Application of multilayer composite functional material in industrial circulating water quality stabilization treatment

A technology of industrial circulating water and functional materials, applied in the field of environmental purification, can solve the problems of insufficient efficiency, stay in the laboratory research stage, and high light requirements, so as to inhibit the decomposition of bacteria and organic matter, inhibit the growth of microorganisms, and reduce the concentration ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A multi-layer composite functional material, the functional material is a substrate layer, a solar reflection layer, a photocatalytic layer, a biocoupling purification layer and a self-cleaning protective layer from bottom to top;

[0054] The solar reflection layer is made of mica-modified silica sol;

[0055] The photocatalytic layer is made of photocatalytic nanogel of rare earth co-doped graphene;

[0056] The biocoupling purification layer contains trace element bioactivation factors;

[0057] The self-cleaning protective layer contains ethyl cellulose;

[0058] The preparation method of the functional material comprises the following steps:

[0059] (1) prepare mica modified silica sol;

[0060] Add 5 kg of mica crystals into 160 L of nano-silica ethanol dispersion (the mass concentration of nano-silica is 5%), then stir at high speed and disperse uniformly by ultrasonic to prepare mica-modified silica sol.

[0061] (2) Preparation of photocatalytic nanogels o...

Embodiment 2

[0074] An application of a multilayer composite functional material in the stable treatment of industrial circulating water, the application method is:

[0075] In the tower pool 7 of the circulating water, the graphene photocatalytic mesh frame 9 and the biological filler frame 10 are hoisted, the graphene photocatalytic mesh frame 9 and the biological filler frame 10 appear in pairs, and the water flows through the tower pool water inlet 8 successively A plurality of graphene photocatalytic mesh frames 9 and biological filler frames 10 flow out from the tower pond water outlet 11;

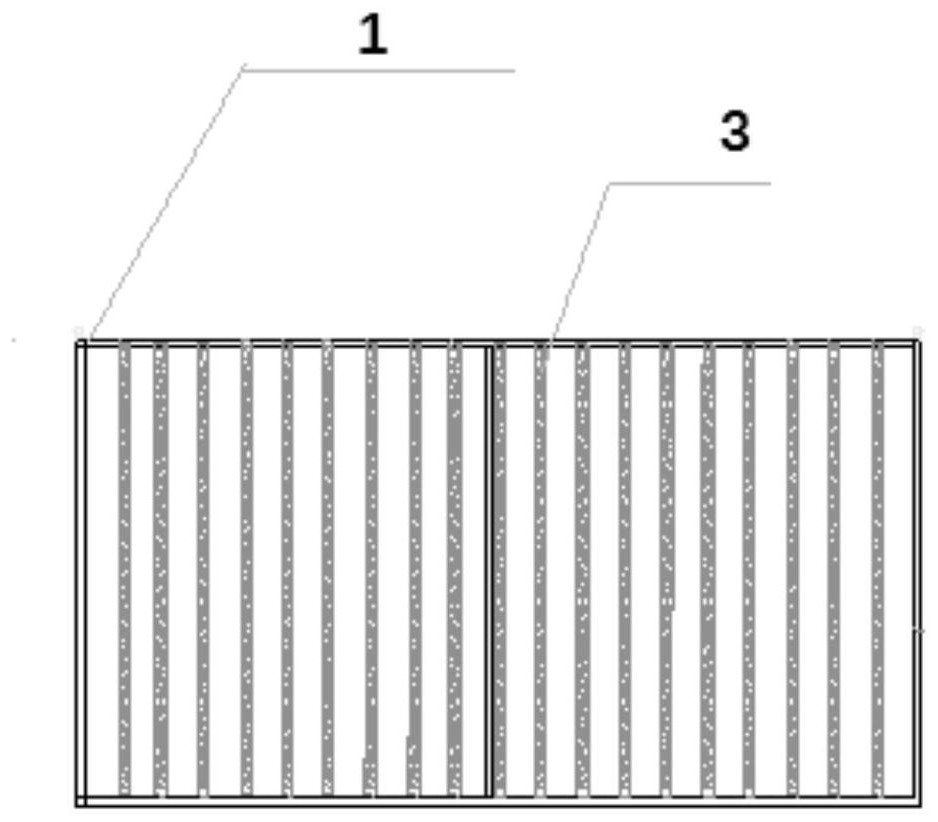

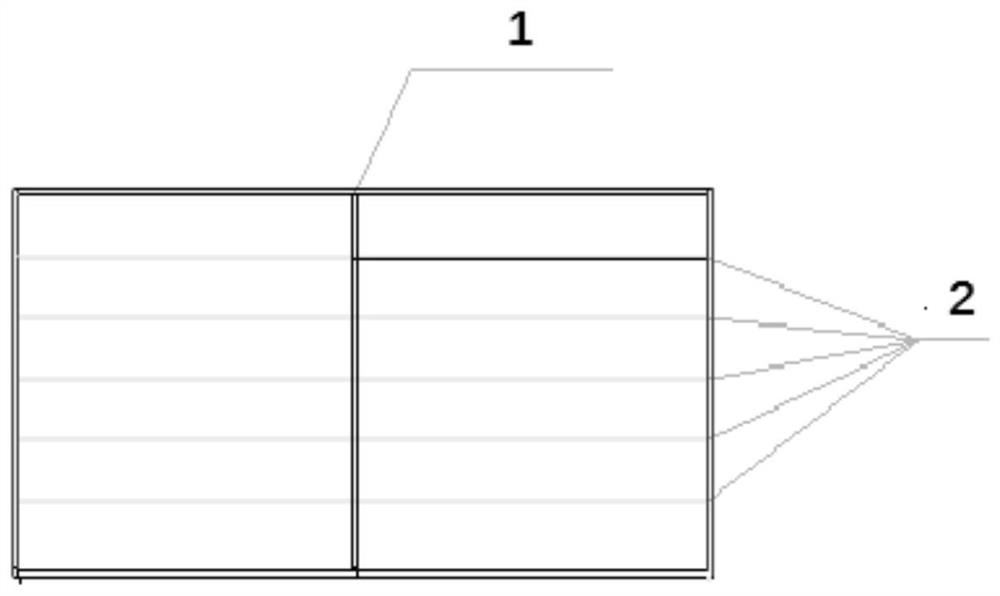

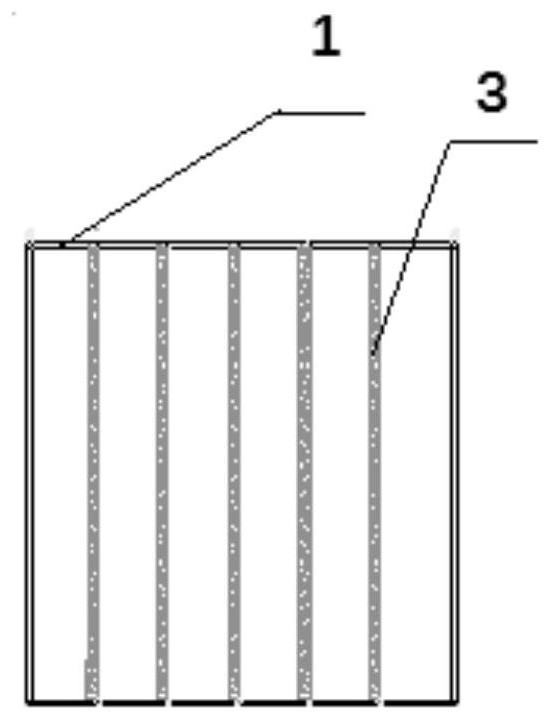

[0076] Described biological filler rack 10 is made of 30# square pipe 1, Composed of round pipe 2 and biological filler rope 3; 30# square pipe 1 is connected end to end to form a cube frame, and several wires are arranged in parallel on the top and bottom of the cube frame The two ends of the round pipe 2 and the biological filler rope 3 are respectively fixed on two wires on the same vertica...

Embodiment 3

[0080] Example 3 According to the method of Example 2, it is applied to the integrated photocatalytic coupling biological purification equipment of the central air-conditioning water system / small industrial circulating water system.

[0081] The central air-conditioning water system / small industrial circulating water system generally adopts a water-collecting cooling tower. There is no independent pool under the cooling tower, but there are several cuboid water collection tanks. Therefore, the graphene photocatalytic mesh frame 9 and the biological filler frame 10 are hoisted on In the sump, it has the effect of scale inhibition, corrosion inhibition and inhibition of harmful microorganisms.

[0082] The operating effect of graphene photocatalytic full ecological treatment of circulating water in a coking plant is shown in Table 1:

[0083] Table 1

[0084]

[0085]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com