Peripherally-distributed water deflection composite reactor for hydrolysis and acidification

A hydrolysis acidification and compound technology, applied in the field of sewage treatment and environmental protection, can solve the problems of blockage of water distribution pipeline, complicated water distribution system, and decreased treatment efficiency, and achieve the effect of management and low investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

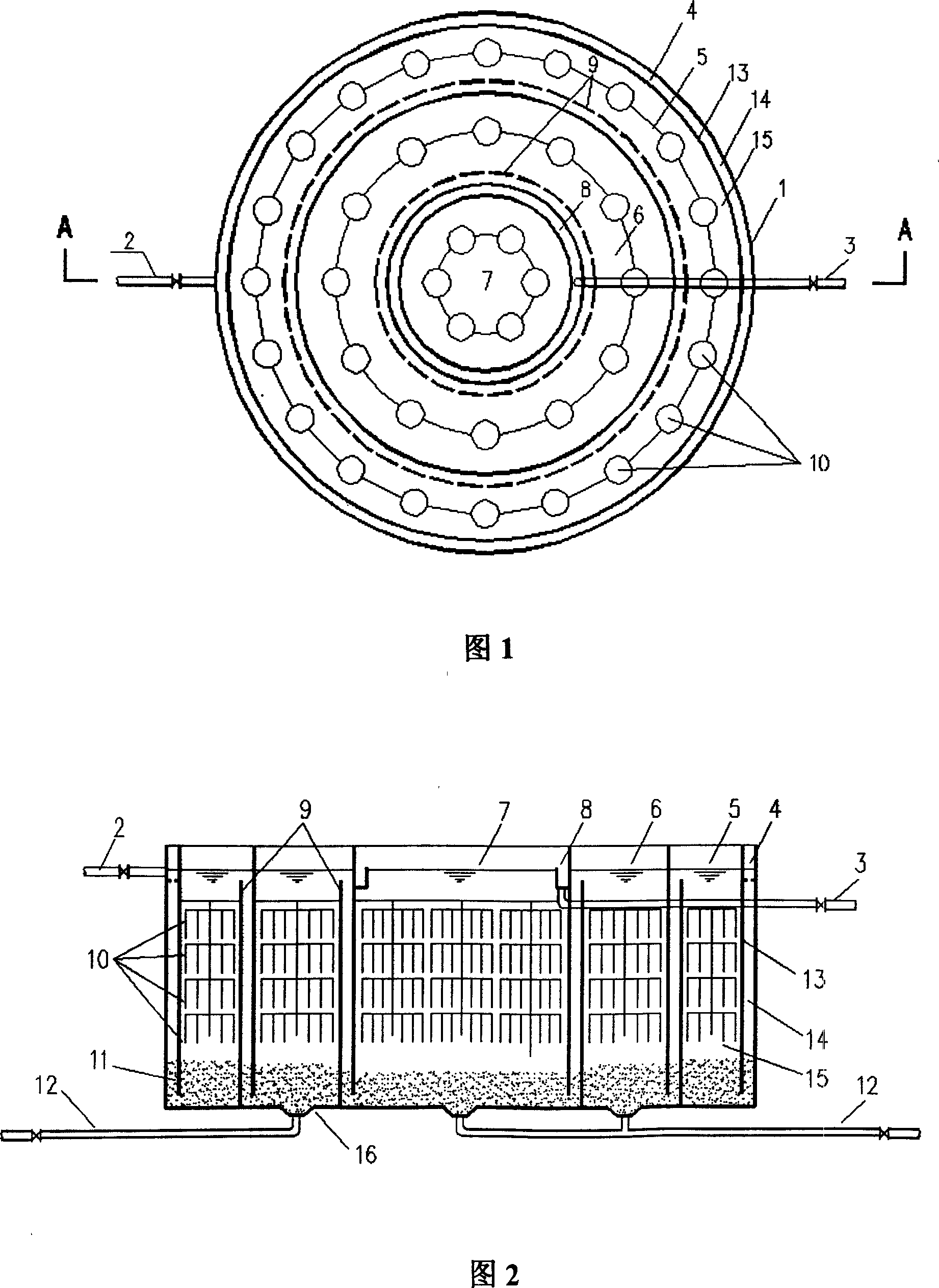

[0019] Referring to Figures 1 and 2, the reactor has a pool body 1, a water inlet pipe 2, a drain pipe 3, and the like. The pool body 1 adopts a circular pool body, which is composed of three concentric circles, and divides the pool body into an outer ring reaction zone 5 , an inner ring reaction zone 6 and a central reaction zone 7 . The outer ring reaction zone 5 is divided into two sub-reaction zones by a rectification plate 13 : a rectification zone 14 and an upflow reaction zone 15 . There is a water distribution tank 4 on the top of the rectification area 14, and the bottom of the tank is evenly provided with water holes for evenly distributing water. Water holes are provided at the bottom of the rectifying plate 13 to connect the rectifying area 14 with the upflow reaction area 15 of the outer ring. A baffle 9 is set between the outer ring reaction zone, the inner ring reaction zone and the central reaction zone, and each zone is connected through the water hole provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com