Selenium-enriched dark plum kernel protein powder, energy bars made of same and preparation method

A protein powder and energy bar technology, which is applied to the functions of food ingredients, protein food ingredients, protein ingredients of waste, etc., can solve the problems of waste of resources, failure to use core shells and nuts, etc., to achieve easy operation and improve stomach Intestinal function, the effect of regulating normal flora

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

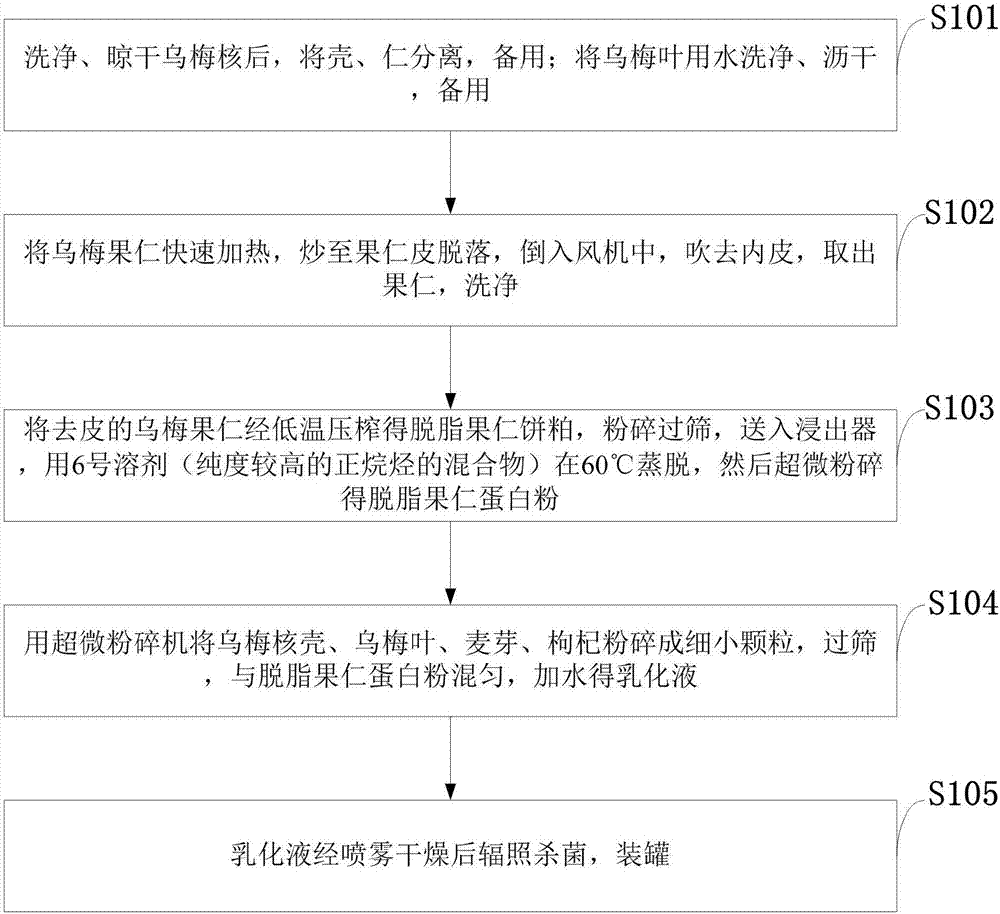

[0037] Such as figure 1 As shown, the preparation method of the selenium-enriched black plum kernel protein powder that the embodiment of the present invention provides comprises the following steps:

[0038] S101: After washing and drying the ebony core, separate the shell and kernel, and set aside; wash the ebony leaves with water, drain, and set aside;

[0039] S102: Quickly heat the ebony nuts, stir-fry until the skins of the nuts fall off, pour them into a fan, blow off the inner skin, take out the nuts, and wash them;

[0040] S103: Press the peeled ebony kernels at low temperature to obtain defatted nut cakes, crush and sieve, send them to the extractor, use No. 6 solvent (a mixture of n-alkanes with higher purity) to evaporate at 60°C, and then ultra- Finely pulverized to obtain defatted nut protein powder;

[0041] S104: Grinding the ebony core shell, ebony leaves, malt, and wolfberry into fine particles with an ultrafine pulverizer, sieving, mixing with defatted nu...

Embodiment 1

[0061] The preparation method of the selenium-enriched black plum kernel protein powder provided by the embodiment of the present invention comprises:

[0062] Take 400g of black plum kernels with full particles and uniform texture, wash them with water and dry them, then separate the shells and kernels with a kernel smasher. Take 200g ebony leaves and wash them with water, drain and set aside. Take 180g of malt and 120g of wolfberry, wash them with water, dry them, and set aside. Put the separated ebony nuts into a pot, heat quickly to 60°C, fry until the skin of the nuts falls off, remove them, pour them into a fan, blow off the inner skin, take out the nuts, and wash them. Use a low-temperature cold-pressed oil press to squeeze the ebony kernels for 5 to 10 minutes at 15 MPa / min, remove the oil, and obtain a nut cake. The nut meal cake is crushed at high speed, passed through a 100-mesh sieve, and sent to the extractor. Use No. 6 solvent (a mixture of normal alkanes with...

Embodiment 2

[0064] The energy bar prepared by the selenium-enriched black plum kernel protein powder provided by the embodiment of the present invention specifically includes:

[0065] Weigh 32g of oatmeal and 27g of red dates, crush them into fine particles, and set aside. Weigh 100g of sugar alcohol and add it into the heating kettle at 50°C and keep stirring until it dissolves. Then add 45g of refined vegetable oil, stir for 5min, then add 12g of pectin, stir for 5min to form a mixed adhesive. Weigh 250g of selenium-enriched ebony kernel protein powder and extrude it with an extruder, cut or crush the obtained extruded puffed product into granular puffed matter with a knife, pass through a 10-mesh sieve, and add it to the mixed binder Mix well, pour into molds and sprinkle with oatmeal and red dates. Then put it in the refrigerator to freeze and set it, freeze it at -10~-18°C for 40 minutes, take it out and demould it. Put the frozen and shaped energy bar into an oven, bake it at 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com