Thermal power plant weak acid cation bed regeneration wastewater quality grading reuse system and thermal power plant weak acid cation bed regeneration wastewater quality grading reuse method

A technology of weak acid cation bed and wastewater regeneration, applied in the direction of ion exchange bed cleaning/flushing, etc., can solve problems such as blockage of equipment, large amount of wastewater, failure, etc., and achieve the effect of reducing concentration and not easy to precipitate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

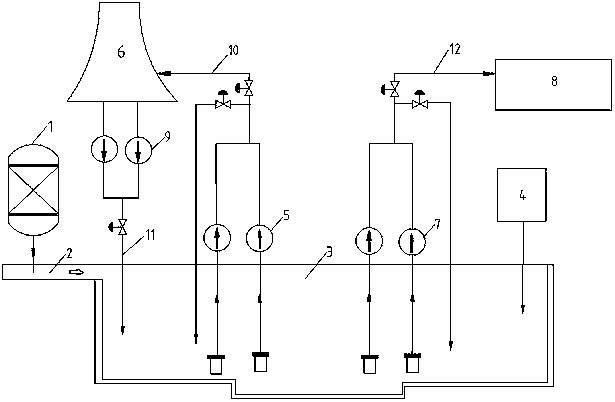

[0024] see figure 1 , in this embodiment, a thermal power plant weak acid cation bed regenerated waste water separation and reuse system, including weak acid cation bed 1, drainage ditches 2, waste water collection pool 3, alkali adding device 4, recovery water pump 5, cooling tower 6, complex Water pump 7, desulfurization reuse pool 8, circulating water drainage pump 9.

[0025] The regeneration outlet of the weak acid cation bed 1 is connected with the drainage ditch 2, the drainage ditch 2 is connected with the waste water collection tank 3, the waste water collection tank 3 is connected with the alkali adding device 4, and the waste water collection tank 3 is connected with the water inlet of the cooling tower 6 through the recovery water pipe 10 Connected, recovery water pump 5 is installed on the recovery water pipe 10, the waste water collection tank 3 is also connected with the water inlet of the desulfurization reuse water pool 8 through the reuse water pipe 12, the r...

Embodiment 2

[0035] The raw water pretreatment system of a thermal power plant in Shaanxi adopts a weak acid cation bed softening treatment process, with an average daily treatment capacity of about 20,000m 3 , producing about 1600m of recycled wastewater 3 . The regeneration steps of the weak acid cation bed are as follows: backwashing (30min, 120m 3 / h) → acid regeneration (90min, 100m 3 / h) → replacement (30min, 100m 3 / h) → positive washing (60min, 180m 3 / h). About 440 m of waste water is generated by weak acid cation bed regeneration once 3 , The sulfate ion content in the regenerated wastewater is about 3400 mg / L, and the calcium ion content is about 2000 mg / L.

[0036] After this technological transformation, the drainage in the backwashing and forward washing stages (about 240 m 3 ) is recovered to the cooling tower through the recovery water pump as make-up water, drainage in the regeneration and replacement stages (about 200 m 3 ) and cooling tower circulating water (abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com