Patents

Literature

167 results about "Solid suspension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solid formulations of crystalline compounds

InactiveUS20100222311A1Fast dispersionFast dissolutionBiocidePowder deliverySolubilityAdditive ingredient

Described herein are formulations of active pharmaceutical ingredients, where the active pharmaceutical ingredients or drugs are included in a solid suspension with one or more solid additives. The formulations described herein are useful for formulating any drug or active pharmaceutical ingredient, including those that have limited solubility in organic and / or aqueous solvent systems.

Owner:PURDUE RES FOUND INC

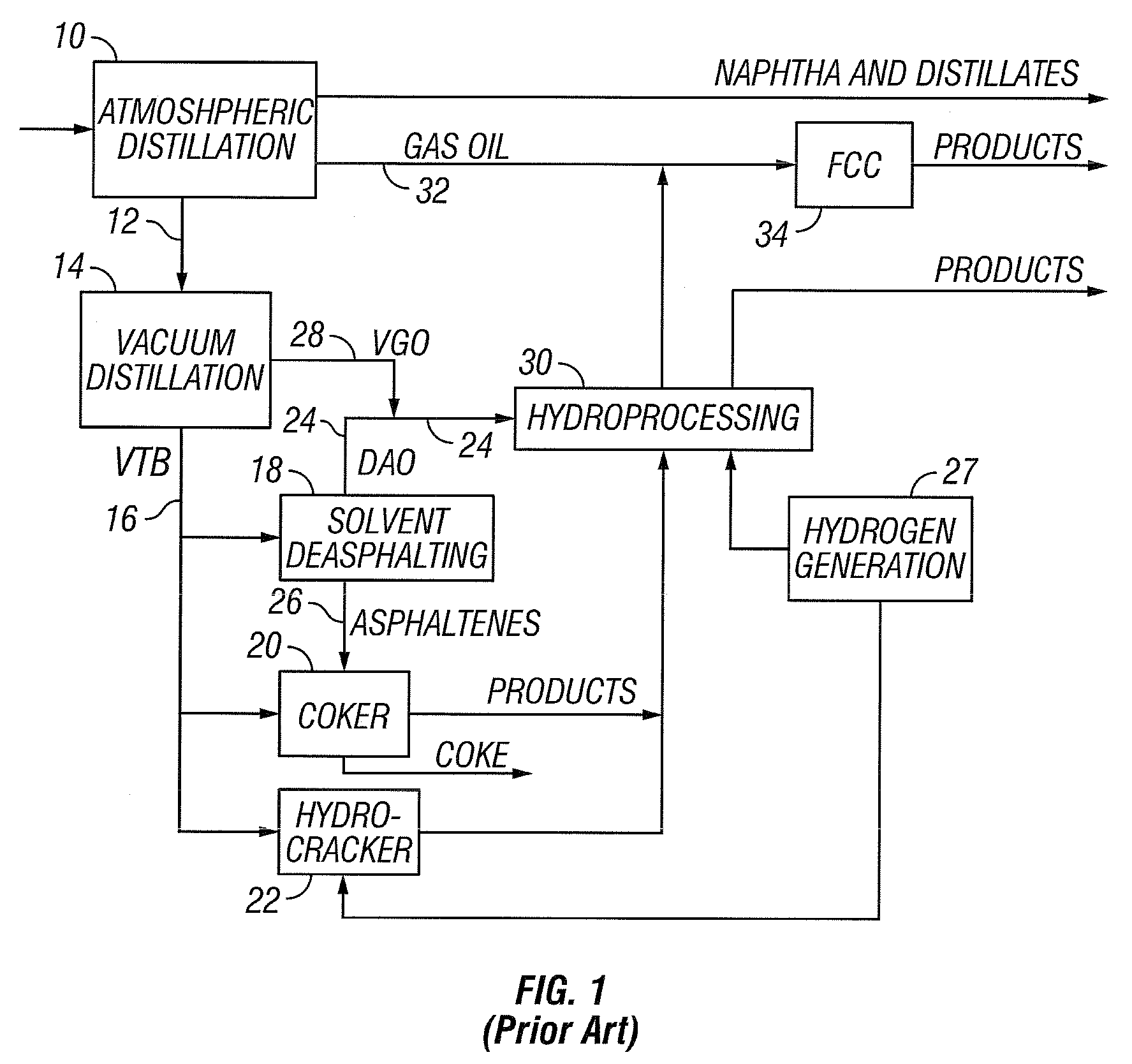

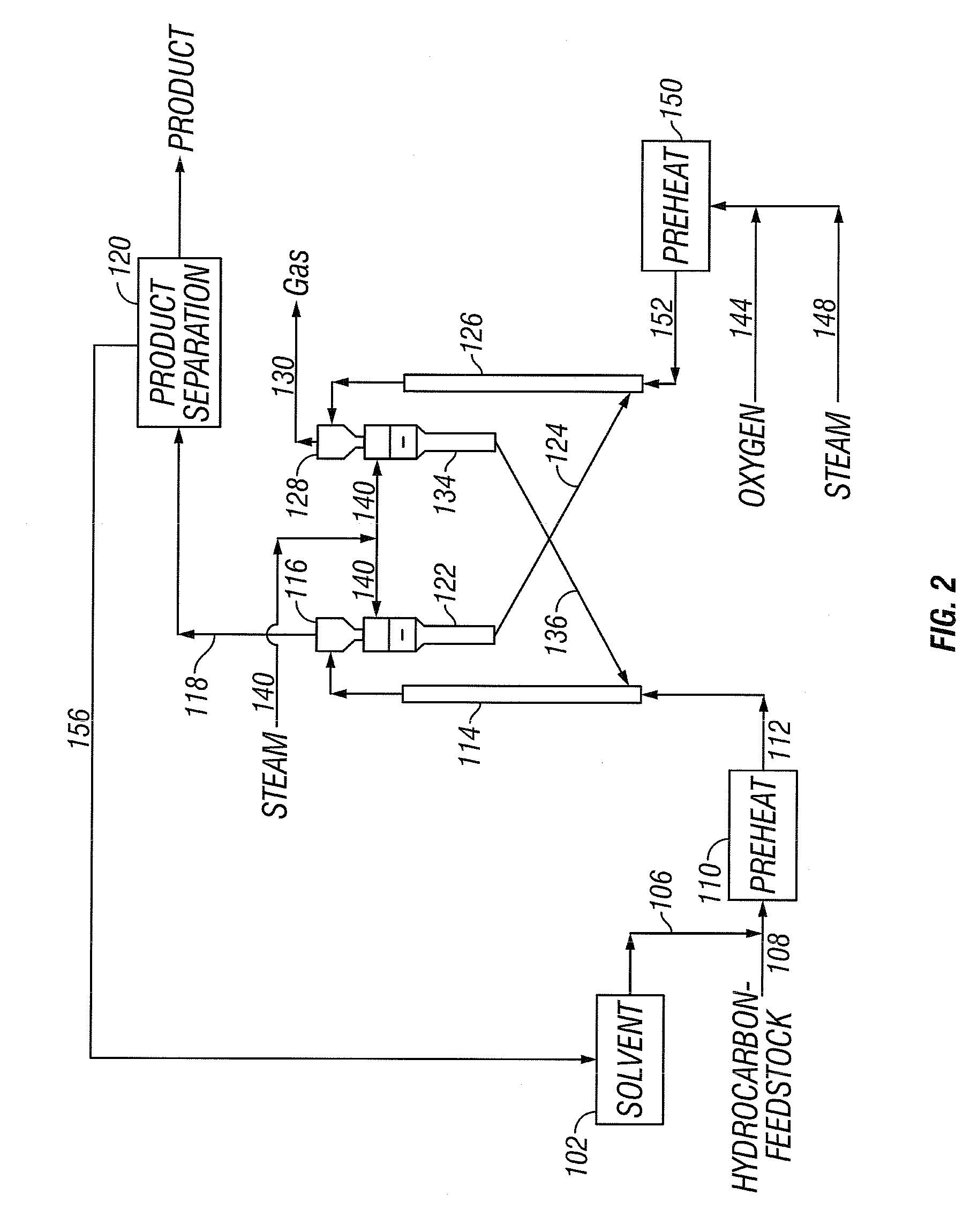

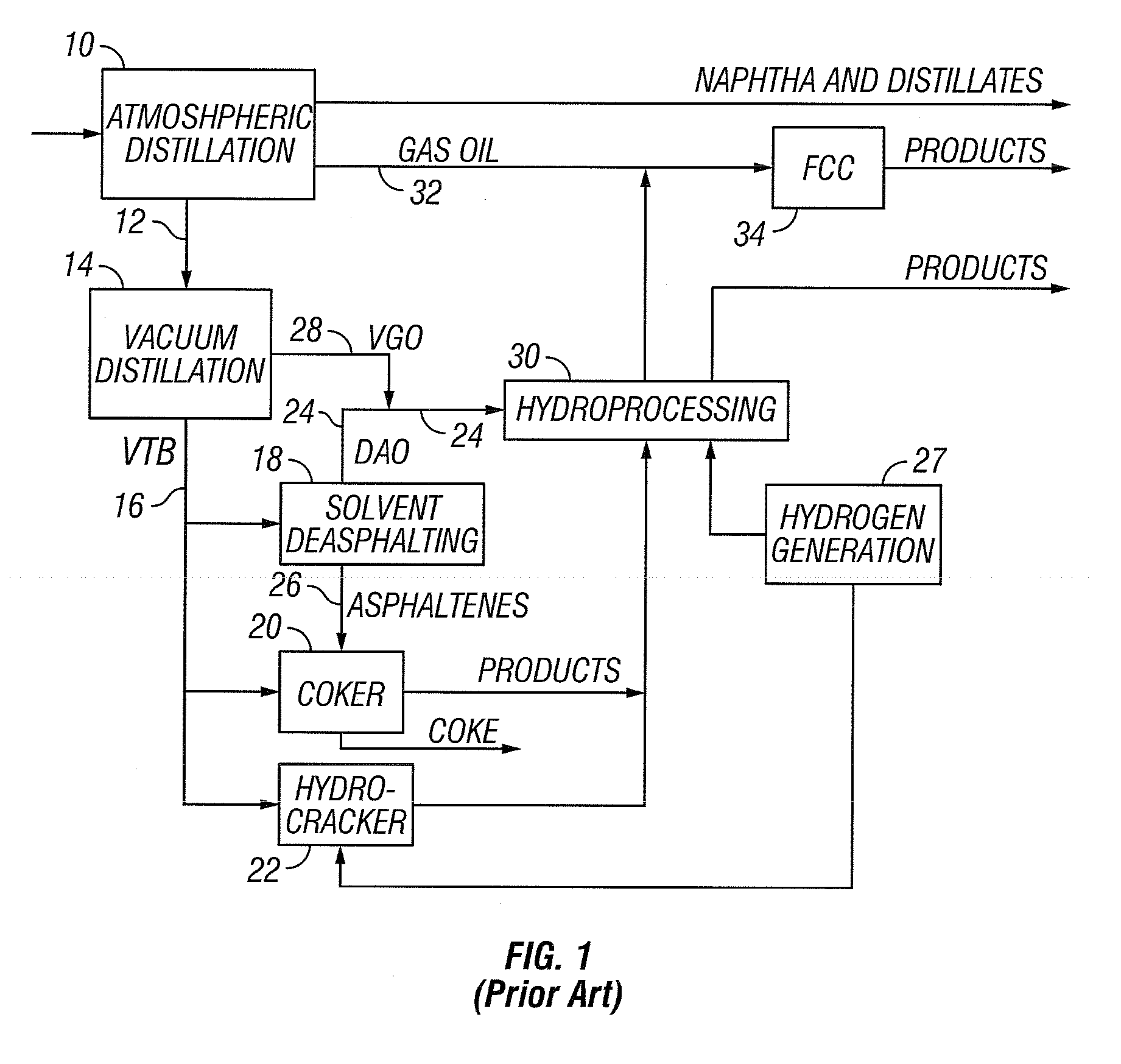

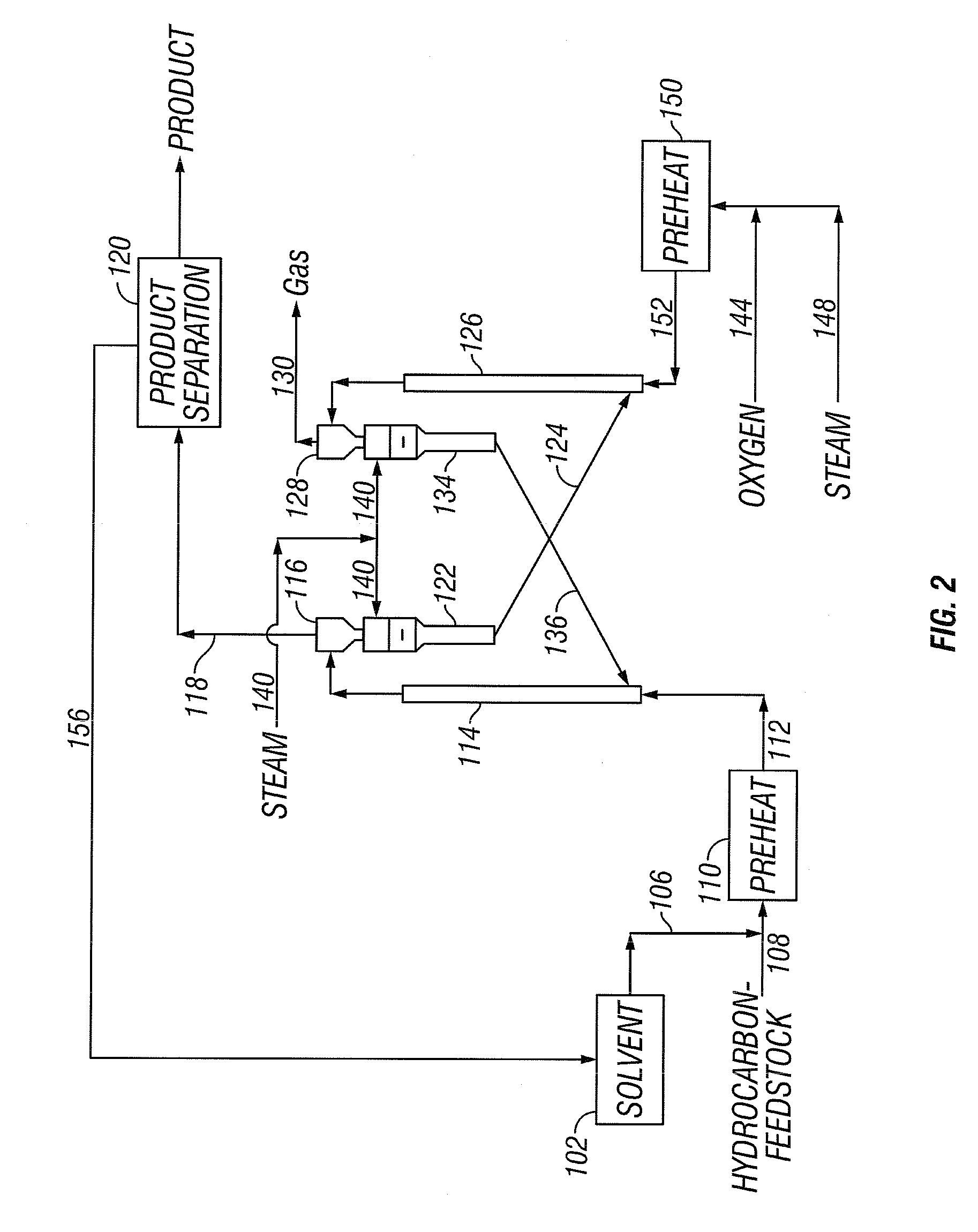

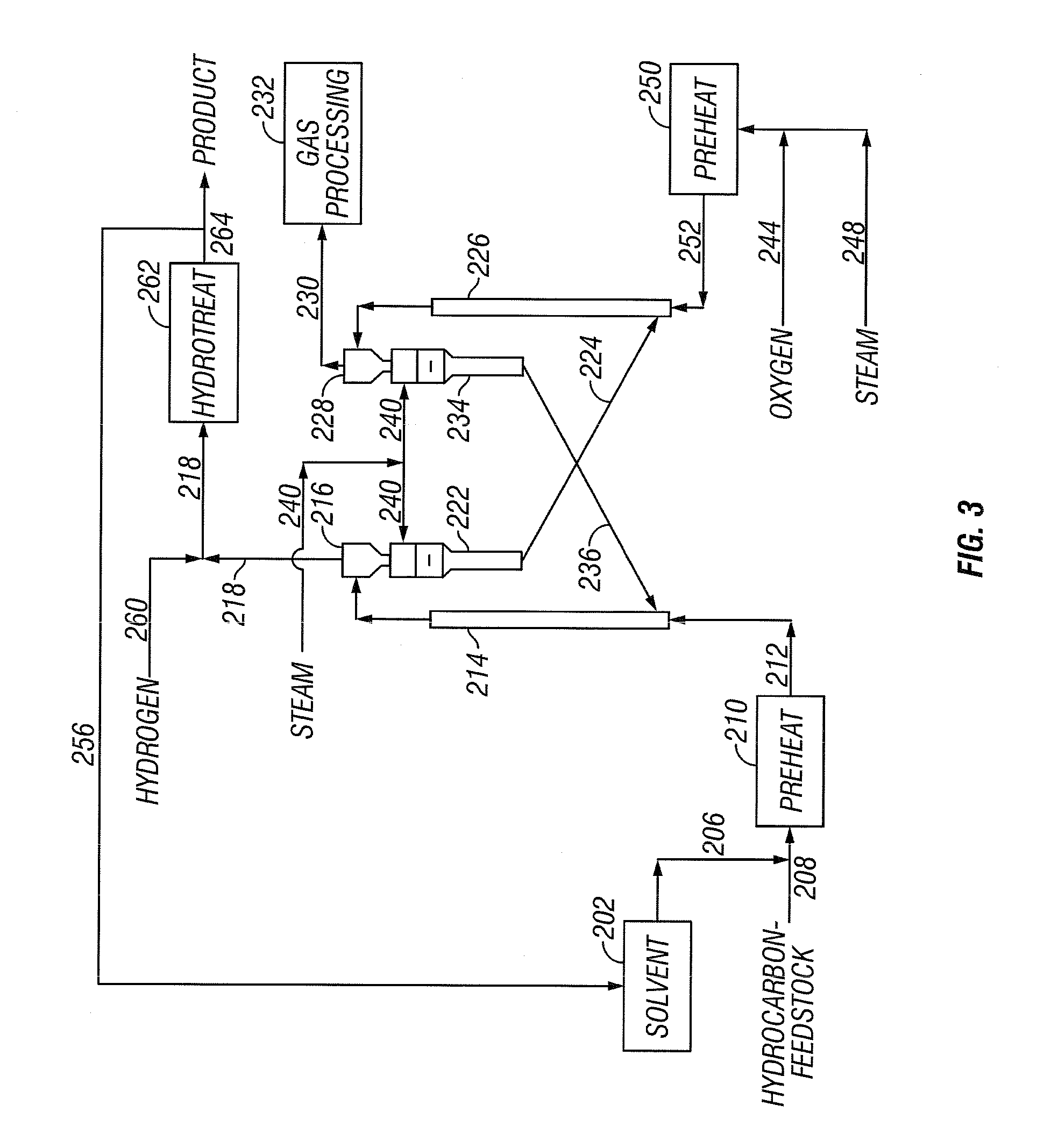

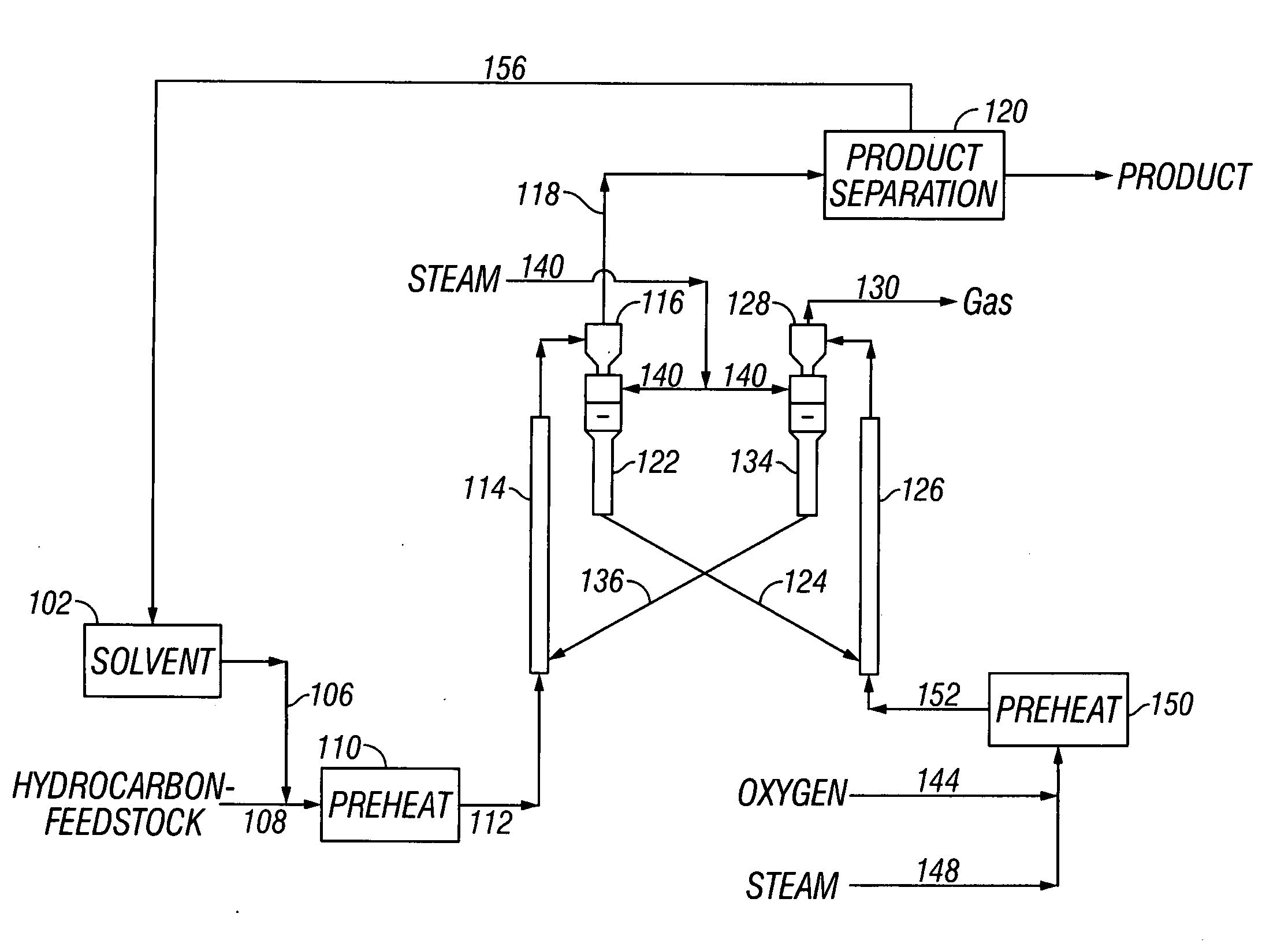

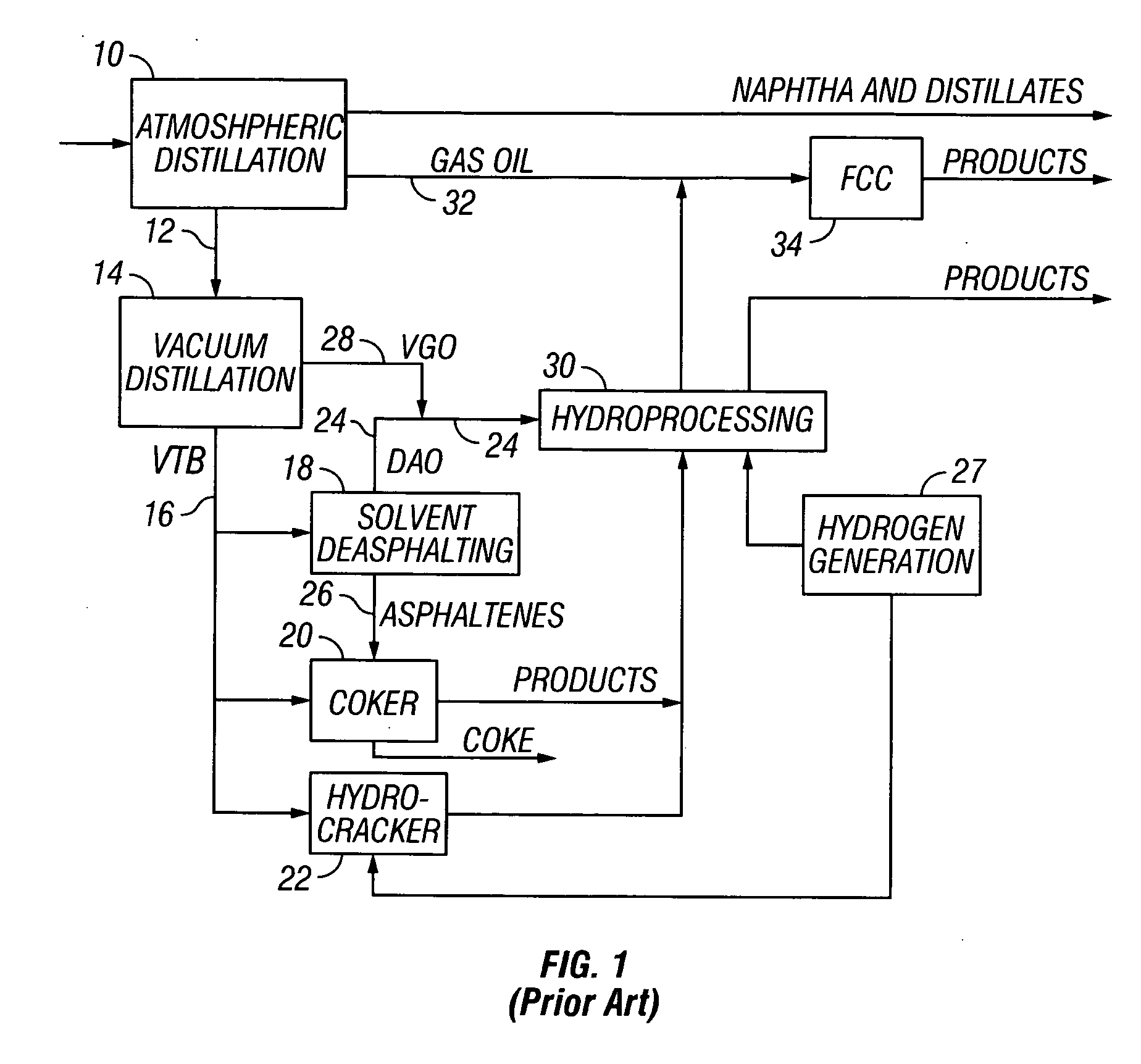

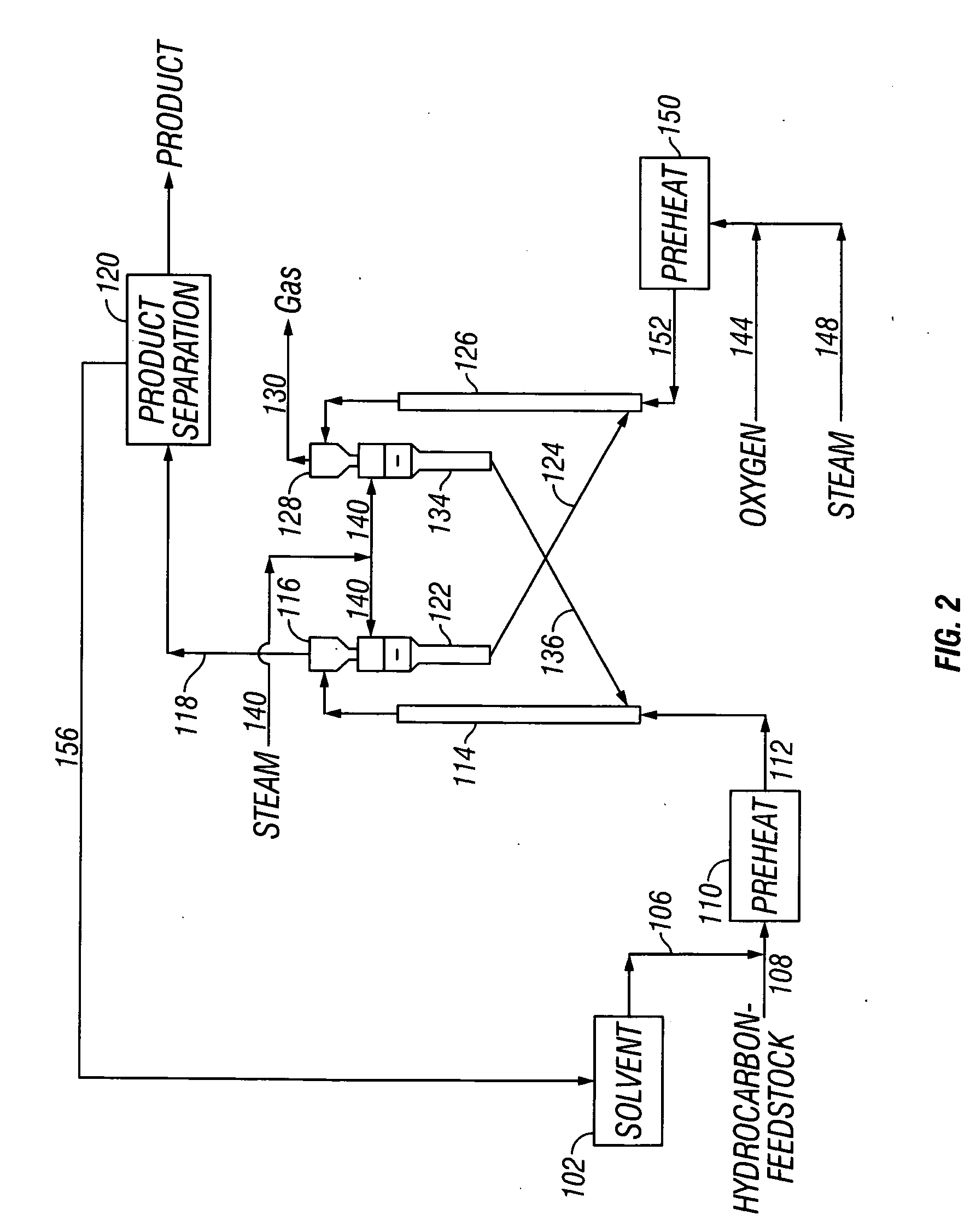

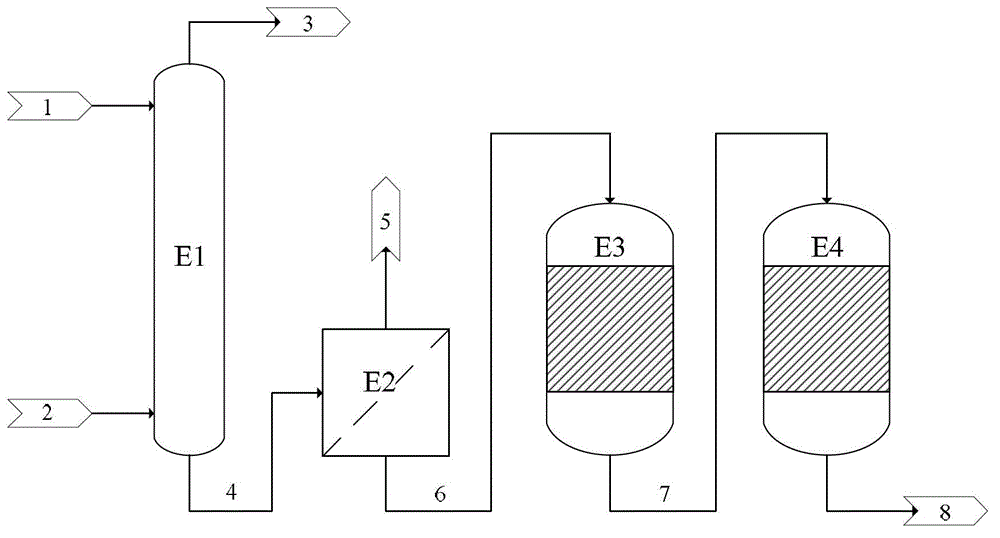

Supercritical hydrocarbon conversion process

ActiveUS7144498B2Thermal non-catalytic crackingTreatment with plural serial cracking stages onlyReaction temperatureUnit operation

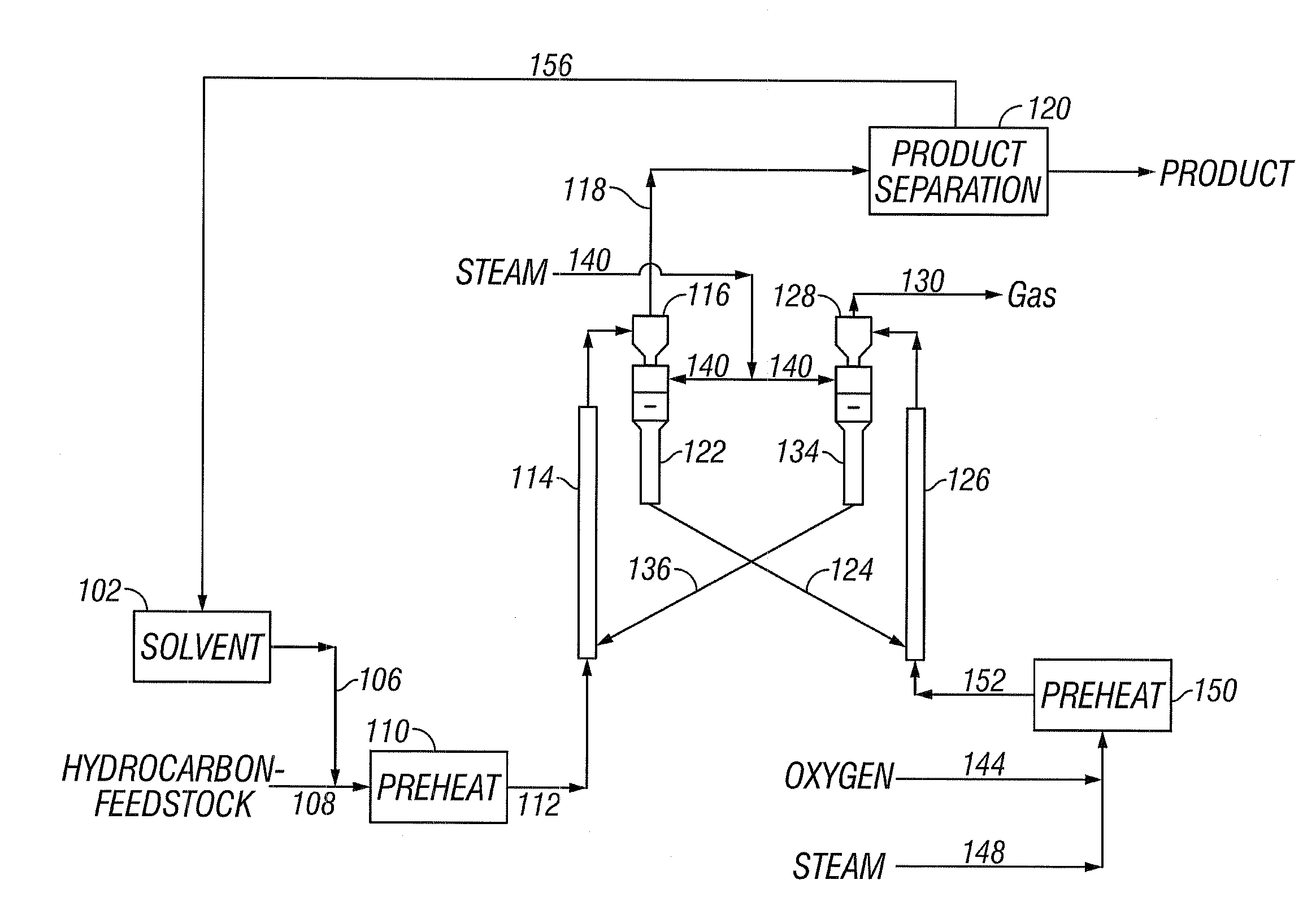

Supercritical conversion of hydrocarbons boiling above 538° C. (1000° F.) with a solvating hydrocarbon at a weight ratio of solvating hydrocarbon to high-boiling hydrocarbons of at least 2:1 and at conditions above the critical temperature and pressure of the high-boiling hydrocarbons-solvent mixture, in the presence of hot fluidized solids. The hydrocarbons are supplied to a reaction zone at a temperature below that of the hot solids supplied thereto, whereby the resulting hydrocarbons-solids suspension has a thermal equilibrium temperature corresponding to the reaction temperature. The conversion has high rates of sulfur, nitrogen and metals removal, nearly complete conversion to lower molecular weight products, high naphtha and distillate selectivity, and low coke formation. The supercritical conversion can replace crude distillation, vacuum distillation, solvent deasphalting, coking, hydrocracking, hydrotreating, and / or fluid catalytic cracking, and / or used in parallel with such unit operations for debottle-necking or increasing capacity.

Owner:KELLOGG BROWN & ROOT LLC

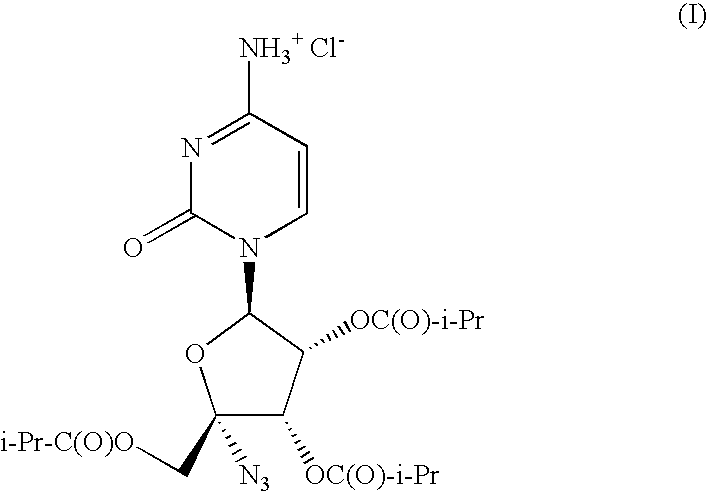

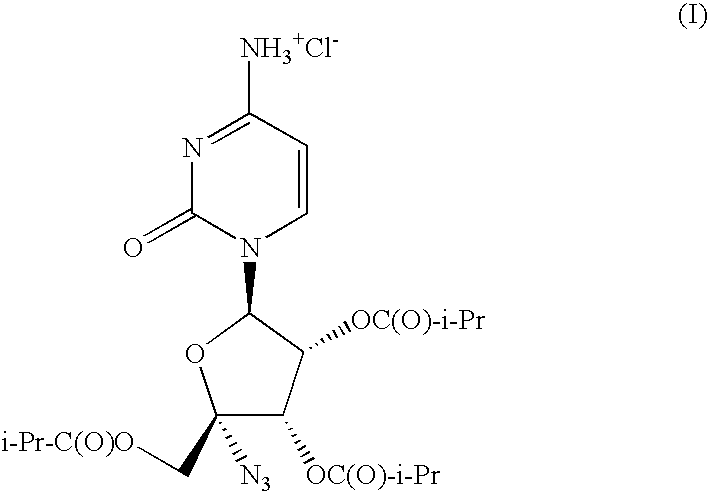

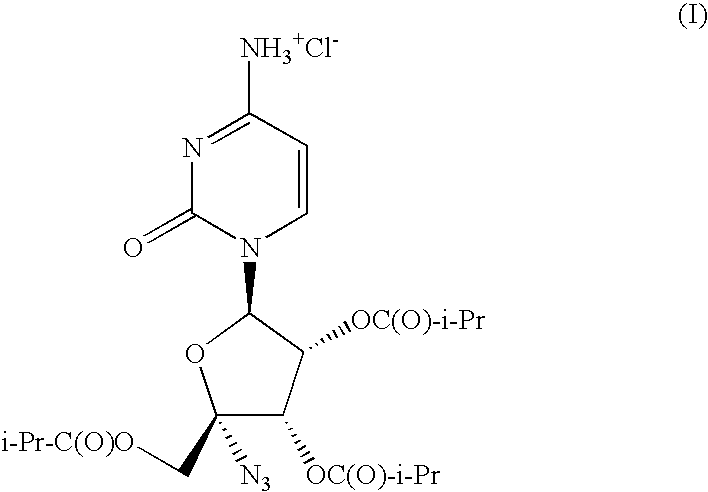

Pharmaceutical composition and process

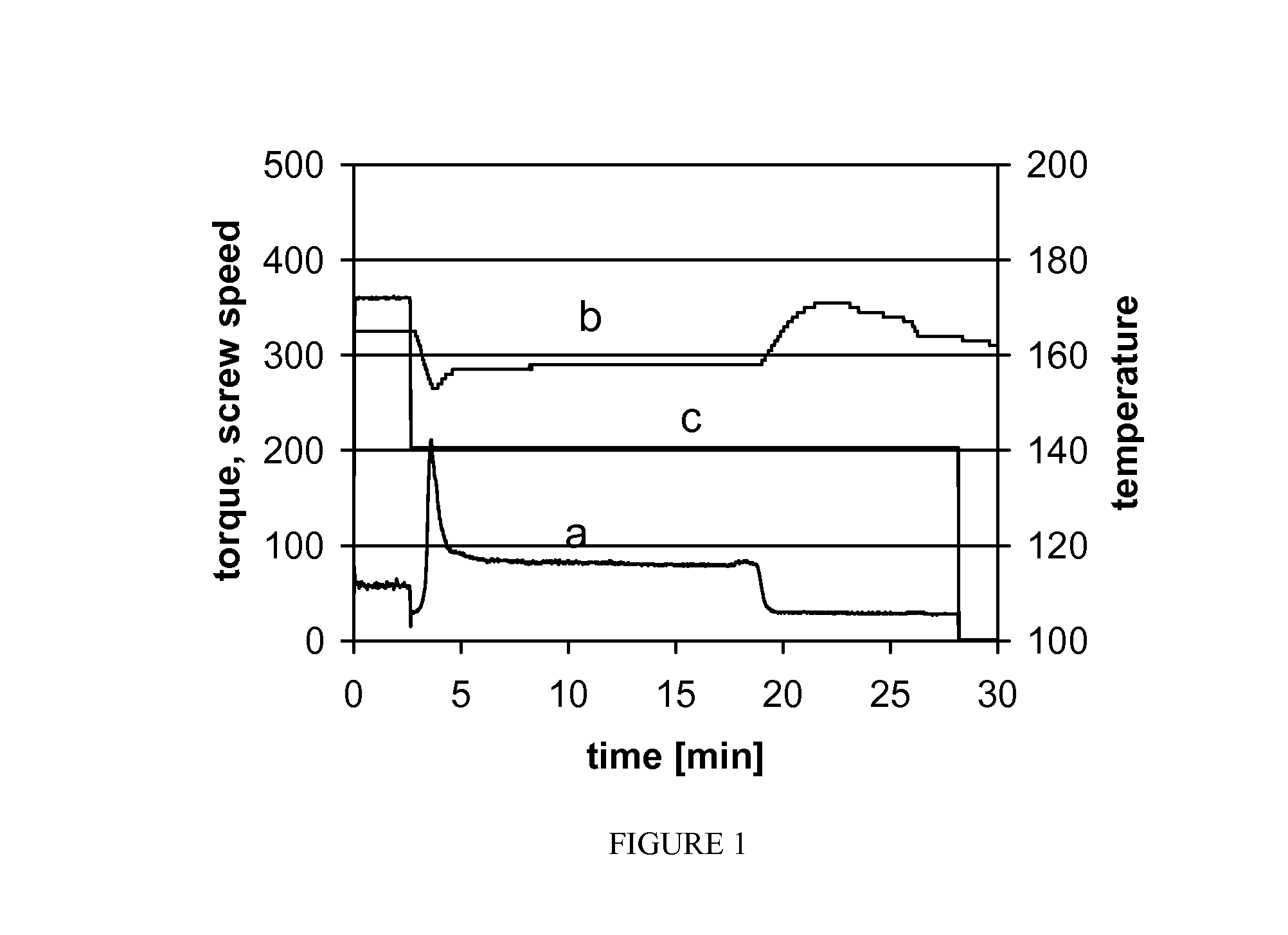

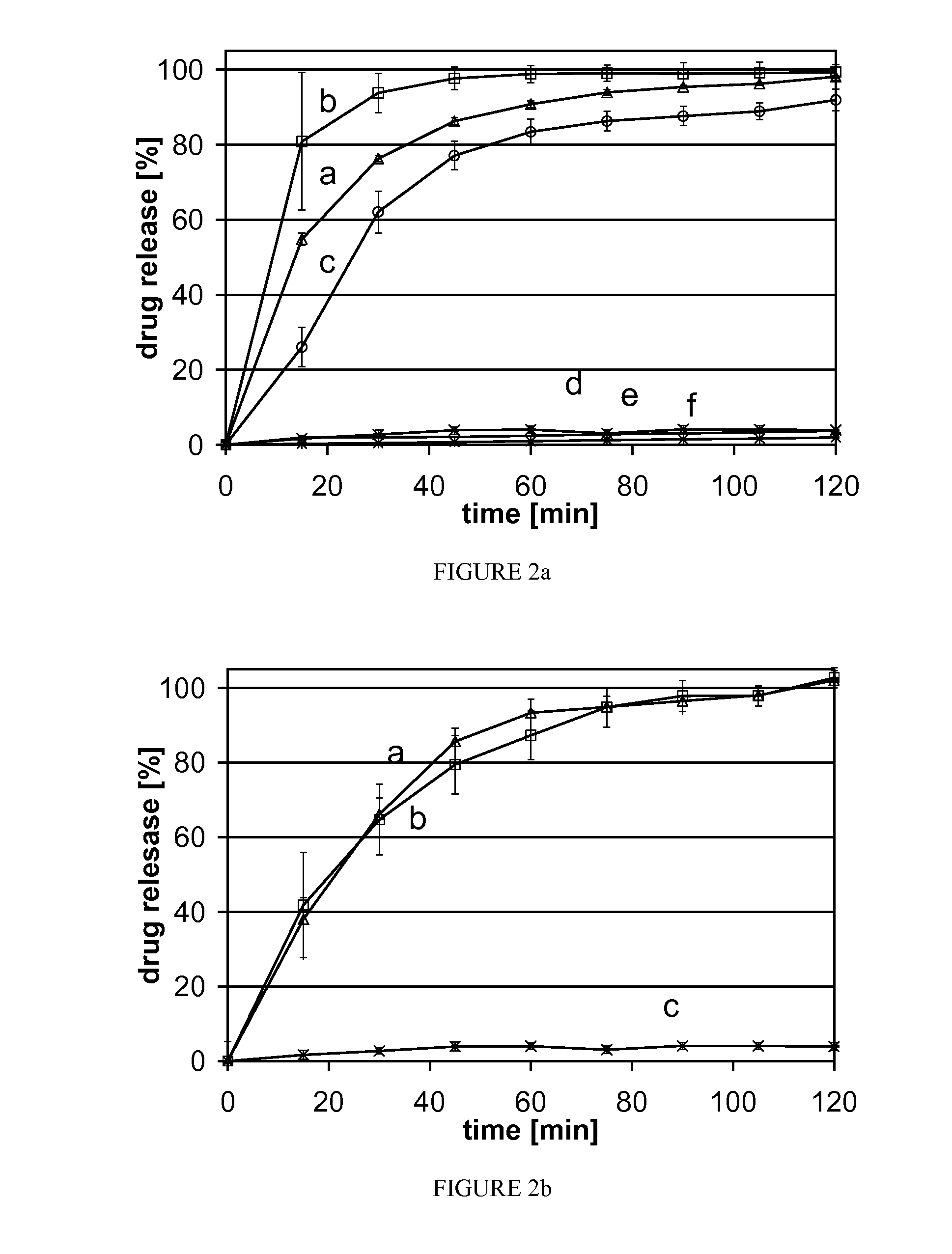

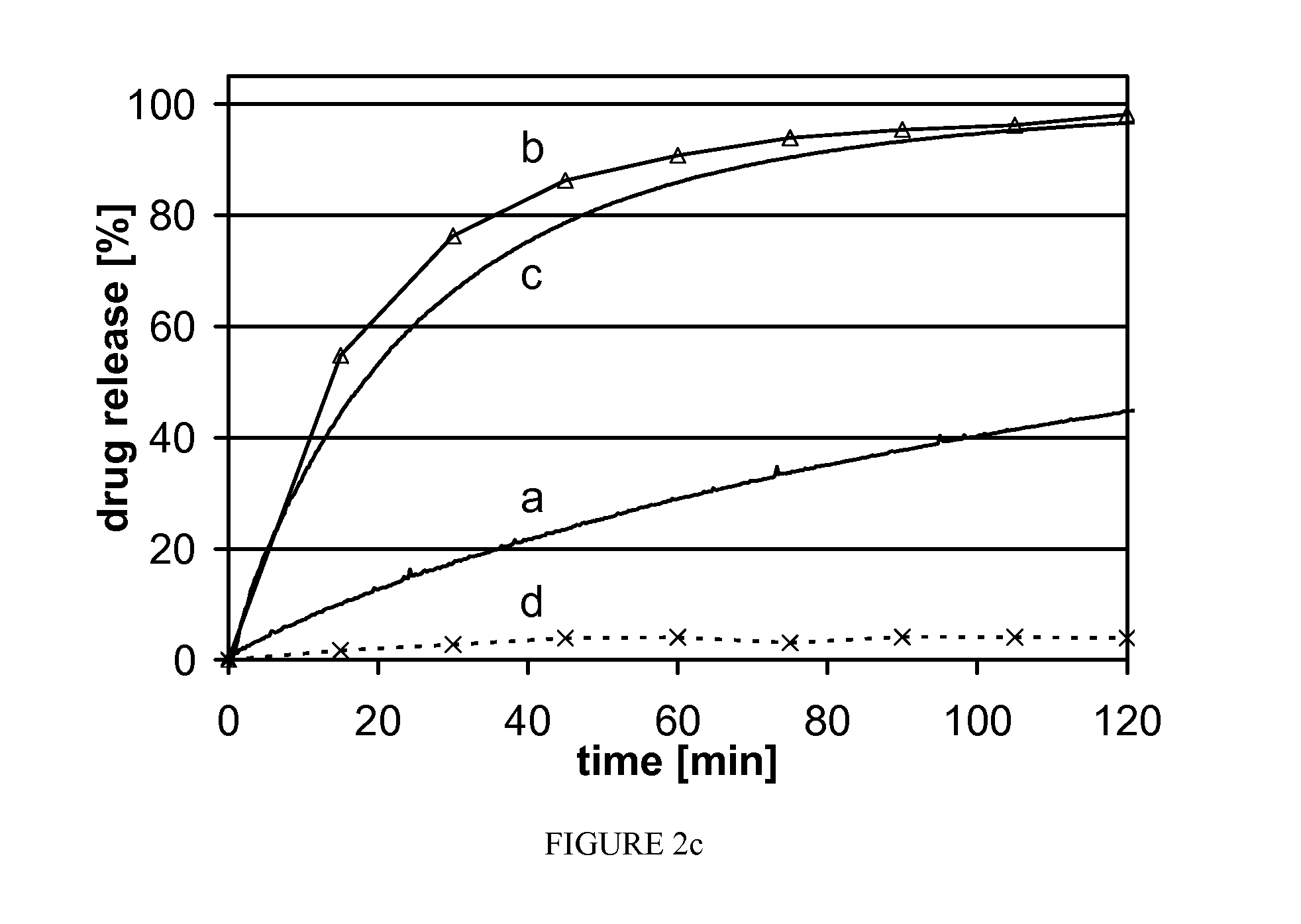

The present invention relates to a pharmaceutical composition comprising a solid suspension prepared by hot melt extrusion of isobutyric acid (2R,3S,4R,5R)-5-(4-amino-2-oxo-2H-pyrimidin-1-yl)-2-azido-3,4-bis-iso-butyryloxy-tetrahydro-furan-2-ylmethyl ester; hydrochloride salt (I) and a polyethylene glycol (PEG) / polypropylene glycol (PPG) block copolymer.

Owner:ROCHE PALO ALTO LLC

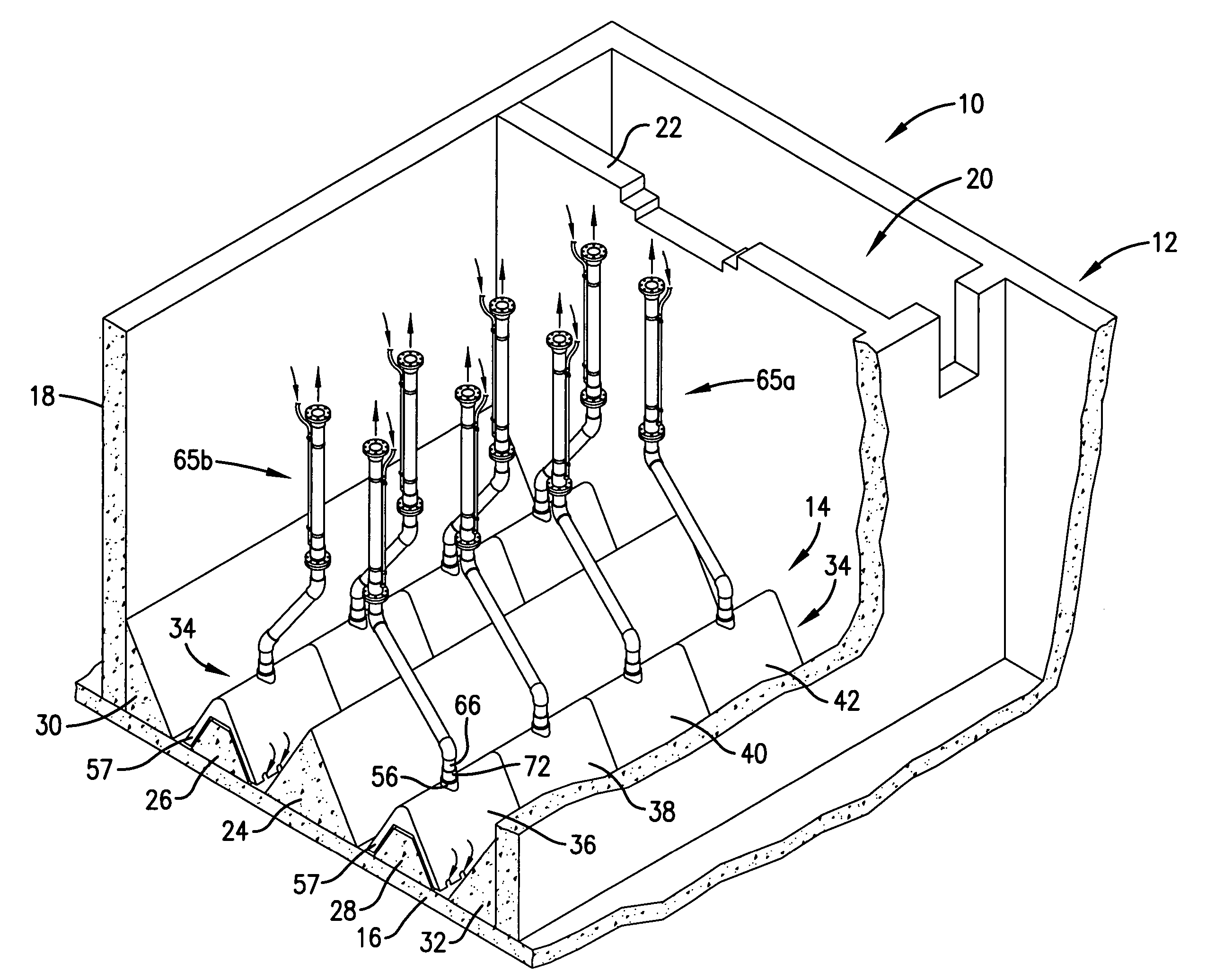

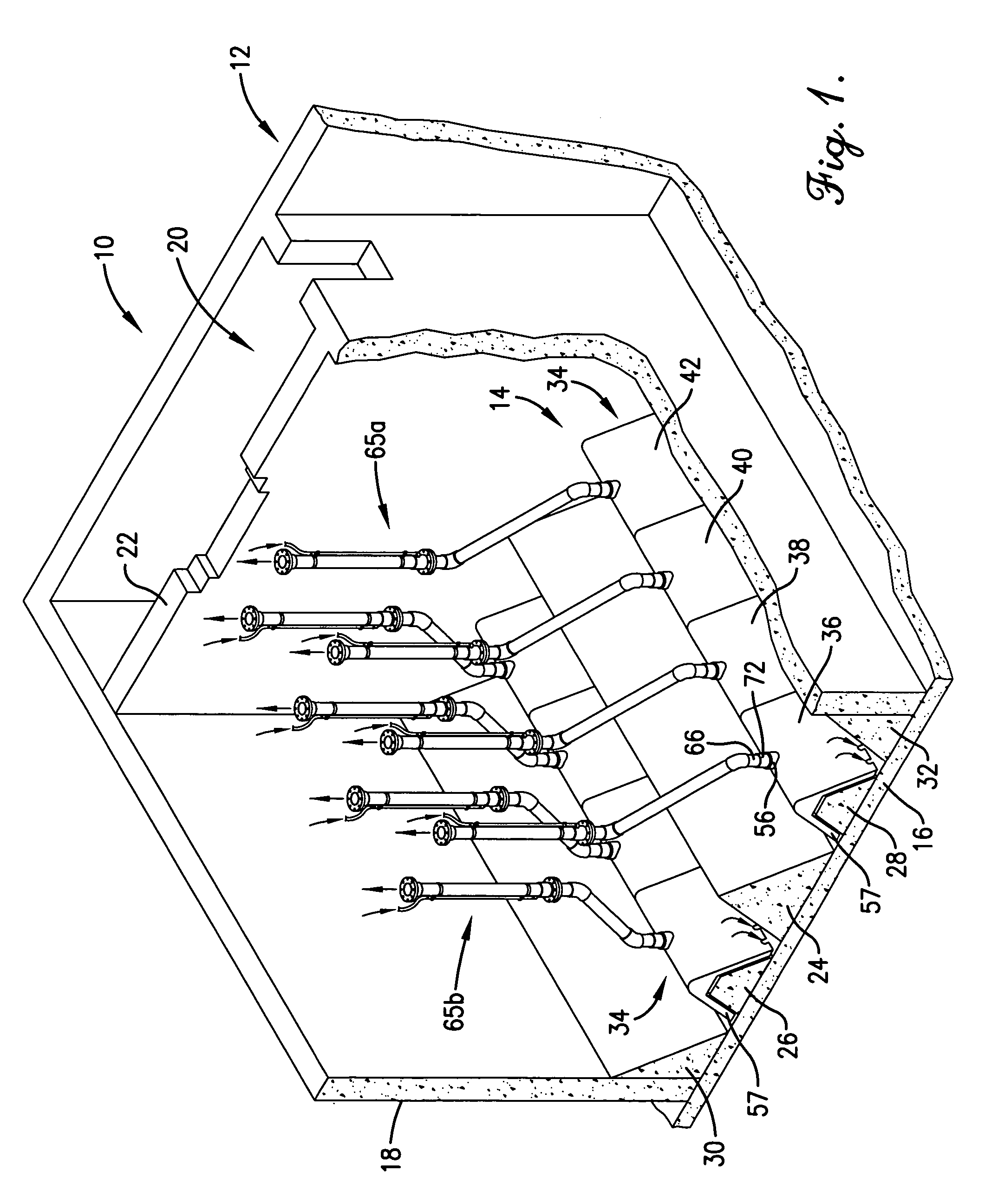

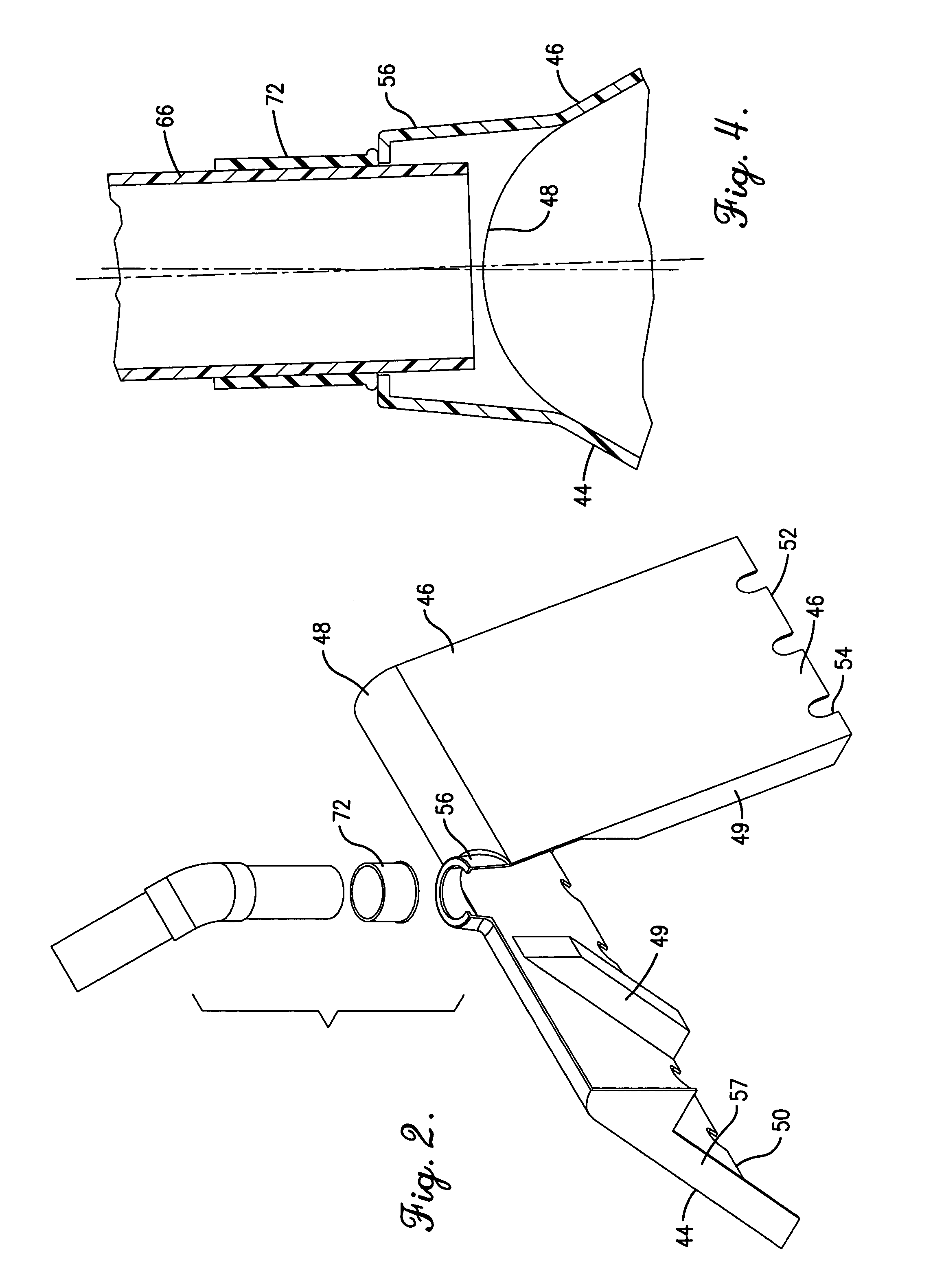

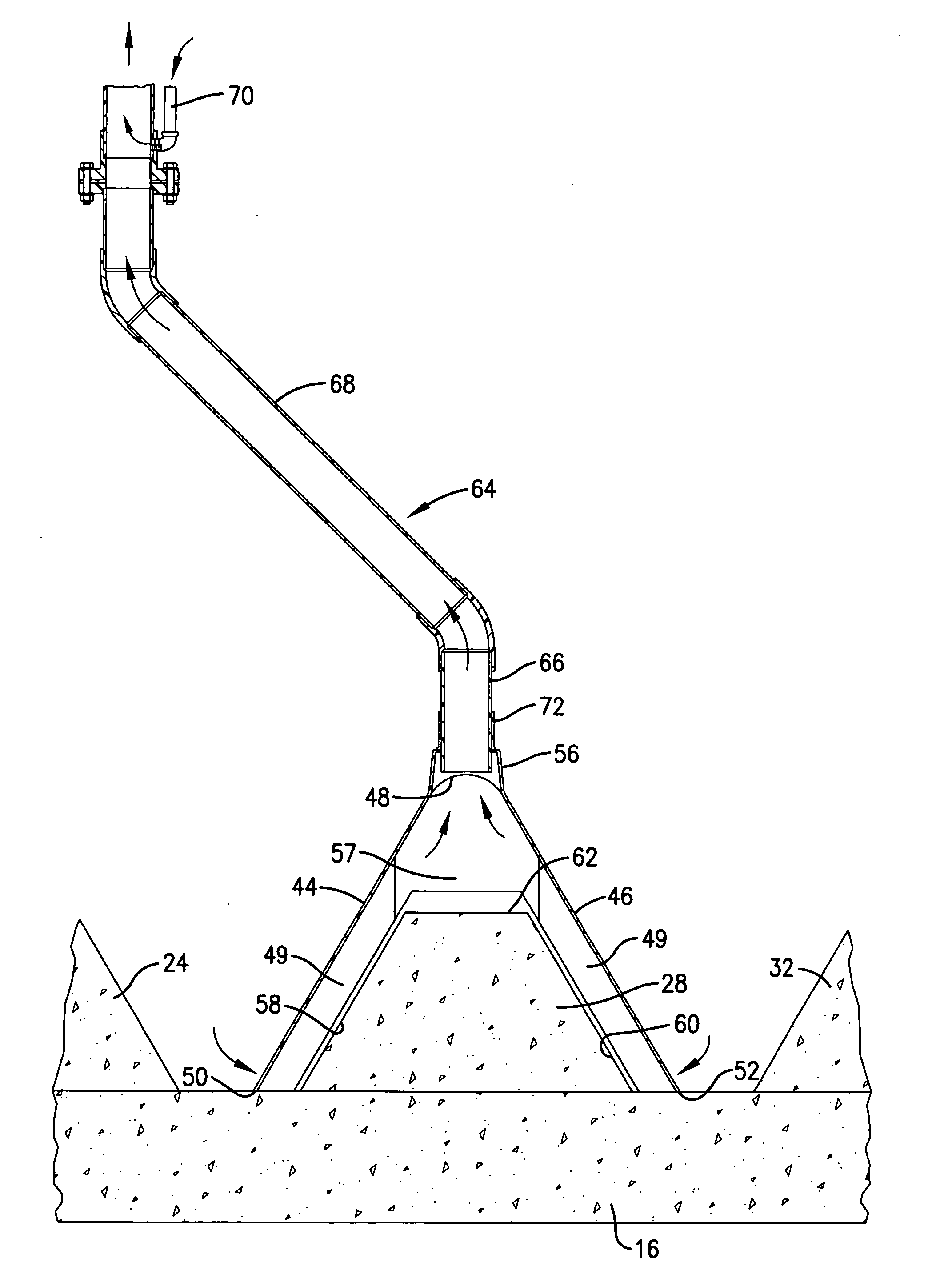

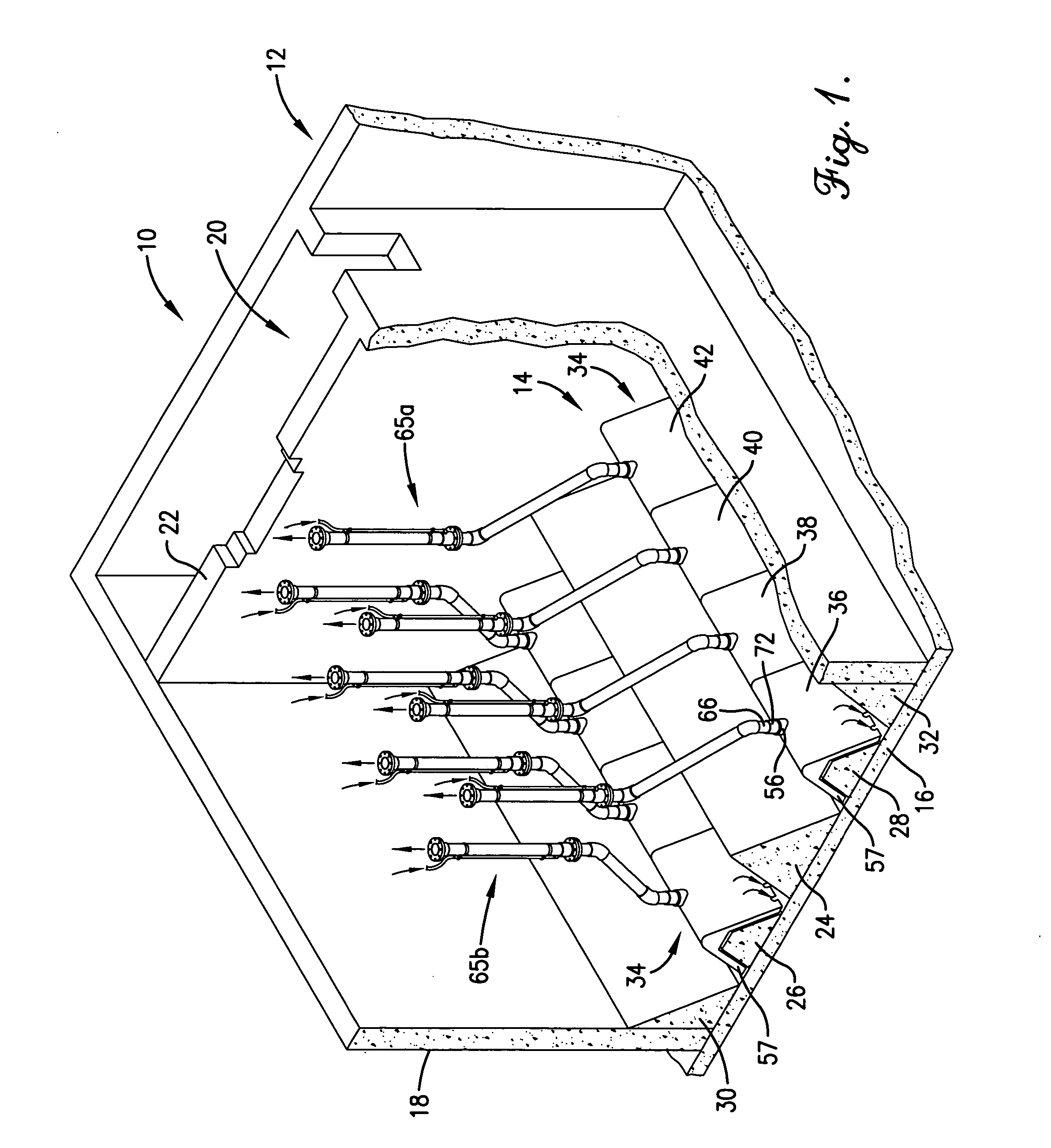

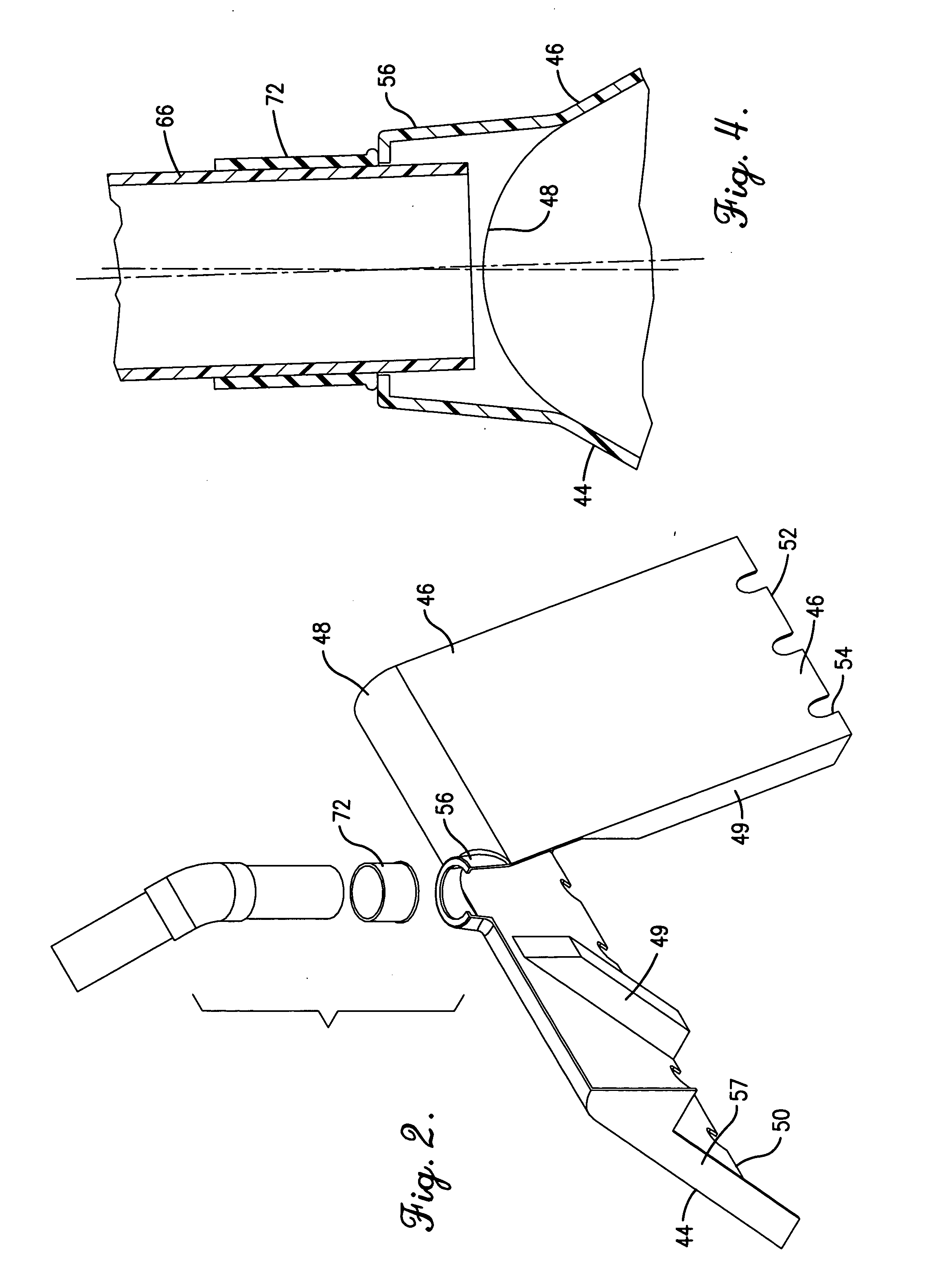

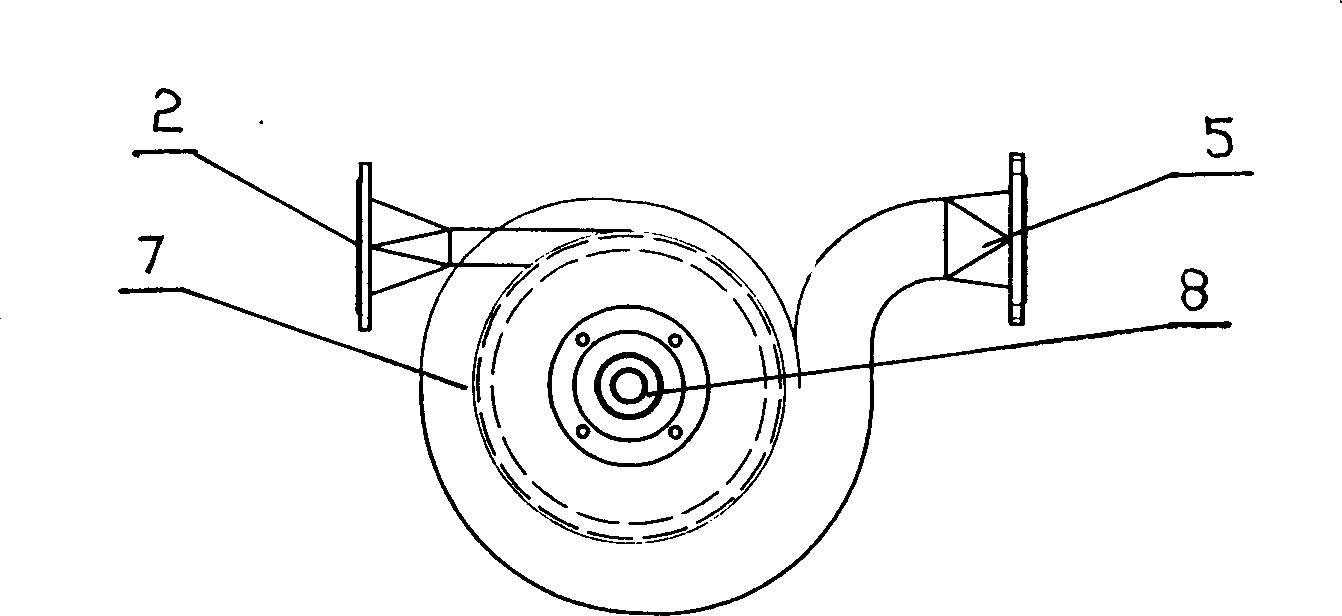

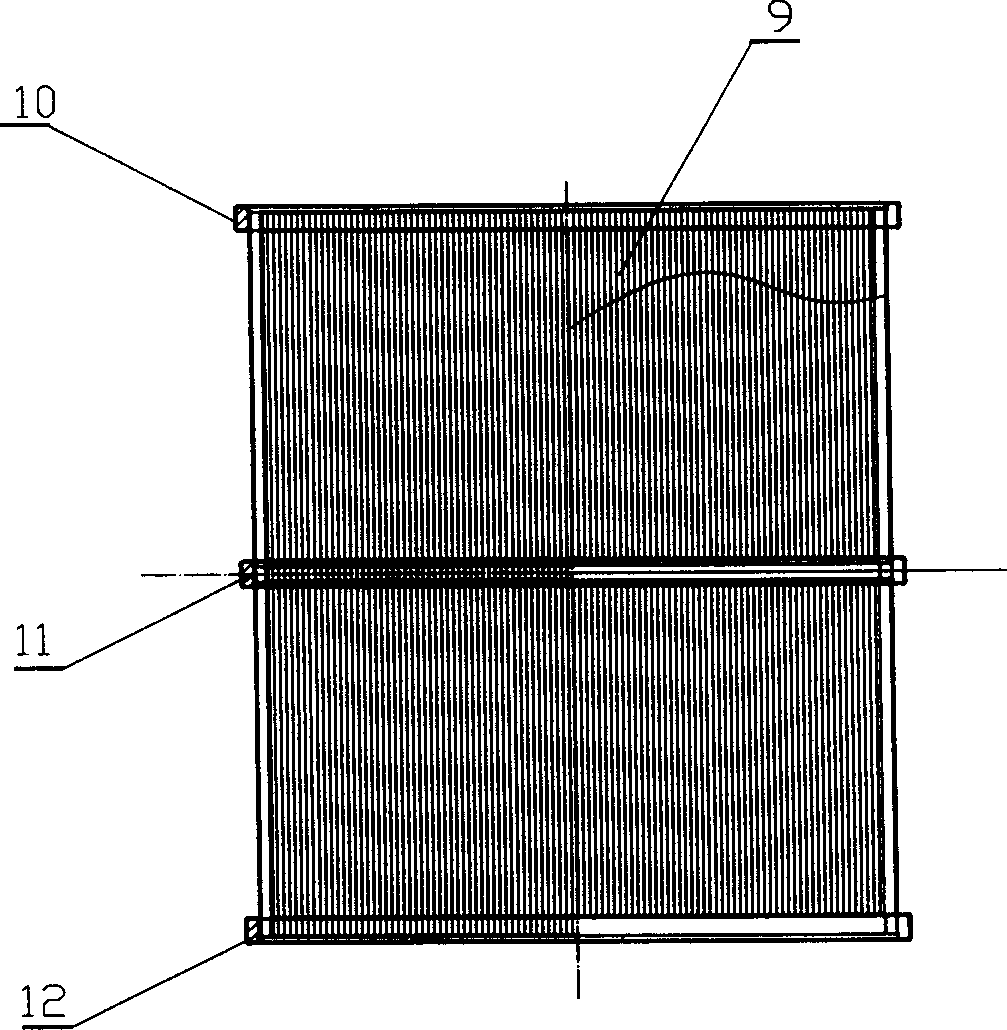

Sedimentation removal assembly for flow-through sedimentary tank

ActiveUS7284670B2Settling tanks feed/dischargeWater/sewage treatmentDownstream processingEngineering

Solids removal assemblies (14) adapted for use in flow-through or batch-type sedimentation tanks (12) are provided which increase the efficiency of solids removal and eliminate physical scraping devices common with such sedimentation tanks. The preferred removal assemblies (14) include an elongated hood (34) disposed over a cooperating and complementally configured fill structure (26,28), which fills the majority of the internal volume of the hood (34). The hood (34) includes converging sidewalls (44, 46) having lower most inlet openings (54) and spaced, tubular outlets (56) adjacent the apex thereof. Outlet pipes (64) are operably coupled with each of the hood outlets (56) for suction withdrawal of waste water-solids suspensions which are then conveyed for downstream processing. The hood (34) and fill structure (26, 28) cooperatively define restricted flow paths for the waste water-solids suspensions, and assist in the creation of relatively high velocity movement of the suspensions to prevent bridging or clogging by collective solids adjacent the bottom of the tanks (12).

Owner:AERO MOD

Supercritical Hydrocarbon Conversion Process

ActiveUS20050167333A1Reduce molecular weightThermal non-catalytic crackingTreatment with plural serial cracking stages onlyReaction temperatureUnit operation

Supercritical conversion of hydrocarbons boiling above 538° C. (1000° F.) with a solvating hydrocarbon at a weight ratio of solvating hydrocarbon to high-boiling hydrocarbons of at least 2:1 and at conditions above the critical temperature and pressure of the high-boiling hydrocarbons-solvent mixture, in the presence of hot fluidized solids. The hydrocarbons are supplied to a reaction zone at a temperature below that of the hot solids supplied thereto, whereby the resulting hydrocarbons-solids suspension has a thermal equilibrium temperature corresponding to the reaction temperature. The conversion has high rates of sulfur, nitrogen and metals removal, nearly complete conversion to lower molecular weight products, high naphtha and distillate selectivity, and low coke formation. The supercritical conversion can replace crude distillation, vacuum distillation, solvent deasphalting, coking, hydrocracking, hydrotreating, and / or fluid catalytic cracking, and / or used in parallel with such unit operations for debottle-necking or increasing capacity.

Owner:KELLOGG BROWN & ROOT LLC

Sedimentation removal assembly for flow-through sedimentary tank

ActiveUS20060091072A1Settling tanks feed/dischargeWater/sewage treatmentDownstream processingWastewater

Solids removal assemblies (14) adapted for use in flow-through or batch-type sedimentation tanks (12) are provided which increase the efficiency of solids removal and eliminate physical scraping devices common with such sedimentation tanks. The preferred removal assemblies (14) include an elongated hood (34) disposed over a cooperating and complementally configured fill structure (26,28), which fills the majority of the internal volume of the hood (34). The hood (34) includes converging sidewalls (44, 46) having lower most inlet openings (54) and spaced, tubular outlets (56) adjacent the apex thereof. Outlet pipes (64) are operably coupled with each of the hood outlets (56) for suction withdrawal of waste water-solids suspensions which are then conveyed for downstream processing. The hood (34) and fill structure (26, 28) cooperatively define restricted flow paths for the waste water-solids suspensions, and assist in the creation of relatively high velocity movement of the suspensions to prevent bridging or clogging by collective solids adjacent the bottom of the tanks (12).

Owner:AERO MOD

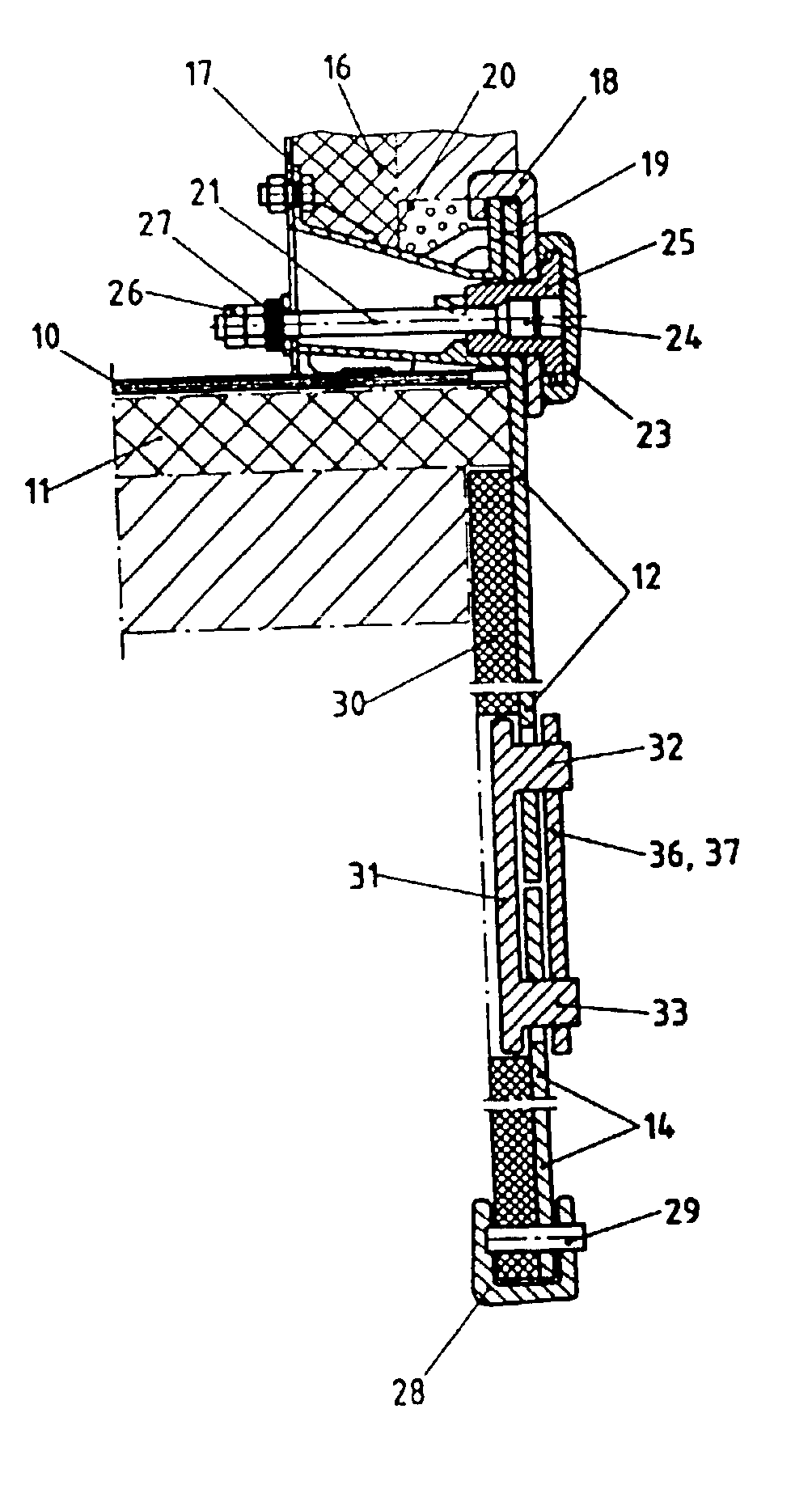

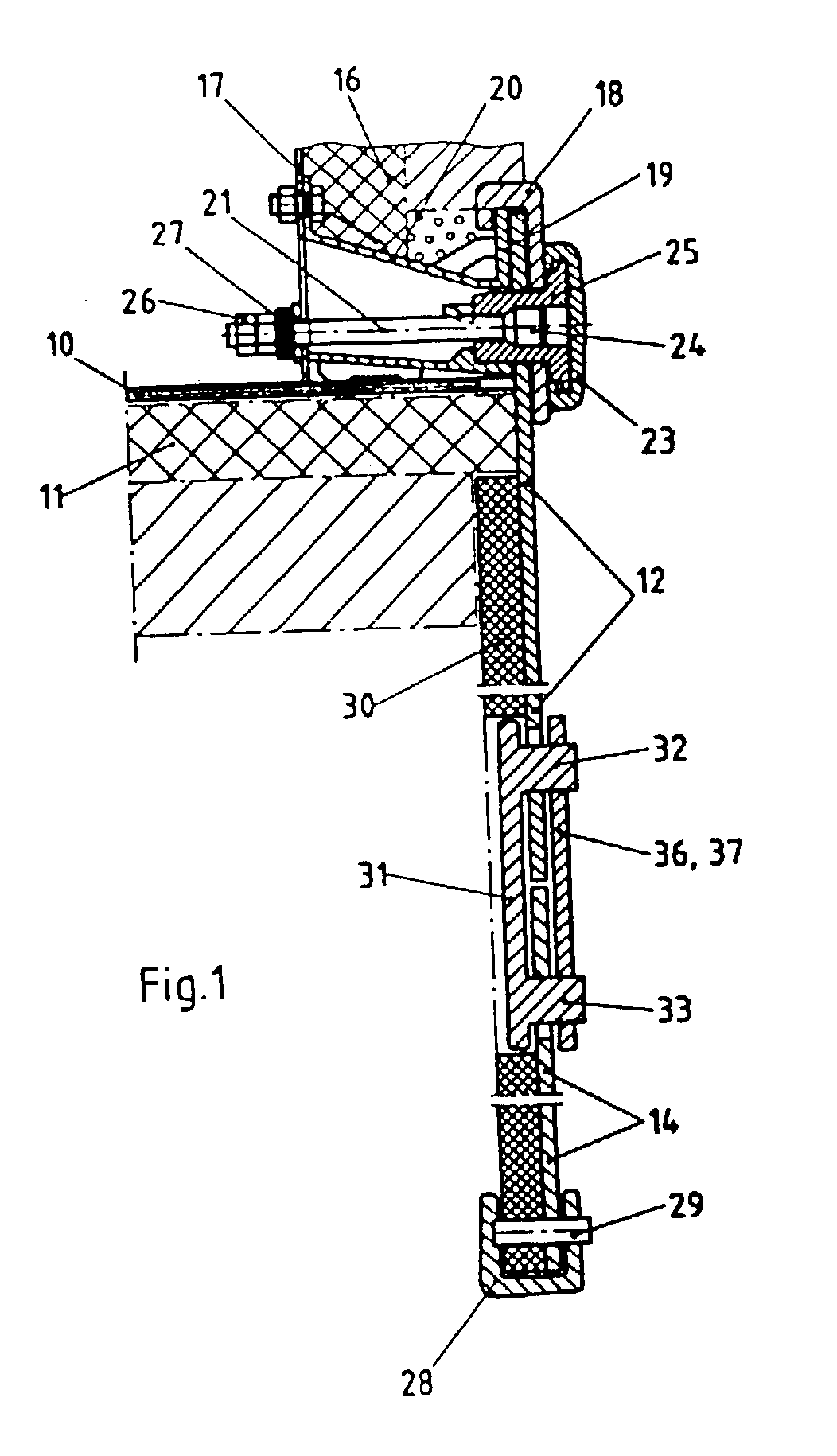

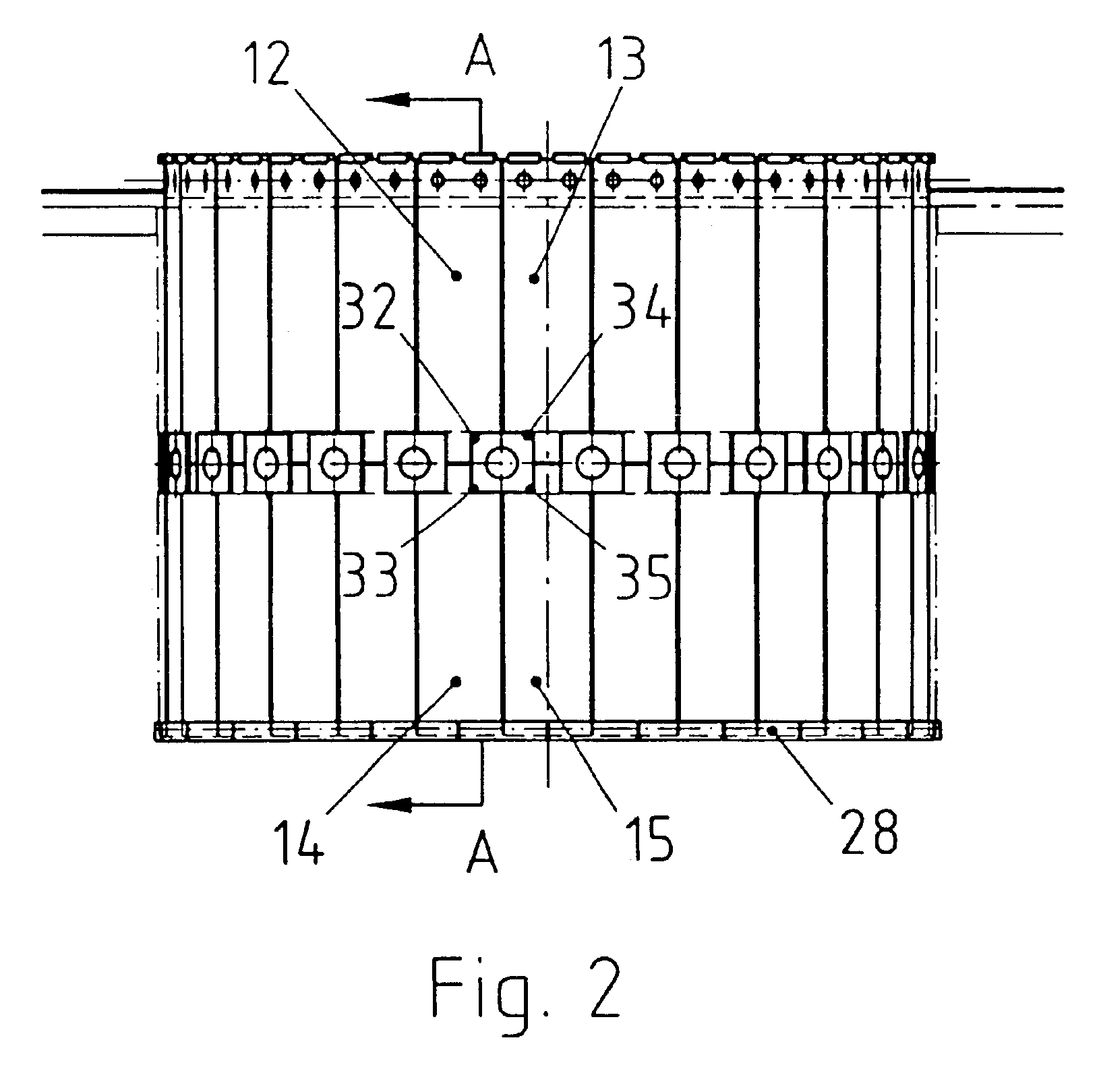

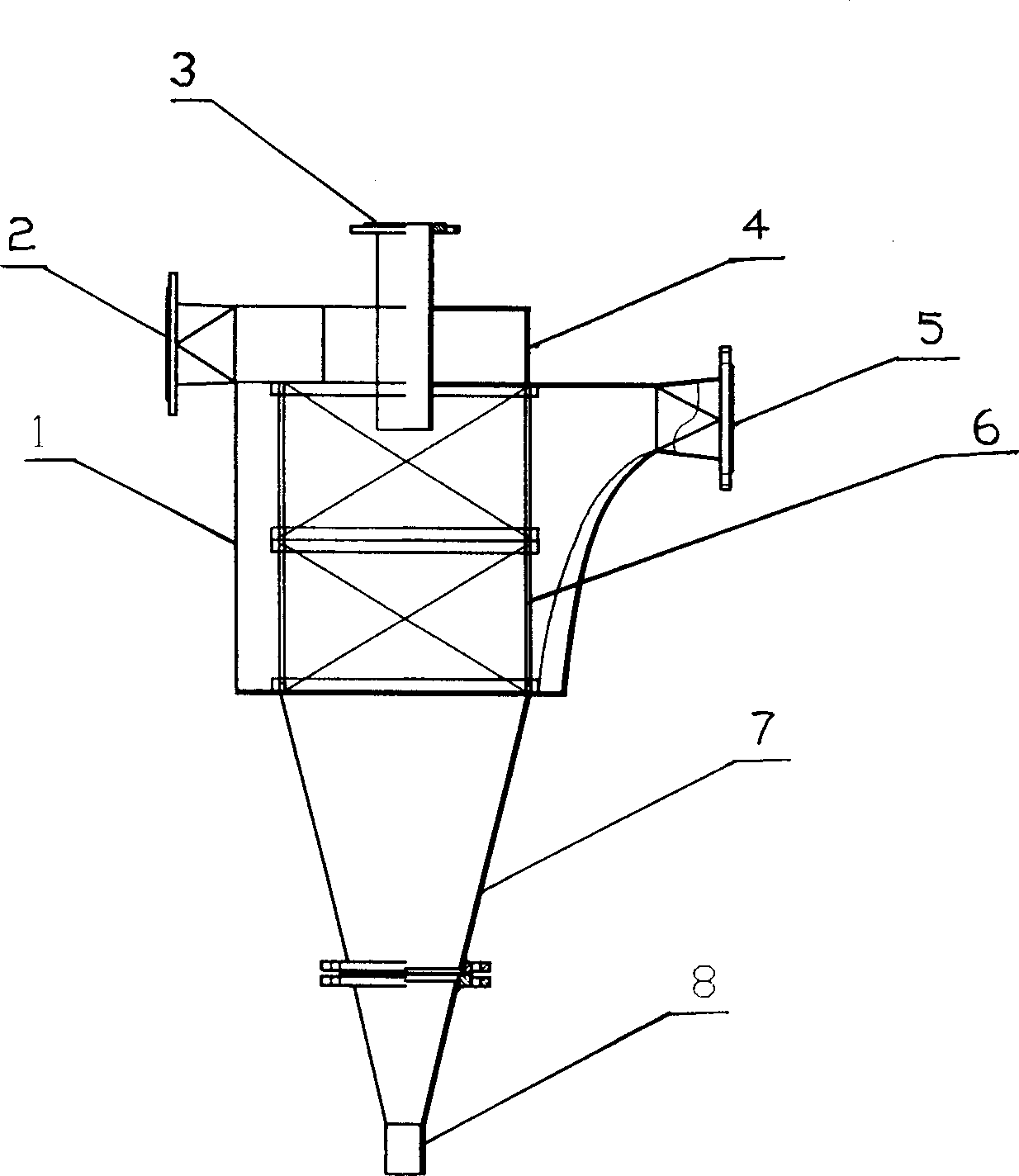

Cyclone separator

InactiveUS6837913B2Easy to useSimple to fabricateCombination devicesPipe supportsCycloneMechanical engineering

A hot gas cyclone separator is provided with a segmented dip tube whose smooth sheet metal dip-tube segments have tops which are securely fastened to a cap of the separator in hook like manner by U-shaped angle rails. The adjacent lower ends of the dip-tube segments may also be interconnected by angle rails having U-shaped profiles which serve to protect the lower end of the dip tube from excessive wear caused by the impinging hot gas / solids suspension.

Owner:KHD HUMBOLDT WEDAG GMBH

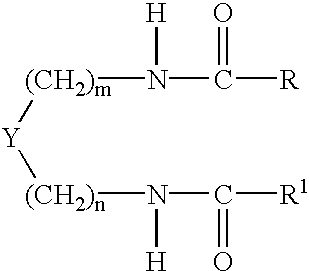

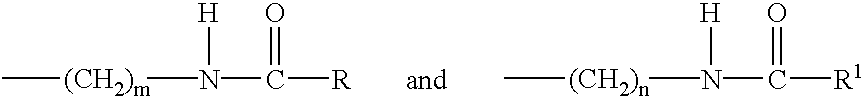

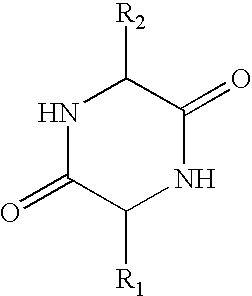

Antiperspirant compositions

Clear solid suspension antiperspirant compositions comprise 0.5 to 50% by weight of a particulate antiperspirant active material of which less than 50% by weight of its particles are below 110pm diameter and a refractive index of from 1.49 to 1.57 at 22° C. is suspended in a water-immiscible carrier liquid of which at least 50% by weight is selected from liquid non-volatile silicone oils and liquid alkyl-aryl esters and not more than 25% by weight of the carrier liquid comprises a volatile silicone oil. The carrier liquid and the antiperspirant have refractive indexes which differ by no more than 0.02 at 22° C and the structurant which solidifies the carrier liquid comprises a fibre-forming non-polymeric structurant, and preferably an N-acyl aminoacid amide such as GPl and / or a cyclodipeptide such as a thymol derivative of (2S-cis)-(-)-5-benzyl-3,6-dioxo-2-piperazine acetic acid.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

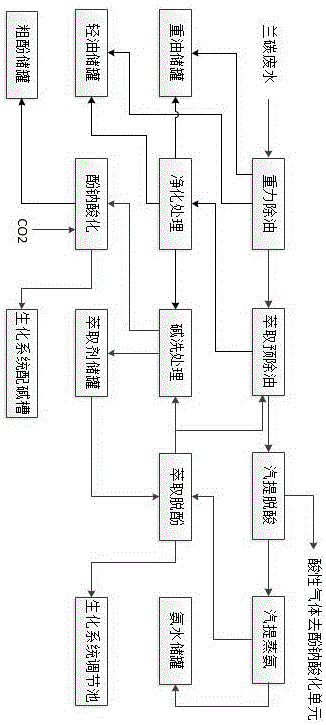

Method for recovery and comprehensive resource treatment of phenol and ammonia in semi-coke waste water

ActiveCN107434335AReduce solubilityPrevent re-evaporationFatty/oily/floating substances removal devicesWater contaminantsSodium saltTreatment system

The invention discloses a method for recovery and comprehensive resource treatment of phenol and ammonia in semi-coke waste water. The method comprises the following steps: performing standing on the semi-coke waste water to realize gravity oil removing and separating recovery, filtering an effluent through a coke filter to remove a solid suspension, and introducing the effluent in an extraction pre-oil removal reactor for deeply removing oil residue, coke powder and tar pollutants in the waste water; performing stripping depickling on the waste water after extraction and pre-oil removal, performing ammonia distilling and performing extraction processing to remove and recover the acidic gas, ammonia and phenol in the waste water, and introducing the processed waste water which reaches the standard in a biochemical treatment system; performing extraction processing to obtain a phenol-rich organic phase, and converting phenols in an extract phase to sodium phenolate through alkali washing processing to realize separation of an extractant and the phenols; and introducing a sodium phenolate solution to an acidifying workshop section for acidifying to prepare crude phenol and sodium salt. The method can realize separation and enrichment of phenols, heavy oil, light oil, ammonia and acidic gas in the semi-coke waste water, realizes resource recovery, at the same time, realizes regeneration and cycle utilization of the extractant and alkali lye, and has good application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

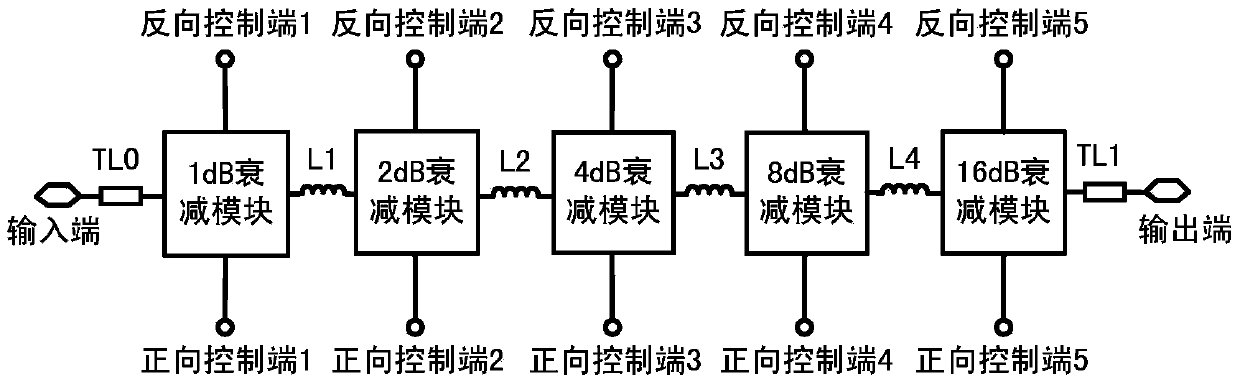

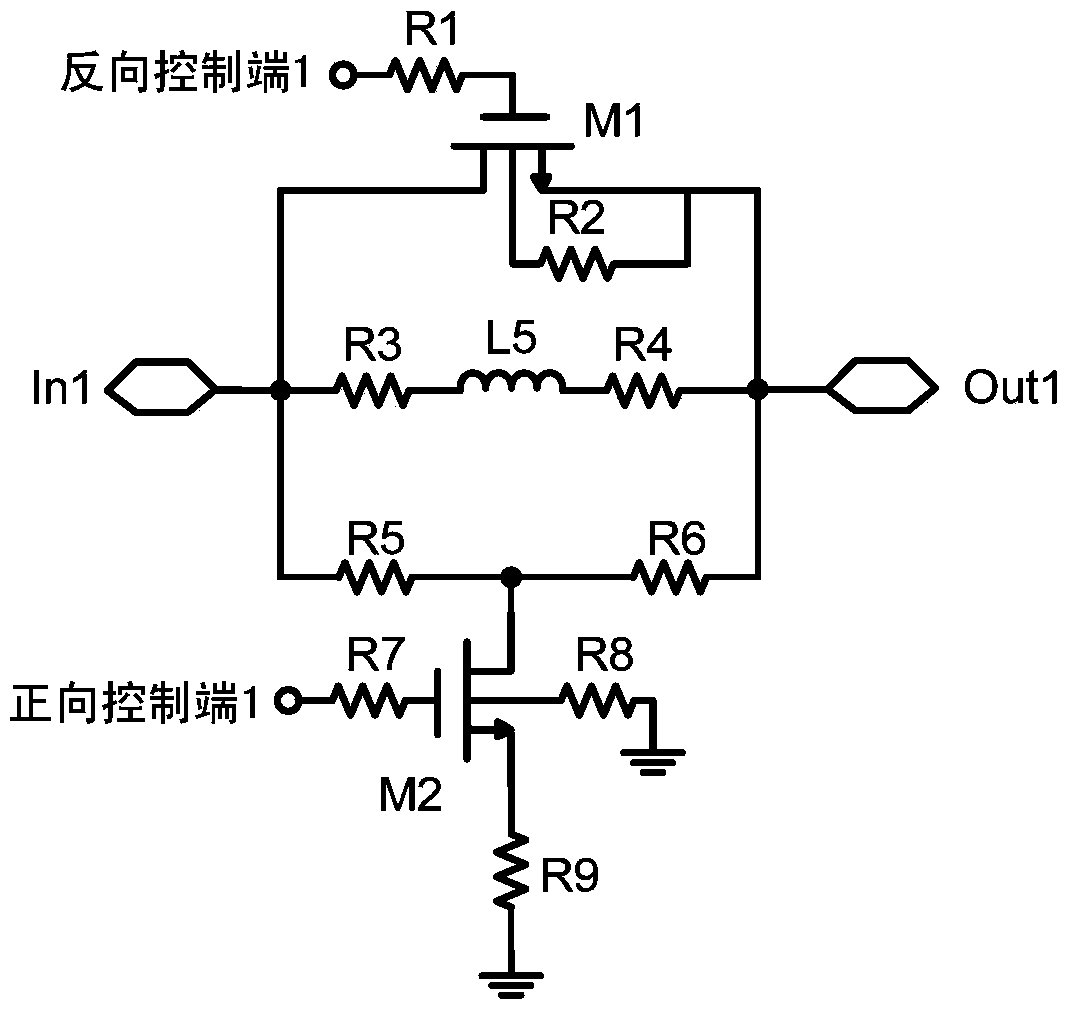

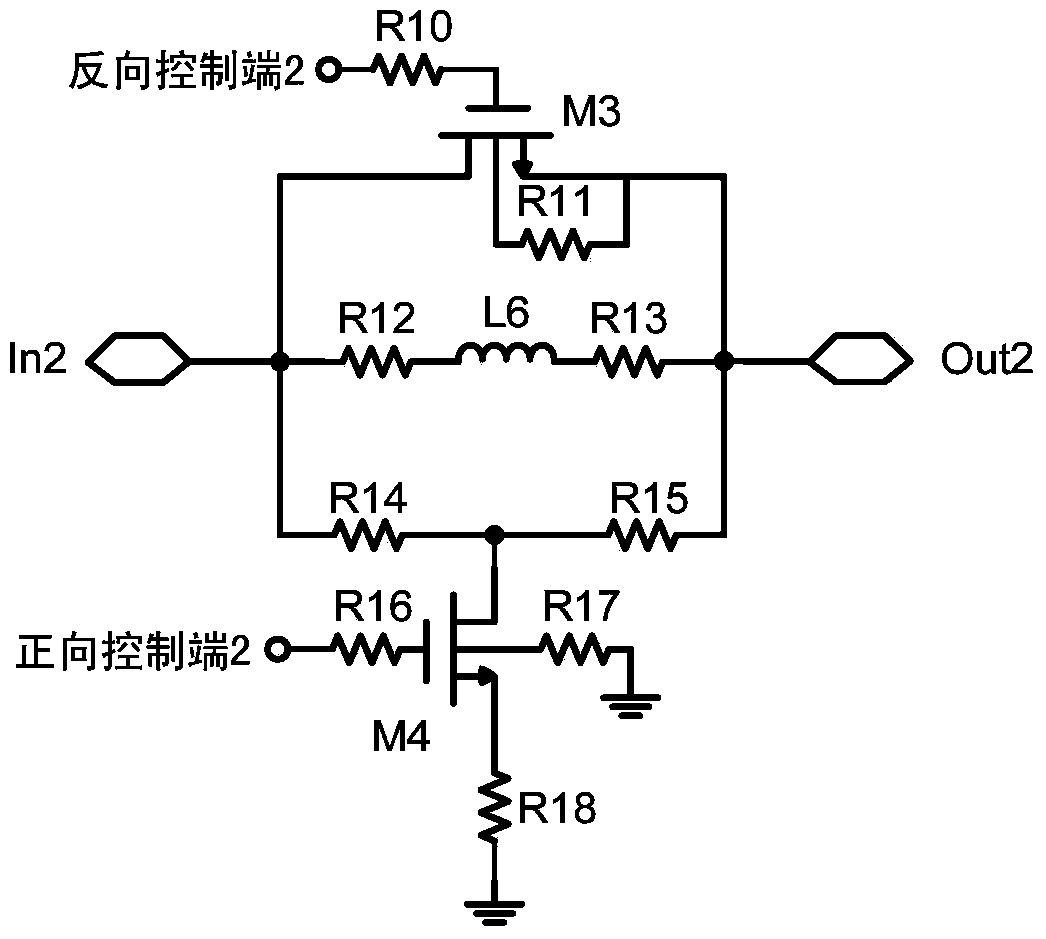

Silicone substrate high-linearity low-phase-shift ultra-broad-band digital attenuator

ActiveCN103427781AOvercoming lossTo overcome the large additional phase shiftMultiple-port networksEngineeringField-effect transistor

The invention discloses a silicone substrate high-linearity low-phase-shift ultra-broad-band digital attenuator which comprises a 1dB attenuating module, a 2dB attenuating module, a 4dB attenuating module, a 8dB attenuating module and a 16dB attenuating module. Two NMOS field effect transistors which are of a channel parallel-connection resistor structure and of a solid suspension structure and manufactured through SiGe BiCMOS technology are adopted to be used as control switches, five sets of complementary digital signals are used for controlling the five attenuating modules independently to work, a low-pass network is used for conducting phase compensation, inductance is used for matching between the adjacent attenuating modules, matching between the input end of the1dB attenuating module and 50 omega input impedance and matching between the output end of the 16dB attenuating module and 50 omega output impedance are realized through transmission wires, the working frequency range is 1-25GHz, and low-differential-loss low-phase-shift attenuation of signal amplitudes under 32 states can be realized with the 1dB length stepping in the attenuating range of 0-31dB. The silicone substrate high-linearity low-phase-shift ultra-broad-band digital attenuator has the advantages of being low in differential loss, low in accessory phase shift, high in linearity, low in production cost and low in chip area, and can be used for large-amplitude signal processing and single chip integration.

Owner:XIDIAN UNIV

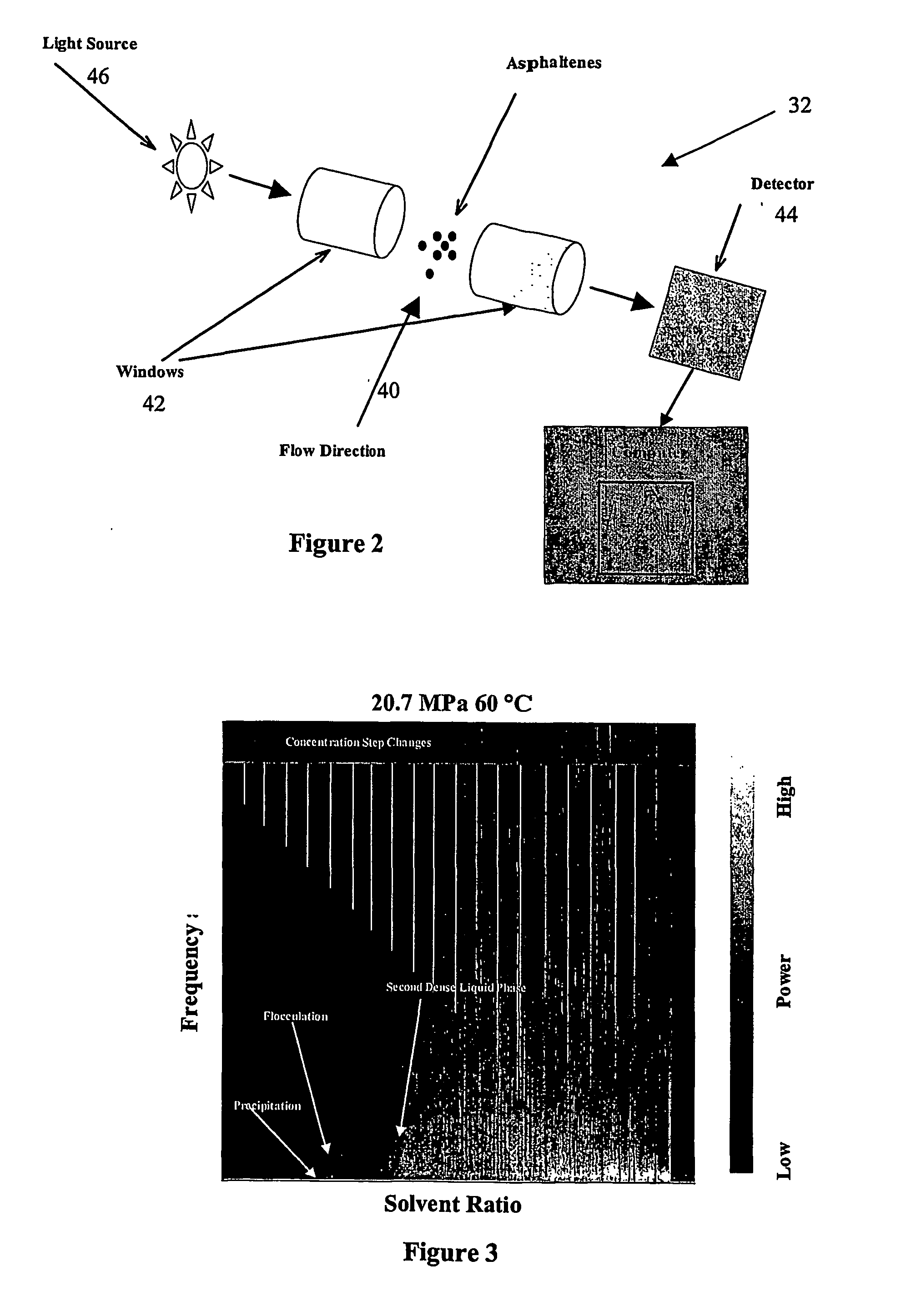

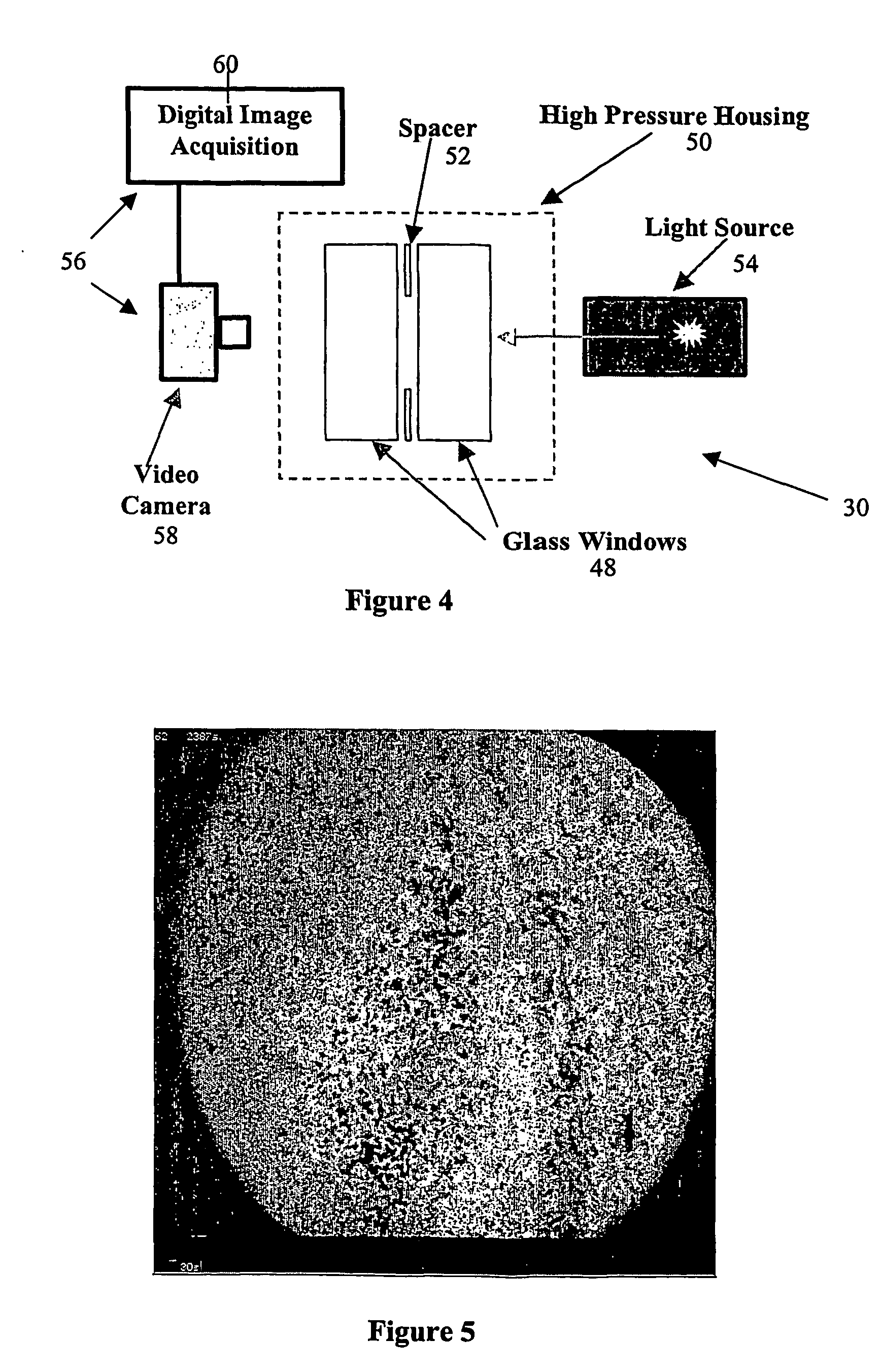

Method of characterizing a dispersion using transformation techniques

InactiveUS20070134804A1Well representedEasy to useTransmissivity measurementsAnalysis by subjecting material to chemical reactionFast Fourier transformFrequency spectrum

A method for analyzing a dispersion such as an oil / solid suspension or an oil / water emulsion. A set of original domain data is collected relating to an attribute of the dispersion, such as light transmittance therethrough. The set of original domain data is then transformed into a transformed set of original domain data which is in the frequency domain. Any transformation technique, such as a fast Fourier transform, may be used to transform the original domain data from a first domain, such as a time or spatial domain, into the frequency domain. The dispersion is then characterized using the transformed set of original domain data. One or more frequency domain spectra may be generated from the transformed set of original domain data, which frequency domain spectra express a parameter relating to the attribute of the dispersion as a function of frequency, in which case the characterizing step may be performed using the frequency domain spectra.

Owner:ALBERTA RES COUNCIL INC

Stimulant Sensitive Flocculation and Consolidation

InactiveUS20080190860A1Dehydration fastMixing methodsSedimentation separationFlocculationLiquid medium

The present invention relates to methods for the separation of materials from heterogeneous fluids and provides a means of effecting stimulant-sensitive flocculation and consolidation of solid suspensions within a liquid medium. Specifically, the present invention provides a method of controlling the state of a suspension of solid particles in a liquid, including applying to the suspension a stimulus adapted to control inter-particle forces between the solid particles. The stimulus is reversibly operable to control attraction and / or repulsion. Means of consolidating a sediment bed and of separating the resultant liquids-rich and solids-rich phases are also within the ambit of the invention.

Owner:NEWCASTE INNOVATION LTD

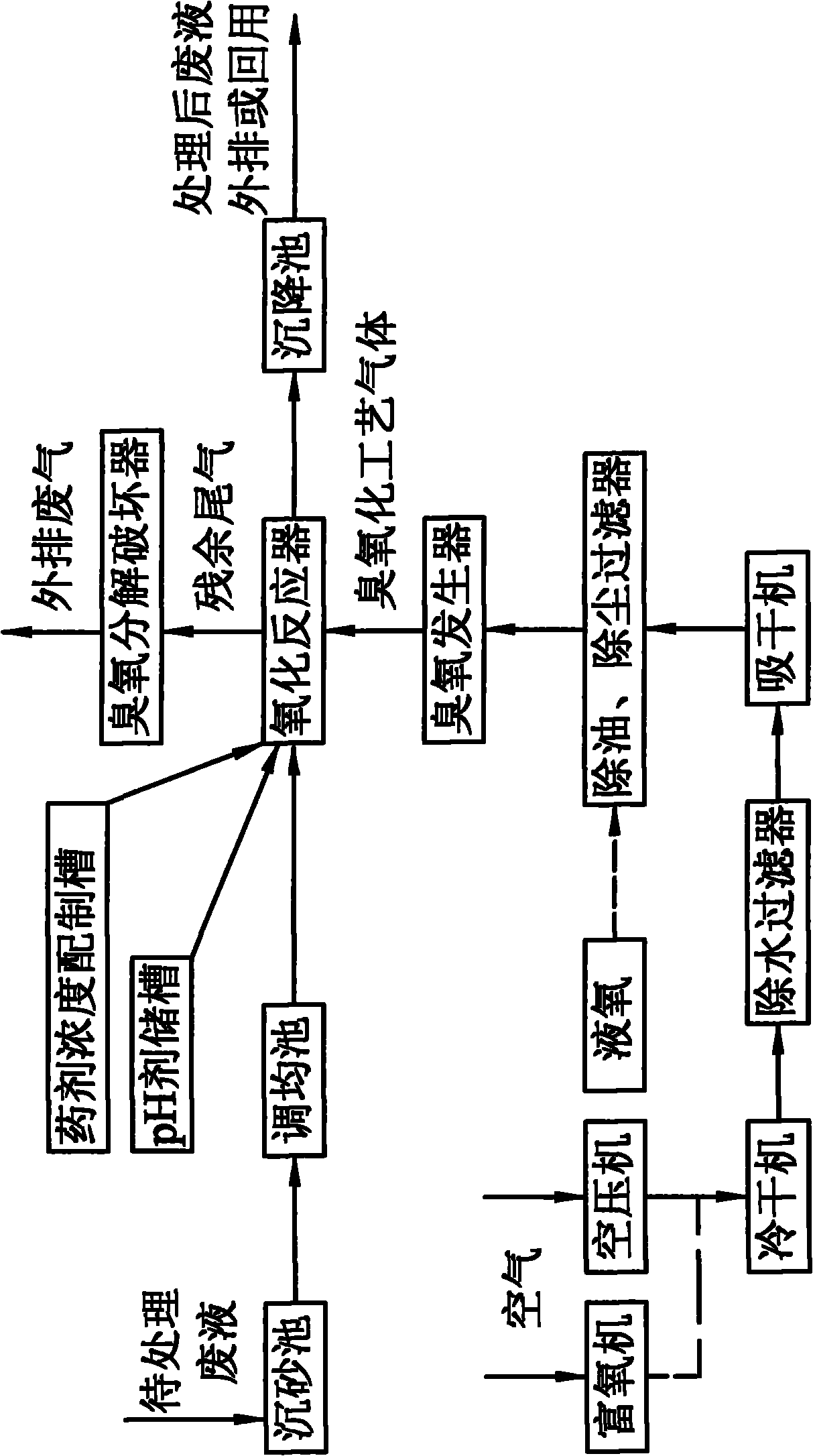

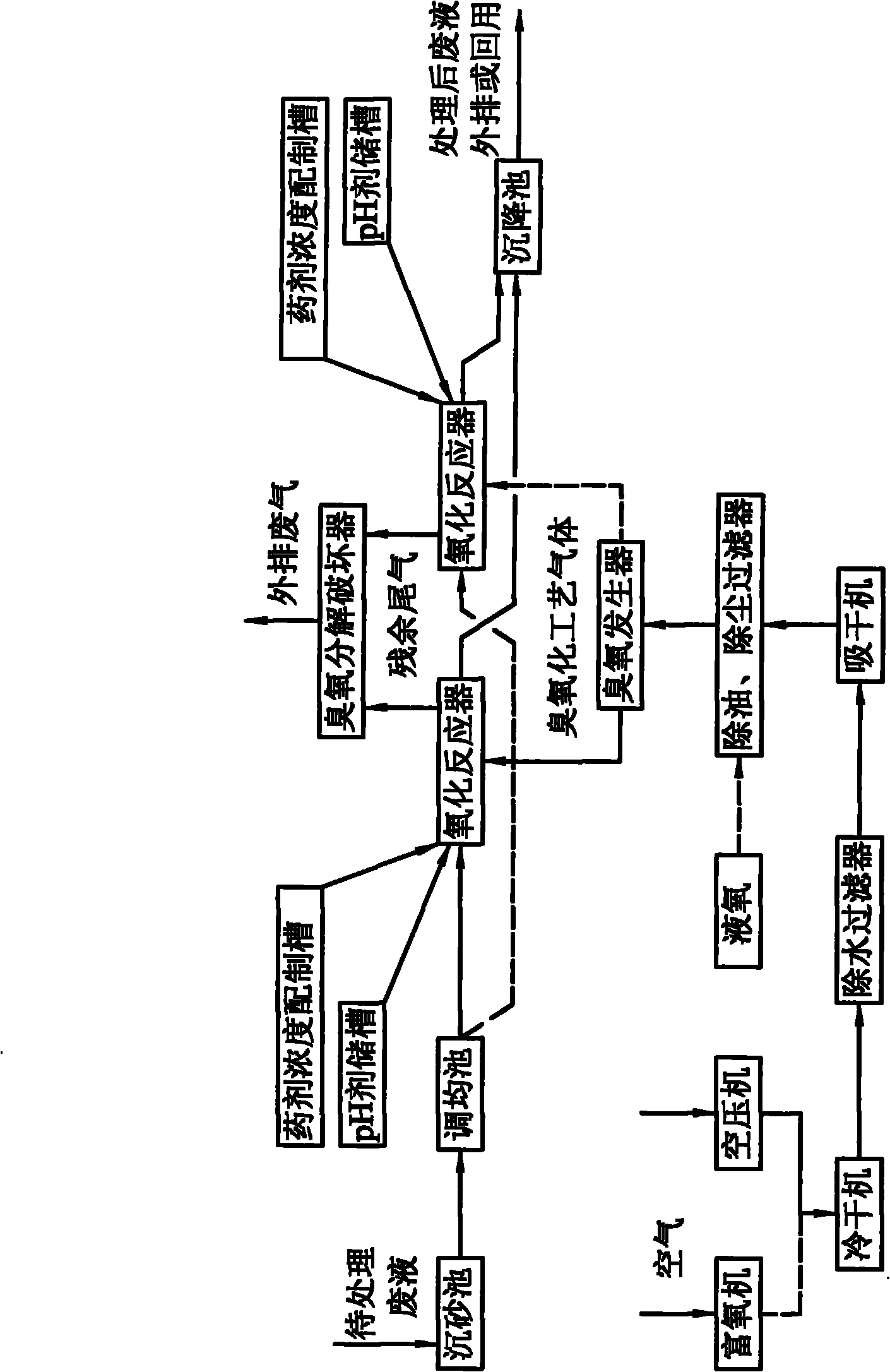

Method for removing cyanide, thiocyanate, COD and arsenic in waste liquid

ActiveCN102070264ALow costReduce complexityWater contaminantsMultistage water/sewage treatmentLiquid wasteThiocyanate

The invention discloses a method for removing cyanide, thiocyanate, COD and arsenic in waste liquid, comprising the following steps: the cyanide, the thiocyanate, the COD and the arsenic in the waste liquid are deeply treated by utilizing ozonized gas, a mode with continuous treatment and direct discharge can be adopted, also a mode with batch treatment and intermittent discharge can be adopted, and the implementation process of the method is easy to control; in the range of the pH value with sectioned control, the generation concentration and mass velocity of ozone do not need to be required strictly, the problem that single technology can not treat the cyanide, the thiocyanate, the COD and the arsenic in the waste liquid deeply can be solved, the cost and the operation complexity of technological equipment are reduced, and the environmental pollution is reduced; solid suspensions (SS) in the treated waste liquid is removed by settlement, and clear liquor is directly discharged outwards or returned to the upstream technology for repeated use; the contents of pollutants in the treated waste liquid are stable, the total content of the cyanide is less than 0.2mg / L(waste water); the content of the thiocyanate is less than 5mg / L(waste water); the total content of the COD is less than 30mg / L; the total content of the arsenic is less than 0.5mg / L(waste water), and no secondary pollutants are generated in the reaction process.

Owner:CHANGCHUN GOLD RES INST +1

Supercritical hydrocarbon conversion process

InactiveUS20070090021A1Thermal non-catalytic crackingCadmium sulfidesUnit operationReaction temperature

Supercritical conversion of hydrocarbons boiling above 538° C. (1000° F.) with a solvating hydrocarbon at a weight ratio of solvating hydrocarbon to high-boiling hydrocarbons of at least 2:1 and at conditions above the critical temperature and pressure of the high-boiling hydrocarbons-solvent mixture, in the presence of hot fluidized solids. The hydrocarbons are supplied to a reaction zone at a temperature below that of the hot solids supplied thereto, whereby the resulting hydrocarbons-solids suspension has a thermal equilibrium temperature corresponding to the reaction temperature. The conversion has high rates of sulfur, nitrogen and metals removal, nearly complete conversion to lower molecular weight products, high naphtha and distillate selectivity, and low coke formation. The supercritical conversion can replace crude distillation, vacuum distillation, solvent deasphalting, coking, hydrocracking, hydrotreating, and / or fluid catalytic cracking, and / or used in parallel with such unit operations for debottlenecking or increasing capacity.

Owner:MCCALL THOMAS F +4

Multifunctional composite type solid-liquid cyclone separator

InactiveCN1410167ARealize multiple functionsImprove removal efficiencyReversed direction vortexCycloneAcute angle

A multifunctional cyclone solid-liquid separator is composed of a casing consisting of spiral barrel and conic barrel, a tangential water inlet tube, a tangential water outlet tube, a bottom flow port, an overflow tube, and a cylindrical baffler consisting of arrangement of multiple guide plates with radical acute angles. Its advantages are multiple functions including guiding flow, isolating separation and cyclone separation, high removing effect to small particles, and low energy consumption.

Owner:TSINGHUA UNIV

Pharmaceutical composition and process

The present invention relates to a pharmaceutical composition comprising a solid suspension prepared by hot melt extrusion of isobutyric acid (2R,3S,4R,5R)-5-(4-amino-2-oxo-2H-pyrimidin-1-yl)-2-azido-3,4-bis-iso-butyryloxy-tetrahydro-furan-2-ylmethyl ester; hydrochloride salt (I) and a polyethylene glycol (PEG) / polypropylene glycol (PPG) block copolymer.

Owner:ROCHE PALO ALTO LLC

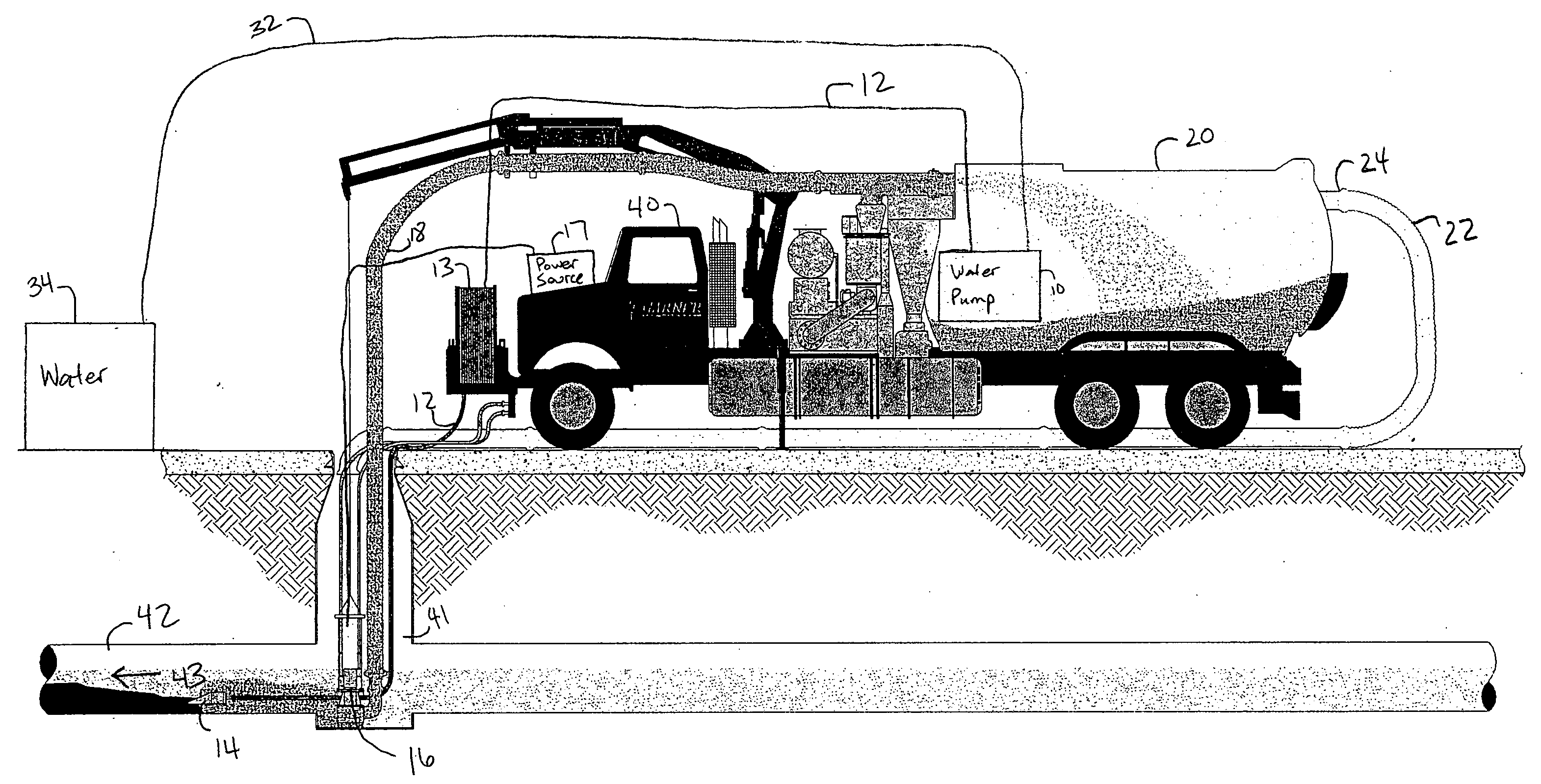

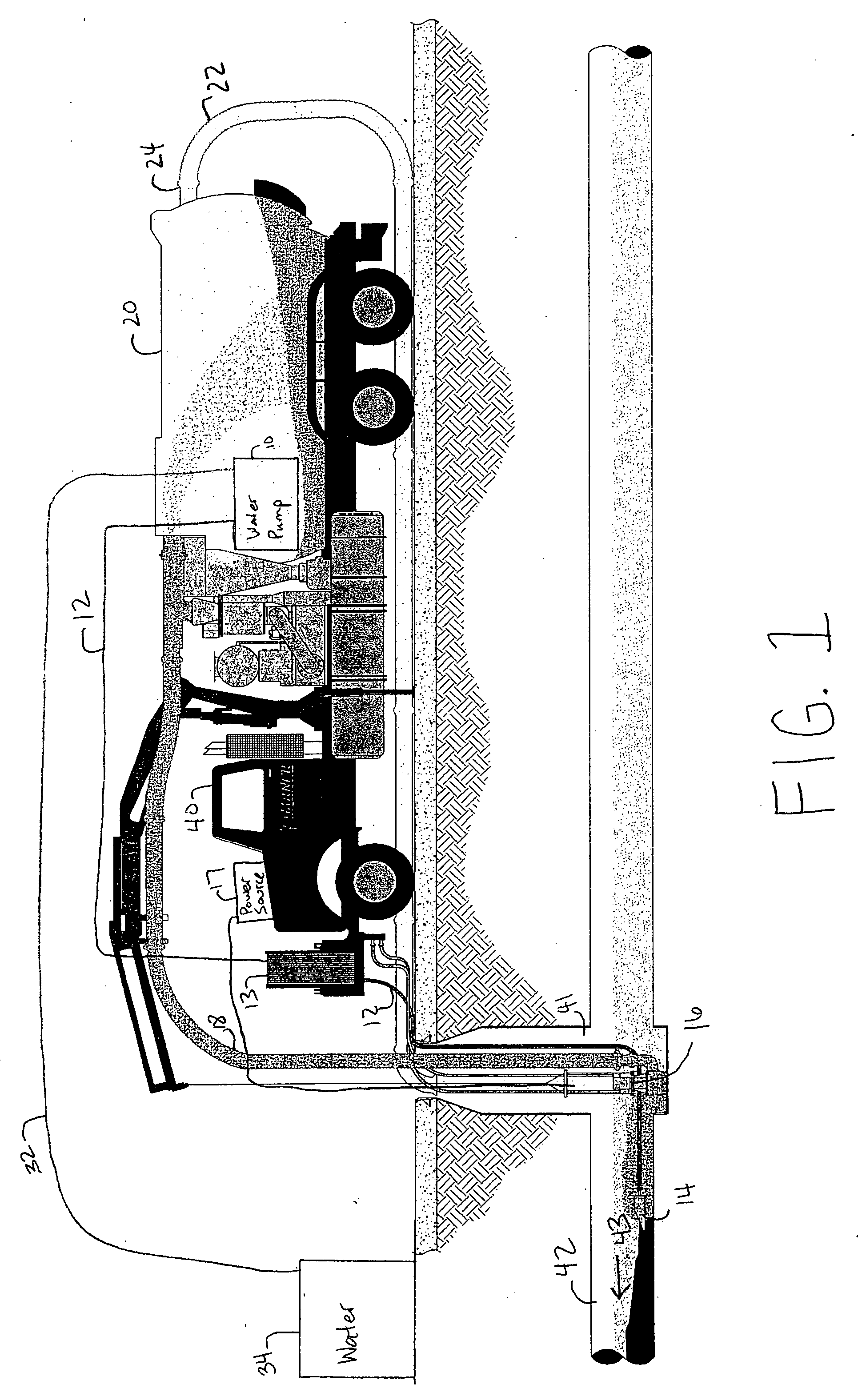

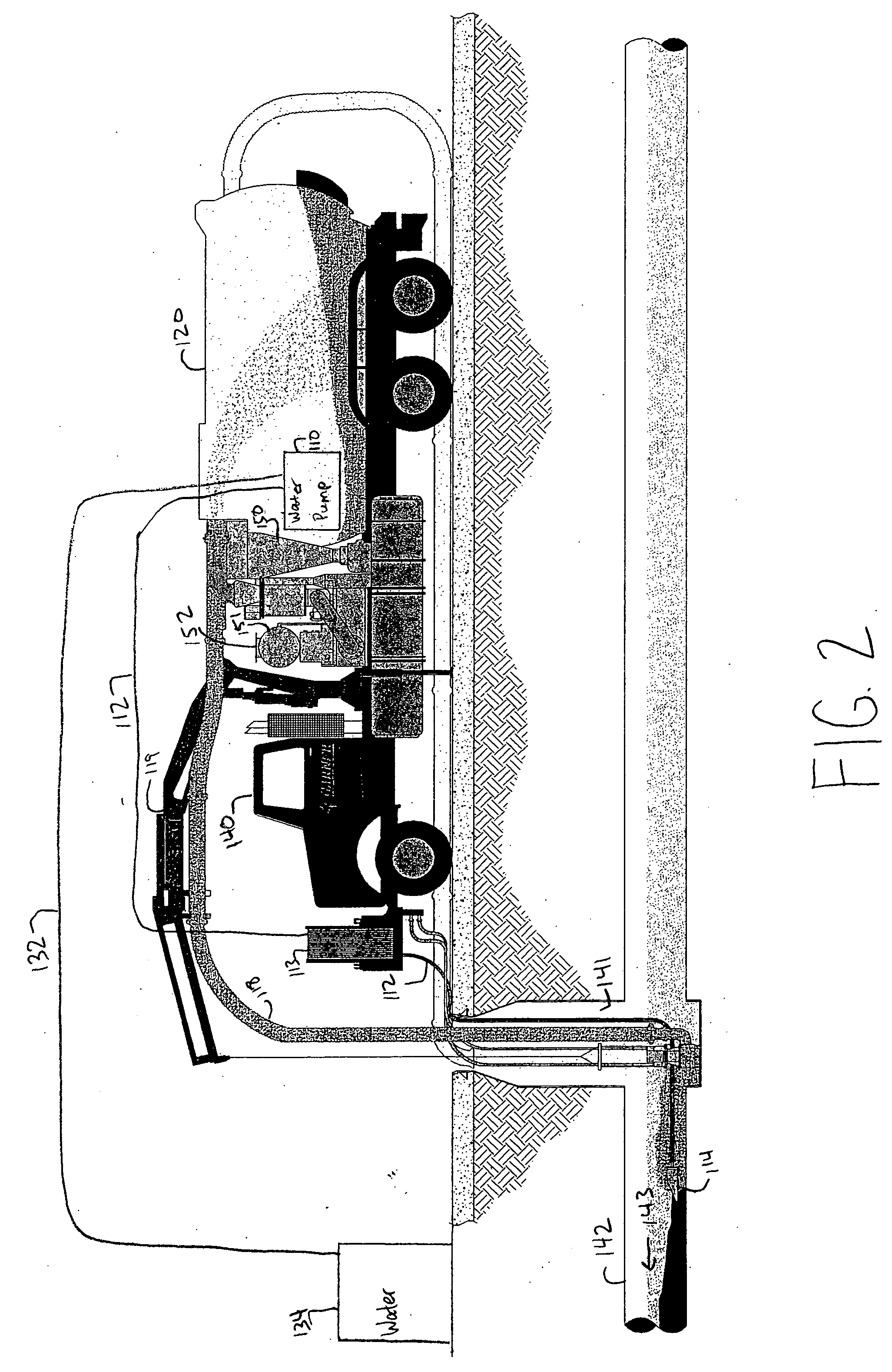

Apparatus for cleaning pipes having pumping and vacuuming capability

InactiveUS20060179603A1Improve efficiency and costEliminate needSewer cleaningSuction cleanersSlurrySolid particle

An apparatus for cleaning waste collection systems of solid materials. The apparatus is capable of cleaning waste systems in two known ways. First, a pumping method uses normal and injected water flow to suspend the solids in a slurry. A submersible pump moves the slurry from a collection point up to a pressurized container where the water content of the slurry is decanted and reused as injection water while the particulate material settles to the bottom of the pressurized container. Second, a vacuum system may be used to move the slurry from the waste system to the waste container. The vacuum system creates a negative pressure differential, causing material to be pulled through a vacuum tube and into the waste container. When the container becomes substantially full of solid particles, it may be emptied at a dumpsite.

Owner:U S SUBMERGENT TECH LLC

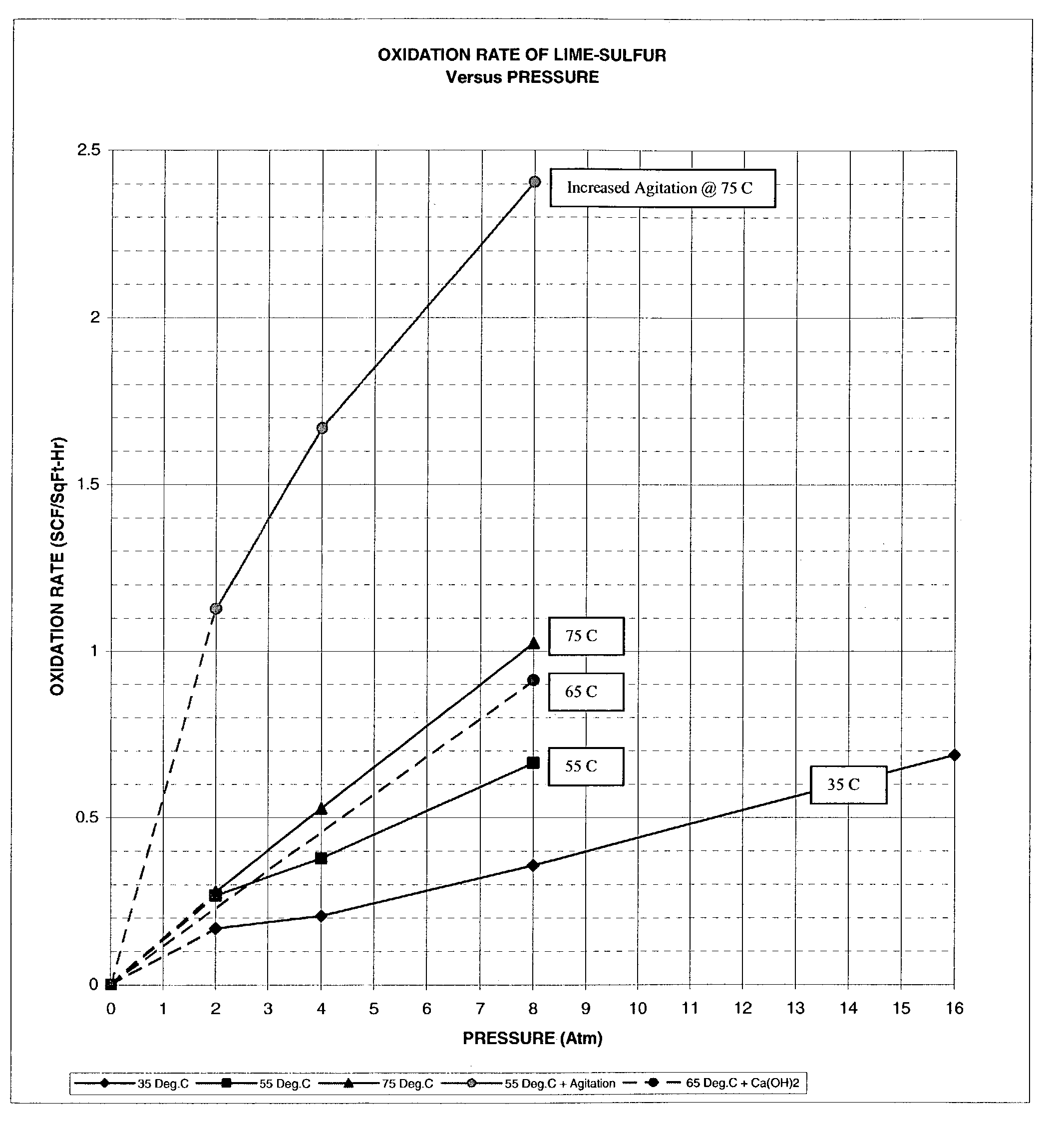

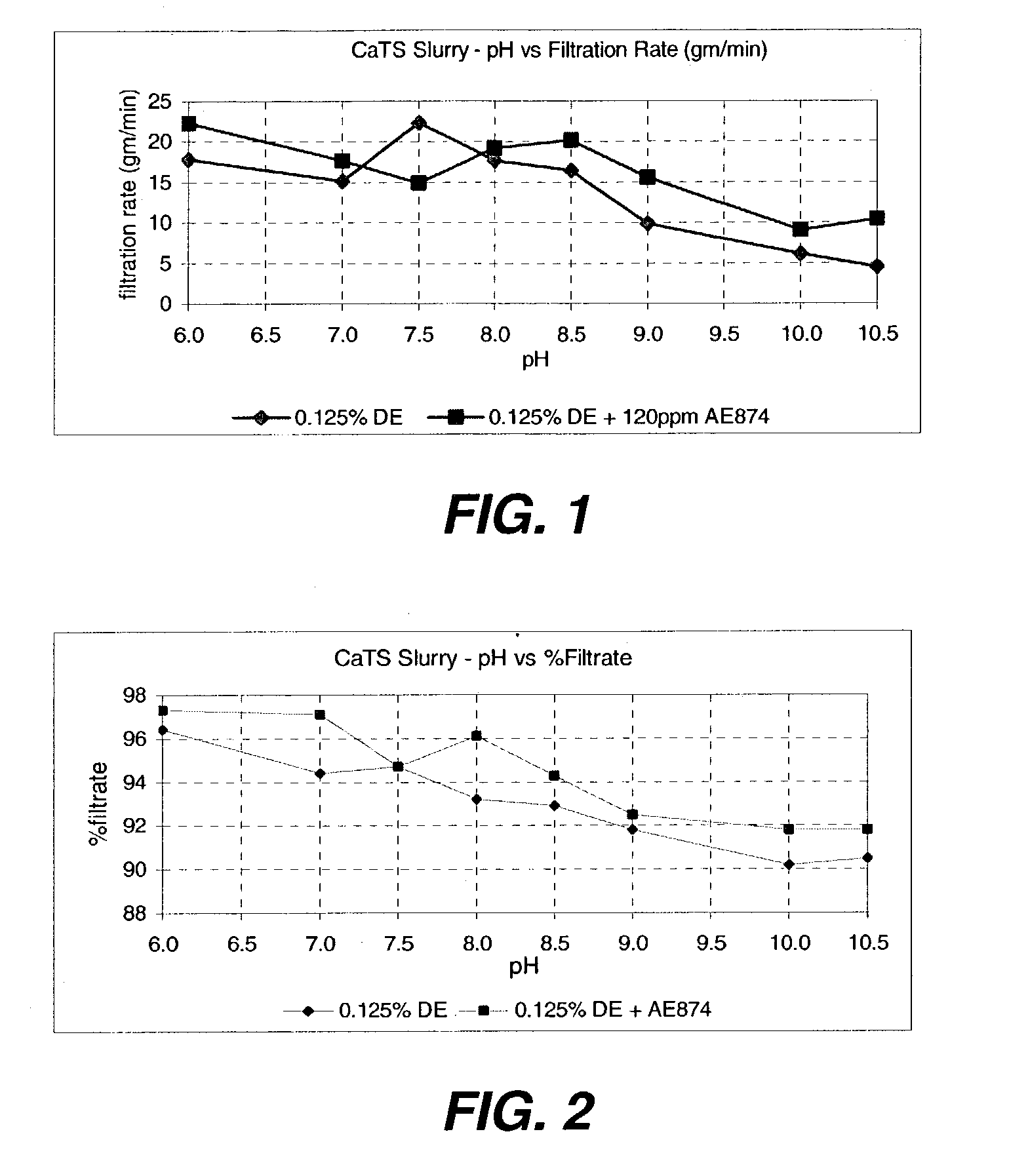

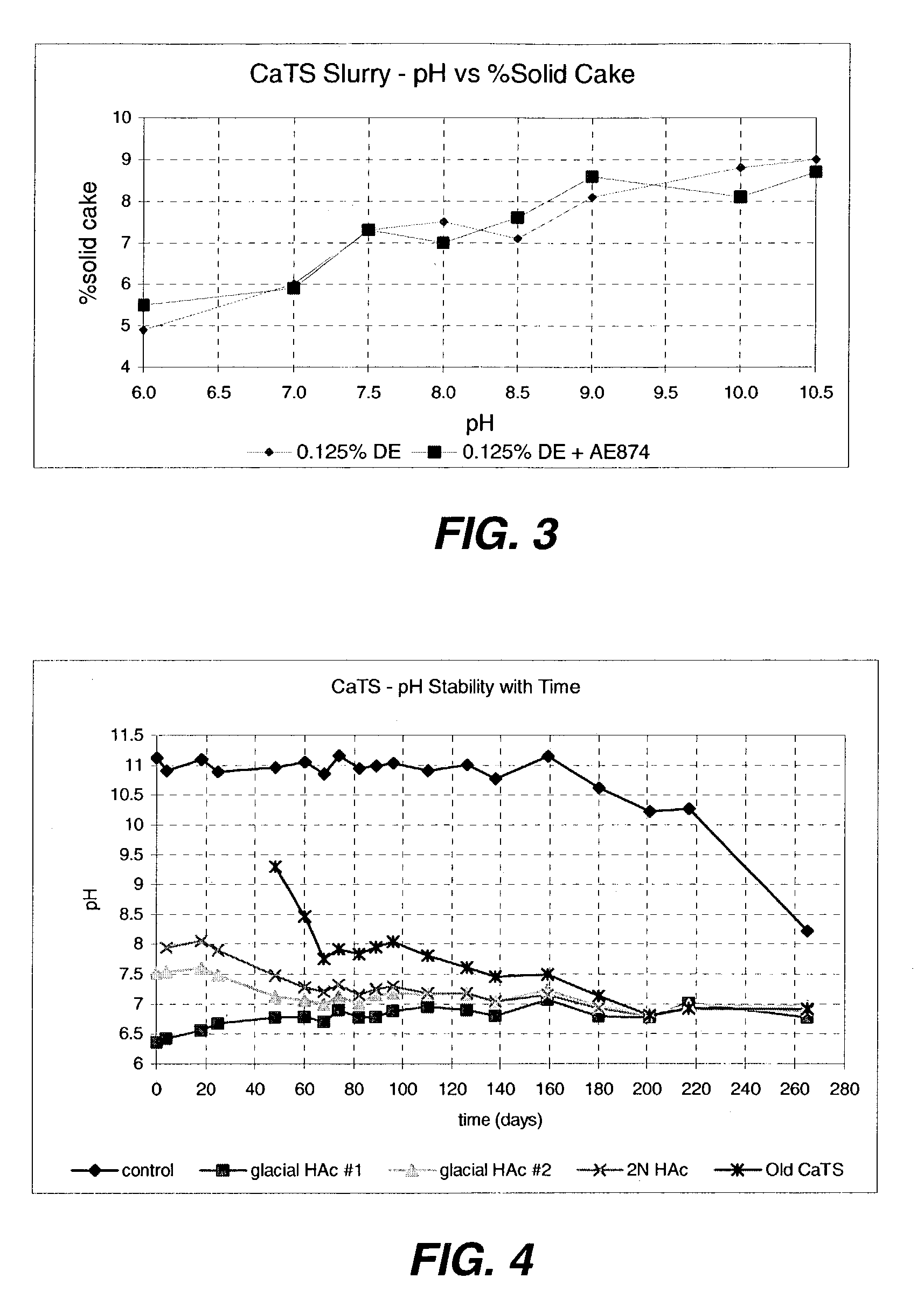

Process for preparing calcium thiosulfate solution

InactiveUS6984368B2Thiosulfates/dithionites/polythionitesMagnesium/calcium/strontium/barium sulfides/polysulfidesParticulatesSulfur

An efficient process to produce calcium thiosulfate (CaS2O3) from lime, sulfur and oxygen is described. By selecting appropriate process conditions such as mole ratios of lime to sulfur, temperature and pressure of the reaction process and the oxidation conditions, including rate and duration, the concentration of byproducts in the resulting suspension can be reduced to about 2% by weight or less. The solid particulate dispersion in the suspension tends to form a slimy solid suspension that is hard to filter if not treated properly. The suspension then can be acidified and treated with a flocculent. This agglomerates the solids into a floc that filters with ease. The resulting calcium thiosulfate is a clear liquid with concentrations achievable up to 29%.

Owner:TESSENDERLO KERLEY INC

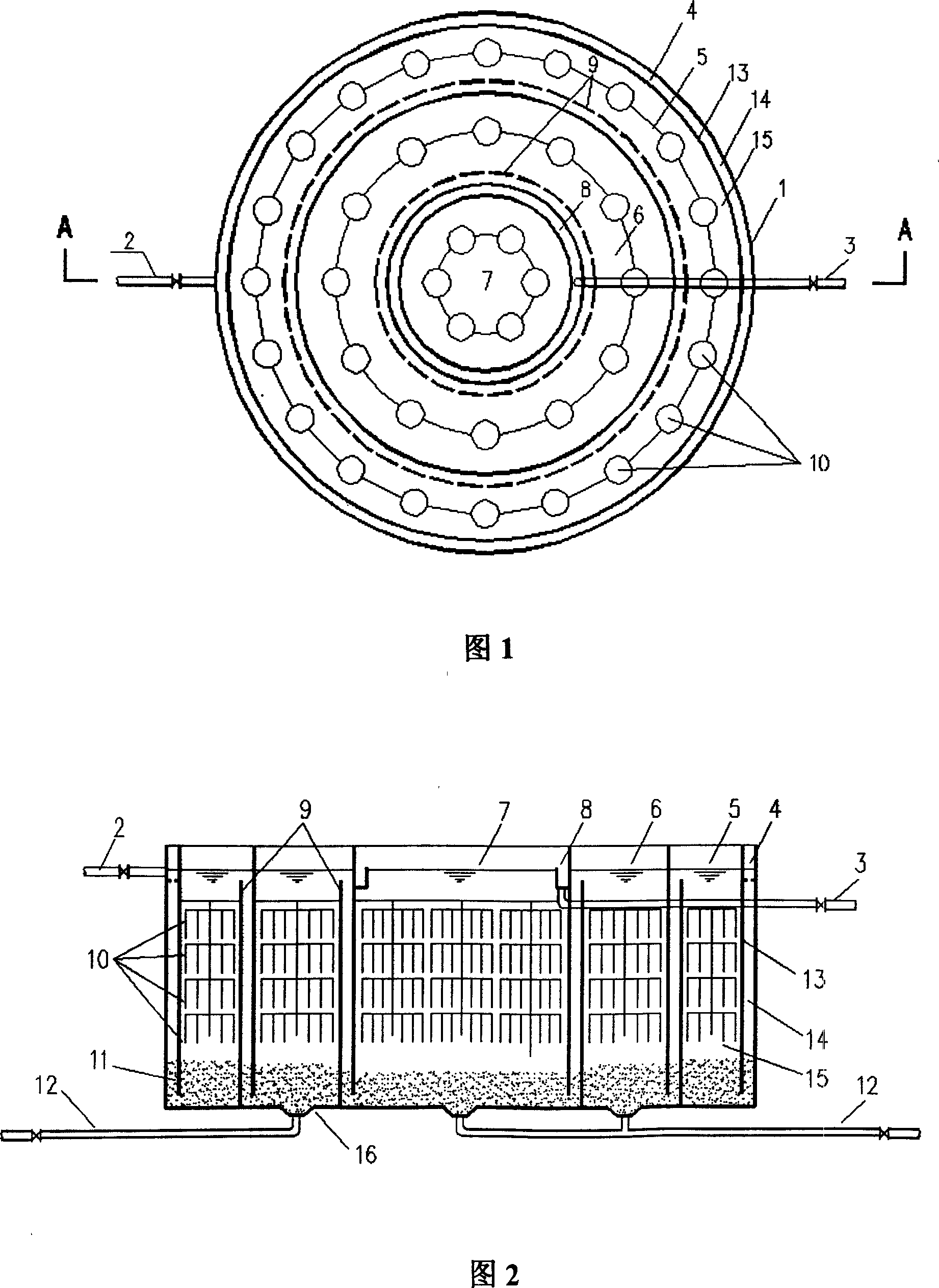

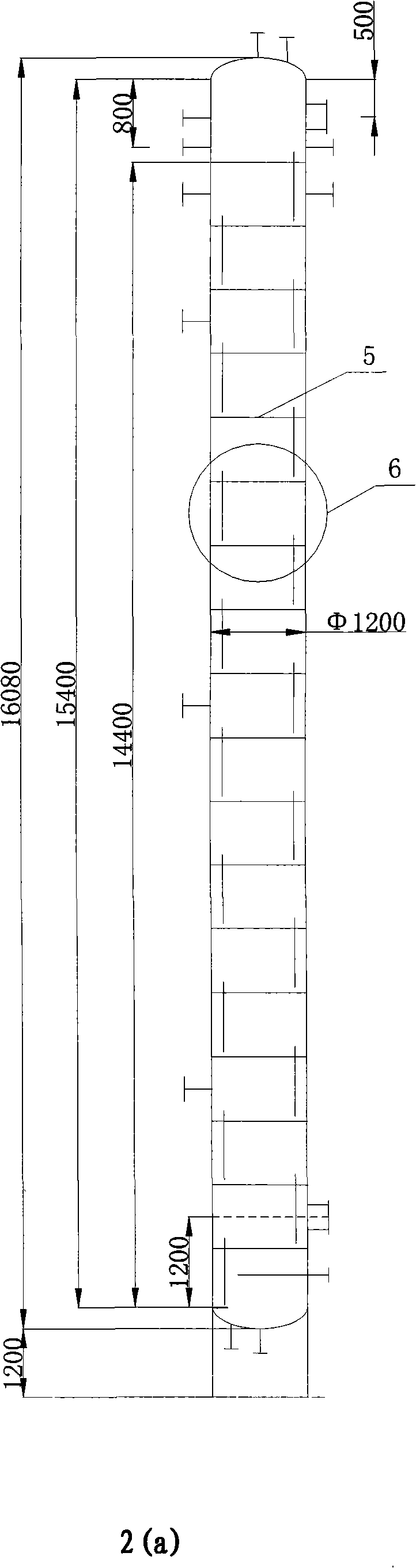

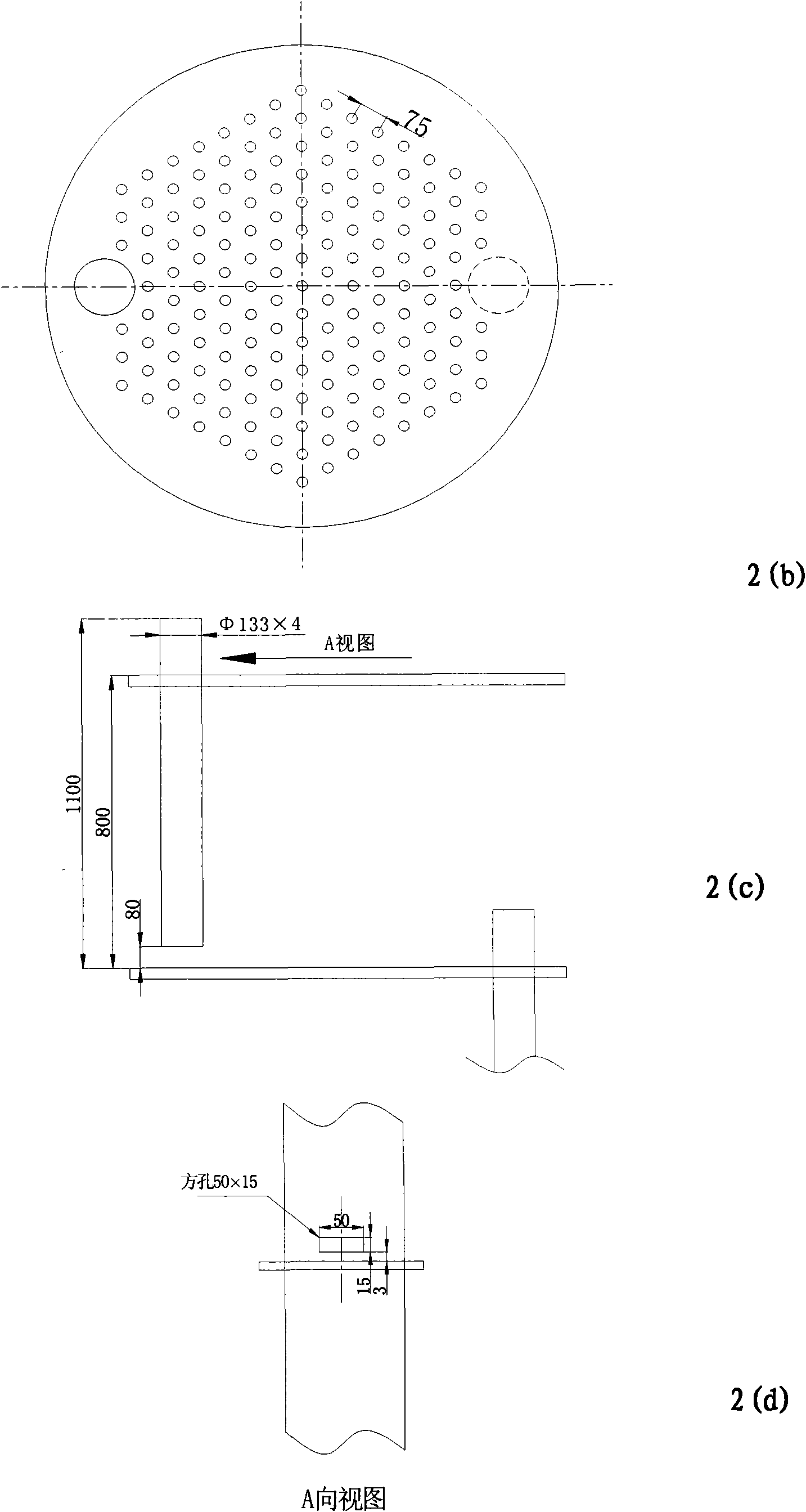

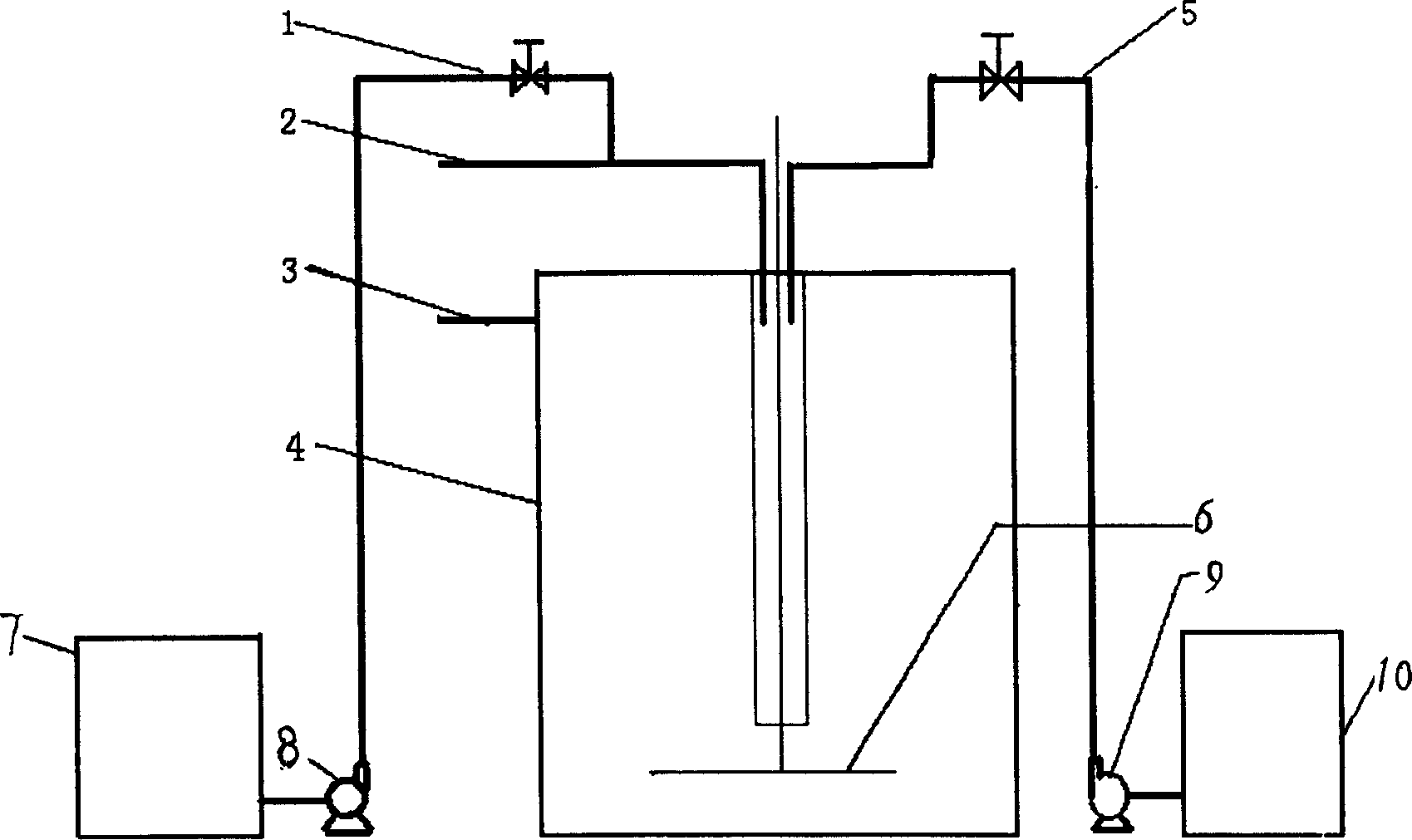

Peripherally-distributed water deflection composite reactor for hydrolysis and acidification

InactiveCN1962480AEasy to handleImprove impact resistanceSustainable biological treatmentBiological water/sewage treatmentDraining tubeSludge

The invention discloses a baffling composite hydrolytic acidifying reactor to request to protect peripherial water, which comprises the following parts: pond, fill, inlet pipe and outlet pipe, wherein the pond is composed of three-grade concentric circle with inlet pipe connecting outer-race distribution groove; the distribution groove is set along circumference with water hole on the groove bottom evenly to supply water; the water passes the distribution hole on the commutating board bottom, which is baffled into outer-race, inner-race and middle reacting regions; the reacting region bottom is floating sludge bed with middle region as half flexible fill region, which intercepts most of solid suspension and colloidal matter in the effluent; the solid organics is decomposed into soluble organics and decomposed further; the vent pipe is laid on the outlet groove bottom of middle reacting region, which contains outlet water.

Owner:CHONGQING UNIV

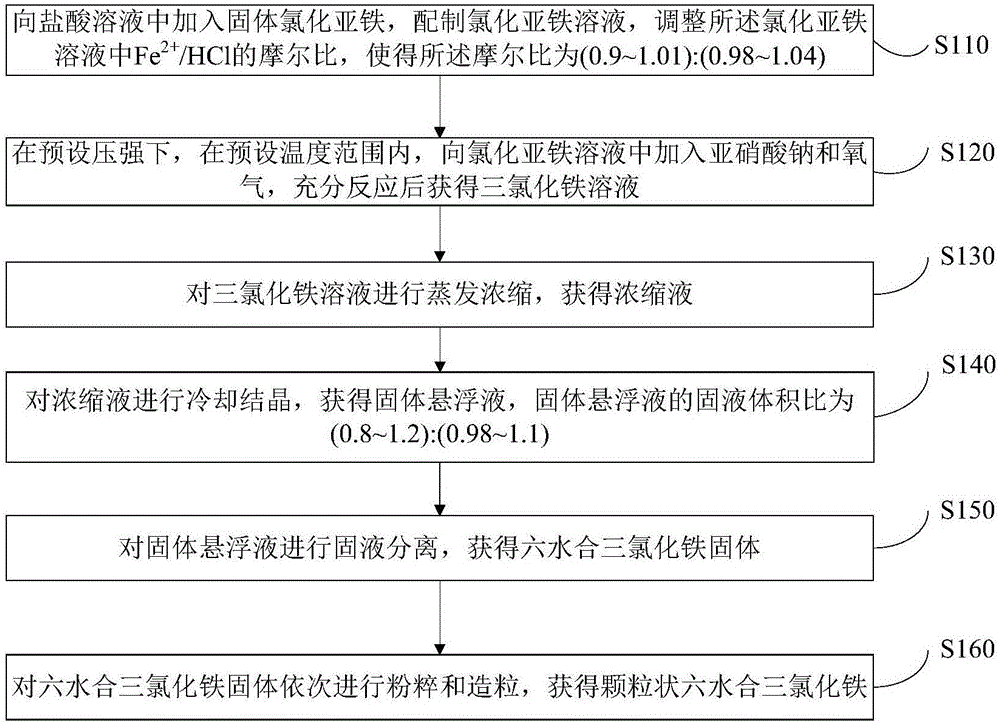

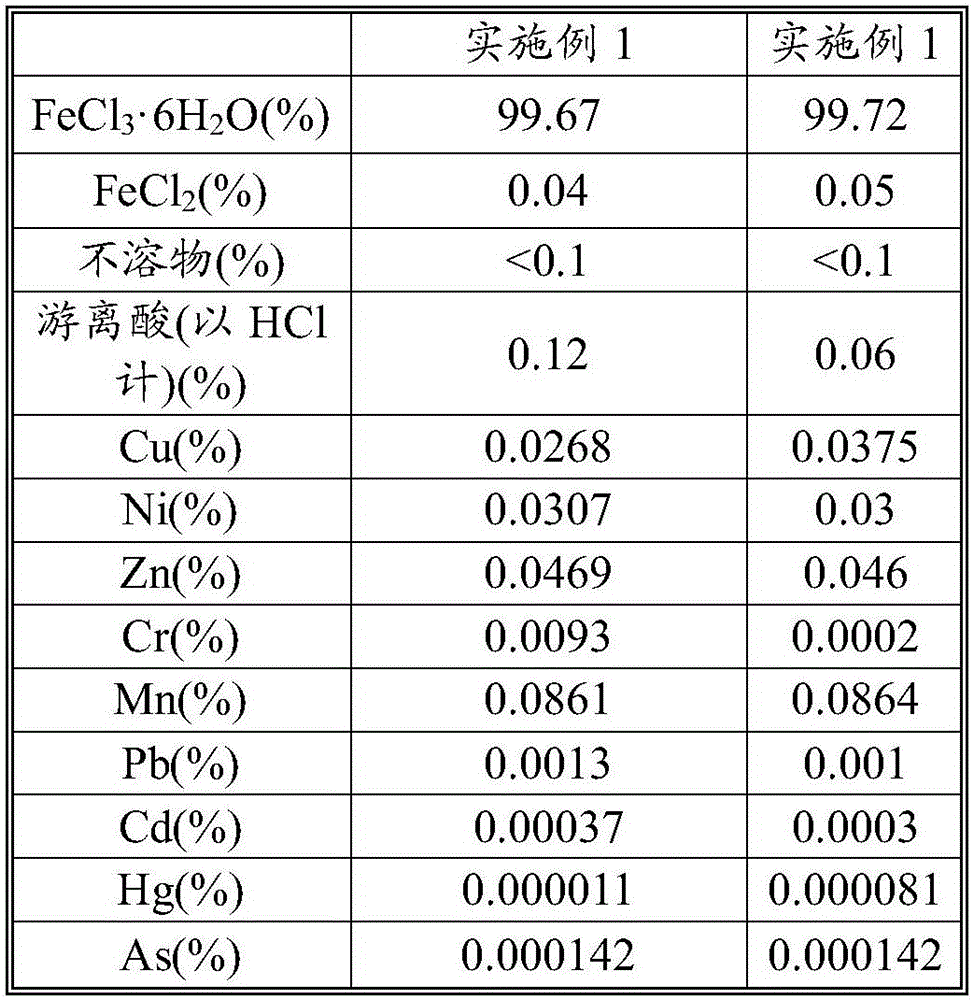

Production method for granular ferric trichloride hexahydrate

The invention relates to a production method for granular ferric trichloride hexahydrate. The production method for the granular ferric trichloride hexahydrat includes the steps that solid ferrous chloride is directly added into a hydrochloric acid solution, a ferric trichloride solution is obtained through an oxidation reaction, and is evaporated and concentrated, cooling crystallization is carried out, and solid suspension liquid with the solid-liquid volume ratio of (0.8-1.2):(0.98-1.1) is obtained; then the solid suspension liquid is subjected to solid-liquid separation, the obtained solid is subjected to crushing granulation, and the high-purity granular ferric trichloride hexahydrate which is not prone to deliquescence is obtained. In addition, according to the production method for the granular ferric trichloride hexahydrate, a traditional chloro-alkali industry production line and cold storage facilities do not need to be matched, artificial putting molding and artificial demolding are not required, and the production method is simple.

Owner:TANGSHAN 3R CHEM CO LTD

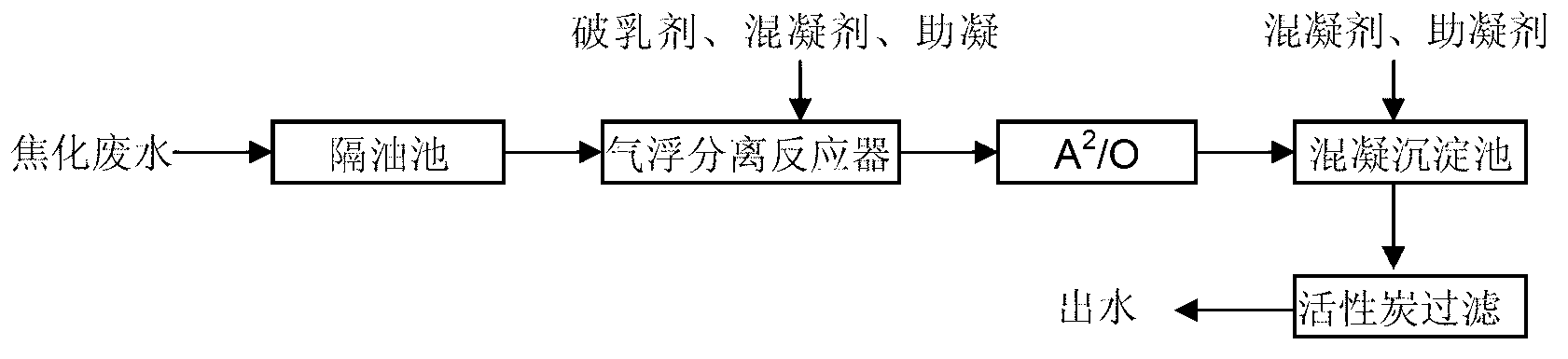

Treatment method for improving removal rate of benzo (a) pyrene in coking wastewater

InactiveCN103304095AImprove removal efficiencyMeet disposal discharge requirementsWater contaminantsMultistage water/sewage treatmentActivated carbon filtrationTurbidity

The invention relates to a treatment method for improving removal rate of benzo (a) pyrene in coking wastewater. The method is characterized by comprising the following steps of: (1) conveying the coking wastewater into an oil separation tank, and removing suspension oil in water; (2) conveying the wastewater from the oil separation tank into an air floatation reactor, adding a coagulant, a coagulant aid and a demulsifier into the air floatation separation reactor; (3) conveying the effluent of the air floatation separation reactor into an A2 / O biological treatment process; (4) conveying the effluent of the biological treatment process into a coagulation sedimentation basin, adding the coagulant and the coagulant aid into the coagulation sedimentation basin; (5) conveying the effluent of the coagulation sedimentation basin into an active carbon filtering basin. The method has the advantages that the air floatation and turbidity removal procedures are strengthened based on the distribution characteristics of the benzo (a) pyrene which mostly forms solid suspension or is dissolved in oil, removal of benzo (a) pyrene in coking wastewater is efficient, and the increasingly stringent wastewater treatment and discharge requirements are met.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Fermentation and infiltration vaporization coupling technique for producing ethanol

The invention belongs to a separation technique of fermentation and pervaporation coupling to produce alcohol, which is characterized in that the separating technique comprises separating solid suspension mater and liquid part in a fermentation tank, transporting liquid part to a pervaporation steaming film separator through a pump, and lowering clogging at the bottom of the fermentation tank through the circulation of permeation residual liquid. The improved fermentation technique is more suitable for the connection of pervaporation technique, which increases the matching degree between fermentation and pervaporation coupling, and leads the integral production technique in downstream pervaporation technique to be more stable. The separation technique not only lowers the possibility of infecting bacteria through a new process flow, but also lowers film pollution in the process of downstream pervaporation separation, which lays an industrial foundation for the process of improving fermentation productivity and continuously fermenting. The distinctive characteristics of the method are that the method has low production cost and convenient employment, which has industrialized prospect.

Owner:NANJING UNIV OF TECH

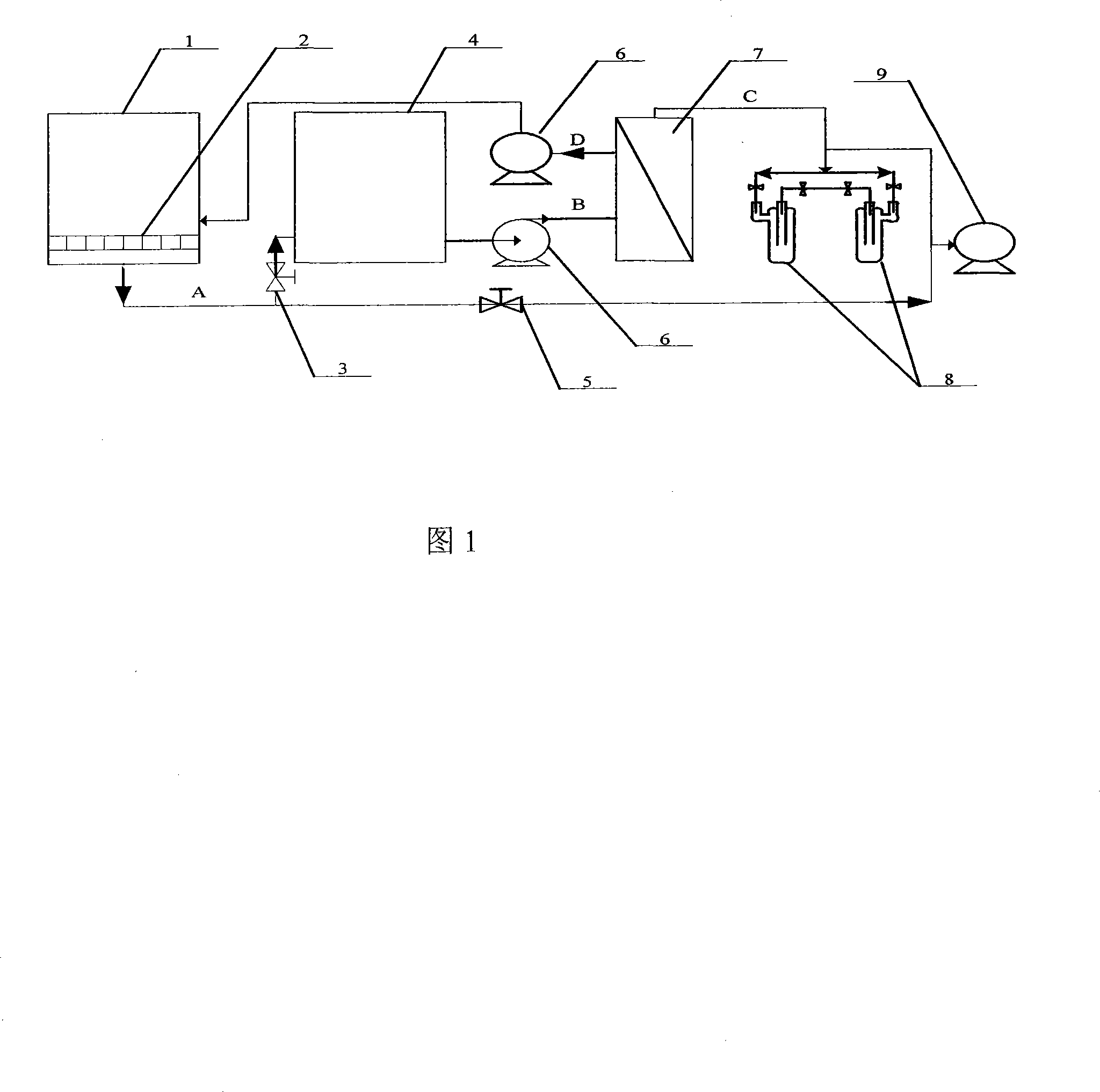

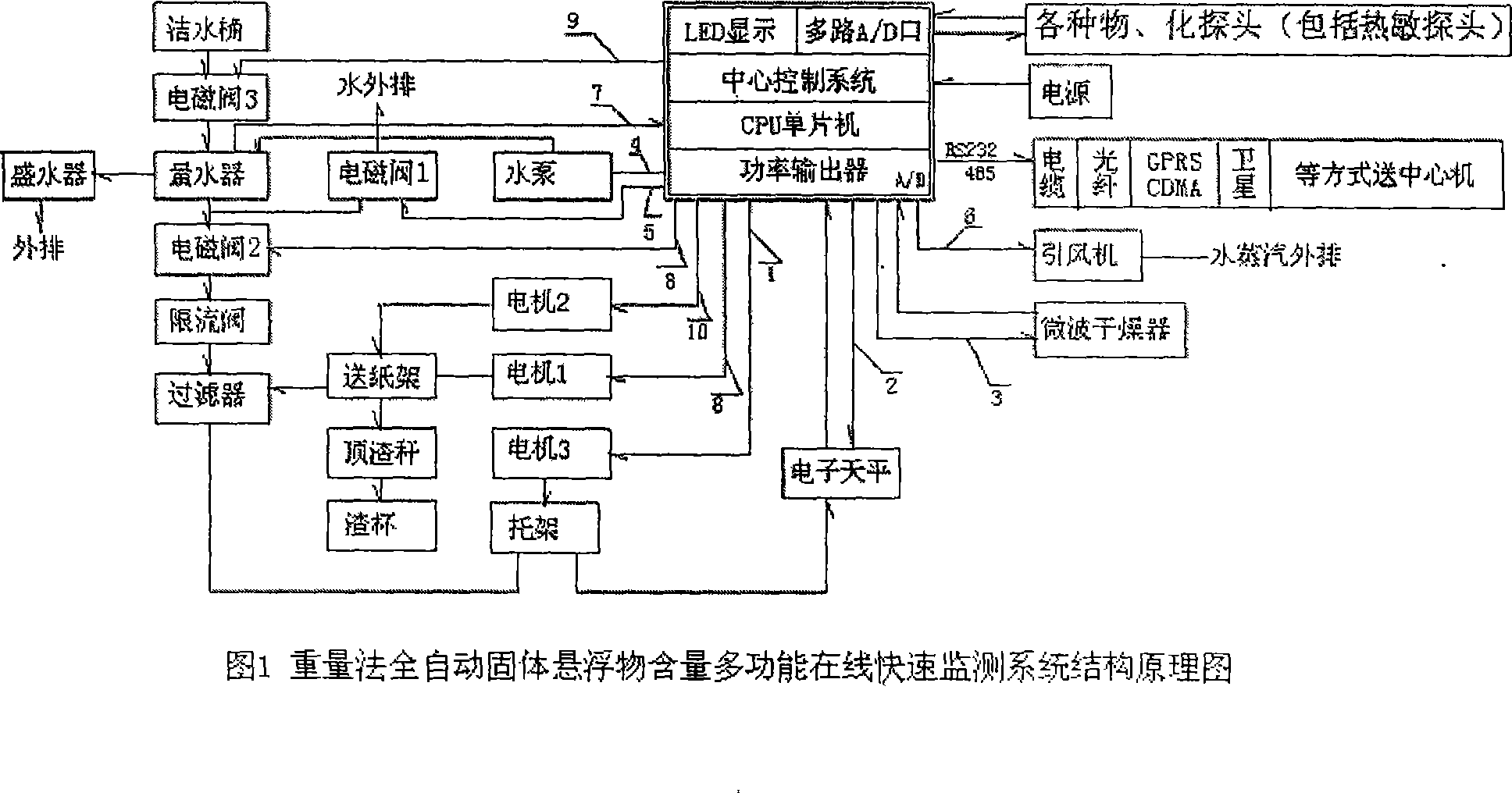

Full automatic solid suspension content multifunction on-line fast monitoring system by gravimetric method

The invention discloses a multi-functional full-automatic online monitoring device of suspended substance, which is based on gravimetric method, meets GB11901-89 norm and can complete measurement quickly. It is composed of automatic extracting system, automatic filter system, automatic washing system, automatic drying system, automatic weighing system, automatic central controlling system, data transmitting system and power system. It also can realize online measuring of other physical and chemical parameters. When need testing, central controlling system drives automatic extracting system to extract water sample which is used to clean pipes and water measuring bottle. After filling, the water measuring bottle is sent to automatic filter system for filtering. Clear filter residue and start automatic drying system to dry it, then, utilize automatic weighing system to weight. All data is calculated and saved by central controlling system and finally is transmitted to manage center by data transmitting system.

Owner:杨杰

Method for using sea water or salt water to oil field water injection and collecting process

InactiveCN101148984ASimple and fast operationReduce energy consumptionFluid removalParticulatesTurbidity

The process of utilizing sea water or bittern for oil field water flooding and compounding polymer solution includes the following steps: the first separating in the hydraulic cyclonic separator to eliminate suspended solid particle, the subsequent ultrafiltering with ultrafiltering membrane to eliminate colloid and residual oil and lower turbidity, and final nanometer filtering or filtering in reverse osmosis membrane to lower the mineralization degree and organic matter content, eliminate trace amount of oil and obtain water product. The water output from the cyclonic and membrane separating system is applied in oil reservoir displacement. The present invention applies integrated cyclonic and membrane separating technology in providing water for oil reservoir displacement, and has the advantages of small floor space, low power consumption, high efficiency and broad application foreground.

Owner:OCEAN UNIV OF CHINA

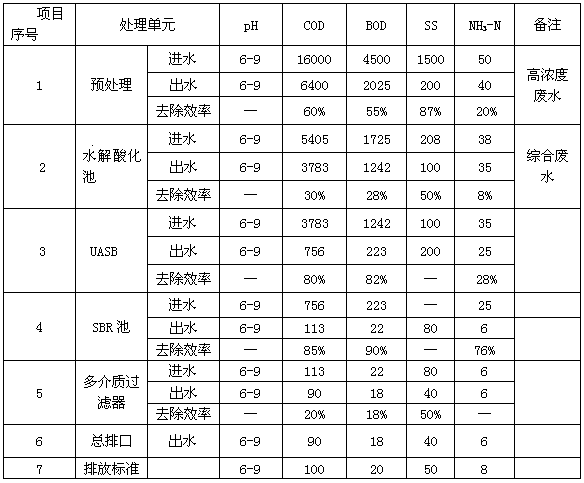

Chinese patent medicine production wastewater treatment technology

InactiveCN103739142AReduce chemical oxygen demand CODReduce biochemical requirement BODSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentMedicineAmmonia nitrogen

The invention discloses a Chinese patent medicine production wastewater treatment technology, and belongs to the technical field of wastewater treatment. The technology comprises the steps of (1) pretreatment, (2) coagulation precipitation treatment, (3) anaerobic treatment, (4) aerobic treatment, (5) filtering treatment, and (6) sludge treatment. Chinese patent medicine wastewater undergoes pretreatment, coagulation precipitation, anaerobic treatment, aerobic treatment and the like, so the chemical oxygen demand (COD), the biochemical oxygen demand (BOD), the concentration of solid suspension (SS) and the content of ammonia nitrogen (NH3-N) in the wastewater are greatly reduced, and the influences on the environment are reduced.

Owner:ANHUI GREEN TITAN ENVIRONMENTAL TECH

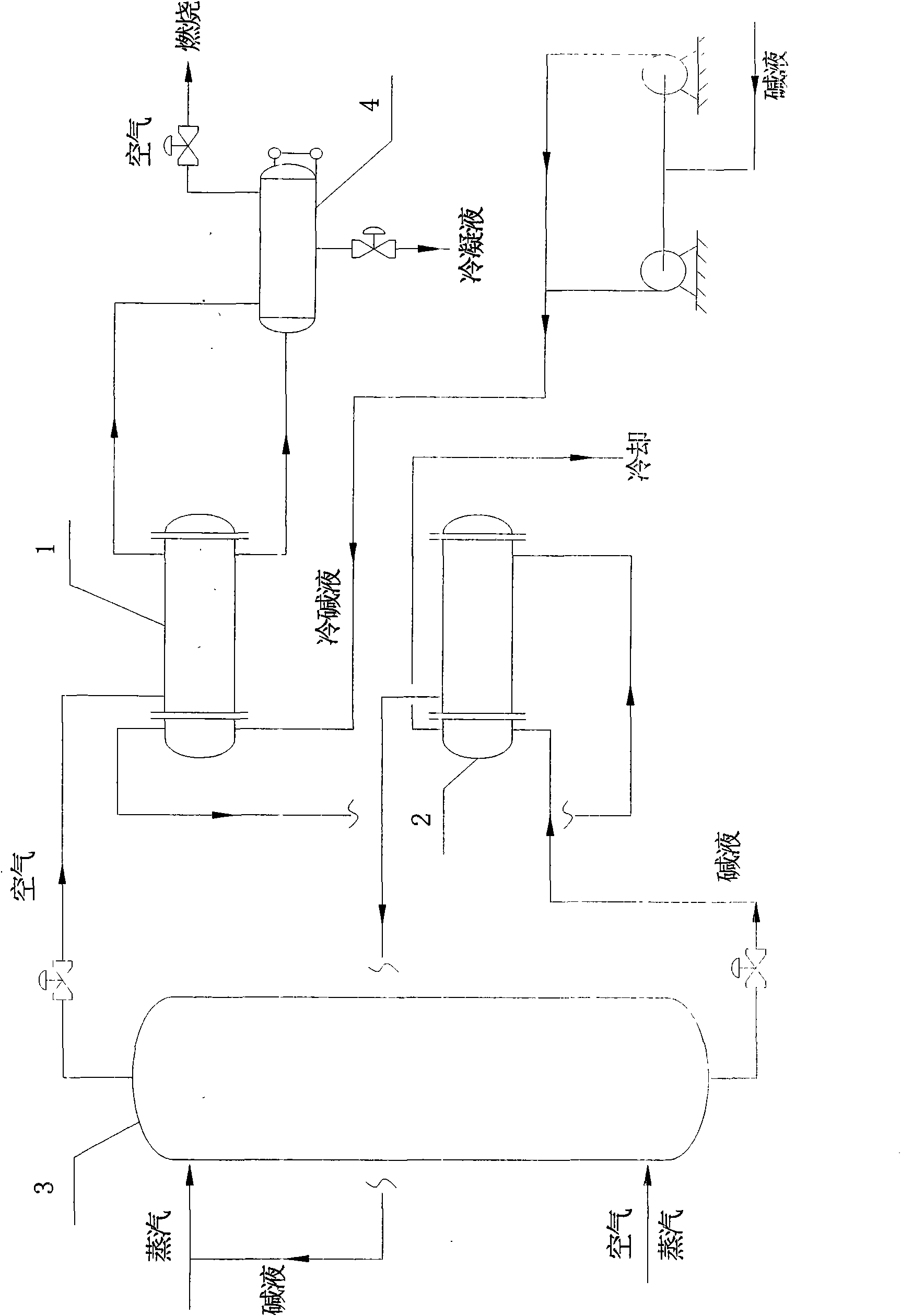

Process for advanced treatment of waste alkali in hydrogen sulfide removal

InactiveCN101579603AEliminate tower blockageIncrease oxidation rateDispersed particle separationIncinerator apparatusChemical industryCatalytic hydrogenation

The invention relates to a process for advanced treatment of waste alkali in hydrogen sulfide removal, belonging to the field of environmental protection in chemical industry. The process provided by the invention improves the effect of the oxidation reaction, improves the air lifting effect of the heavy hydrocarbons in the alkali and removes the stoppage phenomenon of the sieve shaped oxidation reactor. The process uses the deep liquid level reactor composed of a sieve plate and a down comer to oxidize the waste alkali of hydrogen sulfide removals, improves the gas-liquid mass transfer and reaction driving force through the reversed contacting of the gas-liquid, and obviously improves the oxidation effect of the alkali and the air lifting effect of the volatile organic materials; for waste alkali in hydrogen sulfide removal that the COD is 30,000 to 50,000 ppm, the deprivation rate is more than 98%. The specially designed down comer removes the collection of the solid suspension at the tray and overcomes the congestion phenomenon during the process. The process is suitable for advanced innocent treatment of waste alkali of pyrolysis gas in refinery, catalytic hydrogenation desulfurization tail gas and various sulfureted hydrogen containing tail gases after NaOH or Na2CO3 solution absorbes.

Owner:BEIJING UNIV OF CHEM TECH

Stimulant sensitive flocculation and consolidation

InactiveUS20120160776A1Dehydration fastWater/sewage treatment by irradiationWater treatment compoundsFlocculationLiquid medium

The present invention relates to methods for the separation of materials from heterogeneous fluids and provides a means of effecting stimulant-sensitive flocculation and consolidation of solid suspensions within a liquid medium. Specifically, the present invention provides a method of controlling the state of a suspension of solid particles in a liquid, including applying to the suspension a stimulus adapted to control inter-particle forces between the solid particles. The stimulus is reversibly operable to control attraction and / or repulsion. Means of consolidating a sediment bed and of separating the resultant liquids-rich and solids-rich phases are also within the ambit of the invention.

Owner:NEWCASTE INNOVATION LTD

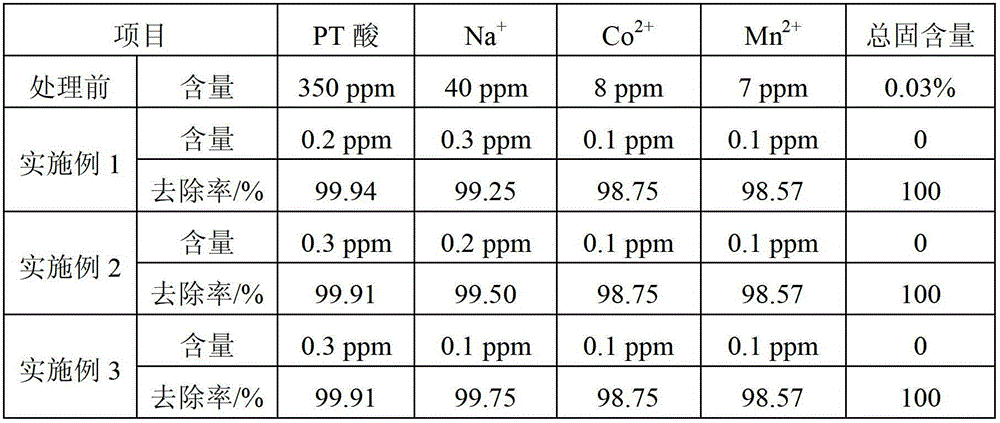

Combined process for treatment of PTA (pure terephthalic acid) refined waste water

InactiveCN102874955AEmission reductionSolve easy blockageMultistage water/sewage treatmentNature of treatment waterFiltration membraneIon exchange

A combined process for treatment of PTA (pure terephthalic acid) refined waste water comprises the following steps: firstly, aromatic acid in the PAT refined waste water is extracted in an extraction column by using para-xylene into an extract phase, and the extract phase is conveyed to an oxidation unit to serve as a reaction raw material; a raffinate phase is conveyed to a micro-filtration membrane separation device, so that solid suspension particles in the raffinate phase are removed; and a penetrating fluid enters a resin adsorption device and an ion exchange device, so that residual aromatic acid and metal ions in the penetrating fluid are removed, and treated water meets the water standard of a PAT refining unit. According to the method, the water and the aromatic acid therein are recycled, so as to reduce the unit consumption of products and water consumption, and bring remarkable economic benefits.

Owner:NANJING UNIV OF TECH

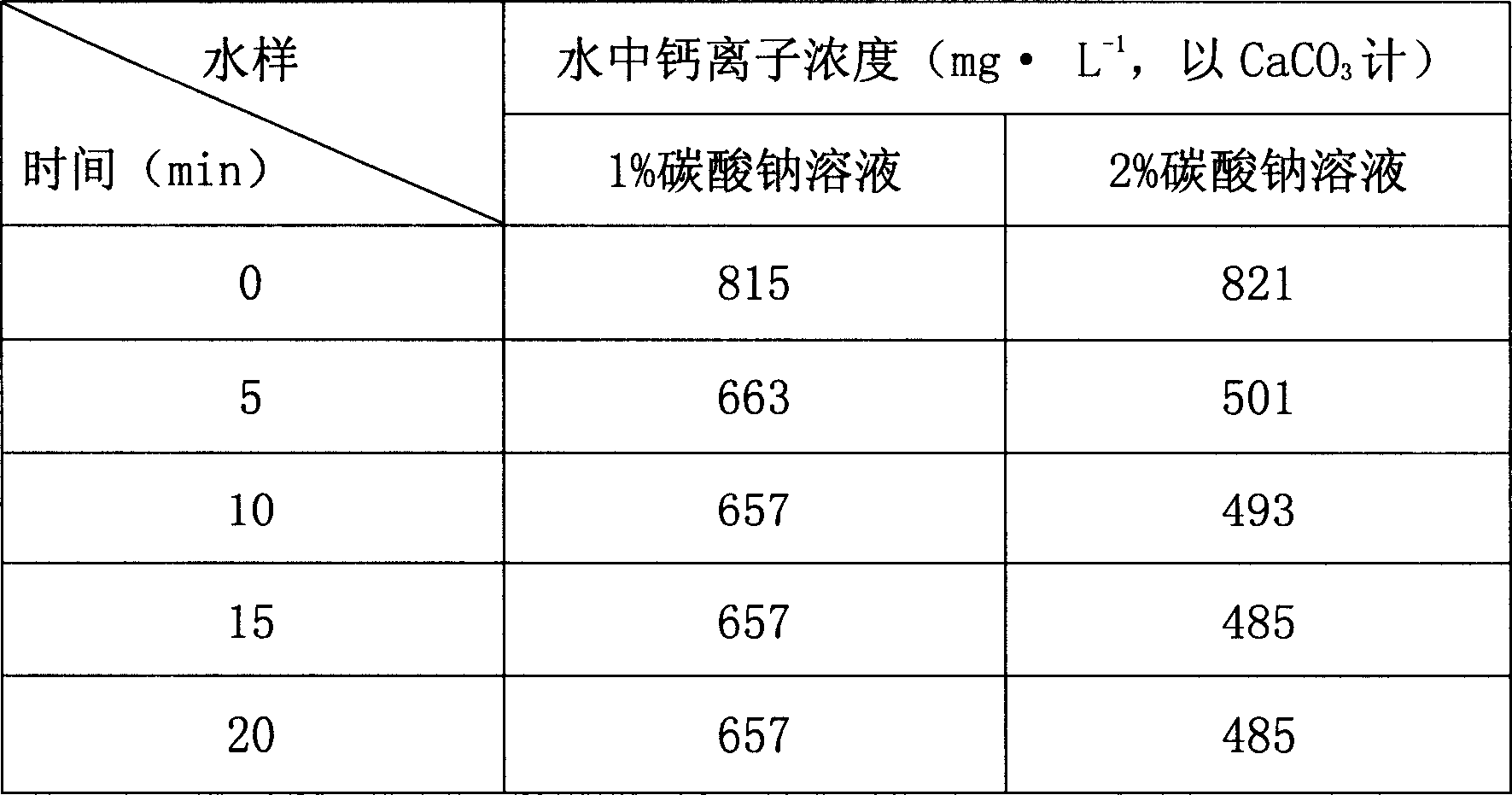

Softening and coagulating treatment process of gas scrubbing water

InactiveCN1526662AReduce hardnessReduce calcium hardnessWater softeningWater/sewage treatment by flocculation/precipitationSolid matterCalcium carbonate crystals

The softening and coagulating treatment process of gas scrubbing water with high calcium hardness and high solid suspension content is one simultaneous softening and coagulating process, in which sodium carbonate solution of 1-15 % concentration is added in proper position of coagulating deposition tank and the created calcium carbonate crystal and the suspended solid matter coagulate under the action of the coagulant. The present invention features that under the condition of maintaining the water pH unchanged, the concentration of calcium ion and suspended solid in water is reduced in simplified technological process, not expanded apparatus capacity and long term stable operation of the system. The present invention is also suitable for the coagulation and deposition treatment of other industrial effluent with high calcium hardness and high solid suspension content.

Owner:SHANGHAI HUAYI ENERGY CHEM +1

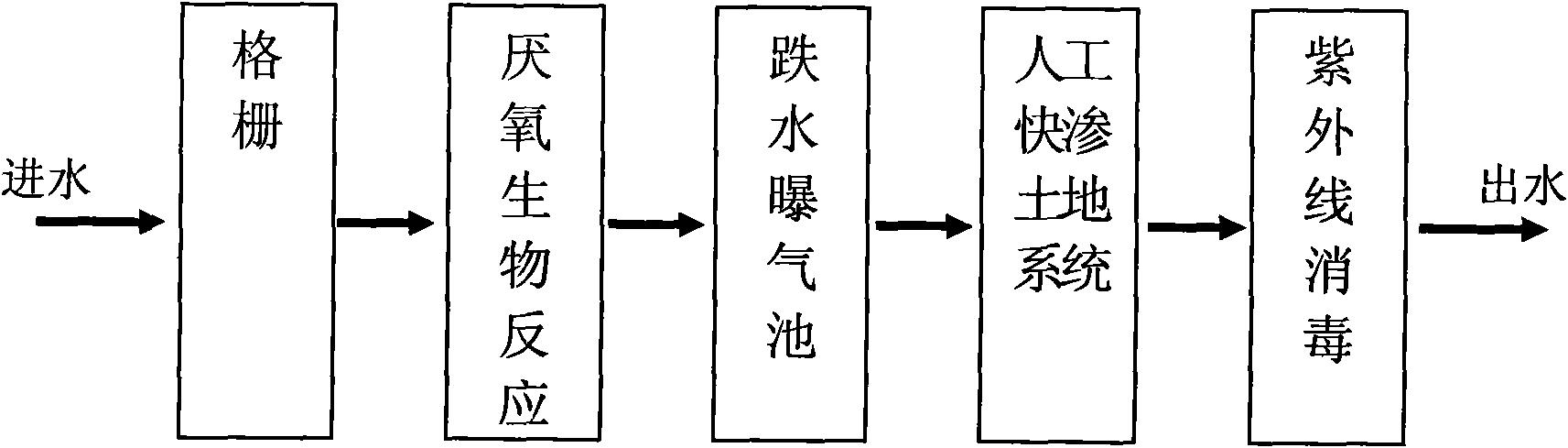

Sewage treatment method suitable for hilly small towns

InactiveCN101597126AGuaranteed uptimeReduce loadWater/sewage treatment by irradiationTreatment with anaerobic digestion processesTreatment effectSludge

The invention relates to a sewage treatment method, which is applicable to the west area where the economic technology is comparatively backward and hilly small towns in Yangtze River Valley. The sewage passes through a grating and large suspensions are removed, then the sewage enters an anaerobic biological reaction tank, most solid suspensions and partial organic substances are removed, the effluent carrying oxygen in the air falls through multi-level from the elevation and flows into a water fall aeration tank at the lower part, and a part of the organic substances is removed; then the effluent enters an artificial rapid infiltration system, and pollutants such as the organic substances, nitrogen, phosphorus and the like are removed through the processes of interception, filtration, adsorption, nitration, denitrification and the like of a soil ecosystem; and finally, through ultraviolet disinfection, the effluent is discharged after reaching standards. The method has the characteristics of low energy consumption and expense, simple operation, maintenance and management, little sludge yield, good treatment effect, and the like.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com