Softening and coagulating treatment process of gas scrubbing water

A technology for gas washing and treatment process, which is applied in water softening, flocculation/sedimentation water/sewage treatment, etc. It can solve the problems of increased changes in water treatment equipment and large equipment investment, and achieves remarkable effects, simple operation and controllability. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

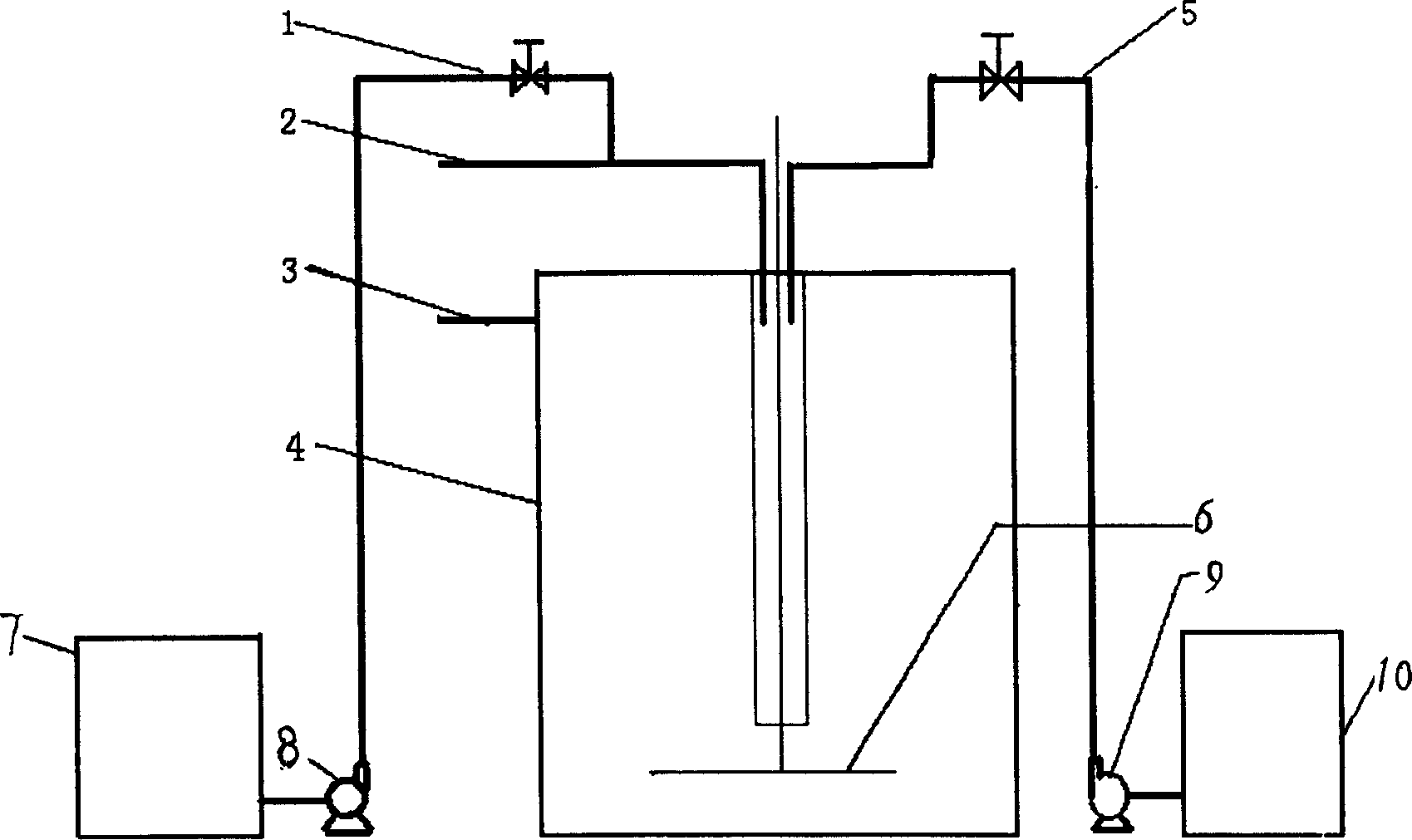

[0018] attached figure 1 It is a schematic flow chart of the softening coagulation process of Embodiment 1 of the present invention.

[0019] In the coal gasification device, the water from the gas scrubber is mixed with the water from the gasification furnace with a solid content of 0.44% and a temperature of 220-230°C with high solid content and high hardness (referred to as black water). , sent to the settling tank through pipeline 2, the calcium hardness in the water is 800~2000mg·L -1 (as CaCO 3 count). The black water is added from the descending pipeline in the center of the settling tank. In the pipeline before adding, use a pump to inject a sodium carbonate solution with a concentration of 5% to 10% through pipeline 1, and the flow rate is about 0.2% to 0.5% of the black water flow rate. %, sodium carbonate solution and black water are fully mixed in the pipeline and then enter the settling tank. Add polyacrylamide solution into pipeline 5, its relative molecular ...

Embodiment 2

[0022] The water to be treated is the gas washing circulating water of a steel plant, with a hardness of 900mg·L -1 (as CaCO 3 meter), the content of suspended solids (coal ash) is 2g·L -1 , the coagulant used is polyacrylamide (molecular weight: 12 million) polyferric sulfate.

[0023] (1) Add 2mg·L -1 Polyacrylamide, large particle flocs are formed during the addition process, 5 minutes after stopping stirring, most of the flocs settle, and after 15 minutes, the absorbance of water is 0.002, and the solution is clear;

[0024] (2) Stir and add 4ml of 5% sodium carbonate solution to 1000ml of water sample at a temperature of 50°C, and add 2mg·L -1 Polyacrylamide coagulant, the solution appears turbid and forms large particle flocs, 5 minutes after stopping stirring, most of the flocs settle, and after 15 minutes, the absorbance of water is 0.001, and the solution is clear;

[0025] (3) Add 4ml of 5% sodium carbonate solution with stirring to 1000ml of water sample at a te...

Embodiment 3

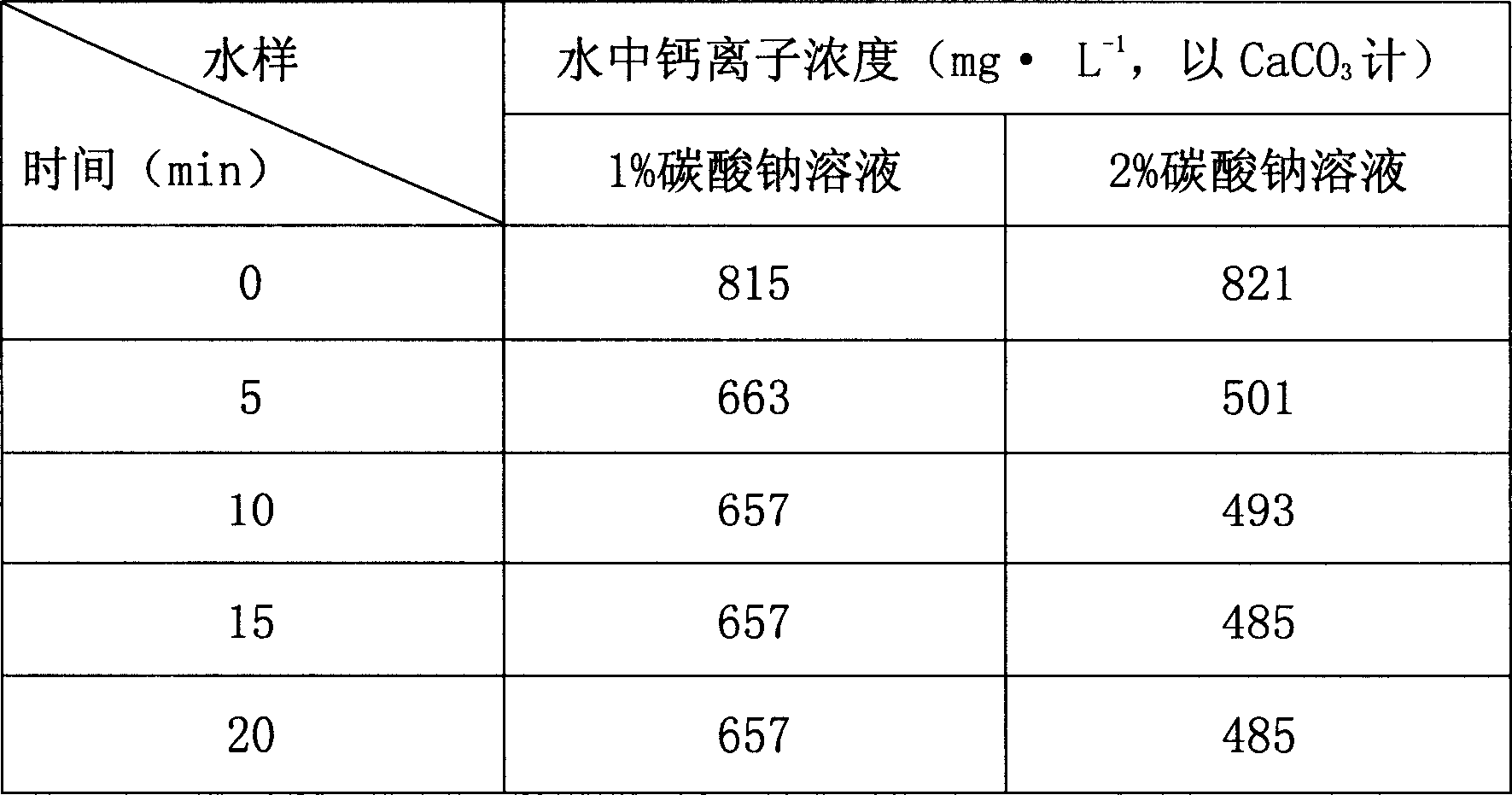

[0028] The industrial water of an enterprise has a pH value of 8.6 and a calcium ion concentration of 820mg·L -1 (as CaCO 3 meter), the temperature is 50°C. Add 20ml of 1% and 2% sodium carbonate solution to 1000ml water sample respectively, and the changes of calcium ion concentration in water are shown in Table 1.

[0029] Table 1 The change of calcium ion concentration in sodium carbonate softening experiment (mg L -1 )

[0030]

[0031] Adding a concentration of 5%, 10% sodium carbonate solution, the experimental results are similar to 1%, 2% sodium carbonate solution.

[0032] The test results show that adding sodium carbonate solution can reduce the calcium ion in the water in a short time. From the reduction value of total hardness and the comparison of the amount of sodium carbonate added, it can be seen that the added sodium carbonate reacts substantially completely.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com