Fermentation and infiltration vaporization coupling technique for producing ethanol

A technology of pervaporation and pervaporation membrane, applied in the field of fuel ethanol preparation, can solve the problems of increasing yeast mortality, unstable fermentation process, and decreasing fermentation rate, and achieve the improvement of pollution phenomenon, the promotion of cell activity and density, and the elimination of inhibition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

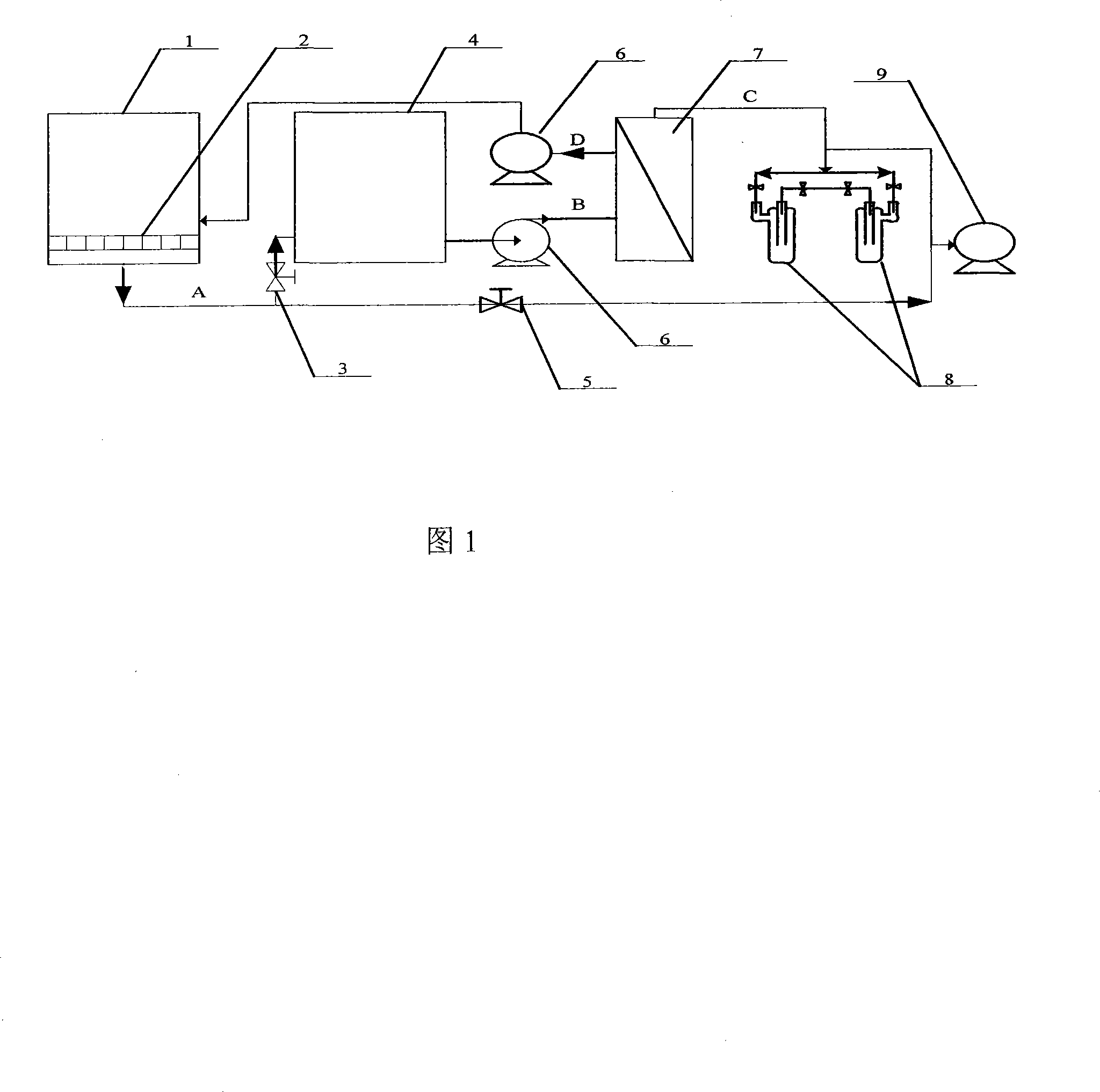

[0019] After the straw is processed by steam explosion and enzymatically hydrolyzed, the slurry is made into the fermentation tank 1, and after microbial fermentation at a temperature of 30°C for 30 hours, when the volume concentration of ethanol in the liquid phase in the tank is detected to reach 3%, the vacuum pump 9 is turned on to control Valves 3 and 5, the clear liquid in the fermentation tank enters the storage tank 4 through the sheet-type inorganic separation membrane separator, and the clear liquid in the storage tank 4 is transported into the pervaporation separator through the feed pump 6, and the vacuum degree is maintained at 500Pa. The ethanol in the liquid continuously enters the tubular polydimethylsiloxane / ceramic composite pervaporation membrane and is vaporized into the cooler 8 to be collected, and the collected ethanol concentration reaches 35v%.

Embodiment 2

[0021] After the corn is acid-treated and enzymatically hydrolyzed, the slurry is made into the fermenter 1, and after microbial fermentation at 40°C for 46 hours, when the volume concentration of ethanol in the liquid phase in the tank reaches 8%, the vacuum pump 9 is turned on and the control valve 3 is turned on. and 5, the clear liquid in the fermentation tank enters the storage tank 4 through the sand steel plate filter type separator, and the clear liquid in the storage tank 4 is transported into the pervaporation separator through the feed pump 6, and the vacuum degree is maintained at 200Pa, and the clear liquid in the clear liquid The ethanol continuously enters into the tubular MFI series molecular sieve pervaporation membrane and is vaporized into the cooler 8 to be collected, and the collected ethanol concentration reaches 69v%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com