A kind of glue production water treatment process equipment and using method thereof

A technology for processing and producing water, applied in water/sludge/sewage treatment, natural water treatment, dehydration/drying/concentrated sludge treatment, etc., and can solve problems such as low dehydration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

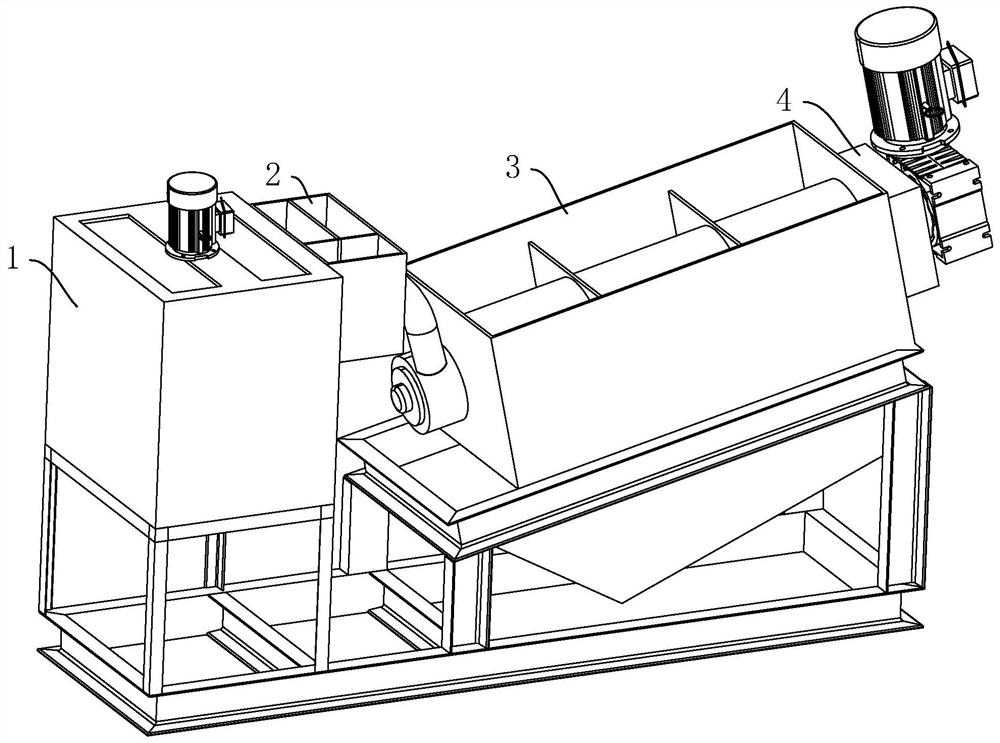

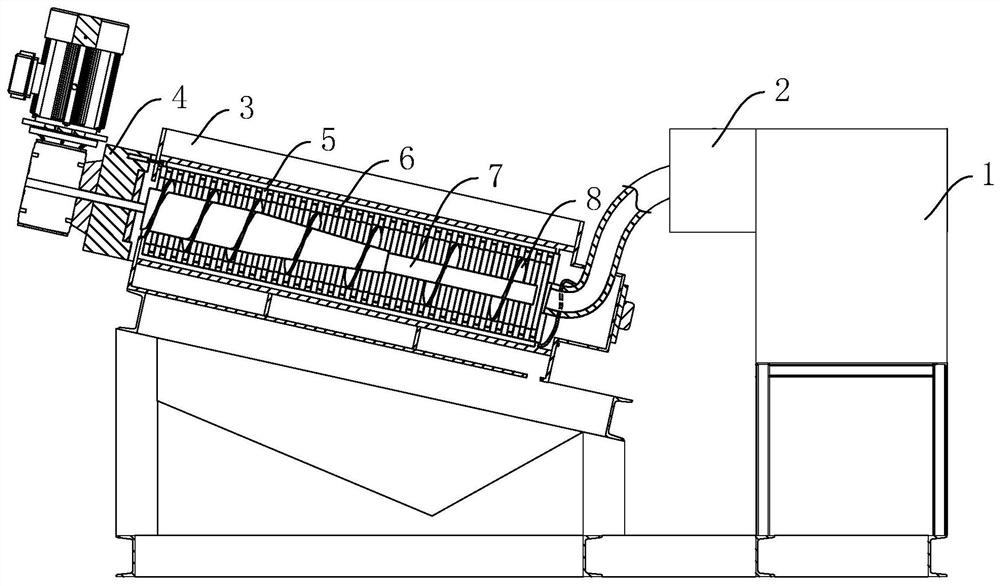

[0041] A kind of glue production water treatment process equipment, such as figure 1 As shown, it includes a mixing tank 1 and a stacked screw filter press. When in use, inject raw water and flocculant into the mixing tank 1 . The mixing tank 1 fully stirs the raw water and the flocculant, so that the particles in the raw water are fully combined. Afterwards, the material inside the mixing tank 1 is injected into the screw filter press. The stacked screw filter press filters the material, so that the water and the combined relay phase are separated to meet the national discharge requirements.

[0042] The stacked screw filter press includes a mud feeding box 2, a casing 3 and a mud discharging box 4 arranged in sequence. During use, the water in the raw water is discharged from the casing 3, and the particles combined in the raw water are discharged from the mud discharge box 4.

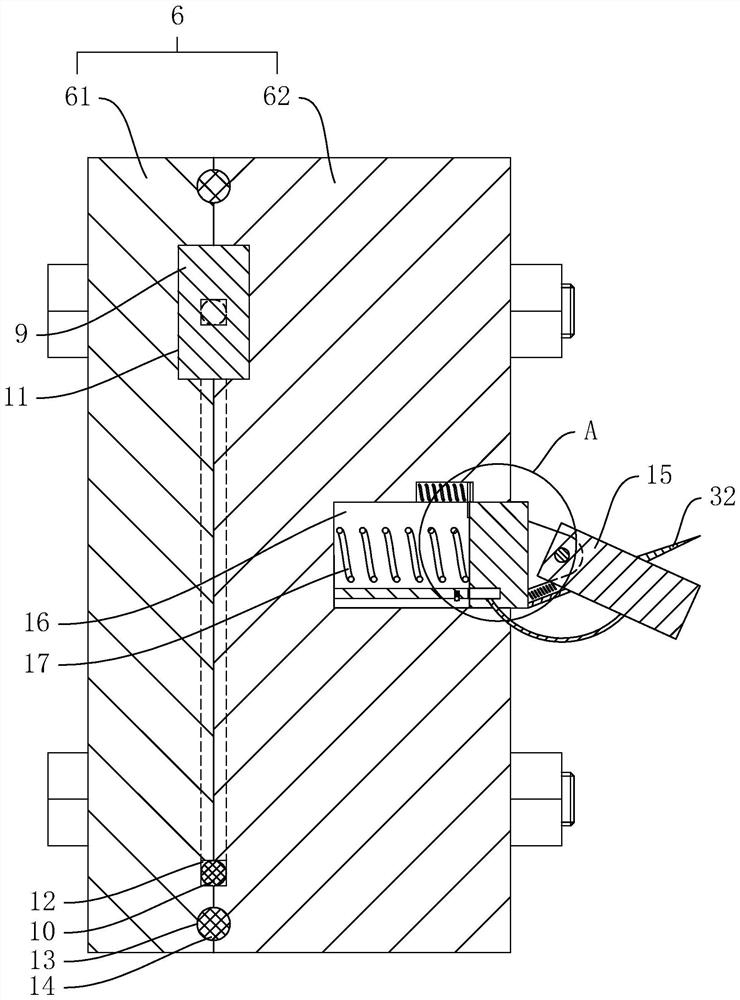

[0043] Such as figure 2 As shown, the housing 3 is provided with a fixed plate 5 and a mova...

Embodiment 2

[0053] A kind of use method of the production water treatment process equipment of glue as described in embodiment one, comprises the steps:

[0054] Step 1: Inject raw water of quality M into the mixing tank;

[0055] The second step: add 0.25%M-0.35%M polyacrylamide to the mixing tank;

[0056] The third step: the concentration of adding 0.2%M-0.4%M in the mixing tank is 20% ferric chloride solution;

[0057] Step 4: Use a mixing bucket to stir for 5 minutes, so that some impurities in the raw water can be flocculated;

[0058] Step 5: Add caustic soda or sulfuric acid to the mixing tank to adjust the pH to 6-8;

[0059] Step 6: Stand for 3 minutes;

[0060] Step 7: Add 0.25%M-0.5%M polyaluminum chloride to the mixing tank;

[0061] Step 8: Use a mixing bucket to stir for 5 minutes, so that some impurities in the raw water can be flocculated;

[0062] Step 9: Inject the material in the mixing tank into the screw filter press for pressure filtration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com