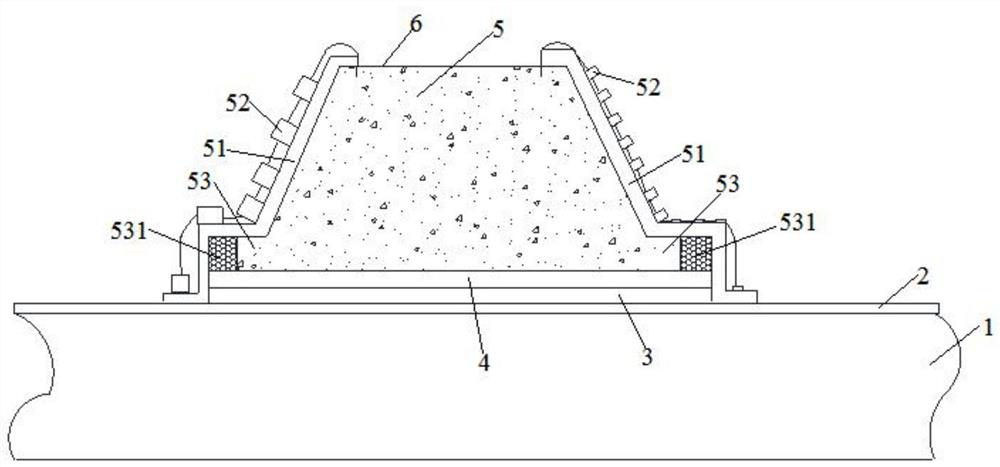

Temporary road structure and construction method thereof

A technology for temporary roads and construction methods, applied in infrastructure engineering, roads, roads, etc., can solve problems such as poor road smoothness, impermeable membrane puncture, deformation, etc., to achieve low environmental pollution hazards, avoid sinking or deformation, Good road smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] After more than 20 years of operation accumulation, the supporting facilities in a certain urban waste landfill are seriously aging, especially the water section of the original flood discharge tunnel is insufficient, and heavy rainfall will lead to HDPE laid on the surface of the waste dump in the landfill area. The rainwater on the anti-seepage membrane (hereinafter referred to as "anti-seepage membrane") cannot be discharged in time, and seeps down into the garbage dump, causing the garbage dump to slide; at the same time, the original flood discharge tunnel is equipped with leachate pipes, which have been exposed to rainwater for a long time. Scouring can easily cause damage to the pipeline, and it cannot be repaired in time when it rains, resulting in mixed flow of rain and sewage to pollute the environment. In order to realize the diversion of rainwater and sewage and ensure the safety of the landfill reservoir area, it is urgent to build a flood discharge tunnel s...

Embodiment 2

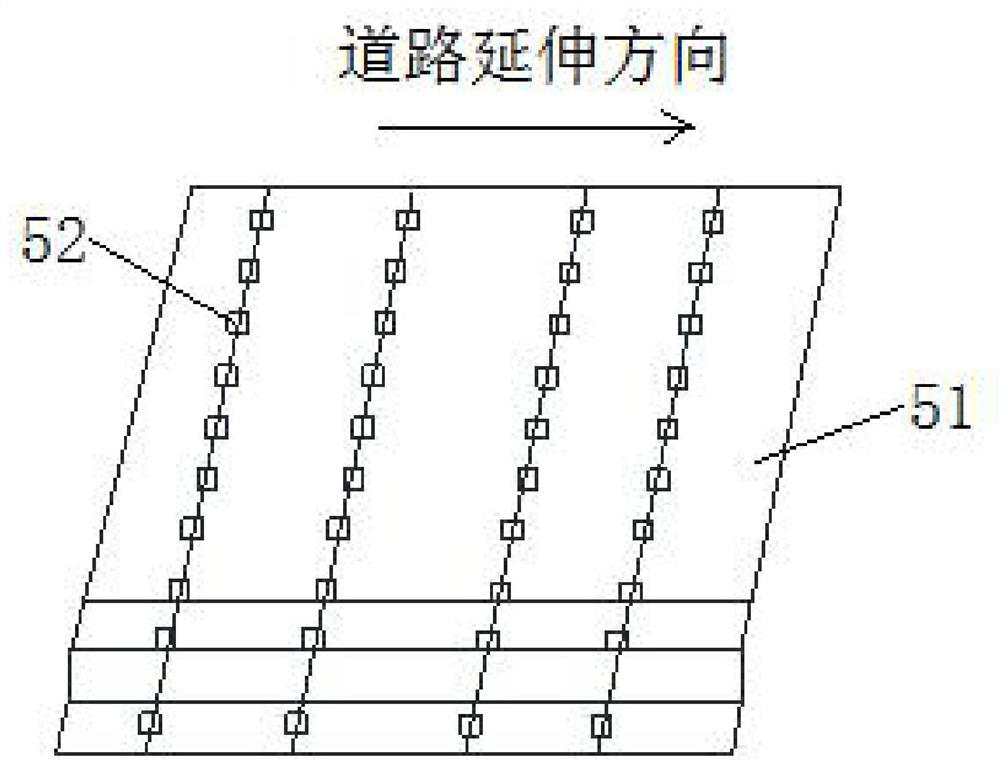

[0060] The construction method of the temporary road structure on the original anti-seepage membrane 2 of the garbage dump body 1 in embodiment 1 specifically comprises the following steps:

[0061] Step A: Carry out construction stakeout according to the horizontal direction of the road, sprinkle ash lines on the original anti-seepage membrane 2 of the garbage dump body 1 to mark the road construction scope.

[0062] Step B: Remove the presser foot sandbag on the surface of the original anti-seepage membrane 2 on the garbage dump body 1 within the construction scope. After the removal is completed, lay a new layer of the first anti-seepage membrane with a thickness of 2 mm on the surface of the original anti-seepage membrane 2 Layer 3, the first anti-seepage film layer 2 is a plurality of anti-seepage films spliced together, and the adjacent two anti-seepage films are connected by hot-melt welding to form a whole, which plays a backup role for the original anti-seepage film....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Permeability coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com