Process for advanced treatment of waste alkali in hydrogen sulfide removal

A technology for advanced treatment and removal of hydrogen sulfide, which is applied in incinerators, chemical instruments and methods, separation methods, etc. problems, to achieve the effect of improving the stripping effect, eliminating the phenomenon of tower blockage, and improving the oxidation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

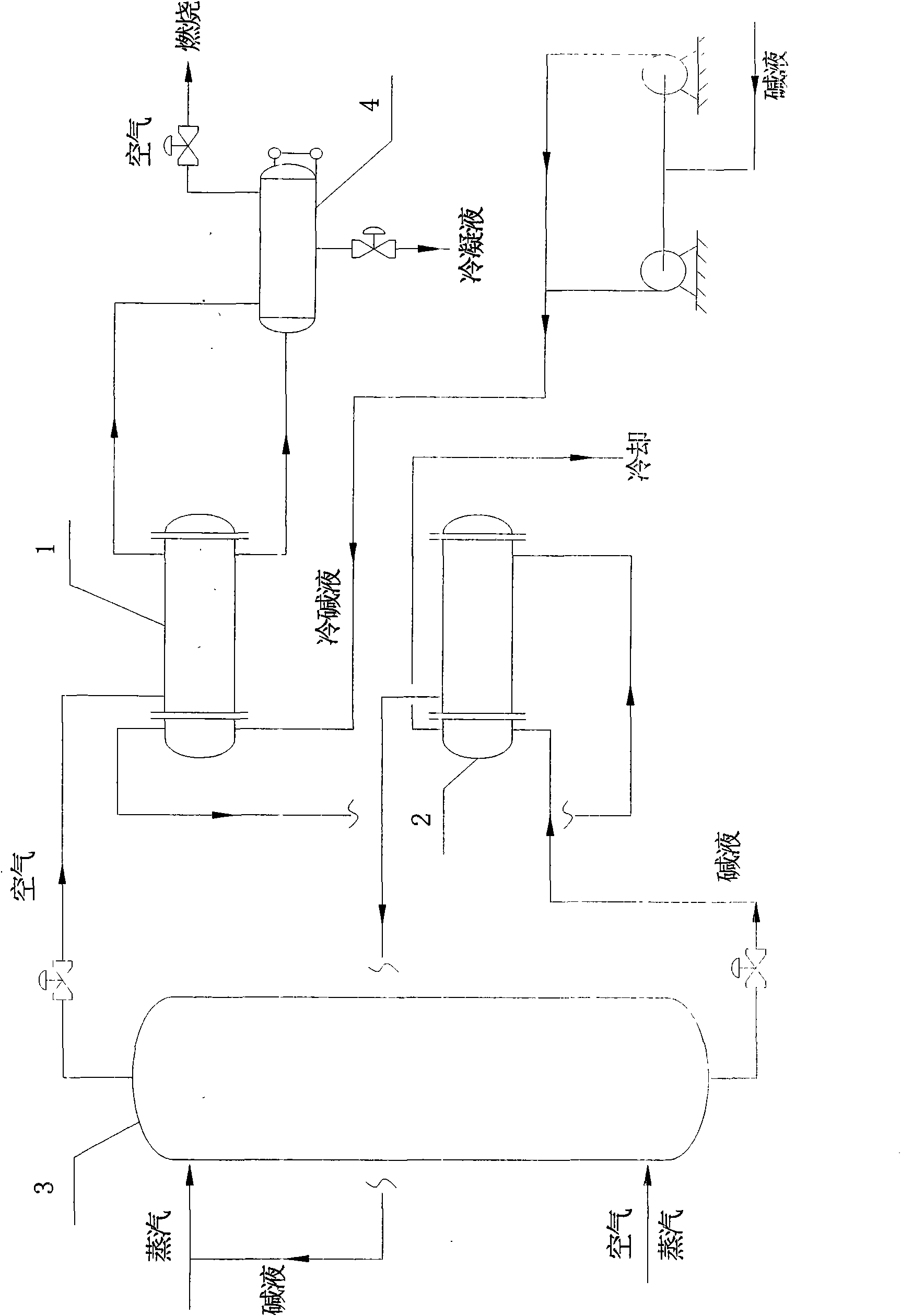

[0020] Such as figure 1 As shown, the spent lye preheated by the lye preheater 2 (the flow rate is 2t / h) and the water vapor (the flow rate is 160kg / h) are mixed by the static mixer and then heated to 120°C, and enter the deep liquid layer from the top oxidation reactor. Pressure 0.6MPa Flow 300NM 3 The air per hour and the water vapor with a flow rate of 25kg / hour are mixed by a static mixer and then heated to 125°C, and enter the deep liquid layer oxidation reactor from the bottom. After the oxidation reaction (residence time) in the oxidation reactor for 6 hours, the spent caustic liquor is discharged from the bottom of the oxidation reactor into the heat exchanger to recover heat, and then the sample is analyzed and discharged after being lowered to normal temperature through another heat exchanger.

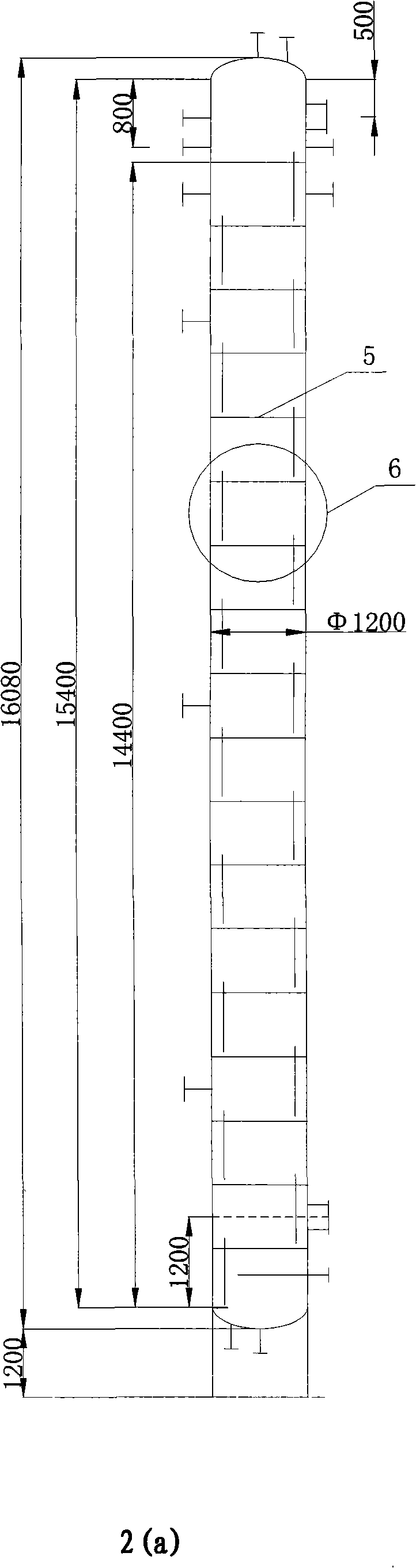

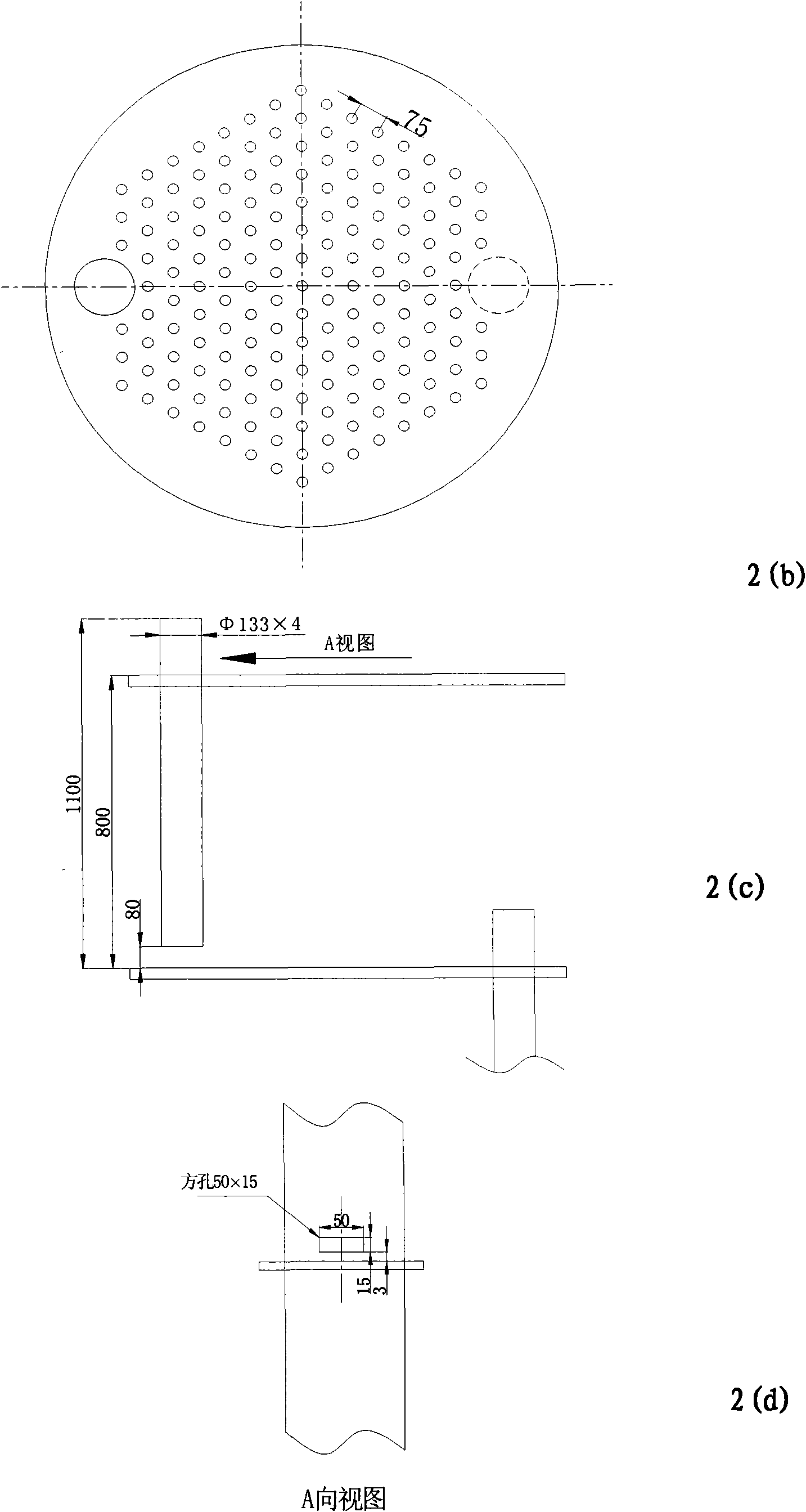

[0021] The oxidation reactor 3 is a sieve plate tower with a downcomer 6 . The air goes up through the sieve holes, and the proper air / liquid flow ratio makes the sieve pl...

Embodiment 2

[0024] Such as figure 1 As shown, the waste lye preheated by the heat exchanger (the flow rate is 3t / h) and the water vapor (the flow rate is 250kg / h) are mixed through the static mixer and then heated to 125°C, and enter the deep liquid layer oxidation reactor from the top . Pressure 0.6MPa Flow 400NM 3 The air per hour and the water vapor with a flow rate of 35kg / hour are mixed by a static mixer and then heated to 130°C, and enter the deep liquid layer oxidation reactor from the bottom. After 7 hours of oxidation reaction (residence time) in the oxidation reactor, the spent caustic liquor is discharged from the bottom of the oxidation reactor into the heat exchanger to recover heat, and then the sample is analyzed and discharged after being lowered to normal temperature through another heat exchanger.

[0025] In the experiment, initial condition is the same as embodiment 1, COD is 560ppm in the discharge spent caustic soda that is treated through above-mentioned process, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com