Method for removing cyanide, thiocyanate, COD and arsenic in waste liquid

A technology of thiocyanate and cyanide, which is applied in the field of thiocyanate, COD and arsenic, to remove cyanide in waste liquid, and can solve problems such as inability to treat cyanide in depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0115] The composition of a gold concentrate cyanidation leaching residue leaching waste liquid is shown in Table 3

[0116] Table 3 Composition of a gold concentrate cyanidation leaching residue leaching waste liquid

[0117] Unit: mg / L, pH dimensionless

[0118]

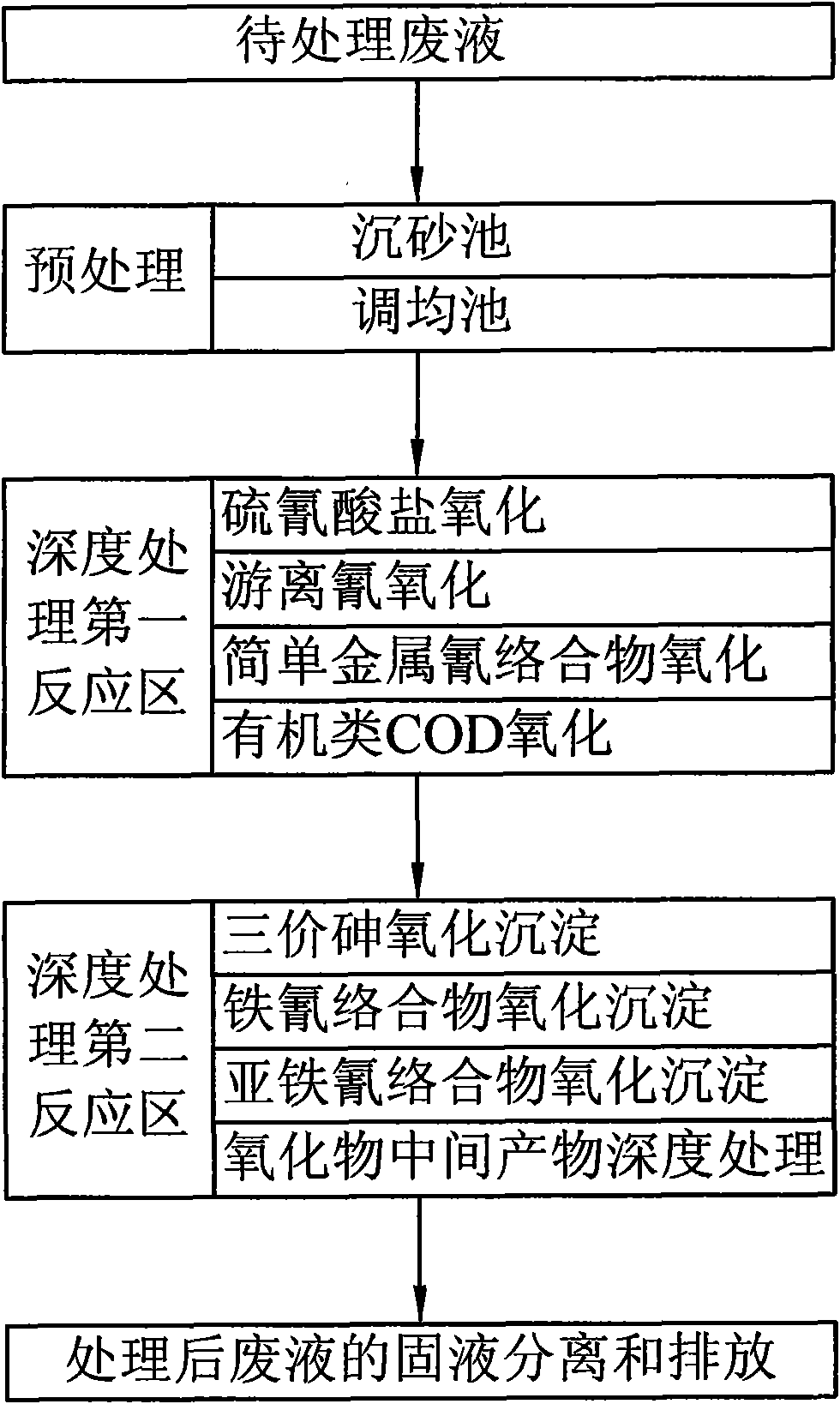

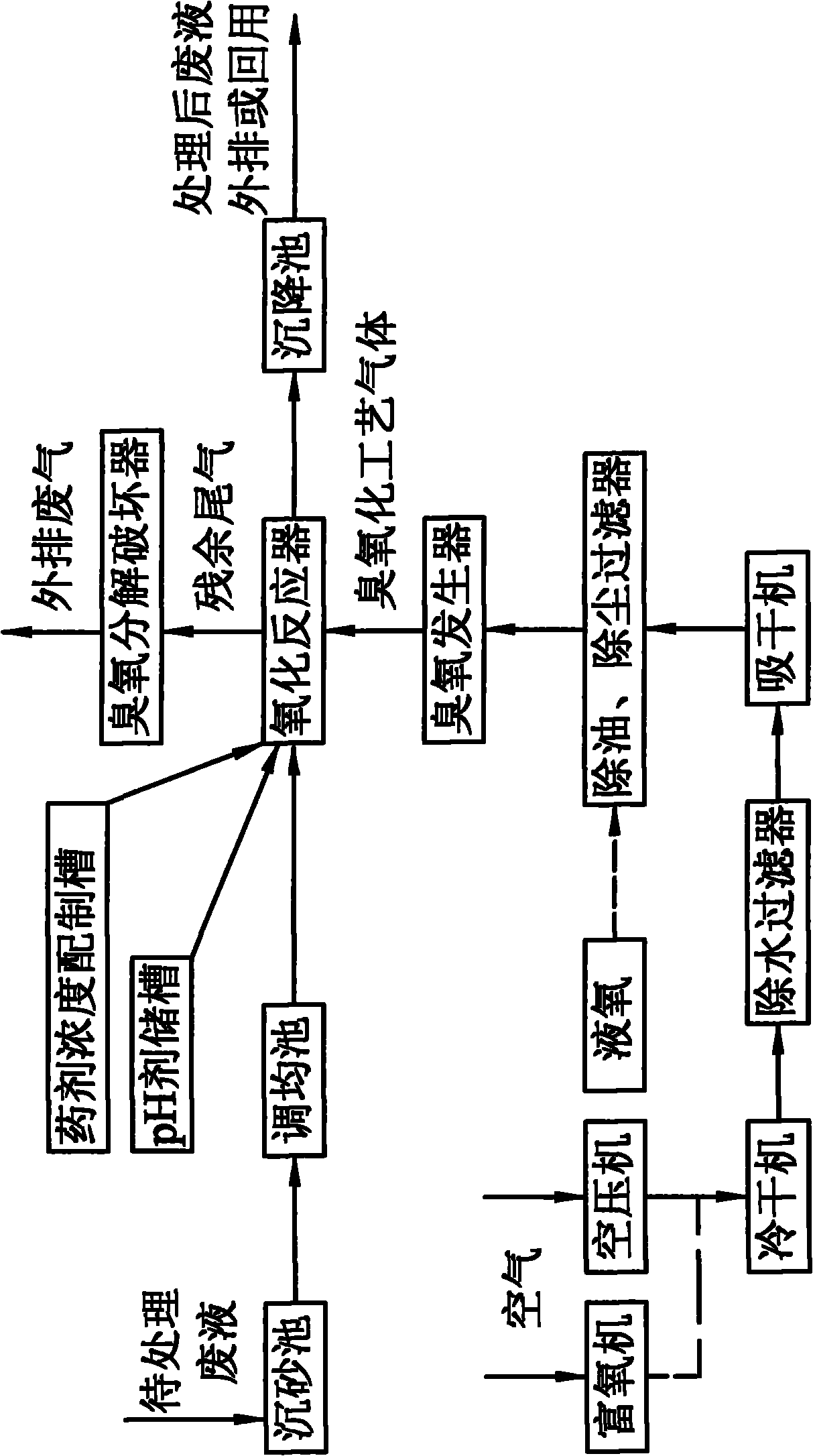

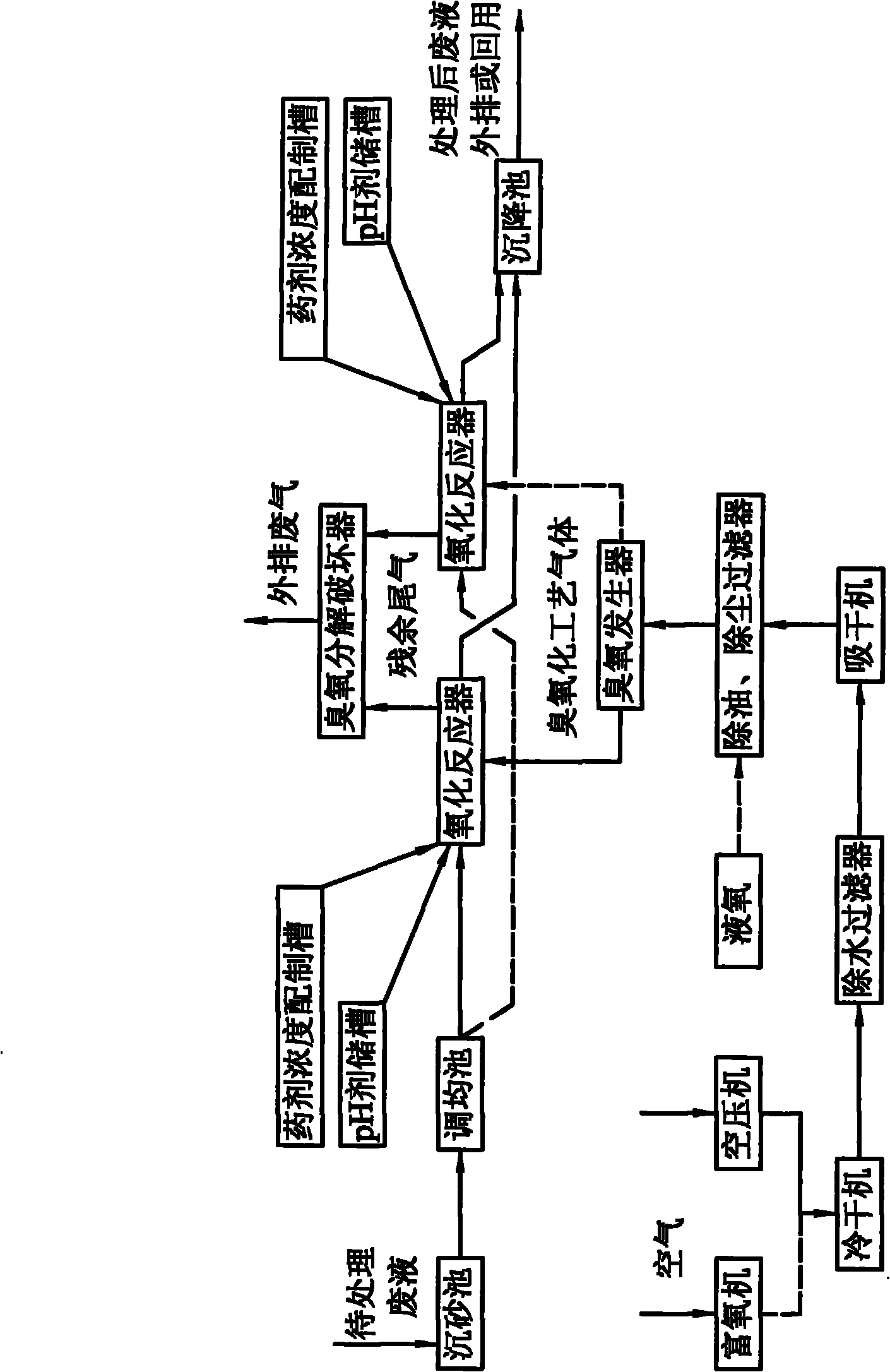

[0119] From the composition of the above wastewater quality, it can be seen that the main pollutants of wastewater are CN T 、SCN - , As, COD, where SCN - The proportion of COD is relatively high, so the reaction process is mainly for the analysis and determination of the above four pollutants. see figure 1 and figure 2 Shown:

[0120] (1) Pretreatment section: After the waste liquid to be treated passes through the grit chamber to settle the solid suspended matter in the waste liquid, it enters the equalization tank.

[0121](2) Continuous treatment: Turn on the upper liquid pump to extract the liquid to be treated from the equalizing tank at the maximum flow rate, and pour it into the oxidation reactor ...

Embodiment 2

[0130] The composition of a gold ore cyanidation leaching cycle barren solution, see Table 5

[0131] Table 5 Summary of composition of barren liquid sampling and analysis in cyanidation leaching system of a factory

[0132] Unit: mg / L, pH dimensionless

[0133] serial number

CN T

SCN -

Cu

Pb

Fe

Zn

As

COD

pH

1

343.82

1591.25

0.0167

micro

0.0003

micro

-

1703.14

12

2

315.85

1320.34

0.0172

micro

0.0003

micro

-

1540.92

12

3

341.75

1569.43

0.0166

micro

0.0003

micro

-

1681.10

12

4

310.68

1317.83

0.0167

micro

0.0003

micro

-

1529.82

12

5

311.54

1318.24

0.0152

micro

0.0003

micro

-

1549.97

12

6

310.68

1320.97

0.01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com