A box-dividing molding machine

A molding machine and box separation technology, which is applied in the field of sand casting, can solve the problems of serious wear of the walking mechanism of the linked sand box, heavy oil cylinder quality, pollution, etc., achieves great promotion and application value, reduces capital investment, and reduces pollution hazards. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

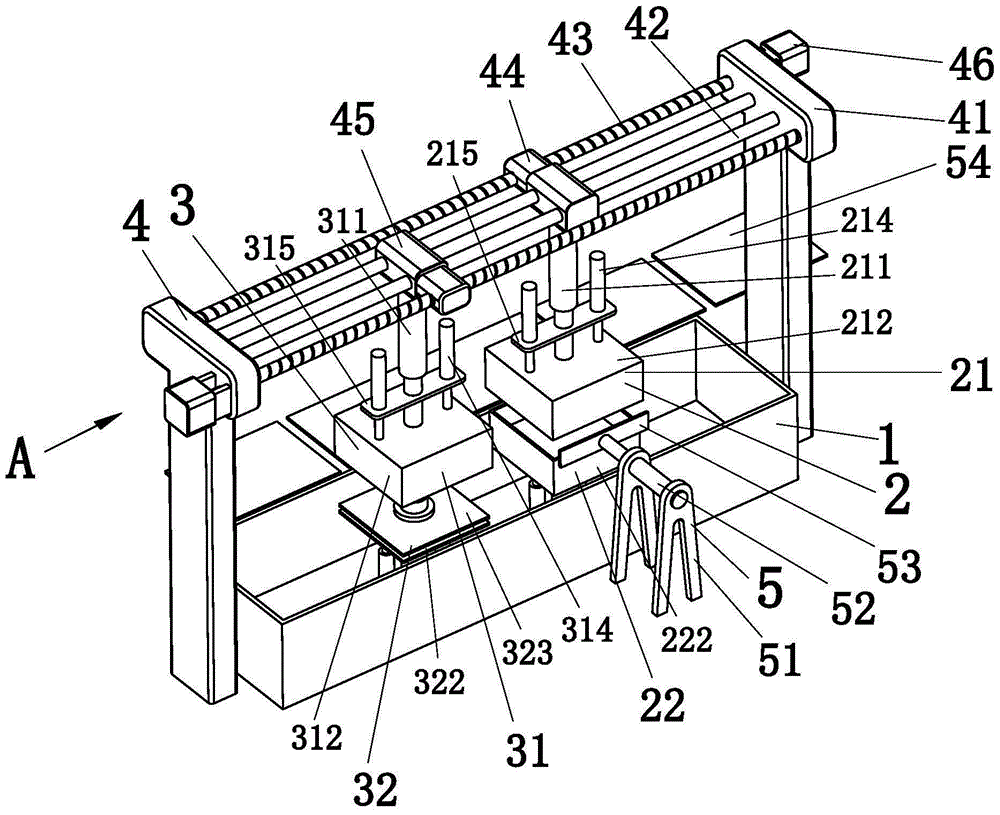

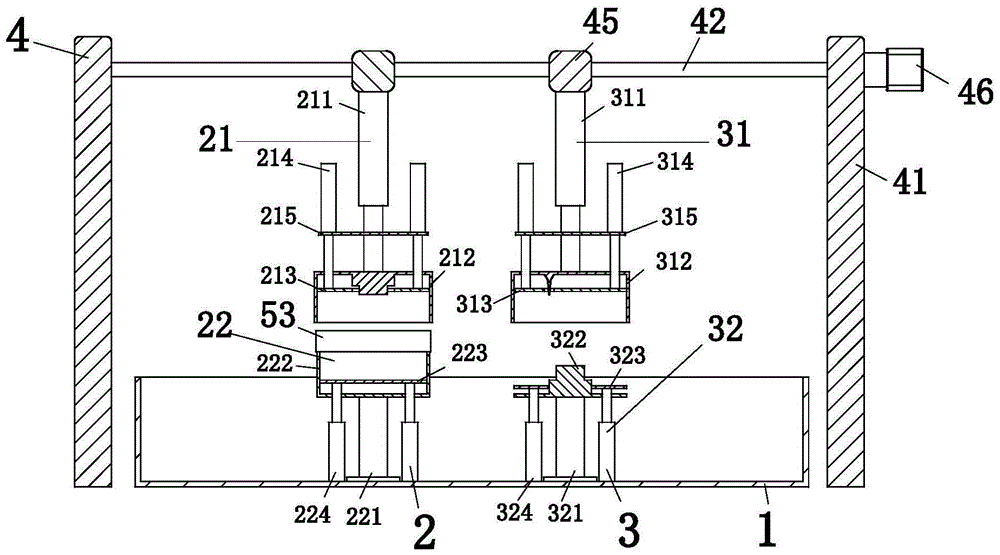

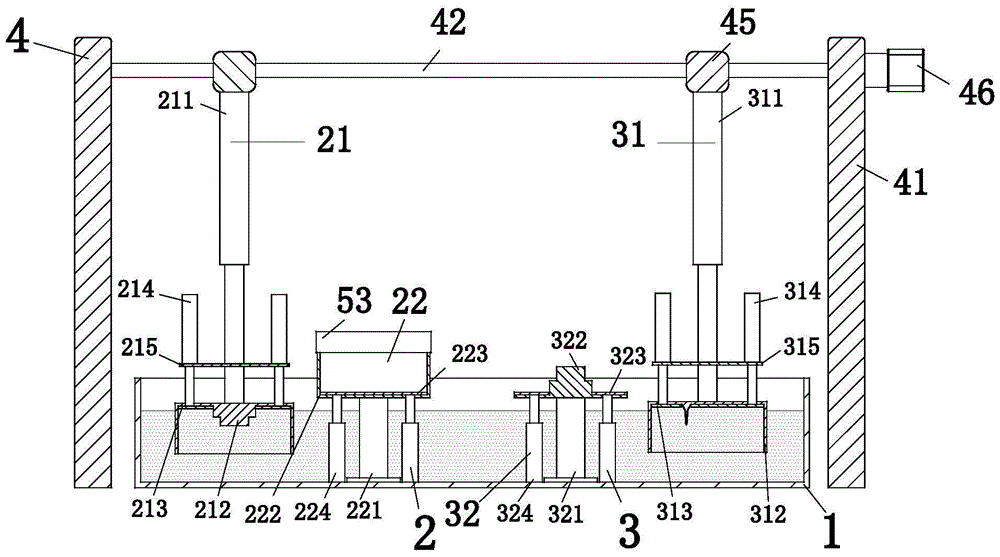

[0034] Such as Figure 1 to Figure 9 As shown, a kind of sub-box molding machine according to the present invention includes a sand box 1, a lower box molding device 2, an upper box molding device 3, a walking device 4 and a pushing device 5, and the sand box 1 is a rectangular box The sand box 1 is used to store the mixed foundry sand.

[0035] The lower box molding device 2 includes a moving part I21 and a fixed part I22. The moving part I21 includes a hydraulic cylinder I211, a lower mold box 212, a lower stripping plate 213 and two lower stripping pneumatic cylinders 214. The hydraulic cylinder I211 is vertically arranged, and the cylinder body of the hydraulic cylinder I211 is connected to the traveling device 4; the lower mold box 212 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com