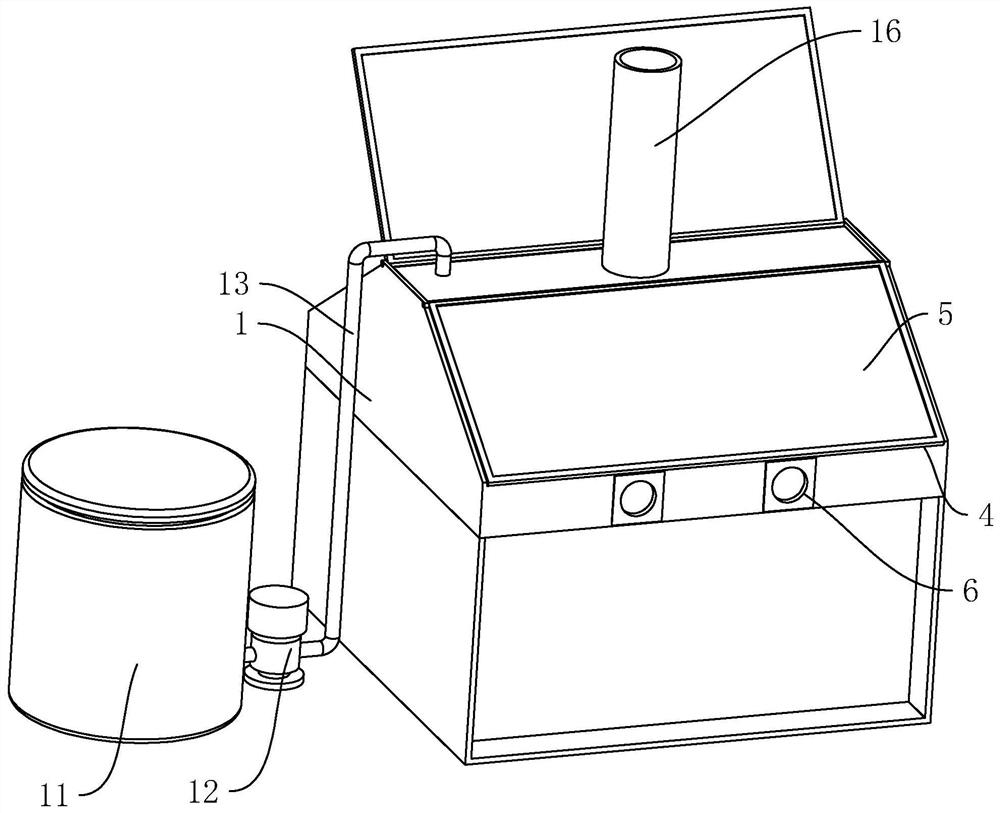

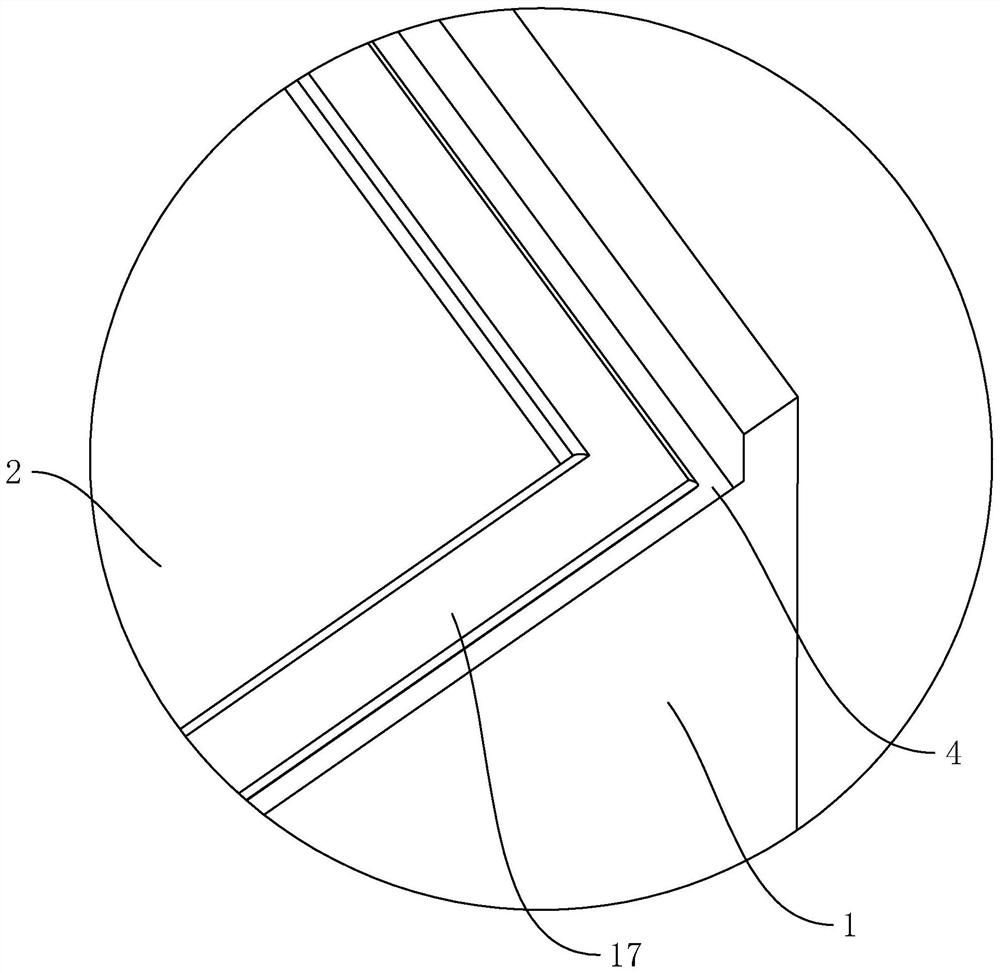

Filling and capping operation station for nail polish

ActiveCN113307211AImprove efficiencyAutomatically realize orderly arrangement and stackingBottle-handling machinesLiquid bottlingEngineeringMechanical engineering

The invention discloses a filling and capping operation station for nail polish, relates to packaging equipment, and aims to solve the problem that the health of workers is affected due to the fact that manual filling and capping are mostly completed in a relatively open environment, the key point of the technical scheme is that the filling and capping operation station for the nail polish comprises a cabinet body, wherein the cabinet body is provided with a filling chamber and a cover sealing chamber, the filling chamber and the cover sealing chamber are both provided with visual windows, the visual windows are provided with transparent glass, the filling chamber and the cover sealing chamber are both provided with two hand holes, the hand holes are provided with oversleeves, the ends of the oversleeves are provided with gloves, and the cabinet body is provided with an alternating mechanism, a discharging channel and a stacking mechanism, and the stacking mechanism is loaded with a stacking box. According to the filling and capping operation station for the nail polish, manual filling and capping of the nail polish in a sealed environment can be achieved in cooperation with workers, and the hidden danger that the health of the workers is affected by irritant gas is effectively reduced.

Owner:十条印刷器材科技(平湖)有限公司

Stainless steel metal-bearing solid waste pelletizing process

The invention belongs to the field of metallurgical raw material treatment and resource recycling, and relates to a stainless steel metal-bearing solid waste pelletizing process. The stainless steel metal-bearing solid waste pelletizing process comprises the steps that (1) chromite and stainless steel metal-bearing solid waste are mixed in proportion, and a mixture is obtained after ore grinding treatment; (2) bentonite and water are added into the mixture according to the proportion with the mass ratio of the mixture to the bentonite to the water being (86-90):(1-2.5):(7-16), and pelletizingis carried out after even mixing to obtain fresh pellets; and (3) the fresh pellets are preheated for 6-16 min at the temperature ranging from 850 DEG C to 1,100 DEG C to obtain preheated pellets, then the preheated pellets are roasted for 12-18 min at the temperature ranging from 1,200 DEG C to 1,350 DEG C, and high-quality pellets are obtained. According to the stainless steel metal-bearing solid waste pelletizing process, the proportion of the mixture, the bentonite and the water is reasonably controlled, meanwhile, the temperature and time of the preheating process and the roasting processare controlled within the specific range, the compressive strength of the finally-obtained pellets is high, the good drum strength and wear resistance index are achieved, and the subsequent transporting and in-furnace smelting requirements can be met.

Owner:BERIS ENG & RES CORP

Reutilizing method of HW13 waste epoxy resin and HW12 waste printing ink slag powder

InactiveCN111318556AReduce Pollution PotentialIncrease crosslink densitySolid waste disposalTransportation and packagingFirming agentProcess engineering

The invention relates to the technical field of treatment and recycling of HW49 hazardous waste, in particular to a reutilizing method of HW13 waste epoxy resin and HW12 waste printing ink slag powder. The method comprises the steps of preparing, blending, stirring, forming, cutting and the like. The preliminarily treated H13 waste epoxy resin powder and HW waste printing ink slag powder are mixedin a proportion, then a proper amount of PVC-SC5, active light calcium carbonate, a curing agent, toner and PE wax are added, thermoplastic forming is carried out after stirring and mixing, a novel section material is prepared after cooling and cutting a formed product, advanced treatment on the hazardous waste including the HW13 waste resin and HW12 waste printing ink slag is achieved, the industrial chain is extended, the principle of treating waste with waste, and turning waste into wealth is carried forward, and besides, the generated novel section material is endowed with corrosion resistance and oxidation resistance of part of raw materials.

Owner:珠海安能环境科学研究院有限公司

A box-dividing molding machine

ActiveCN104841890BRealize automated productionIncrease productivityMoulding machinesMolding machineEngineering

The invention relates to the technical field of sand mold casting, and concretely relates to a box division molding machine. The box division molding machine comprises a sandbox, a lower box molding device, an upper box molding device, a walk device and a push device, and the sandbox is a rectangular box body; the lower box molding device and the upper box molding device are positioned in the sandbox, the lower box molding device is positioned at the left side of the sandbox, and the upper box molding device is positioned at the right side of the sandbox; the walk device is positioned above the sandbox, the upper ends of the walk device and the lower box molding device are connected with the upper end of the upper box molding device, and the walk device is used for moving the lower box molding device and the upper box molding device; and the push device is positioned just behind the lower box molding device, and the push device is used for sending box closed sand mold to a conveyer belt and allowing the box closed sand mold to enter a next process. The box division molding machine adopting a manual coal beating machine principle realizes automatic production of box division castings, and also has the advantages of simple structure, low manufacturing cost and high production efficiency.

Owner:河北中和铸造有限公司

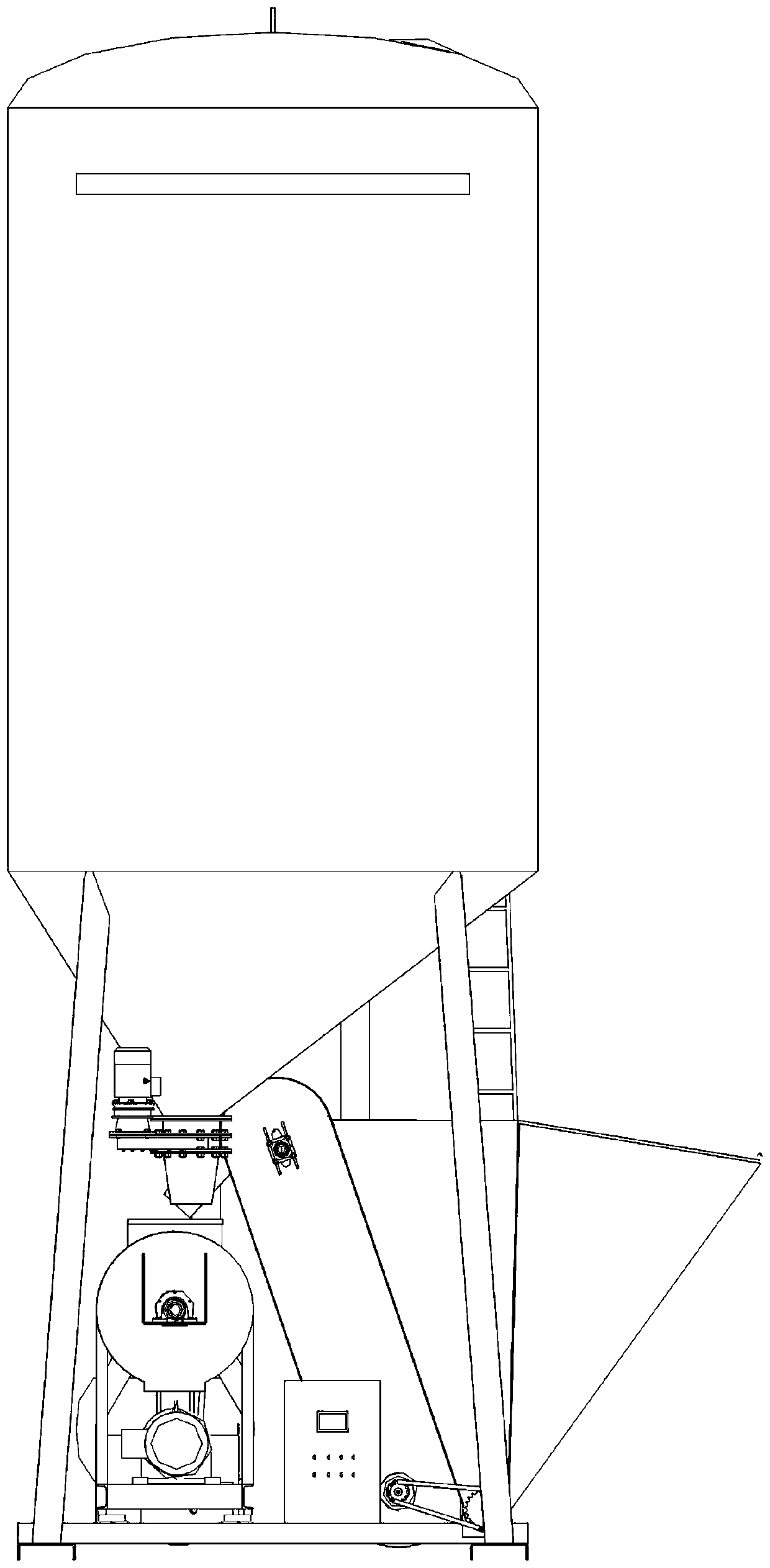

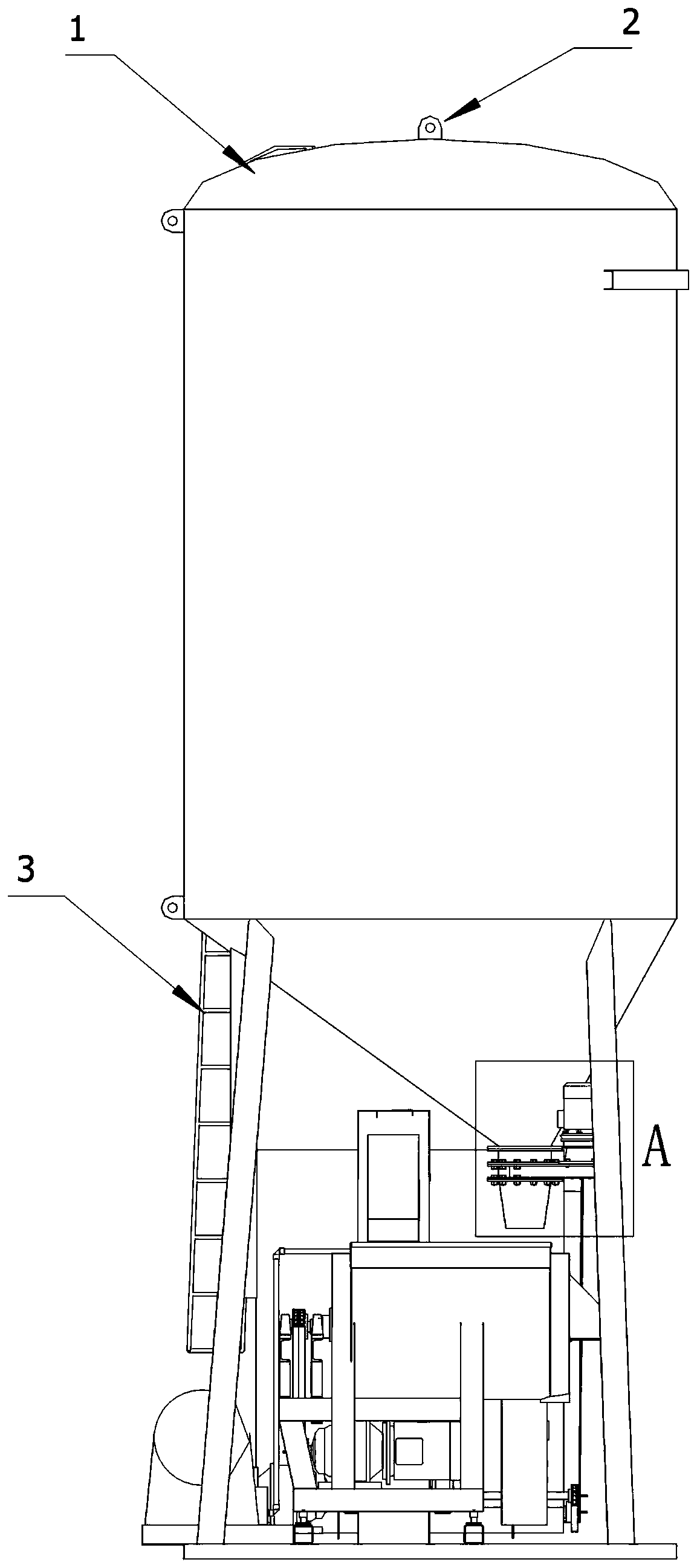

Mobile type multifunctional building material producing device

PendingCN110815580ASimple structureGuarantee the quality of finished productsMixing operation control apparatusIngredients weighing apparatusArchitectural engineeringEngineering

The invention discloses a mobile type multifunctional building material producing device. The mobile type multifunctional building material producing device comprises a base, and a tank body with a loading pipe and a ventilation pipe. The tank body is arranged on the base, a material conveying device, a stirrer and an additive metering pump device with an external additive outlet are arranged on the base, a discharging device is arranged on a discharging opening in the lower end of the tank body, two feeding openings are formed in the stirrer, one feeding opening is in abut joint with a discharging opening of the discharging device, one feeding opening is in abut joint with a discharging opening of the material conveying device, the stirrer is provided with a liquid adding opening shared by an additive and water, the external additive outlet is connected to the liquid adding opening of the stirrer, electronic balances are arranged on a stirrer support and four legs of the tank body, acontrol box is arranged on the base, and the control box is connected with the electronic balance of the stirrer, the electronic balances of the tank body, the stirrer, the additive metering pump device, the material conveying device and the discharging device. The device is mainly used for non first-tier and second-tier cities, manpower cost and construction cost are reduced, and production efficiency is improved.

Owner:陕西未来筑业实业有限公司

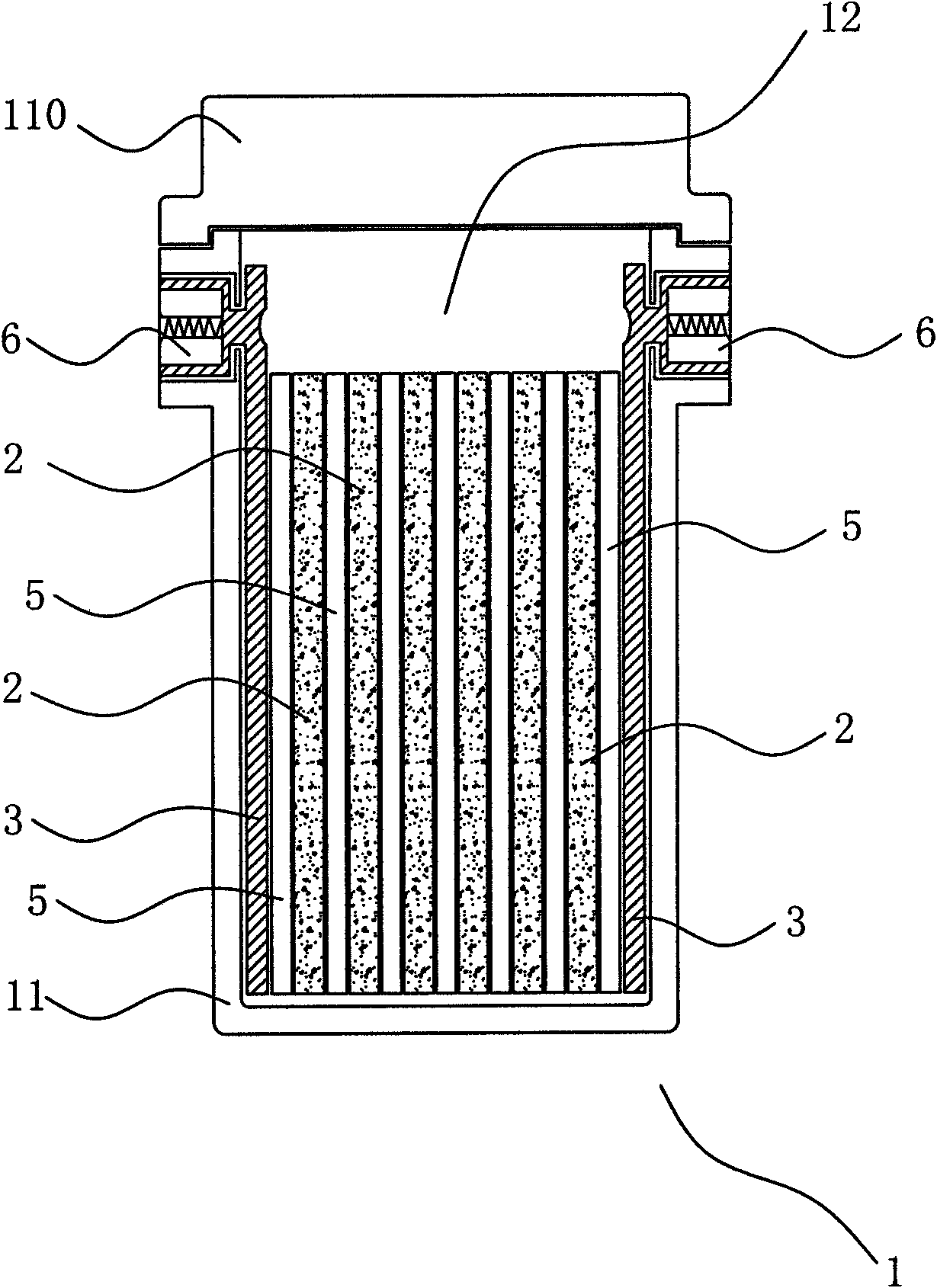

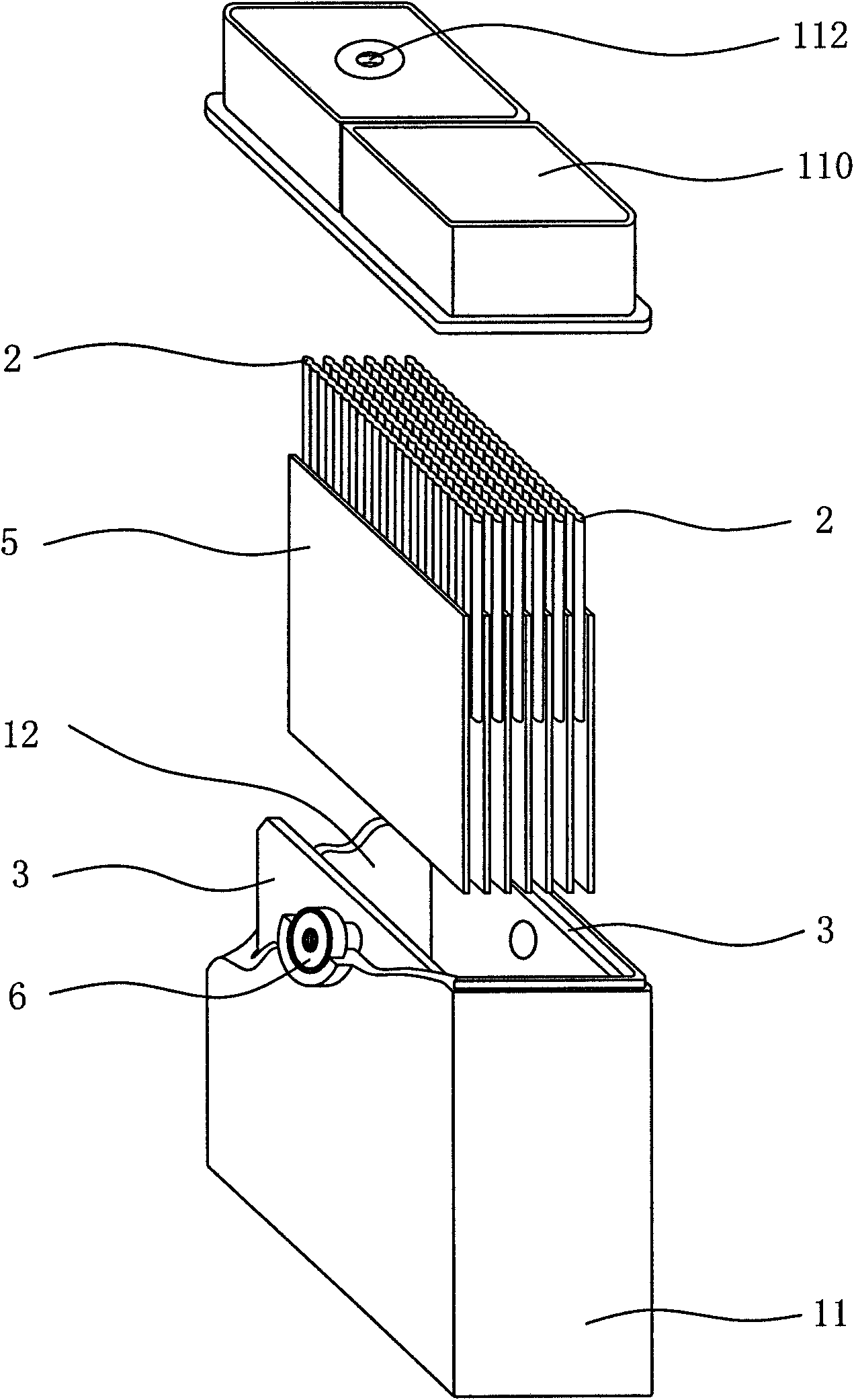

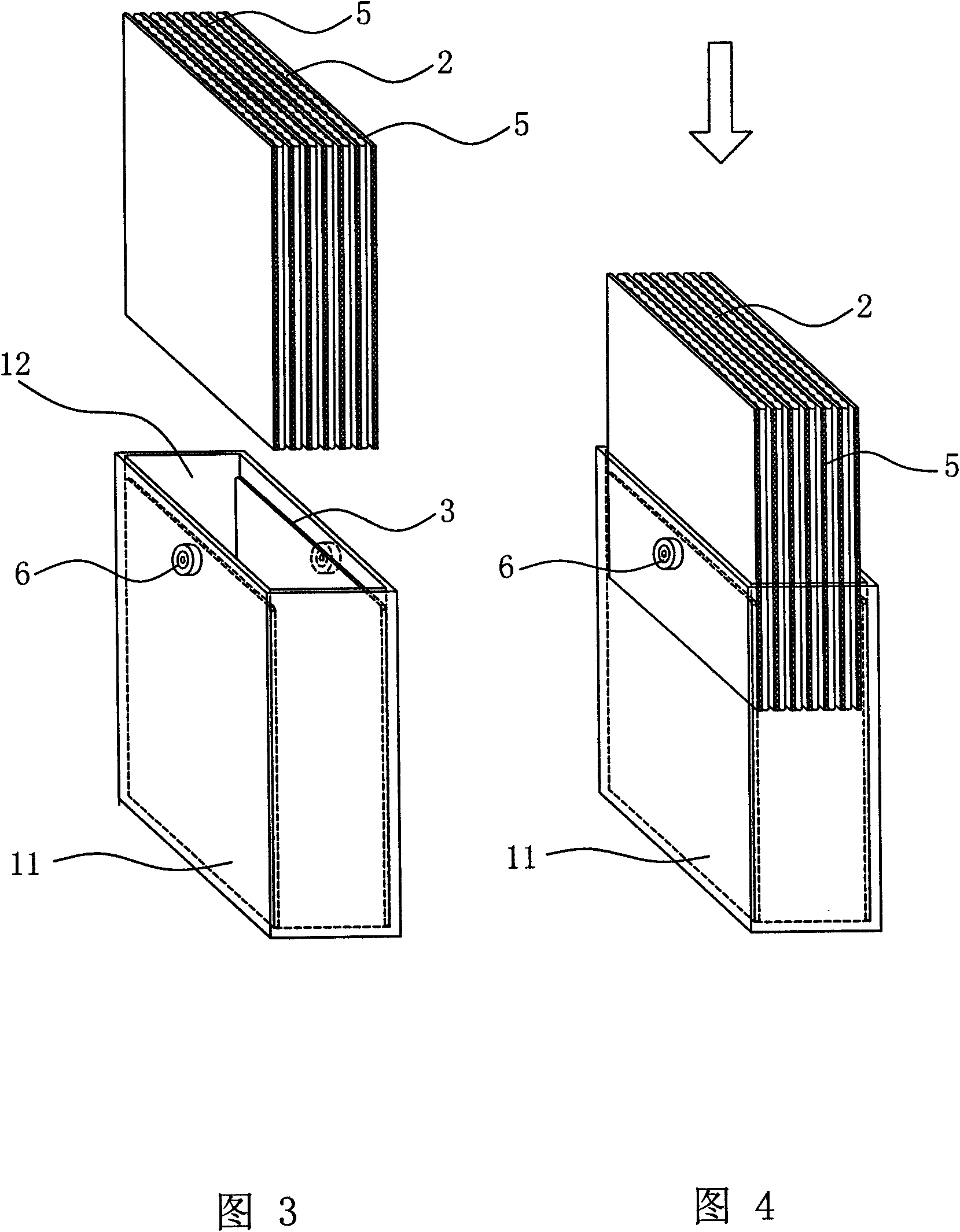

Excitation type high energy power supply apparatus

InactiveCN102983365AEliminate Pollution PotentialReduce installationFinal product manufactureCell component detailsCurrent collectorExternal connection

The invention relates to an excitation type high energy power supply apparatus, which is characterized in that a storage battery having an output negative voltage or an output positive voltage comprises a housing, a cover positioned above the housing, at least a storage battery monomer groove arranged inside the housing and filled with an electrolyte, at least two electric energy bodies, at least a separator, at least two current collectors and at least two external connection terminals, wherein the electric energy bodies, the separator and the current collectors are positioned inside the storage battery monomer groove, the electric energy bodies are separated through the separator, and the current collectors are respectively connected with the external connection terminals, such that external leakage of lead dust, lead smoke, acid waste water and acid mist during production can be effectively avoided, pollution hidden danger is effectively eliminated, pollution treatment equipment installation is effectively reduced, production investment is substantially saved, environment is protected, pollution is eliminated, charging cost is saved, a structure is simple, standards of workpieces for forming parts are single, assembly line production is achieved, labor is saved, production cost is reduced, and the apparatus is applicable for large mass production.

Owner:KUSN JINDING NEW ENERGY TECH

Production device of high-moisture beef-flavor squid product

ActiveCN111955683AIncrease productivityImprove product qualityClimate change adaptationSpecial goods bakingProcess engineeringConveyor belt

The invention belongs to the field of food processing, and particularly relates to a production device of a high-moisture beef-flavor squid product. The production device comprises a box, wherein thebox is fixedly connected with a motor, an output shaft of the motor is in transmission connection with a conveyor belt, the output shaft of the motor is movably connected with a press roller through atransmission part, the press roller and the conveyor belt are cooperatively arranged, the box is provided with a roasting plate, the press roller and the roasting plate are slidably connected, a wiredrawing mechanism is arranged at the end, close to the roasting plate, of the box, the box and the roasting plate are cooperatively arranged through a heating part, a cleaning roller is arranged at the end, away from the roasting plate, of the box, and the cleaning roller and the press roller are cooperatively connected. The integrated production device is arranged for the high-moisture beef-flavor squid product, so that baking-tableting-wire drawing work of squid is completed once after cleaning, the production efficiency of the beef-flavor squid product is improved, the hidden danger of pollution to the squid product in the production process is reduced, and the production quality of the beef-flavor squid product is improved.

Owner:烟台海裕食品有限公司 +1

A method for efficient and comprehensive utilization of arsenic and antimony in arsenic and antimony dust

ActiveCN107365913BReduce Pollution PotentialEliminate Pollution PotentialProcess efficiency improvementArsenic productSodium salt

The invention relates to an efficient comprehensive utilization method of arsenic and antimony in arsenic and antimony smoke and belongs to the technical field of non-ferrous metallurgy. The method comprises the specific steps that the arsenic and antimony smoke is subjected to stge treatment, fine powder smoke obtained through separation is put into hot water according to the formula that the liquid-solid ratio is 5:1, agitation leaching is conducted for 60 min at the temperature is 85 DEG C, and solid-liquid separation is conducted after leaching; an oxidizing agent is slowly added into leaching liquid, the volume percentage of the oxidizing agent is 3%, stirring is continuously conducted for 60 min, and arsenic-containing leaching post-liquid and antimony-containing leaching residues are obtained after filtering; a sodium salt solution is added into the leaching post-liquid, the mixture is subjected to low-temperature concentration and crystallization under the microwave condition after sufficient stirring, sodium arsenate crystals are obtained after centrifugal filtering, and crystallization mother liquor is used circularly; and the sodium arsenate crystals are sent to microwave drying equipment to be dried, and products are obtained after drying. According to the method, the arsenic and antimony smoke is subjected to stage treatment according to the grain size, enrichment and separation of arsenic and antimony can be achieved, operation is easy, and the cost is effectively reduced; and separated arsenic-enriched smoke is leached, refined and crystallized, arsenic products are formed for export sales, antimony-containing materials return to the procedure, and resource recycling is achieved.

Owner:红河绿地环保科技发展有限公司

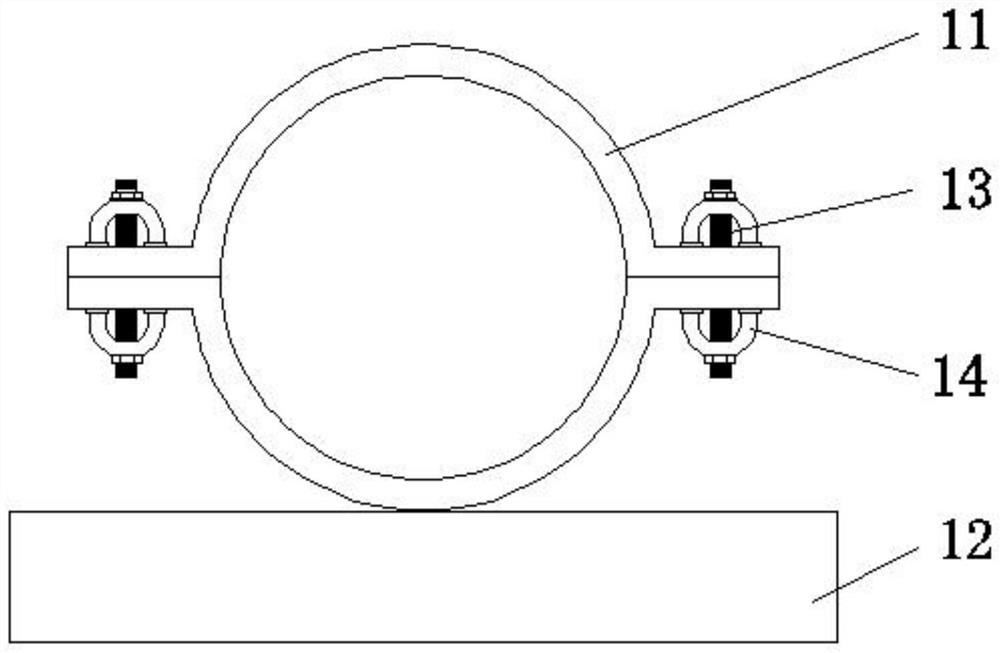

A cutter suction dredger and method for treating sludge

ActiveCN109653279BGuaranteed SuspensionReduce Pollution PotentialMechanical machines/dredgersAquatic ecosystemSludge

The invention discloses a cutter suction dredger and a sludge treatment method. The cutter suction dredger comprises a ship body. A centrifugal dredge pump is fixedly mounted on one side of the top ofthe ship body. An adjusting device is fixedly mounted in the position, located on one side of the centrifugal dredge pump, of the top of the ship body. A horizontal plate is fixedly mounted on the top of the adjusting device. According to the cutter suction dredger and the sludge treatment method, when the ship body arrives at a designated location, the position of a reamer is adjusted through the adjusting device; a first motor drives the reamer to rotate; sludge crushed by the reamer is delivered to a designated mire area through the centrifugal dredge pump via a sludge suction pipe and a sludge outlet pipe; it is ensured that the sludge outlet pipe is suspended on the water surface through fixing sleeves, compression foam, screw rods and nuts; hidden danger of endogenous pollution of areservoir is reduced through the sludge treatment method; release of pollutant is reduced; the self-cleaning capacity of lakes and the water quality of the reservoir are improved; and meanwhile, restoration of the diversity of aquatic organisms is promoted, and restoration of a reservoir aquatic ecosystem is promoted.

Owner:湖南中皖骏环保科技有限公司

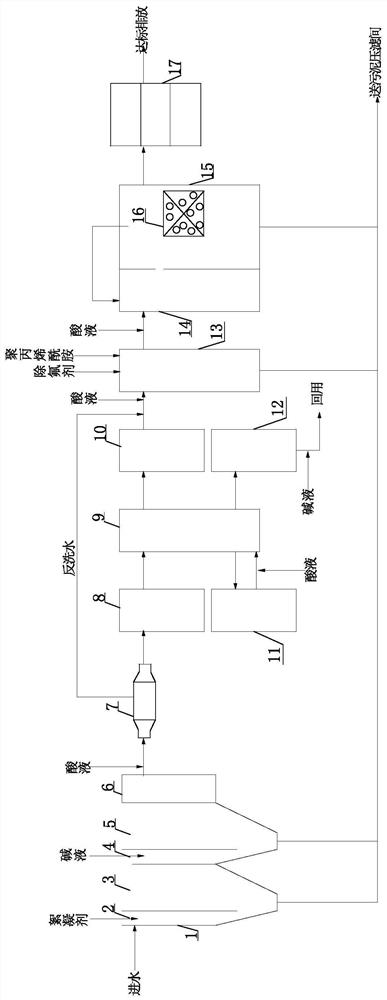

Coal gasification sewage reuse treatment method and device

ActiveCN112679029AReduce calcium hardnessEliminates the risk of fouling of concentratesMultistage water/sewage treatmentNature of treatment waterCoal waterAmmoniacal nitrogen

The invention belongs to the technical field of coal gasification sewage treatment, and particularly relates to a coal gasification sewage reuse treatment method and a device. The method comprises the following steps: adding a flocculating agent into the coal gasification sewage to remove suspended ash, adding alkali liquor to remove calcium hardness, removing ammonia to reduce ammonia nitrogen in the water, filtering in a filtering unit, carrying out electro-adsorption desalination, recycling the produced water for supplementing water to coal water slurry, carrying out defluorination treatment on the concentrated water, and finally carrying out biochemical treatment until the water is discharged after reaching the standard. According to the coal gasification sewage reuse treatment method and device, high-water-yield reuse of the coal gasification sewage can be guaranteed, meanwhile, the amount of concentrated water and the content of organic matter are reduced, and the standard treatment cost of the concentrated water is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com