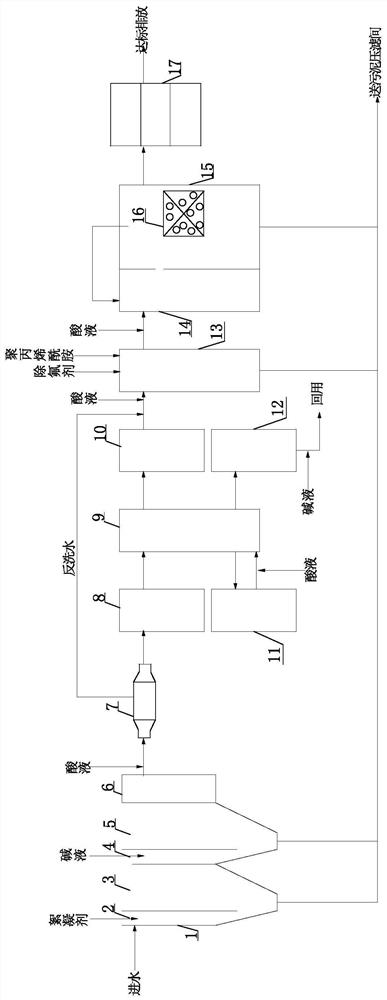

Coal gasification sewage reuse treatment method and device

A technology of coal gasification sewage and treatment methods, which is applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, natural water treatment, etc. It can solve the problems of large sewage water volume, large dosage of chemicals, high investment and operation costs, etc. problems, to achieve the effect of reducing the amount of concentrated water and organic matter content, the proportion of organic matter and ammonia nitrogen content is appropriate, and the water resource utilization rate is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] A coal gasification device consumes 1,700 tons of raw coal, about 1,100 tons of water for coal-water slurry, and about 2,400 tons of sewage discharged outside. Regardless of evaporation loss, it can be seen that other auxiliary, washing, cooling and other facilities use more than 1,300 tons of water. Adopting the process of the present invention, the raw water is off-white, with a conductivity of 3700 μS / cm, calcium hardness of 750 mg / L, alkalinity of 680 mg / L, fluoride ions of 15 mg / L, ammonia nitrogen of 270 mg / L, and COD of 500 mg / L. When the flocculant dosage is 100mg / L, the turbidity of the flocculated water is 1.4NTU, and the suspended ash is removed. The pH value of alkali addition reaction is 10.2~10.5, the calcium hardness of alkali precipitation effluent is 150~180mg / L, and the ammonia nitrogen of gasification membrane effluent is 20~30mg / L.

[0081]The effluent from the ammonia removal area enters the filter unit after the pH value is adjusted by the acid sol...

Embodiment 2

[0133] A coal gasification device consumes 1,700 tons of raw coal, about 1,100 tons of water for coal-water slurry, and about 2,400 tons of sewage discharged outside. Regardless of evaporation loss, it can be seen that other auxiliary, washing, cooling and other facilities use more than 1,300 tons of water. Adopting the technology of the present invention, the raw water is off-white, with conductivity of 3700 μS / cm, calcium hardness of 750 mg / L, alkalinity of 680 mg / L, fluoride ion of 18 mg / L, ammonia nitrogen of 300 mg / L, and COD of 700 mg / L. When the flocculant dosage is 50mg / L, the turbidity of the flocculated water is 2.0NTU, and the suspended ash is removed. The pH value of alkali addition reaction is 9.5~9.8, the calcium hardness of alkali precipitation effluent is 200~250mg / L, and the ammonia nitrogen of gasification membrane effluent is 30~40mg / L.

[0134] The effluent from the ammonia removal area enters the filter unit after the pH value is adjusted by the acid solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com