Mobile type multifunctional building material producing device

A production equipment and multi-functional technology, which can be used in batching weighing instruments, clay preparation devices, and raw material supply devices for sales, etc., can solve the problems of unstable batch quality of finished mortar products, damage to the health of workers, and harsh working environments. Achieve the effect of improving social productivity and production technology of building materials, improving the utilization rate of land resources, and improving the quality of construction projects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

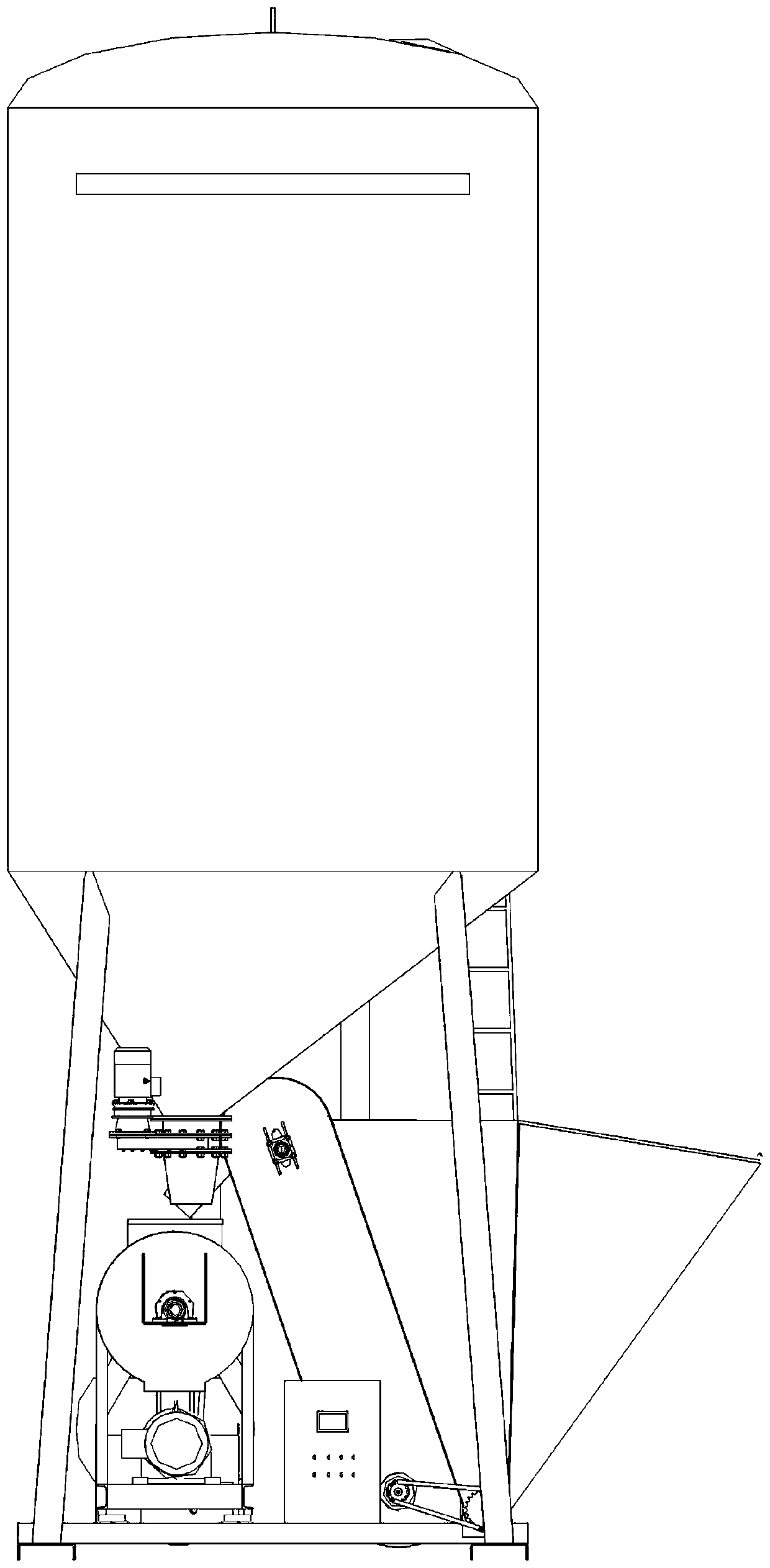

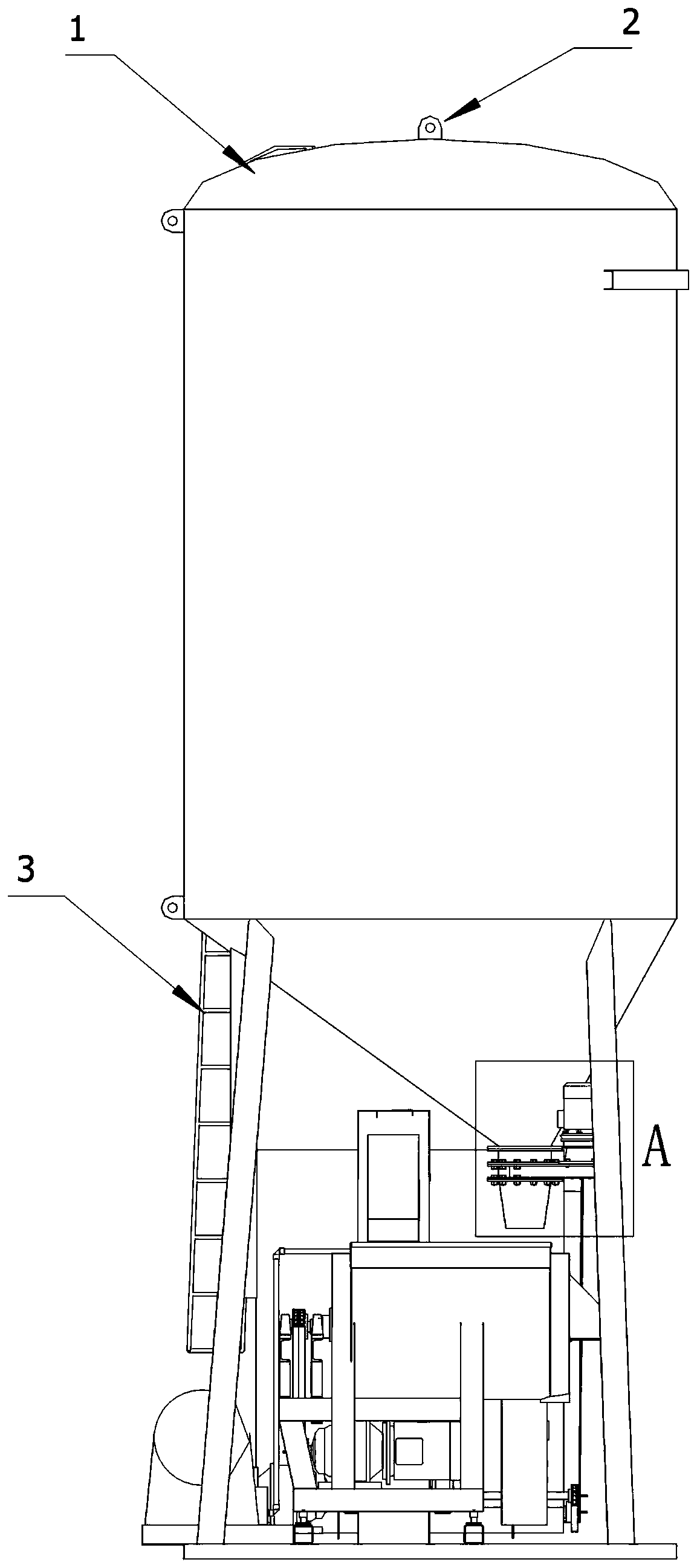

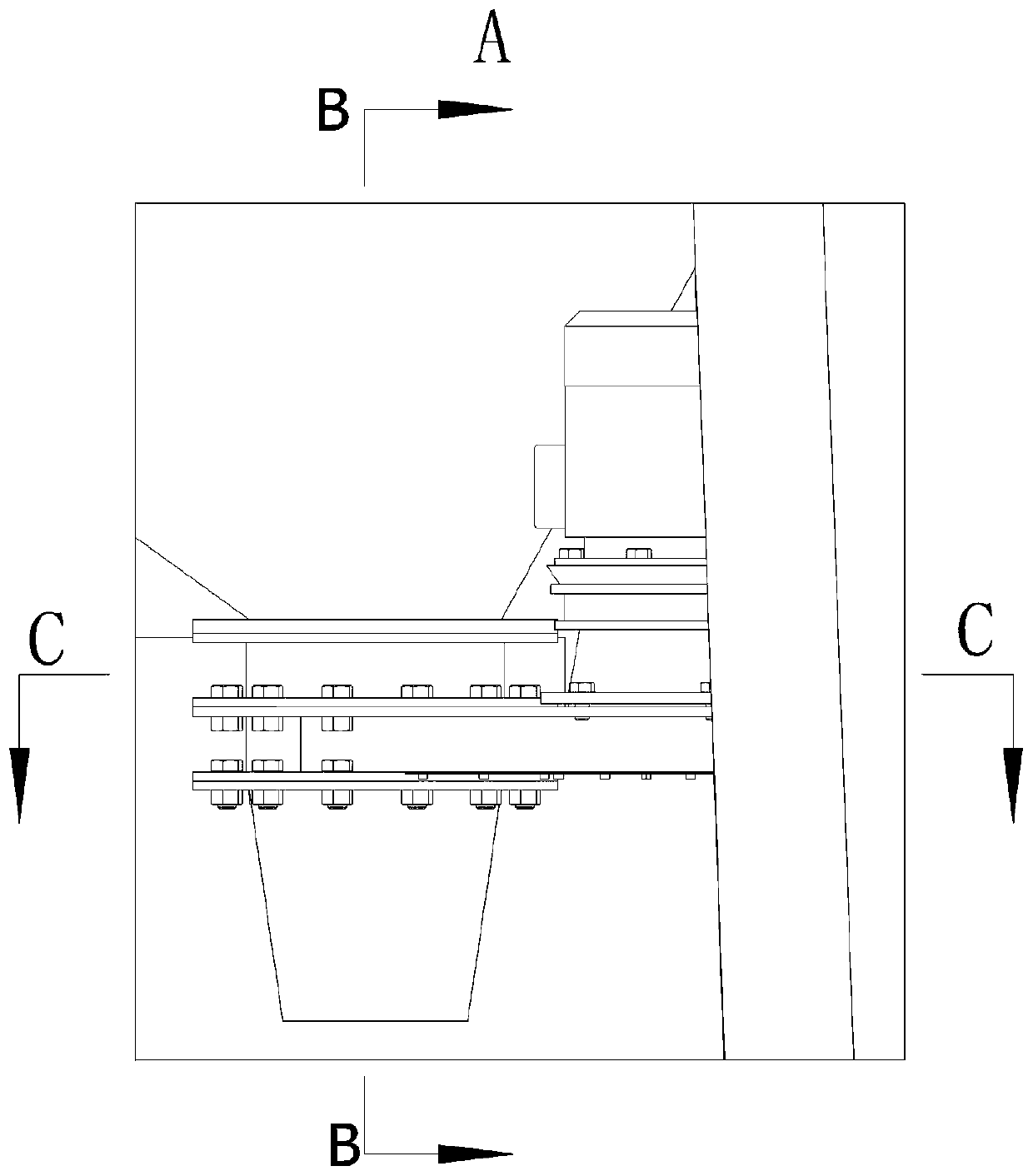

[0055] see Figure 1 to Figure 18 , a mobile multifunctional construction material production equipment, including a tank body 1, a base 10, a material conveying device, a feeding device, a mixer 6 and an admixture metering pump device 4; the tank body 1 is installed on the base, and the base 10 is equipped with a material conveying device, a mixer 6 and an additive metering pump device 4, and a feeding device is installed on the discharge port at the lower end of the tank body 1. Two feeding ports are provided on the mixer 6, and one feeding port is connected with the feeding port. The discharge port 24 of the device is docked, and the other feed port is docked with the discharge port of the material conveying device. The mixer 6 is also provided with a common filling port for external addit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com