Sample preparation operation control method

A technology of operation control and control method, applied in the directions of transportation, packaging, storage devices, etc., can solve the problem of not realizing the automation of sample bottle transportation, storage, cleaning, etc., and achieve the effect of reducing hidden dangers of pollution and eliminating hidden dangers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

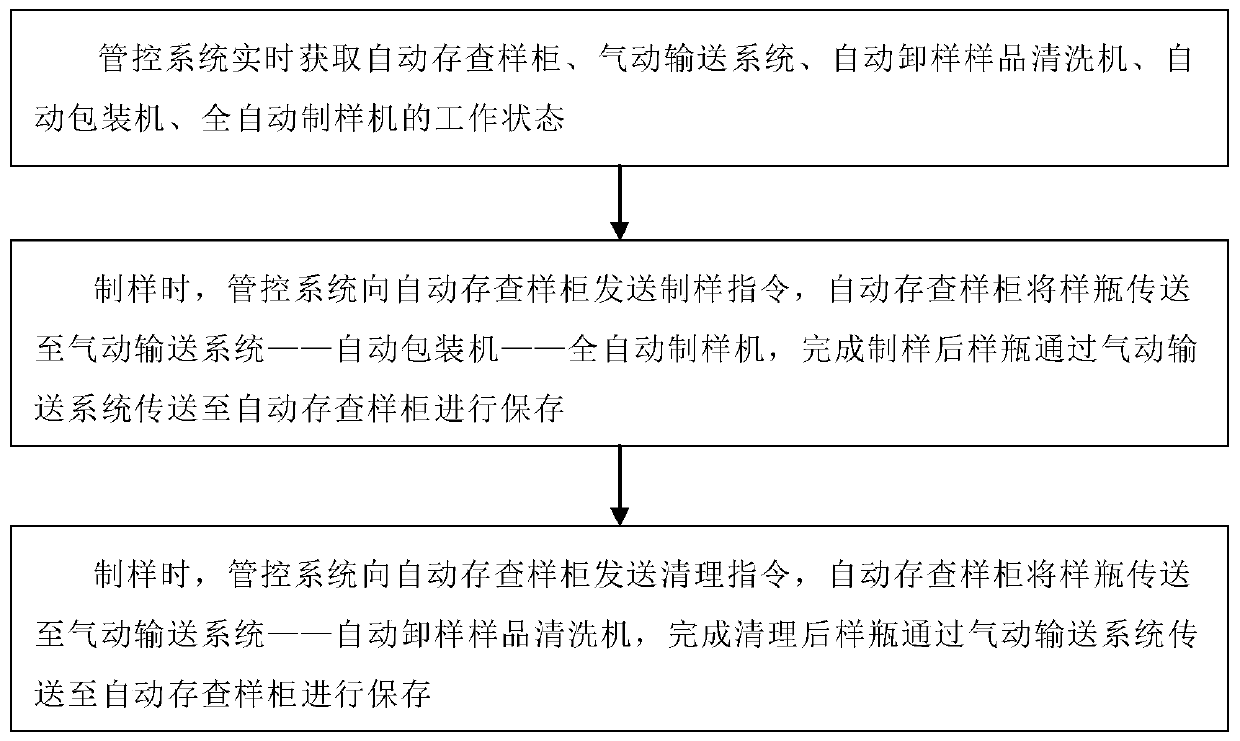

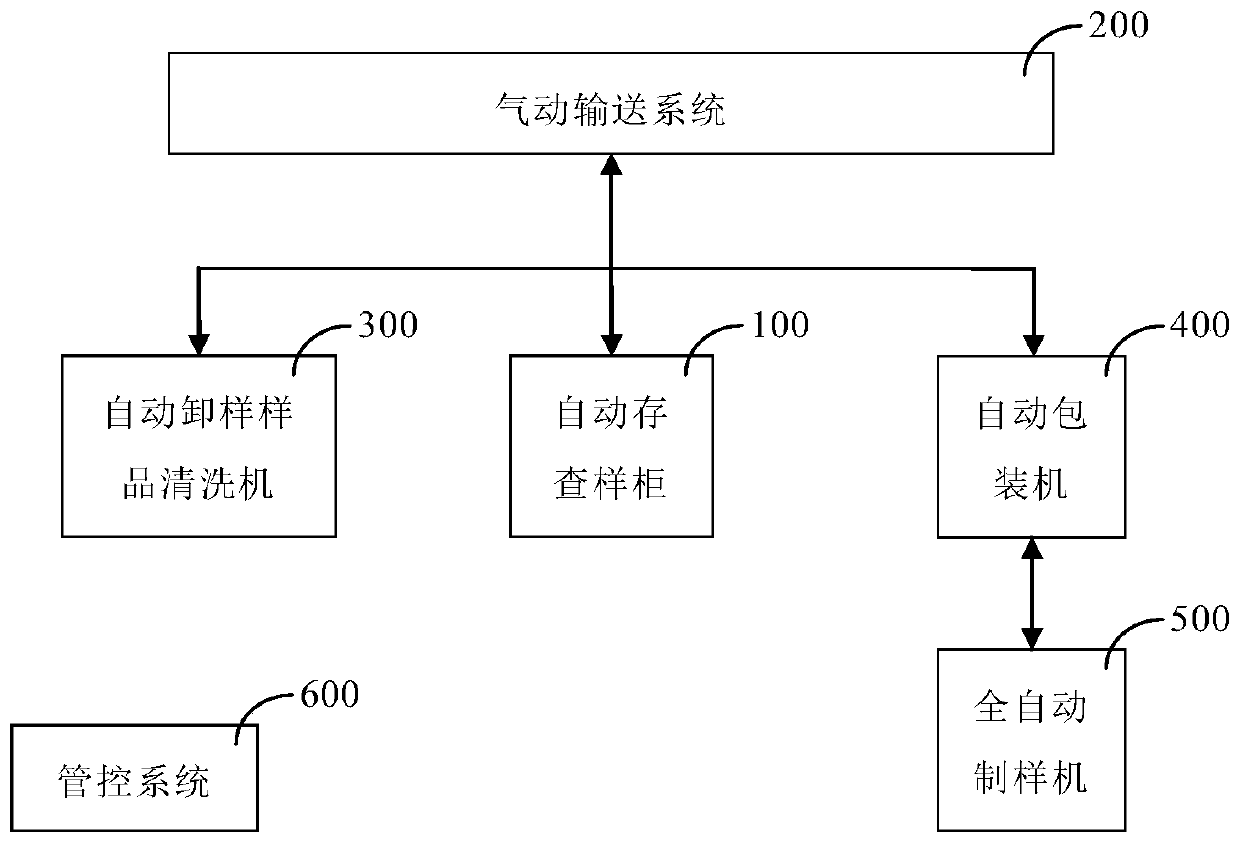

[0059] When sample preparation is required, the following steps are included:

[0060] S11. The management and control system 600 sends sample preparation instructions to the automatic sample storage cabinet 100, the pneumatic conveying system 200 and the automatic packaging machine 400;

[0061] S12. The automatic storage and inspection sample cabinet 100 transmits the empty sample bottle to the pneumatic conveying system 200;

[0062] S13, the pneumatic conveying system 200 conveys the empty sample bottle to the automatic packaging machine 400;

[0063] S14, the automatic packaging machine 400 uncaps and transfers the bottle body to the automatic sample making machine 500;

[0064] S15, the automatic sample making machine 500 prepares samples, and after completion, the bottle body is sent to the automatic packaging machine 400;

[0065] S16. The automatic packaging machine 400 seals and packs the sample bottle and transfers it to the pneumatic conveying system 200;

[006...

Embodiment 2

[0069] When cleaning vials is required, include the following steps:

[0070] S21. The management and control system 600 judges according to the recorded sample storage time, and generates a cleaning instruction when the storage time is greater than 3 months;

[0071] S22. The management and control system 600 judges whether the automatic storage and inspection sample cabinet 100, the pneumatic conveying system 200 and the automatic sample unloading sample cleaning machine 300 are in an idle state, if it is judged to be yes, then perform step S23, if it is judged to be otherwise, stop for a period of time and re-execute step S22;

[0072] S23. The management and control system 600 sends a cleaning signal to the automatic sample storage cabinet 100, the pneumatic conveying system 200 and the automatic unloading sample cleaning machine 600;

[0073] S24. The automatic storage and inspection sample cabinet 100 transmits the sample bottles to be cleaned to the pneumatic conveying ...

Embodiment 3

[0079] When the sample bottle enters the sample preparation operation control system from the automatic storage and inspection sample cabinet 100, the following steps are included:

[0080] S31, the sample bottle is manually put into the bottle opening of the automatic storage and inspection sample cabinet 100;

[0081] S32, the sample bottle generates an electronic label and transmits the information to the management and control system 600;

[0082] S33, the sample bottle is stored in the automatic storage and inspection sample cabinet 100.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com