Biochemical treatment method and apparatus for high calcium and high magnesium waste water

A biochemical treatment device and biochemical treatment technology, applied in multi-stage water treatment, water/sewage treatment, anaerobic digestion treatment, etc., can solve problems such as secondary pollution of solid waste, reduce calcium hardness, have a wide range of applications, and process Effects with low requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

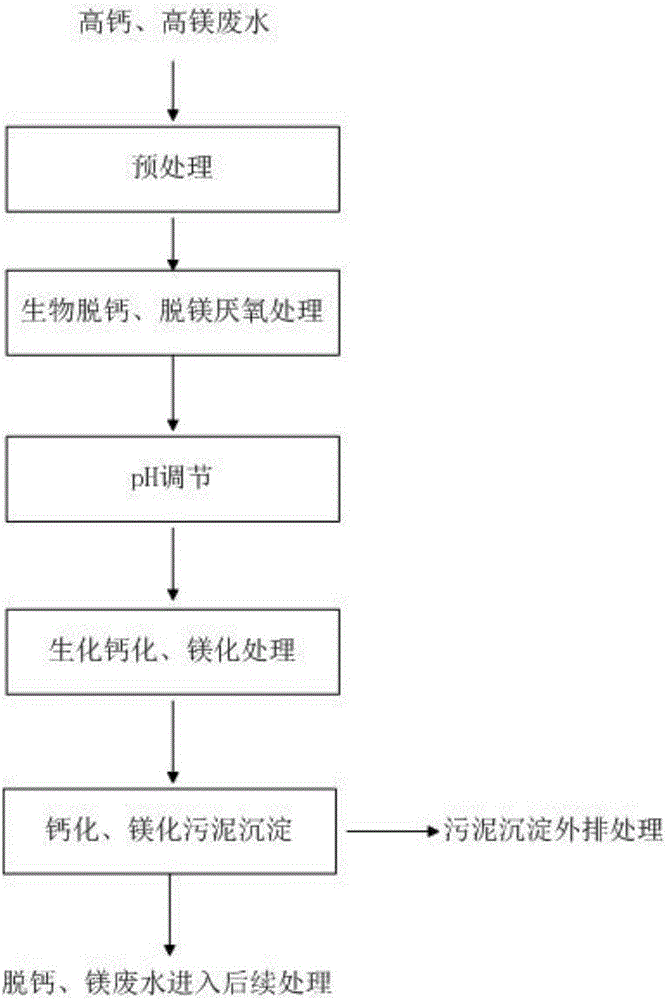

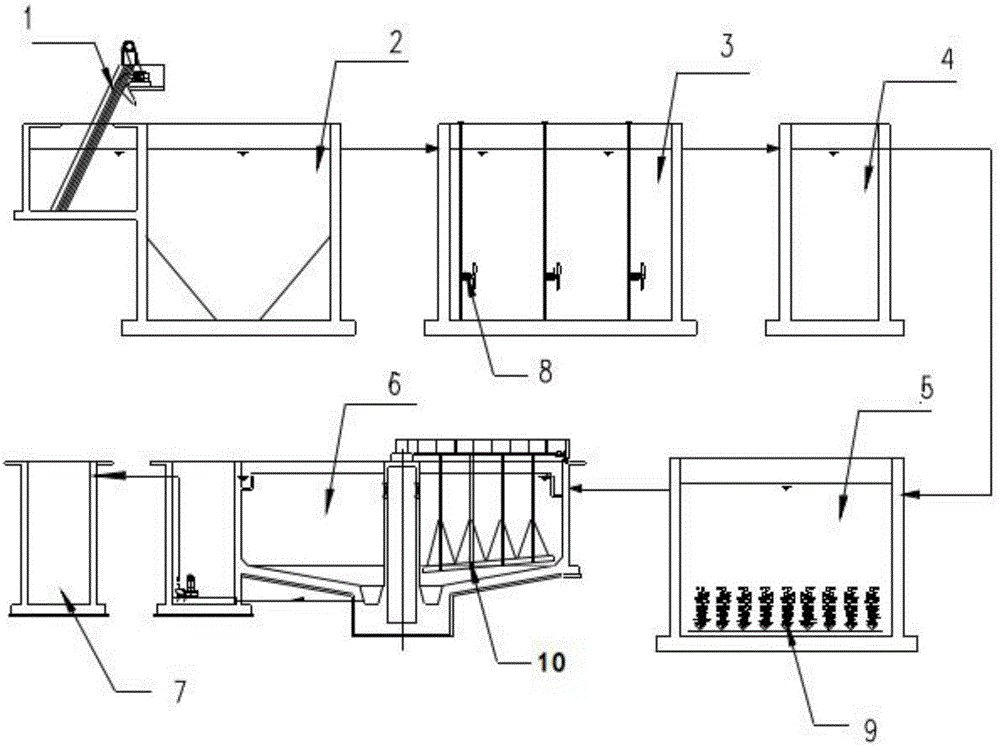

[0039] A biochemical treatment method for high-calcium and high-magnesium wastewater, comprising the following steps:

[0040] S1. Wastewater pretreatment: The wastewater containing calcium ions and COD ≥ 300mg / L, in which the concentration of calcium ions ≤ 10000mg / L, is filtered through fine grids and flocculant PAC is added to the sedimentation tank to carry out precipitation to remove high Most of the suspended solids in the calcium wastewater, so that the concentration of suspended solids is below 300mg / L; then maintain the pH value of the wastewater at 6.2-6.3; when the fine grid is filtered, the flow rate of the wastewater through the grid is 0.5m / s;

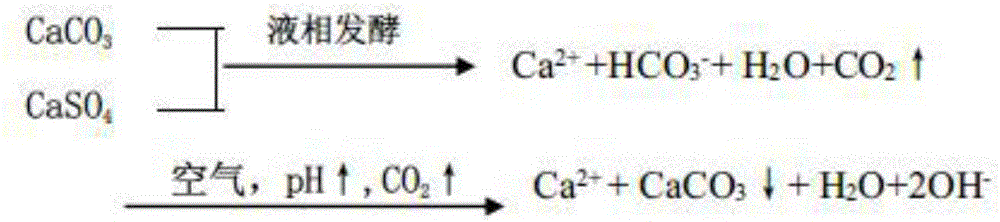

[0041] S2. Biological decalcification anaerobic treatment: the pretreated wastewater enters the biological decalcification and magnesium removal anaerobic reaction tank, and under the action of anaerobic microorganisms in the anaerobic sludge, the biological decalcification hydrolysis acidification reaction is carried out;...

Embodiment 2

[0045] A biochemical treatment method for high-calcium and high-magnesium wastewater, comprising the following steps:

[0046] S1. Wastewater pretreatment: The wastewater containing magnesium ions and COD ≥ 300mg / L, in which the concentration of magnesium ions ≤ 10000mg / L, is filtered through fine grids and flocculant PAM is added to the sedimentation tank to carry out precipitation to remove high Most of the suspended solids in calcium and high magnesium wastewater make the concentration of suspended solids below 300mg / L; then maintain the pH value of the wastewater at 6.9-7; the flow rate of wastewater passing through the grid is 1.0m / s during fine grid filtration;

[0047] S2. Biological magnesium removal anaerobic treatment: the pretreated wastewater enters the biological decalcification and magnesium removal anaerobic reaction tank, and under the action of anaerobic microorganisms in the anaerobic sludge, the biological magnesium removal hydrolysis acidification reaction i...

Embodiment 3

[0051] A biochemical treatment method for high-calcium and high-magnesium wastewater, comprising the following steps:

[0052] S1. Wastewater pretreatment: Wastewater containing calcium ions and magnesium ions, and COD ≥ 300mg / L, wherein the concentration of calcium ions ≤ 10000mg / L, the concentration of magnesium ions ≤ 10000mg / L, is filtered through a fine grid and placed in a sedimentation tank Add flocculants PAM and PAC to the water to remove most of the suspended solids in the high-calcium and high-magnesium wastewater by precipitation, so that the suspended solids concentration is below 300mg / L; then maintain the pH value of the wastewater at 6.5-6.8; fine grid filtration The flow velocity of waste water through the gate is 0.8m / s;

[0053] S2. Biological decalcification and magnesium removal anaerobic treatment: The pretreated wastewater enters the biological decalcification and magnesium removal anaerobic reaction tank, and under the action of anaerobic microorganisms...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com