Sewage treatment method suitable for hilly small towns

A sewage treatment method and technology for small towns, applied in the field of small towns in mountainous areas, can solve the problems of poor operation of sewage treatment plants in small towns, difficult sewage treatment processes, complex operation and management, etc., and achieve low sludge production, low energy consumption and Reduced operating costs and easy maintenance and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

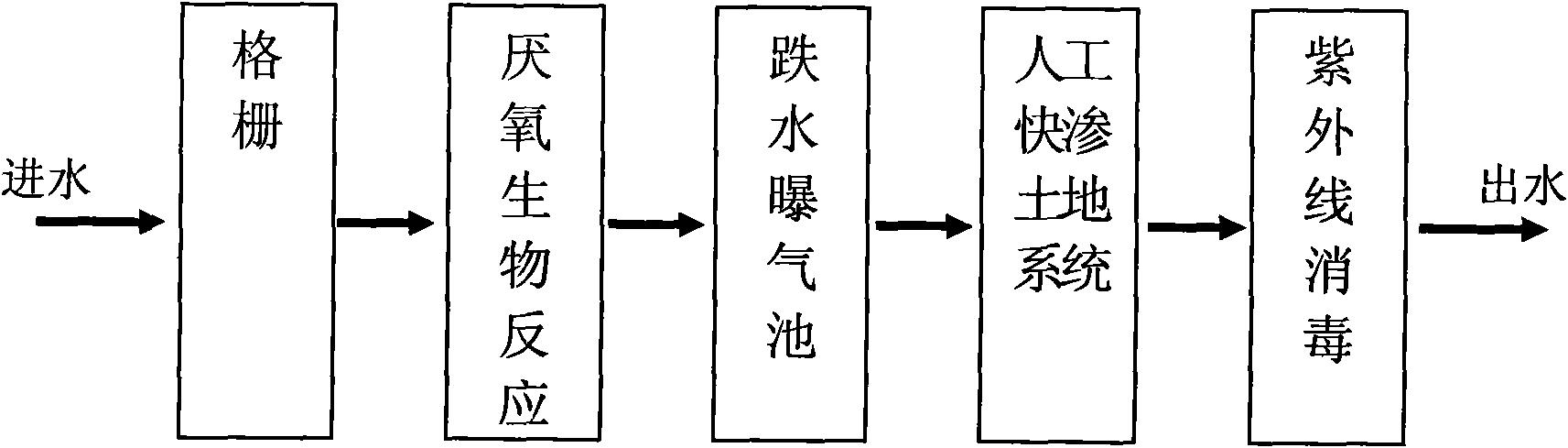

[0020] Such as figure 1 Shown, sewage treatment method of the present invention is made of five steps, is respectively:

[0021] (1) Sewage firstly removes large suspended solids and floating solids through the grid; the function of this step is to reduce the load on subsequent treatment structures and ensure the normal operation of the subsequent sewage treatment system. Theoretically, the smaller the gap between the grids, the better, so that more suspended and floating substances can be removed, which is more conducive to subsequent processing.

[0022] (2) The sewage treated in the first step enters the anaerobic biological reaction tank and stays for 16 to 24 hours, and there is activated sludge in the anaerobic biological reaction tank; the function of this step: remove large amounts of sewage in the anaerobic biological reaction tank Part of suspended solids a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com