Water-permeable asphalt mixture doped with BMF basalt fiber

A technology of basalt fiber and permeable asphalt, applied in the field of highway building materials, can solve the problems of high cost of raw materials, prone to rutting, aging of asphalt membrane, etc., and achieve the effect of improving high temperature resistance stability, prolonging service life and good road surface smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

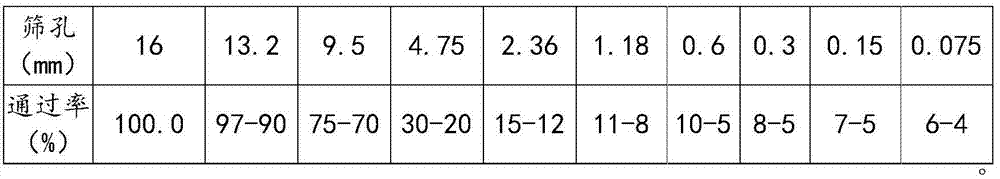

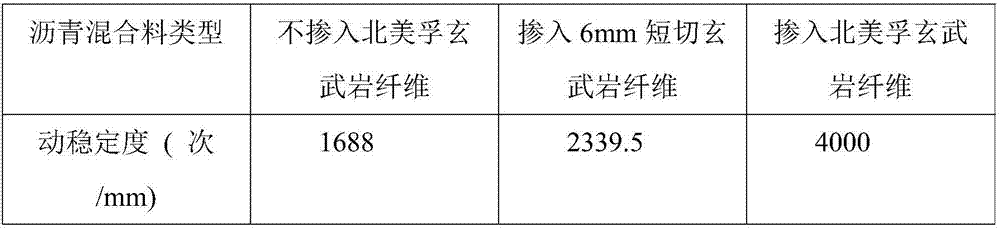

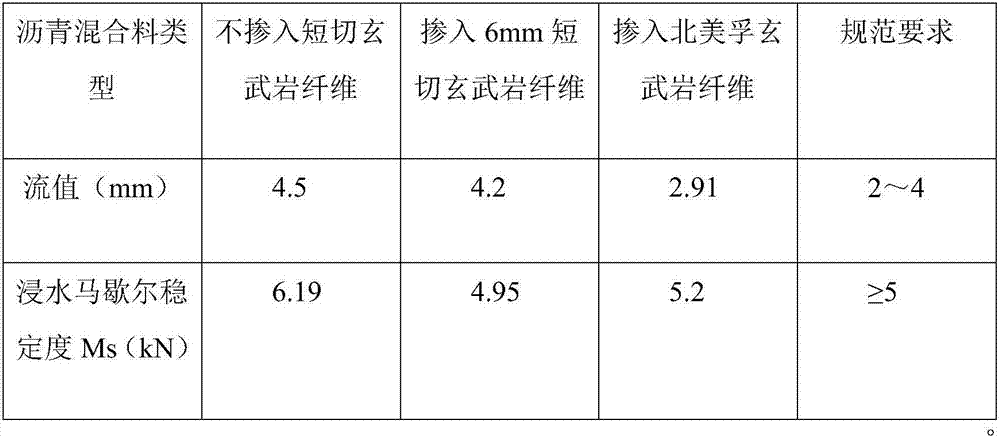

[0033] First, heat the finished SBS modified asphalt to a molten state in an oven at 165°C, and then preheat 11,760g of coarse and fine aggregates and 240g of mineral powder (limestone with a particle size below 0.075mm) in an oven at 195°C for more than 6 hours for heat preservation. Heat to the mixing temperature of 170°C, then add 11760g of preheated coarse and fine aggregates (the mass of 1# material, 2# material, 3# material and 4# material are 3960g, 5640g, 660g, 1500g respectively) and mix Mix in the pot for 15 seconds, mix in 36g of North American Fu basalt fiber and 50.1g of HVA high-viscosity agent and mix for 90 seconds, add 552g of the above-mentioned SBS modified asphalt for heat preservation and mix for 90 seconds, mix in 240g of preheated mineral powder and mix 90s, rolling and molding with a wheel roller forming machine, and making the described a kind of rutting slab specimen mixed with North American basalt fiber permeable asphalt mixture; the asphalt mixture ...

Embodiment 2

[0035] First, heat the finished SBS modified asphalt to a molten state in an oven at 165°C, and preheat 3920g of coarse and fine aggregates and 80g of mineral powder (limestone with a particle size of 0.075mm or less) in an oven at 195°C for more than 6 hours for heat preservation. Heat to the mixing temperature of 170°C, then add 3920g of preheated coarse and fine aggregates (the mass of 1# material, 2# material, 3# material and 4# material are 1320g, 1880g, 220g, 500g respectively) and mix Mix in the pot for 15 seconds, add 12g of North American Fu basalt fiber and 16.7g of HVA high-viscosity agent and mix for 90 seconds, add 192g of the above-mentioned SBS modified asphalt for heat preservation and mix for 90 seconds, mix in 80g of preheated mineral powder and mix 90s, the Marshall test piece was prepared by the compaction method, and the Marshall test piece was formed by mixing the North American Fu basalt fiber permeable asphalt mixture, and the asphalt mixture was graded ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com