Production method for granular ferric trichloride hexahydrate

A kind of technology of ferric chloride hexahydrate and production method, applied in directions such as ferric halide, can solve problems such as easy deliquescence process, low purity of ferric chloride, complexity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

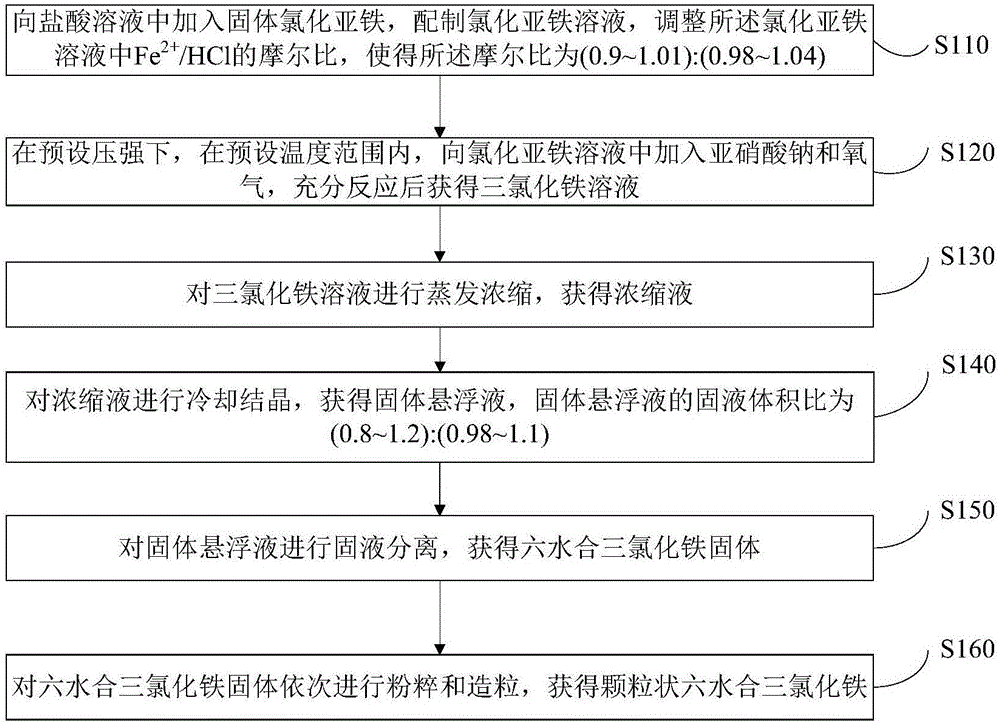

Method used

Image

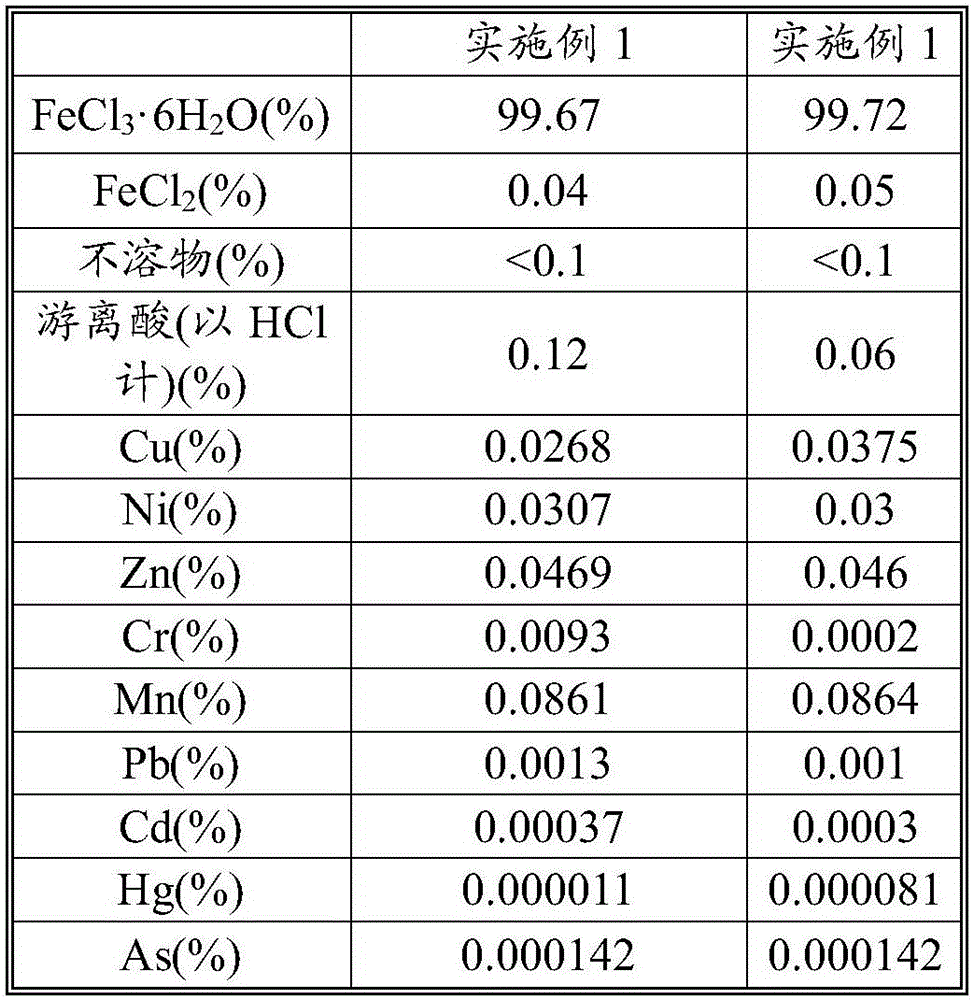

Examples

Embodiment 1

[0062] Add 2.6t of industrial hydrochloric acid in the stirring tank, and the acidity of industrial hydrochloric acid is 0.52% in terms of HCl. Add 2.5 t of ferrous chloride tetrahydrate solid into industrial hydrochloric acid, stir and dissolve to obtain ferrous chloride solution. Continue to add 1.35t industrial hydrochloric acid in ferrous chloride, in terms of HCl, the acidity of industrial hydrochloric acid is 31.16%, stir well, make Fe in the solution 2+ The molar ratio with HCl is 1:1.03;

[0063] Transport the ferrous chloride solution into the oxidation reaction kettle, add 6.5kg of catalyst sodium nitrite solution, add oxygen from the middle of the reaction kettle, control the internal pressure of the reaction kettle to 0.08MPa, and the reaction temperature to 75°C, through the circulation pump, The reaction solution is circulated from the bottom of the reactor to the top of the reactor, and then sprayed into the reactor from the top of the reactor, and continuously o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com