A method for efficient and comprehensive utilization of arsenic and antimony in arsenic and antimony dust

A soot and high-efficiency technology, applied in the direction of improving process efficiency, can solve the problems of a large amount of waste liquid, high cost, secondary pollution, etc., and achieve the effect of recycling, simple process and reducing the number of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

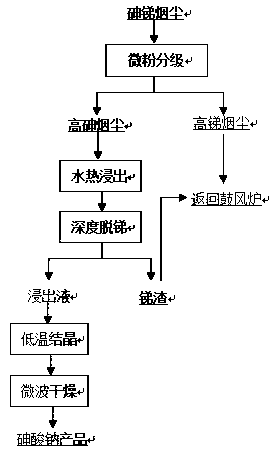

Method used

Image

Examples

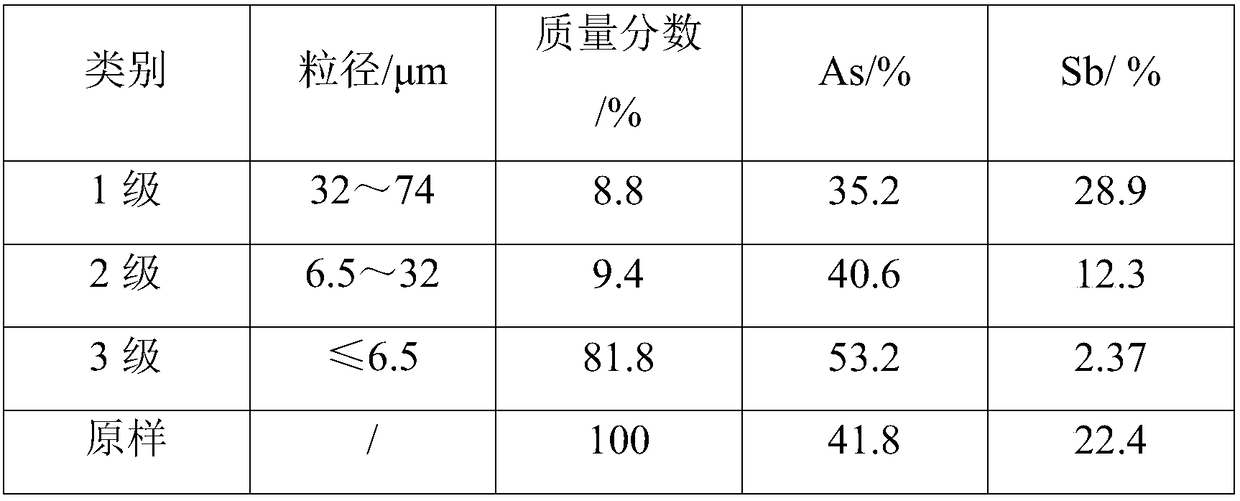

Embodiment 1

[0021] The arsenic and antimony fumes are classified by a hydrocyclone classification device. The flow rate is 800mL / min, and the feed pressure is 0.03-0.2MPa. According to the particle size, the arsenic and antimony fumes are divided into three particle size dusts. The particle size distribution And element content is shown in Table 1. Add hot water to the fine dust ≤6.5μm obtained by classification at a liquid-to-solid ratio of 5:1, stir and leach at 85°C for 60 minutes, and separate solid and liquid after leaching; slowly add an oxidizer at 3vol% to the leaching solution, continue stirring for 60 minutes, and filter Obtain the oxidized liquid and the oxidized residue; add an appropriate amount of sodium salt solution to the oxidized liquid, mix well, concentrate the crystal at 75℃ under microwave conditions, centrifuge and filter to obtain the sodium arsenate crystals, and the crystallization mother liquor is recycled; the sodium arsenate crystals are sent After the microwav...

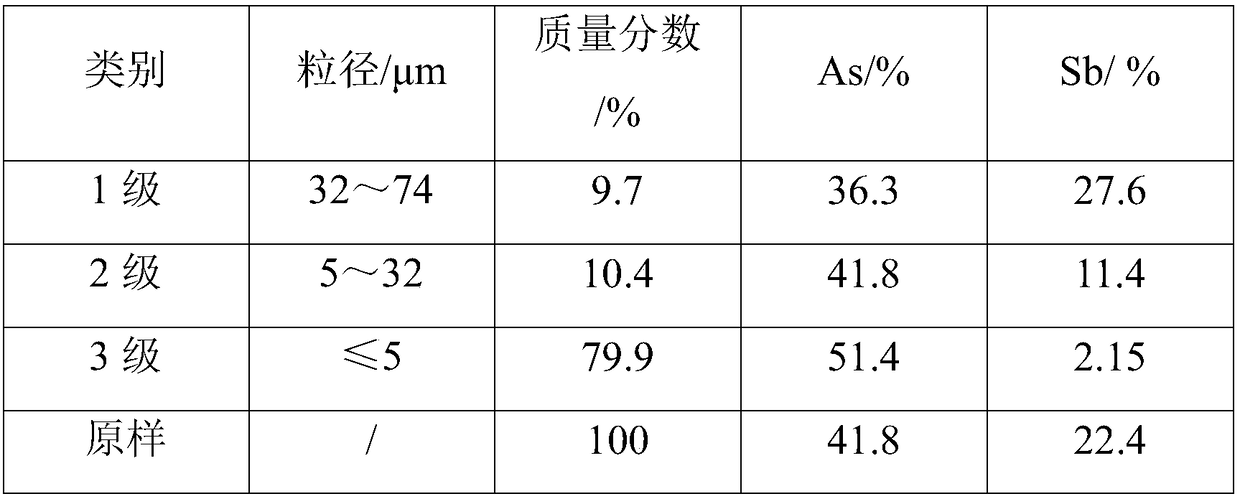

Embodiment 2

[0025] The arsenic and antimony smoke dust is classified by a vortex air current classification device. The power is 2.5kW and the feeding rate is 8kg / h. According to the particle size, the arsenic and antimony smoke is divided into three particle size dusts, and their particle size distribution and element content See Table 2. Add hot water to the fine dust ≤5μm obtained by classification at a liquid-solid ratio of 5:1, stir and leach at 85°C for 60 minutes, and separate solid and liquid after leaching; add an oxidizer at 3vol% to the leaching solution, stir continuously for 60 minutes, and filter to obtain an oxidized product Liquid and oxidation residue; add appropriate amount of sodium salt solution to the oxidized liquid, mix well, concentrate and crystallize at 75℃ under microwave conditions, centrifuge and filter to obtain sodium arsenate crystals, the mother liquor of crystallization is recycled; the sodium arsenate crystals are sent to the microwave equipment After bei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com